ENG CHI

CL 950

&

CL 950 (WITHOUT CANOPY)

ENG

User Manual

INSTALLATION/MAINTENANCE

用手册户

安装

/ 维护

CHI

ENG

Table of Contents

1. Foreword ......................................................... 4

2. Technical description..................................... 4

2.1 General............................................................ 4

2.2 Technical specifications................................ 4

2.3 Physical Dimensions:..................................... 4

3. Installation....................................................... 4

3.1 Installation instructions................................. 5

3.2 Adjusting the shelf ......................................... 5

3.3 Connection to the mains supply ................... 6

4. Maintenance.................................................... 6

4.1 Preventive Maintenance................................. 6

4.2 Cleaning........................................................... 6

4.3 Operation......................................................... 6

4.4 Replacing the LED tube light ......................... 6

4.5 Cabin light operation...................................... 7

4.6 Changing the advertising plate of the

light box........................................................... 7

5. Service............................................................. 7

6. First Aid........................................................... 9

7. Warranty........................................................10

8. Figures........................................................... 10

CHI

目录

1.

前言...................................................................11

2. 技格术规 .............................................................11

2.1 概述...................................................................11

2.2

技参数术 .............................................................11

2.3 构尺寸结 .............................................................11

3.

安装...................................................................11

3.1 安装指导.............................................................12

3.2 架搁调节.............................................................12

3.3 主源接电连...........................................................13

4. 维护...................................................................13

4.1 防性预维护...........................................................13

4.2 清洁...................................................................13

4.3 操作...................................................................13

4.4 替换LED灯管......................................................13

4.5 箱内灯的开关........................................................14

4.6 更盖广告宣牌换顶传................................................14

5. 修维 ................................................................... 14

6. 急救助措施紧 ........................................................16

7. 保质 ................................................................... 16

8. 片图 ................................................................... 16

ENG

4

1. Foreword

Thank you for purchasing this new Ice Cold Merchandiser (ICM) from Frigoglass.

Before using this unit please read the instructions below carefully. We want you to enjoy

the benefits of this cooler with trouble-free operation for many years. A well-maintained

Frigoglass ICM will help you increase your sales and profits.

2. Technical description

2.1 General

The merchandiser must be connected to a grounded mains outlet with a minimum fuse

rating of 10A. The outlet must be easily accessible for the purposes of installation and

servicing. During installation, other authorities may impose additional requirements in

respect of lighting, alarm equipment and similar.

2.2 Technical specifications

Rating voltage 240V~,50Hz

Total Volume 971L

Thermostat 0~ 7.2°C

Ambient Temp 5M2

Defrosting Automatic

Capacity 840 Cans (330ml)

2.3 Physical Dimensions:

Model Width Height Depth Weight

CL 950 1278 mm 2250 mm 765 mm 220 kg

CL 950 WITHOUT

CANOPY

1278 mm 2104 mm 765 mm 210 Kg

3. Installation

After unpacking, check the cabinet for any damage caused during transportation. In

the event of damage, please contact the forwarding company.

Allow the merchandiser to stand upright for at least 1 hour

prior to connecting to the mains supply. This gives the oil

time to run back to the compressor after transit and

installation.

ENG

5

3.1 Installation instructions

a. Always ensure that your merchandiser is installed on level floor. There are 2

adjustable feet at the front and back under the chassis. Please adjust until the

ICM levels. Check by using a spirit, if available.

Do not install the merchandiser under direct sunlight or near

heat sources

b. Install a 38mm spacer behind the unit to ensure a gap behind the unit for proper

air circulation.

Failure to comply with the instructions may result in highenergy consumption and poor performance of the unit.

c. Mains connection: If the mains cord supplied is not long enough, do not use an

extension lead. Ask an electrician to fit a 10A (or 13A) mains socket closer to the

merchandiser. Never allow the merchandiser to be connected to an extension

lead on a permanent basis.

d. The merchandiser must stand upright for at least 1 hour after transportation and

prior to start up. (This gives the oil time to run back to the compressor after transit

and installation.)

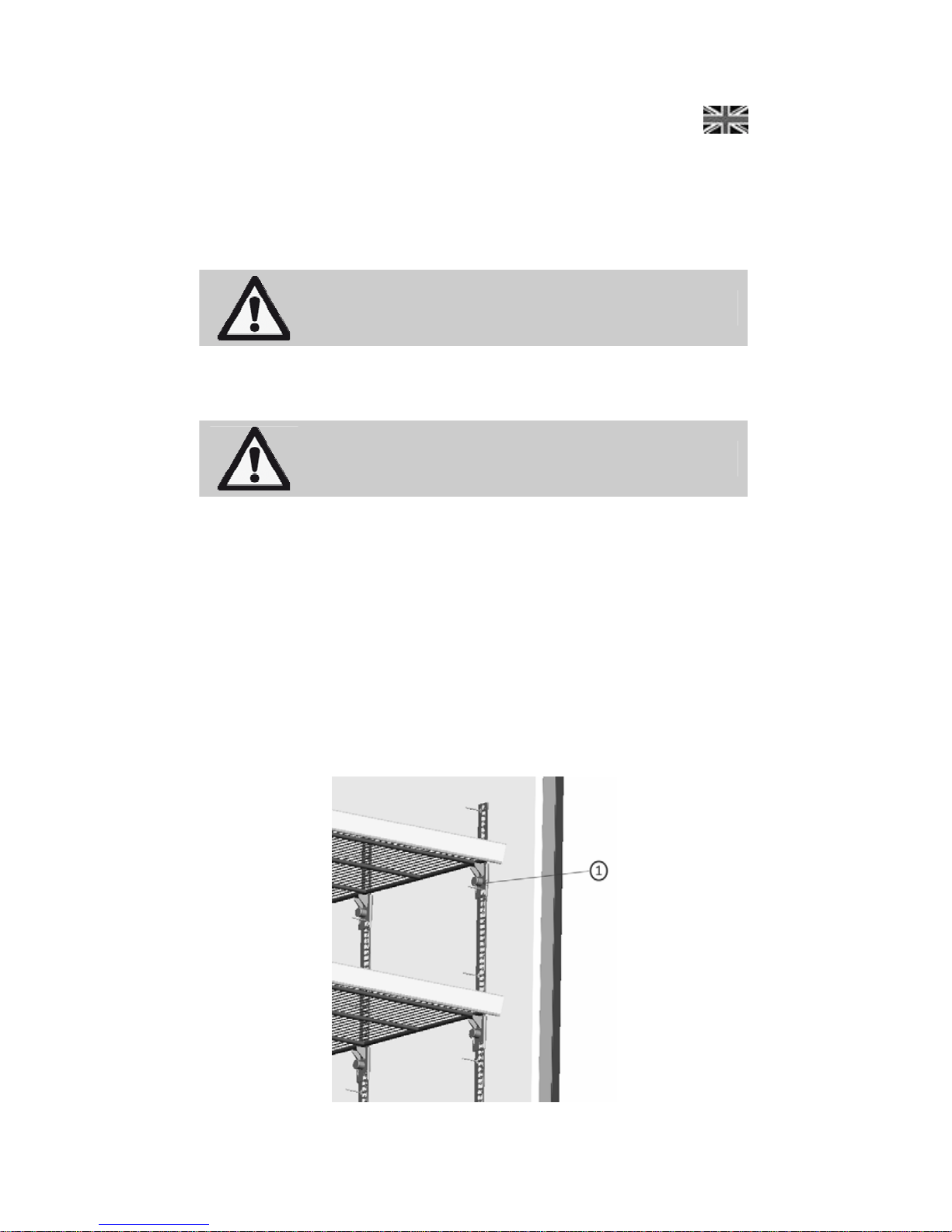

3.2 Adjusting the shelf

To adjust the shelf first unload it, lift it and unclip the shelf clips (1). Move the shelf

clips. Place the clips in the desired position and reposition the shelf. Make sure that

the horizontal metal rods at the bottom of the shelf are between the front and back

shelf clips.

ENG

6

3.3 Con necti on to the mains supp l y

Connect the ICM to a 230V, 50Hz power supply on a min 10A fused & grounded

socket. Do not use extension cables. If the power cord is not long enough, either

install a new socket nearby or ask an authorized electrician to replace the cord with a

longer one.

4. Maintenance

Prior to any cleaning or maintenance procedure, unplug the

ICM!

4.1 Preventive Maintenance

1. Clean the condenser once or twice yearly using a vacuum cleaner.

2. Use mildly soapy water to clean the interior of the ICM. Use a window-cleaning

agent to clean the glass surface.

4.2 Cleaning

It is important to clean the merchandiser twice a year. In order to avoid mould

formation, odours, etc. product compartments must also be thoroughly cleaned. The

interior of the ICM has to be cleaned with a mild soapy cloth.

Remember to disconnect the mains from the socket before

cleaning the ICM’s interior or exterior.

4.3 Operation

Energy saving tips:

For energy saving and ICM’s better performance:

• Load your ICM at night-time so that the drinks are cold once you get there in the

morning.

• Store your back-up stock in a cool and/or dark place so that when reloaded, the

ICM will need much less time to cool them down.

• Wipe moisture off the products you place in the ICM.

• Avoid opening the door for long periods of time.

4.4 Replaci ng the L ED tube light

Before replacing the LED tube light, unplug the ICM.

ENG

7

There are 4 LED tube lights in the ICM. One is located in the middle of the canopy and

two inside the cabin; one at the side and the other at the top. To replace the

fluorescent tube, do the following:

For the middle light inside the cabin:

• Unscrew the column-like lids which connect the ends of the tube light with the

bulb holder (2 pieces each for the upper and lower side).

• To remove the tube light (along with the lids), twist it slightly towards the cabin.

• Replace with new LED tube light and reposition the lids.

• Fix the lids in place by screwing them in (Fig. 1).

For the canopy light:

You can replace the LED tube-light with a new one by unscrewing it and removing the

advertising plate form the canopy (Fig. 2)

Insert the advertising plate of the light box.

For the cabin top light:

• Unsnap the transparent light-cover by unscrewing the bolt away from you. Now

you can access the tube light.

• Continue unscrewing the tube light until you see the pin. Remove the tube light

from the bulb holder.

• Install the new LED tube light and fix it into place.

• Re-install the transparent cover and screw the bolt (Fig. 3).

4.5 Cabin light operation

The switch for the light is located on the top of the evaporator plate of the light box.

Press to switch on/off all the tubes (Fig. 4).

4.6 Changing the advertising plate of the light box

• Pull the advertising plate off the canopy (Fig. 5).

• Insert the new advertising plate.

5. Service

PRIOR TO ANY CLEANING OR MAINTENANCE PROCEDURE,

UNPLUG THE ICM!

If the ICM is not functioning properly or is out of order, please check the following

before calling the authorized service provider:

ENG

8

FAULT POSSIBLE REASONS HANDLING

Power cord not plugged in. Plug it in.

The ICM does

not work.

No power coming through

the socket.

Check for fuse on the mains

Wrong EMS set point

Lower the set point as follows:

Press the "set" button, then

keep the “down" button

pressed until the you reach

the desired value, and then

press the "set" button again.

The ICM has recently been

reloaded with warm

products. It takes 11-18

hours to cool them down.

Preferably, reload the ICM

before night closing.

The ICM is loaded in such a

way that the air-circulation in

the interior is getting

blocked.

Load the ICM according to the

standards you have been

provided with by the company.

The condenser is blocked.

Dust has accumulated on the

condenser.

Clean the condenser using a

vacuum cleaner.

The door has been left open.

Press the defrost button and

defrost manually.

The door does not seal

properly.

Call a Service technician

The ICM does

not cool

properly. The

products are

warm.

Leakage in the cooling

system.

Repair the leakage (this type

of repair should be performed

by an authorized technician)

For this particular ice cold

merchandiser, a powerful

mechanism is needed and

consequently a certain

amount of noise cannot be

avoided.

Ice Cold Merchandisers are of

dynamic type, so a certain

amount of noise cannot be

avoided.

Intense metallic noise. Call a Service technician

The ICM

sometimes

makes noise.

Inclined or curved floor.

Level the ICM properly by

adjusting its feet.

ENG

9

FAULT POSSIBLE REASONS HANDLING

The door has been left open.

This feature is designed to

reduce the ambient air ingress

while opening the door.

Energy-saving mode during

the compressor off cycle.

This feature is designed to

save energy during the

compressor off cycle.

Evaporator fan

is not running

Others Call a Service technician

The drainage hose for

condensate water is out of

the tray.

Call a Service technician

There is water

on the floor.

There is a leakage in the

tray.

Call a Service technician

The lights don’t

work.

The light is switched off. Switch on the light.

If after all the above-mentioned checks the problem with your ICM remains, please

contact the customer service department of your supplier and provide the following

information:

• ICM Type

• ICM Serial number

• Brief description of the problem / observation

6. First Aid

The appliance uses refrigerant (R134a) for operation, which

under normal conditions is found in small amounts in the

refrigerating unit and it is not expected to cause danger in

case of leakage. However, high exposure levels to R134a can

cause loss of senses and asphyxia. Liquid drops can cause

burns and eye irritation.

In case of accident, proceed to the following:

ACCIDENT: IMMEDIATE ACTION:

Inhalation of refrigerant Take deep breaths of clean air. If necessary, oxygen

or artificial respiration must be provided.

The administration of epinephrine or similar drugs

should be avoided.

Contact with eyes Wash your eyes thoroughly with plenty of water for at

least 15 minutes and then consult a doctor

Contact with skin Rinse immediately with water.

ENG

10

7. Warranty

The appliance is covered by a warranty as this has been agreed upon sale.

8. Figures

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

CHI

11

1. 前言

祝贺您作出明智的决定,

从飞格乐思购买了新的冰柜。在使用冰柜之前,请您仔细阅读本手册。我们衷心地希望

您能享受此冰柜长期稳定运行给您带来的好处。一台维护良好的飞格乐思冰柜将帮助您

提高销售额,从而给您的公司带来更大的利润。

2. 技

术规

格

2.1 概述

冰柜必须使用带接地的独立电源插座,保险丝规格至少10A。为方便安装和维护,插座

应处在比较容易触及的位置。在安装过程中,其它权威机构可能会就照明、报警装置等

等提出额外的要求。

2.2 技

术

参数

额定电压

240V~,50Hz

总容积

971L

箱内温度

0~ 7.2°C

气候类型

5M2

除霜 自动

容量 840 罐 (330ml)

2.3

结

构尺寸

型号 宽 高 深 重量

CL 950 1278 2250 765 220 kg

CL 950 WITHOUT

CANOPY

1278 2104 765 210 Kg

3. 安装

在卸货之后,请检查机器是否在运输途中有所损伤。如有损伤,请联系运输公司或我公

司售后服务部相关人员。

在通电之前让冰柜保持直立状态至少1小时,以保证在运输和安装之后

压缩机能充分回油。

CHI

12

3.1 安装指

导

a. 确保冰柜安装在水平地面上。在机组底盘下面有2个可调节的支脚,请调节使冰柜

水平。如有可能,使用动态水平仪校准。

不要把冰柜安装在阳光可直接照射或靠近热源处。

b. 在机

组

后面安装38mm的定位条,保证机组后部留有间隙以利于空气流通和散热。

不按指导操作可能会导致高能耗和低性能。

c. 主

电源连

接:如果主电源线不够长,不要使用延长插线板。请要求电工

在靠近冰柜合适的位置安装10A

(或13A)的主

电

源插座。切勿把冰柜接到延长插线板上。

d. 冰柜在启

动前必须竖

直放置至少1小时(以利于压缩机回油)。

3.2

搁架调节

要调节搁架,首先卸货,接着抬起搁架,往外拉起搁架支撑座○,1

弹簧把手,移动搁架支撑座,使搁架支撑座在合适的位置,重新放好搁架。确保搁架底部

的水平金属棒处在前后支撑座中间。

CHI

13

3.3 主

电源连

接

冰柜需连接到240V~,

50Hz,带至少10A保险丝、接地的插座上。不要使用延长线连接。如果电源线不够长,

需要在冰柜附近安装新的插座或者要求有资格的电工用更长的电源线替换冰柜自带电源

线。

4.

维护

在进行任何维护或清洁工作时请先拔掉冰柜的电源插头。

4.1

预防性维护

1. 每年使用真空吸尘器清洁冷凝器1到2次。

2. 使用温和的肥皂水清洁冰柜内部以及玻璃表面。

4.2 清

洁

每年需清洁冰柜2次,为了避免发霉、异味等现象产生,冰柜内部产品存放区域也必须

彻底清洁,请使用蘸温和肥皂水的软布来清洁冰柜内部。

切记在清洁冰柜内部或外部时请先断电。

4.3 操作

节能提示:

为节能和保证冰柜更佳的性能,请您注意以下内容:

• 在晚上给您的冰柜装货,这样能在第二天早上及时提供冷饮。

• 把您的存货储存在凉爽及阴暗处,这样当补充货物时冰柜可以更快的对它们进行冷

却。

• 物在放进冰柜前擦掉表面的水份或水珠。

• 避免长时间打开冰柜门。

4.4 替

换

LED灯管

切记在更换LED灯管前请先断电。

冰柜共有四条LED灯管,在箱体内部中间有一条竖直的灯管,而在箱体内部的顶部区域

左右各有一条灯管,还有一条灯管在灯箱里面。请按以下说明替换灯管:

CHI

14

冰柜共有四条LED灯管,在箱体内部中间有一条竖直的灯管,而在箱体内部的顶部区域

左右各有一条灯管,还有一条灯管在灯箱里面。请按以下说明替换灯管:

对柜内中间的竖灯:

• 拧松旋下灯管两端与灯座相连的圆柱形端盖(上下各2件)。

• 稍扭转灯管,朝箱体内侧可拉出灯管(连圆柱形端盖一起)。

• 换上新的LED灯管,套上圆柱形端盖。

• 把灯管灯座,拧紧圆柱形端盖 (参考图1)。

对顶盖灯管

• 朝外拉出广告宣传牌可看到顶盖灯管,扭转灯管取出并换上新的LED灯管(参考图2)

。

• 插回广告宣传牌。

对柜内的顶灯

• 卸下灯管两侧的固定螺钉,取下透明灯罩, 即可对灯管进行操作。

• 扭转灯管直到看见插销,从灯座里取出灯管。

• 换上新的LED灯管。

• 装回透明灯罩,拧紧固定螺栓 (参考图3)。

4.5 箱内灯的开关

开关位于箱体内顶部中间位置。按下此开关可开或关闭箱内的竖灯及顶部灯管

(参考图4)。

4.6 更

换顶

盖广告宣传牌

• 朝外抽出广告宣传牌(参考图5)。

• 插入要替换的广告宣传牌。

5.

维

修

进行任何清洁或维护工作前, 必须拔掉插头!

如果冰柜不运行或工作不良,在联系获得授权的维修商之前请检查下列各项.

CHI

15

现象 可能的原因 处理方法

电源线未插入. 插入电源线

冰柜不工作.

插座无电. 检查保险丝

EMS 设置有误

调低设定点. 方法如下,

按下”设定”按钮, 连续按压”

调低”按钮直至期望值,

再按下”设定”按钮*

冰柜最近装载了温饮品。冰柜需

11-18 个小时来冷却

最好在夜间关门前给冰柜装

载.

饮品摆放不妥使冰柜内部气体流

动受阻.

请根据我公司提供的摆放标

准装载饮品.

冷凝器通风受阻, 翅片表面积尘 用吸尘器清扫翅片表面

柜门开启时间过长.

按下除霜按钮,

进行手动除霜.

柜门密封不严. 联系维修人员.

冰柜制冷不足。

饮品温度较高

制冷系统泄露.

修复泄露

(由专业人员进行维修)

对于此种冰柜,需要一种强大的

机械装置,因此一定量的噪音是

不可避免的

冰柜是含有运动件的,

所以会产生一定量的噪音.

强烈的金属噪音.

联系维修人员.

冰柜有时发出噪

音.

地面不平. 调整底脚, 使冰柜保持水平.

门已开启

此功能是为了在开门时,避

免环境空气流入冰柜

压缩机停机时的节能模式

此项功能是为了在压缩机停

机时节能

蒸发器风扇不转.

其它 联系维修人员

冷凝水排水管脱出底盘 联系维修人员.

地面积水.

底盘漏水. 联系维修人员.

灯不亮.

灯开关关闭 打开开关

进行上述检查后, 如果冰柜问题依然存在, 请联系维修部并提供如下信息:

• 冰柜型号.

• 冰柜序列号.

• 问题/现象的简单描述.

CHI

16

6.

紧

急救助措施

该装置使用绿色环保制冷剂 (R134a)

工作,正常情况下在制冷回路中只有少量。即使在发生泄漏的情况下,

也不会发生危险。但是,R134a 的高度接触会引起感觉丧失及窒息。

液滴会引起皮肤和眼睛冷灼伤.

如果发生意外事故,建议如下

事故 应立即采取的措施

吸入制冷剂 转移到新鲜洁净空气处。如有必要,进行供氧或人工呼吸。

必须避免使用肾上腺素或同类药物。

接触到眼睛 用大量清水彻底地清洗至少 15 分钟,然后就医.

接触到皮肤 立即用清水冲洗。

7.

质

保

该装置具有质保,该质保在销售时签署.

8. 片图

图1

图 2

CHI

17

图 3

图 4

图 5

Loading...

Loading...