Fri-Jado TDR 5 P eco, TDR 8 P eco, TDW 5 P, TWD 8 P Service Manual

WWW.FRIJADO.COM

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

SERVICE MANUAL

TDR P

eco

- ROTISSERIE OVEN MODELS

TDW - WARMER MODELS

- NOTICE -

This manual is prepared for the use of trained Service Technicians

and should not be used by those not properly qualified. If you

have attended a training for this product, you may be qualified to

perform all the procedures in this manual.

This manual is not intended to be all encompassing. If you have

not attended a training for this product, you should read, in its

entirety, the repair procedure you wish to perform to determine

if you have the necessary tools, instruments and skills required to

perform the procedure. Procedures for which you do not have the

necessary tools, instruments and skills should be performed by a

trained technician.

Reproduction or other use of this Manual, without the express

written consent of Fri-Jado, is prohibited.

MODELS

TDR 5 P

eco

TDR 8 P

eco

TDW 5 P

TDW 8 P

Model TDR 5 P

eco

Model TDR 8 P

eco

Page 2

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 3

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

TABLE OF CONTENTS

Versions

Version Issue date

dd/mm/yy

Remarks

07/2012 01/07/2012 First release.

02/2013 01/02/2013 TDW 5 and 8 added. Small adjustments.

05/2013 01/05/2013 TDR 5 and TDW 5 deeper version added as standard. Small adjust-

ments.

09/2013 30/09/2013 Sizes for TDR 5 adapted in Technical data

01/2014 01/01/2014 Small textual changes. Exploded views and trouble shooting modi-

fied. Error 55 explanation added.

10/2014 01/10/2014 New bracket sensors, new errors, various updates.

Page 4

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

TABLE OF CONTENTS

Index .......................................................................................................................................................... 4

General technical data

.............................................................................................................................. 6

Technical data

....................................................................................................................................... 6

Programming instructions for the TDR 5 - 8 P and TDW 5 - 8

............................................................... 7

The automatic cook correction

........................................................................................................... 25

Removal and replacement of parts for the TDR 5 and TDR 8

.............................................................. 26

Right or left side panel

........................................................................................................................ 26

Top cover

.............................................................................................................................................. 26

Operating panel (general)

.................................................................................................................. 26

Electric panel

........................................................................................................................................ 27

Replacing a lamp

................................................................................................................................. 27

Operating panel, glass + backplate + keypad

.................................................................................... 27

Power and I/O board

........................................................................................................................... 28

CPU board

............................................................................................................................................ 28

Replacing of broken buzzer

................................................................................................................ 29

Keypad

.................................................................................................................................................. 29

Infra-red halogen lamp holder

........................................................................................................... 30

Infra-red halogen lamp holder bottom rotisserie (stacked TDR 8)

................................................... 31

Contactor

.............................................................................................................................................. 32

Relay for thermistor function blower (from ser.nr. 100067527)

....................................................... 32

Door switch

.......................................................................................................................................... 32

High limit thermostat

.......................................................................................................................... 33

PT 1000 sensor

...................................................................................................................................... 33

Blower motor

....................................................................................................................................... 34

Blower motor bottom rotisserie (stacked TDR)

................................................................................. 35

Drive motor

.......................................................................................................................................... 36

Heating element

.................................................................................................................................. 37

Door adjustment (left side)

................................................................................................................. 37

Door glass inside

.................................................................................................................................. 38

Door outside

........................................................................................................................................ 38

Removal and replacement of parts for the TDW 5 and TDW 8

........................................................... 39

Blower motor

....................................................................................................................................... 39

Thermometer

....................................................................................................................................... 39

Thermostat

........................................................................................................................................... 40

Main switch

.......................................................................................................................................... 40

Heating element

.................................................................................................................................. 41

Halotherm lamp

................................................................................................................................... 41

Parameter listing TDR P

.......................................................................................................................... 42

Introduction

......................................................................................................................................... 42

Reaching the parameter menus

.......................................................................................................... 42

Manager menu - description of the submenus

.................................................................................. 44

Service menu - description of the submenus

..................................................................................... 45

Adapting parameters

.......................................................................................................................... 47

Loading software

................................................................................................................................. 47

Read and store recipies in manager menu

......................................................................................... 48

Read and store recipies and parameters in service menu

................................................................. 49

INDEX

Page 5

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

TABLE OF CONTENTS

Parameter List P ................................................................................................................................... 51

Electrical tests and service procedures

.................................................................................................. 52

Heating element test

........................................................................................................................... 52

Contactor, drive motor and blower test

............................................................................................. 52

PT1000 sensor test

............................................................................................................................... 53

Error codes on display

......................................................................................................................... 53

Control location

................................................................................................................................... 54

General troubleshooting list

.................................................................................................................. 55

Troubleshooting for the TDR 5 and 8 rotisseries

............................................................................... 55

Troubleshooting for the TDW 5 and 8 warmers

................................................................................ 57

Error 55 explanation

............................................................................................................................ 58

Analytic troubleshooting list

................................................................................................................. 59

Servicing and repairing the TDR 5 and 8 rotisseries

.......................................................................... 59

Servicing and repairing the TDW 5 and 8 P warmers

........................................................................ 64

Exploded views & partlists

..................................................................................................................... 66

TDR 5 P - sheet metal work

................................................................................................................. 66

TDR 5 P - components

.......................................................................................................................... 68

TDR 5 P - doors

..................................................................................................................................... 70

TDR 8 P - sheet metal work

................................................................................................................. 72

TDR 8 P - components

.......................................................................................................................... 74

TDR 8 P - doors

..................................................................................................................................... 76

TDW 5 P - sheet metal work

................................................................................................................ 78

TDW 5 P - components

....................................................................................................................... 80

TDW 8 P - sheet metal work

................................................................................................................ 82

TDW 8 P - components

........................................................................................................................ 84

Electrical diagrams

.................................................................................................................................. 86

Circuit diagram TDR 5 and 8 P

........................................................................................................... 86

Wiring diagram TDR 5 and 8 P

........................................................................................................... 87

Circuit diagram TDR 5 and 8 P (untill serial number 100067527)

..................................................... 88

Wiring diagram TDR 5 and 8 P (until serial number 100067527)

..................................................... 89

Circuit diagram TDR 5 P (until 01-07-2012)

........................................................................................ 90

Circuit diagram TDR 8 P (until 01-07-2012)

........................................................................................ 91

Wiring diagram TDR 5 and 8 P (until 01-07-2012)

............................................................................ 92

Circuit diagram TDR 5 + 5 P bottom unit (until 01-07-2013)

............................................................ 93

Circuit diagram TDR 8 + 8 P bottom unit (until 01-07-2012)

............................................................ 94

Wiring diagram TDR 5 + 5 and 8 + 8 P bottom unit (until 01-07-2012)

.......................................... 95

Circuit diagram TDR 5 P

with TDW 5 (until 01-07-2012) ................................................................... 96

Wiring diagram TDR 5 P

with TDW 5 (until 01-07-2012) .................................................................. 97

Circuit diagram TDW 5

........................................................................................................................ 98

Wiring diagram TDW 5

........................................................................................................................ 99

Circuit diagram TDW 8

...................................................................................................................... 100

Wiring diagram TDW 8

...................................................................................................................... 101

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 6

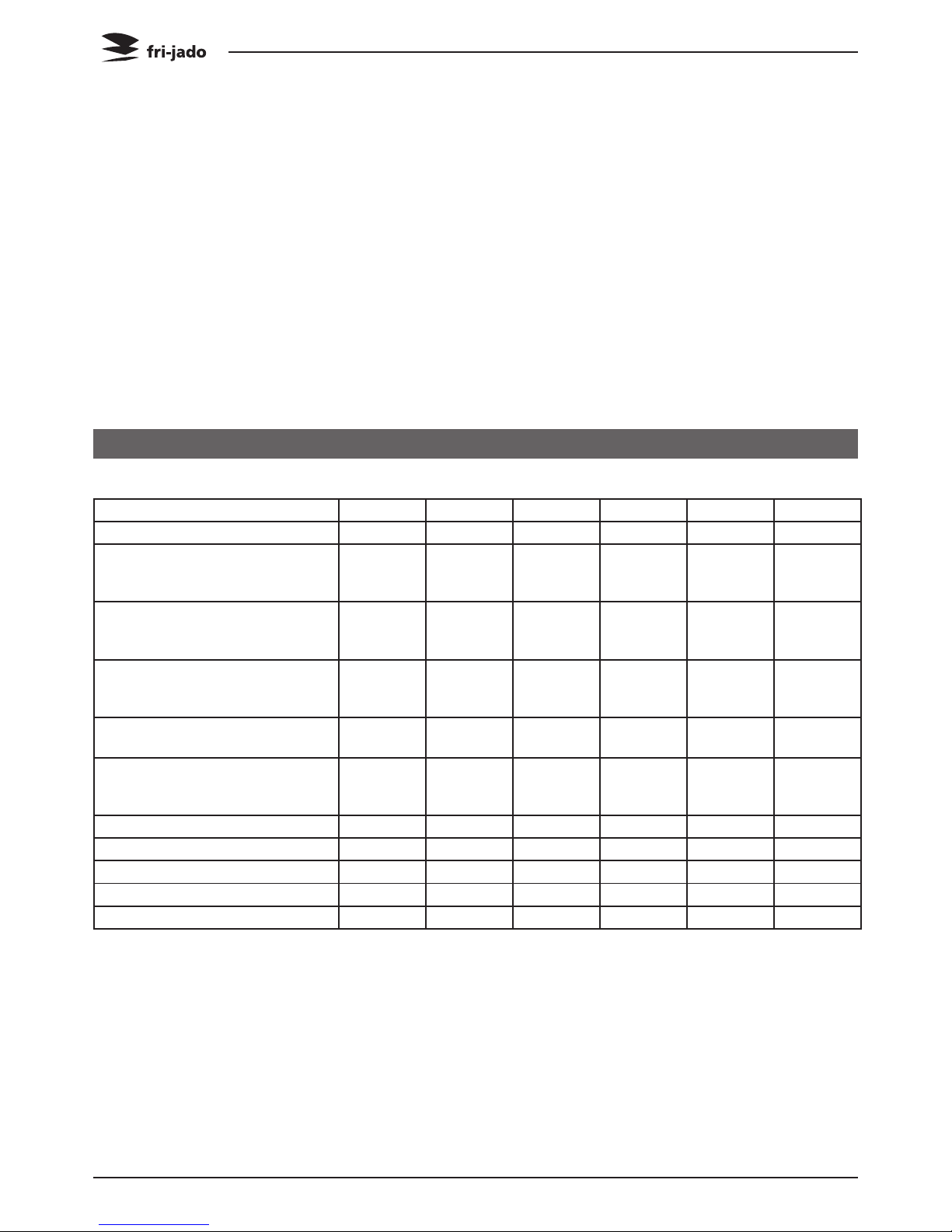

GENERAL TECHNICAL DATA

GENERAL TECHNICAL DATA

This manual covers the TDR P

eco

series rotisserie ovens and the TDW series warmers. Ovens

and warming cabinets come in two sizes. Ovens and cabinets will alsobe delivered in stacked

versions.

• TDR 5 – Oven with five spits ( 15 to 20 chickens )

• TDR 8 – Oven with eight spits ( 32 to 40 chickens )

• TDW 5 - Warming cabinet for 25 to 30 chickens

• TDW 8 - Warming cabinet for 35 to 40 chickens

All of the information, illustrations and specifications contained in this manual are based on

the latest product information available at the time of printing.

Type TDR 5 TDRW 5 TDR 8 TDRW 8 TDW 5 TDW 8

Power (W) 6600 9400 10500 14000 2800 3500

Fuses needed with power connection 400 V, 3N ~50…60 Hz

( 3 phases with zero )

3x 16 A 3x 16 A 3x 16 A 3x 32 A - -

Fuses needed with power connection 200 or 230 V, 3 ~50…60 Hz

( 3 phases without zero )

3x 20A 3x 32 A 3x 32 A 3x 35 A - -

Fuses needed with power connection 230 V, 1N ~50…60 Hz

( 1 phase with zero )

- - - - 1x 16 A 1x 16 A

Standard plug from factory 5-pole

Acc IEC309 and CEE-form

16 A

3P+N+E

16 A

3P+N+E

16 A

3P+N+E

32 A

3P+N+E

- -

Standard plug from factory single

pole

_ _ _ _ 2-pole

earthed

plug 16 A

2-pole

earthed

plug 16 A

Net weight (kg) 130 235 185 340 100 150

Gross weight (kg) 160 275 216 390 120 176

Height (mm) 910 1790 1065 2095 910 1065

Width (mm) 835 835 995 995 835 995

Depth (mm) 710 710 830 830 710 830

• Standard set of tools.

• Metric wrenches, sockets and hex socket key wrenches.

• Multi-meter and AC current clamp meter.

• Temperature tester.

• Insulation value tester (Megger).

• Field Service Grounding Kit.

TECHNICAL DATA

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 7

PROGRAMMING INSTRUCTIONS

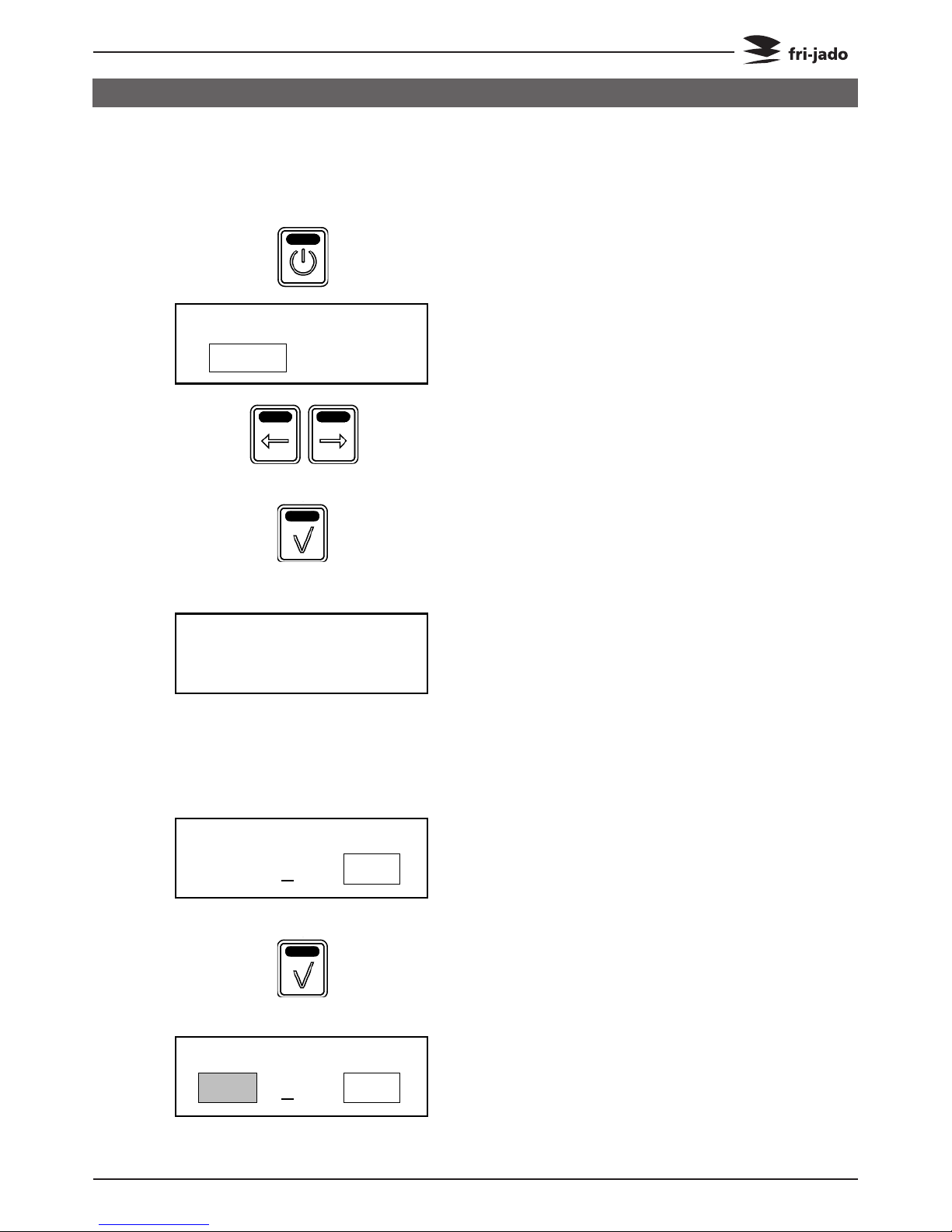

PROGRAMMING INSTRUCTIONS FOR THE TDR 5 - 8 P AND TDW 5 - 8

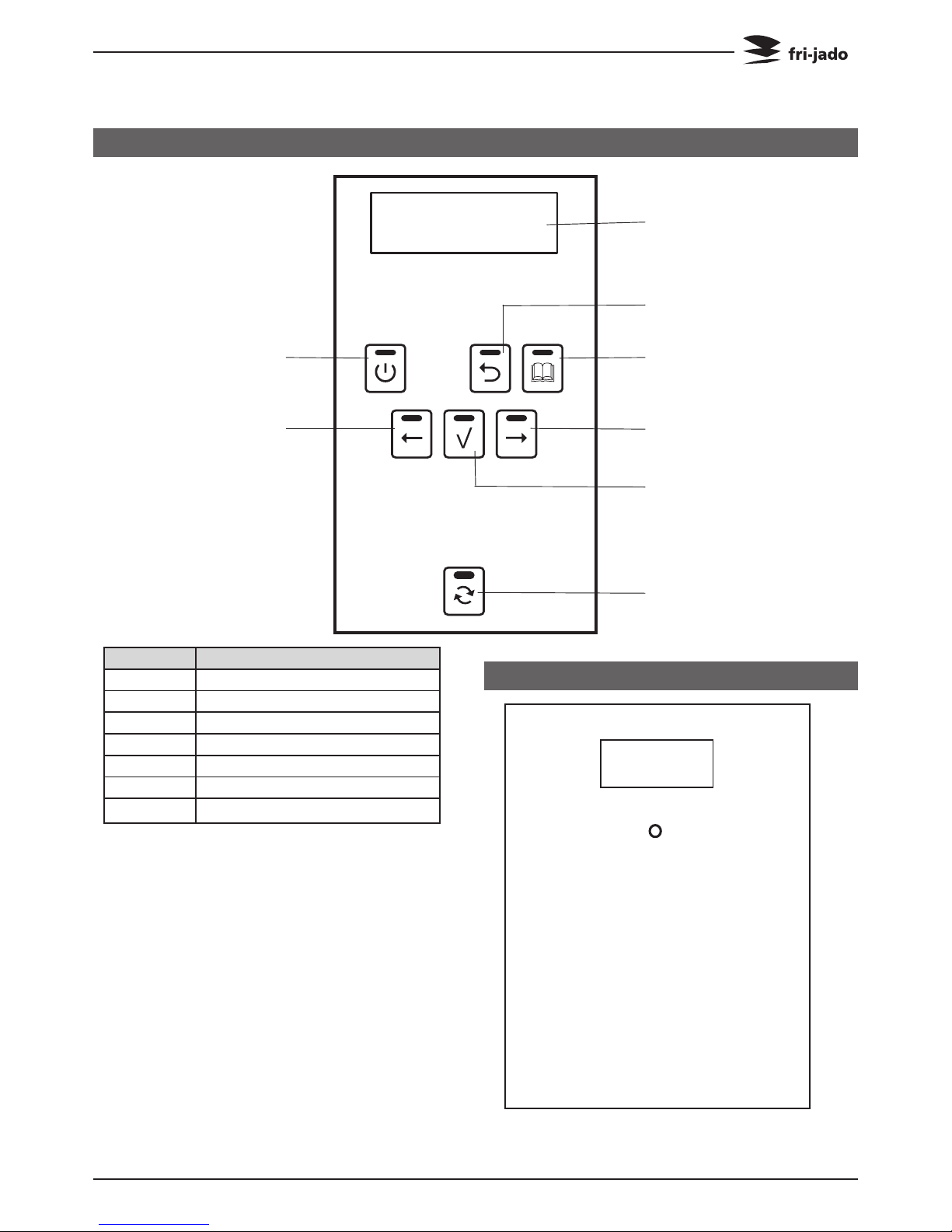

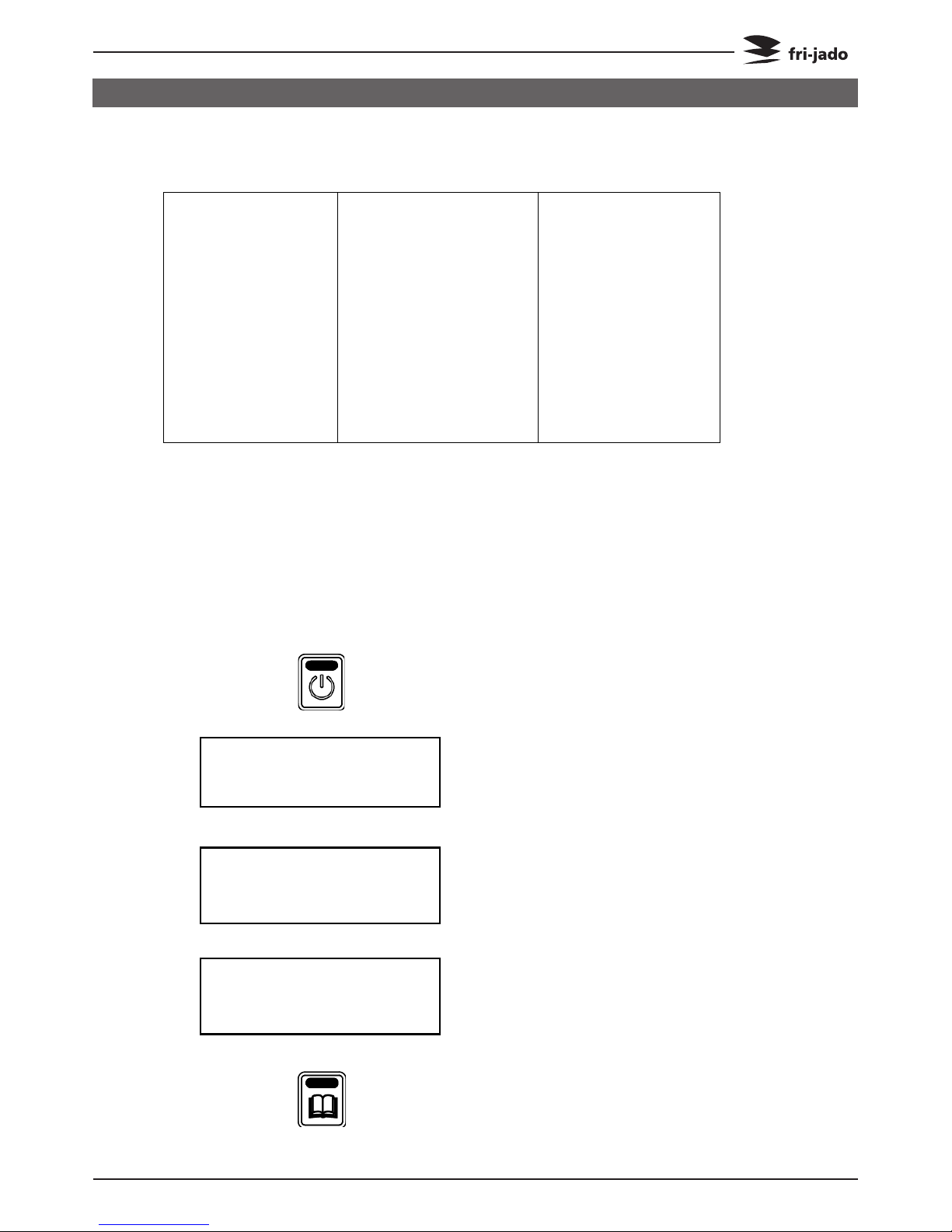

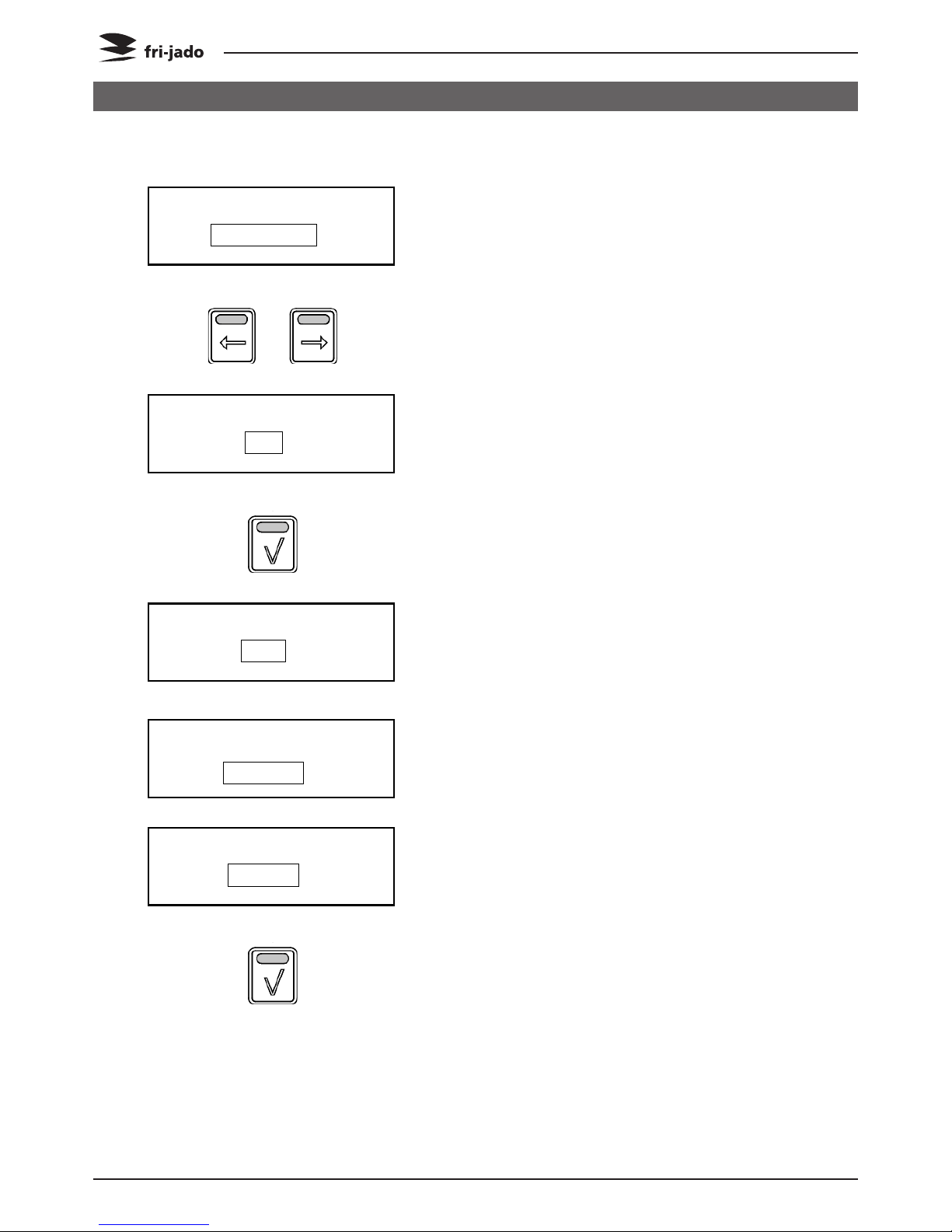

OPERATING PANEL

CHICKEN

85 1

2 3 7

Display

On / Off

Rotor

OK

Forward

List

Undo

Back

Key Function

On / Off Switching the unit On / Off

Undo Go back to previous menu

List Recipe / programming modus

Forward One step ahead in setting

Rotor Switching the rotor on

OK Acknowledge a function or change

Back One step back in setting

OPERATING PANEL WARMER

0 = Off

1 = 25°C / 77°F

2 = 40°C / 104°F

3 = 60°C / 140°F

4 = 80°C / 176°F

5 = 95°C / 203°F

Thermometer °C

Thermostat dial

Page 8

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

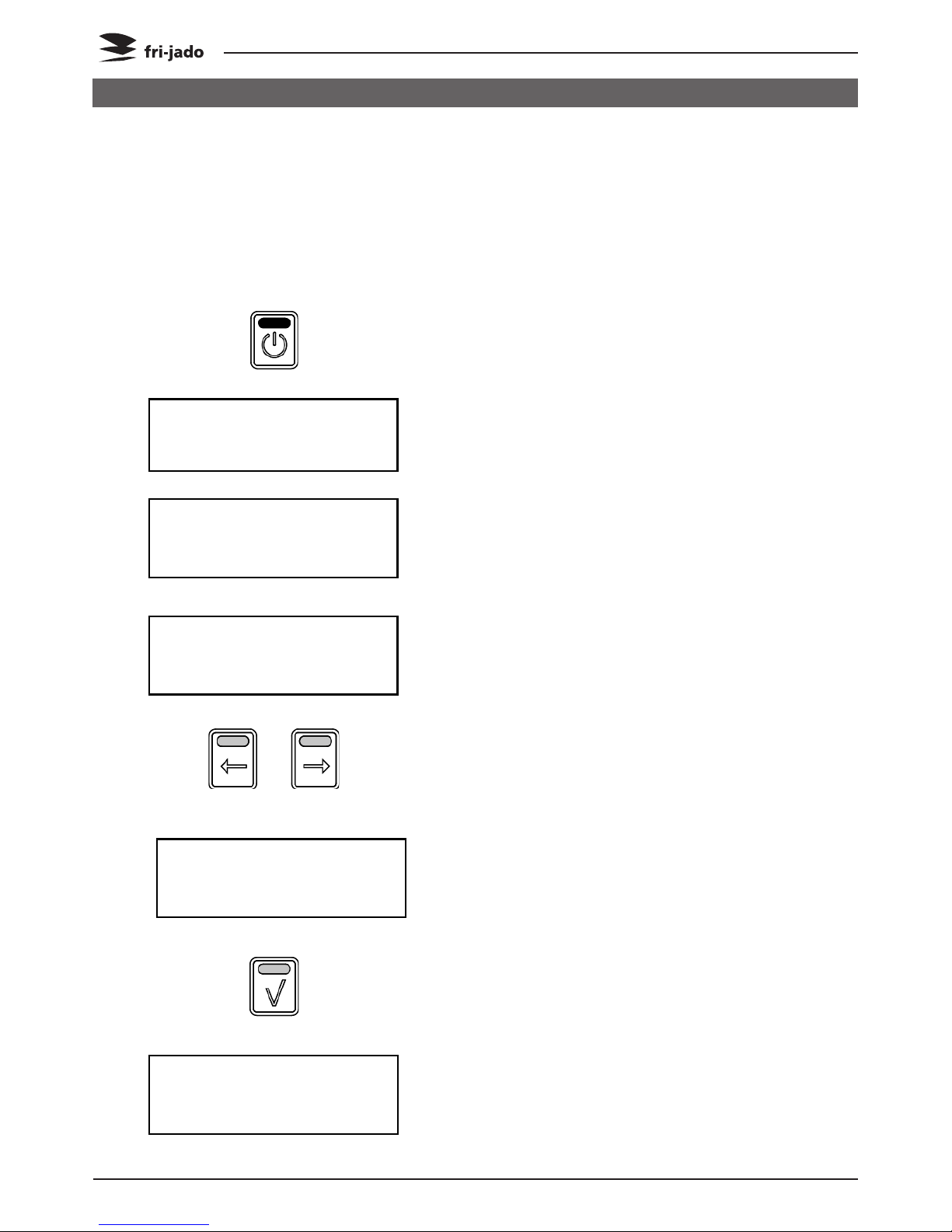

OPERATION

TDR-P

eco

Models

Interface P Eco

TDR

Version x.x.x

Drumstick

Chicken

98 99 1 2 3

180°C Preheat

5. OPERATION

Buttons are lit when functional.

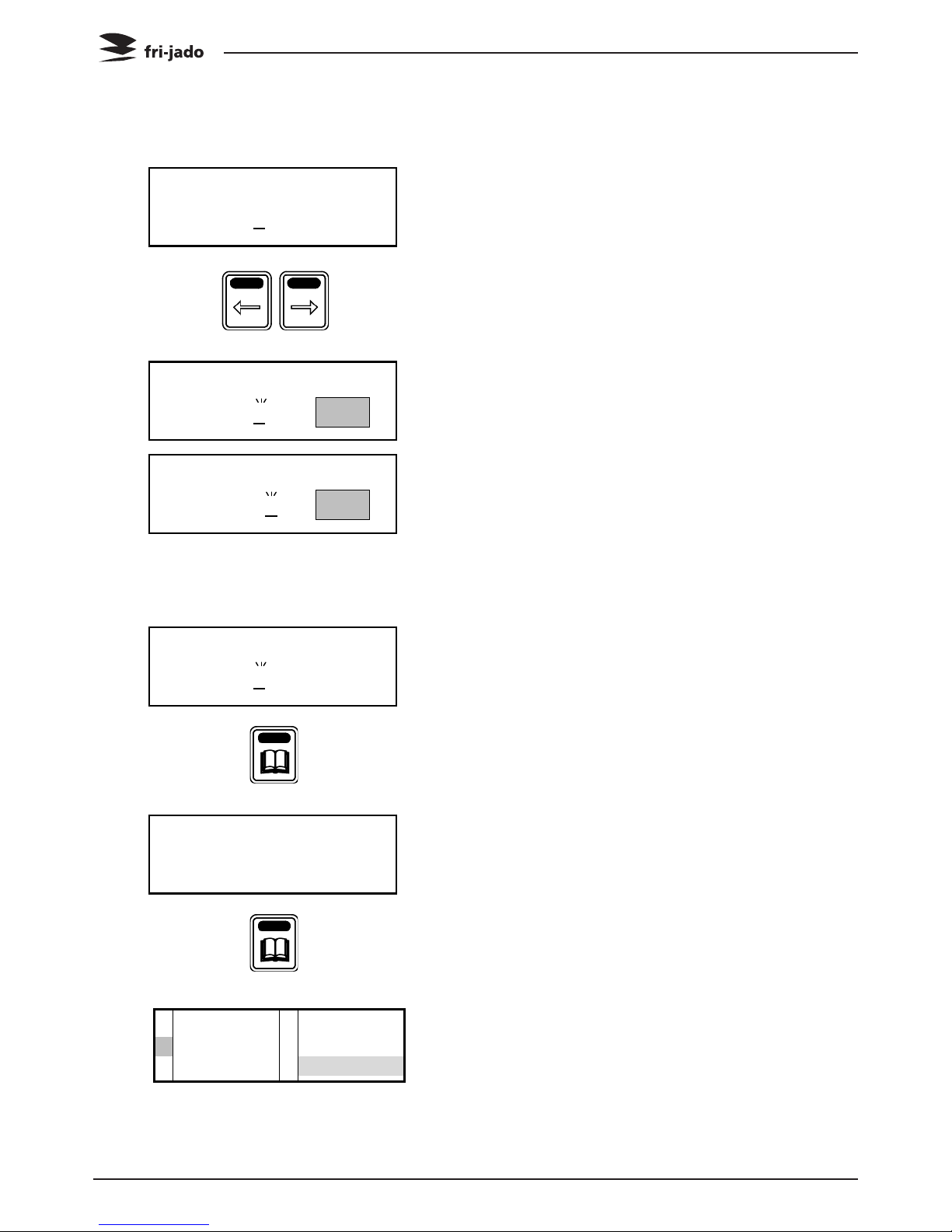

5.1. Operation of the rotisserie

1. Press Start.

2. Display shows Fri-Jado logo.

3. Display shows software version.

4. Display shows latest cooking

program.

5. Use the arrow buttons for program

selection.

6. Display shows selected program.

7. Confirm the selected program.

8. Display shows pre-heat

(only when pre-heat is defined).

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 9

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

LOAD

or

START

Did you empty

The fat tray?

180°C 0:59

1 Chicken

230°C P123 10:60

1 Chicken

230°C P123 10:55

UNLOAD

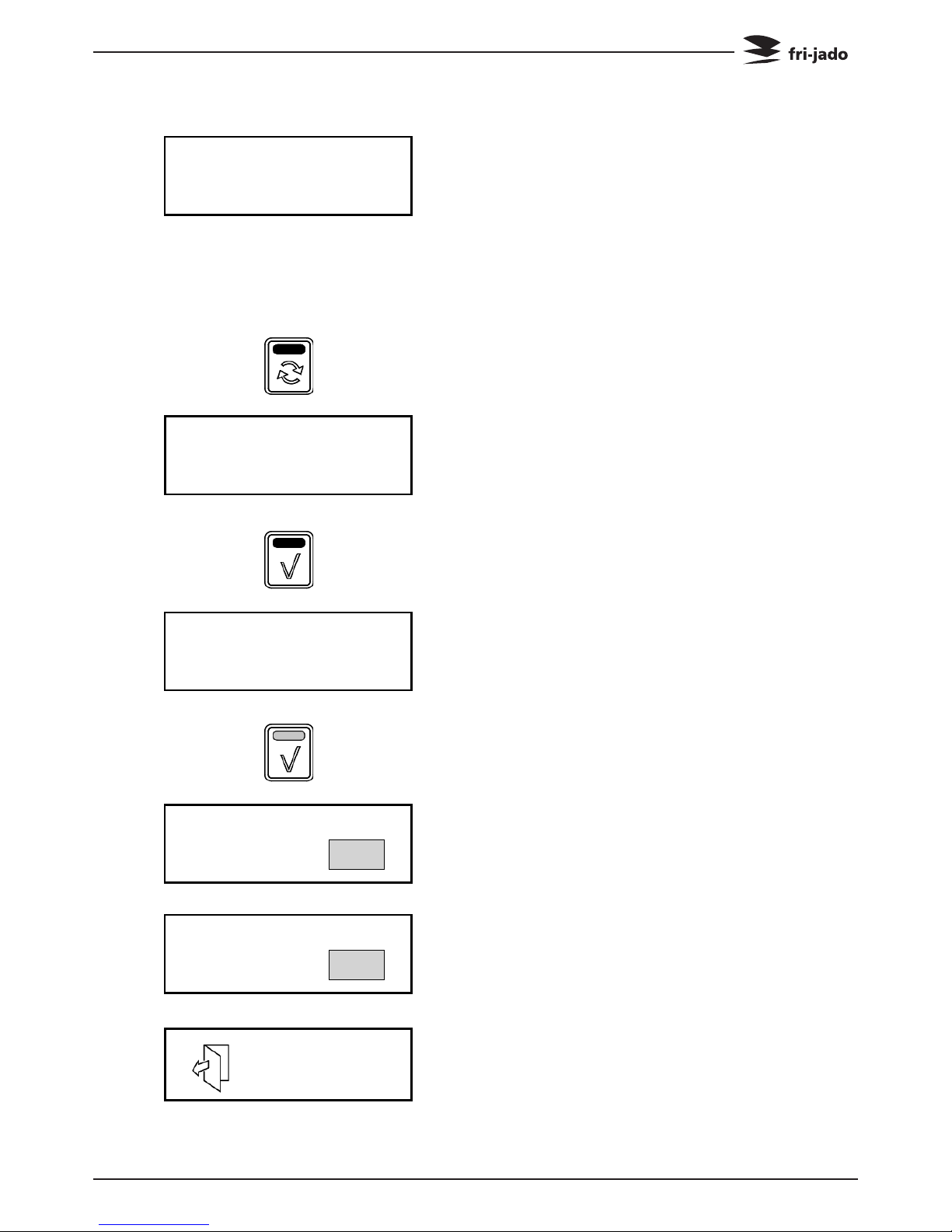

9. Pre-heat ready

(unit returns a sound signal).

Note: press OK or open the door to

stop the signal.

Display shows the next step of the

program.

Note: Screen 9 and 11 alternate

each 5 seconds.

10. When loading: press the rotor button

to turn the rotor.

11. After loading, close the door.

A reminder to empty the fat tray

appears.

12. Press OK to confirm.

13. Display show programmed

temperature and time (hour : min).

14. (Optional) Press OK button for

the actual temperature and time

(shows about 2 seconds).

15. During the last minute the time blinks.

16. Display show the remaining time, the

interval is 5 seconds.

17. Open the door.

Page 10

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

Measure Core Temp.

2 Chicken

:00 Add time?

UNLOAD

Chicken

98 99 1 2 3

18. A reminder to measure the core

temperature appears.

Note: Screen 17 and 18 alternate

every 5 seconds.

19. (Optional, visible for 5 min. ) request

for additional time (minutes) after

opening the door.

Note: Add time is only available

when activated in the service menu.

20. (Optional) press right arrow for one

minute increase, press left arrow for

one minute decrease.

When activated program continues

at step 13.

21. Program ready, open door.

22. Press the rotor button to rotate the

rotor.

23. Close the door (if required clean the

unit).

24. Display shows the last operated

program.

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 11

PROGRAMMING INSTRUCTIONS

OPERATION OPTIONS

TDR-P

eco

Models

Stop?

1 NO YES

Chicken

98 99 1 2 3

1 Chicken

230°C P123 10:05

1 Chicken

220°C P123 10:05

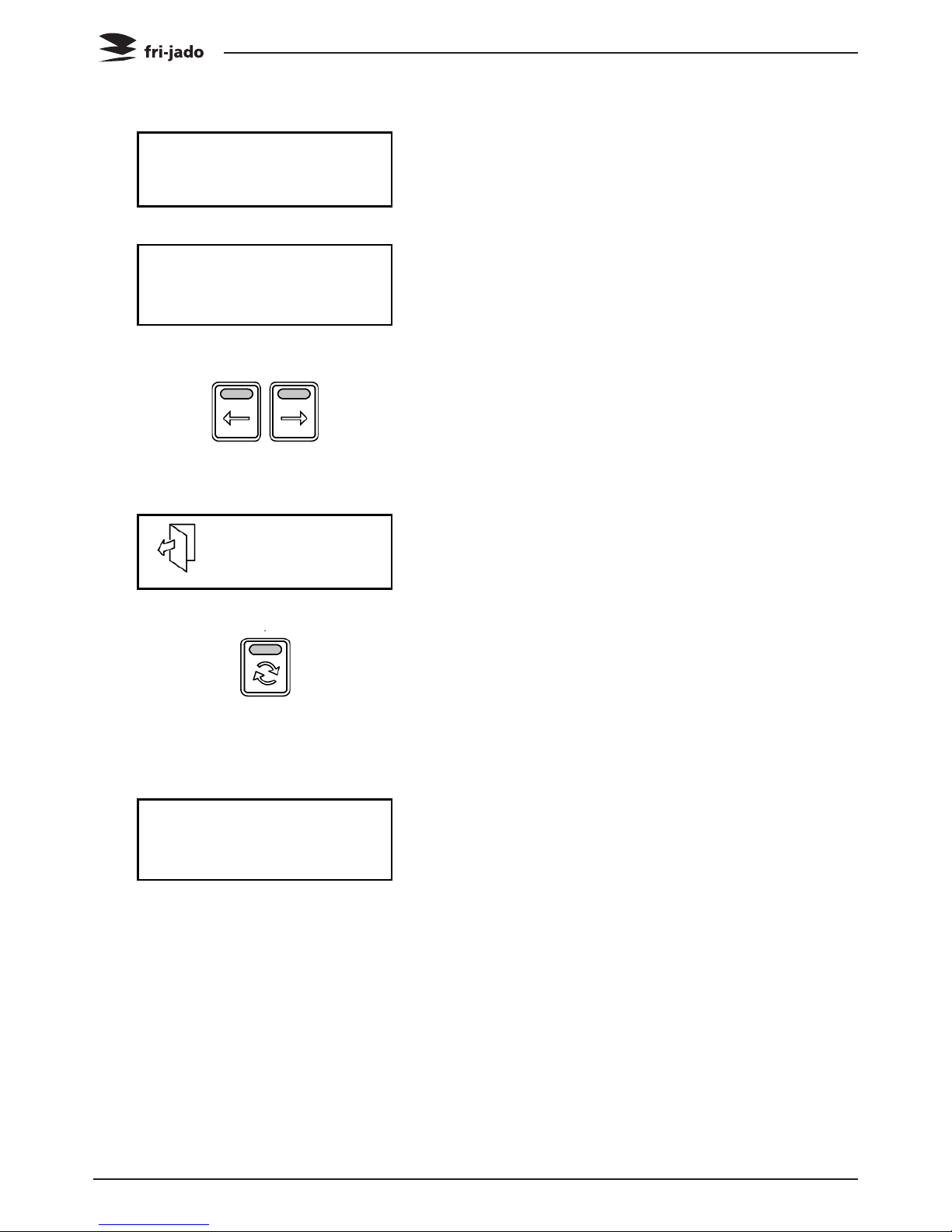

5.2. Operation options

5.2.1. To end a running program.

1. Press and hold start for 3 seconds.

2. Make a choice with the arrow

buttons.

Note: Select NO to abort ending the

program.

3. Confirm the selection.

(Within 5 seconds).

4. Display shows the last operated

program.

5.2.2. Check the actual temperature

1. For example: Check the current

temperature in

program 1 Chicken, step 1.

2. Press the OK button.

3. The display shows during 3 seconds

the actual temperature.

Page 12

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

1 Chicken

230°C P123 10:05

1 Chicken

230°C P123 0:01

1 Chicken

230°C P123 0:05

1 Chicken

180°C P123 10:20

180°C 0:20

5.2.3. Check the remaining time in a program

1. Use the arrow buttons to show the

remaining time pro step.

2. Time left at step 1

(first digit blinks).

3. Time left at step 2

(second digit blinks).

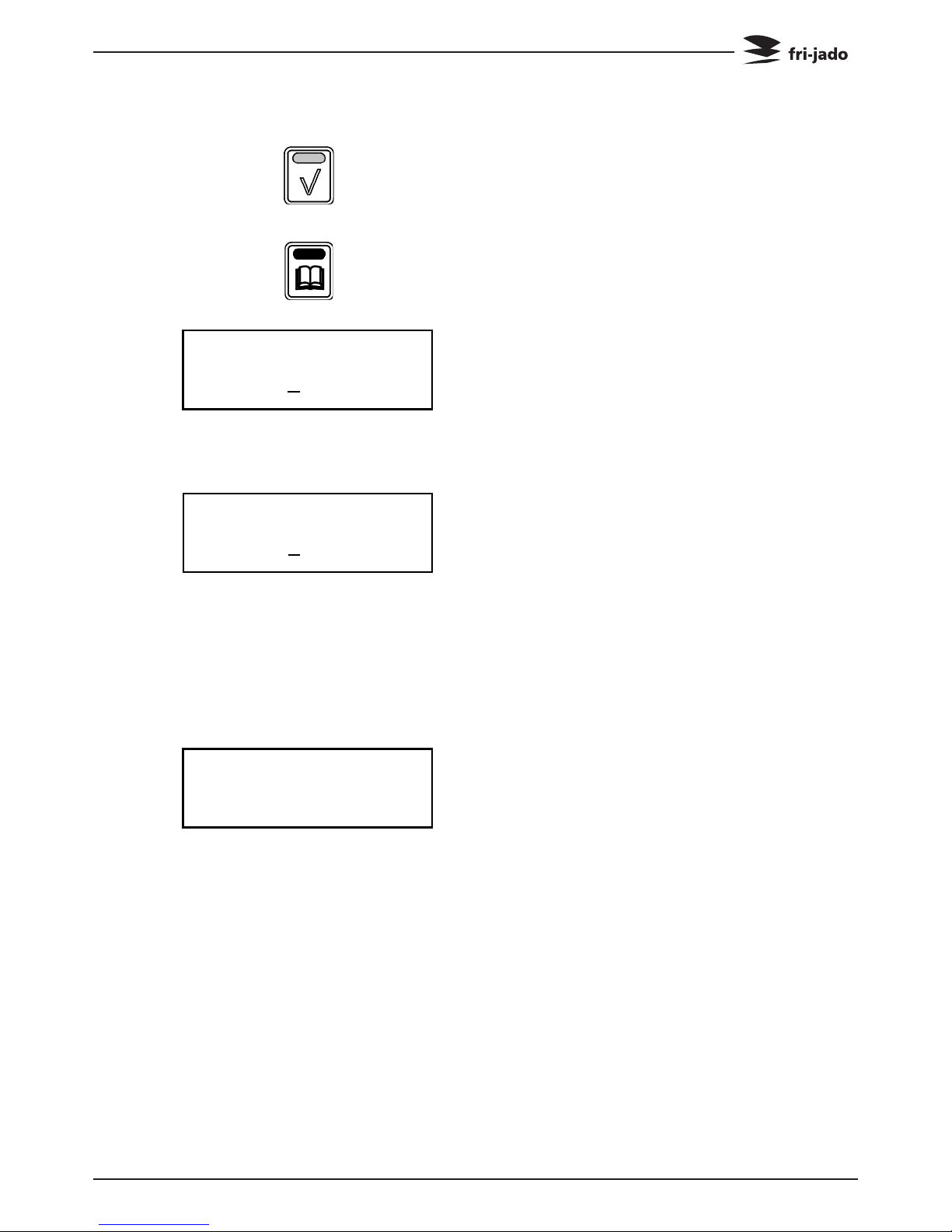

5.2.4. Show all actual program information

1. Display shows actual program.

(step one is active).

2. Press List button.

3. Display shows the programmed

temperature and time.

4. Press List button again for additional

information.

P

180 0:07 3 230

0:05

0:05

1

180

0:20

0:20 H 085

0:10

0:10

2

210

0:10

0:10 C + 00:00:00

5. Display shows the programmed steps

and remaining times in one overview.

(Step – temperature – program time – actual time)

P: Preheat

1-3: Program step

H: Holding

C: Cook correction

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 13

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

1 Chicken

180°C P123 10:20

1 Chicken

ECO

180°C P123 10:20

180°C 0:20

6. Press the OK button to update the

screen

(automatically refreshed every 15

seconds).

7. Press List button to go back.

8. Display returns to the original

operating display.

5.2.5. Eco function

Optional: only available when activated

in the service menu.

In the ECO mode the accumulated heat

in the cavity will be used to cook the

product.

Depending on the settings, the product

and program an energy saving of 5% can

be achieved.

5.2.6. Cook correction

Optional: only available when activated

in the service menu.

Cook correction: Depending on the load

of products the cooking time will be

automatically adjusted.

The first cook is the reference cook and

will be used to fix the correct parameters.

The activation of the cook correction is

NOT visible in this display.

Page 14

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

180°C 0:20

1 Chicken

180°C P123 10:20

1 Chicken

210°C P123 10:20

1 Chicken

230°C P123 10:20

1 Chicken

220°C P123 10:20

1 Chicken

220°C P123 0:15

5.2.7. Display information

1. Display shows the programmed

temperature and time.

2. Press the list button.

3. Display shows after 3 seconds

cooking step + temperature + time.

Note: the current cooking step is

underlined.

4. Use arrow button for next screen.

5. Cooking step 1 is finished, sound

signal is returned.

Display shows next cooking step +

temperature + time.

6. Cooking step 2 is finished, sound

signal is returned.

Display shows next cooking step +

temperature + time.

7. Display shows the actual temperature

Note: the actual temperature blinks.

8. Display shows the remaining time.

Note: the remaining time blinks, after

5 seconds the original display is

shown again.

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 15

PROGRAMMING INSTRUCTIONS

PROGRAMMING

TDR-P

eco

Models

Interface P Eco

TDR

Version x.x.x

Drumstick

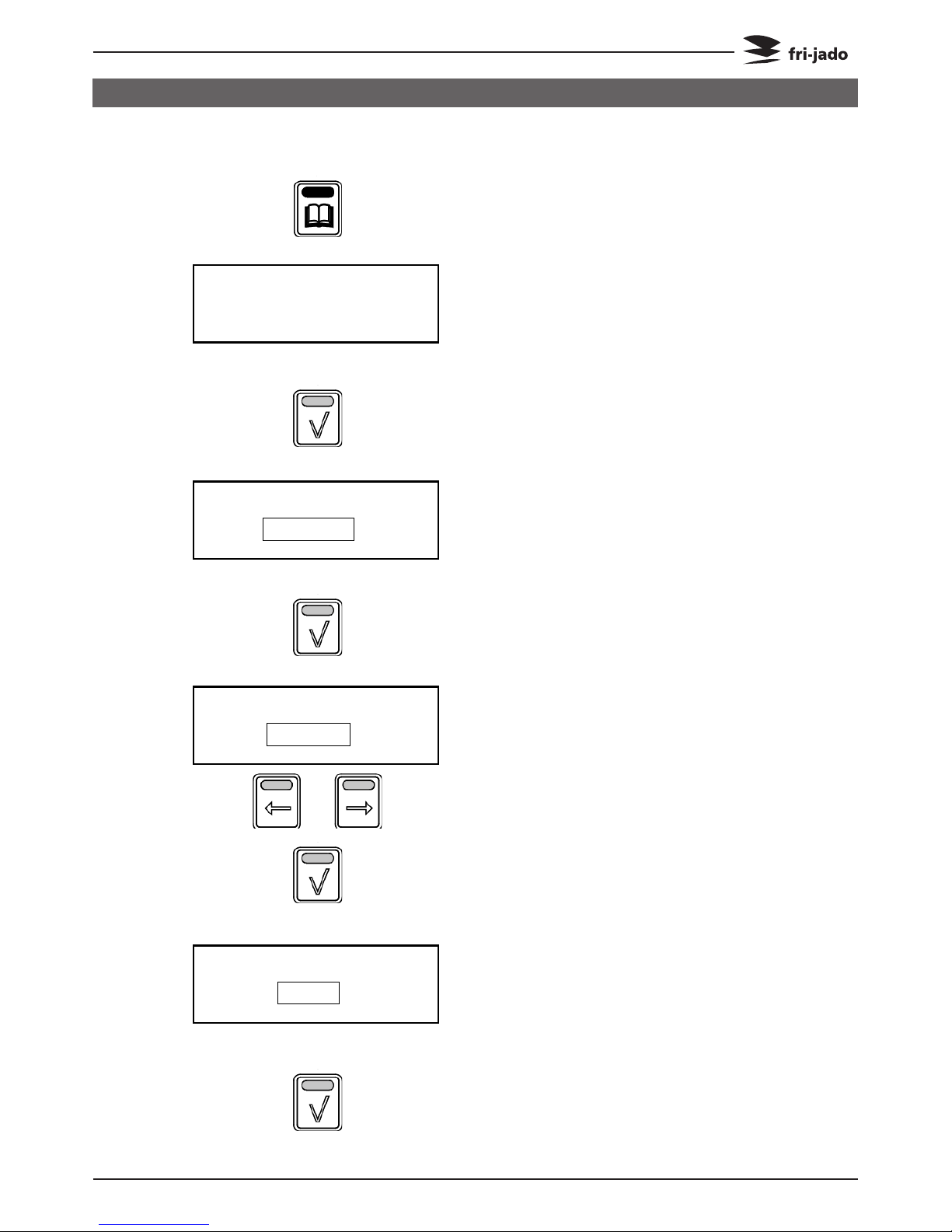

6. MANAGER MEN U

6.1. Manager menu items

Programming

New

Edit

Delete

Copy

Parameters

Pre-Heat

Preheat temperature

Holding

Holding temperature

Cook correction*

Eco function*

Language

Big digits

Sound preheat

Sound step

Sound done

Change pin

Clock

Transfer

Version

USB

Reading recipes

Store recipes

* Only visible when selected in the service menu.

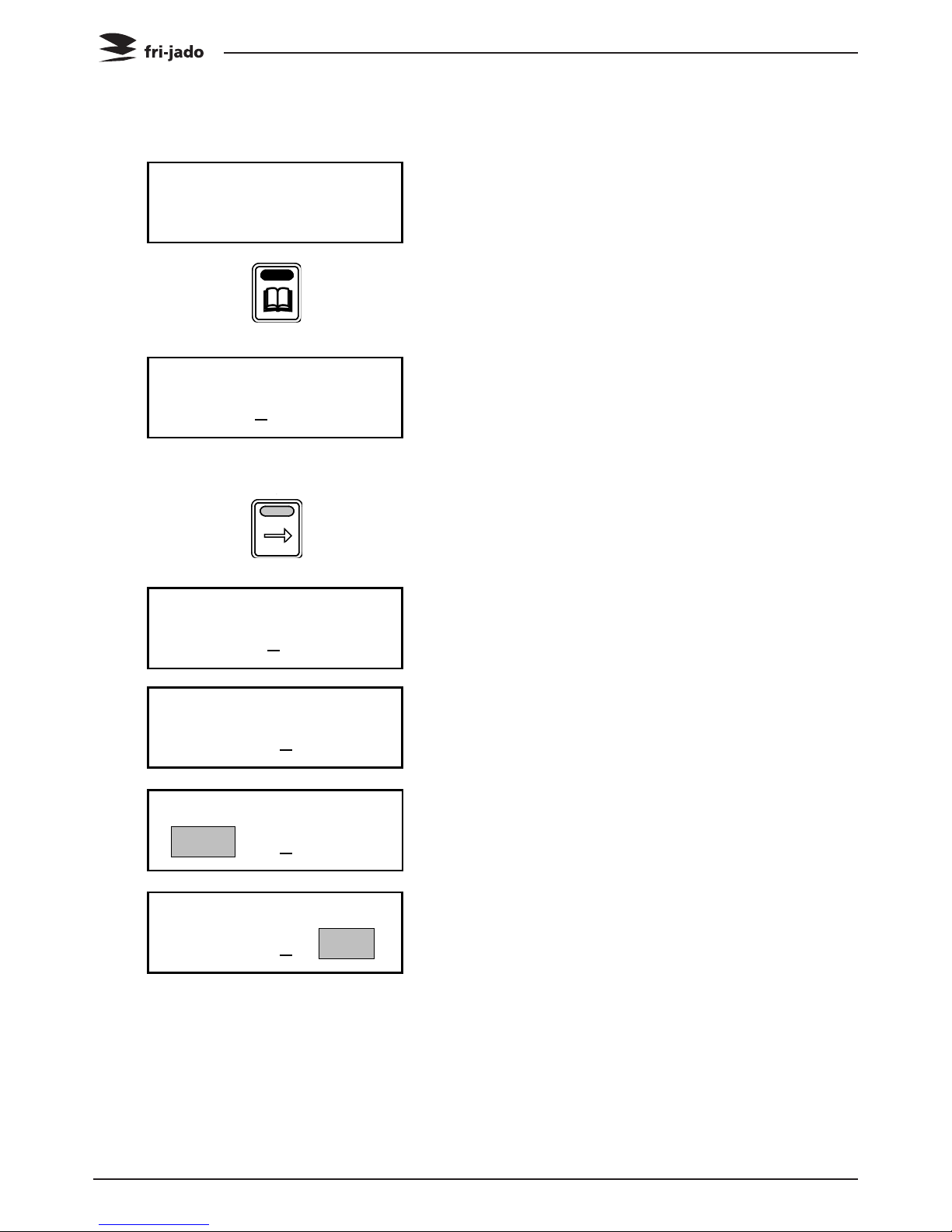

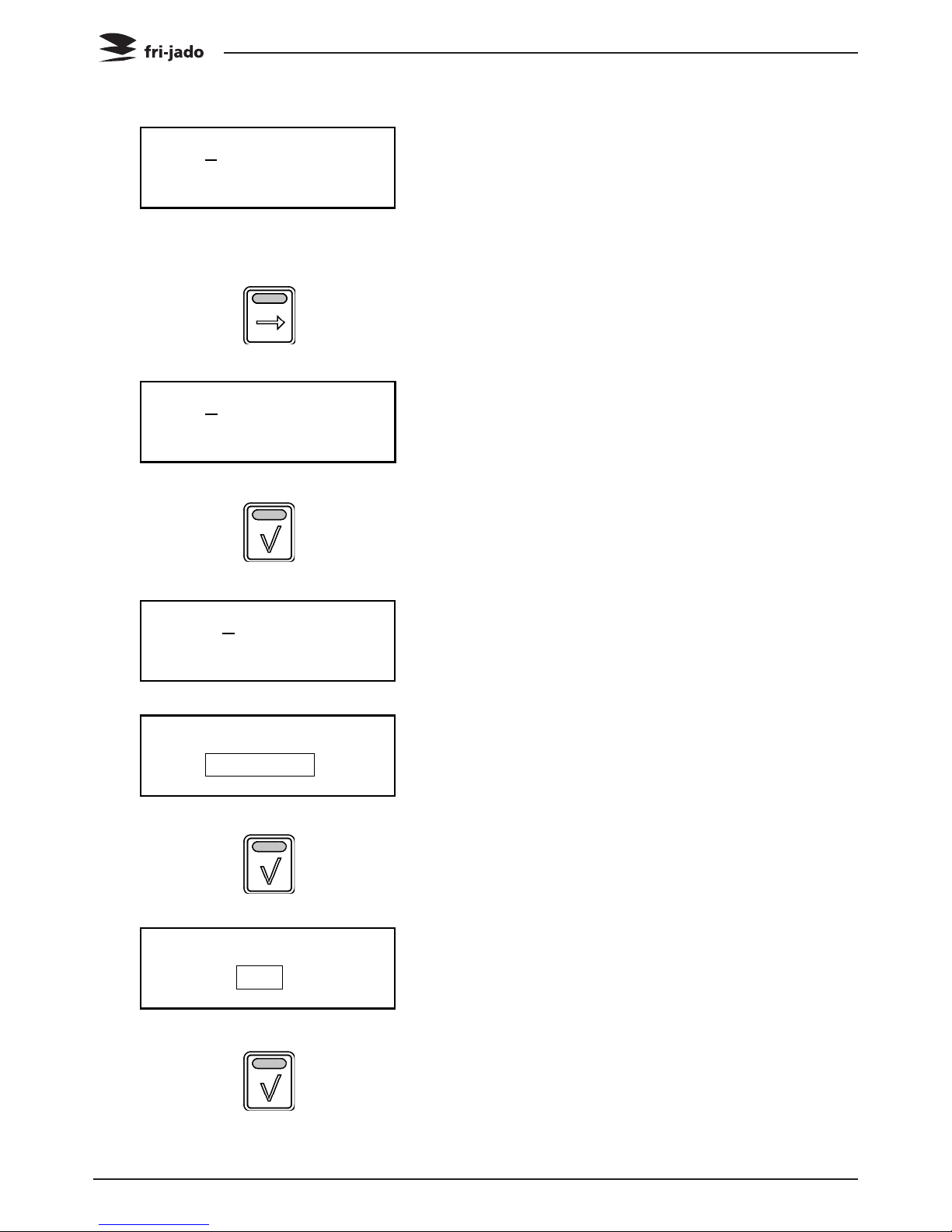

6.2. Programming the rotisserie

Possible programming steps:

- Preheat

- Step 1

- Step 2

- Step 3

- Holding

1. Start the unit.

2. Logo appears.

3. Unit information appears.

4. Last used program appears.

5. Press the list button.

Page 16

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

Pin 0 - - -

Give User PIN code

Pin 1 - - -

Give User PIN code

Pin * 0 - -

Give User PIN code

MANAGER MENU

USB Programming 1Para.

RECIPES

NEW 1EDIT

6. Enter the User PIN code.

Note: the original PIN code is 1111.

The operator can change the User

PIN code.

7. Use the arrow button to enter the PIN

code.

8. Press the arrow right button to

change the first digit.

9. Press the OK button to confirm.

10. The next digit is activated.

Change as required using the arrow

button.

Confirm with the OK button.

Repeat for the other digits.

11. Manager menu is activated.

Use the arrow buttons to toggle

between the sub menu’s.

12. Select “Programming” and Press the

OK button to co nfirm.

13. Use the arrow buttons to select a

new or existing recipe.

14. Press the OK button to confirm.

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 17

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

10

Choose new number

10 A--------------

ABC for others

10 TEST

10 TEST

Preheat Y Temp 210°C

15. The first available number is shown.

Note: use the arrow right button to

select the next available number.

16. Press the OK button to confirm.

17. Enter the recipe name.

Use the arrow button to change the

character.

Note: ABC can be changed with the

use of the list button into lower /

higher case or special characters.

18. Press the OK button to confirm.

19. The new recipe name is shown

Note:

To change the name of the recipe

use the back arrow button and press

the OK button.

20. Press the OK button to confirm.

21. Set the preheat function and

temperature (default set on 210 °C /

425°F). Press the left arrow button

and the OK button to change the preheat setting.

Note: Pre-heat is only available when

activated in the parameter list.

Preheat functions:

Y: Yes

N: No

C: Continuously

Page 18

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

10 Step 1

Temp 1 - - °C

10 Step 1

Temp 21 - °C

10 Step 1

Temp 215 °C

10 Step 1

Temp 215 °C Time 1 - -

22. Press the OK button to confirm.

23. Set the “step 1” temperature.

Starting with the first digit.

24. Use the arrow buttons to

increase/decrease the value of the

selected digit.

25. Press the OK button to confirm.

26. Set the second digit.

27. Press the OK button to confirm.

28. Set the third digit.

29. Press the OK button to confirm.

30. Set the “step 1” time.

Starting with the first digit.

Note:

Enter the time in minutes.

31. Use the arrow buttons to

increase/decrease the value of the

selected digit.

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 19

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

10 Step 1

Temp 215 °C Time 21 -

10 Step 1

Temp 215 °C Time 210

10 Step 1

Temp 215 °C Time 210

10 Step 2

Temp 215 °C

10 Holding

Temp 85 °C Time 999

32. Press the OK button to confirm.

33. Set the second digit.

34. Press the OK button to confirm.

35. Set the last digit.

36. Press the OK button to confirm.

37. The Step is now completed.

Select the right arrow and press the

OK button to go to the next step.

Select the left arrow button and press

the OK button to go back to the last

setting.

Select the and press the OK

button to finish programming.

38. Program the next step (when

required). See step 1 for the

procedure.

39. After step 3 or when entering no time

at step 2 (or 3) the holding step will

appear. Set the temperature and time

as required.

Note:

Set the time to 999 for continuous

operating.

Only available when activated (refer

to section 6.3).

Page 20

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

10 TEST

Save 1Disc

RECIPES

NEW 1EDIT

MANAGER MENU

Usb Programming 1Para

Drumstick

5 6 7 8 9

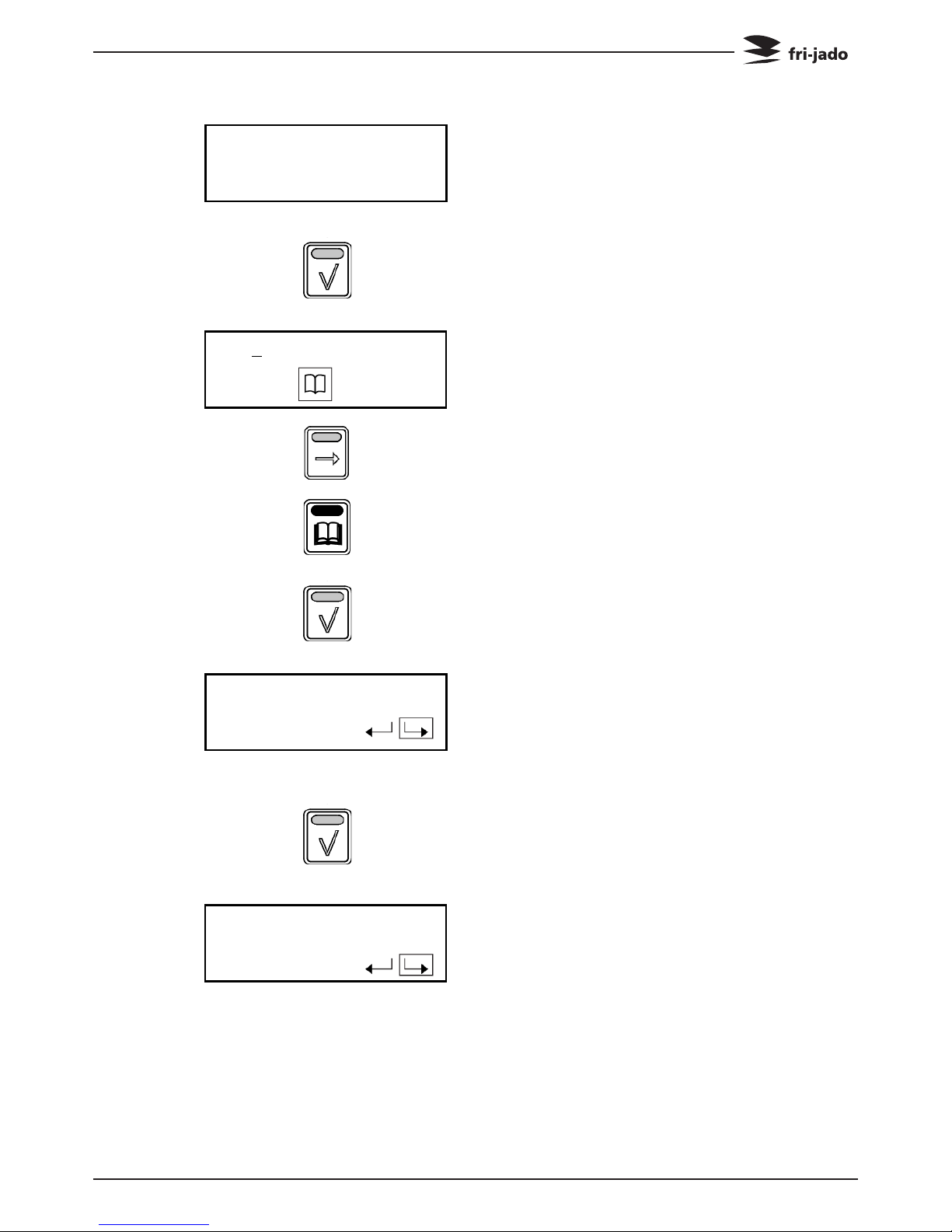

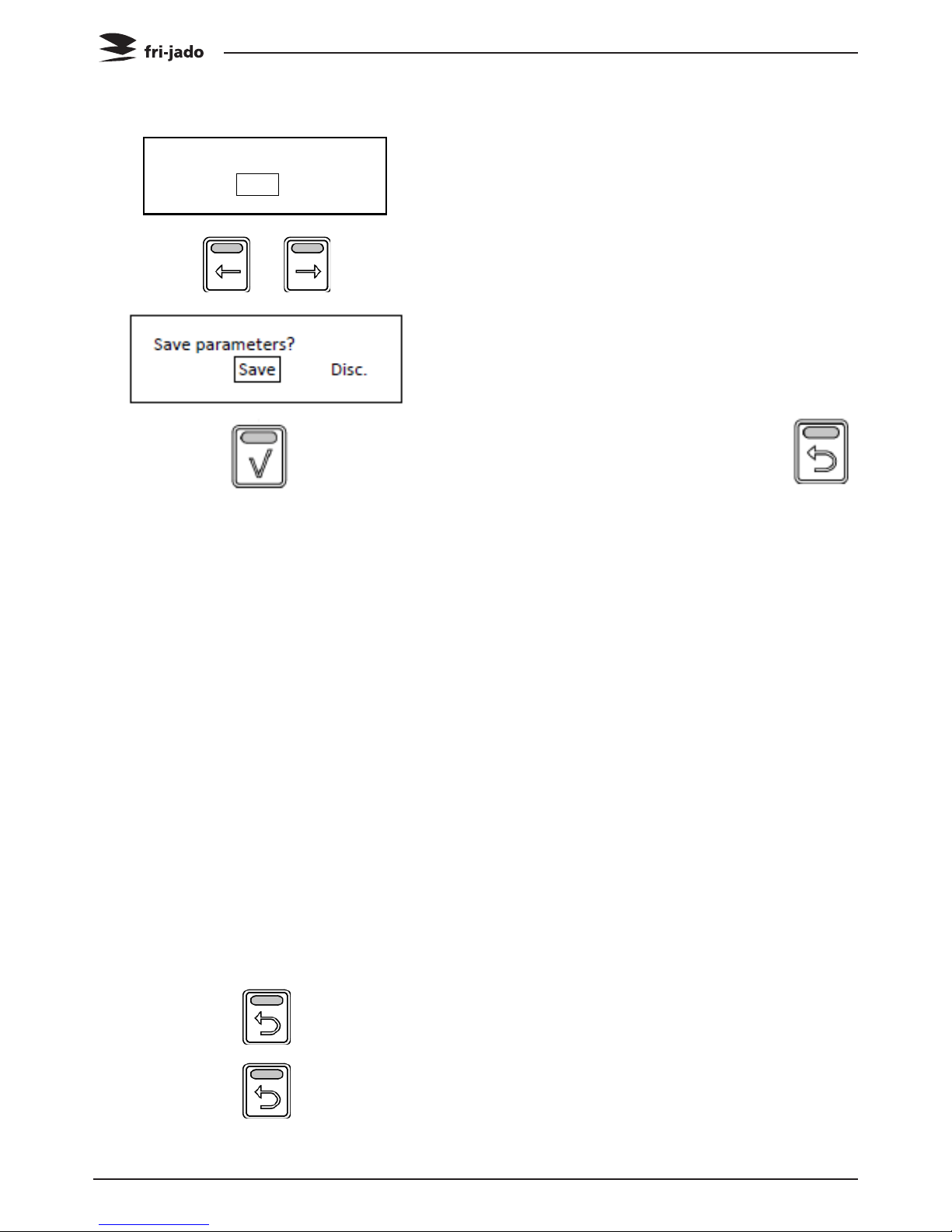

40. When ready programming press the

OK button to co nfirm.

41. Save the finished programs.

Note: if the program is not saved all

changes are lost!

42. Press the OK button to confirm.

43. The screen returns to the RECIPES

menu.

44. Press back to enter the manager

menu.

45. Manager menu appears.

46. Press back to enter the user menu.

47. The last program used is shown.

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 21

PROGRAMMING INSTRUCTIONS

MANAGER MENU: PARAMETERS

TDR-P

eco

Models

Pin * * * *

Give User PIN code

MANAGER MENU

Edit. Parameters 1Pin.

Language: Dutch

Cha. NEXT PAR. 1Prev.

Language: Dutch

Change Next

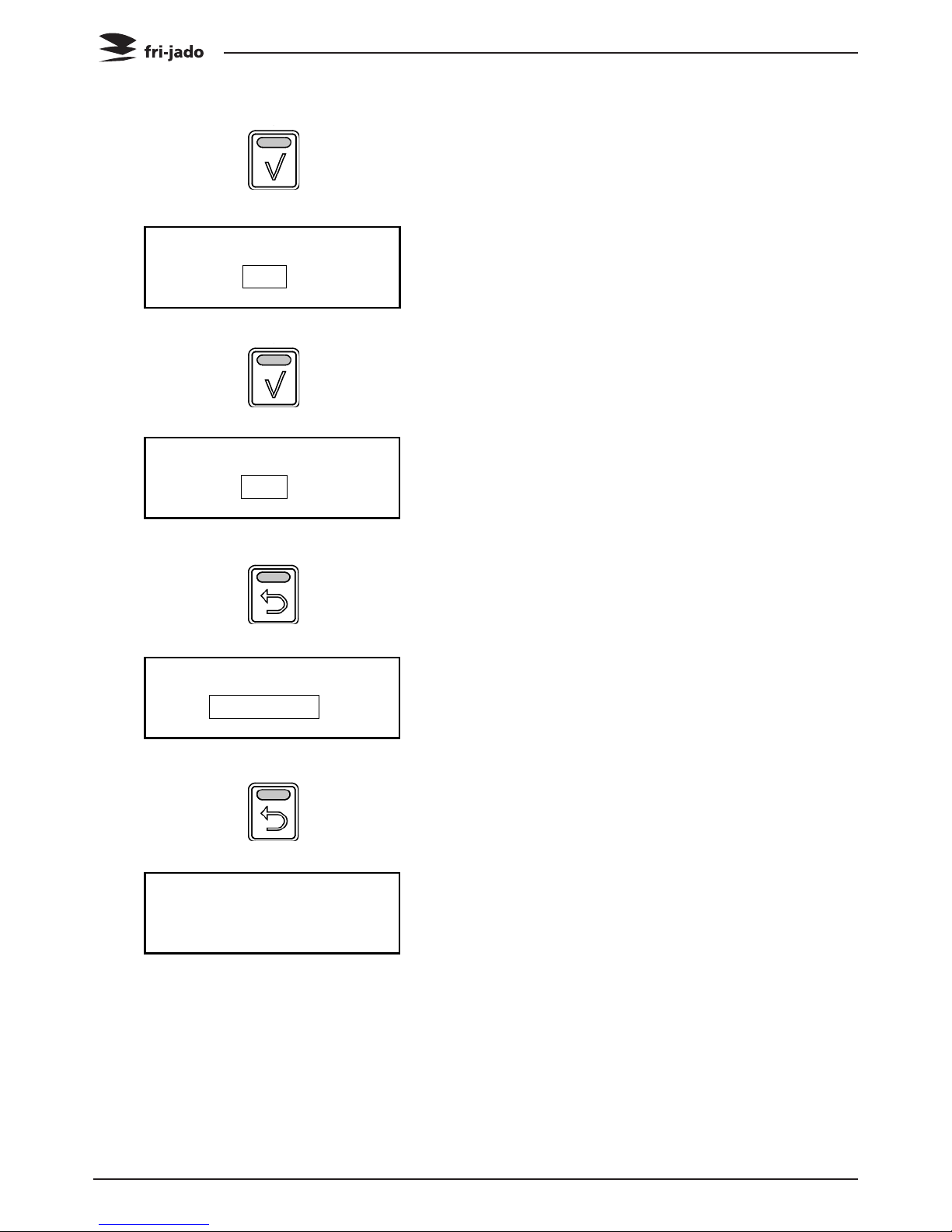

6.3. Programming parameters

1. Press the list button.

2. Enter your user PIN code.

3. Press the OK button to confirm.

4. Press the arrow buttons to select

Parameters.

5. Press the OK button to confirm.

6. Press the arrow buttons to select

Change or Previous.

Press the OK button to select the

next parameter.

7. To change the language, select

Change.

8. Press the OK button to change.

Page 22

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

TDR-P

eco

Models

Language: English

Change Next 1Previous

Save parameters?

Save 1Disc.

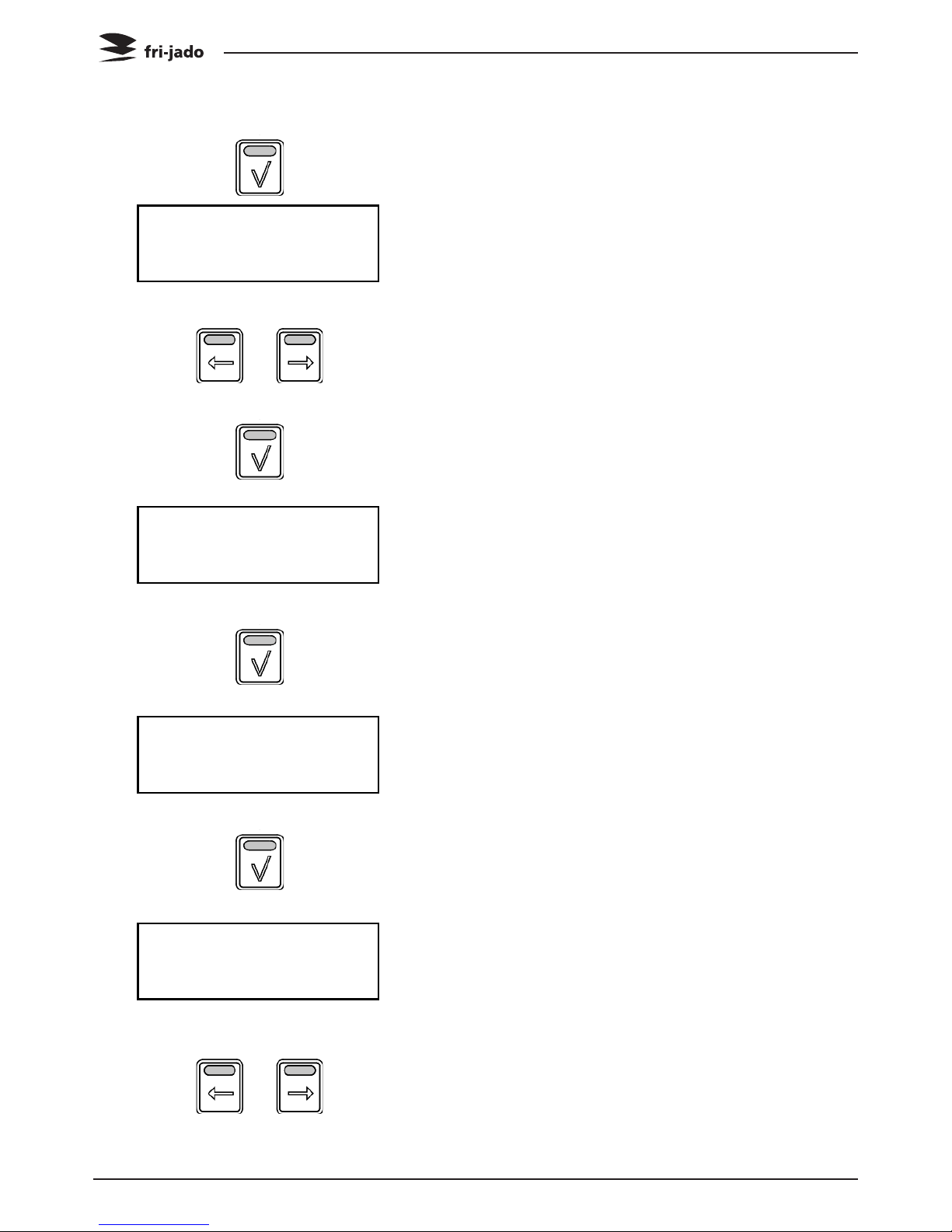

9. Use the arrow buttons to select

Change, Next or Previous.

Press back to enter the manager

menu.

10. Press the OK button to confirm or

select Discard to cancel.

11. Use the arrow buttons to select the

other settings:

Big Digits

YES/NO: Default set at YES

Sound preheat

Sound T1-T3 Default set at T1

Volume 1-4 Default set at 2

Sound Step

Sound T1-T3 Default set at T2

Volume 1-4 Default set at 1

Sound Done

Sound T1-T3 Default set at T3

Volume 1-4 Default set at 3

Preheat

YES/NO: Default set at NO

Preheat Temperature

50-250 °C (122-482 °F) Default set at 210°C (410°F)

Holding

YES/NO: Default set at YES

Holding Temperature

50-250 °C (122-482 °F) Default set at 85°C (185°F)

Cook correction

YES/NO: Default set at YES

Eco function

YES/NO: Default set at YES

Press back to enter the manager menu.

Press (again) back to enter the user menu.

10. Use the arrow buttons to select

Save and press the OK button to confirm.

This is valid for software version V1.04-09

or higher.

Note: when you select the Undo key the

changes will not be saved and you go

back to step 4.

10a. Untill software version V1.03.10 you

had to press the undo key to go to save.

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 23

PROGRAMMING INSTRUCTIONS

MANAGER MENU: CHANGE PINCODE

TDR-P

eco

Models

MANAGER MENU

Para Change Pin 1Clock

MANAGER MENU

Pin Clock 1Copy

MANAGER MENU

Clock Transfer 1Vers.

Pin 0 0 0 0

Enter new code

2012 / 10 / 1 8:01 AM

SET TIME 112..

Insert stick and press

enter

Interface P Eco

TDR

Version x.x.x

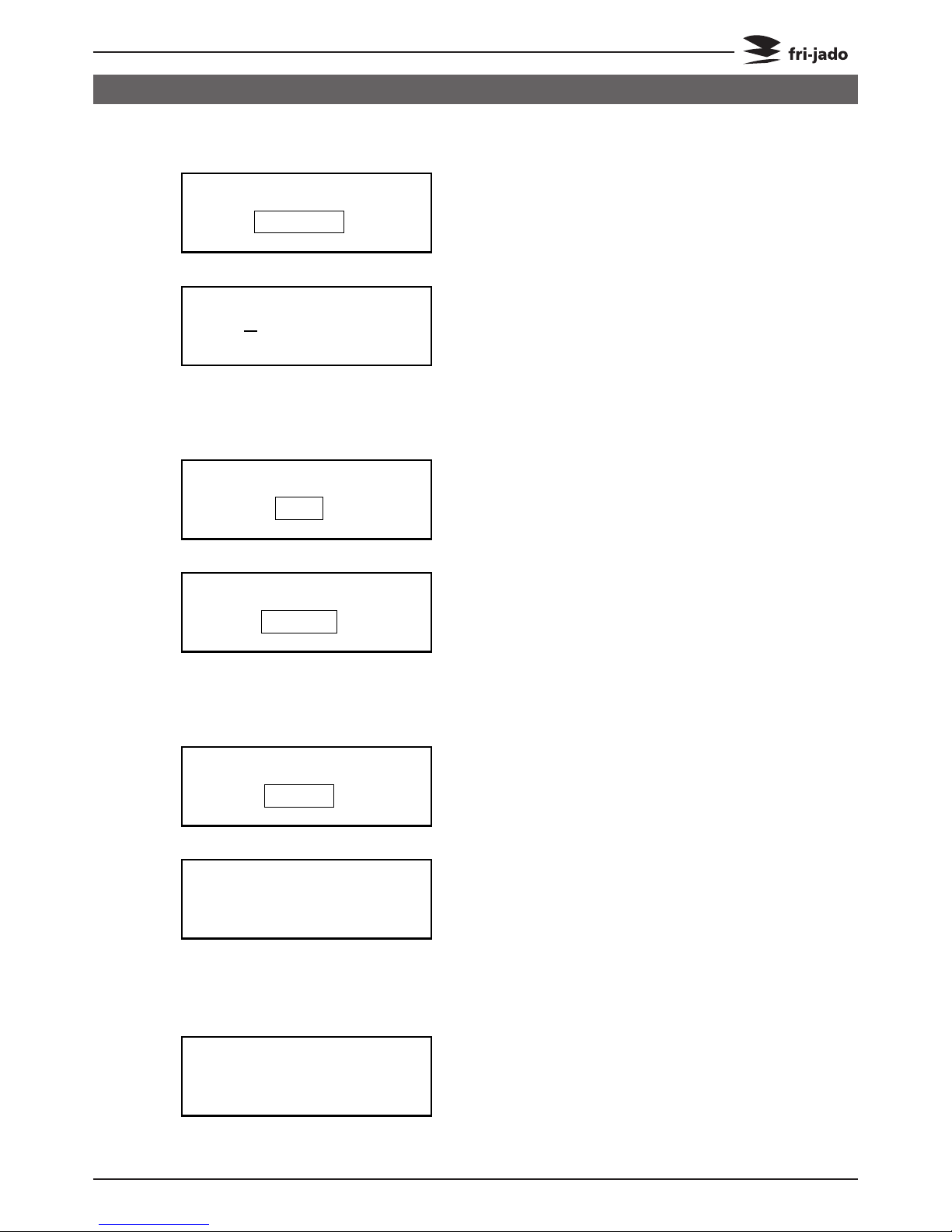

6.4. Change pin code

1. Manager menu.

2. Select Change Pin.

3. Press the OK button.

4. Enter the new pin code.

5. Press the OK button.

6.5. Clock

1. Manager menu.

2. Select Clock.

3. Press the OK button.

4. Set the correct date and time.

5. Press the OK button.

6.6. Transfer

1. Manager menu.

2. Select Transfer.

3. Press the OK button.

4. Insert stick and press OK.

6.7. Version

1. Display shows software version.

Page 24

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

PROGRAMMING INSTRUCTIONS

OPTIONS MANAGER MENU: USB

Note: When reading new programs all

existing programs will be deleted.

TDR-P

eco

Models

MANAGER MENU

USB Programming 1Para.

MANAGER MENU

USB Edit

USB

Read Sto.

A_ _ _ _ _ _ _ _

Save File Name

A

Save File Name

6.8. USB

1. Manager menu.

2. Use the arrow buttons to select the

USB function.

3. Screen shows the USB function.

Place the USB stick into the USBslot.

4. Press the OK button to confirm.

5. Use the arrow buttons to select Read

to exchange an existing program or

STORE to save a program.

Option STORE:

6. Enter the file name by using the

arrow buttons and OK button.

7. Select Save.

8. Press the OK button to confirm.

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

Page 25

PROGRAMMING INSTRUCTIONS

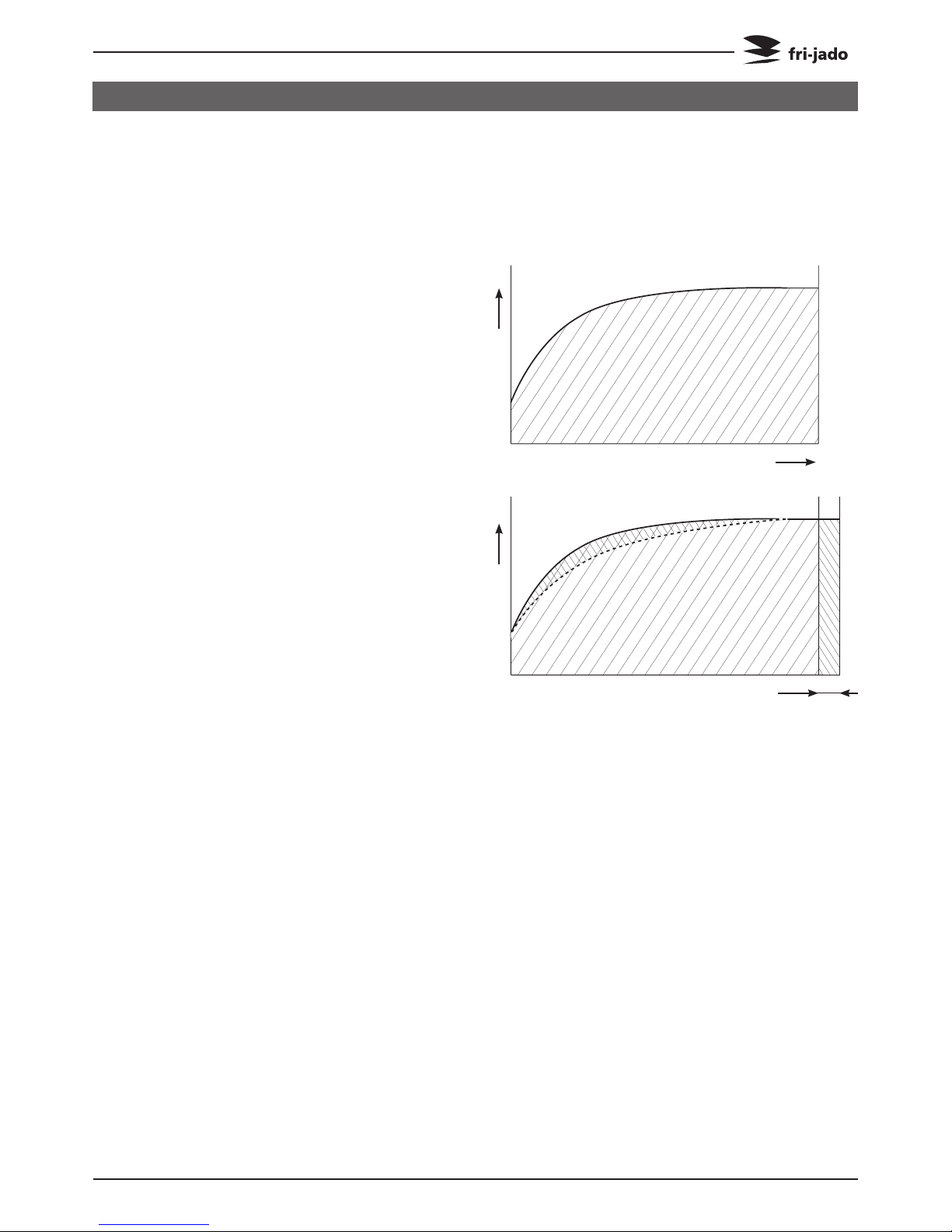

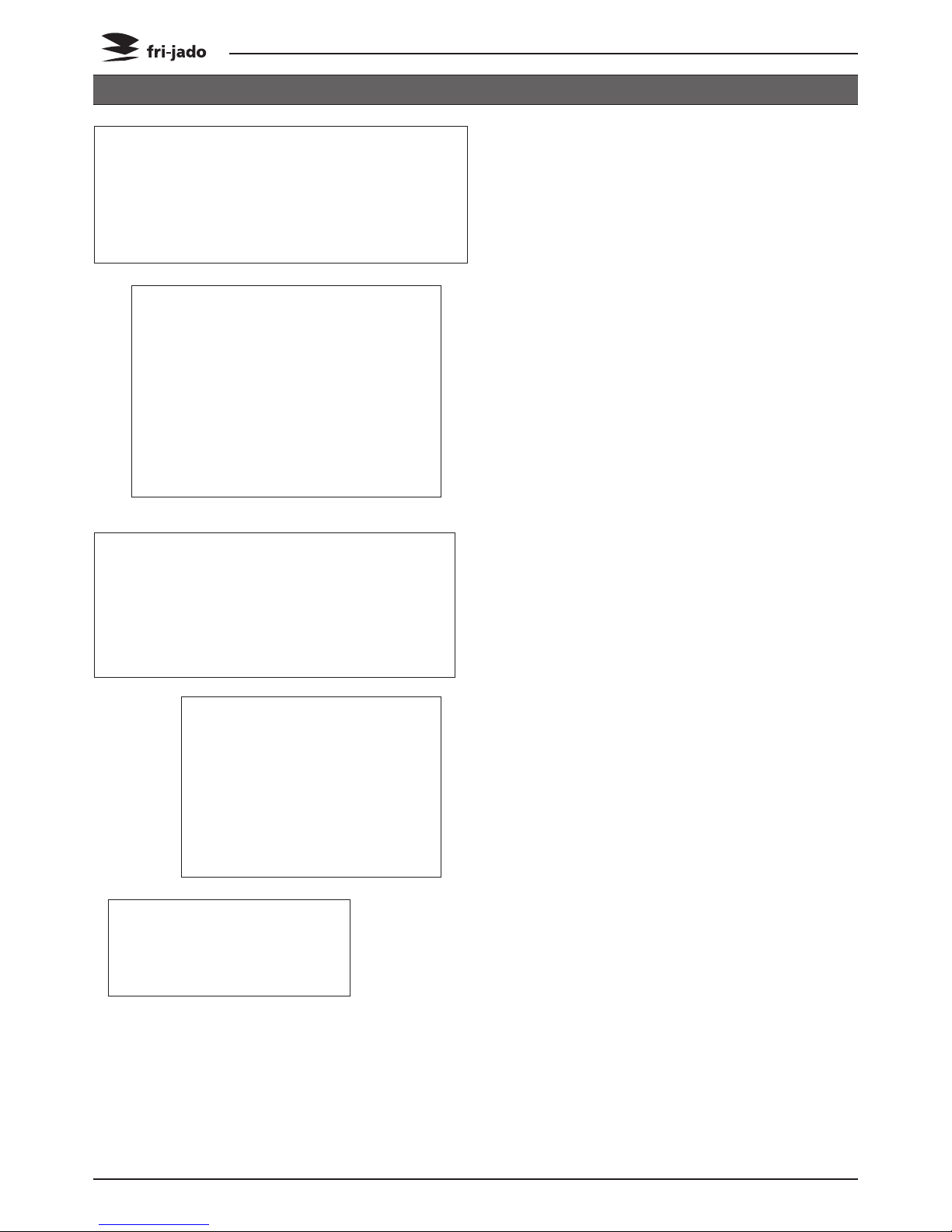

°C

°C

Extra time

Cooking time

Temparature curve

with half load

The program calculates the surface from the

diagram below the curved line. (temperature

* time). The result is the so called heat num

ber. This heat number is stored into the cook

ing program.

All further cooking programs will try to get

the same heat number.

The second diagram shows an example with

full load. It takes more time for the unit to

reach the programmed cooking temperature.

See dashed line. The surface above the dashed

line represents the missing part of the heat

number. The cook correction will put this miss

ing part behind the normal cooking time.

Therefore extra time is added in order to

reach the desired heat number.

It is also possible that time is deducted in case

a smaller load has been put into the oven.

Time will be added in case of:

A bigger load.

A colder load. (straight from the freezer).

A lower mains voltage.

Somebody opened the door.

Time will be deducted in case of:

A smaller load.

A warmer load. (defrosted)

A higher mains voltage.

Note 1:

In case the time or temperature will be

changed in the cooking program, the heat

number will be adapted with this amount.

Note 2: Only if you delete a program or

change the name the “learning”process starts

again from the beginning.

The automatic cook correction facility will automaticly add or deduct time to the pro

grammed cooking time in order to have constant cooking quality.

After programming a new program, the first cooking process will be the “learning” process.

It is recommended to do the first cook with a half load.

THE AUTOMATIC COOK CORRECTION

The heat number is stored in the cooking

program. In case such a program is copied

and stored in another rotisserie, the heat

number goes with it.

It is possible that in case the program has

changed a lot, the cook correction is not

able to perform well anymore. In that case

the program has to be deleted and repro

grammed with the good parameters.

It is possible to disable this cook cor

rection feature in the service parameters.

See “parameter listings” -> “cook correction”.

Page 26

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

REMOVAL AND REPLACEMENT OF PARTS

WARNING: Disconnect the electrical power to the machine

at the main circuit box. Place a tag on the circuit box indicating the circuit is being serviced.

1. Remove the cross head screws that secure

the panel to the frame.

2. Remove the panel.

3. Reverse the procedure to install.

1. Remove the right side panel according

prior procedure.

2. Remove the screws securing both large

and small top covers.

3. Remove the top cover. (Lift at right side

and remove to the left).

4. Reverse the procedure to install.

1. Remove the right side panel according prior

procedures

2. Remove the bolt, nut and ring on the top

side on the backside of the operating panel.

3. Pull the panel away from the top side.

4. Remove the flatcables and earth cable from

the CPU board on the backside.

5. Remove the panel.

6. Reverse the procedure to install.

REMOVAL AND REPLACEMENT OF PARTS FOR THE TDR 5 AND TDR 8

RIGHT OR LEFT SIDE PANEL

TOP COVER

OPERATING PANEL (GENERAL)

Page 27

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

REMOVAL AND REPLACEMENT OF PARTS

1. Remove the right side panel according

prior procedure.

2. Disconnect the wiring.

3. Remove on the inside bottom of the electric panel the bolt and nuts.

4. Slide the electric panel upwards to remove

this.

5. Reverse the procedure to install.

1. Remove the right hand panel according

prior procedure.

2. Remove the operating panel according

prior procedure.

3. Remove the 4 nuts and rings on the CPU

board and remove the board.

4. Replace the USB connection from old to

new operating panel.

5. Reverse the procedure to install.

Note 1: For connection flatcable of the keypads

see CPU board on page 28.

Note 2: For older units with earth wire in right

hand bottom corner. Take care that the ring

terminal doesn’t make contact with with the

solder point (see arrow) .Otherwise the illumination of the display and keys can be out.

ELECTRIC PANEL

OPERATING PANEL, GLASS + BACKPLATE + KEYPAD

REPLACING A LAMP

1. Remove the right side panel according

prior procedure.

2. Disconnect the wiring and flatcable on the

board.

3. Remove the board from the clips by pressing the clips together.

4. Reverse the procedure to install.

Page 28

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

REMOVAL AND REPLACEMENT OF PARTS

Before changing the CPU board and display be

sure to download (with a USB stick) or write

down the grilling programs and the parame

ters.

1. Remove the right side panel according

prior procedure.

2. Remove the operating panel according

prior procedure.

3. Remove the 4 nuts and rings on the CPU

board and remove the board.

4. Reverse the procedure to install.

5. Read the grilling programs and parameters

from the USB stick to the CPU board.

Note 1: Flatcable keypad must be connected

to connector “Touchpanel 1” on CPU board.

Note 2: “Touchpanel 2” is flatcable connection

for the rotor switch keypad on customer side.

Note 3: For older units with earth wire in

right hand bottom corner. Take care that the

ring terminal doesn’t make contact with with

the solder point (see arrow) .Otherwise the illumination of the display and keys can be out.

CPU BOARD

POWER AND I/O BOARD

Page 29

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

REMOVAL AND REPLACEMENT OF PARTS

1. Remove the right side panel, the operating

panel and the CPU board according prior

procedures.

2. Remove the keypad and degrease the

surface of the glass.

3. Glue the new keypad on its place with the

red colored connectors on the bottom side.

4. Reverse the procedure to install.

Note 1: For connection flatcable of the

keypads see CPU board on page 28.

Note 2: When the keypad is on the panel on

customer side you need a long extended

flatcable for connection to the CPU board.

KEYPAD

REPLACING OF BROKEN BUZZER

1. Remove the right side panel according

prior procedure.

2. Remove the operating panel according

prior procedure.

3. Stick connector of new buzzer in plug next

to the existing broken buzzer (see white

arrow).

4. Reverse the procedure to install.

Note: buzzer can dangle loosely without any

problem.

Page 30

Service Manual TDR5/8 P TDW5/8 P form 9123911 rev. 10/2014

REMOVAL AND REPLACEMENT OF PARTS

Caution: Do not touch the glass with your

hands. The moisture from your hands could

affect the live span of the lamp. This moisture can be removed with alcohol while the

lamp is cold.

Note: Use a clean rag or paper towel to replace the lamp.

1. Remove the bolts that secure the protection guard of the Halogen lamp and

remove the guard.

2. Push the lamp to either side and pull it

down to remove the lamp.

3. Remove the top cover according prior

procedure.

4. Disconnect the wiring on the terminal

block.

5. Remove the insulation above the light

fixture.

6. Remove the screws that secure the lamp

holder and remove the holder from the

inside.

7. Reverse the procedure to install.

Note 1: Be sure that the “drop”on the lamp

is pointing downwards.

Note 2: Check the lamp reflecting shield and

replace this if corroded.

INFRA-RED HALOGEN LAMP HOLDER

Loading...

Loading...