Fri-Jado STG5 Installation Manual

INSTRUCTIONS

STG - ROTISSERIE OVEN MODELS

STW - WARMER MODELS

MODELS

Prog. Controls STG5-P

STG7-P

STG7-P-GAS

Intelligent STG5-i

STG7-i

Warmers STW5

STW7

Model STG7-P

● IMPORTANT ●

READ BEFORE USING ROTISSERIE/WARMER

Installation, operation and care of

www.frijado.com

Part-number form 912.3476 0904

2

TABLE OF CONTENTS

MODELS .................................................................................................................... 3

GENERAL .................................................................................................................. 6

Features and options .............................................................................................. 6

Ovens ...................................................................................................................... 7

Warmers ................................................................................................................. 7

Stacking .................................................................................................................. 7

1. INSTALLATION ...................................................................................................... 8

1.1 Location ............................................................................................................ 8

1.2 Legs / casters .................................................................................................... 9

1.3 Supplemental installation instructions ............................................................... 9

1.4 Installation codes and standards ..................................................................... 10

1.5 Electrical connections ..................................................................................... 11

1.6 Electrical data.................................................................................................. 12

1.7 STG7-P-GAS only: Gas connection ................................................................ 13

1.8 STG7-P-GAS only: Gas pressures and orifices .............................................. 13

1.9 STG7-P-GAS only: Flue connections .............................................................. 13

2. BEFORE FIRST USE ........................................................................................... 14

3. OPERATION ........................................................................................................ 14

3.1 Control panels ................................................................................................. 15

3.2 Programmable controls ................................................................................... 16

3.3 Intelligent oven control panel .......................................................................... 22

3.4 Preparing the product ...................................................................................... 36

3.5 Loading products onto accessories ................................................................ . 36

3.6 Loading accessories into the oven .................................................................. 39

3.7 Unloading accessories from the oven ............................................................. 41

3.8 Suggested roasting guidelines ........................................................................ 42

3.9 Emptying grease drawer ................................................................................. 43

3.10 Warmer controls ................................................................ ............................ 44

3.11 Using warmers (models STW5 and STW7)................................................... 44

4. CLEANING ........................................................................................................... 45

4.1 Cleaning stainless steel surfaces .................................................................... 45

4.2 Cleaning non-stick coated surfaces ................................................................ 46

4.3 Cleaning probe ................................................................................................ 47

4.4 Cleaning grease drawer .................................................................................. 47

4.5 Cleaning warmers ........................................................................................... 47

4.6 Cleaning quartz lamps .................................................................................... 48

4.7 Monthly cleaning (or more often if necessary)................................................. 48

5. MAINTENANCE ................................................................................................... 48

3

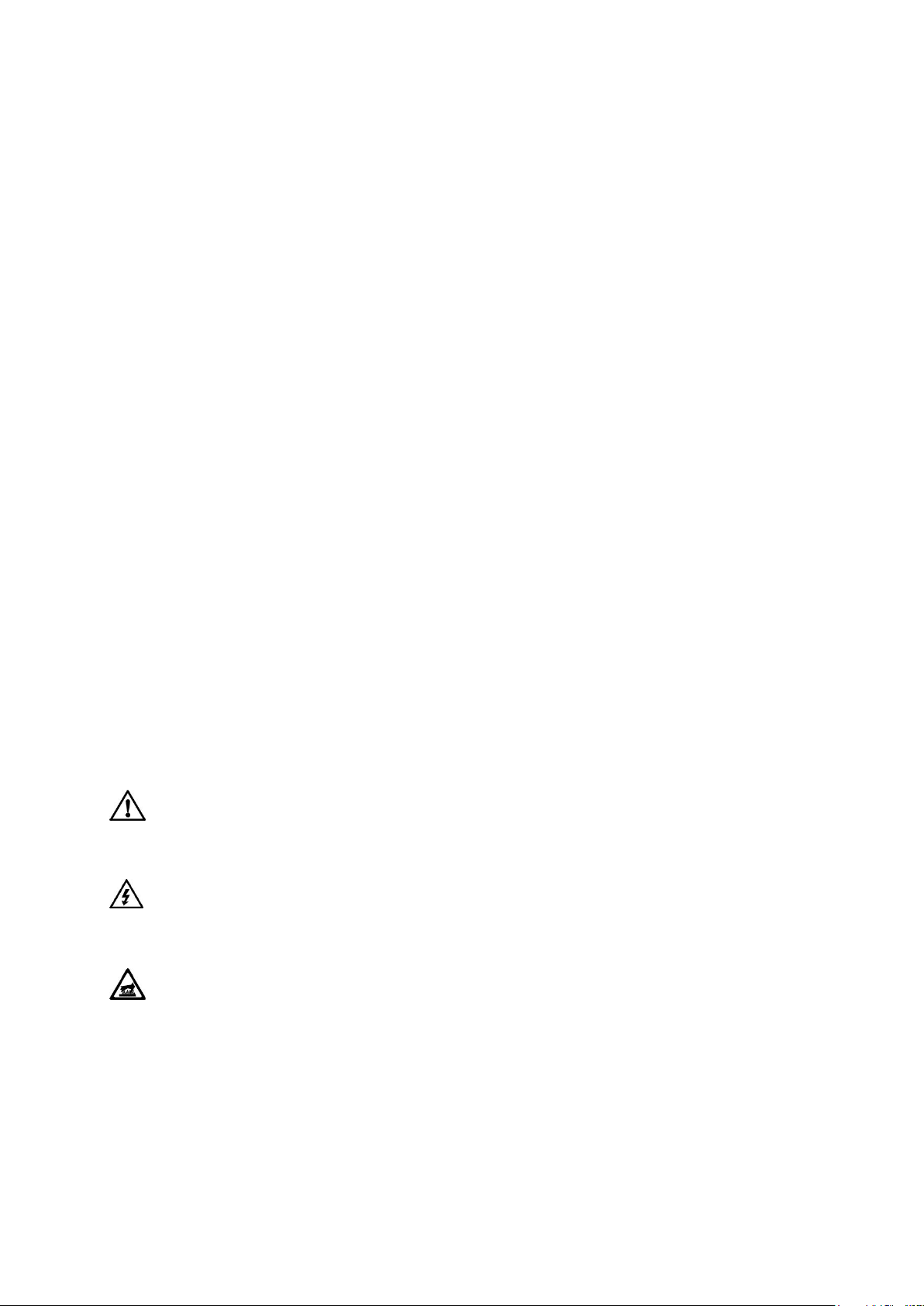

MODELS

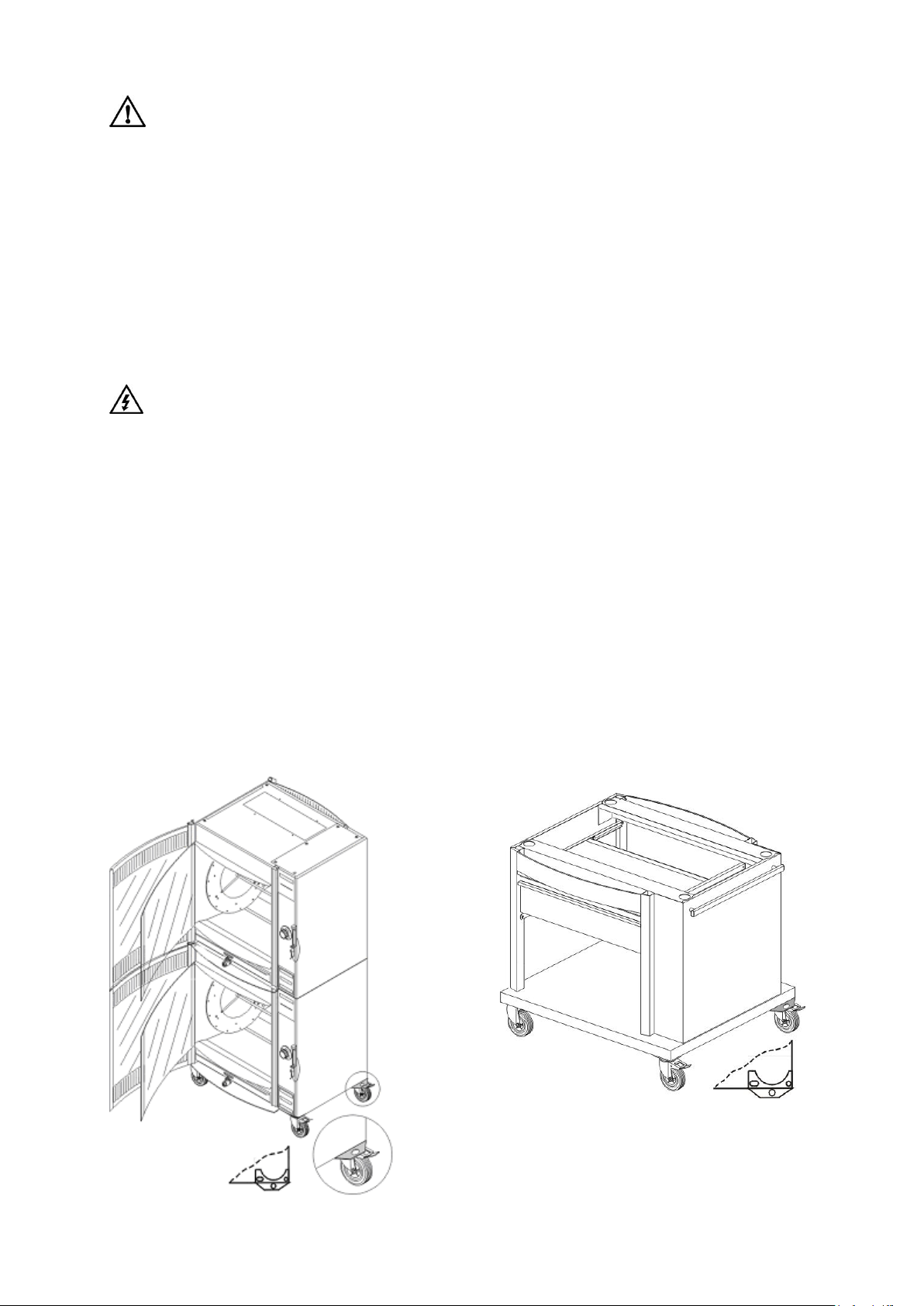

Model STG5-P, STG7-P and STG7-P-GAS

Oven

(STG7-P displayed)

Model STG5-i and STG7-i Oven

(STG7-i displayed)

Model STW5 and STW7 Warmer

(STW7 displayed)

Model STW5 and STW7 Warmer

(STW7 displayed)

Model STG5-P Oven / STW5 Warmer and

STG7-P Oven / STW7 Warmer (displayed)

Model STG5-i Oven / STW5 Warmer and

STG7-i Oven / STW7 Warmer (displayed)

• Rotisserie ovens with Programmable Controls shown; meat probe is optional

4

5

Installation, Operation and Care of

=

WARNING

Failure to observe this warning may result in personal injury, death, or

equipment damage.

=

WARNING

Risk of electrical shock. Failure to observe this warning may result in

personal injury, death, or equipment damage.

=

WARNING

Hot! Risk of burns. Wear heat-protective gloves.

STG - ROTISSERIE OVEN MODELS AND

STW – WARMER MODELS

BEFORE USING THE OVEN OR WARMER FOR THE FIRST TIME,

CAREFULLY READ THIS ENTIRE MANUAL.

IMPORTANT NOTICE: The user is responsible for reading and following

these instructions to ensure the safe and proper installation, operation,

and maintenance of the ovens and warmers. The manufacturer

expressly disclaims any and all liability for any and all damage or injury

resulting from failure to follow and comply with these instructions, or

from failure to exercise reasonable care in the handling, operation,

cleaning, and repair of the ovens and warmers, and failure to explicitly

include any warnings or instructions in this manual shall not give rise to

any claim for damages. If you have any questions concerning the

installation, operation, care, or maintenance of the ovens or warmers

that are not covered by these instructions, please contact the

manufacturer at:

Fri-Jado Inc.

877 – 374 – 5236 (toll free)

SAFETY SYMBOLS

The following symbols are used throughout this manual to alert the user to specific

hazards:

Please read the safety instructions in this manual carefully and use the ovens

and warmers only as described in these instructions to avoid injury or damage.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE!

© 2008 Fri-Jado BV, Etten-Leur, The Netherlands

Customers are permitted to copy these instructions for private use.

6

V-Spit

Turkey

Spit

Basket

Chicken rack

Meat

forks

Warmer

shelves

3 rack

4 rack

5 rack

STG5

5 1 5 5 NA

NA 5 NA

STG7

7

1 7NA 7 7 7 NA

STW5

NA

NA

NA

NA

NA

NA

NA

3

STW7

NA

NA

NA

NA

NA

NA

NA

3

GENERAL

The Fri-jado STG Series Rotisserie Ovens and STW Warmers feature model wide

tempered glass doors, both front and back. On the ovens, however, the back door

may be replaced by a closed insulated panel. Bright quartz lighting promotes visual

appeal.

The interior and exterior are made of stainless steel for good cleaning. The inside of

the closed insulated panel, the rotor system and the accessories are provided with a

non- stick coating for even better cleaning ability.

Ovens and warmers are available in two sizes:

STG5 - Oven with 5 spits (15-20 chickens)

STW5 - Warming cabinet

STG7 - Larger oven with 7 spits (28-35 chickens)

STW7 - Warming cabinet

FEATURES AND OPTIONS

Quantity per oven. All parts are optional.

Do not mix accessories on the rotor.

A Probe to measure the core temperature of the product is an option.

THIS PRODUCT HAS A ONE-YEAR WARRANTY FOR PARTS AND LABOR. PARTS THAT ARE

NOT COVERED BY THIS WARRANTY ARE LAMPS AND GLASS. THE SOLE AND EXCLUSIVE

REMEDY OF THE PURCHASER IS LIMITED TO REPAIR OR REPLACEMENT OF THE PRODUCT,

AT THE SOLE DISCRETION OF FRI-JADO, INC. THIS LIMITED REPAIR AND REPLACEMENT

WARRANTY IS THE SOLE WARRANTY PROVIDED FOR THIS PRODUCT AND FRI-JADO, INC.

EXPRESSLY EXCLUDES AND DISCLAIMS ALL OTHER WARRANTIES, INCLUDING

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY IS VOID

WHERE DAMAGE RESULTS FROM IMPROPER USE OF THE PRODUCT OR THE PURCHASER

USES THE PRODUCT IMPROPERLY.

7

OVENS

Top

Bottom

STG7-P

STG7-I

STG7-P-GAS

STG7-P

STG7-I

STW7

Same size wheeled base

STG5-P

STG5-I

STG5-P

STG5-I

STW5

Same size wheeled base

The ovens are provided with programmable control operation.

The STG ovens use self-basting spits with optional chicken racks, meat forks, or

baskets. The rotation of the spits, racks, meat forks or baskets with the combination

convection and radiant heat provide thorough cooking and even browning in the

oven. The oven's grease drawer has a drain valve for elimination of excess fat and

can be completely removed for cleaning.

WARMERS

The STG warmers feature low velocity, high humidity air circulation which keeps

foods moist. The STW warming cabinets have three shelves.

STACKING

Units may, ex factory, be stacked in the following combination:

Stacked units each have their individual power supply.

8

1. INSTALLATION

WARNING

Prior to installation, test the electrical service to assure that it agrees with the

specifications on the machine data plate located on the right side panel near

the controls.

WARNING

For STG7-P-GAS only : Prior to installation, test the gas supply (natural or

propane) to assure that it agrees with the specifications on the machine data

plate located on the right side panel near the controls.

WARNING

Appliances equipped with a flexible electric supply cord are provided with a

three- or four-prong grounding plug. This plug must be connected into a

properly grounded three-prong receptacle. If the receptacle is not the proper

grounding type, contact an electrician. Do not remove the grounding prong

from this plug.

WARNING

A minimum wall clearance of 10” (254 mm) from any glass, and 4" (102 mm)

from each side panel must be maintained.

WARNING

For STG7-P-GAS only : The oven must be installed so that the flow of

combustion and ventilation air will not be obstructed. Make sure there is an

adequate supply of air in the room to allow for that required for combustion of

gas at the oven burner

WARNING

Make sure that the windows stay out of the reach of children. During the grill

process the windows get hot.

Immediately after unpacking the oven or warmer, check for possible shipping

damage. If oven or warmer is found to be damaged after unpacking, save the

packaging material and contact the carrier within 15 days of delivery.

1.1 LOCATION

The oven may be placed where cooking may be observed to enhance customer

awareness and must be installed on a level surface.

The installation location must allow adequate clearances for servicing and for proper

operation of the front and rear doors.

Keep the space around the bottom and the ventilation opening in the top of the STG

free of obstacles to guarantee a good air flow in the electrical compartment and

combustion chamber .

9

WARNING

Do not store or use gasoline or other flammable vapors or liquids in the

vincinity of this appliance

WARNING

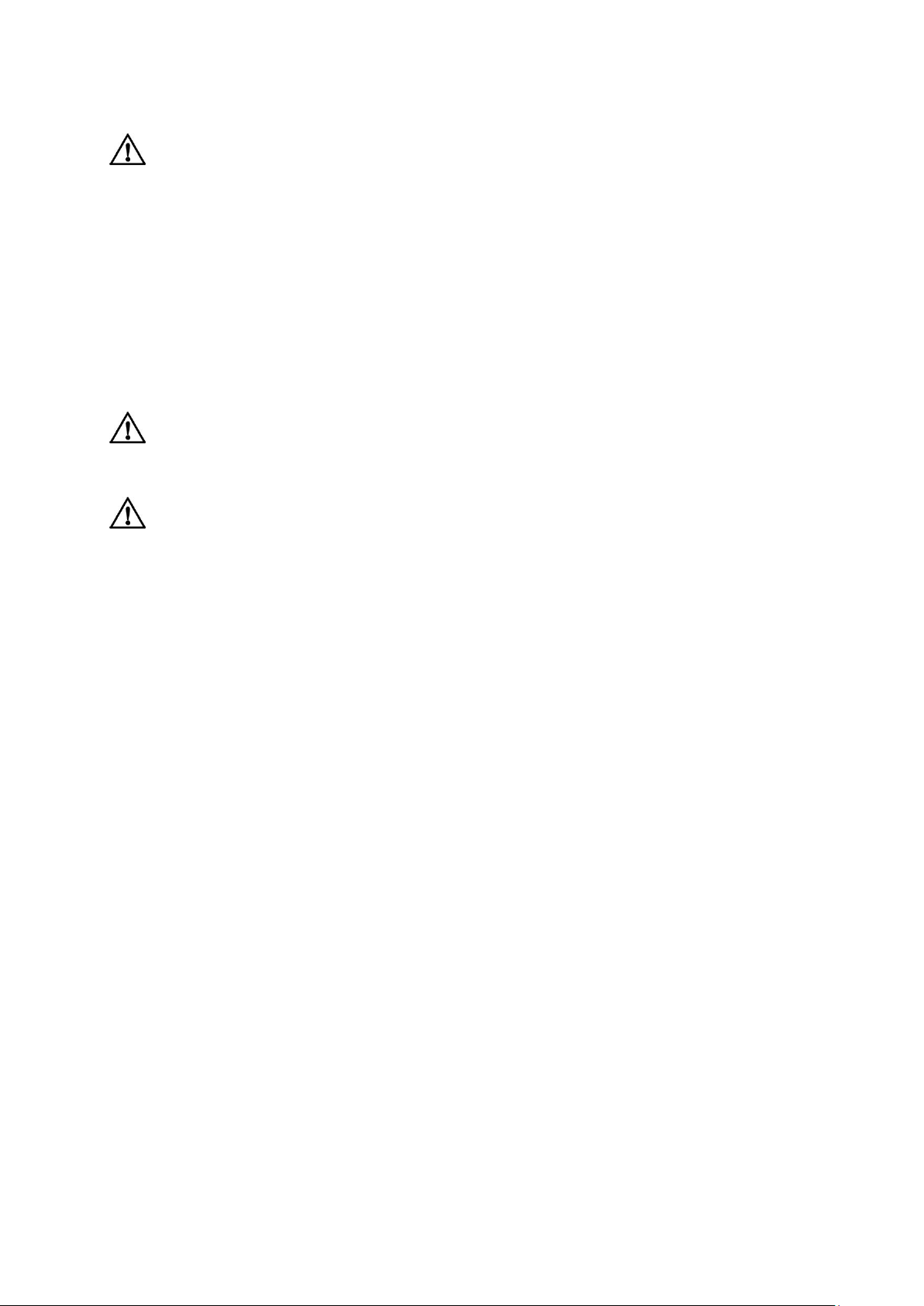

1.2 LEGS / CASTERS

Each oven and warmer is furnished on 2” (50 mm) legs. Stacked units are provided

with casters.

1.3 SUPPLEMENTAL INSTALLATION INSTRUCTIONS

(For model STG(W) 5 and STG(W) 7 units for fixed wiring and stacked or placed

on bases with casters)

Safety standards require that, when this appliance is properly connected to the

electrical power supply using a permanently connection, adequate means be

provided to limit movement of the appliance without depending on or transmitting

stress to the electrical conduit. This means that, as part of the installation, the

base or bottom unit of stacked models must be secured to the building

structure (typically either wall or floor) to limit the movement of the appliance

and, thus, helping to prevent damage to the conduit during cleaning,

maintenance and service operations.

A tether bracket, as shown on the drawing below, is provided with the base or

stacking kit. Based on the routing of the flexible conduit, the bracket must be installed

along with the caster to one corner of the base using the hardware provided. The

remaining open hole in the center of the tether bracket is to be used to secure one

end of the tether (locally supplied chain, cable, etc.). The other end of the tether is to

be secured to an anchoring point in the building structure. Note: Length of tether

must be shorter than the flexible conduit to make sure that during appliance

movement, no stress is transmitted to the conduit.

10

Following installation, check to confirm that, when the appliance is moved to

the limits of the tether in each direction, no stress is transmitted to the electrical

conduit.

If it is necessary to disconnect the restraint, first turn off the gas supply.

Reconnect the restraint before turning the gas supply on and returning the

oven to its original installation position.

Following installation, check to confirm that, when the appliance is moved to

the limits of the tether in each direction, no stress is transmitted to the piping of

the gas supply.

For STG7-P-GAS only:If the oven is to be installed with casters, the installation shall

be made with a connector complying to the Standard for Connectors for Movable Gas

Appliances ANSI-Z21.69 (latest edition), and a quick-disconnect device that complies

with the Standard for Disconnect Devices for Use with Gas Fuel, ANSI-Z21.41 (latest

edition).Provide a gas line strain relief to limit the movement of the oven without

depending on the connector and the quick-disconnect device or its associated piping

to limit oven movement.

Note:

Units may be delivered completely stacked or placed on a base.

1.4 INSTALLATION CODES AND STANDARDS

In the United States, all STG series ovens and STW series warmers or combinations

must be installed according to the following codes:

State and local codes.

National Electric Code, ANSI/NFPA 70 (latest edition). available from National

Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

National Fuel Gas Code, ANSI-Z223.1/NFPA 54 (latest edition), available from

National Fire Protection Association,1 Batterymarch Park, Quincy, MA 02269.

ANSI/NFPA 96, ” Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations” (latest edition), available from National Fire

Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

In Canada, all STG series ovens and STW series Warmers or combinations must be

installed according to the following codes:

Local codes.

Canadian Electric Code, CSA C22.1 (latest edition) available from the

Canadian Standard Association, 178 Rexdale Boulevard, Toronto, Ontario,

CANADA, M9W 1R3

11

CAN/CGA-B149.1, “Installation for Natural Gas Burning Appliances and

WARNING

Electrical and grounding connections must comply with the applicable

portions of the national electrical code and / or other local electrical codes.

WARNING

Disconnect electrical power supply and place a tag at the disconnect switch

indicating that you are working on the circuit.

WARNING

Appliances equipped with a flexible electric supply cord are provided with a

three-prong grounding plug. This plug must be connected into a properly

grounded three-prong receptacle. If the receptacle is not the proper

grounding type, contact an electrician. Do not remove the grounding prong

from this plug.

WARNING

Ensure that the electrical power supply agrees with the specifications on the

oven's data plate and complies with the wiring diagram, located behind the

oven side panel and under the drive motor.

WARNING

For STG7-P-GAS only : Do not turn on the power supply on until after the gas

connections have been made and checked for leaks.

Equipment” (latest edition) available from the Canadian Standard Association,

178 Rexdale Boulevard, Toronto, Ontario, CANADA, M9W 1R3.

CAN/CGA-B149.2 , “Installation for Propane Burning Appliances and

Equipment” (latest edition) available from the Canadian Standard Association,

178 Rexdale Boulevard, Toronto, Ontario, CANADA, M9W 1R3.

1.5 ELECTRICAL CONNECTIONS

Access the electrical connection point by removing the side panel(s) where the

controls are located.

Refer to the ELECTRICAL DATA chart on the next page.

12

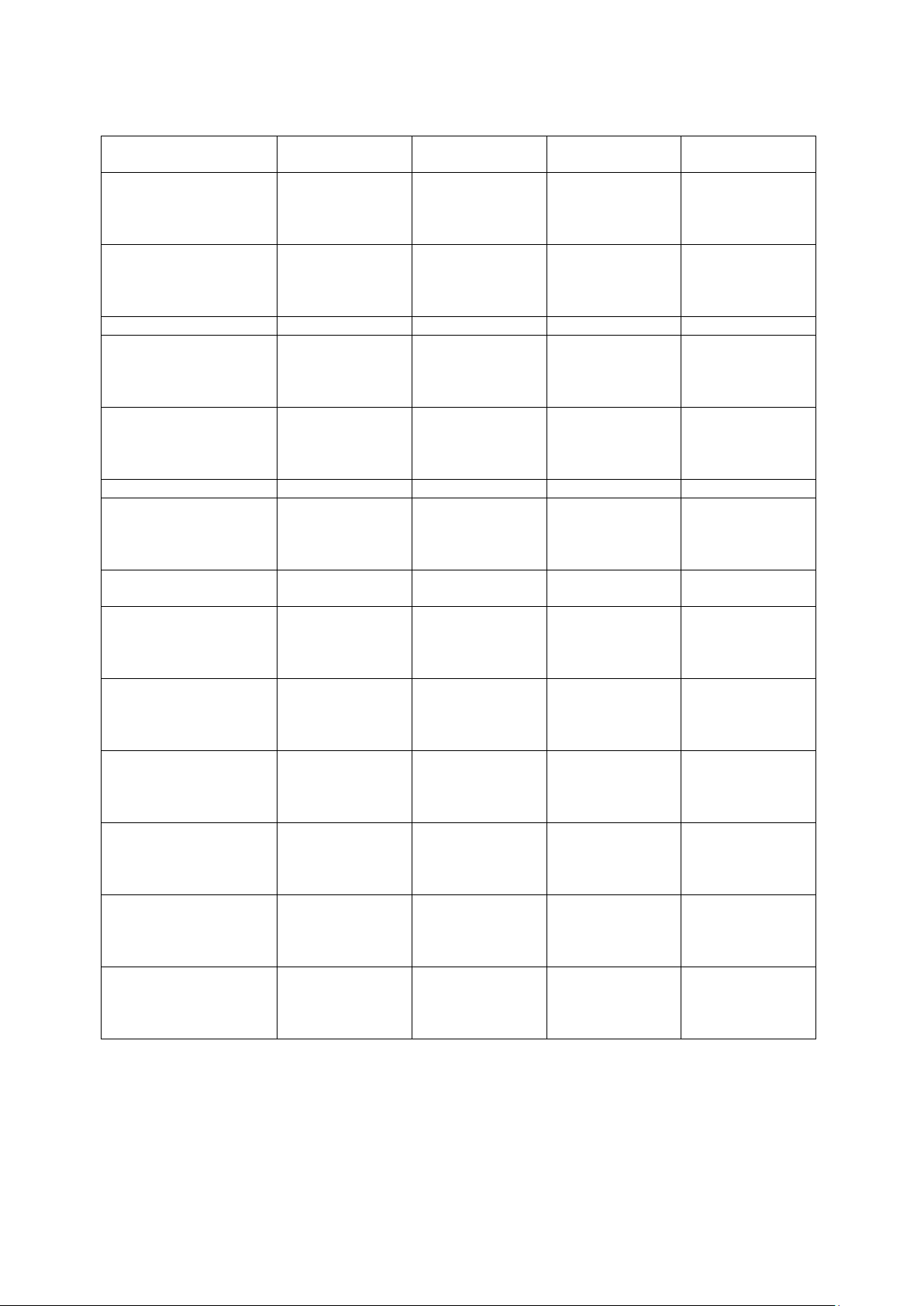

1.6 ELECTRICAL DATA

MODEL

VOLTS

HERTZ

PHASE

CIRCUIT SIZE*

(AMPS)

STG5

208

208

240

240

60

60

60

60

1

3

1

3

35

20

35

20

STG7

208

208

240

240

60

60

60

60

1

3

1

3

60

35

60

35

STG7-P-GAS

115

60 1 3

STW5

208

208

240

240

60

60

60

60

1

3

1

3

15

10

15

10

STW7

208

208

240

240

60

60

60

60

1

3

1

3

15

15

20

15

STACKED MODELS

(2) STG5

208

208

240

240

60

60

60

60

1

3

1

3

(2) 35

(2) 20

(2) 35

(2) 20

(2) STG7

208

240

60

60 3 3

(2) 35

(2) 35

(2) STW5

208

208

240

240

60

60

60

60

1

3

1

3

30

-

35

-

(2) STW7

208

208

240

240

60

60

60

60

1

3

1

3

30

35

40

30

STG5 & STW5

208

208

240

240

60

60

60

60

1

3

1

3

35 + 30

-

35 + 35

-

STG7 & STW7

208

208

240

240

60

60

60

60

1

3

1

3

35 + 30

35 + 35

35 + 40

35 + 30

STG7-P-GAS & STG7

115 & 208

115 & 208

115 & 240

115 & 240

60

60

60

60

1 & 1

1 & 3

1 & 1

1 & 3

3 + 60

3 + 35

3 + 60

3 + 35

STG7-P-GAS & STW7

115 & 208

115 & 208

115 & 240

115 & 240

60

60

60

60

1 & 1

1 & 3

1 & 1

1 & 3

3 + 15

3 + 15

3 + 20

3 + 15

Maximum Circuit Breaker size / minimum circuit amperage compiled in accordance

with the National Electric Code (latest edition).

13

1.7 STG7-P-GAS only: Gas connection

WARNING

Check all joints in the gas supply line for leaks prior to starting.

Use soap and water solution. Do not use an open flame.

WARNING

Disconnect the oven from the gas supply piping system during any pressure

testing on the gas supply piping system.

All gas supply connections and any pipe joint compound used must be resistant to

the action of propane gases.

Codes require that a gas shutoff valve be installed in the gas line ahead of the oven.

The gas inlet is located on the rear panel near the bottom.

Connect the oven to the gasline after leveling. Gas supply line must be at least the

equivalent of 1/2 “ (12.7 mm) iron pipe. Make sure the pipes are clean and free of

obstructions, dirt, and piping compound.

After piping has been checked for leaks, fully purge gas pipes to remove air.

1.8 STG7-P-GAS only: Gas pressures and orifices

Natural Gas

The burner orifices are sized to deliver the nameplate input rating at a gas manifold

pressure of 6” (152.4 mm) W.C. (water column). The gas pressure regulator is

integral to the gas solenoid valve, and is factory set to supply 6” (152.4 mm) W.C.

(water column) as required for natural gas.

Propane gas

The burner orifices are sized to deliver the nameplate input rating at a gas manifold

pressure of 10” (254 mm) W.C. (water column). The gas pressure regulator is integral

to the gas solenoid valve, and is factory set to supply 10” (254 mm) W.C. (water

column) as required for propane gas.

1.9 STG7-P-GAS only: Flue connections

Ventilation requirements will vary with each installation and must comply with

applicable portions of NFPA Standard #96 and with local codes. Considerations to be

kept in mind include :

Flue connections should never be made directly to the oven.

The oven should be located under a hood which has adequate connection to

an exhaust duct and extends 6” (15 cm) beyond the oven sides.

Clearance above the oven flue should be adequate for the products to escape

so that there is no interference with the heat circulation in the oven. Refer to

ANSI/NFPA 96, ” Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations” (latest edition).

14

2. BEFORE FIRST USE

WARNING

Disconnect electrical power before cleaning.

WARNING

In the event of powerfailure, do not attempt to operate this device

WARNING

Hot glass, grease, and parts can cause burns. Use care when operating and

servicing the oven.

WARNING

Check the grease drawer after each cooking process and empty already when

about half full to avoid overflowing. Push the grease drawer completely into the

oven after placing it back to prevent damage to the window.

Refer to EMPTYING GREASE DRAWER.

WARNING

STG7-P-GAS only : In the event a gas odor is detected, shut down units at

main shutoff valve and contact the local gas company or gas supplier for

service.

Oven must be "burned in" to release any odors that might result from heating the new

oven surfaces.

1. Clean oven, accessories, and warmer (if present), both inside and outside, with

warm soapy water. Refer to "Cleaning" in this manual for further

instructions.

2. Rinse thoroughly and wipe dry with a soft clean cloth. Avoid water contact

with quartz lamps.

3. Operate oven at maximum temperature setting of 480°F (250°C) for 45 minutes.

When provided, operate the warmer at maximum thermostat setting (mark 5) for

45 minutes.

Smoke with an unpleasant odor will normally be given off during this burn-in

period. Provide adequate room ventilation and avoid inhaling.

3. OPERATION

15

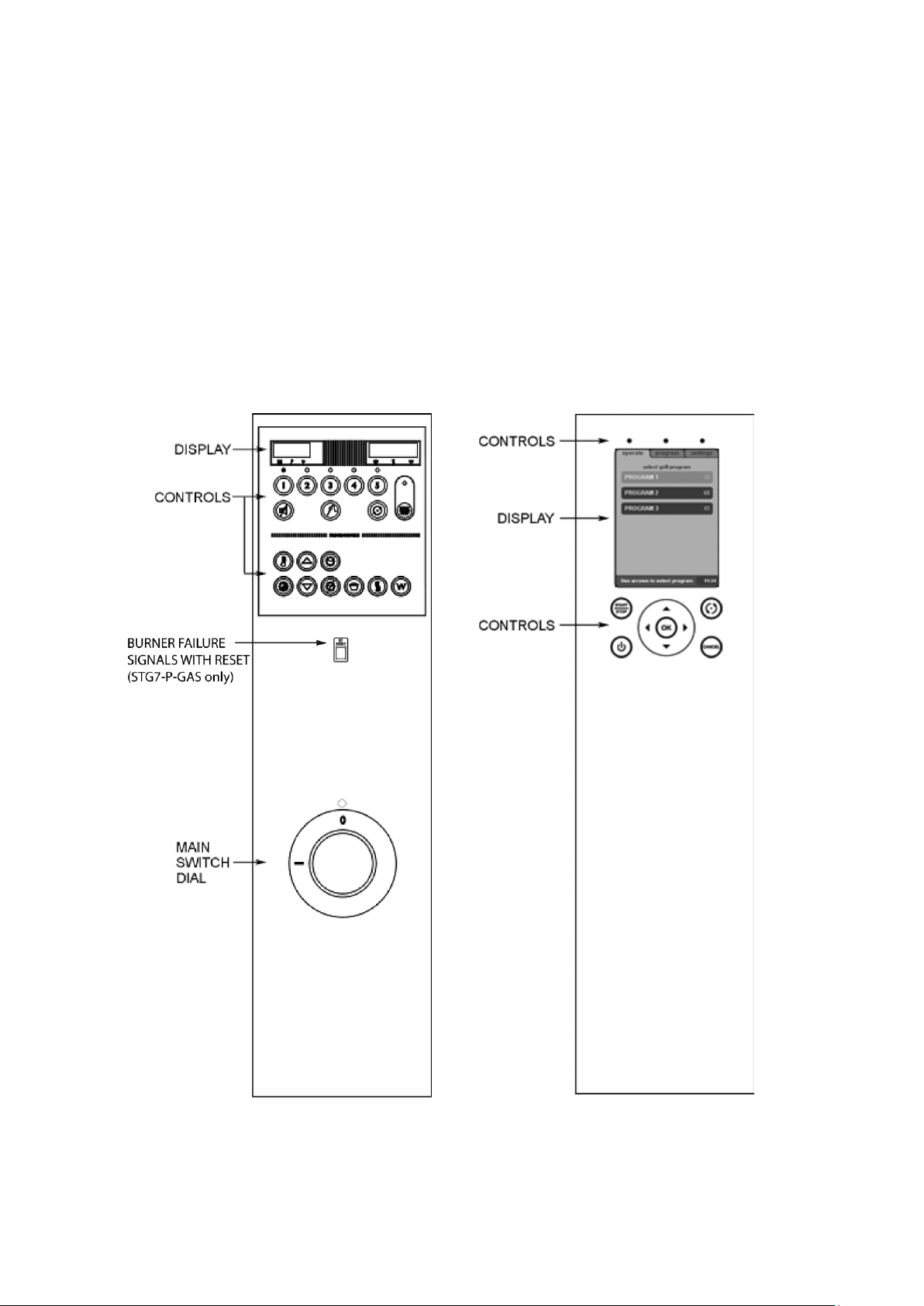

3.1 CONTROL PANELS

Programmable oven control panel

(STG-P)

Shows “Program 1” and “15Pr” when

first turned on.

Colon flashes, remaining cooking time

shows.

For operating instructions for the

programmable control (STG-P) see

„3.2 Programmable oven control panel‟.

Intelligent oven control panel (STG-i)

The STG control panel is equipped with

a large LCD display. Above and below

this screen are touch sensitive keys

that control the oven.

For operating instructions for the

intelligent control (STG-i) see

„3.3 Intelligent oven control panel‟.

Loading...

Loading...