Fri-Jado TG50-M Installation Manual

INSTRUCTIONS

TG

-

ROTISSERIE OVEN

MODELS

Installation, operation and care of

MODELS

Manual controls TG50- M

TG110-M

TG330-M

TG550-M

Model TG330-M

READ BEFORE USING ROTISSERIE/WARMER

● IMPORTANT ●

www.frijado.com

Part-number form 912.3474 / 0802

MODELS

Model Oven TG50-M Model Oven TG110-M

Model Oven TG330-M Model Oven TG550-M

2

TABLE OF CONTENTS

MODELS .................................................................................................................... 2

GENERAL .................................................................................................................. 5

F

EATURES AND OPTIONS

INSTALLATION .......................................................................................................... 6

L

OCATION

L

EVELING

L

EGS/CASTERS

A

SSEMBLY

S

UPPLEMENTAL INSTALLATION INSTRUCTIONS

I

NSTALLATION CODES AND STANDARDS

E

LECTRICAL CONNECTIONS

E

LECTRICAL DATA

................................................................................................................. 6

.................................................................................................................. 6

.......................................................................................................... 6

................................................................................................................ 7

...................................................................................................... 9

BEFORE FIRST USE ............................................................................................... 10

OPERATION ............................................................................................................ 10

O

VEN CONTROLS

O

VEN CONTROLS

TG50-M ....................................................................................... 11

TG110-M, TG330-M

PREPARING THE PRODUCT.................................................................................. 14

L

OADING PRODUCTS ONTO ACCESSORIES

L

OADING PRODUCTS ONTO SPITS

L

OADING ACCESSORIES INTO THE OVEN

L

OADING ACCESSORIES INTO THE OVEN

L

OADING ACCESSORIES INTO THE OVEN

U

NLOADING ACCESSORIES FROM THE OVEN

S

UGGESTED ROASTING GUIDELINES

E

MPTYING GREASE DRAWER

CLEANING ............................................................................................................... 24

C

LEANING STAINLESS STEEL SURFACES

C

LEANING NON-STICK COATED SURFACES

C

LEANING GREASE DRAWER

C

LEANING QUARTZ LAMPS

M

ONTLY CLEANING (OR MORE OFTEN IF NECESSARY

MAINTENANCE ....................................................................................................... 27

............................................................................................ 5

.............................................................. 7

........................................................................ 8

........................................................................................ 8

AND

TG550-M ............................................. 12

.................................................................. 14

.............................................................................. 15

(TG330-M

AND

TG550-M)............................ 17

(TG50-M)..................................................... 19

(TG110-M)................................................... 20

............................................................... 20

.......................................................................... 22

..................................................................................... 22

..................................................................... 25

.................................................................. 25

..................................................................................... 26

........................................................................................ 26

).................................................. 27

3

Installation, Operation and Care of

TG ROTISSERIE OVEN MODELS

BEFORE USING THE OVEN FOR THE FIRST TIME,

CAREFULLY READ THIS ENTIRE MANUAL.

IMPORTANT NOTICE: The user is responsible for reading and

following these instructions to ensure the safe and proper

installation, operation, and maintenance of the ovens and warmers.

The manufacturer expressly disclaims any and all liability for any

and all damage or injury resulting from failure to follow and comply

with these instructions, or from failure to exercise reasonable care

in the handling, operation, cleaning, and repair of the ovens and

warmers, and failure to explicitly include any warnings or

instructions in this manual shall not give rise to any claim for

damages. If you have any questions concerning the installation,

operation, care, or maintenance of the ovens or warmers that are

not covered by these instructions, please contact the manufacturer

at:

Fri-Jado Inc.

877 – 374 – 5236

SAFETY SYMBOLS

(toll free)

The following symbols are used throughout this manual to alert the user to specific

hazards:

= WARNING

Failure to observe this warning may result in personal injury, death, or

equipment damage.

= WARNING

Risk of electrical shock. Failure to observe this warning may result in

personal injury, death, or equipment damage.

= WARNING

Hot! Risk of burns. Wear heat-protective gloves.

Please read the safety instructions in this manual carefully and use the ovens

and warmers only as described in these instructions to avoid injury or damage.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE!

© 2005 Fri-Jado BV, Etten-Leur, The Netherlands

Customers are permitted to copy these instructions for private use.

4

GENERAL

The TG Series Rotisserie Ovens feature stainless steel interior and exterior for ease

of cleaning. The rotor system, spits, chicken racks or baskets and combination

convection and radiant heat provide thorough cooking and even browning yet

eliminate hot spots. Oven controls provide “Manual” operation where the END TIME

or PROCESS TIME can be preset.

Model TG50-M:

The grease drawer can be completely removed for cleaning. A tempered glass door

on the operator/customer side, and quartz lighting promote visual appeal and

stimulate customer interest.

Model TG110-M, TG330-M and TG550-M:

The grease drawer has a drain plug for elimination of excess fat and can be

completely removed for cleaning. Tempered glass doors, both front and back, and

quartz lighting promote visual appeal and stimulate customer interest.

Doors can be re-hinged; contact your local service agency.

Ovens are available in following seizes:

TG50 - Oven with 3 spits (6-9 chickens)

TG110 - Oven with 4 spits (12-20 chickens)

TG330 - Oven with 7 spits (28-35 chickens)

TG550 - Oven with 14 spits (56-70 chickens)

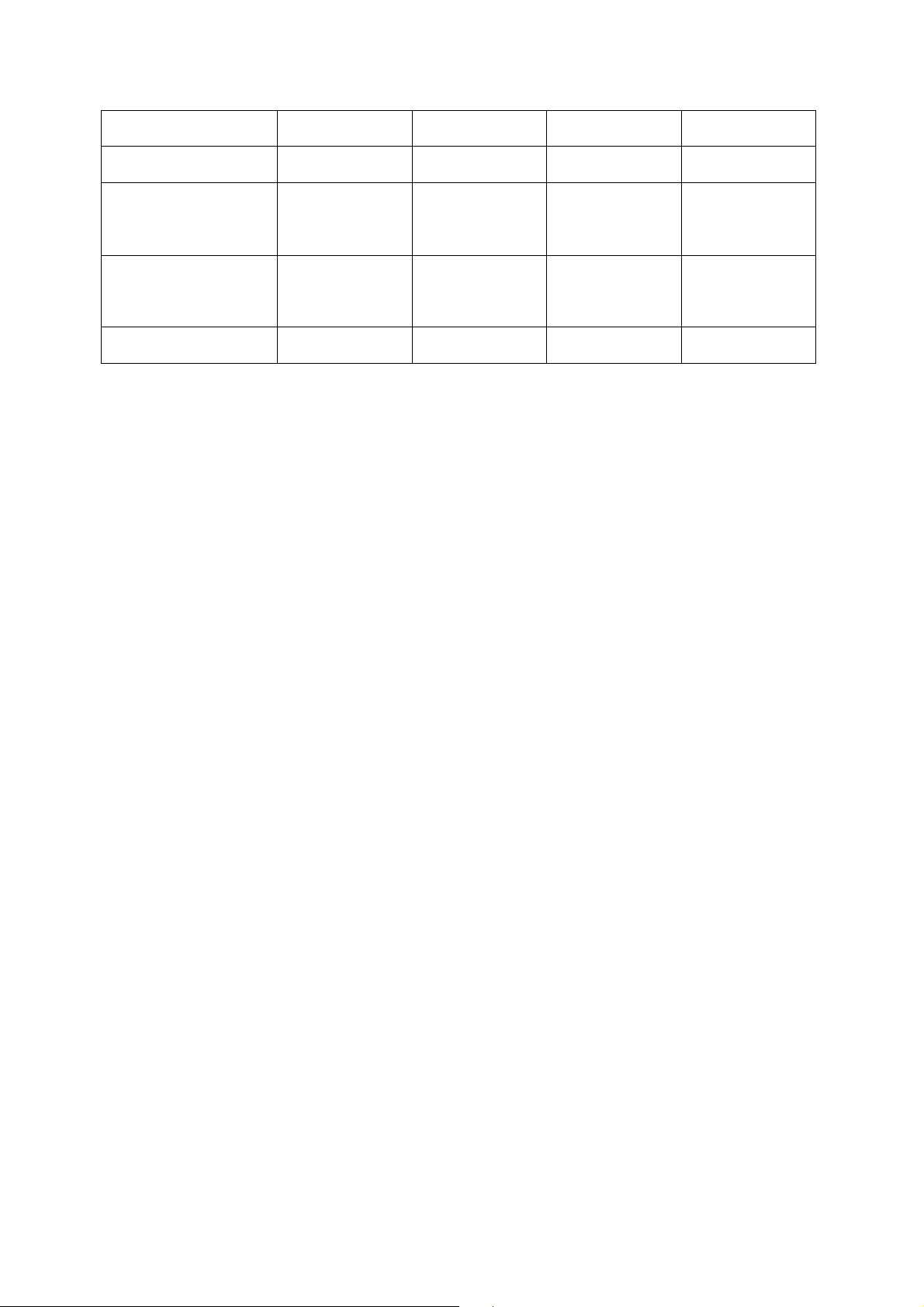

FEATURES AND OPTIONS

Quantity per oven. All parts are optional.

Chicken rack

Spit Basket Turkey

Spit

TG50-M NA 3 NA NA NA 3

TG110-M NA 4 1 NA NA 4

TG330-M 7 7 1 7 7 7

TG550-M 14 14 2 14 14 14

4 rack 5 rack Meat

forks

Do not mix accessories on the rotor.

THIS PRODUCT HAS A ONE-YEAR WARRANTY FOR PARTS AND LABOR. PARTS THAT ARE

NOT COVERED BY THIS WARRANTY ARE LAMPS AND GLASS. THE SOLE AND EXCLUSIVE

REMEDY OF THE PURCHASER IS LIMITED TO REPAIR OR REPLACEMENT OF THE PRODUCT,

AT THE SOLE DISCRETION OF FRI-JADO, INC. THIS LIMITED REPAIR AND REPLACEMENT

WARRANTY IS THE SOLE WARRANTY PROVIDED FOR THIS PRODUCT AND FRI-JADO, INC.

EXPRESSLY EXCLUDES AND DISCLAIMS ALL OTHER WARRANTIES, INCLUDING

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY IS VOID

WHERE DAMAGE RESULTS FROM IMPROPER USE OF THE PRODUCT OR THE PURCHASER

USES THE PRODUCT IMPROPERLY.

5

INSTALLATION

Immediately after unpacking the oven, check for possible shipping damage. If oven is

found to be damaged after unpacking, save the packaging material and contact the

carrier within 15 days of delivery.

TG550-M and TG330-M are secured to the skid with four screws which must be

removed.

WARNING

Prior to installation, test the electrical service to assure that it agrees with the

specifications on the machine data plate located on the right side panel near

the controls. (for the TG50-M on the upper right if you face the back of the

oven)

LOCATION

The oven may be placed where cooking may be observed to enhance customer

awareness, but must be installed on a level surface if the oven or warmer is not on

casters.

The installation location must allow adequate clearances for servicing and for proper

operation of the front and rear doors.

WARNING

A minimum wall clearance of 10” (254 mm) from any glass, and 4" (102 mm)

from each side panel must be maintained.

Keep the space around the bottom and the ventilation openings in the top of the units

free of obstacles to guarantee a good air flow in the electrical compartment.

LEVELING

1. Place oven in the installation position and place a carpenter's level on top of

the oven.

2. Turn the adjustable legs to level the oven front-to-back and side-to-side.

WARNING

The oven should not be accessible to the customer. Hot glass and parts can

cause burns.

LEGS/CASTERS

Counter models, TG110-M, TG220-M and TG330-M , are furnished with 11/2" legs.

TG550-M is furnished with 2 swivel and 2 locking swivel casters.

6

ASSEMBLY

Place the two bottom plates in the oven. The two plates slant to the middle to allow

fat to drip into the grease drawer.(See the above figure).

The TG5500-M bottom plates are the same size and equal to the TG330-M.

NOTE: Bottom plate on the customer side is smaller in the top unit of the TG550-M.

The model TG50-M does not feature removable bottom plates.

SUPPLEMENTAL INSTALLATION INSTRUCTIONS

(For model TG550-M)

WARNING

Safety standards require that, when this appliance is properly connected to the

electrical power supply using flexible conduit, adequate means be provided to limit

movement of the appliance without depending on or transmitting stress to the

electrical conduit. This means that, as part of the installation, the unit must be

secured to the building structure (typically either wall or floor) to limit the

movement of the appliance and, thus, helping to prevent damage to the conduit

during cleaning, maintenance and service operations.

A tether bracket, as shown in the figure below, is installed along with the caster to

one corner of the unit. The remaining open hole in the center of the tether bracket is

to be used to secure one end of the tether (locally supplied chain, cable, etc.). The

other end of the tether is to be secured to an anchoring point in the building structure.

Note: Length of tether must be shorter than the flexible conduit to make sure that

during appliance movement, no stress is transmitted to the conduit.

Following installation, check to confirm that, when the appliance is

moved to the limits of the tether in each direction, no stress is

transmitted to the electrical conduit.

7

INSTALLATION CODES AND STANDARDS

In the United States, all STG series ovens and STW series Warmers or combinations

must be installed according to the following codes:

State and local codes.

National Electric Code, ANSI/NFPA (latest edition). Copies may be obtained from the

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada, all STG series ovens and STW series Warmers or combinations must be

installed according to the following codes:

Local codes.

Canadian Electric Code, CSA C22.1 (latest edition) available from the Canadian

Standard Association, 5060 Spectrum Way, Suite 100, Mississauga, Ontario, Canada

L4W 5N6.

ELECTRICAL CONNECTIONS

WARNING

Electrical and grounding connections must comply with the applicable

portions of the national electrical code and / or other local electrical codes.

WARNING

Disconnect electrical power supply and place a tag at the disconnect switch

indicating that you are working on the circuit.

WARNING

Appliances equipped with a flexible electric supply cord are provided with a

three- or four-prong grounding plug. This plug must be connected into a

properly grounded three- or four-prong receptacle. If the receptacle is not the

proper grounding type, contact an electrician. Do not remove the grounding

prong from this plug.

Access the electrical connection point by removing the side panel(s) where the

controls are located.

WARNING

Ensure that the electrical power supply agrees with the specifications on the

oven's data plate and complies with the wiring diagram, located behind the

oven side panel and under the drive motor

Refer to the ELECTRICAL DATA chart on the next page.

8

ELECTRICAL DATA

MODEL VOLTS HERTZ PHASE CIRCUIT SIZE*

(AMPS)

TG50-M 208

240

TG110-M 208

208

240

240

TG330-M 208

208

240

240

TG550-M 208

240

60

60

60

60

60

60

60

60

60

60

60

60

1

1

1

3

1

3

1

3

1

3

3

3

20

20

35

20

35

20

60

35

60

35

70

70

Maximum Circuit Breaker size / minimum circuit amperage compiled in accordance

with the National Electric Code (latest edition).

9

Loading...

Loading...