Fri-Jado FJ 1000 Service Manual

SERVICE MANUAL

FRI-JADO FJ 1000

STG - ROTISSERIE OVEN MODELS

STW - WARMER MODELS

MODELS FJ1000*

Programmable controls STG5 P

STG7 P

Warmers STW 5

STW 7

* Fri-Jado produced Programmable Rotisseries and Warmers with serial numbers starting with 1000

- NOTICE -

This manual is prepared for the use of trained Service Technici-

ans and should not be used by those not properly qualified. If

you have attended training for this product, you may be quali-

fied to perform all the procedures in this manual.

This manual is not intended to be all encompassing. If you have

not attended training for this product, you should read, in its

entirety, the repair procedure you wish to perform to determine

if you have the necessary tools, instruments and skills required

to perform the procedure. Procedures for which you do not have

the necessary tools, instruments and skills should be performed

by a trained technician.

Reproduction or other use of this Manual, without the express

written consent of Fri-Jado, is prohibited.

USA

WWW.FRIJADO.COM

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

PAGE

Page 2

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

TABLE OF CONTENTS

Versions

Version Issue date

Remarks

dd/mm/yy

01/2012 05/01/2012 Switch, castors and electric diagrams adjusted.

03/2014 01/03/2014 Textual changes. Troubleshooting adapted. Exploded views modified.

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 3

INDEX

Index .......................................................................................................................................................... 4

General technical data

Technical Data U.S. Standard Models ................................................................................................... 6

Technical Data U.S. Special Models

Programming instructions for the STG5 / STG7 and STW5 / STW7

Optional settings for the STG5 and STG7

Removal and replacement of parts for the STG5 and STG7

Right or left side panel

Top cover .............................................................................................................................................. 11

Knob ..................................................................................................................................................... 12

Operating panel ................................................................................................................................... 12

Electric panel

Display

.................................................................................................................................................. 13

........................................................................................................................................ 13

Panel and keypad assembly ................................................................................................................ 14

Namepanel ........................................................................................................................................... 14

Power and I/O board ........................................................................................................................... 14

Quartz lamp ......................................................................................................................................... 15

Main switch .......................................................................................................................................... 15

High limit thermostat .......................................................................................................................... 16

Contactor .............................................................................................................................................. 16

Heating element .................................................................................................................................. 17

Blower motor ....................................................................................................................................... 17

Blower motor bottom rotisserie (stacked STG) .................................................................................. 18

PT500 sensor ......................................................................................................................................... 18

Drive motor .......................................................................................................................................... 19

Door adjustment (left side) ................................................................................................................. 20

Door inside ........................................................................................................................................... 20

Door outside ........................................................................................................................................ 21

Removal and replacement of parts for the STW 5 and STW 7

Blower motor ....................................................................................................................................... 22

Thermometer ....................................................................................................................................... 22

Thermostat ........................................................................................................................................... 23

Main switch .......................................................................................................................................... 23

Heating element .................................................................................................................................. 24

Halotherm lamp ................................................................................................................................... 24

Electrical tests and service procedures

Heating element test ........................................................................................................................... 25

Contactor, drive motor and blower test ............................................................................................. 25

PT500 Sensor test

Keypad test

.......................................................................................................................................... 27

Changing Quartz light functions ........................................................................................................ 27

Control location ................................................................................................................................... 28

.............................................................................................................................. 6

....................................................................................................... 6

....................................................... 7

............................................................................................... 9

................................................................ 11

........................................................................................................................ 11

............................................................ 22

.................................................................................................. 25

................................................................................................................................. 26

Page 4

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

TABLE OF CONTENTS

General troubleshooting list .................................................................................................................. 29

Troubleshooting the STG 5/7 Rotisseries ............................................................................................ 29

Troubleshooting the STW 5/7 warmers .............................................................................................. 30

Analytic troubleshooting list

Servicing and repairing of the rotisseries STG 5/7P

Servicing and repairing of the Warmers STW 5/7

Exploded views & partlists

................................................................................................................. 31

........................................................................... 31

.............................................................................. 35

..................................................................................................................... 36

STG 5 P - sheet iron work .................................................................................................................... 36

STG 5 P - components .......................................................................................................................... 38

STG 5 P - doors

..................................................................................................................................... 40

STG 7 P - sheet iron work .................................................................................................................... 42

STG 7 P - components .......................................................................................................................... 44

STG 7 P - doors ..................................................................................................................................... 46

STW 5 - sheet iron work ...................................................................................................................... 48

STW 5 - components ............................................................................................................................ 50

STW 7 - sheet iron work ...................................................................................................................... 52

STW 7 - components ............................................................................................................................ 54

Electrical diagrams

.................................................................................................................................. 56

STG 5 P circuit diagram ........................................................................................................................ 56

STG 5 P wiring diagram ....................................................................................................................... 57

STG 5 P wiring diagram (till serial number 100050804) .................................................................... 58

STG 7 P circuit diagram ........................................................................................................................ 59

STG 7 P wiring diagram ....................................................................................................................... 60

STG 7 P wiring diagram (till serial number 100050804) .................................................................... 61

STW 5 circuit diagram .......................................................................................................................... 62

STW 5 wiring diagram ......................................................................................................................... 63

STW 7 circuit diagram .......................................................................................................................... 64

STW 7 wiring diagram ......................................................................................................................... 65

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 5

GENERAL TECHNICAL DATA

GENERAL TECHNICAL DATA

This manual covers the STG series rotisserie ovens and the STW series warmers starting with

serial number #1000 (called FJ1000 from here). Ovens and warming cabinets come in two sizes.

Ovens and cabinets will also be delivered in stacked versions.

• STG5–Ovenwith5spits(15to20chickens)or5baskets(15chickens).

• STG7–Ovenwithsevenspits(28to35chickens)or7baskets(28chickens).

• STW5Warmingcabinetfor25to30chickens.

• STW7Warmingcabinetfor35to40chickens.

All of the information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of printing.

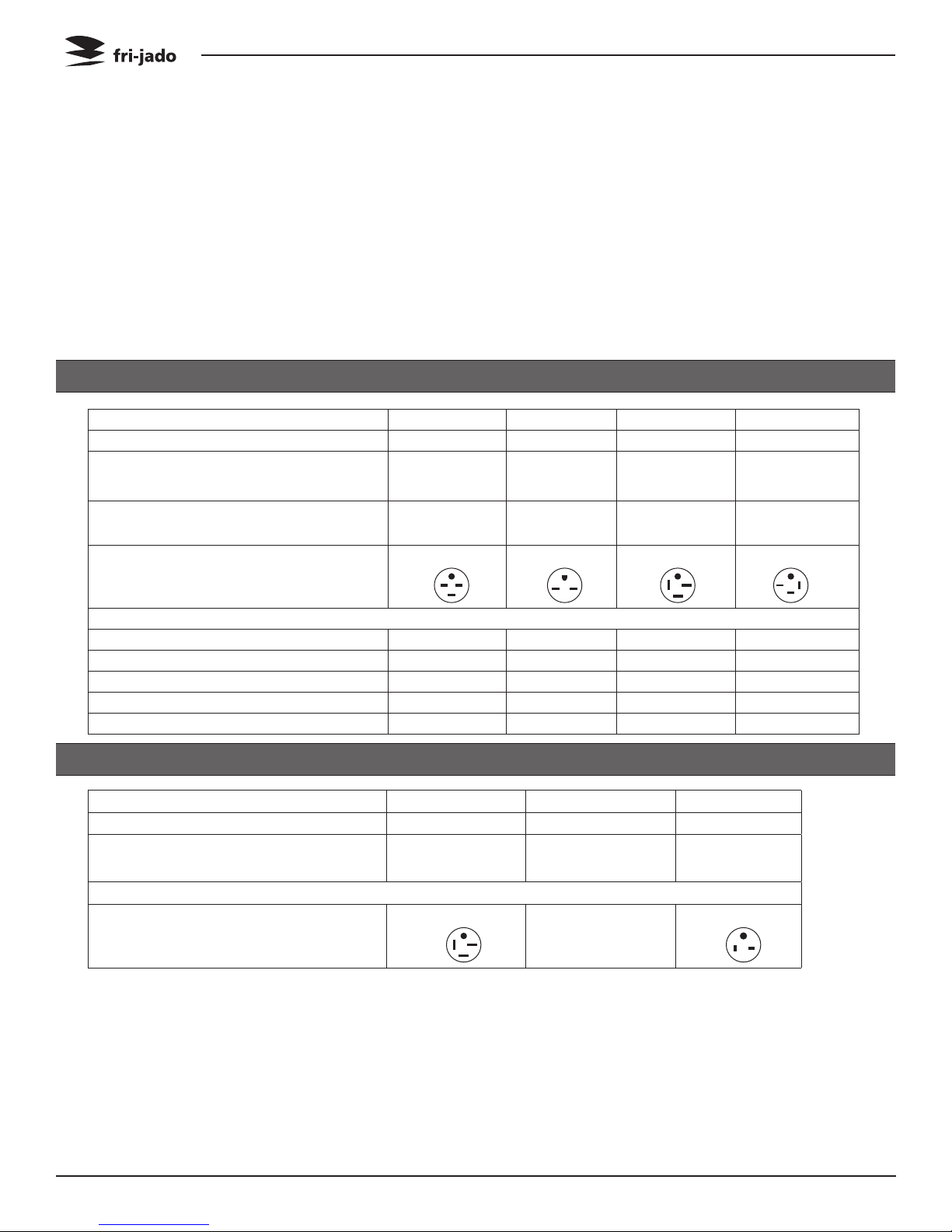

TECHNICAL DATA U.S. STANDARD MODELS

Type STG 5 STW 5 STG 7 STW7

Power 6500W 2800W 10200W 3500W

Fuses needed with power connection

208 V, 3 ~ 60 Hz (3 phases without

zero)

Fuses needed with power connection

208 V, 1N ~ 60 Hz (1 phase with zero)

Standard plug from factory NEMA 15-30P NEMA 6-15P NEMA 15-50P NEMA 15-20P

Stacked STG/STW cabinets: each cabinet comes with separate power cord!!

Net weight 269 lbs. 220 lbs. 399 lbs. 331 lbs.

Gross weight 350 lbs. 269 lbs. 478 lbs. 363 lbs.

Height 34 1/4” 34 1/4” 40 3/8” 40 3/8”

Width 32 9/16” 32 9/16” 38 13/16” 38 13/16”

Depth 25 5/8” 25 5/8” 33 1/2” 33 1/2”

3x 20 A - 3x 35 A 3x 20 A

_

G

Z

X

Y

1x 15 A

G

_ _

G

Z

X

Y

G

Z

X

Y

TECHNICAL DATA U.S. SPECIAL MODELS

Type STG 5 STG 7 STW7

Power 6100W 9500W 3500W

Fuses needed with power connection

208 V, 1N ~ 60 Hz (1 phase with zero)

Stacked STG/STW cabinets: each cabinet comes with separate power cord!!

Standard plug from factory NEMA 6-50P n/a ( fixed wiring ) NEMA 6-20P

Tools

• Standardsetoftools.

• Metricwrenches,socketsandhexsocketkeywrenches.

• Multi-meterandACcurrentclampmeter.

• Temperaturetester.

• Insulation value tester (Megger).

• FieldServiceGroundingKit.

Page 6

1x 35 A 1x 60 A 1x 20 A

G

Z

X

Y

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

G

PROGRAMMING INSTRUCTIONS

PROGRAMMING INSTRUCTIONS FOR THE STG5 / STG7 AND STW5 / STW7

DISPLAY AND KEYS

Time Display

Temperature Display

Program indicators

Program keys

Buzzer key

Probe key

Temperature key

Up-Down key

Time key

SETTING THE STW

8888888410 0030

Temperature hold indicator

Second step indicator

First step indicator

Start / Stop

Rotor key

Time of day

Program end

Temperature hold process

Second cooking step

First cooking step

SETTING THE STG

THERMOMETER

THERMOSTAT DIAL

Turn thermostatdial to desired temperature

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

When the main switch is turned to “1” the

display lights up and the rotisserie is ON.

Page 7

PROGRAMMING INSTRUCTIONS

SETTING ACTUAL TIME 15 PROGRAMS

888410 88881040

ENTERING A PROGRAM

888p01 8888prog

Press and hold Time of

day key

Press Up or Down key

Release Time of day key

Select Program number

Press both Up and Down

keys during 2 seconds

After the unit is swit-

888p01 888815pr

ched-on the time display

indicates: 15PR

Key 1:

1x = program 01

2x = program 06

3x = program 11

Key 2:

1x = program 02

2x = program 07

3x = program 12

FIRST COOKING STEP (TIME)

Press Cooking process

888000 88880040

key

Cooking symbol lights

up

FIRST COOKING STEP (TEMPERATURE)

Press and hold the Tem-

888410 88880040 888000 88880030

perature key

Press Up or Down key

SECOND COOKING STEP (TIME)

Press and hold the Time

key

Press Up or Down key

Press Grilling process key

Grilling symbol lights up

Press and hold the Time

key

Press Up or Down key

Page 8

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

PROGRAMMING INSTRUCTIONS

SECOND COOKING STEP (TEMPERATURE) TEMPERATURE HOLD

888355 88880030

LOADING PROGRAM

888185 88880000

Press and hold Tempera-

ture key

Press Up or Down key

Press program number

to load pre-set values

Press Temperature Hold

888185 88880000

process key

Temperature Hold symbol lights up

Press and hold the Temperature key

Press Up or Down key

PROGRAM START & LOADING

Press Start / Stop key

888000 88880040

On indicator lights up

Press Rotor key to start

turning the rotor

OPTIONAL SETTINGS FOR THE STG5 AND STG7

INTERRUPTING ACTIVE PROGRAM

Press Rotor key

888380 88880046

Heaters and front lamp

switch off

Rotor stops

On indicator is blinking

Process time in hold

Press Rotor key again to

stop

Load the rotisserie with

products

SET ADDITIONAL BUZZER SIGNAL

Select a pre-defined

888p01 88881055

program

Press and hold Buzzer

key

Press Down key

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 9

PROGRAMMING INSTRUCTIONS

SET PROGRAM END TIME DISPLAY SET TIME & TEMPERATURE

Select a pre-defined

888p01 88881030 888410 88880040

ADJUSTING ACTIVE PROGRAM

program

Press and hold the Pro-

gram end key

Press Up key

PREHEAT INDICATION

Press and hold Temperature or Time key

888390 88880035 888prh 88880059

Adjust temperature or

time with Up or Down

key

Select a pre-defined

program

Press Cooking, Grilling

or Temperature hold key

No time indictaion for

Temperature hold

Visible during process or

program selection

Under 40°C (104°F) the

display shows PRH

TEMPERATURE PROBE (OPTIONAL)

Press the Rotor key

888185 88880046

Page 10

Insert the probe in the

meat up to the core

Press Temperature sen-

sor key; after 20 seconds

the temperature reading

swtiches off

INDICATIONS DURING PROCESS

• Processindicatorsshowsactualprocess

after completion indicator switches off

• Timedisplayshowsremainingprogram

time which is the sum of the remaining

cooking and grilling time

• Temperaturedisplayindicatesactual

temperature in the grill. Under 40°C

(104°F) the display shows PRH (preheat)

• Whenremainingtimereaches0,the

process indicators and the On-indicator

switches off

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS FOR THE STG5 AND STG7

WARNING: Disconnect the electrical power to the machine at

the main circuit box. Place a tag on the circuit box indicating

the circuit is being serviced.

RIGHT OR LEFT SIDE PANEL

1. Remove the screws that secure the panel

to the frame.

2. Remove the panel.

3. Reverse the procedure to install.

TOP COVER

1. Remove the left side panel according

prior procedure.

2. Remove the screws securing both large

and small top covers.

3. Remove the top cover. (Lift at left side and

remove to the left).

4. Reverse the procedure to install.

Note: STG 5 has an optional special top cover

for access to the circulation blower. Standard

no cover for the blower.

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 11

REMOVAL AND REPLACEMENT OF PARTS

KNOB

1. Remove cover plate on the knob with a

small screw driver.

2. Loosen the srew inside the knob.

3. Remove the knob with ring.

4. Reverse the procedure to install.

Note: check that the ring behind the knob is

in the right position and runs free from the

panel.

OPERATING PANEL

1. Remove the right side panel according

prior procedure.

2. Remove the knob according prior procedure.

3. Remove the screw that secures the panel.

4. Remove the 2 bolts on the backside of the

operating panel (top and bottom side,

only for the STG 7).

5. Remove the screws that secure the meat

probe holder and remove the holder (if

supplied).

6. Remove the flatcable on the power section.

7. Remove the clip on the back, top left side

that secures panel and frame.

8. Remove the instrument panel.

9. Reverse the procedure to install.

Page 12

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

REMOVAL AND REPLACEMENT OF PARTS

ELECTRIC PANEL

1. Remove the operating panel according

prior procedure.

2. Remove on the front side the screws that

secure the panel.

3. Remove on the inside bottom of the electric panel the bolt and nuts.

4. Disconnect the wiring.

5. Slide the electrical panel backwards.

6. Reverse the procedure to install.

DISPLAY

1. Remove the right side panel according

2. Disconnect the flatcable on the display.

3. Remove the clip on the back, top left side

4. Remove the nuts and washers on the

5. Remove the nuts and plastic rings that

6. Reverse the procedure to install.

prior procedure.

that secures panel and frame.

backside of the display and remove the

metal cover.

secure the board and remove the board.

Do not forget to disconnect the blue connector on the board.

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 13

REMOVAL AND REPLACEMENT OF PARTS

PANEL AND KEYPAD ASSEMBLY

1. Remove the operating panel according

prior procedure.

2. Remove the display according prior procedure.

3. Remove the nuts that secure the keypad

and remove the keypad.

4. Reverse the procedure to install.

NAMEPANEL

1. Remove the operating panel according

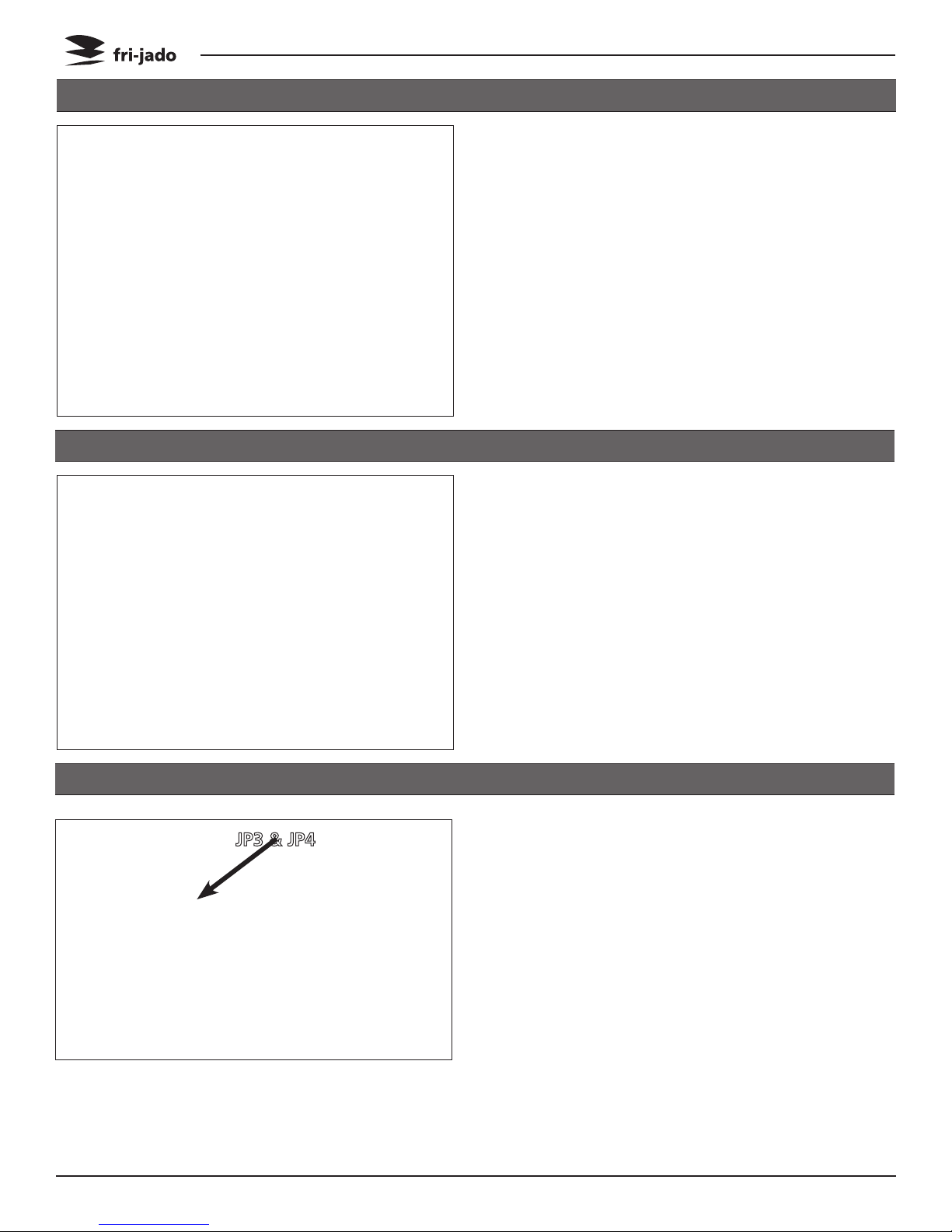

JP3 & JP4

prior procedure.

2. Remove the 4 nuts that secure the panel

and remove the panel.

3. Reverse the procedure to install.

POWER AND I/O BOARD

1. Remove the right side panel according

prior procedure.

2. Disconnect wiring and flatcable on the

board.

3. Remove the board from the clips by pres-

Page 14

sing the clips together.

4. Reverse the procedure to install.

Note: When installing a new board, ensure

that JP3 and JP4 on new board are set the

same as on the old board.

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

REMOVAL AND REPLACEMENT OF PARTS

QUARTZ LAMP

Caution: Do not touch the glass with your hands.

The moisture from your hands could affect the

live span of the lamp. This moisture can be removed with alcohol while the lamp is cold.

Note: Use a clean rag or paper towel to replace

the lamp.

1. Remove the insulators of the lamp, see arrow.

2. Remove the bolt from each end of the lamp

and remove the lamp.

3. Install the lamp with the painted side towards

the top of the oven. Hold the metal with your

hand when tightening the bolts to prevent

the metal from twisting and damaging the

lamp.

4. Tighten the insulators evenly to prevent

damage.

MAIN SWITCH

1. Remove the instrument panel according

prior procedure.

2. Loosen the screws on the electric panel that

secure the switch.

3. Remove the switch and disconnect the wiring.

4. Reverse the procedure to install.

Note: The main switch until serial nuber

Main switch till serial

number 100050804

New main switch

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

100050804 is different than the new

main switch.

Page 15

REMOVAL AND REPLACEMENT OF PARTS

HIGH LIMIT THERMOSTAT

1. Remove the right side panel according prior

procedure.

2. Remove the suction and fan plate on the cei-

STG5

STG7

ling on the inside of the oven.

3. (STG 5 only) Remove the nut on the clamp

(see black arrow) and slide clamp towards

yourself. Loosen the screw in the clamp that

secures the probe and remove the probe.

4. (STG 7 only) Remove the thermostat-probe

from the clip in the oven and guide it outside

through the opening in the side wall.

5. Remove the screws on the electric panel that

secure the thermostat (see white arrow).

6. Remove the thermostat and disconnect the

wiring.

7. Reverse the procedure to install.

Note: Set the new high limit thermostat to its

maximum position.

CONTACTOR

1. Remove the right side panel according prior

procedure.

2. Disconnect the lead wires to the switch.

3. Push the locking tab down with a screw

driver and lift the contactor out to remove

it from the mounting bracket.

4. Reverse the procedure to install.

Page 16

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

REMOVAL AND REPLACEMENT OF PARTS

HEATING ELEMENT

1. Remove the rotor discs, right side panel,

suction and fan plate on the ceiling according prior procedures.

STG5

STG7

2. Disconnect the wiring from the element.

3. Remove the mounting nut.

4. Remove the element from the mounting

clip and pull it from the wall.

5. Reverse the procedure to install.

BLOWER MOTOR

1. Remove the right side panel and the top

cover according to prior procedures.

2. Remove the rotor discs, suction and fan

plate on the ceiling inside the oven.

3. Remove the wing nut on the fan blade and

remove fan blade. (Left handed threads)

4. Disconnect wiring of the motor.

5. Remove the screws that secure the motor

and remove the motor.

6. Reverse the procedure to install.

Note: The blower(s) are equipped with a capacitor of 1,5 uF. Check the direction of rotation

of the motor (clockwise, see arrow) and change the wiring if necessary.

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 17

REMOVAL AND REPLACEMENT OF PARTS

BLOWER MOTOR BOTTOM ROTISSERIE (STACKED STG)

1. Remove the right side panel according prior

procedures.

2. Remove the rotor discs, suction and fan

plate on the ceiling inside the bottom oven.

3. Remove the wing nut on the fan blade

and remove the fan blade. (Left handed

threads).

4. Remove fat drawer from upper oven.

5. Remove the bolts that secure the intermediate plate and remove this plate.

6. Remove the drip trays from the upper oven.

7. Remove the bolts that secure the top plate

(STG 5 must have a special top cover!) and

remove the top plate.

8. Disconnect wiring of the motor.

9. Remove the screws that secure the motor

and remove the motor.

10. Reverse the procedure to install.

Note: The blowers are equipped with a capacitor of 1,5 uF. Check the direction of rotation of

the motor (clockwise, see arrow) and change

the wiring if necessary.

PT500 SENSOR

1. Remove the right side panel according to

prior procedure.

Page 18

2. Disconnect the wiring of the sensor.

3. Remove the screw that secures the sensor

and remove the sensor.

4. Reverse the procedure to install.

Note: The wiring cable is an insulated cable

with a earthing screen.

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

REMOVAL AND REPLACEMENT OF PARTS

DRIVE MOTOR

1. Remove the right side panel and rotor discs

according prior procedure.

2. Disconnect the wiring of the motor. Check

where the wire, marked A is connected.

3. Remove the screws that secure the fan cover

and remove the cover.

4. Note down how far the drive arm or drive

block sticks out from the inner wall (see

white or black arrow).

5. (STG 5 only) Remove the nuts that secure the

motor and remove the motor.

6. (STG 7 only) Set the drive arm in a position

vertical downwards. This can be done manually or by turning the fan blade by hand.

7. Mark the position of the motor support with

a marker.

8. Remove the bolts that secure the motor and

the nuts that secure the motor support and

remove the motor.

9. Check the white Teflon ring. Replace this if

necessary.

10. Check the position of the red gasket between motor support and the side wall. Replace this if necessary.

11. Install the fan blade on the new motor.

12. Reverse the procedure to install.

Note: Always make a test run of 15 minutes on

maximum temperature to insure the motor is

well mounted and adjusted and turns parallel

to the side wall.

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 19

REMOVAL AND REPLACEMENT OF PARTS

DOOR ADJUSTMENT (LEFT SIDE)

1. Remove the left side panel according prior

procedure.

2. Loosen the nuts (A) of the upper hinge. The

B

A

C

A

DOOR INSIDE

door must be closed.

3. Loosen the locknut (B) and adjust the bolt

(C) in or out to adjust the door.

4. Tighten the nuts of the hinge and mount

the left-hand panel.

1. Separate the inside door from the outside

door.

2. Lift the inside door upward out of the hinges.

3. Place the new door in the hinges.

4. Close the inside door on the outside door.

Note: Tightening of nuts max. 6 Nm. or

4.5 lbf.ft

Page 20

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

REMOVAL AND REPLACEMENT OF PARTS

DOOR OUTSIDE

1. Lift the inner door out of the hinges and lay

this aside.

2. Remove the left side panel according prior

procedure.

3. Remove the 2 nuts behind the upper hinge

and loosen the locknut according prior procedure. The door must be closed.

4. Hold the door on both sides and move this

towards yourself, before lifting it out of the

hinge on the bottom side. See to it that the

washers stay on the hinge.

Also remove the top hinge.

5. Place the top hinge on the new door.

6. Place the new door on the hinge on the

bottom side and push the 2 studs on the top

hinge through the openings on the top side

and screw the nuts on it .

7. Adjust the door according prior procedure.

Note: Tightening of nuts max. 6 Nm. or

4.5 lbf.ft

Service Manual STG5/7 STW5/7 form 9123647 rev. 03/2014

Page 21

Loading...

Loading...