SERVICESERVICE

MANUALMANUAL

SPLIT TYPE AIR CONDITIONERSPLIT TYPE AIR CONDITIONER

CONTENTS

1.PART NAMES AND FUNCTIONS...................

2.SPECIFICATION............................................

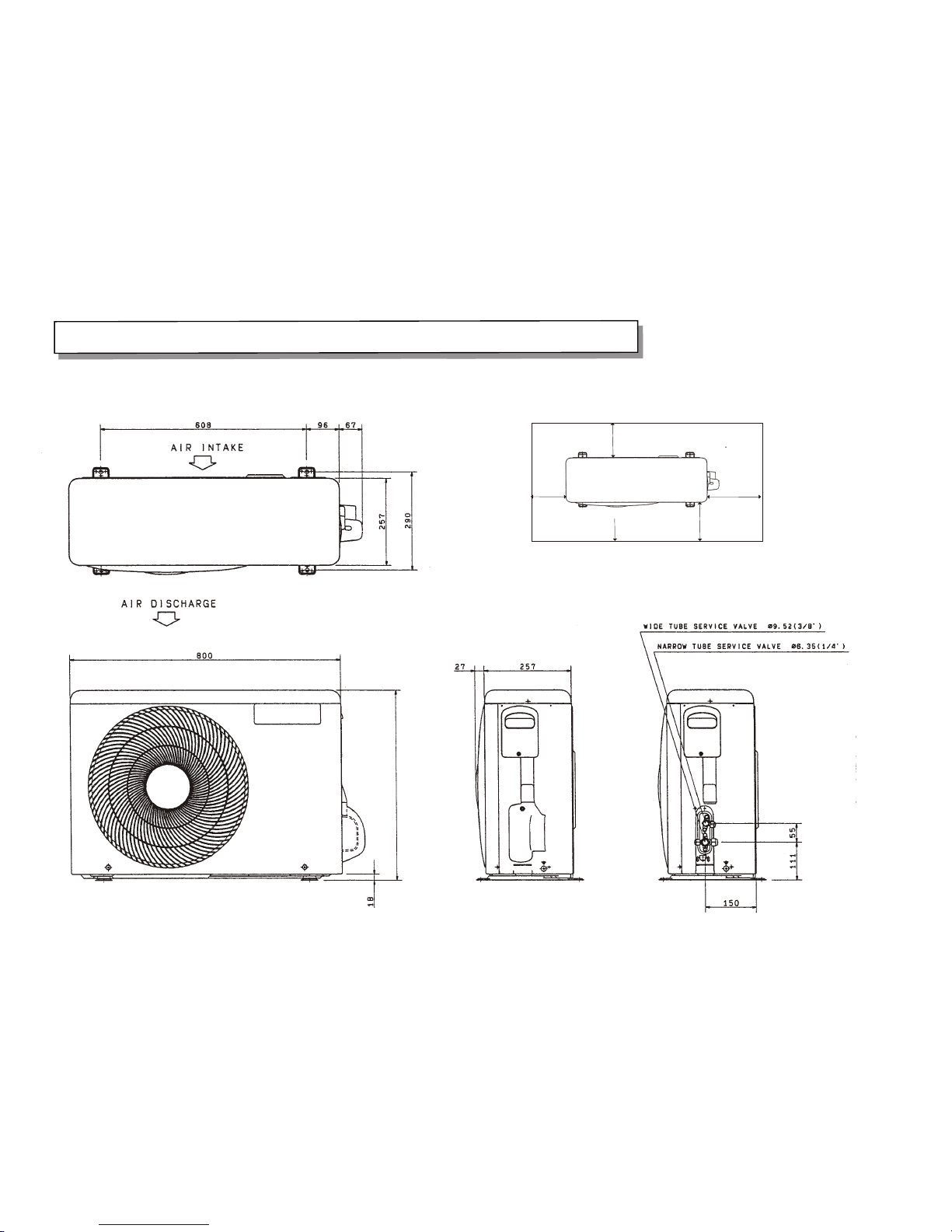

3.OUTLINES AND DIMENSIONS.......................

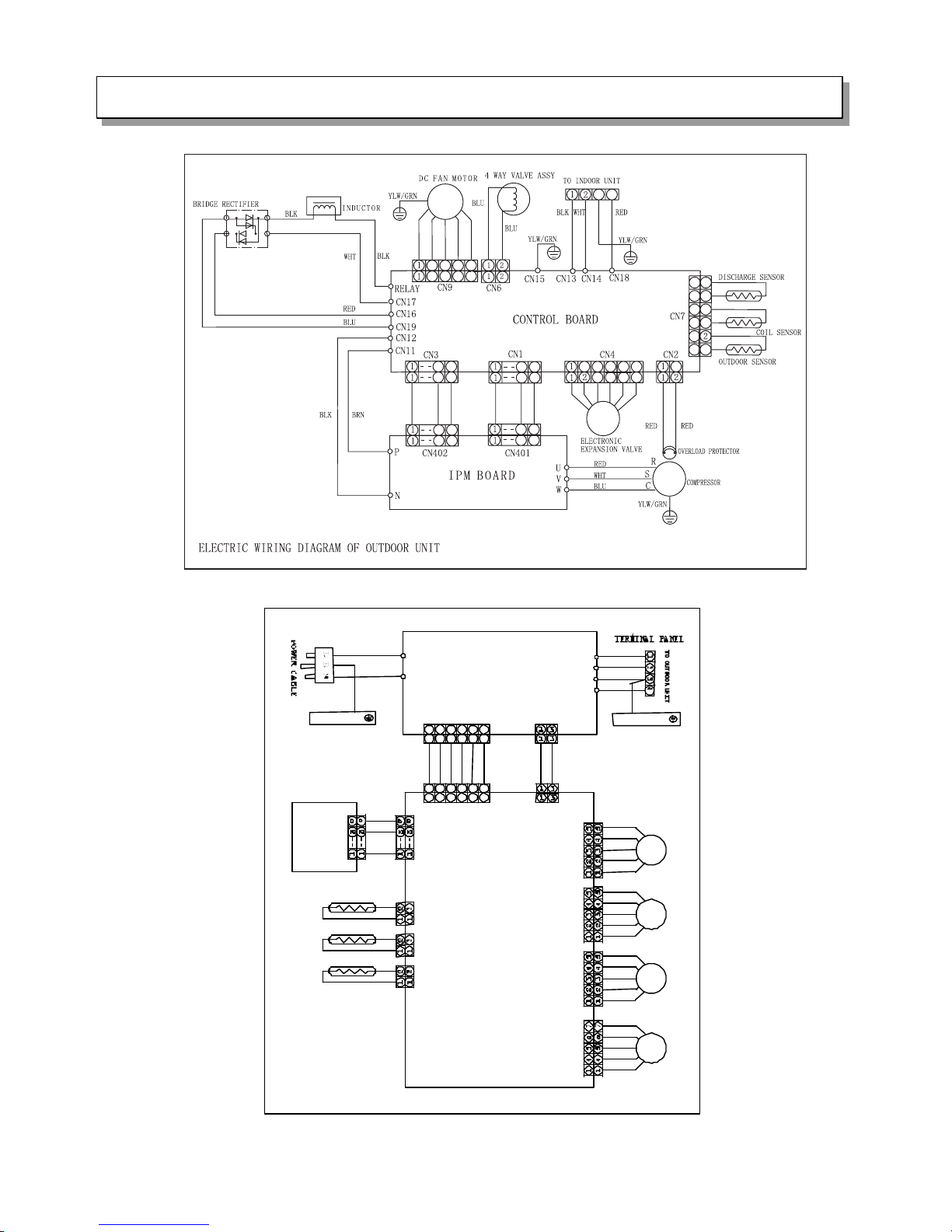

4.WIRING DIAGRAM.........................................

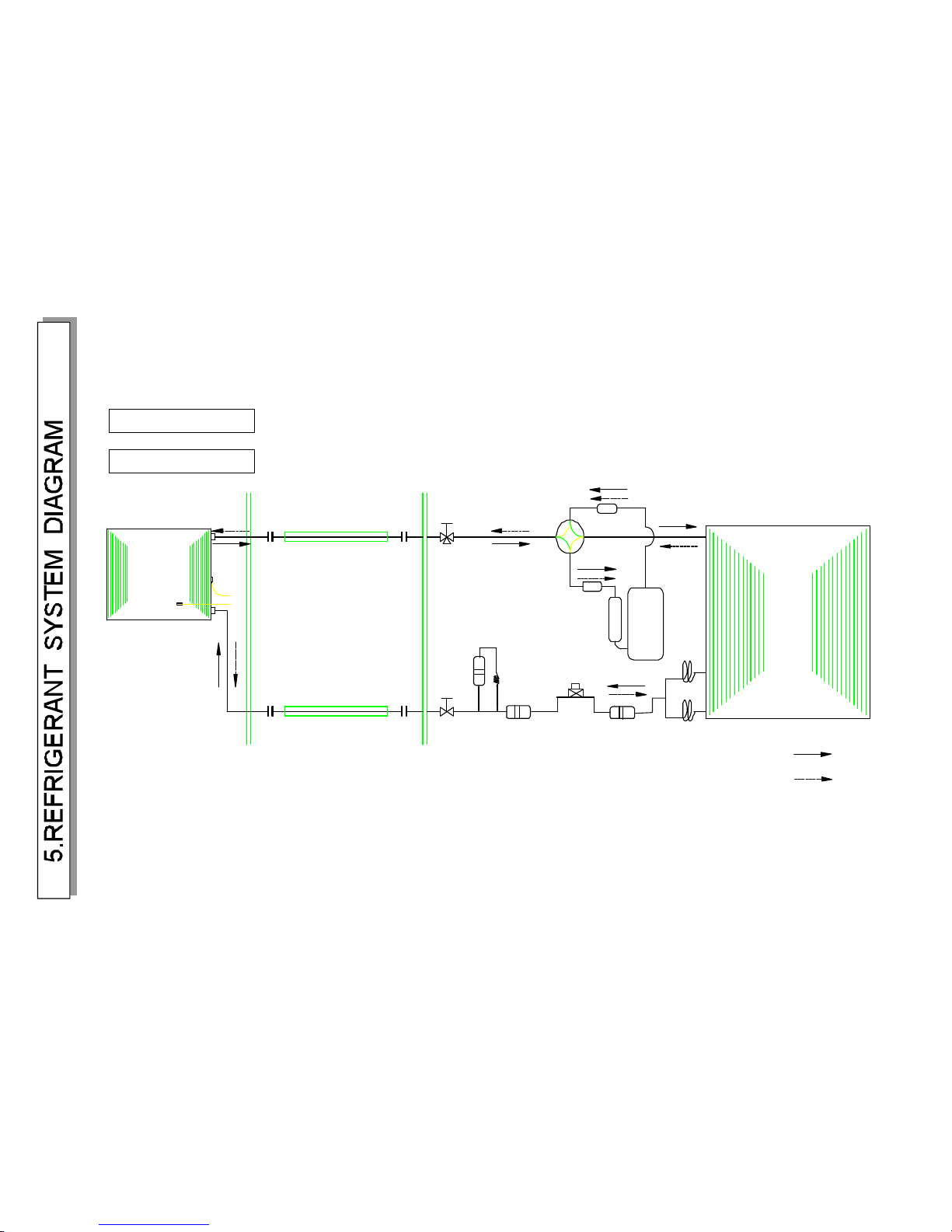

5.REFRIGERANT SYSTEM DIAGRAM...............

6.CONTROL MODE ................................

7.SERVICE FLOW CHART......................................

8.ELECTRIC .CONTROL.............................

9.SENSOR PARAMETER................................

10.DISASSEMBLY INSTRUCTIONS...................

11.PARTS LIST.................................................

HKEB-HCNB-261-X

HKEB-HCNB-351-X

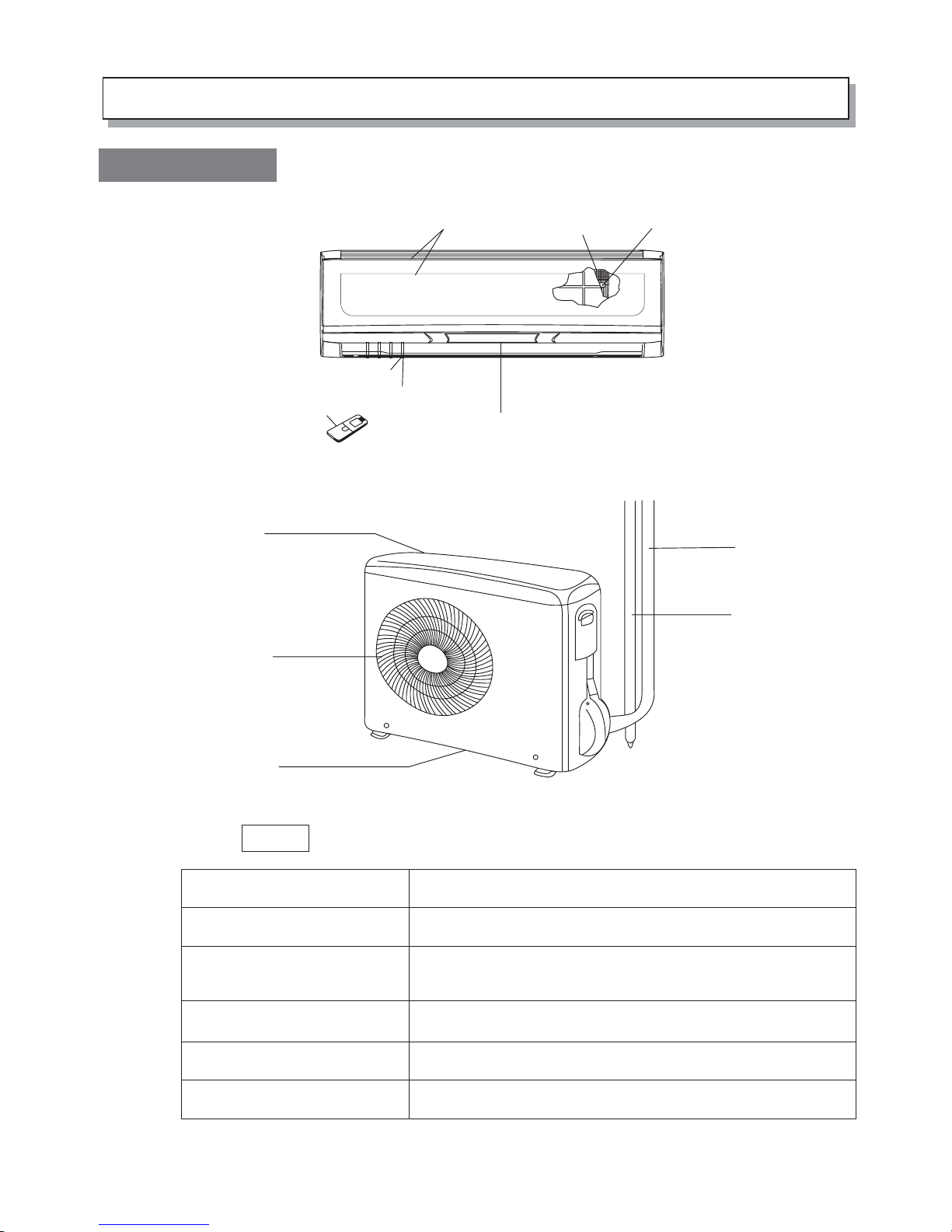

1. PART NAMES AND FUNCTIONS

1.Diagram of Structure

This air conditioner consists of an indoor unit and an outdoor unit. You can

control the air conditioner with the remote controller.

NOTE

Air Intake

Air Outlet

Remote Controller

Refrigerant Tubes

Outdoor(Condensing)Unit

Drain Hose

Air from the room is drawn into this section and passes

through air filters which remove dust.

Conditioned air is blown out of the air conditioner through

the air outlet.

The wireless remote controller controls power ON/OFF,

operation mode selection, temperature, fan speed, timer

setting, and air sweeping.

The indoor and outdoor units are connected by copper

tubes through which refrigerant gas flows.

The outdoor unit contains the compressor, fan motor, heat

exchanger coil, and other electrical components.

Moisture in the room condenses and drains off through this hose

Air filter

Air outlet

Impeller

Blue backlight LCD screen

Indoor sensor

Remote controller

Tubes and cable

Drain hose

Air inlet (rear and side)

Air outlet

Water drainage

Indoor unit

Outdoor unitt

Air intake

Appearance of the indoor may differ from some the picutres in the manual.

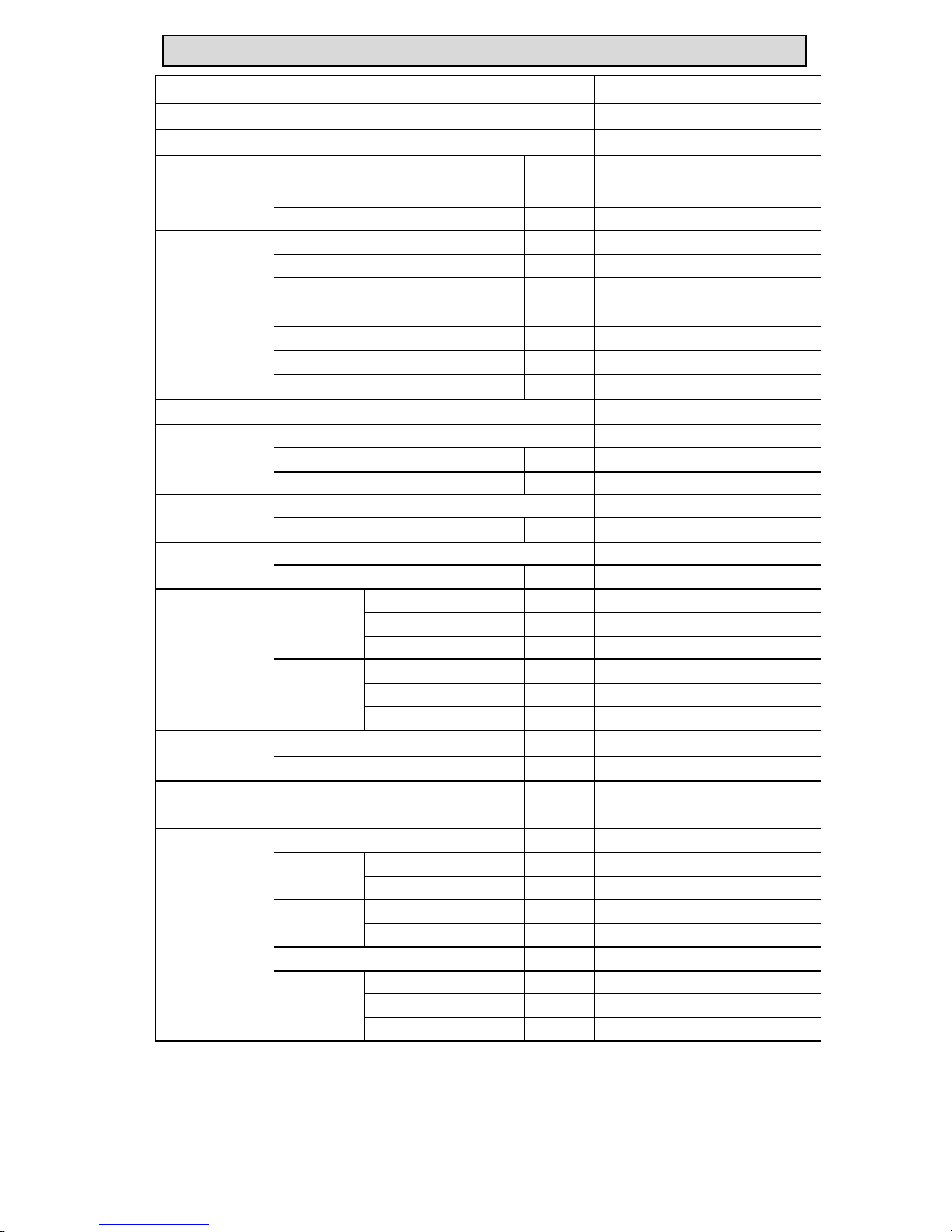

22、、SSPPEECCIIFFIICCAATTIIOONN

NOTE :Test conditions:Cooling : Indoor: DB27℃/ WB19℃ Heating: Indoor: DB20℃/ WB15℃

Outdoor DB35℃/ WB24℃ Outdoor DB7℃/ WB 6℃

Model HKEB -HCNB -261X

Function Cooling Heating

Power supply 220-230V~ 50Hz

Capacity k W 2.5 (0,39-3,2) 3.1 (0,40-3,53)

Dehumidification l /h 1.5

Capacity

Air flow m3/h 800 800

Power outlet A 16

Running current A 3.54/5.89 4.8/8.08

Power input k W 0.53 (0,3-1,05) 0.66 (0,3-1,25)

Auxiliary heater A(KW) --

Starting current A -Power factor % 90%

Electrical data

Compressor motor current A --

Coefficient of performance(C.O.P) 4.7/4.7

Model DA91A1F-22FD

Output W 750

Compressor

Winding resistance (at20℃)

Ω

1.10

Model SIC-37CV-F835-1 Indoor

fan motor Winding resistance (at20℃)

Ω -

Model DR-8938-504A-G Outdoor

fan motor Winding resistance (at20℃)

Ω -

Width mm 870

Height mm 225

Indoor unit

Depth mm 305

Width mm 800

Height mm 565

Dimensions

Outdoor unit

Depth mm 260

Indoor unit kg 11 Weight

Outdoor unit kg 34.5

Liquid pipe mm 6.35 Refrigerant

piping Gas pipe mm 9.52

Air direction 6

Indoor unit dB 46Sound leve l

(Hi)

Outdoor unit dB 53

Indoor unit rpm 1200 Fan speed

(Hi)

Outdoor unit rpm 760

Refrigerant filling capacity(R410A) kg 1.15

RT1(at25℃) k Ω 5

RT2(at25℃) k Ω 5

Special remarks

Sensor

RT 3(at0℃) k Ω 16.44

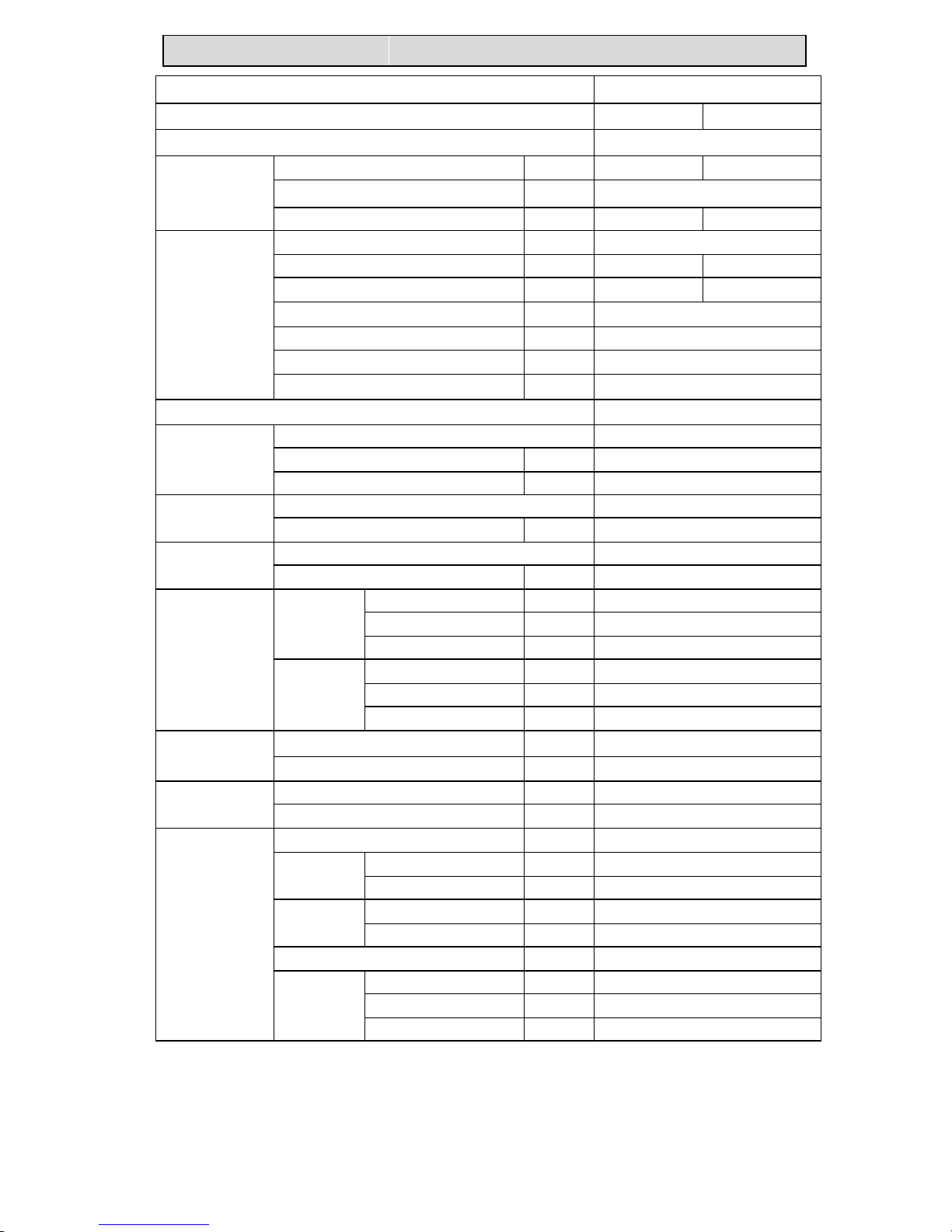

22、、SSPPEECCIIFFIICCAATTIIOONN

NOTE :Test conditions:Cooling : Indoor: DB27℃/ WB19℃ Heating: Indoor: DB20℃/ WB15℃

Outdoor DB35℃/ WB24℃ Outdoor DB7℃/ WB 6℃

Model HKEB - HCNB - 351 X

Function Cooling Heating

Power supply 220-230V~ 50Hz

Capacity k W 3.5 (0,39-3,98) 4.0 (0,4-4,49)

Dehumidification l /h 1.5

Capacity

Air flow m3/h 800 800

Power outlet A 16

Running current A 4.75/7.0 5.62/9.5

Power input k W 0.98 (0,3-1,3) 0.94 (0,3-1,6)

Auxiliary heater A(KW) --

Starting current A -Power factor % 90

Electrical data

Compressor motor current A --

Coefficient of performance(C.O.P) 3.57/4.26

Model DA91A1F-22FD

Output W 750

Compressor

Winding resistance (at20℃)

Ω

1.10

Model SIC-37CV-F835-1 Indoor

fan motor Winding resistance (at20℃)

Ω -

Model DR-8938-504A-G Outdoor

fan motor Winding resistance (at20℃)

Ω -

Width mm 870

Height mm 225

Indoor unit

Depth mm 305

Width mm 800

Height mm 565

Dimensions

Outdoor unit

Depth mm 260

Indoor unit kg 11 Weight

Outdoor unit kg 34.5

Liquid pipe mm 6.35 Refrigerant

piping Gas pipe mm 9.52

Air direction 6

Indoor unit dB 46 Sound leve l

(Hi)

Outdoor unit dB 53

Indoor unit rpm Fan speed

(Hi)

Outdo or unit rpm

Refrigerant filling capacity(R410A) kg 1.15

RT1(at25℃) k Ω 5

RT2(at25℃) k Ω 5

Special remarks

Sensor

RT 3(at0℃) k Ω 16.44

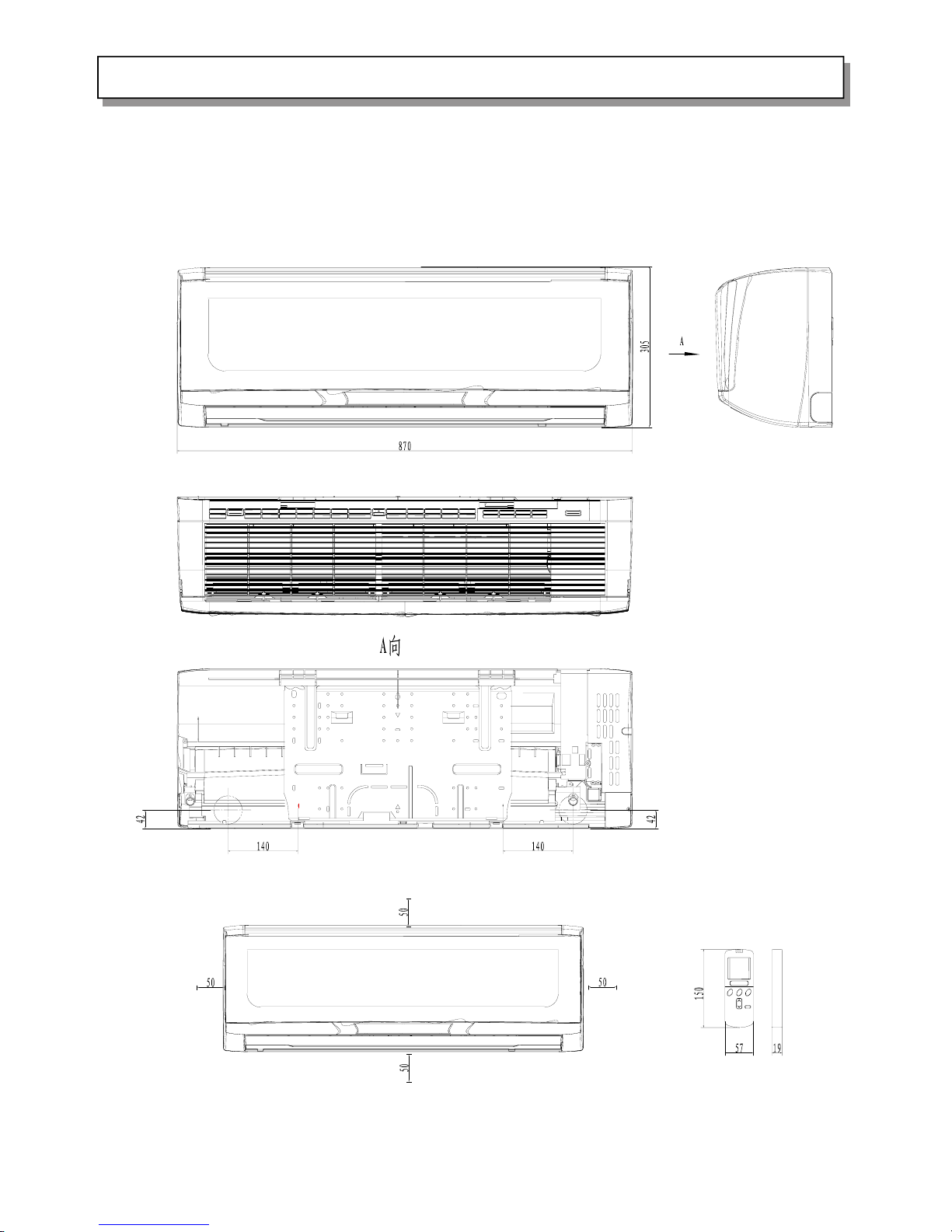

5.REFRIGERANT SYSTEM DIAGRAM3.OUTLINES AND DIMENSIONS

HKEB - HCNB 261-351 X

>25cm

>5cm

>10cm

Outlet

>40cm

5.REFRIGERANT SYSTEM DIAGRAM

3.OUTLINES AND DIMENSIONS

567.5

4.WIRINGDIAGRAM

ROOMSENSOR

COILSENSOR

CN101

FILTERBOARD

AIR OUTLETSENSOR

DISPLAY BOARD

CONTROLBOARD

21124334655

6

CN102

CN401

CN103

CN104

CN105

EVAPORATOR

CN701

CN106

21124334655

6

CN201

CN603

CN602

CN606

CN605

CN604

CN609

CN608

CN607

CN701

BRN

YLW/GRN

RED

YLW/GRN

WHT

BLK

YLW/GRN

BLU

EVAPORATOR

HORIZONTAL

FLAPMOTOR1

HORIZONTAL

FlAP MOTOR2

VERTICAL

FLAP MOTOR

DC FAN MOTOR

ELECTRIC WIRING DIAGRAM OF INDOOR UNIT

2

1

0

1

0

1

1

1

1

1

0

1

0

1

1

1

1

7

7

8

8

7

7

8

7

7

8

8

4

3

3

4

6

5

5

6

1

1

2

3

3

44

5

5

6

6

43

2 4

3

3

4

6

5

5

6

HKEB HCNB 261 X

(.52)φ9

(6.35)φ

Compressor

Rerigerant pipe

(With heat insulator)

Service valve

Indoortemperature

Heatexchanger

sensor

Flare connection

Refrigerant pipe

(With heat insulator)

Flare connection

Service valve

INDOORUNIT

Heatex changer

OUTDOORUNIT

Muffler

Desiccationfilter

4-way valve

Heating cycle

Cooling cycle

sensor

Indoorcoil

Muffler

Strainer

φ×51.500

Capillary tube

φ×51.500

Strainer

Electric expansion valve

HKEB HCNB 351 X

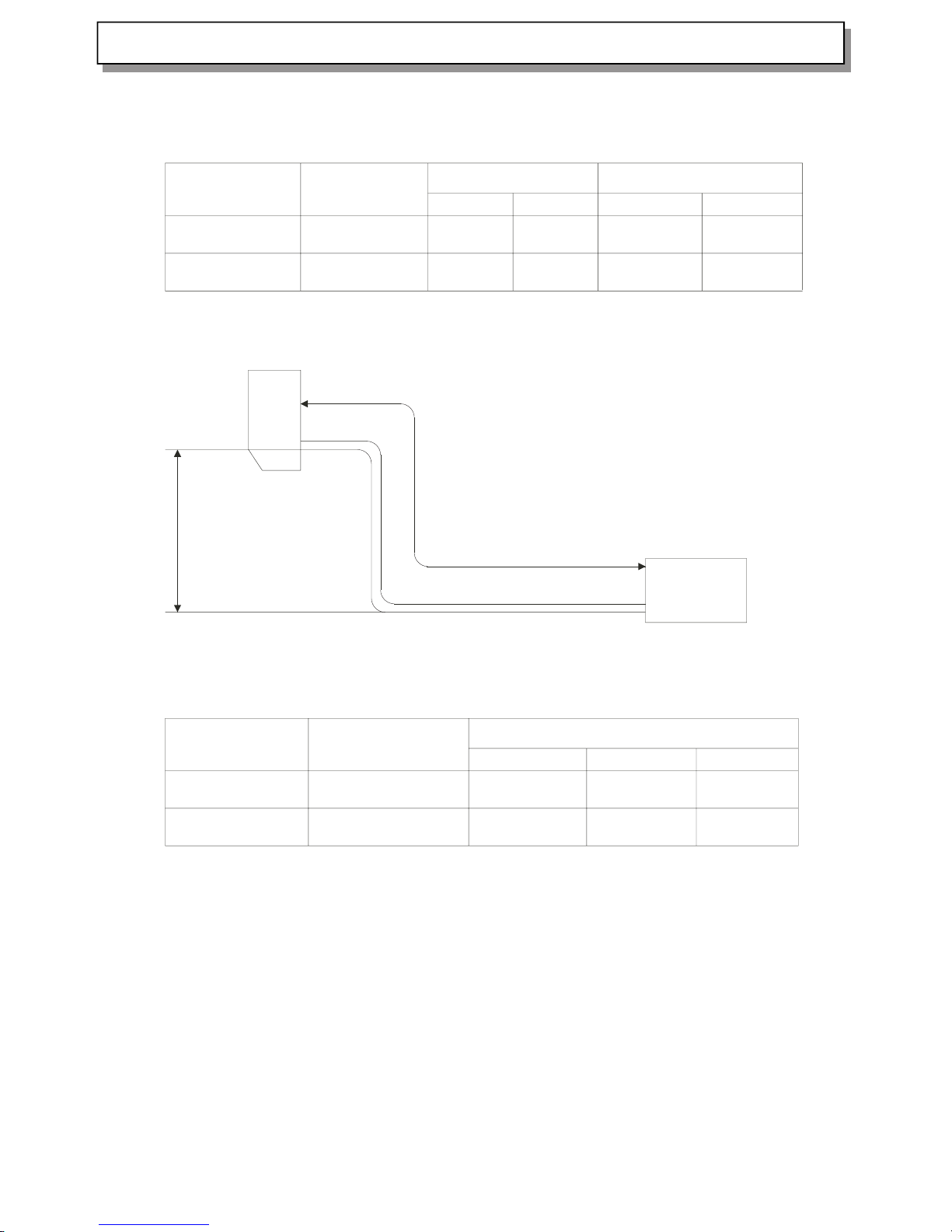

Limitations to refrigerant piping length and height difference

Maximum allowed refrigerant piping length (single line) and height difference

Models

HKEB-HCNB 261X

HKEB-HCNB 351X

Max. piping length

(m), single line: A

Piping diameter (mm)

Liquid side Gas side

9.52

6.35

9.52

6.35

Height Difference (m)

Indoor Unit above

Indoor unit below

15

15

7

7

7

7

Max. allowed

height difference:

7 metres

Max. refrigerant piping length (A): 15 metres

Indoor

Unit

Outdoor

Unit

Additional refrigerant charge (R410A refrigerant)

Models

HKEB-HCNB 261X

HKEB-HCNB 351X

Precharged amount

(g) up to 7 metres

1150

1150

Additional R410A charge according to piping length

7m

0g

0g

10m

75g

75g

15m

200g

200g

Calculation of the additional refrigerant charge: R410A g = [(A-7) meters x 25g/m]

Temperature range for regular operation:

Outdoor air temperature: • In Cooling mode: +16°C ~ +43°C

• In Heating mode: -15°C ~ +30°C

If this appliance is operated under temperature conditions out of the above specified temperature range, this may result

in malfunction and/or operation could stop due to intervention of built-in protective functions.

5.REFRIGERANT SYSTEM DIAGRAM

EVACUATION PROCEDURES

Connect the refrigerant pipes (both the liquid and gas

pipes) between the indoor and the outdoor units.

Remove the service port cap of the stop valve on the sid e o f the

outdoor unit gas pipe. (The sto p valv e w ill no t wor k in i ts initial

state fresh out of the factory (totally closed with cap on).

Connect the gage manifold valve and the vacuum pump to the service port o f the stop valve on the ga s pipe

side of the outdoor unit.

Run the vacuum pump for more than 15 minutes and at this time confirm that the pressure gage indicates

-0.1 Mpa (-76 cmHg).

Check the vacuum with the gage manifold valve, then close the gage manifold valve, and stop the

vacuum pump.

Leave it as is for one or two minutes .Make sure the pointer of the gage manifold valve remains in the.

same position.

Close

Open

Hexagonal

wrench

Stop valve

pipe

Connection

Gage manifold valve

Stop valve

Liquid pipe

Stop valve

Hexagonal

wrench

Gas pipe

Caps

Service port

Vacuum pump

Remove the gage manifold valve qu ickly from the ser vice port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves

on gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

£º

Pipe length

7m maximum

No gas charge is

needed.

Pipe length

exceeding 7m

Charge the prescribed

amount of gas.

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

5.REFRIGERANT SYSTEM DIAGRAM

6.CONTROL MODE

1.Functional features

1.1 The compressor’ s motor system is fitted with DC brushless sensor without position, with

reliable and efficient performance;

1.2 The indoor and outdoor air supply motor is of built-in DC brushless type.

1.3 Throttle control by electronic expansion valve.

2 Main controlling functions

2.1 Controlling functions of the remote controller (see operation and installation manual)

2.2 Display icons of the indoor unit

Indicating lights

“ Simultaneous Operation Power Limitation” indicator: When the “ simultaneous

operation power limitation” function is started, this light goes on.

“ Timing” indicator: It goes on when “ timing” is selected.

“ Sleep” indicator: It goes on when “ sleep” is selected.

“ Night” indicator: No available for this unit.

Room temperature display

Fre

1-30(Hz)S1

31-50(Hz)S1S2

51-70(Hz)S1S2S3

71-90(Hz)S1S2S3S4

91(Hz) S1S2S3S4S5。

Room temperature is displayed in the “House”: The actually measured temperature of the unit

body or the remote controller is displayed.

Outdoor temperature display:

The outdoor temperature is displayed when detected by the outdoor unit. Otherwise, there is no

display.

Working mode display

During operation, such information as cooling, heating, dehumidifying is displayed. When the air

conditioner works in the Automatic Mode, the Auto icon, as well as the cooling/heating

information is displayed.

Fan speed display

The three blades of high, medium and low speeds are shown at the same time. “A” is displayed

when Auto Speed is selected.

Left and right swinging display

S1 S2 S3 S4 S5

6.CONTROL MODE

Surrounding air: K0, K1, K2, K4, K5

Directional air: Left K0, K1, K2, K3

Directional air: Right K0, K3, K4, K5

Directional air: Center K0, K2, K3, K4

Swinging air: K0K1, K0K2, K0K3 respectively according to the actual working status

Error message

Press the Emergency button for over 5 seconds when the power is on, the air conditioner will give

out alarm as follows: indoor unit trouble at the indoor temperature reading area and outdoor unit

trouble at the outdoor temperature area; the message is blinking at a frequency of 1Hz.

3.Temporary switch

3.1 If the remote controller is missing, press the temporary switch and the system starts in the

automatic mode, press the switch again to stop the system. Automatic mode follows:

A indoor temperature> 26℃ cooling mode temperature setting 26℃

B indoor temperature> 23℃ heating mode temperature setting 26℃

C 23℃≤indoor temperature≥26℃ fan mode

Indoor fan speed is automatic in automatic mode.

3.2 Hold down the temporary switch for 5 seconds or longer and the system is forced to run in the

cooling mode regardless of indoor temperature.

3.3. How to start the outdoor unit without the indoor unit

Short-circuit the two CN404 terminals on the IPM board of the outdoor unit, and switch on

the power, the air conditioner will start heating operation, and the outdoor fan is working; then

open the short circuit, the air conditioner will start cooling operation (the compressor starts 50

seconds later), and the fan is still working. Cut off the power, the outdoor unit will stop running.

4.Control mode

4.1 Automatic

4.1.1 When the air conditioner is switched on and the remote controller is set to Auto mode, the

air conditioner will select running modes automatically according to the difference

between the room temperature and the setting temperature.

4.1.2 The running mode will be set when the machine is first switched on. Once set, the

running mode cannot be changed within 30 minutes.

4.1.3 If the difference between the room temperature and the setting temperature exceeds 3

degrees, change the running mode immediately.

4.1.4 If the machine is turned off and restarted using the remote controller, the above conditions

are still good.

4.1.5 If the machine is powered off and restarted, the running mode must be re-selected.

4.1.6 The running frequency will be determined by the temperature difference.

4.2 Cooling

4.2.1 In the cooling mode, the preset temperature is determined by the remote controller. The

temperature range is 16℃—30℃.

6.CONTROL MODE

4.2.2 The compressor will start immediately when the machine is first powered on; it will take at

least 3min for the compressor to restart if the machine is restarted.

4.2.3 The fan speed changes in auto mode.

T

setting

- T

indoor

Fan speed T

setting

- T

indoor

Fan speed

1℃

Low

1℃

Low

2℃

Low

2℃

Mid

3℃

Mid

3℃

Mid

4℃

Mid

4℃

High

Temperature

difference

≥5℃

High

Temperature

difference

≥5℃

High

4.2.4 Compressor control

The running frequency of the compressor depends on the difference between the set

temperature and the detected room temperature. The larger the difference, the higher the frequency.

When the room temperature is lower than the set temperature, the compressor stops running

(provided the compressor keeps running for more than 5 minutes).

Min Max Rated Frequency.

15 100 42

4.3 Outdoor fan

One-speed, which runs simultaneously with the compressor.

4.4 Cooling overload

When T

external coil

≥70℃, the compressor stops. When T

external coil

≤50℃, the air conditioner

starts automatically in 3 minutes.

4.5 Anti-freezing function, the anti-freezing and frequency limiting functions of the evaporator

are effective:

When T

coil

> 10℃, the working frequency of the compressor is not limited;

When T

coil

< 7℃, the working frequency of the compressor begins dropping;

When T

internal coil

< -1℃ for 3 minutes, the indoor fan works normally after the compressor is

shut down.

When T

internal coil

≥7℃ and the compressor has stopped working for 3 minutes, the compressor

will restart running.

4.6 Current protection

is the normal working current value of E2ROM,I

max

is the ceiling current value of

E2ROM.

6.CONTROL MODE

I < IO -1.5A Without limitation.

I>I

O

+1.5A Frequency drops.

I≥I

max

Operation stops.

5. Dehumidification

5.1 In the dehumidification mode, the temperature is determined by the remote controller. The

temperature range is 16℃—30℃. The controller will determine the running mode according

to the indoor and outdoor temperature difference.

5.2 When the room temperature is 2℃ higher than the preset temperature, cooling run will be

5.3 T

set temperature

– T

room temperature

≥1℃ The compressor and the outdoor fan stop working,

and the indoor fan runs at a speed of 600 rpm.

6.Heating

6.1 When T

internal coil

≥ 38℃, the indoor fan works in accordance with the setting of

the remote controller.

T

setting

- T

indoor

Fan speed T

setting

- T

indoor

Fan speed

1℃

Low

1℃

Low

2℃

Mid

2℃

Low

3℃

Mid

3℃

Mid

4℃

Mid

4℃

Mid

5℃

High

5℃

Mid

Temperature

difference

≥6℃

High

Temperature

difference

≥6℃

High

6.2 Current protection

IO is the normal working current value of E2ROM,I

max

is the ceiling current value

of E2ROM.

I < IO -1.5A Without limitation.

I>I

O

+1.5A Frequency drops.

I≥I

max

Operation stops.

6.3 Defrosting

6.3.1 The defrosting is done through changing the flow direction of refrigerant inside of the

four-way valve.

6.3.2 Defrosting conditions:

Continuous heating run for more than 30min

During single machine operation, T

outdoor

– T

outdoor coil

≥ 12℃ and lasts 8minutes

6.3.3 Defrosting process:

Compressor and outdoor fan motor off → four-way valve off → compressor on →

defrosting conditions met → compressor off → four-way valve on → compressor on →

outdoor fan on → end

6.3.4 Overhot protection for the indoor heat exchanger

6.CONTROL MODE

When the temperature of the indoor coil≥78℃, the compressor will stop;

When the temperature≥63℃, the outdoor flow speed will turn to the low speed, and the

compressor runs at the descending frequency;

When the temperature<58℃, the compressor will prohibit the frequency from rising.

7 . Air cleaning

The outdoor unit doesn’ t work in this mode, and the indoor fan runs in cooling mode.

8.Protection

8.1 Abnormal sensor: when the sensor is short circuited or cut off, the compressor will stop, and

the trouble code will be displayed.

8.2. IPM error

In the case of IPM abnormalities, e.g. overheat (100℃), overcurrent (17A), or low driving

voltage (below 12V), both the compressor and the outdoor fan stop running, and the

corresponding error code is displayed.

8.3 Temperature protection for the compressor exhaust

When the compressor exhaust temperature <93℃, the compressor runs at the ascending

frequency;

When the temperature ≥93℃, and <115 ℃the compressor runs at the limit to the frequency

ascending;

When the temperature >115 ℃, the compressor stops.

8.4 Abnormal power supply voltage protection

When the supply voltage is above 260V or below 150V, the compressor stops, and the trouble

code is displayed.

8.5 No load protection

Measure the total current. When the current in the outdoor unit is lower than 0.15A, the

compressor will stop operation and no load protection error is displayed.

8.6 . Economical running

During economical run (this function is set on the remote controller), the working current will be

limited (to 60% of the max working current).

9 Automatic control of the electronic expansion valve

9.1 Power-on reset

Upon power-on reset, the expansion valve shuts off for 600 seconds first, and then opens to

a degree fit for the frequency.

9.2 The expansion valve regulates according to the outlet air temperature of the compressor.

Compressor rotor position signal not available

There is an LED indicator on the IPM board of the outdoor unit. During operation of the

compressor, the LED blinks to indicate frequency restriction conditions of the compressor.

6.CONTROL MODE

Content of trouble Indoor display code

Indoor sensor trouble

1

Evaporator sensor trouble

2

Evaporator freezing

3

Over hot of indoor heat exchanger

4

Communication trouble

5

Over current of compressor 7

Fan motor trouble

8

Indoor EEPROM 13

Outdoor sensor trouble 21

OUTDOOR

Outdoor sensor trouble 1

Outdoor coil sensor trouble 2

Discharge sensor 3

Compressor position 4

Communication trouble 5

Over current of whole system 6

No load 7

Abnormal power voltage 8

Compressor start-up failure 9

Higher outdoor exchange tempreture 10

Defrosting 11

IPM trouble 12

Data failure of outdoor E2PROM 13

Outdoor Fan 15

1. Normal operation, no frequency restriction.

2. Power voltage restriction.

3. Condenser temperature restriction.

4. Total current restriction.

5. Outlet air temperature restriction.

6. Indoor heat exchange temperature restriction for cooling operation.

7. Indoor fan speed restriction.

8 AD interface frequency conversion restriction.

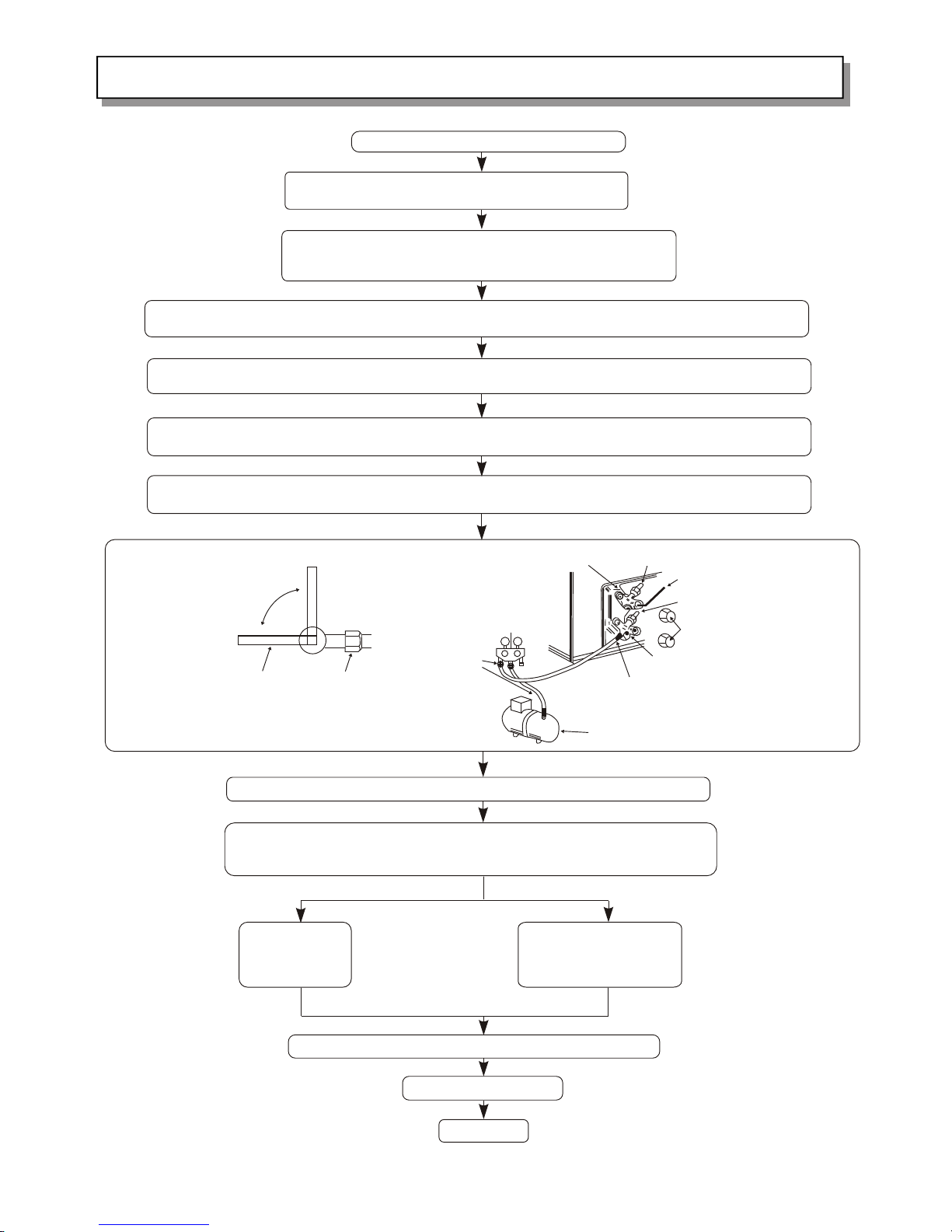

Switch on the power

supply

Yes

Check the

result

Display board

prolem

Yes

No

Indoor control

board Is faulty

replace it

Check all wires

are connected

correctly

Start up self-test

function

Replace the battery

press RESET

botton ,retry remote

operation and

replace remote

Yes

Display board

problem

No

Yes

Check operation

Is the fuse

blown?

Yes

Check and find short

circuit or open circuit

among other components such

as fan motor?

Indoor control board

faulty

Error code 1

Indoor temperature

sensor trouble

Error code 2

Indoor coil

sensor trouble

Does LCD screen

display Normally?

Are the

wires

poorly

connected?

Does it receive

the remote

control signal?

Is the remote

controller in

good condition ?

After replacing

the display

board,Is there

still trouble?

Replace the

indoor board,Is

there still

trouble?

Is indoor

control board

short

circuit?

After replacing

the display

board,Is there

still trouble?

No

Yes

Yes

Yes

Yes

No

No

No

Measure

resistance

between

CN607 ①

and②

Measure

resistance

between

CN608 ①

and②

Does the

resistances of

thermistor have

the

characteristics on

page 31

Replace the

thermistor

Connect CN607 and

CN608、CN609.

Turn ON the power

supply and press

the EMERGENCY

OPERATION SWITCH

Replace the

indoor board

Ok *1

Does the

unit

operate 10

minutes or

more?

*1 Defective contact of the connector is considered

Yes

Yes

No

No

No

No

No

7.SERVICE FLOW CHART

Error code 7

Indoor air outlet

sensor trouble

Measure

resistance

between

CN609 ①

and②

Occur by chance

Error code 3

Indoor heat exchanger

is iced up

No

Indoor coil sensor

faulty,replace and

check operation

Yes

Switch to heat operation to defrost the heat

exchange coil,change back to cooling and

check operation

Check operation

Indoor control

board faulty ,

replace it

Normal

protection

No

Yes

Occur by chanceYes

Error code 4

indoor heat exchanger

is over loaded

Indoor coil sensor

faulty,replace and

check operation

Yes

Switch off the power,start up the

air conditoner in 10 minutes

Outdoor control

board

faulty,replace it

Yes

No

Indoor control

board faulty

replace it

No

Normal

protection

No

Yes

Switch off the power,replace the

outdoor control board and then

start up the air conditoner.

Swich off the power,replace the

outdoor control board and then

start up the air conditoner.

Is indoor heat

exchanger iced up?

Is compressor

still running?

Is indoor heat

exchanger

freezing up again?

Is the system

in good

condition?

Is compressor

still

running?

Is indoor heat

exchanger very

hot?

Is the system

in good

condition?

Is the system

in good

condition?

Error code 8

indoor fan motor trouble

No

Yes

Indoor control board

faulty and replace it

Set the air conditioner

operate in fan mode

Yes

No

No

Occor by chanceYes

Repair the indoor

fan motor

Does voltage repeat 0V DC

and 15V DC?

Is indoor fan

motor

running?

Insert screwdriver into to

rotate indoor fan motor

slowly for 1 revolution or

over,and measure voltage

NO.6(+) and NO.3(-) on CN701.

Does fan motor

stop with the

remote

controller

Does the socket CN701 of

indoor control board have

power input(DC 310V AND DC

15V)

Check if filters

are clean?

Ckeck if liquid

line strainer is

blocked?

If dirdy,wash

filters

No

Yes

Yes

If blocked,replace

the strainer

No

Check operation

7.SERVICE FLOW CHART

No

Yes

No

Error code 5

communication

problem

Connect the indoor

and outdoor unit

again according to

the wiring diagram

Yes

Yes

Replace the outdoor

control board and

start up again

Ourdoor control

board trouble

Yes

No

Indoor control

board fault,

replace it

No

No

There is a short circuit

behind the startup

resistor

The IPM.control

and wave filter

board Is faulty

or short

circuited

No

No

Yes Yes Replace it

No

No

No

Indoor FILTER board

faulty replace it

Yes

Connection wire

fault,tighten and

check

Yes

Connection wire

fault,tighten and

check

Connection wire

fault,tighten and

check

Yes

Connection wire

problem

Repair wiring as

required

Replace the

faulty unit

Yes

faulty electrical

connection

replace the

faulty

components

Yes

Outdoor control board

faulty replace it

Yes

Replace IPM board

and fuse

No

Check operation

Yes

No

Display board fault,

replace it

Yes

Normal protection and

replace fuse

No

Is the voltage

input of startup

resistor correct?

Is there power

output of indoor

unit main

relay(RL101)?

Is there 240V AC

between 1 and 2 on the

indoor terminal

block

Is there 240V AC

between 1 and 2 on

the outdoor terminal

block

Is the fuse in

control box

(20A) blown?

The startup

resistor Is

overhot?

Does the power

indicator (LED)of

outdoor control

board light up?

Are all the lead

wires connected

between indoor and

outdoor unit?

Is the system

in good

condition?

The control system of outdoor

unit has short circuit

trouble,check the connection

wire,wave filter board,outdoor

control board,IPM,rectifier and

electrolytic capacitor

Is outdoor

control board

short circuited?

Is IPM board short

circuited?

Check indoor and outdoor

interconnecting wiring for

short circuit

Is the system

in good

condition?

Is the

Fuse3(3.15A)

fuse of blown?

Is the

Fuse1(20A) fuse

of blown?

No

No

Yes

No

7.SERVICE FLOW CHART

Yes

Rectifier faulty

replace it

Yes

Replace the

faulty board

Does the

rectifier have

alternating

current input?

Is the reactor

and wave filter

board open

circuit?

No

Is the

resistor

TH101

correct?

Replace the

resistor

NO

NO

Error code outdoor 3

compressor over heat

protection

No

Outdoor control board

faulty , replace it

Replace it

No

Yes

Normal

protection

Yes

Yes

Replace

discharge

sensor

No

Error code outdoor 6

over current protection

No

Outdoor

control board

fault

Yes

Normal

protection

Yes Yes

No

Yes

Occur by chance

Error code 27

none load protection

No

replace outdoor

control board

IPM fault,

replace it

No

Yes

Yes

No

Yes

Compressor

faulty

Outdoor wave filter board

trouble and replace it

Check operation

No

Yes

Error code outdoor 8

voltage of power

supply Is abnormal

Outdoor control

board fault,

replace it

No

Normal protection

Error code outdoor

15

fan motor error

Switch off the power

supply and start up in

3 minutes

Is the over hot

switch of

compressor open

circuit?

I

s the resistance

of compressor

discharge sensor

correct?

Swich off and

start up

again,Is it ok?

Is the

operating

current beyond

Normal range?

Is the surface

of compressor

very hot?

Switch off and

start up

again,Is it

ok?

Replace the

outdoor IPM

control board,Is

it ok?

Replace the

outdoor control

board,Is it ok?

Is the voltage of power

supply Normal of AC

176-264V?

Is there DC 310

voltage input

between P-N on

IPM board

Is there voltage

output between IPM

board and U-V-W?

Is the compressor

running?

Replace compressor

Check operation

Yes

7.SERVICE FLOW CHART

No

Occor by chanceYes

Does fan

motor

run normal?

outdoor control board

faulty and replace it

Yes

No

Repair the outdoor

fan motor

Does voltage repeat

0V DC and 15V DC?

Insert screwdriver into to

rotate indoor fan motor

slowly for 1 revolution or

over,and measure voltage

NO.6(+) and NO.3(-) on CN9.

Does the socket CN9 of

outdoor control board have

power input(DC 310V AND DC

15V)

Yes

No

Replace

outdoor

EEPROM

EEPROM error

YES

NO

Error code outdoor10

condenser over load

No

Yes

Outdoor control board

faulty replace it

Yes

No

Normal

protection

Outdoor coil

sensor fault

Trouble code

outdoor3

EEPROM trouble

Outdoor control

fault, replace it

Error code outdoor12

IPM trouble

No

Yes

IPM fault and

replace it

Is the

IPM heat sink very

hot?

No

Yes

Normal protection

Assure good

ventilation

of outdoor

unit and good

contact

between IPM

and heat sink

Yes

No

Yes

Normal protection

No

Yes

No

Is the

IPM heat sink very

hot?

Yes

Yes

Yes

No No

Check operation

Replace the

outdoor control

board,Does this

fault disappear?

Replace the wave

filter

board,Does this

fault disappear?

IPM trouble

appear

frequently?

Start up the air

conditioner in 30

minutes,does it

work Normally?

IPM fault appears

frequently?

Is the resistance of

outdoor coil sensor

correct?

Does the trouble

disappear in 3

minutes ?

Is the outdoor

heat exchanger

really hot?

Trouble code

indoor13

EEPROM trouble

Indoor control board

fault , replace it

Replace

sensor

Check operation

Error code

outdoor 1

outdoor

temperature

sensor trouble

Error code

outdoor 2

outdoor coil

sensor trouble

Measure

resistance

between CN7

① and②

Measure

resistance

between CN7

③ and④

Does the

resistances of

thermistor have

the

characteristics on

page 31.

Replace the thermistor

Connect CN7.

Turn ON the power

supply and press

the EMERGENCY

OPERATION SWITCH

Replace the

outdoor board

Ok *1

Does the

unit operate

10 minutes

or more?

*1 Defective contact of the connector is considered

Yes

Yes

No

No

Yes

7.SERVICE FLOW CHART

Error code outdoor 4

compressor rotor

position test error

No

Yes

Outdoor IPM control

board faulty replace

it

NO

YES

Normal

pretection

EEPROM error

replace the outdoor

EEPROM,then start up

the ai-condioner and

test

Shut down the

air-conditioner and

start up after 5

minutes or

more,then test

Error code outdoor 9

compressor start up

error

No

Yes

Outdoor IPM control

board faulty replace

it

NO

YES

Normal

pretection

EEPROM error

replace the outdoor

EEPROM,then start up

the ai-condioner and

test

Shut down the

air-conditioner and

start up after 5

minutes or

more,then test

7.SERVICE FLOW CHART

DC310V

+V15+V15

SENSOR

SENSOR

SENSOR

+12V+12V

+5V+5V

Display board

Electrical outlet

Step motor

Step motor

7805 12V+7805 12V

7805 5V+7805 5V

220V From power board()220V From power board()

Step motor

+5V+ 5V

+12V+12V

+12V+12V

+12V+12V

FAN MOTOR CONTROL

Control

To power board()

Control

To power board(

SI

HKEB - HCNB 351 X

HKEB - HCNB 261 X

8.ELECTRIC CONTROL BOARD

220V Output

+12V+12V

220V Input

From power supply()

220V Input

From power supply()

+5V+5V

220 Output

SI

TO TERMINAL

SI

HKEB - HCNB 351 X

HKEB - HCNB 261 X

8.ELECTRIC CONTROL BOARD

220V INPUT

From terminal

board()

220V

INPUT

From terminal

board()

+5V

+15V

Electric expansion

valve control

Electric expansion

valve

control

4-way valve4-way valve

+12V

sensor

Fan motor controlFan motor control

DC+

DC-

+15V

CONTROL

SINGAL TO IPM()

CONTROL

SINGAL TO IPM()

AC OUTPUT

SI

DC+DC+

DC-DC-

TO I PM

TO I PM

INPUT

8.ELECTRIC CONTROL BOARD

HKEB - HCNB 351 X

HKEB - HCNB 261 X

HKEB - HCNB 351 X

HKEB - HCNB 261 X

8.ELECTRIC CONTROL BOARD

IPM BACK

T('c) R(K o) V (v) T('c) R(K o) V(v) T('c) R(Ko) V(v)

- 20 3 9.58 0.5307 9 1 0.1 1 .5878 3 8 3 .265 2.9504

- 19 3 7.58 0.5558 1 0 9 .684 1.6338 3 9 3 .151 2.9932

- 18 3 5.69 0.5818 1 1 9 .284 1.6805 4 0 3 .041 3.0358

- 17 3 3.91 0.6087 1 2 8 .903 1.7276 4 1 2 .936 3.0775

- 16 3 2.23 0.6363 1 3 8.54 1 .7749 4 2 2 .835 3.1188

- 15 3 0.65 0.6648 1 4 8 .194 1.8226 4 3 2 .739 3 .159

- 14 2 9.15 0.6942 1 5 7 .864 1.8704 4 4 2 .646 3 .199

- 13 2 7.74 0.7244 1 6 7 .549 1.9185 4 5 2 .556 3.2387

- 12 26 .4 0 .7556 1 7 7 .249 1.9667 4 6 2 .471 3.2771

- 11 2 5.14 0.7875 1 8 6 .962 2.0151 4 7 2 .388 3.3155

- 10 2 3.95 0.8202 1 9 6 .688 2.0636 4 8 2 .309 3.3528

- 9 2 2.82 0.8539 2 0 6 .427 2. 112 4 9 2 .233 3.3896

- 8 2 1.75 0.8885 2 1 6 .178 2.1603 5 0 2 .159 3.4262

- 7 2 0.74 0.9237 2 2 5 .939 2.2089 5 1 2 .089 3.4615

- 6 1 9.79 0.9596 2 3 5 .712 2. 257 5 2 2 .021 3.4965

- 5 1 8.88 0.9966 2 4 5 .494 2.3053 5 3 1 .956 3.5306

- 4 1 8.02 1.0343 2 5 5 .286 2.3533 5 4 1 .893 3.5644

- 3 17 .2 1 .0731 2 6 5 .086 2.4014 5 5 1 .832 3.5977

- 2 1 6.43 1.1122 2 7 4 .896 2.4489 5 6 1 .774 3.6299

- 1 15 .7 1.152 2 8 4 .714 2.4963 5 7 1 .718 3.6616

0 15 1 .1929 2 9 4 .539 2.5436 5 8 1 .664 3.6926

1 1 4.34 1.2342 3 0 4 .372 2.5904 5 9 1 .612 3.7231

2 1 3.71 1.2765 3 1 4 .212 2.6369 6 0 1 .562 3.7528

3 1 3.11 1.3195 3 2 4 .059 2. 683 6 1 1 .513 3.7824

4 1 2.55 1.3623 3 3 3 .912 2.7288 6 2 1 .467 3.8106

5 1 2.01 1.4063 3 4 3 .772 2.7738 6 3 1 .422 3.8386

6 11 .5 1 .4506 3 5 3 .637 2.8188 6 4 1 .379 3.8658

7 1 1.01 1.4959 3 6 3 .508 2.8631 6 5 1 .337 3.8927

8 1 0.55 1. 541 3 7 3 .384 2. 907

THE PARAMETER OF THE COIL AND INDOOR AND OUTDOOR SENSOR

9.SENSOR PARAMETER

9.SENSORPARAMETER

T ('C) R (O ) V ( v) T ( ' C ) R ( O ) V ( v) T('C) R (O ) V( v)

-10 313.4 0.3 31 44.74 1.545 71 9.659 3.372

-9 297.2 0.315 32 42.89 1.59 72 9.331 3.409

-8 281.9 0.331 33 41.13 1.636 73 9.016 3.446

-7 267.5 0.348 34 39.44 1.682 74 8.712 3.483

-6 253.9 0.365 35 37.84 1.729 75 8.421 3.519

-5 241.1 0.383 36 36.3 1.776 76 8.14 3.554

-4 229 0.402 37 34.84 1.823 77 7.869 3.588

-3 217.6 0.421 38 33.44 1.871 78 7.609 3.622

-2 206.8 0.441 39 32.11 1.919 79 7.359 3.655

-1 196.6 0.462 40 30.83 1.967 80 7.118 3.688

0 186.9 0.483 41 29.61 2.016 81 6.885 3.72

1 177.8 0.506 42 28.45 2.064 82 6.662 3.751

2 169.2 0.529 43 27.34 2.112 83 6.446 3.781

3 161 0.552 44 26.27 2.161 84 6.239 3.811

4 153.3 0.577 45 25.25 2.21 85 6.039 3.84

5 146 0.602 46 24.28 2.258 86 5.846 3.869

6 139 0.629 47 23.35 2.307 87 5.661 3.897

7 132.5 0.656 48 22.46 2.355 88 5.482 3.924

8 126.3 0.684 49 21.6 2.404 89 5.309 3.951

9 120.4 0.712 50 20.79 2.452 90 5.143 3.977

10 114.8 0.742 51 20.01 2.499 91 4.982 4.003

11 109.5 0.772 52 19.26 2.547 92 4.827 4.028

12 104.4 0.804 53 18.54 2.595 93 4.678 4.052

13 99.66 0.836 54 17.85 2.642 94 4.534 4.076

14 95.13 0.869 55 17.19 2.689 95 4.395 4.099

15 90.82 0.902 56 16.56 2.735 96 4.261 4.122

16 86.74 0.937 57 15.96 2.781 97 4.132 4.144

17 82.85 0.972 58 15.38 2.826 98 4.007 4.165

18 79.16 1.008 59 14.82 2.872 99 3.886 4.187

19 75.65 1.045 60 14.29 2.916 100 3.77 4.207

20 72.32 1.083 61 13.78 2.96 101 3.658 4.227

21 69.15 1.122 62 13.28 3.005 102 3.549 4.246

22 66.13 1.161 63 12.81 3.048 103 3.444 4.265

23 63.27 1.201 64 12.36 3.09 104 3.343 4.284

24 60.54 1.242 65 11.93 3.132 105 3.15 4.32

25 57.94 1.283 66 11.51 3.174 106 3.059 4.337

26 55.46 1.325 67 11.11 3.214 107 2.97 4.354

27 53.11 1.368 68 10.73 3.254 108 2.884 4.37

28 50.86 1.411 69 10.36 3.294 109 2.802 4.386

29 48.72 1.455 70 10 3.333 110 2.721 4.401

30 46.68 1.5

THEPARAMETEROFTHEDISCHARGESENSOR

10. DISASSEMBLY INSTRUCTIONS

1.Remove the grille

1)Take out the screw of the installation plate and remove

the installation plate.

2)Take out the screws of the mounting plate .

3)Hold the both sides of the front panel and drag it towards

oneself and remove it.

4)Take out the screws of the ornamengt grille and remove the

ornament grille.

5)Take away the air filters in the grille.

6)Open the screw cover ,then take out the screws of the

grille and remove the grille.

7) Remove the mounting plate.

HKEB 261 X

OPERATION PROCEDURE

PHOTOS

Screw

Installation Plate

Screw

Mounting Plate

Base Ass'y

Front Panel

Grille

Ornament Grille

Air Filter

Screw

Screw

Display Board

2.Remove the electrical control box

1)Take out the screw of the electrical cover and remove it.

2)Remove the indoor coil sensor from the sensor bracket.

3)Take out the screws of the electrical control box and

disconnect all the connectors on the printed circuit

board,then remove the electrical box.

Screw

Electrical Cover

Indoor Coil Sensor

Screw

Terminal Screw

Screw

HKEB 351 X

10. DISASSEMBLY INSTRUCTIONS

1)Remove the air outlet frame.

2) Take out the screws of the evaporator supportor and remove

the evaporator supportor.

3) Take out the screws of the motor cover and remove the motor

cover.

4) Take away the mounting plate and then remove the evaporator.

3.Remove the air outlet frame and the evaporator

1)Take out the screw of the rubber cover and remove the

rubber cover.

2)Remove the screw connecting the fan motor and the

cross-flow fan.

3)Remove the fan motor and the bearing ass'y.

4)Remove the cross-flow fan.

4. Remove the fan motor and the cross-flow fan

HKEB 261 X

Evaporator

Air Outlet Frame

Screws

Evaporator Supportor

Screws

Motor Cover

Mounting late

Cross-Flow Fan

Base Ass'y

Fan Motor

Fan Motor

Screws

Screw

Rubber Cover

Bearing Ass'y

HKEB 351 X

1.Remove the top panel and the front panel

1)Take out the screws of the top panel and remove the top

panel.

2)Take out the screws of the strengthen plate and remove it.

3) Take out the screws of the front panel and remove the panel.

2.Remove the electrical control box

1)Take out the screws of the valve cover and remove the

valve cover.

2)Take out the screws of the side cover and remove the cover.

3)Take out the screws of the electrical box cover and remove it.

4) Disconnect all the wires in the electrical control box and the

other parts.

4)Take out the screws of the electrical control box and remove

electrical control box.

OPERATION PROCEDURE

PHOTOS

10. DISASSEMBLY INSTRUCTIONS

HCNB 261 X - HCNB 351 X

Screw

Screw

Screw

Top Panel

Side Cover

Valve Cover

Front Panel

Fan Guard

Screw

Screw

Strengthen Plate

Screw

Screw

Screw

Screw

Screw

Screw

Electrical cover

Outside fan

Fan supportor

Electrical Box

Condenser Ass'y

1)Take out the screws of the back panel.

2)Remove the back panel.

3.Remove the back panel

1)Take out the special nut of the fan and remove the fan.

2)Take out the screws of the fan motor and remove the fan motor.

3)Take out the screws of the fan supporter and remove the

fan supporter.

4)Take out the screws of the partition plate and remove

the partition plate.

1)Check-up the condenser ass'y.

2)Check-up the compreesor ass'y.

3)Check-up the base ass'y.

5.Check-up the other parts of the outdoor units

Compreesor ass'y

Base ass'y

Condenser ass'y

Fan

Special nut

HCNB 261 X - HCNB 351 X

Fan Supportor

Seperator Plate

Screw

Screw

10. DISASSEMBLY INSTRUCTIONS

4.Remove the fan ,fan motor,fan supportor and the separate

plate.

Loading...

Loading...