Frigobox HKEB-HCNB-261-X, HKEB-HCNB-351-X Service Manual

SERVICESERVICE

MANUALMANUAL

SPLIT TYPE AIR CONDITIONERSPLIT TYPE AIR CONDITIONER

CONTENTS

1.PART NAMES AND FUNCTIONS...................

2.SPECIFICATION............................................

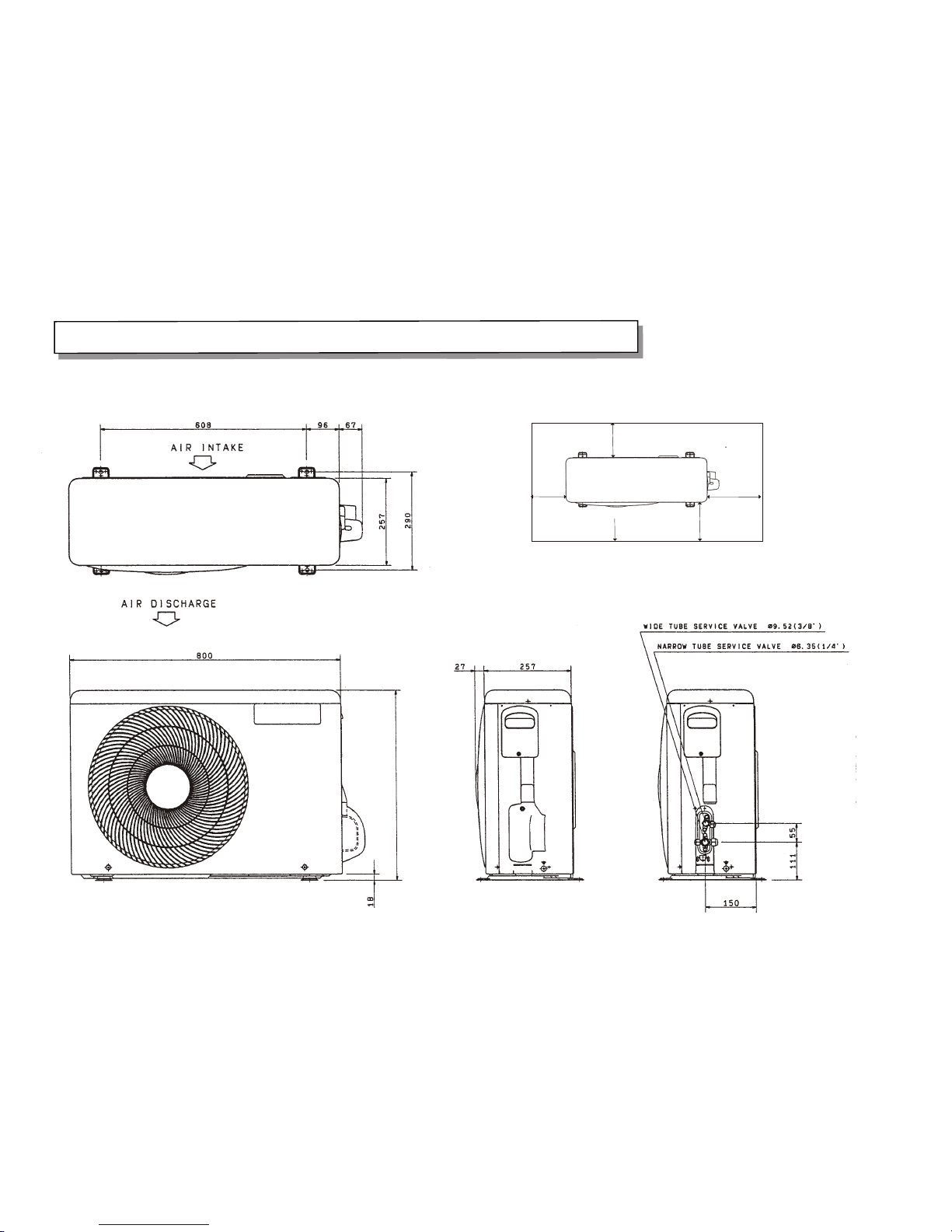

3.OUTLINES AND DIMENSIONS.......................

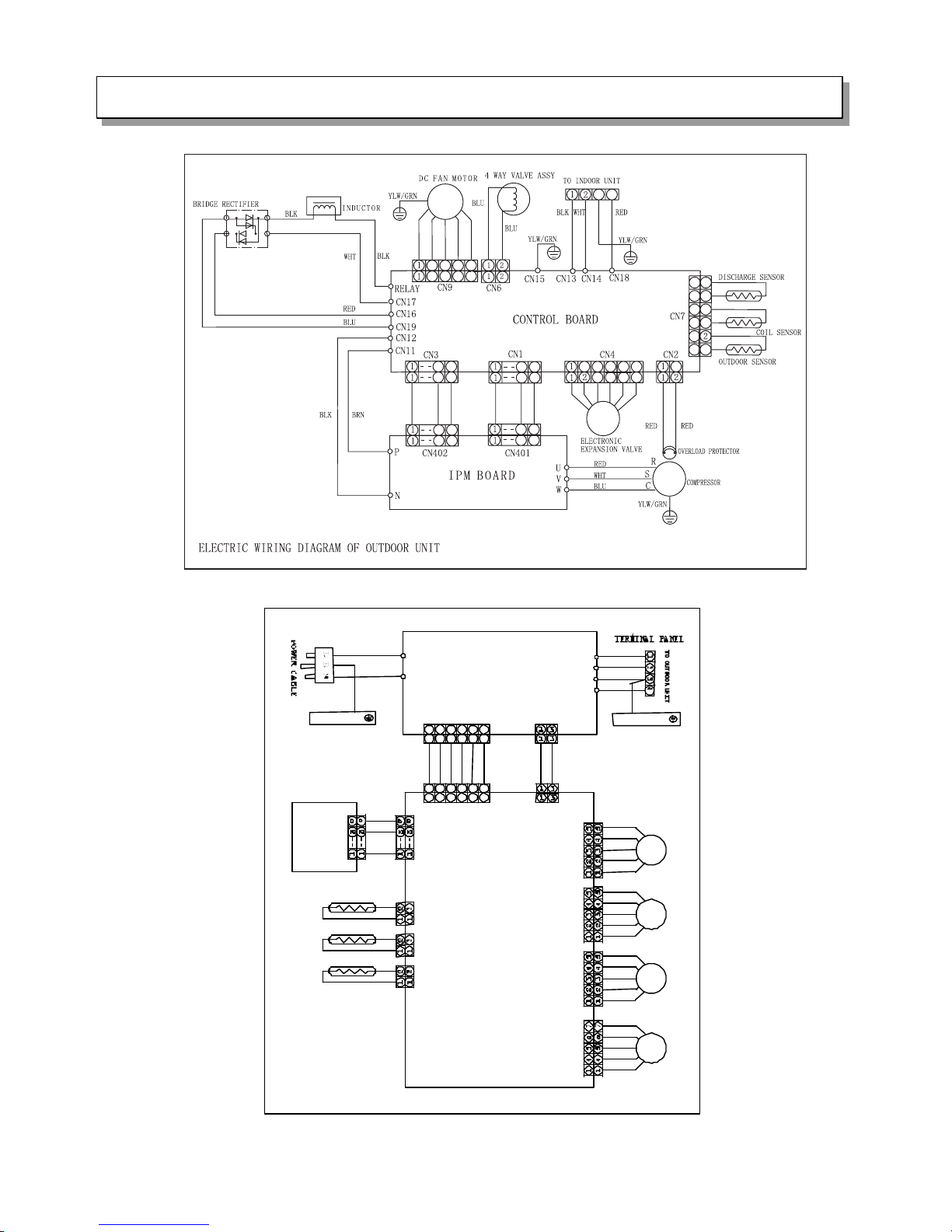

4.WIRING DIAGRAM.........................................

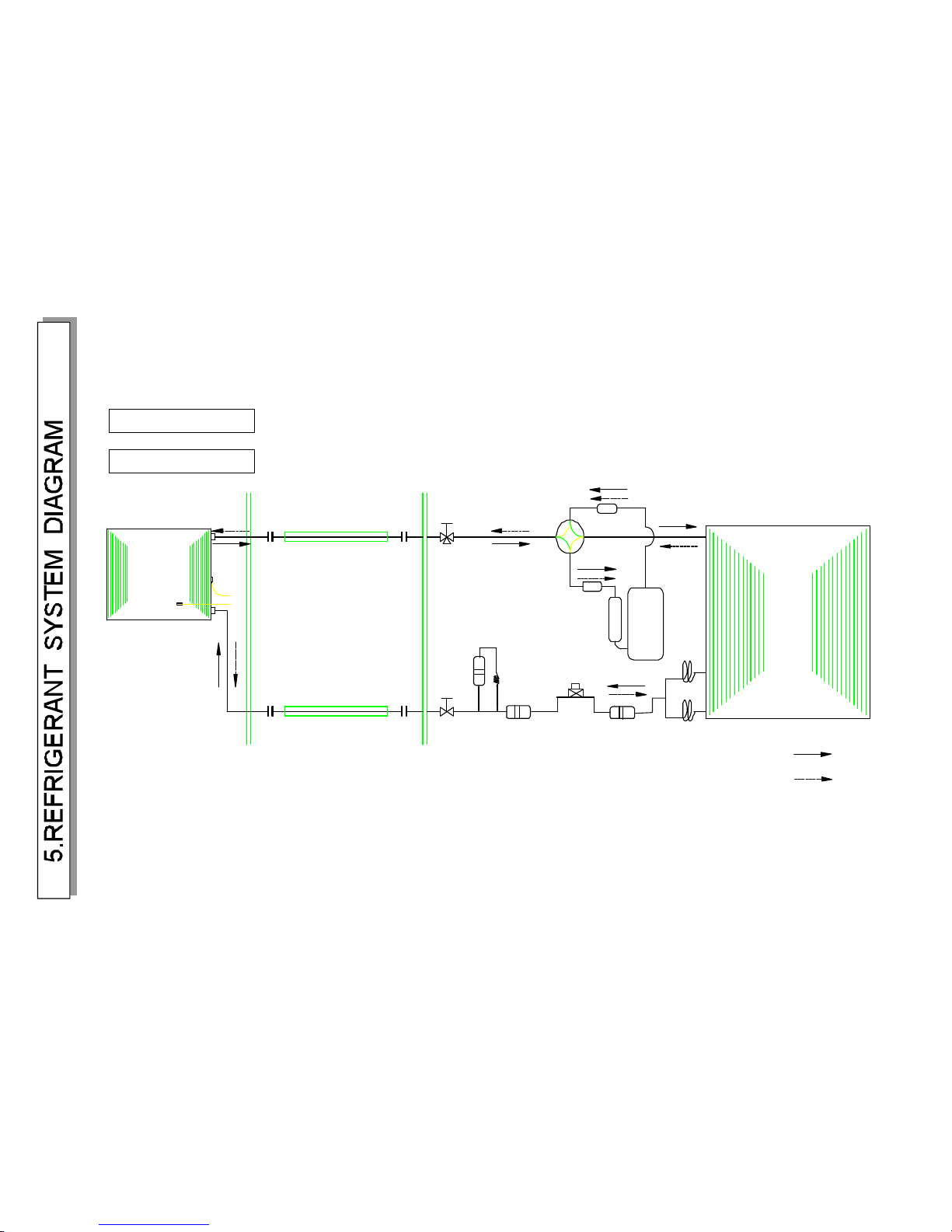

5.REFRIGERANT SYSTEM DIAGRAM...............

6.CONTROL MODE ................................

7.SERVICE FLOW CHART......................................

8.ELECTRIC .CONTROL.............................

9.SENSOR PARAMETER................................

10.DISASSEMBLY INSTRUCTIONS...................

11.PARTS LIST.................................................

HKEB-HCNB-261-X

HKEB-HCNB-351-X

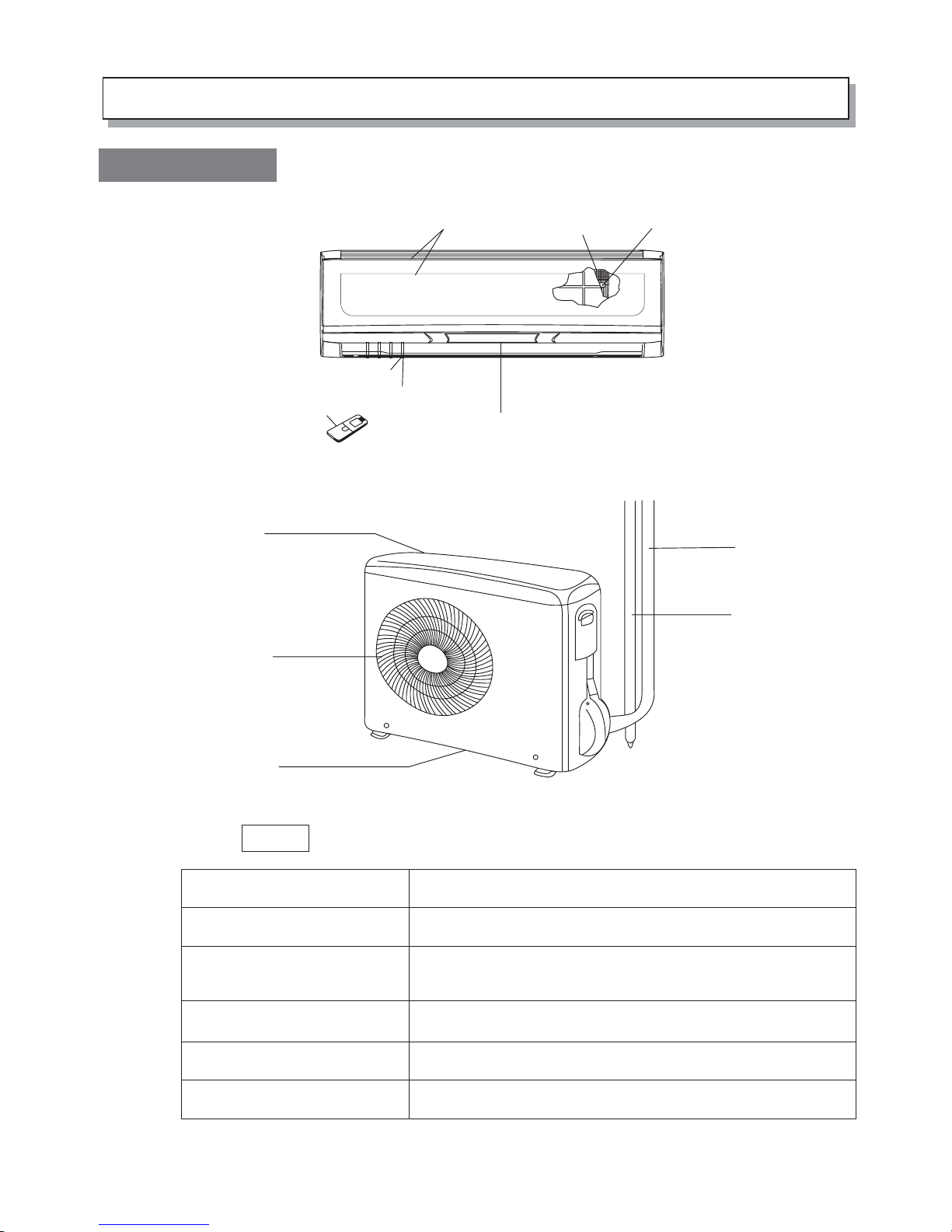

1. PART NAMES AND FUNCTIONS

1.Diagram of Structure

This air conditioner consists of an indoor unit and an outdoor unit. You can

control the air conditioner with the remote controller.

NOTE

Air Intake

Air Outlet

Remote Controller

Refrigerant Tubes

Outdoor(Condensing)Unit

Drain Hose

Air from the room is drawn into this section and passes

through air filters which remove dust.

Conditioned air is blown out of the air conditioner through

the air outlet.

The wireless remote controller controls power ON/OFF,

operation mode selection, temperature, fan speed, timer

setting, and air sweeping.

The indoor and outdoor units are connected by copper

tubes through which refrigerant gas flows.

The outdoor unit contains the compressor, fan motor, heat

exchanger coil, and other electrical components.

Moisture in the room condenses and drains off through this hose

Air filter

Air outlet

Impeller

Blue backlight LCD screen

Indoor sensor

Remote controller

Tubes and cable

Drain hose

Air inlet (rear and side)

Air outlet

Water drainage

Indoor unit

Outdoor unitt

Air intake

Appearance of the indoor may differ from some the picutres in the manual.

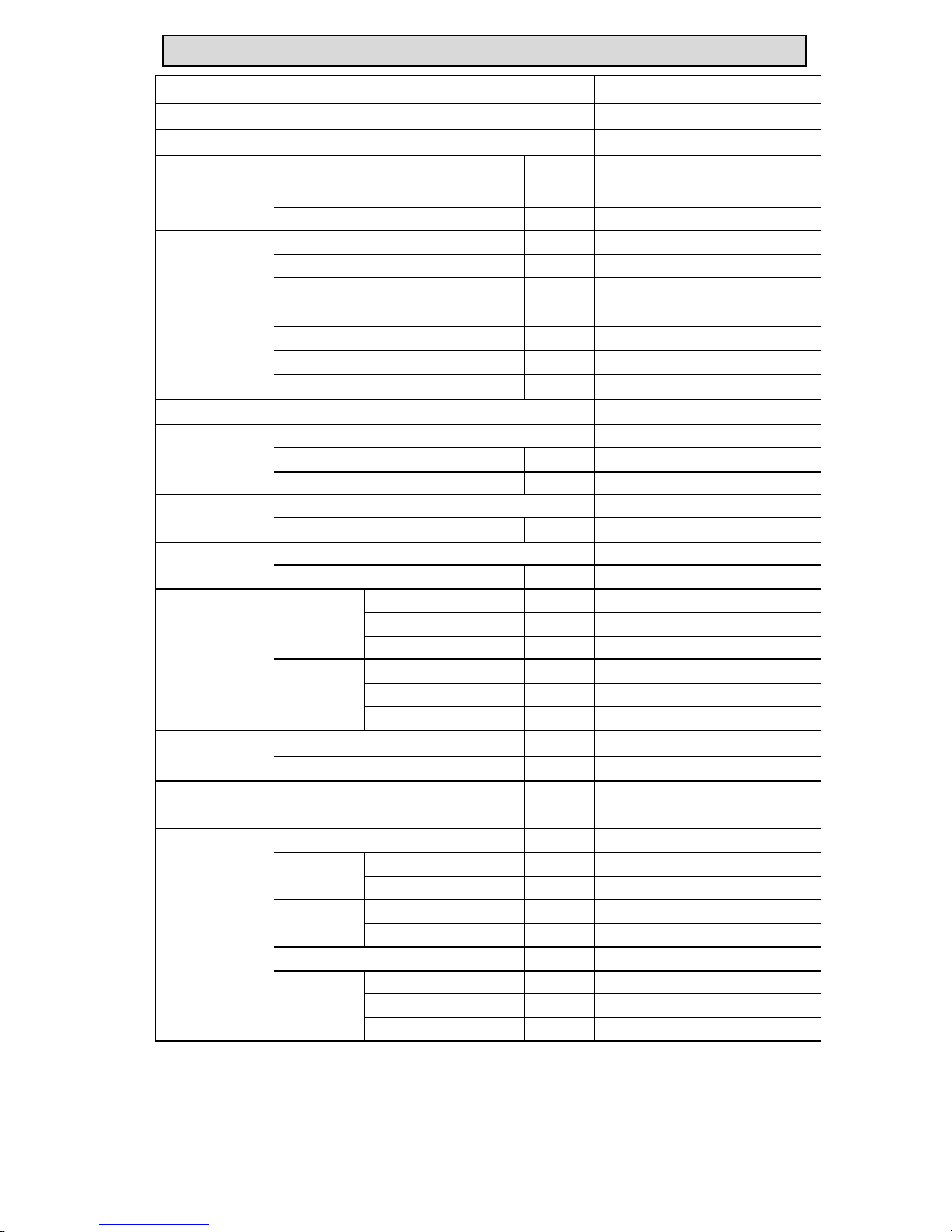

22、、SSPPEECCIIFFIICCAATTIIOONN

NOTE :Test conditions:Cooling : Indoor: DB27℃/ WB19℃ Heating: Indoor: DB20℃/ WB15℃

Outdoor DB35℃/ WB24℃ Outdoor DB7℃/ WB 6℃

Model HKEB -HCNB -261X

Function Cooling Heating

Power supply 220-230V~ 50Hz

Capacity k W 2.5 (0,39-3,2) 3.1 (0,40-3,53)

Dehumidification l /h 1.5

Capacity

Air flow m3/h 800 800

Power outlet A 16

Running current A 3.54/5.89 4.8/8.08

Power input k W 0.53 (0,3-1,05) 0.66 (0,3-1,25)

Auxiliary heater A(KW) --

Starting current A -Power factor % 90%

Electrical data

Compressor motor current A --

Coefficient of performance(C.O.P) 4.7/4.7

Model DA91A1F-22FD

Output W 750

Compressor

Winding resistance (at20℃)

Ω

1.10

Model SIC-37CV-F835-1 Indoor

fan motor Winding resistance (at20℃)

Ω -

Model DR-8938-504A-G Outdoor

fan motor Winding resistance (at20℃)

Ω -

Width mm 870

Height mm 225

Indoor unit

Depth mm 305

Width mm 800

Height mm 565

Dimensions

Outdoor unit

Depth mm 260

Indoor unit kg 11 Weight

Outdoor unit kg 34.5

Liquid pipe mm 6.35 Refrigerant

piping Gas pipe mm 9.52

Air direction 6

Indoor unit dB 46Sound leve l

(Hi)

Outdoor unit dB 53

Indoor unit rpm 1200 Fan speed

(Hi)

Outdoor unit rpm 760

Refrigerant filling capacity(R410A) kg 1.15

RT1(at25℃) k Ω 5

RT2(at25℃) k Ω 5

Special remarks

Sensor

RT 3(at0℃) k Ω 16.44

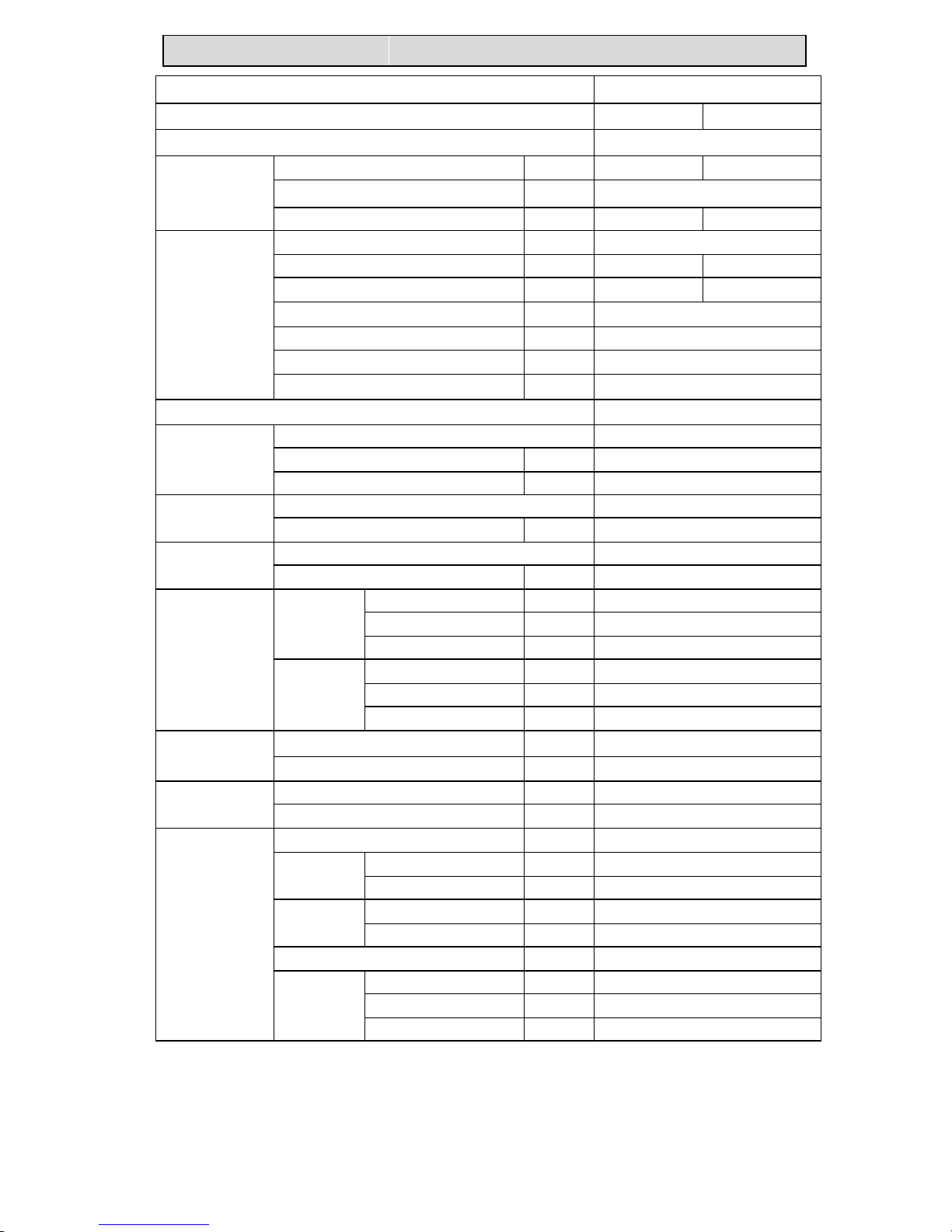

22、、SSPPEECCIIFFIICCAATTIIOONN

NOTE :Test conditions:Cooling : Indoor: DB27℃/ WB19℃ Heating: Indoor: DB20℃/ WB15℃

Outdoor DB35℃/ WB24℃ Outdoor DB7℃/ WB 6℃

Model HKEB - HCNB - 351 X

Function Cooling Heating

Power supply 220-230V~ 50Hz

Capacity k W 3.5 (0,39-3,98) 4.0 (0,4-4,49)

Dehumidification l /h 1.5

Capacity

Air flow m3/h 800 800

Power outlet A 16

Running current A 4.75/7.0 5.62/9.5

Power input k W 0.98 (0,3-1,3) 0.94 (0,3-1,6)

Auxiliary heater A(KW) --

Starting current A -Power factor % 90

Electrical data

Compressor motor current A --

Coefficient of performance(C.O.P) 3.57/4.26

Model DA91A1F-22FD

Output W 750

Compressor

Winding resistance (at20℃)

Ω

1.10

Model SIC-37CV-F835-1 Indoor

fan motor Winding resistance (at20℃)

Ω -

Model DR-8938-504A-G Outdoor

fan motor Winding resistance (at20℃)

Ω -

Width mm 870

Height mm 225

Indoor unit

Depth mm 305

Width mm 800

Height mm 565

Dimensions

Outdoor unit

Depth mm 260

Indoor unit kg 11 Weight

Outdoor unit kg 34.5

Liquid pipe mm 6.35 Refrigerant

piping Gas pipe mm 9.52

Air direction 6

Indoor unit dB 46 Sound leve l

(Hi)

Outdoor unit dB 53

Indoor unit rpm Fan speed

(Hi)

Outdo or unit rpm

Refrigerant filling capacity(R410A) kg 1.15

RT1(at25℃) k Ω 5

RT2(at25℃) k Ω 5

Special remarks

Sensor

RT 3(at0℃) k Ω 16.44

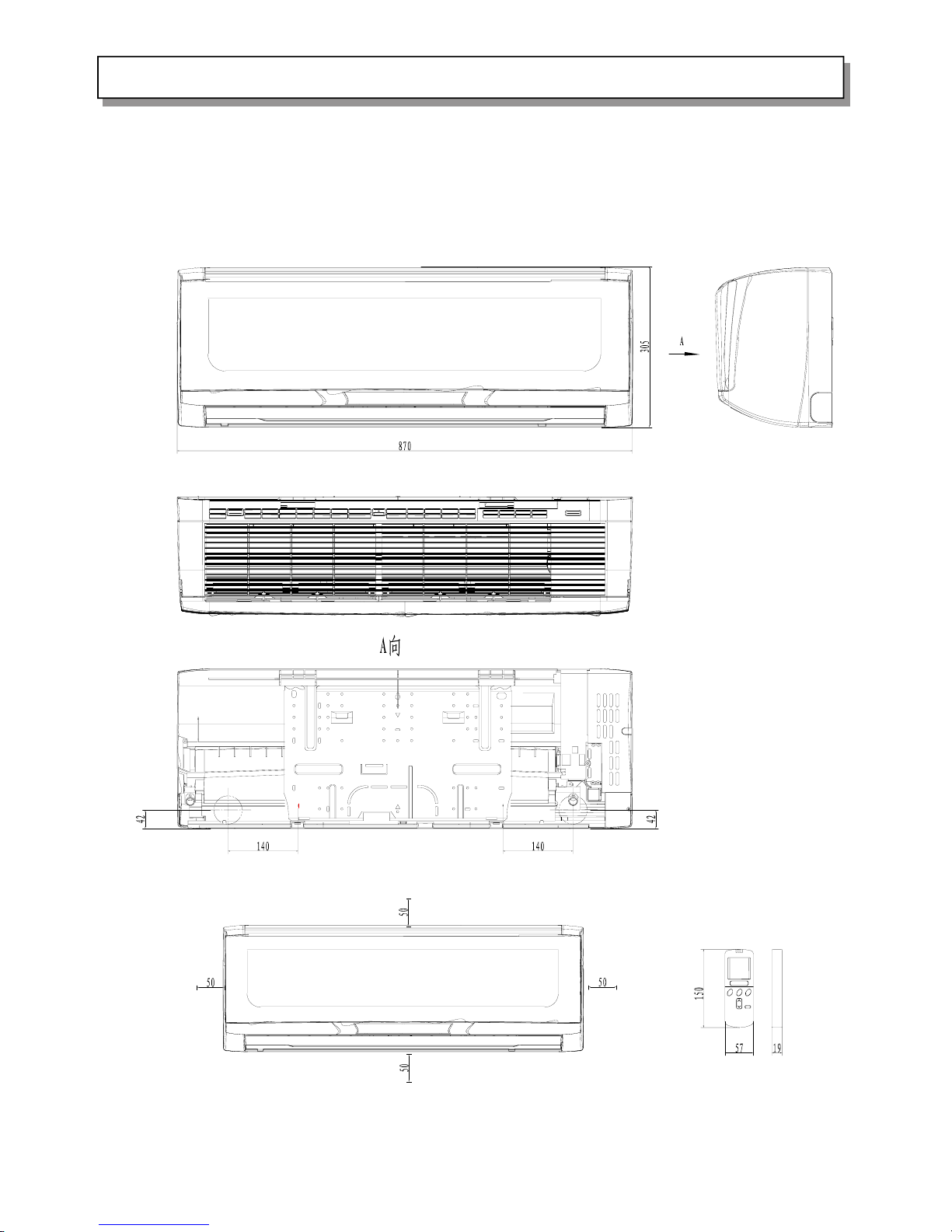

5.REFRIGERANT SYSTEM DIAGRAM3.OUTLINES AND DIMENSIONS

HKEB - HCNB 261-351 X

>25cm

>5cm

>10cm

Outlet

>40cm

5.REFRIGERANT SYSTEM DIAGRAM

3.OUTLINES AND DIMENSIONS

567.5

4.WIRINGDIAGRAM

ROOMSENSOR

COILSENSOR

CN101

FILTERBOARD

AIR OUTLETSENSOR

DISPLAY BOARD

CONTROLBOARD

21124334655

6

CN102

CN401

CN103

CN104

CN105

EVAPORATOR

CN701

CN106

21124334655

6

CN201

CN603

CN602

CN606

CN605

CN604

CN609

CN608

CN607

CN701

BRN

YLW/GRN

RED

YLW/GRN

WHT

BLK

YLW/GRN

BLU

EVAPORATOR

HORIZONTAL

FLAPMOTOR1

HORIZONTAL

FlAP MOTOR2

VERTICAL

FLAP MOTOR

DC FAN MOTOR

ELECTRIC WIRING DIAGRAM OF INDOOR UNIT

2

1

0

1

0

1

1

1

1

1

0

1

0

1

1

1

1

7

7

8

8

7

7

8

7

7

8

8

4

3

3

4

6

5

5

6

1

1

2

3

3

44

5

5

6

6

43

2 4

3

3

4

6

5

5

6

HKEB HCNB 261 X

(.52)φ9

(6.35)φ

Compressor

Rerigerant pipe

(With heat insulator)

Service valve

Indoortemperature

Heatexchanger

sensor

Flare connection

Refrigerant pipe

(With heat insulator)

Flare connection

Service valve

INDOORUNIT

Heatex changer

OUTDOORUNIT

Muffler

Desiccationfilter

4-way valve

Heating cycle

Cooling cycle

sensor

Indoorcoil

Muffler

Strainer

φ×51.500

Capillary tube

φ×51.500

Strainer

Electric expansion valve

HKEB HCNB 351 X

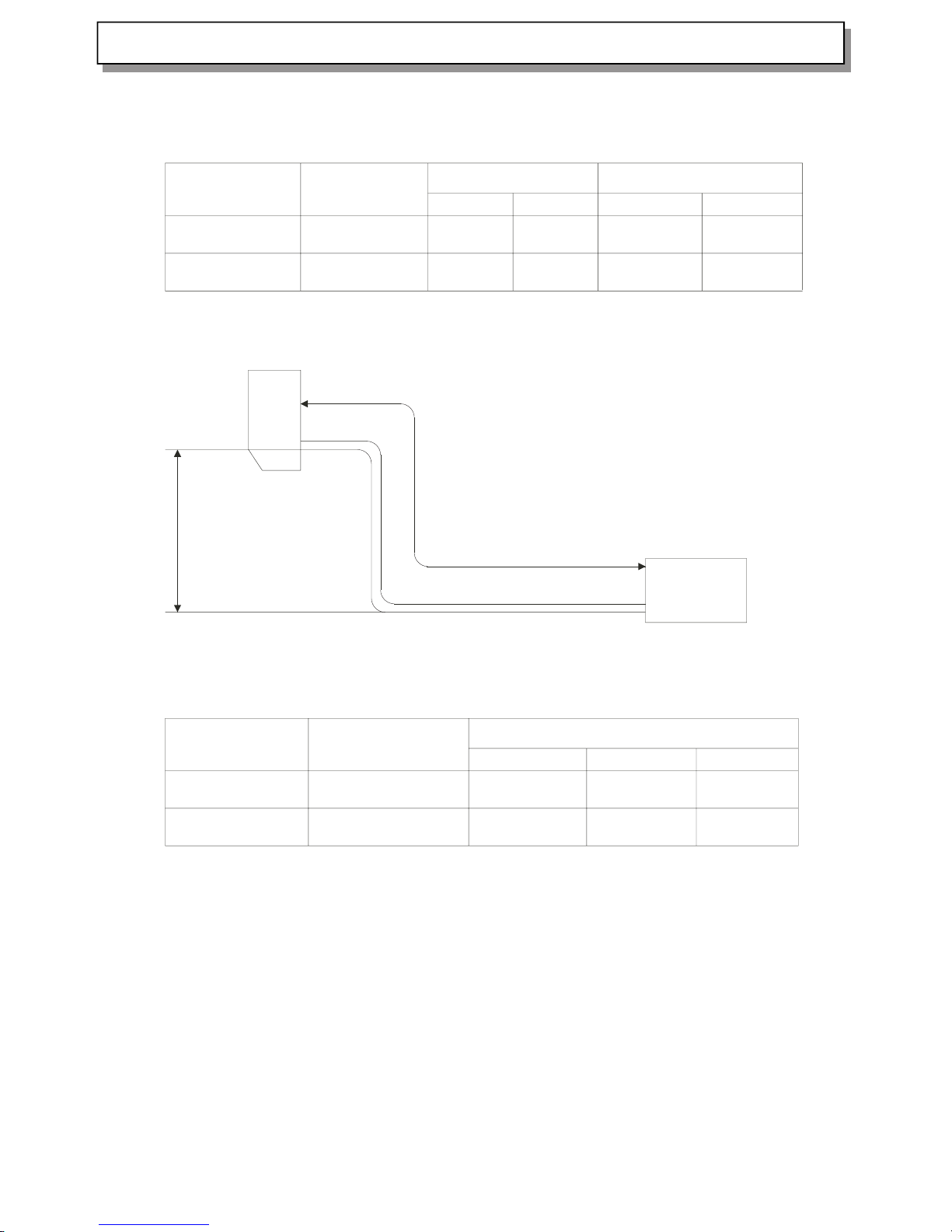

Limitations to refrigerant piping length and height difference

Maximum allowed refrigerant piping length (single line) and height difference

Models

HKEB-HCNB 261X

HKEB-HCNB 351X

Max. piping length

(m), single line: A

Piping diameter (mm)

Liquid side Gas side

9.52

6.35

9.52

6.35

Height Difference (m)

Indoor Unit above

Indoor unit below

15

15

7

7

7

7

Max. allowed

height difference:

7 metres

Max. refrigerant piping length (A): 15 metres

Indoor

Unit

Outdoor

Unit

Additional refrigerant charge (R410A refrigerant)

Models

HKEB-HCNB 261X

HKEB-HCNB 351X

Precharged amount

(g) up to 7 metres

1150

1150

Additional R410A charge according to piping length

7m

0g

0g

10m

75g

75g

15m

200g

200g

Calculation of the additional refrigerant charge: R410A g = [(A-7) meters x 25g/m]

Temperature range for regular operation:

Outdoor air temperature: • In Cooling mode: +16°C ~ +43°C

• In Heating mode: -15°C ~ +30°C

If this appliance is operated under temperature conditions out of the above specified temperature range, this may result

in malfunction and/or operation could stop due to intervention of built-in protective functions.

5.REFRIGERANT SYSTEM DIAGRAM

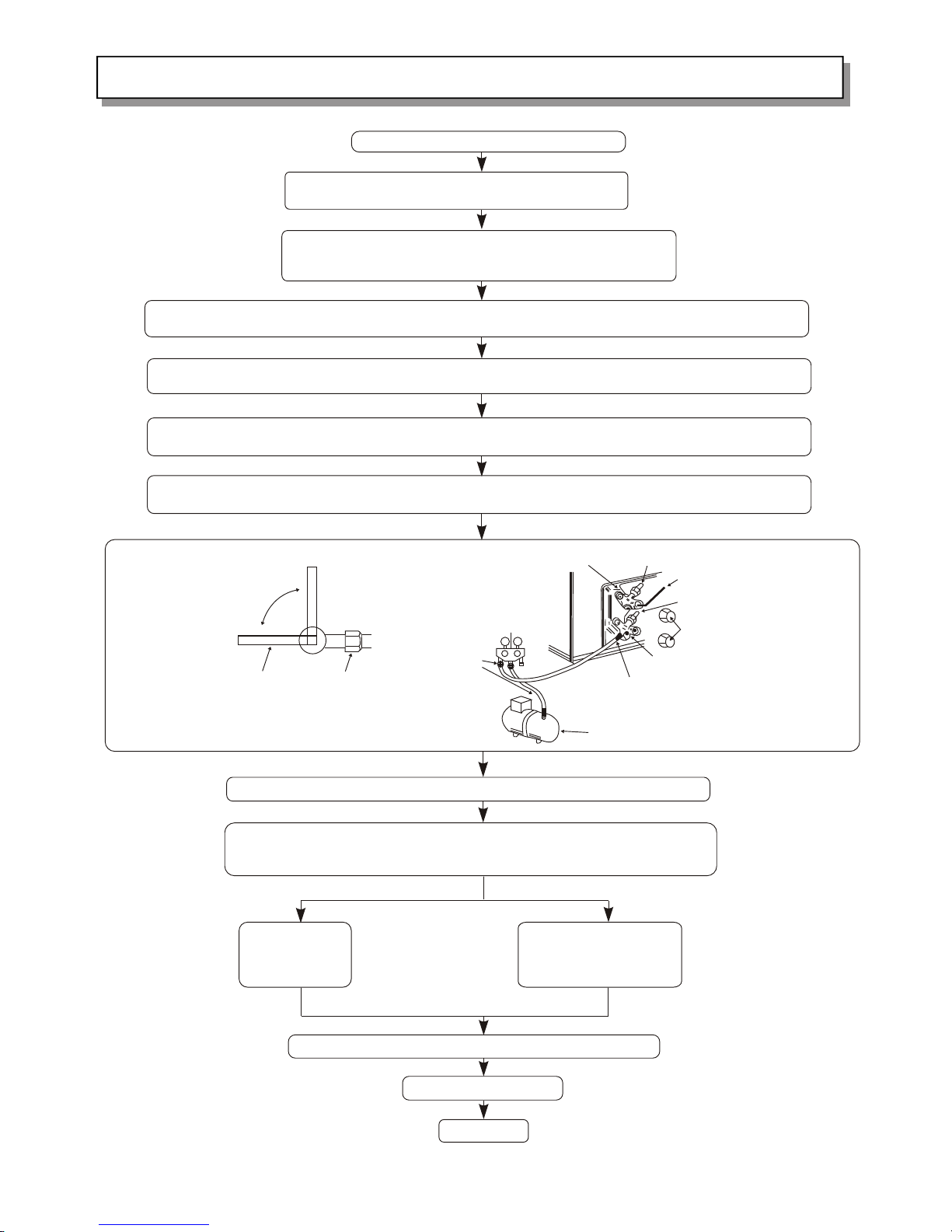

EVACUATION PROCEDURES

Connect the refrigerant pipes (both the liquid and gas

pipes) between the indoor and the outdoor units.

Remove the service port cap of the stop valve on the sid e o f the

outdoor unit gas pipe. (The sto p valv e w ill no t wor k in i ts initial

state fresh out of the factory (totally closed with cap on).

Connect the gage manifold valve and the vacuum pump to the service port o f the stop valve on the ga s pipe

side of the outdoor unit.

Run the vacuum pump for more than 15 minutes and at this time confirm that the pressure gage indicates

-0.1 Mpa (-76 cmHg).

Check the vacuum with the gage manifold valve, then close the gage manifold valve, and stop the

vacuum pump.

Leave it as is for one or two minutes .Make sure the pointer of the gage manifold valve remains in the.

same position.

Close

Open

Hexagonal

wrench

Stop valve

pipe

Connection

Gage manifold valve

Stop valve

Liquid pipe

Stop valve

Hexagonal

wrench

Gas pipe

Caps

Service port

Vacuum pump

Remove the gage manifold valve qu ickly from the ser vice port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves

on gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

£º

Pipe length

7m maximum

No gas charge is

needed.

Pipe length

exceeding 7m

Charge the prescribed

amount of gas.

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

5.REFRIGERANT SYSTEM DIAGRAM

Loading...

Loading...