SERVICE MANUAL

Air Conditioners

CAUTION

READ THIS MANUAL CAREFULLY TO

DIAGNOSE TROUBLE CORRECTLY

BEFORE OFFERING SERVICE .

MODEL:

IMPORTANT INFORMATION

ƽҏFeatures

ƽҏComfortable: wide-angle airflow

ƽhealth air purifying

ƽquiet operation

ƽҏsuper energy efficient

ƽMain Specification

ƽCooling CapacityΚ 2600/3500/5300W

ƽRated Power/Current(cooling)Κ680/990/1600W/7.8A

ƽEER: 3.8/3.5/3.3W/W

ƽHeating CapacityΚ 3200/3800/6600W

ƽRated Power/Current(heating): 1185/1455/1930W/9.2A

ƽCOP: 2.7/2.6/3.4W/W

ƽAir Volume(Indoor): 500/550m

3

/h

ƽPower: 1PH 220-230V~ 50 Hz

MODEL: HKEL 261 XR + HKEL 351 XR

IMPORTANT INFORMATION

ƽҏFeatures

ƽҏComfortable: wide-angle airflow

ƽhealth air purifying

ƽquiet operation

ƽҏsuper energy efficient

ƽMain Specification

ƽCooling CapacityΚ 2600/5200W

ƽRated Power/Current(cooling)Κ680/1520W/7.5A

ƽEER: 3.8/3.29W/W

ƽHeating CapacityΚ 3200/6500W

ƽRated Power/Current(heating): 1185/1880W/8.8A

ƽCOP: 2.8/3.2W/W

ƽAir Volume(Indoor): 500m

3

/h

ƽPower: 1PH 220-230V~ 50 Hz

MODEL: HKEL 261 XR x 2

Before disposing an old air conditioner that

goes out of use, please make sure it's inoperative and safe. Unplug the air conditioner

in order to avoid the risk of child entrapment.

It must be noticed that air conditioner system

contains refrigerants, which require specialized waste disposal. The valuable materials

contained in an air conditioner can be recycled

.Contact your local waste disposal center for

proper disposal of an old air conditioner and

contact your local authority or your dealer if

you have any question. Please ensure that

the pipework of your air conditioner does not

get damagedprior to being picked up by the

relevant waste disposal center, and contribute

to environmental awareness by insisting on an

appropriate, anti-pollution method of disposal.

Cautions

Disposal of the old air conditioner

All the packaging materials employed in the

package of your new air conditioner may be

disposed without any danger to the

environment.

The cardboard box may be broken or cut into

smaller pieces and given to a waste paper

disposal service. The wrapping bag made of

polyethylene and the polyethylene foam pads

All these valuable materials may be taken to

a waste collecting center and used again after

adequate recycling.

Consult your local authorities for the name

and address of the waste materials collecting

centers and waste paper disposal services

nearest to your house.

Disposal of the packaging of your

new air conditioner

Before starting the air conditioner, read the

information given in the User's Guide carefully. The User's Guide contains very important observations relating to the assembly,

operation and maintenance of the air

conditioner.

The manufacturer does not accept responsibility for any damages that may arise due

to non-observation of the following

instruction.

Damaged air conditioners are not to be

put into operation. In case of doubt, consult

your supplier.

Use of the air conditioner is to be carried

out in strict compliance with the relative

instructions set forth in the User's Guide.

Installation shall be done by professional

people, don't install unit by yourself.

For the purpose of the safety,the air conditioner must be properly grounded in accordance with specifications.

Always remember to unplug the air

conditioner before openning inlet grill. Never

unplug your air conditioner by pulling on

the power cord. Always grip plug firmly and

pull straight out from the outlet.

All electrical repairs must be carried out

by qualified electricians. Inadequate repairs

may result in a major source of danger for

the user of the air conditioner.

Safety Instructions and Warnings

Do not damage any parts of the air

conditioner that carry refrigerant by piercing

or performating the air conditioner's tubes

with sharp or pointed items, crushing or

twisting any tubes, or scraping the coatings

off the surfaces. If the refrigerant spurts

out and gets into eyes, it may result in

serious eye injuries.

Do not obstruct or cover the ventilation

grille of the air conditoner.Do not put fingers

or any other things into the inlet/outlet and

swing louver.

Do not allow children to play with the air

conditioner.In no case should children be

allowed to sit on the outdoor unit.

The refrigerating circuit is leak-proof.

1.Applicable ambient temperature range:

Specifications

The machine is adaptive in following

situation

10 .The power plug and connecting cable

must have acquired the local attestation.

2. If the power supply cord is damaged, it

must be replaced by the manufacturer

or its service agent or a similar qualified

person.

3. If the fuse of indoor unit on PC board is

broken,please change it with the type of

T. 3.15A/ 250V. If the fuse of outdoor

unit is broken,change it with the type of

T.25A/250V

4. The wiring method should be in line with

the local wiring standard.

5. After installation, the power plug should

be easily reached.

6. The waste battery should be disposed

properly.

7. The appliance is not intended for use

by young children or infirm persons

without supervision.

8. Young children should be supervised

to ensure that they do not play with

the appliance.

9.Please employ the proper power plug,

which fit into the power supply cord.

Cautions

Cooling

Indoor

Maximum:D.B/W.B

Maximum:D.B/W.B

Maximum:D.B

Maximum:D.B

Maximum:D.B

Minimum:D.B/W.B

Maximum:D.B/W.B

Minimum:D.B/W.B

Outdoor

Indoor

Outdoor

Heating

32oC/23oC

24oC/18oC

-7oC/-8oC

43oC/26oC

18oC

27oC

15oC

18oC/14oC

Outdoor

Maximum:D.B/W.B

Minimum:D.B/W.B

24oC/18oC

-15oC

(INVERTER)

11.In order to protect the units,please turn

off the A/C first, and at least 30 seconds

later, cutting off the power.

Series' brief Introduction

1. Comfortable: wide-angle airflow

The vertical dual-flap and horizontal wide-angle louvers ensure the cool/warm air

reaching every corner of the room.

2. Health air purifying and negative ion function

An air purifying filter with deodorizing and disinfecting function keeps the air clean

and users healthy. The negative ion generator can produce the negative ion that

make the air fresher and cleaner.

3. Quiet operation

Fan with Random-pitched Blades.

Random-pitched blades help to reduce operating noise while maintaining a high

airflow rate.

4. Energy efficient

The design of inner-grooved copper tube greatly increases the refrigerant contact

area and the efficiency of cooling/heating functions.

5. Convenience

Washable panel and Auto-restart function:

- The grille can be removed easily and washed when necessary.

- All series have auto-restart function after a power failure. At the end of a blackout,

all Units automatically restart with the previous settings.

6. Wide variety of functions

24-Hour Timer:

24-Hour Timer allows Users to select the exact time they would like the air conditioner

to turn on and turn off.

7. Night-set models

When the air conditioner is operating on the timer-off circuit. The preset room

temperature gradually rises (going down in Heating) before the Unit's stop. Users can

sleep comfortably without sudden change in temperature.

8. "Dry" Program

This function automatically reduces the level of humidity while maintaining the preset

indoor temperature.

A

B

Indoor unit number

Unit A

Unit B

Unit A + B

Unit A

Unit B

Unit A + B

Unit A

Unit B

Unit A + B

Unit A

Unit B

Unit A + B

kW

COOL

HEAT

Ph-V-Hz

I.U. ~ O.U.

A

A

n°

Liquid side mm(inch)

Gas side mm(inch)

m

m

Kg

m

g/m

°C

°C

Dimension (W*H*D) A mm 795 265 182 795 265 182 795 265 182

Packing (W*H*D) A mm 865 330 272 865 330 272 865 330 272

Net/Gross weight Kg

dB(A) 42 39 35 42 39 35 42 39 35

dB(A) 34 31 27 34 31 27 34 31 27

Litres/h

m3/h 500 440 410 500 440 410 500 440 410

n°

mm

type

Dimension (W*H*D) mm 815 680 295 815 680 295 815 680 295

Packing (W*H*D) mm 960 760 406 960 760 406 960 760 406

Net/Gross weight Kg

dB(A)

dB(A)

m3/h

57

49

2100

3

16

Wireless IR

59/66

Outdoor Unit Specifications

49

2100

+18°C ~ +43°C

-15°C ~ +24°C

7,6/10,6

1,2 * 2

Indoor Unit Specifications

7,6/10,6

1,2 * 2

1,8

5 + 5

20

Capillary Tube

φ6.35(1/4’) x 2

φ9,52(3/8’) x 2

15

5/5

9,2

10

2 + 2

R410A

Refrigerant circuit

8,8

10

2 + 2

R410A

Max. current

A

B

1-220~240V-50HZ

O.U.

3,31

3,42

Electrical data

1,46

1,46

1,93

0,99

0,99

1,60

3,42

3,80

6,60

5,30

3,80

Inverter

2

3,50

3,50

HCNL 531 XR

HKEL 351 XR

HKEL 351 XR

57

3

16

Wireless IR

59/66

+18°C ~ +43°C

-15°C ~ +24°C

1,8

5 + 5

20

Capillary Tube

φ6.35(1/4’) x 2

φ

9,52(3/8’) x 2

15

5/5

A

B

1-220~240V-50HZ

O.U.

3,46

1,19

1,19

1,88

0,68

0,68

1,52

3,20

6,50

5,20

3,20

Inverter

2

2,60

2,60

HCNL 531 XR

HKEL 261 XR

HKEL 261 XR

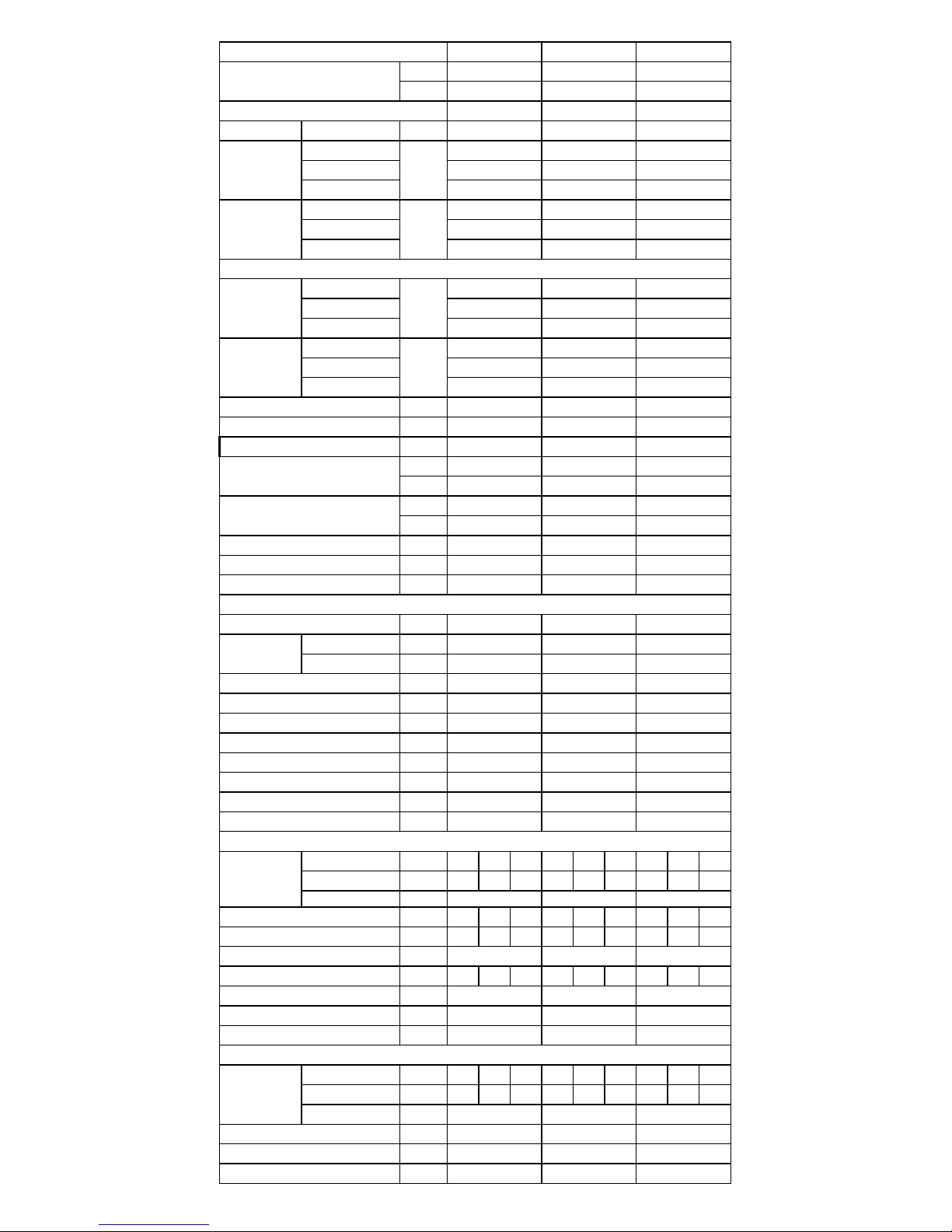

ENERGY CLASS

Refrigerant

Drain hose diameter

Indoor unit

Remote Controller (st. equipment)

Temperature range heating

Moisture Removal (Indoor)

Outdoor Air flow

Outdoor Noise level 1 m (MAX)

Outdoor Noise level 2,5 m (MAX)

Outdoor unit

MAX Splitting with Refrigerant Precharge

Indoor Noise level 1 m (Hi/Mi/Lo)

Indoor Noise level 2,5 m (Hi/Mi/Lo)

Indoor air flow (Hi/Mi/Lo)

Fan speeds

Temperature range cooling

Refrigerant Control

Additional Refrigerant Charge

Model Outdoor unit

Cooling Capacity

Model Indoor unit

Heating Capacity kW

Type

kW

Cooling Input kW

Heating Input kW

Power supply

EER

COP

Annual Consumption (500h/Y)

Starting current

Wiring cables i.u./o.u. (without ground)

Splitting level difference (out.-ind./ind.-out.)

Refrigerant Precharge

Refrigerant Pipe

Splitting distance indoor/outdoor

HCNL 531 XR

HKEL 261 XR

HKEL 351 XR

Inverter

2

2,60

3,50

5,30

3,20

3,80

6,60

0,68

0,99

1,60

1,19

1,46

1,93

3,31

3,42

A

B

1-220~240V-50HZ

O.U.

9,2

10

2 + 2

R410A

φ6.35(1/4’) x 2

1,2 * 2

φ9,52(3/8’) x 2

15

5/5

1,8

49

2100

3

16

Wireless IR

59/66

760 800 800

57

5 + 5

20

Capillary Tube

+18°C ~ +43°C

-15°C ~ +24°C

7,6/10,6

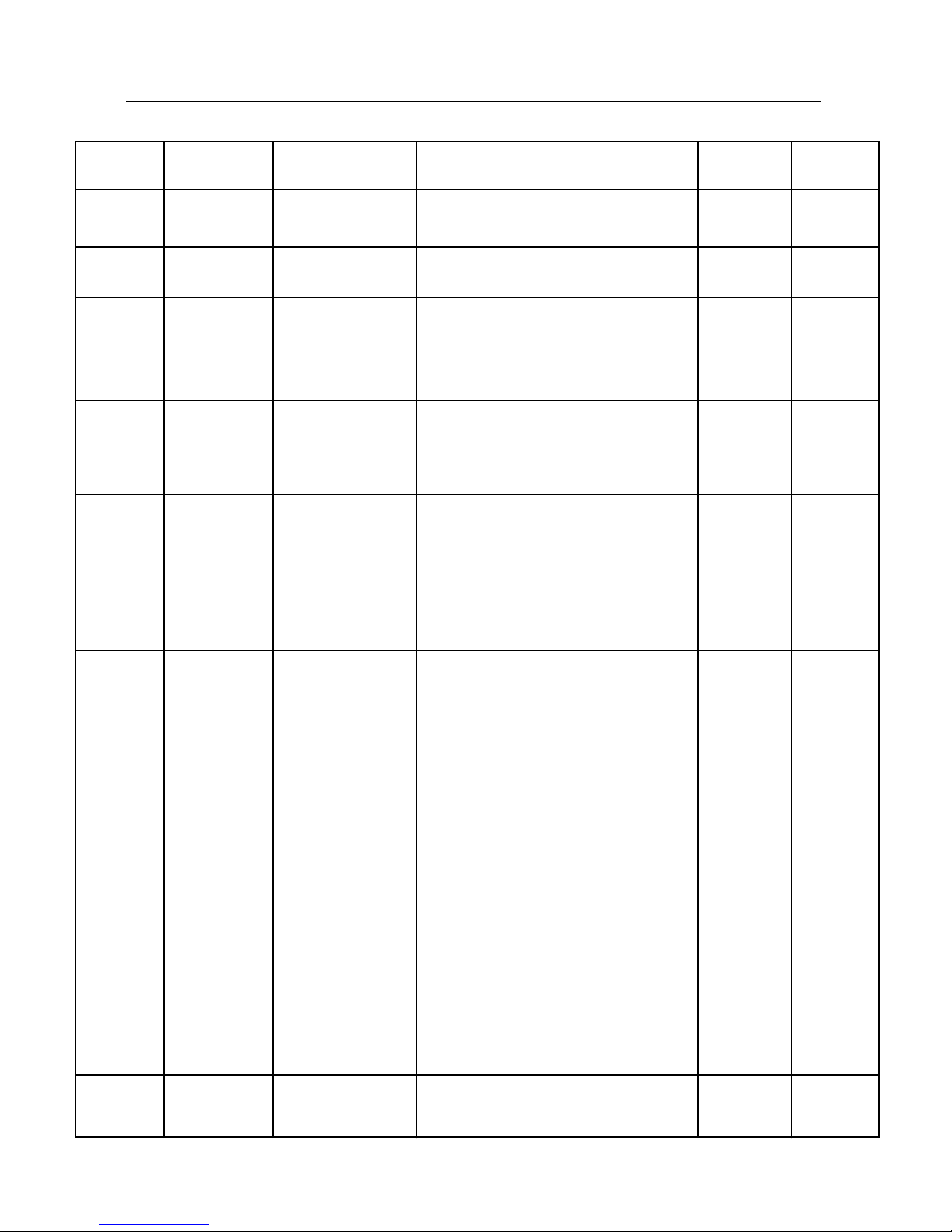

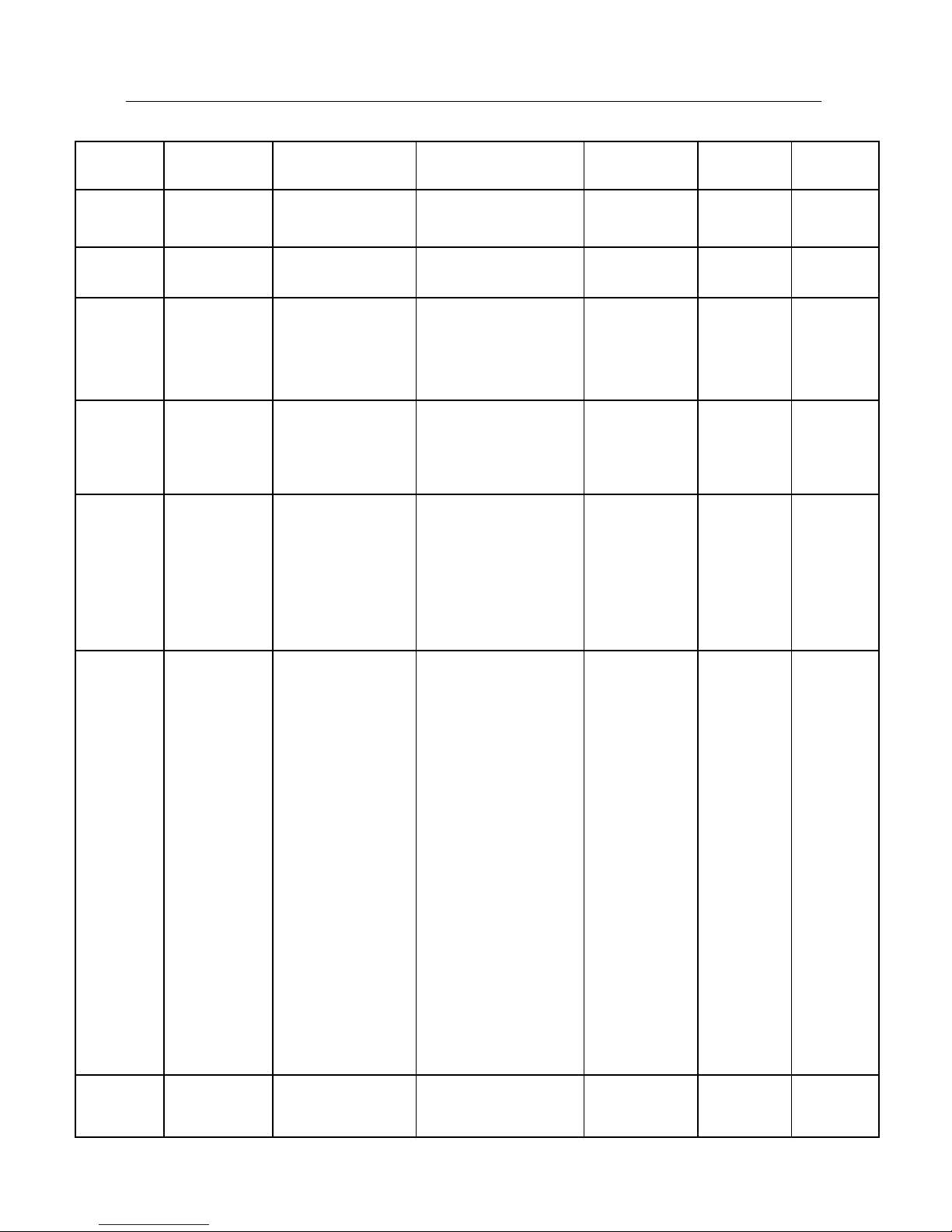

Number Na

me Refer No. Description Quality

Failure

Rate(%

)

Remark

1

remote

controller

0010403793 None 1 0.2

*

2 battery 001A4600001 None 2 0.1

3

mounting

plate

0010101275

Fix mounting plate

according to

installation position

and pip

e direction

0

4 drain pipe 001A0900011

Choose the place

that can drain

water and connect

pipe easily

1 0.1

5

connectin

g

pipe

----

The maxi

mal

length of the

conne

cting pipe is

15m,the ma

ximal

he

ight between

indoor unit and

outdoor unit is 5m

1 0.2

*

6

connecting

wire

----

The conecting

methods include

ring terminal and

direct

terminal

.Ring

terminal

connecting

method:Unscrew

the

screws ,and

put it through the

ring of connecting

line ends,then

connect it into the

terminal block.

Direct terminal

connecting

method:unscrew

the screws,then

fully i

nsert the

cable ends into.

.

1

0.2

*

7 manual 001A7265614 Operation 1 0

HKEL 261 XR x 2

Number Na

me Refer No. Description Quality

Failure

Rate(%

)

Remark

1

remote

controller

0010403793 None 1 0.2

*

2 battery 001A4600001 None 2 0.1

3

mounting

plate

0010101275

Fix mounting plate

according to

installation position

and pip

e direction

0

4 drain pipe 001A0900011

Choose the place

that can drain

water and connect

pipe easily

1 0.1

5

connectin

g

pipe

----

The maxi

mal

length of the

conne

cting pipe is

15m,the ma

ximal

he

ight between

indoor unit and

outdoor unit is 5m

1 0.2

*

6

connecting

wire

----

The conecting

methods include

ring terminal and

direct

terminal

.Ring

terminal

connecting

method:Unscrew

the

screws ,and

put it through the

ring of connecting

line ends,then

connect it into the

terminal block.

Direct terminal

connecting

method:unscrew

the screws,then

fully i

nsert the

cable ends into.

.

1

0.2

*

7 manual 001A7265614 Operation 1 0

HKEL 261 XR + HKEL 351 XR

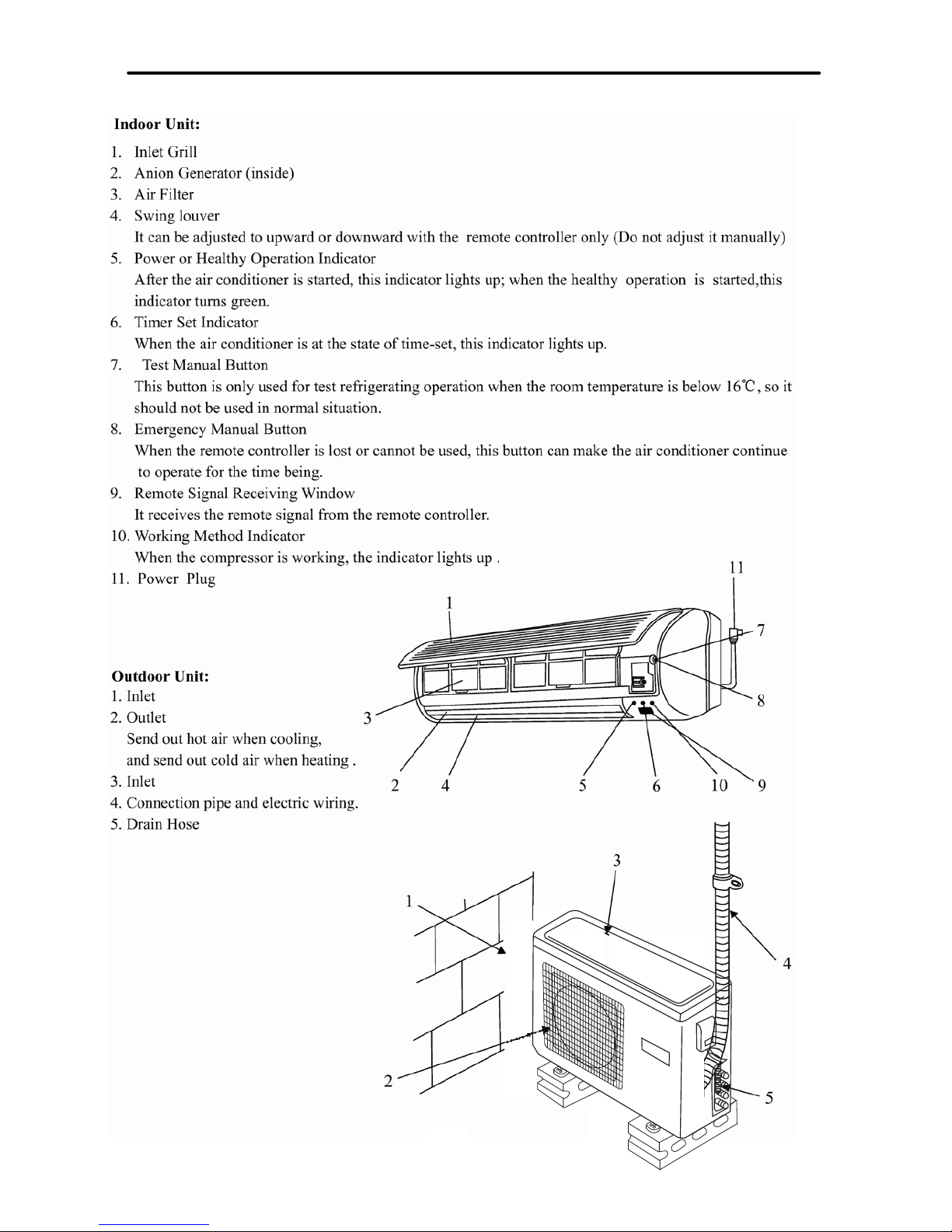

Description and function of main components and accessories

795

265

182

Net dimensions for outdoor unit

583

815

869

680

319.5

352

295

Net dimensions for indoor unit

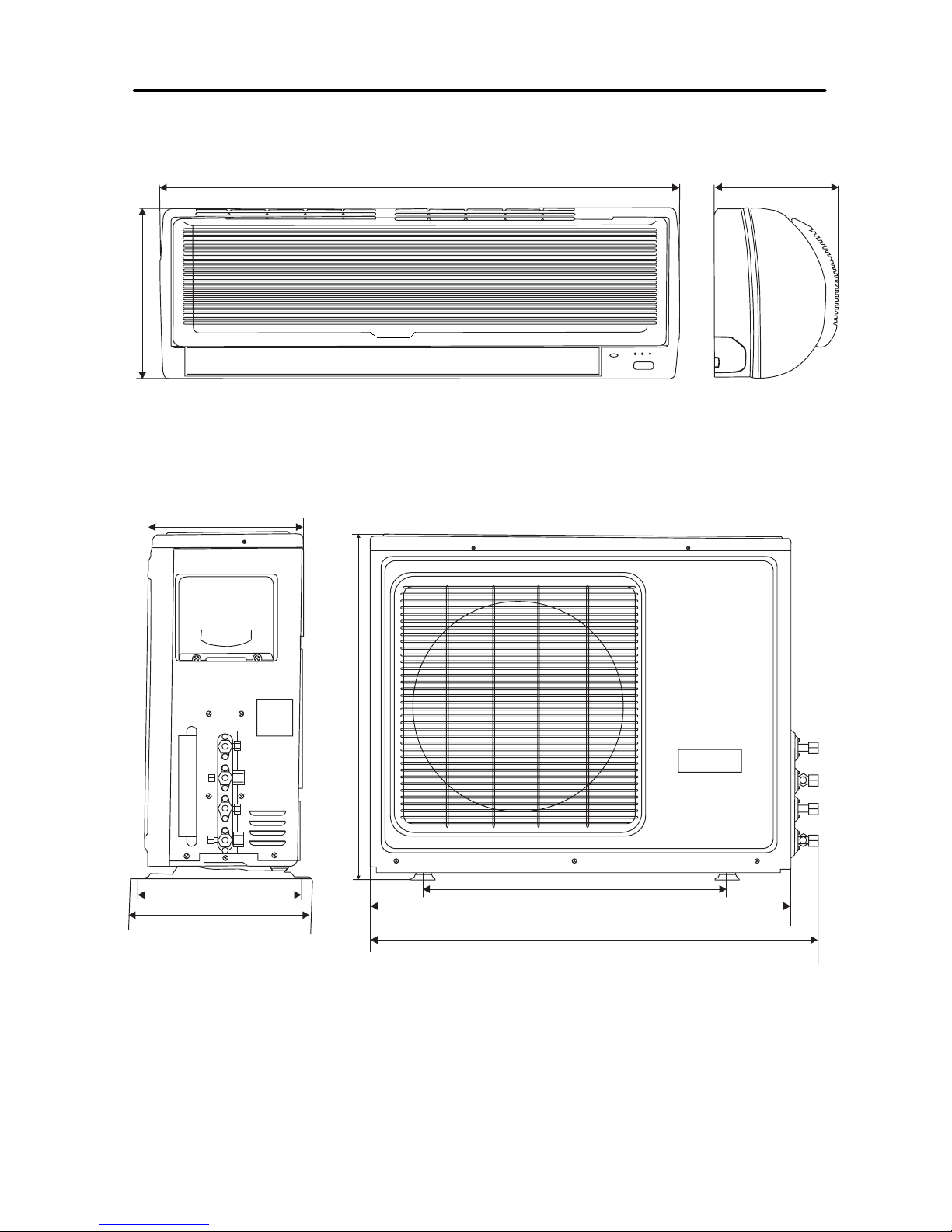

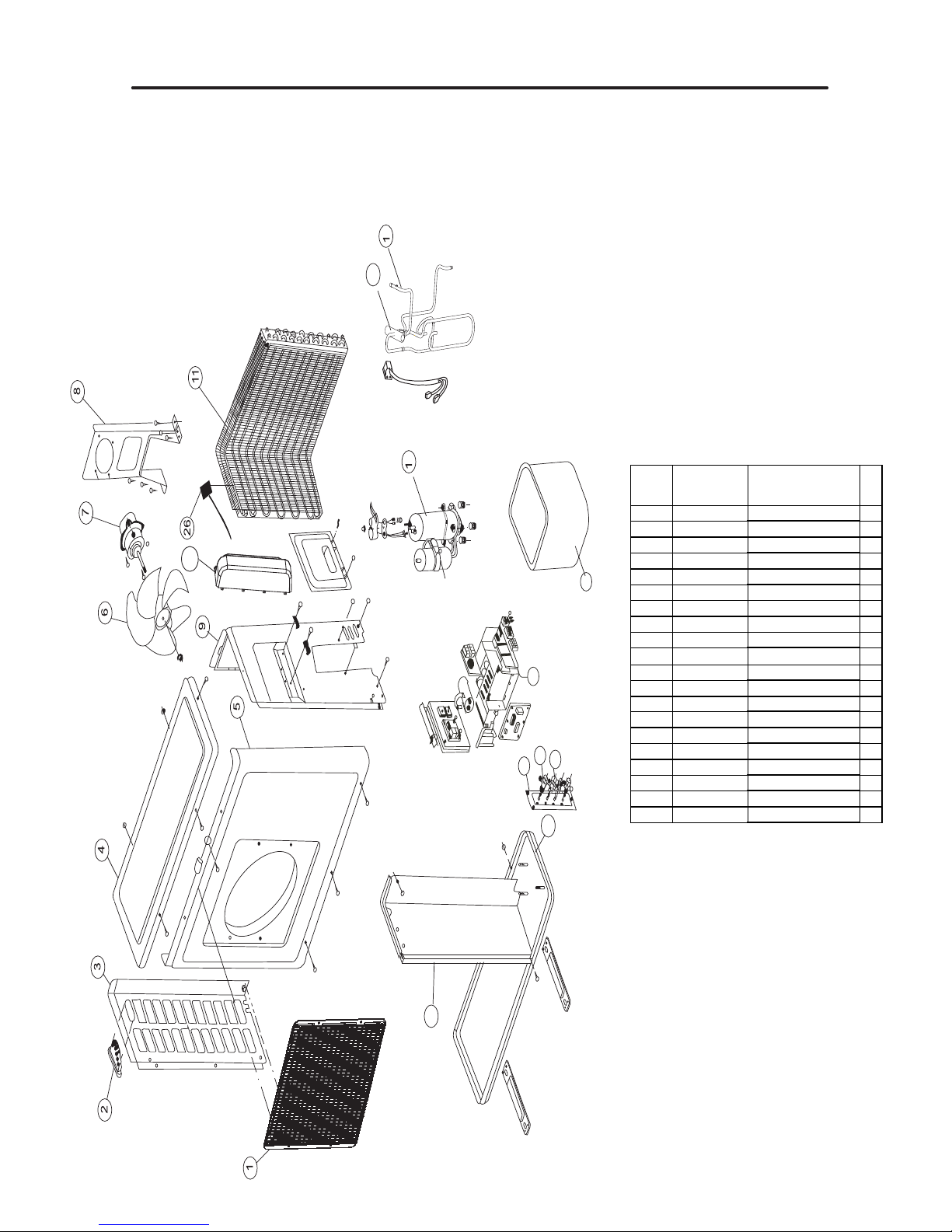

KNOCK-DOWN DRAWINGS

INDOOR UNIT

1

3

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

No. in

exploded

view

Spare parts

number

Spare parts description

in english

Qty

1 001A1232082 Inlet grille assy. 1

2 001A2400060 Air filter 2

3 0010

101525

Fron

t panel assy.

1

4 001A1232077 Flap 1

5 001A0900064 Drain pan assy. 1

6 001A0400055 Evaporator assy. 1

7 001A0300005 Bearing 1

8 0010202415 Cross flow fan 1

9 001A0100206 Frame assy. 1

10 001A1301216 Mounting plate 1

001A3000052 Fan motor 1

001A1431372 Motor cover 1

12 001A3800032 Transformer 1

13 0010403740 PCB 1

14 0010403686 Te rminal block 1

15 001A0600287 Receiver board 1

16 001A09000

11

Drain hose 1

17 001A30

00072

Swing

motor

1

18 0010403793 Remote controller

1

19 001A1434039 Drain tube 1

20 001A2400059 Air purifying

2

21 001A3900059 Sensor 1

22 0010400724 Negative ion generator 1

11

No. in

exploded

view

Spare parts

number

Spare parts description

in english

Qty

1 001A1232082 Inlet grille assy. 1

2 001A2400060 Air filter 2

3 0010101525 Front panel assy. 1

4 001A1232077 Flap 1

5 00

1A0900064

Dra

in pan assy.

1

6 001A0400055 Evaporator assy. 1

7 001A0300005 Bearing 1

8 0010202415 Cross flow fan 1

9 001A0100206 Frame assy. 1

10 001A1301216 Mounting plate 1

001A3000052 Fan motor 1

001A1431372 Motor cover 1

12 001A3800032 Transformer 1

13 0010403741 PCB 1

14 0010403686 Terminal block 1

15 001A0600287 Receiver board 1

16 001A0900011 Drain hose 1

17 001A3000072 Swing motor 1

18 0010403793 Remote controller

1

19 001A1434039 Drain tube 1

20 001A2400059 Air purifying

2

21 001A3900059 Sensor 1

22 0010400724 Negative ion generator 1

11

HKEL 261 XR

HKEL 351 XR

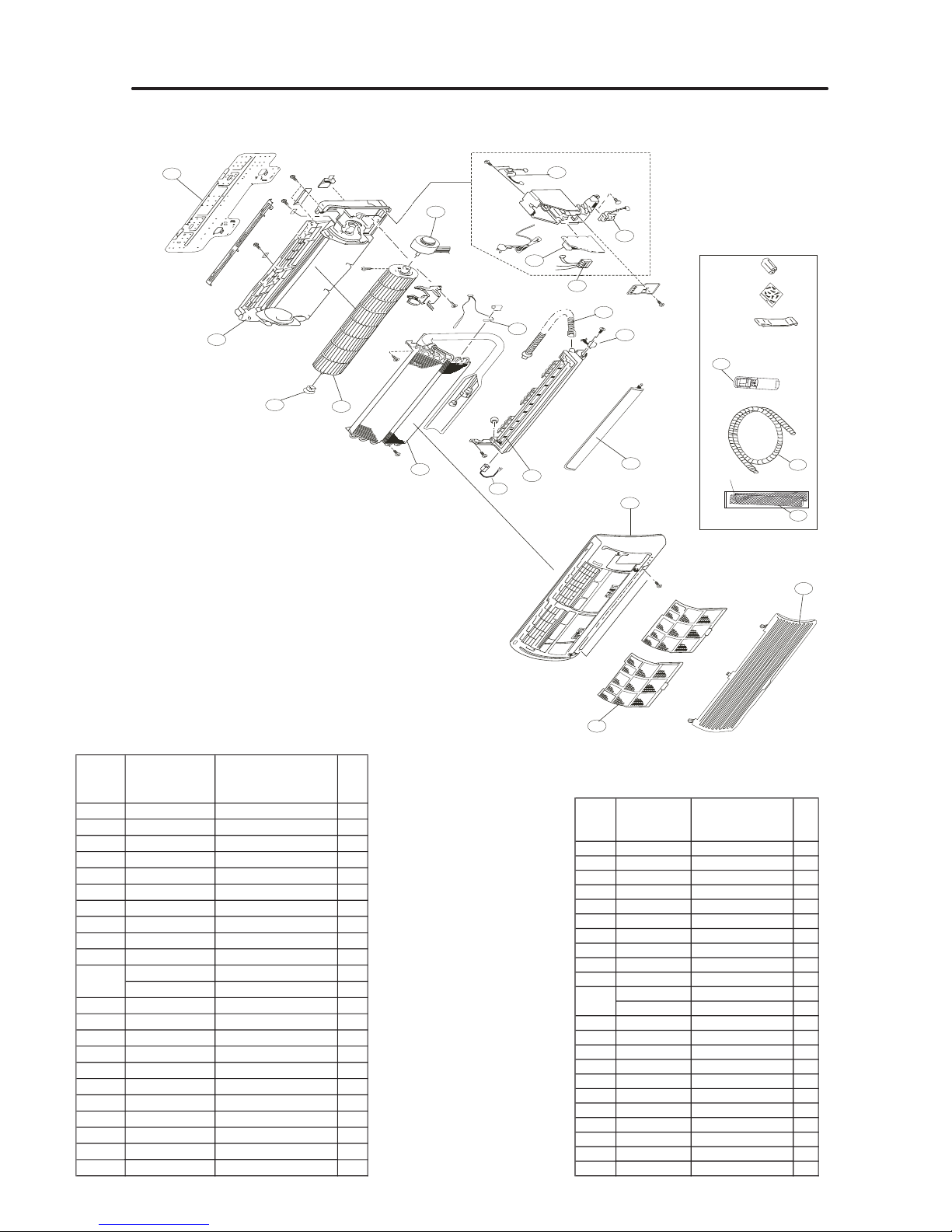

29

13

15

16

17

18

19

20

2

0

14

No. in

explode

d view

Spare parts

number

Spare parts description

in english

Qty

1

0

010203945

Front guard 1

2

001A14361

82

Handle 1

3

001A1101039

Left side panel 1

4

001A0100124

To p pane

l

1

5

0010101

525

Fro

nt panel

1

6

0

01A2331024

Axial fan 1

7

001A30007

6

Motor 1

8

001A1301133

Motor s

upport

1

9

0010101524

Right side panel 1

10

0010706971

Compressor 1

11

0010707166

Heat excha

nger

1

12

0010707160

Pipe assy. 1

13

0010703

520

4-way valve Assy 1

14

0010806619

Electric box Assy 1

15

001A1301304

Split board 1

16

0010806754

Bottom plate assy 1

17

001A1301127A

Stop valve support 1

18

0010705

987

Stop valve 2

19

0010705988

Stop valve 2

20

001A17621544

OUTDOOR UNIT

HCNL 531 XR

ELECTRICAL CONTROL

catalog

1. application range

2. operation modes

3. strength operation

4. mute operation

5. air refreshing

6. timing operation

7. dormant mode

8. urgent switch input

9. low load protection control

10.high load protection control

11.low heating processing

12.indoor and outdoor communication

13.remote control signal codes

14.abnormal operation of indoor system

15.EEPROM control

16.malfunction list resume (to 0010403739/3740)

17.abnormal conditions confirmation

18.special functions

19.airflow conducing board control

20.other additional functions

appindex

1. Application range

conditionic and its expanded types.

Note: Close S2 and open S1 before connecting to the power source. Enter the time-cut mode after

the connection.

Close S1 and open S2 before connecting to the power source. Enter the time-cut mo de after the

connection.

2. Operation modes.

1. Full-automatic approach.(

After the air conditonic is switched on, when the system is at the automa tic option, the

appropriate operation mode will be chosen according to the difference between the set temperature

and the indoor temperature . In the following option conditions, Tr stands fo r indoor temperature

and Ts stands for set temperature.

The system will choose the operation mode according to the following conditions when entering

into the automatic operation option for the first time.

Tr≥Ts-3℃ Choose the cooling mode

Tr<Ts-3℃ Choose the warming mode

Under the automatic option, the system will switch between the cooling and warming modes

according to the change of the indoor temperature. If the air conditionic is under the cooling mode,

when the set temperature for stopping th e compressor is reached, the compre ssor will be stopped.

The indoor temperature will be tested aga in 15 minut es after the s top of the co mpressor . At the

moment, if the tested temperat ure is un der the Tr<Ts-3℃ condition, the system will be switched into the

warming mode. If not, the system will remain in the cooling mode. If the air conditionic is under the warming mode,

when the set temperature for stopping th e compressor is reached, the compre ssor will be stopped.

The indoor temperature will be tested aga in 15 minut es after the s top of the co mpressor . At the

moment, if the tested temper ature is under the Tr(compensation value not included)≥Ts+3℃ condition,

the system will be switched into the cooling mode. If not, the system will remain in the warming mode. If the system

is stopped by a change on the set temperature, the decision of mode switching will be made 3 minutes later.

When the system is switched to the automatic option from other opti ons, if the operation

conditions changes ( new decision should be made before new operation), the system will be stopped

for 3 minutes and then enter the relative mode according to the inlet air temperat ure.

This mode has the timing fu nction an d dorman t function. Under the cooling m ode, the c ooling

dormant function is stimulated while the dormant heating function takes effects under the heating

mode.

This mode has the strength/ mute function. Under the cooling mode, the cooling st rength function i s

stimulated while the strength heating function takes effects under the heating mode.

The airflow speed control can choose the low, medium, high or automatic option and send the

airspeed signal to the outdoor system.

Automatic lowered airflow direction board. (the same with the cooling or he ating mode.)

2. Cooling operation mode

* Temperature control range: 16℃---30℃

* Temperature difference: ±1℃

* Control features: When Tr(inpu t airflow)>Ts(set temperature)℃, the compressor will be

opened,the indoor fan will operate at the set speed and the mode signal will be sent to the outdoor

system. When Tr(input airflow)< Ts(set temperature)℃, the compressor will be opened,the indoor

fan will operate at the set speed and the mode signal will be sent to the outdoor system. The system

will keep the original status if Tr= Ts.

* Airflow speed control: (temperature difference 1℃)

Automatic: When Tr>=Ts+3℃, hi gh speed.

When Ts+1℃=<Tr<Ts+3℃, medium speed

When Tr<Ts+1℃, low speed

When the sensor is off, low speed

When the airflow speed has no delay from the high to low switching, the speed should be delayed

for 3 minutes (remain at high speed for 3 minutes.) before the next switch.

Manul: When the system is operating, you can set the high, medium or low speed manually. ( When

the sensor is on or off, the system will chan ge the speed 2 seconds after rec eiving the signal.)

*Airgate location control: the loca tion for the airga te can be set accordin g to your needs.

*Defrosting function: preventing the frosting on the indoor heat exchanger (when cooling or

demoisture). When the compress or works continu ously for 5 minute s (adaptable in EE PROM) and the

temperature of the indoor coils has been below zero centigrade for 10 seconds, the compressor will

be stopped and the malfunction will be recorded in the malfunction list. The indoor system will

continue to run. When the temperat ure of the indoor coil is raised to 7℃, the comp ressor will be

restarted again (the prerequirement of 3 minutes’ delay should be satisfied.)

* timing system on/off function.

* Dormant control function.

* Under the cooling mode, the outdoor sy stem will proces s the frequency conversing of the

compressor according to t he set temperature, indoor temperat ure and the indoor heat exchange

temperature. (refer to the specification for the outdoor system.)

3. Demoisture mode.

* temperature control range: 16---30 ℃

* temperature difference: ±1℃

Control feature: send the demoisture signal to the outdoor system.

When Tr>Ts+2℃, the compressor will be turned on, the indoor fan will operate at the set speed.

When Tr is between the Ts and Ts+2 ℃, the outdoor system will operate at the high demoisture

frequency for 10 minutes and then at the low demoisture mode for six minutes . The indoor fan will

operate at low speed.

When Tr< Ts, the outsystem will be stopped , the indoor fan will be stoppe d for 3 minutes and

then turned to the low speed option.

All the frequency converses have a ±1℃ difference.

* Wind speed control: Automatic:

When Tr >= Ts+ 5℃, high speed.

When Ts+3℃≤Tr< Ts+5℃, medium speed.

When Ts+2℃≤Tr< Ts+3℃, low spee d.

When Tr<Ts+2℃, light speed.

If the outdoor fan stopped, the indoor fan will be paused for 3 minutes.

If the outdoor fan stopped for more than 3 minutes and the outdoor system still operates, the system

will be changed into light speed mode.

When the airflow speed has no del ay from the high to lo w switc hing, the speed should be dela yed

for 3 minutes (remain at high speed for 3 minutes.) before the next switch.

Manual: When the sensor is off or Tr< Ts+3℃, the manual operation can not be made. (obligatory

automatic operation.)

*Airgate location control: the loca tion for the airga te can be set accordin g to your needs.

*Defrosting function: preventing the frosting on the indoor heat exchanger (when cooling or

demoisture). When the compress or works continu ously for 5 minute s (adaptable in EE PROM) and the

temperature of the indoor coils has been below zero centigrade for 10 seconds, the compressor will

be stopped and the malfunction will be recorded in the malfunction list. The indoor system will

continue to run. When the temperat ure of the indoor coil is raised to 7℃, the comp ressor will be

restarted again (the prerequirement of 3 minutes’ delay should be satisfied.)

* coil protection (synchronic overheating protection) are installed for the four directions latch

malfunctions when demoisturing.

* timing system on/off function.

* Dormant control function.

4. Heating operation mode.

* temperature control range: 16---30℃

* temperature difference: ±1℃

* control feature: send the heating signals to the outdoor system.

If Ts≥Tr+1℃, the outdoor compressor is turned on.

If Tr≥ Ts+1℃, the outdoor system is turned off. However, with the previous 5 minutes after

the starting-up, the system ca n’t be stopped even if the changed Tr reached the Ts. The system

can be turned off after these 5 minutes.

If the set temperature is changed to the room temperature, the system will be stopped at once.

If the system is under the heating or automatic heating mode, the set temperature will be added

a compensated value, which usually makes the set temperature on the thermostat have 3 degrees’

compensation.

*Indoor fan control

manual control: You can choose high, medium, low and automatic speed control.

Automatic: When Tr<Ts, high speed.

When Ts=<Tr=<Ts+2℃, medium speed.

When Tr> Ts+2℃, low speed.

When the airflow speed has no del ay from the high to lo w switc hing, the speed should be dela yed

for 3 minutes (remain at high speed for 3 minutes.) before the next switch.

*Airgate location control: the location for the airgate can be set according to your needs.

. Coldair proof operation

1. when the indoor temperature is below 23 centigrades, the indoor fan will be off, when the

temperature is above 23 centigrades, the indoor fan will run at a slight speed.

2. If the coil temperature is above 38 centigrade, the fan will run at the set speed.

3. If the coil temperatur e doesn’t reach 38 centigrade 4 minutes after the start-up of the

slight airflow, the fan will run at the set speed. (Whether the coil temperature falls or not

after the starting up of the slight airflo w, the set speed is stimulated if the tem perature

doesn’t surpass 38 centigrade.)

4. When the compressor works, the i ndoor fan will run at the set speed when the spe ed of the

slight airflow reached the set speed.

Set airflow

38℃

Slight airflow

23℃

* Residue heat sending. The indoor fan will send the residue heat at a low speed for 20 seconds.

If the Tc(indoor coil)< 20 centigrade, the indoor fan will be stopped at once.

* If the system is stopped when the set temperat ure is reached, th e indoor fan will run at

a slight speed within the 3 minute’s waiting mode until Tc< 20 centigrade.

* If the indoor system is turned off, the air direction board will be closed after the stop

of the indoor fan. (the indoor fan will be stopped immediately if there is a malfunction.)

* Defrosting: After receiving the defrosting signal of the outdoor system, the indoor fan will

be stopped, and the malfunctions of the indoor coils and the indoor sensors will be neglected.

In the defrosting period, the default indoor temperature is 10 centigrades, the coil

temperature will be 20 centigrades. With in the defrosting period and the proceeding 2 minutes,

the temperature sensor will not test the abnormalities(including the indoor coil and the indoor

temperature sensor) and the cold air proof operation will be stimulated after these two minutes.

* Overload protection syst em can protect the coil from overheating. The outdoo r system will

be stopped if the 10s continuous tests show that the indoor temperature is above 65 centigrades

(accomdable in EEPROM), a nd the ove rheating ma lfunction is to be rep orted. When the indoor

temperature is below 42 centigrades(accomdable in EEPROM) and the system has been stopped for

more than 3 minutes, it means that the malfunction has been cleared and the outdoor system

will be started again.

* Under the cooling mode, the outdoor sy stem wi ll proces s the fre quen cy conver sing of the

compressor according to the set temperature, indoor temperature a nd the indoor heat exchange

temperature. (refer to the specification for the outdoor system.)

5. Low heating processing.

When the four direction latch switch doesn’t work or the compressor restarts (despite the

defrosting operation and the proce eding 3 minutes) at the heat ing mode, if the heat exchang er

temperature is below "THHOTLTH"(-4.5℃)for "TMHOTLTH"(90seconds), the compressor will be paused

for 3 minutes. The indoor temperature will be restored at " THHOTLTH "(-4.5℃).

3. Strength/ mute operation

* When the system operates, if there is onl y a strength setting and no mute settings, the indoor

fan will have an airflow speed processing and the outdoor fan will have a stre ngth processing. But

if the system has both the strength settin g and the mute set ting, only th e indoor fan will ha ve

the speed processing accordingly and the outdoor fan will not operate any process. If there is only

a mute setting and no strength settings, the indoor fan will have an airflow strength processing

and the outdoor fan will have a speed processing.

* The realization of indoor fan functions: The indoor system sends the strength or mute signal to

the outdoor system. The indoor fan with a set strength will operate at the set str ength speed and

the indoor fan set into a mute mode will send slight airflow.

*1. strength operation

a. the system enters the mode after receiving the ‘strength signal’.

Send strength operation signal to the outdoor system.

Strength operation for 15 minutes.

The strength operation stops or finishes after the 15 minutes.

The mode change finishes the strength operation.

Entering ‘mute’, you can have normal operation or signal control such as timing to finish the

strength operation.

When the system is at the automatic option with the strength/ mute function, if the system enters

the cooling mode, the cooling strength/ mute function will be offered; if the system enters the

heating mode, then the heating strength/ mute function will be offered; if the system enters the

airflow mode, there will be no strength/ mute function.

b. strength heating:

temperature accommodating function.

The airflow is offered by strength heating (adaptable in the EEPROM)

In the defrosting mode, the outdoor fan doesn’t receive strength operation signals.

15 minutes after the stren gth opera tion, the compressor can’t be turned off wi thin 10 minutes .

(except the malfunctions and the off singals)

c. strength cooling:

temperature accommodating function.

The airflow is offered by strength cooling (adaptable in the EEPROM)

The low load protection can’t be stimulated within the 3 minutes after the start up of the

compressor.

d. Demoisture, strengthless airflow operation.

*2. Mute operation

a. the system enters the mode after receiving the ‘mute signal’.

b. send the mute signal to the outdoor system.

c. mute heating:

When the compressor operates, the airflow speed is mute speed. EEPROM is adaptable.

*After the compressor is turned off, the airflow speed can be controlled according to the following conditions.

1. If the system is turned off with a remote control or under an urgent condition, the fan speed will be changed

into light speed within 20 seconds. Then, the fan will stop 20 seconds later. The airflow direction board will be closed

after the 20 seconds’slight airflow.

2. If the system is turned off by a malfunction, the fan will be stopped at once.

3. If the sensor is turned off, the fan will operate at a slight speed.

4. Mute cooling.

Mute cooling: the airflow speed will be mute speed. EEPROM is adaptable.

5. Mute operation can not work under the demoisturing and airflow-sending operation.

4. Air refreshing

After receiving the signal from the remote control, the power indicator turned to yellow green ( the

indicator is oringinally red). If the fan operates, the negative ion generator operates to realize

the negative sending function.

If the indoor fan stops, the negative ion generator is turned off.

When the negative ion generator is turned off, if the air refreshing system is turned on, the negative

ion generator will be turned on when the fan operates.

5. Timing.

You can set 24 hours’ on/off timing accordingly. After the setting, the timing indicator will be

lightened. Also, the light will be turning off after the timing is finished. The followings are

several timing methods.

1.1 system /on timing: The timing indicator will be ligh tened and the indoo r system is under

the waiting mode. The light will be turned off when the timing is finished and the rest of the system

will operate under a normal condition. The timing starts since the last reception of the timing

singal. You can have the dormacy setting under the timing mode, the order of your settings will

be operated according to the timing settings.

1.2 system /off timing: When the system is turned on, the timing indicator is lightened, the rest

of the system will operated under a normal condition. When set time comes, the indicator light will

be turned off and the system will be turned off. If you have set the dormant functions, the order

of your settings will be operated according to the timing settings.

1.3 system /on and off timing: The settings will be completed according to the orders.

6. Dormant operation

*1. According to the option, after you have set the domant setting, the timing indicator will be lightened.

*2. Under the cooling/ demoisture operation, after the setting of the dormant operation, the set temperature will be

raised for 1 centigrade after 1 hour’s operation and will be raised for 1 centigrade 1 hour later. The system will keep

this status for 6 hours and then close.

*3. Under the heating mode, after the setting of the dormant operation, the et temperature will fall 2 centigrades after

1 hour’s operation and will fall 2 centigrades 1 hours later. 3 hours after the preceding operations, the set temperature

will be raised for 1 centigrade and the system will keep this status for 3 hours and then close down.

*4. Indoor fan control under the dormant operation.

If the indoor fan is at the high speed before the dormant operation setting, the speed will be turned to medium after

the setting. If the fan is at the medium speed before the dormant setting, the speed will be turned to low after the

setting. If the fan is at the low speed before the dormant setting, the speed will not change.

7. Urgent on/off input

*1. Press the urgency button the buzzer will ring. The system will enter the automatic mode if you don’t press the

button for more than 5 seconds.

*2. If you press the urgency button for more than 5 seconds, the buzzer will ring twice. At the time, if you loose the

button, the system will enter test operation function. The indicated frequency of the test operation function is 58Hz

and the airflow speed is high. The test operation will be finished after 30 minutes and the system will be closed.

During the test period, the system will quit the test operation after receiving the signal from the remote control. The

low load protection can’t be stimulated her e.

*3. If you press the urgency button for more than 10 seconds, the buzzer will ring for 3 times. If you loose the button,

the malfunction list will be presented, on which the last system malfunction is to be revealed. The malfunction signal

can only be eliminated after the the system has received the indoor or outdoor malfunction correcting singals. The

malfunction list doesn’t receive any remote control signals except the stop signal. If there is no malfunction, no

signals are tobe revealed, but the buzzer still rings.

*4. If you press the urgency button for more than 15 seconds, the buzzer will ring only once. The system will keep

the present status and can receive on/off signals.

*5. When you press the urgency button. Within 15 seconds, no remote signals can be received. After 15 seconds, just

like the remote signal reception mode under normal conditions, the normal remote signals can be received.

8.

opposite operation modes exist of indoor system

When the outdoor system operates, if the indoor system operation differs from the outdoor system, the abnormal

operation malfunction will be reported. 10s after the report, the indoor system will be closed.

Outdoor system mode Indoor system mode conflicts

cooling heating yes

cooling cooling no

cooling airflow no

heating heating no

heating airflow yes

heating cooling yes

9. EEPROM control

When outdoor system is connected to the power circuit, if the EEPROM value differs from the tested value, then the

EEPROM is abnormal.

When the indoor system receives EEPROM the abnormal reading and writing signals from the outdoor system, the

abnormality of the outdoor EEPROM is confirmed.

At the time, the control and urgency signals can not be received.

The problem can be solved through switching off the power supply.

10. Malfunction list resume.

Nothing is presented if there is no code list.

For the malfunction modes, refer to the urgency button specification.

The remote control only receives the sigals for stop. According to the signals, the malfunction

resume presentation finishes.

The resume restores after the power supply restores.

11. abnormality confirmation approaches.

11.1 indoor temperature sensor abnormality: under the operation, the normal temperature ranges from 126 degree to

-31 degree. When the temperature goes beyond this range, the abnormality can be confirmed. If the temperature goes

back into the range, the system will automatically resume.

11.2 indoor heat interaction sensor abnormality: under the operation, the normal temperature ranges fro m 126 degree

to -31 degree. When the temperature goes beyond this range, the abnormality can be confirmed. If the temperature

goes back into the range, the system will automatically resume.

11.3 indoor fanmotor malfunction.

When the indoor fan signal is output, if there is no feedback within 2 minutes, the abnormality can be confirmed.

11.4 Outdoor malfunction processing.

When the outdoor malfunction signal is sent to the indoor system asking for malfunction report, the operation LED

light will report the malfunctions by flashing, the times of flashing stands for the outdoor malfunction codes. If there

is no malfunctions within the outdoor system, the indoor system will continue to run.

11.5 transmission abnormality.

If the indoor system can’t receive the outdoor system for 5 minutes, the communication abnormality can be

confirmed and the outdoor system will be stopped. 170 seconds later, the malfunction can be cleared, 3 minutes after

the turning down of the system can it be started again and the test and inspection is to be restrated.

12. Special functions

*1.Single indoor system operation

* Enter condition: Under the no-electricity cut compensation condition, press the dormant keys

for 6 times within 7 seconds, the system will feedback with 6 rings.

* After the system enters the separate indoor system operation mode, the indoor system will operate

according to the set mode and neglect the communication signals of the outdoor system. However,

it has to send signals to the outdoor system.

* Quitting condition: This mode can be quitted after receiving the quitting signal from the remote

control or urgency system. The indoor system thus can quit the single operation mode.

* Under the single indoor fan operation, the preset outdoor status is as the follows.

The compressor frequency is 58 hz, there is no error or non-defrosting signals, and the sensors

are at the normal temperature.

* Malfunction happens on the two sensor of the indoor system. The indoor heat interaction temperature is fixed at

47 centigrade and the ambient temperature is fixed at 25 centigrade.

* When the single indoor system operation is set, after receiving the signals from the remote control, all kinds of

output control (such as negative ion) can be set normally and cancelled. The screen board will show all kinds of set

conditions ( the setting and canceling of negative ions, the setting and canceling of the timing functions, etc.), among

which the LED will be lightened after entering the single indoor system.

2. Power cut compensation.

* Entering condition: Press dormant button 10 times within 7 second, the buzzer will ring 4 times and the present

system status will be stored into the EEPROM of the indoor system.

* After entering the power cut compensation mode, the processing of the indoor system should be as the followings:

Remote control urgency singal: operate according to the remote control and the urgent conditions, the present status

will be stored into the EEPROM of the indoor system.

* Quitting conditions: Press dormant button 10 times within 7 seconds and the buzzer will ring twice.

3. Fixed frequency operation.

** 1. Fixed cooling: a. under any condition: high speed cooling, set 16℃, press temperature ‘-‘ key

and the set key at the same time,the bu zzer will ring 2 times and the system will enter the fixed

frequency operation.

b. The proceeding programs are as the follows:

Entering the fixed frequency operation, the fixed indication is presented in the communication.

c. Quitting condition: The f ixed frequency cooling c an be quitted after rece iving the remote

signal, and the system will enter the remote setting status.

*2. Medium cooling: under any condition : a. high spe ed cooling, set 16℃, press the dormant key

4 times within 7 seconds and the buzzer will ring 5 times. The system then enters the medium mode.

b. The proceeding programs are as the follows:

Entering the medium cooling operation, the medium power is presented in the communication.

c. Quitting condition: The m edium co oling ca n be quitte d after re ceiving the remo te signal, a nd

the system will enter the remote setting status.

*3. minimal cooling: a. G code (the remote controller) entering condition: press the dormant key

8 times within 7 seconds and the buzzer will ring 7 times. The system then enters the minimal mode.

b. The proceeding programs are as the follows:

Entering the minimal cooling operation, the minimal cooling is presented in the communication.

c. Quitting condition: The minimal cooling can be quitted after receiv ing the remote signal, and

the system will enter the remote setting status.

** 1. Fixed heating: a. under any condition: high speed heating, set 30℃, press temperature ‘+‘ key

and the set key at the same t ime and the buzzer will rin g 2 times.The system will e nter the fixed

frequency operation.

b. The proceeding programs are as the follows:

Entering the fixed frequency operation, the fixed indication is presented in the communication.

c. Quitting condition: The fixed frequency heating can be quitted after receiving the remote signal,

and the system will enter the remote setting status.

*2. Medium heating: under any condition : a. high spe ed heating, set 30℃, press the dormant key

4 times within 7 seconds and the buzzer will ring 5 times. The system then enters the medium mode.

b. The proceeding programs are as the follows:

Entering the medium heating operation, the medium power is presented in the communication.

c. Quitting condition: The m edium he ating ca n be quitte d after re ceiving the remo te signal, a nd

the system will enter the remote setting status.

*3. minimal heating: a. G code(the remote controller) entering condition: press the dormant key

8 times within 7 seconds and the buzzer will ring 7 times. The system then enters the minimal mode.

b. The proceeding programs are as the follows:

Entering the minimal heating operation, the minimal heating is presented in the communication.

c. Quitting condition: The minimal heating can be quitted after receiv ing the remote signal, and

the system will enter the remote setting status.

13. Other additional functions

*1. Self test function, time-reducing function.

1-1 close the code switch S1 and open switch S2 before connecting to the power circuit and the indoor system enters

the time-reducing function, one minute is reduced as one second.

1-2 close the code switch S2 and open switch S1 before connecting to the power circuit and the indoor system enters

the self-test program 3 seconds later. The airflow direction board is closed.

* After the entering into the self test program, the power light will be lighted for one second, and then the clearing

light will be lighted for 1 second. Then, the timing light will be lighted for one second. At last, the dormant light will

be lighted for 1 second. Then the system will be in the off status.

* The indoor system will keep the communication with the outdoor ever since the flash of the self test light.

* The fan motor operates at a medium speed during the self testing.

*2. The display function

Three lights display. ( one of the lights is a double colour light, the light board is 287 light board.)

z Receiving the start up signal, the power light will be lighted, red colour.

z Indoor system requires start up, the operation light will be lighted. (The indoor system can only judge the indoor

condition, not the operation status of the outdoor system.)

z When setting the timing option and the dormant option, the timing light will be lighted; when setting health

option, the power light will turn to yellow green.

z Under the start up malfunction mode, if it is an indoor malfunction, the timing light will flash; if it is an outdoor

malfunction, the operation light will flash. Please refer to the malfunction code list.

*3、airflow speed setting communication.

When the indoor airflow speed changes, the speed option will be sent to the outdoor system. There are 5 options

in all: strong, high, medium, low, slight.

14. Appendix

Appendix 1 : The malfunction code for the indoor and outdoor system interaction

malfunctions.

Indoor system malfunction codes

malfunction

codes

malfunction

1 Indoor temperature sensor system break

2 Indoor heat interaction temperature

sensor system break

3 Frosting under the cooling mode

4 Overheating under the heating mode

5 Inefficient communication between indoor

and outdoor system

6 Momental power cut

7 non

8 No feedback from the indoor fan(PG or DC

motor only)

12 Malfunction in reading or writing E2ROM

Outdoor malfunction codes

Malfunction

codes

Malfunction

1 Ambient sensors circuit break

2

Hot temperature exchanger sensor circuit

breaks or shorts.

3

Outlet temperature sensor circuit breaks

or shorts.

4 DC compressor feedback.

5

Outdoor system communication

malfunction.

6 Current overcharge.

7 No load.

8 Overloaded/ under loaded voltage.

9 DC compressor failure.

10 Refrigerating overload

11 Defrosting mode

12 IPM protection

13 E2 ROM reading failure

14 E2 ROM coining failure

15 Non

16 NO AC power.

17 Aspiration sensor circuit breaks

19 DC compressor speed control failure

21 Coil 1 sensor circuit breaks or shorts

22 Coil 2 sensor circuit breaks or shorts

31 System A communication malfunction

32 System B communication malfunction

OUTDOOR SYSTEM FUNCTIONS

The outdoor system will decide the operation mode based on the principle of ‘first order

preferred’ according to the startup signals of the two indoor systems.

a) cooling: Under the cooling operation, the four direction latch will not be closed.

The outdoor fan will operate at the cooling mode. The compressor will operate under

the cooling frequency.

b) heating: Under the heating operation, the four direction latch will be closed. The

outdoor fan will operate at the heating mode. The compressor will operate under the heating

frequency. When frosts appear at the outdoor sys tem, the system will e nter into the

defrosting operation automatically. After the completion of the defrosting, the system

will be resumed.

1. heat defrosting operation

1.1 Under the heating operation, wh en the indoor heat interaction temperatu re is below the

ambient temperature and the heat inter action temperature is below zero centigrade, the

frosts will appear on the heat exchanger. When the aggregated frost affects the heat

interaction, the defrosting operation will begin.

1.2 frost confirmation condition. When either of the following condition appears, the system

will enter the defrosting mode.

b) continuous operation for 47 minutes and Ta≥5℃, if Te

≤-3℃ for 2 minutes.

b) continuous operation for 47 minutes and Ta<5℃, if Te≤-7℃ for 2 minutes.

c) continuous operation for 47 minutes and Ta<-3℃, if Te≤-9℃ for 2 minutes.

d) If Ta≤-3℃ and the compressor worked for 3 hours without a defrosting operation, the

system will process the defrosting for one time.

1.2.1 Defrosting process: After entering the defrosting operation, the compressor and the fan

will be stopped. The four direction latch will be opened 30 seconds later. And the compressor

will restart 10 seconds later. The system begins the defrosting operation .

1.2.5 defrosting quitting condition:

i) Time control: Defrosting time lasts 10 (EEPROM) minutes, the defrosting operation ends.

ii) Heat interaction control: When Te≥14℃(

EEPROM

), the defrosting operation ends.

1.2.6 Defrosting quitting process

After the completion of the defrosting, the compressor stops. 50 seconds later, the four

direction latch changes direction. 10 seconds later, the compressor will start and the original

heating operation resumes.

1.2.7 After the entering into the frosting mode, the compres sor will operat e at least for

1 minutes before stopping th e defrosting. (Th e timing starts as the four direction latch

starts.)

1.3 Outdoor main relay control

The outdoor main relay closure will be delayed for 2 seconds after connecting to the circuit.

1.4 Outdoor airflow control

1.4.1 airflow control at the cooling mode.

After the compressor is turned on fo r 5 seconds, the outdoor fan will start at a high sp eed.

10 seconds later, the speed w ill be controlled according to the outdoo r ambient temperature.

If the outdoor has only two option, M operates on H and L operates on L.

When the outdoor speed is M or L, the speed will change according to the heat interaction

temperature. The status will be checked every minute.

Ta>28℃,high speed

26℃<Ta<28℃ ,high/ low speed

Ta<26℃: Te≧40℃,high speed

37℃≦Te<40℃,high/ medium speed

35℃≦Te ,medium speed

30℃≦Te<35℃,medium/ low speed

Te<30℃,low speed

1.4.2 the speed control under the heating mode

The outdoor speed varies according to the outdoor ambient temperature. M operates on H under

the two option mode.

Ta>24℃,low speed

24℃>Ta>20℃,low speed/ medium speed

Ta>16℃,medium speed

16℃>Ta>10℃,medium/high speed

Ta<10℃,high speed

1.5 Outdoor four direction control

Under the cooling mode, the outdoor four direction latch is not closed. Under the heating mode,

the latch can be closed. When the heat ing compressor stops, the four direction latch will be

closed 100 seconds later. The latch control under the defrosting operation has been discussed

in the ‘defrosting operation’.

1.7 compressor frequency control

1.7.1 fixed test frequency

To fixing test frequency operation of the outdoor system.

the indoor system can be controlled manually. (refe r to the indoor system sp ecification).

1.7.1.1 If the indoor system has the fixed frequency test operation function, then the outdoor

system will calculate the fixed frequ ency according to th e number of the turned on sy stems

and operate on the calculated frequency until the indoor system quit the test operation. When

the two indoor systems ar e turned on at the sam e time, the outdoor syst em will ent er the

operation mode if either of the indoor systems sends the fixed test frequency.

Ta =24℃

Outdoor speed:

Ta =16℃

Ta =10℃

Ta =20℃

L

M

H

M L

i) The outdoor fixed frequency is set according to the indoor system signals. The operation

is on the frequency stored in EEPROM

ii) The cooling and heating value under the double system operation

Under the single system fixed frequency test, the outdoor system will operate according to

the turned-on indoor system status. The operation will on the frequency relative to the status.

Under the double system operation test, the outdoor system will automatically operates on the

double system fixed test frequency.

1.7.2 Normal operation frequency control

Under the outdoor system normal operation, the fixed frequencies of different indoor systems

should be tested according to the different capacity of the respective indoor systems. Then

the outdoor system will dec ide the opera tion frequenc y according t o the fixed fr equencies,

the difference between set temperature and the indoor temperature and the indoor fan speed.

1.8 malfunction and protection

1.8.1 Three minutes’ waiting mode protection

1) No matter caused by which condition, the outdoor compressor is not allowed to be restart

within 3 minutes after a compressor shut down.

2) If the compressor shut down is caused by malfunctions and the malfunction is corrected

3 minutes after, the compressor can restarted of the correction at once.

1.8.2 Intelligent power module protection.

i) Under the compressor operation, if the IPM protection happens under the voltage over/under

loading, over heating or current over charge, the compressor will stop and res tart 3 minutes

later.

ii) If the IPM protection happens 4 times continuously, the compressor will be totally turned

off and can be restarted only by a second connection to the power supply.

1.8.3 Sensor malfunction protection.

i) There are 6 sensors in the outdoor syst em. The outdoor system will stop if any of the six

sensors has malfunctions. The malfunction will be reported respectively.

ii) After the malfunction has been corrected for 3 minutes, the system can be rest arted.

Outdoor restriction condition codes display:

When the outdoor system operates, because of the various temperature or electrical device

restrictions, the compres sor has to ensure the maximal output withi n a safe frequency range.

This restriction condition only rep resent the most possible condition at the t ime, can only

be used as a reference in experiments.

1# Normal, no restriction

2# Power voltage restriction

3# outdoor heat interaction restric tion under the cooling mode; in door heat

interaction under the heating mode.

4# main current restriction

5# outlet temperature restriction

6# indoor heat interaction temperature restriction. (frosting preven tion)

7# Indoor fan speed restriction

8# Outdoor frequency conversing voltage restriction

1.8.4 The malfunction codes:

After the stopping of the system, the flashing time of the LED02 is the malfunction

code.

For example: Malfunction N.O 4

2.5sec 2.5sec

1# Ambient sensors circuit break.

2# Hot temperature sensor circuit breaks or shorts.

3# Outlet temperature sensor circuit breaks or shorts.

4# DC compressor feedback.

5# Outdoor system communication malfunction.

6# Current overcharge.

7# No load.

8# Overloaded/ under loaded voltage.

9# DC compressor failure.

10# Refrigerating overload.

11# Defrosting mode.

12# IPM protection.

13# E2 ROM reading failure.

14# E2 ROM coining failure.

16# NO AC power.

17# Aspiration sensor circuit breaks.

19# DC compressor speed control failure.

21# Coil 1 sensor circuit breaks or shorts.

22# Coil 2 sensor circuit breaks or shorts.

31# System A communication malfunction.

32# System B communication malfunction.

Dealing with the malfunctions

4# Compressor feedback malfunction: Check the main board CN301 and the module jack CN3.

Check the CN04 on the main board and test the output of 15V DC current between the pins

of CN04. Check the location of the chip COM01 at the back of the mainborad, to see if

there is any circuit shorts. Check the states of the 3 phases of the modules. If the feedbacks

of all the checks and tests are normal, then replace COM01.

5# Outdoor system communication malfunction: check the module jack CN401 on the

main board, to see if the conducts of the jack are normally connected with

the terminal stripe. Test if there is a 5V DC current between the pin 8 and

pin 16 of IC03 on the main board. Check if the pin 3 and pin 13 of this chip

are correctly connected with the pin 44 and pin 45 of the IC01, to test if

there is any circuit shorts. Test if there is any communication wave output

at the pin 4 of PQ 404 and PQ 408 and at the pin 2 of PQ403 and PQ 407 and

if there is any circuit shorts on the systems of the surrounding devices ( the

misconnect between the live line and the zero line.)

6#. Current overcharge: Test if there is any circuit block on the system. Test the 4 diodes

D501-D504 on the main board with a multimeter. Test if there is any 5v circuit shorts at

R501-R503 and D-505. Replace device CT501.

7#. No load: Test the 4 diodes D501-D504 on the main board with a multimeter. Test is there

is any circuit short with GND at R501-R503 and D505( special focus on the possible circuit

short condition the terminal A of D502 and terminal K of D504). To test if there is any

formation of resistance or GND circuit short at the capacitor C501. Replace device CT501.

8# Overloaded/ under loaded voltage: Test if there is 310V DC between the terminal P and N

of the program module. Test if there is any circuit short at R301-R304 , R324 and R325.

Test if there is any formation of resistance or GND circuit short at the capacitor C304.

9# DC compressor start-up failure: Please restart; Check if the input and output at 7805(IC04)

is correct. Check the status of the module on the module board. (the normal reading of the

diode mode on the multimeter should be 0.45 at the P, N, U, V, W disconnect

terminals.);Check the voltage of C4,C5,C6 on the module board is 15V or not.

10#. Refrigeration overload: the temperature of pipe is too high,if the malfunction is

reported frequency, check the refrigerant is enough or not.

11# Defrosting condition: After the completion of the defrosting, the system will return to

normal.

12#. IPM protection: check if the system circuits are at normal condition. Check if there is any

GND short at R08 on the main board, to test if there is any formation of resistance or GND

circuit short at the capacitor C02, or any other protection modes caused by temporal current

surge as a result of inappropriate operation or other reasons.

13#,14# malfunctions: Check if the installation of IC05 on the main is correct. (if the installation

is reversed), and if there is any break at the back of the main board. Replace IC05 directly.

16# No AC power: Check the power supply.

19#DC compressor speed control failure: Restart the compressor after it is turned of for a while.

If the restart doesn’t work, refer the suggestions of NO 9 and NO 4.

31# and 32# A/B system communication problem: please refer to NO 5 and check the indoor

system communication circuit.

vals can be controlled in E2.

CIRCUIT AND WIRING DIAGRAM

1 2 3 4 5 6 78

Title

Number Revi

s

Size

A3

Date: 31-Oct-2005 Sheet of

File: D:\backup-liupeng\ .DDB

刘朋的数据库 Drawn By:

R28

2K/1/4W

S3

R27

10K/1/4W

R25

1K/1/4W

R24

510/1/4W

R23

510/1/4W

R4

1K/1/4W

D7

1N4148

VCC

1

2

3

4

5

6

7

CN8

B7B-PH-K

C7

102/25V

R17

3k/1/4w

3

2

1

CN6

B3B-EH-A

P1

FUSE

3.15A

1

2

3

CN2

B3B-XH-A

A0

1

A1

2

A2

3

GND

4

SDA

5

SCL

6

WP

7

VCC

8

IC02

E2ROM24C01

K101

C114

102/50v

R127

1K/1/4W

R126

10K/1/4W

1

2

3

4

CN4

S4B-XH-A

+12

D8

1N4007

C10

2200u/25v

Z301

560v

C307

474/275V

VCC

C4

104/50v

Vin

1

GND

2

Vout

3

V1

7805

C3

104/50v

1

2

3

4

T301

1

2

CN3

5273-03A

CR1

8MHz

R14

1K/1/4W

R104

10K/1/4w

VCC

R105

1K/1/4w

C101

104/50v

R109

4.7k/1/4w

R110

4.7k/1/4w

C112

4.7u/50v

C111

4.7u/50V

VCC

1

2

3

4

5

6

7

10

11

12

13

14

15

16

9

8

IC04

MC1413P

5

4

3

2

1

CN1

B5B-PH-K-S

S101

speeker

N2

1815

L1

R130

4.7K/1/4W

R131

4.7K/1/4W

R132

10K/1/4w

R133

10K/1/4w

D1

1N4007

D2

1N4007

D3

1N4007

D4

1N4007

O2

TLP521

O3

TLP521

R7

1K/1/4W

R8

100K/1/4W

R9

2K/1/4W

C9

102/50V

VCC

R10

25K/3W

D6

1N4007

Z3

18V

C11

100U/50V

C12

473/50V

R11

4.7k/1/4W

D9

1N4007

C13

103/50V

R12

1K/1/4W

R13

1K/1/4W

R15

120/1/4W

C14

470U/25V

C304

1.2u/450V

1

2

3

4

5

CN5

B3P5-VH

VCC

O5

TLP3616

R18

120/1/2w

C16

102/630v

R6

560/1/4w

C1

104/50v

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20

19

21

22

23

24

25

26

27

28

IC01

807

C8

102/25V

R16

1K/1/4W

C15

104/50v

2

3

1

IC05

MC34064

C17

1u/50v

R19

10k/1/4w

VCC

C18

104/25V

C2

104/25V

C5

100U/25V

C6

104/50v

VCC

R1

10k/1/4w

L2

R2

1k/1/4w

2

1

CN7

5289-2A

P2

RL1

JQ1a-12V

P3

+12

R3

270/1/4w

VCC

+12

+12

+12

C20

104/25V

C21

104/25V

VCC

D5

1N4007

N3

1815

1

2

3

CN9

B3B-XH-A

+12

R5

10K/1/4W

R20

10K/1/4W

R21

4.7K/1/4W

S1

S2

VCC

VCC

R22

5.1K/1/4W

R26

1K/1/4W

SELFKEY

SHORTKEY

AB_CODEChoice

SW3

POWER

TIME

RUN

SCL

SCII

SCIO

RECEIVE

RECEIVE

AIRLED

AIRLED

COM1

POW1

FAN

COM1

POW1

COM

POW

ACV

1A/1.85MH

ACV

2%

2%

SCIO

SCII

POW

COM

WIND

SW1

SDA

HEALTH

HALLP

WIND

SW1SW2

SW3

SW4

BUZZER

HEALTH

PG

AIR

SELF

SELF

SDA

SCL

1 2 3 4 5 6 78

A

B

C

D

8

7654321

D

C

B

A

Title

Number RevisionSize

A2

Date: 20-Jan-2006 Sheet of

File: C:\Documents and Settings\chengyongfu\ \BACKUP~1.DDB

桌面Drawn By:

R16

10K/1/4W

+5

R05

4.7K/1/4W

R401

1K/1/4W

C401

102/50V

R403

4.7K/1/4W

+5

C405

102/50V

R408

4.7K/1/4W

+5

R406

1K/1/4W

C413

102/50V

R418

4.7K/1/4W

C409

102/50V

R413

4.7K/1/4W

P404

SIGD

P401

SIGC

1

2

34

CT501

0057W

E501

220uF/16V

R417

1K/1/4W

C415

102/50V

D403

1N4007

C414

104/50V

ZD403

DZB30C

+5

R419

20K/1/4W

R420

1.8K/1/4W

PTC403

MZ2J102M

C416

103/50V

C412

103/50V

PTC404

MZ2J102M

R415

1.8K/1/4W

R414

20K/1/4W

+5

ZD404

DZB30C

C410

104/50V

D404

1N4007

C411

102/50V

R412

1K/1/4W

R407

1K/1/4W

C407

102/50V

D402

1N4007

C406

104/50V

ZD402

DZB30C

+5

R409

20K/1/4W

R410

1.8K/1/4W

PTC402

MZ2J102M

C408

103/50V

C404

103/50V

PTC401

MZ2J102M

+12

+12

+5

CS

1

SK

2

DI

3

DO4GND

5

ORG

6

DC

7

VCC

8

IC05

E2ROM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

IC07

TD62003

1

2

3

4

5

6

CN11

B6B-XH-A

1

2

3

4

5

6

CN12

B6B-XH-A

1

2

3

4

5

6

CN10

B6B-XH-A

1

2

3

4

5

6

CN09

B6B-XH-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

IC06

TD62003

+5

C207

104/50V

R207

4.7K/1/4W

E207

1uF/50V

R215

10K/1/4W

C206

104/50V

R206

47K/1/4W

E206

1uF/50V

R214

10K/1/4W

R213

10K/1/4W

E205

1uF/50V

R205

4.7K/1/4W

C205

104/50V

C204

104/50V

R204

4.7K/1/4W

E204

1uF/50V

R212

10K/1/4W

R211

10K/1/4W

E203

1uF/50V

R203

4.7K/1/4W

C203

104/50V

C202

104/50V

R210

10K/1/4W

R202

4.7K/1/4W

E202

1uF/50V

C201

104/50V

R209

10K/1/4W

E201

1uF/50V

R201

4.7K/1/4W

1

2CN202

defrost temp .sensor

+5

+5

E03

470u/25v

+12

1

2

CN02

B2B-EH-A

C07

104/50V

R24

1K/1/4W

R25

10K/1/4W

+5

C09

104/50V

C501

104/50V

C200

104/50V

LED01

LED01

R12 1K/1/4W

1 3

Vout

Vin

2

GND

IC04

7805

R04

4.7K/1/4W

D501

1N4148

D505

1N4148

E02

470u/25v

C08

104/50V

10

9

8

7

6

5

4

3

2

1

CN03

B10B-XH-A

E01

1uF/50V

23

1

IC02

MC33064

C02

103/50V

C01

103/50V

R18

560/1/4W

R22

10K/1/4W

R208

10K/1/4W

R26

1K/1/4W

R200

4.7K/1/4W

R503

10K/1/4W

R1910K/1/4W

R08

5.1K/1/4W

R501

390/1/4W

R10 1K/1/4W

R11 1K/1/4W

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32 33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

63

62

64

IC01

8849

+5

R09

4.7K/1/4W

R502

510/1/4W

D504

1N4148

E200

1uF/50V

D502

1N4148

D503

1N4148

R23

1K/1/4W

123456789

RA01

R8*4.7K

C06

104/50V

1 2

L201

330uH

R07

20K/1/4W

+5

R06

4.7K/1/4W

+5

+5

R13 1K/1/4W

R15 1K/1/4W

R14 1K/1/4W

+5 +12

+5

+5

+5

R405

1.8K/1/4W

R404

20K/1/4W

+5

ZD401

DZB30C

C402

104/50V

D401

1N4007

C403

102/50V

R402

1K/1/4W

C04

103/50V

+5

R411

1K/1/4W

+5

R416

1K/1/4W

ALARM

ACN1

SIGA

SCIOA

SCIIA

SCIID

SCIOD

SIGD

ACN1

ACN1

SIGB

SCIOB

SCIIB

SCIIC

SCIOC

SIGC

ACN1

E2 DI

E2 DO

E2 SCK

E2 CS

VA0

VA1

VA2

VA3

VB0

VB1

VB2

VB3

VD3

VD2

VD1

VD0

VC3

VC2

VC1

VC0

AC I

RED

ALARMSELFCHECK

PIPEC T

PIPED TSELFCHECK

VA0

VA1

VA2

VA3

VB0

VB1

VB2

VB3

VC0

VC1

VC2 VC3

E2 CS

VD0

VD1

ZERO

VD2

VD3

SUCT T

PIPEB T

PIPEA T

HEAT T

AIR T

DISCHARGE T

E2 SCK

E2 DO

E2 DI

SCIO

SCII

DC V

AC I

A

B

PDU

PDV

PDW

LED2

PFC

+5

1 16

2 15

3 14

4 13

5 12

6 11

7 10

8 9

IC03

74HC4052

SCIIA

SCIOA

SCIID SCIOD

SCIOB

SCIIB

SCIIC

SCIOC

SCII

SCIO

B

A

+15

+15

R323

100/1/8W

R310

5.1K/1/8W

C303

681/25V

C302

681/25V

C301

681/25V

R320

5.1K/1/8W

R315

5.1K/1/8W

R328

5.1K/1/8W

R326

5.1K/1/8W

R327

5.1K/1/8W

R321

100/1/8W

R322

100/1/8W

R319

5.1K/1/8W

R318

182K/1/8W

R317

182K/1/8W

R316

182K/1/8W

R301

182K/1/8W

R302

182K/1/8W

R303

182K/1/8W

R304

5.1K/1/8W

R305

5.1K/1/8W

R324

100/1/8W

R306

182K/1/8W

R307

182K/1/8W

R308

182K/1/8W

R309

5.1K/1/8W

R311

182K/1/8W

R312

182K/1/8W

R313

182K/1/8W

R314

5.1K/1/8W

5

4

2

312

COM01A

LM339

7

6

1

COM01B

LM339

9

8

14

COM01C

LM339

+5

310V+UV

W

PDU

PDV

PDW

+12

12

RC02

0.1+120/300VAC

12

RC01

0.1+120/300VAC

1

2

CN08

B2P3-VH

+12

+12

+12

+12

RL04

JQ1a-12V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

IC08

TD62003

1

2

3

4

5

CN07

B5P9-CH

RL01

JQ1a-12V

RL02

JQ1a-12V

12

34

RL03

JQ1a-12V

ACL

PTC RELAY

FAN L

FAN M

FAN H

ACN

VALVE

FOUR WAY VALUE

H

M

L

COM

FMC

VALVE

FAN L

FAN M

FAN H

PTC RELAY

16

25

34

K01

BMKG

R01

10K/1/4W

R02

10K/1/4W

R03

10K/1/4W

C05

104/50V

R21

4.7K/1/4W

123456789

CN301

B9B-XH-A

1

2

CN04

B2B-XH-A

1

2

CN01

XH-2

LED02

LED2

R17

1K/1/4W

+5

C

VA11

VA00

VA11

VA00

1

2

3

CN05 +5

C306

104/50V

C10

104/50V

C305

104/50V

AC I

R325

10K/1/8W

C304

104/50V

DC V

1

2

CN06

+12

C

1

2

3

4

CN201

PIPE AB sensor

1

2

3

CN203

suction temp. sensor

1

2

3

CN206

ambient temp.sensor

1

2

3

CN205

discharge temp. sensor

1

2

3

4

CN204

PIPE CD sensor

CR01

16M

A

A

K

K

C

C

E

E

PQ407

TLP521

K

K

A

A

E

E

C

C

PQ408

TLP521

PQ402

TLP521