Service Manual

Table of Contents

1. Range & Conditions..................................................3

2. Specifications..........................................................4

3. Control Specifications...............................................9

4. Dimensional Data...................................................16

5. Performance Charts................................................22

6. Refrigerant Flow Diagram........................................23

7. Circuit Diagram......................................................24

8. Troubleshooting......................................................27

9. Checking Electrical Components...............................31

10. Installation..........................................................33

11. IR Remote Controller.............................................44

Technical Data

1. Range & Conditions

1.1 Operating Range

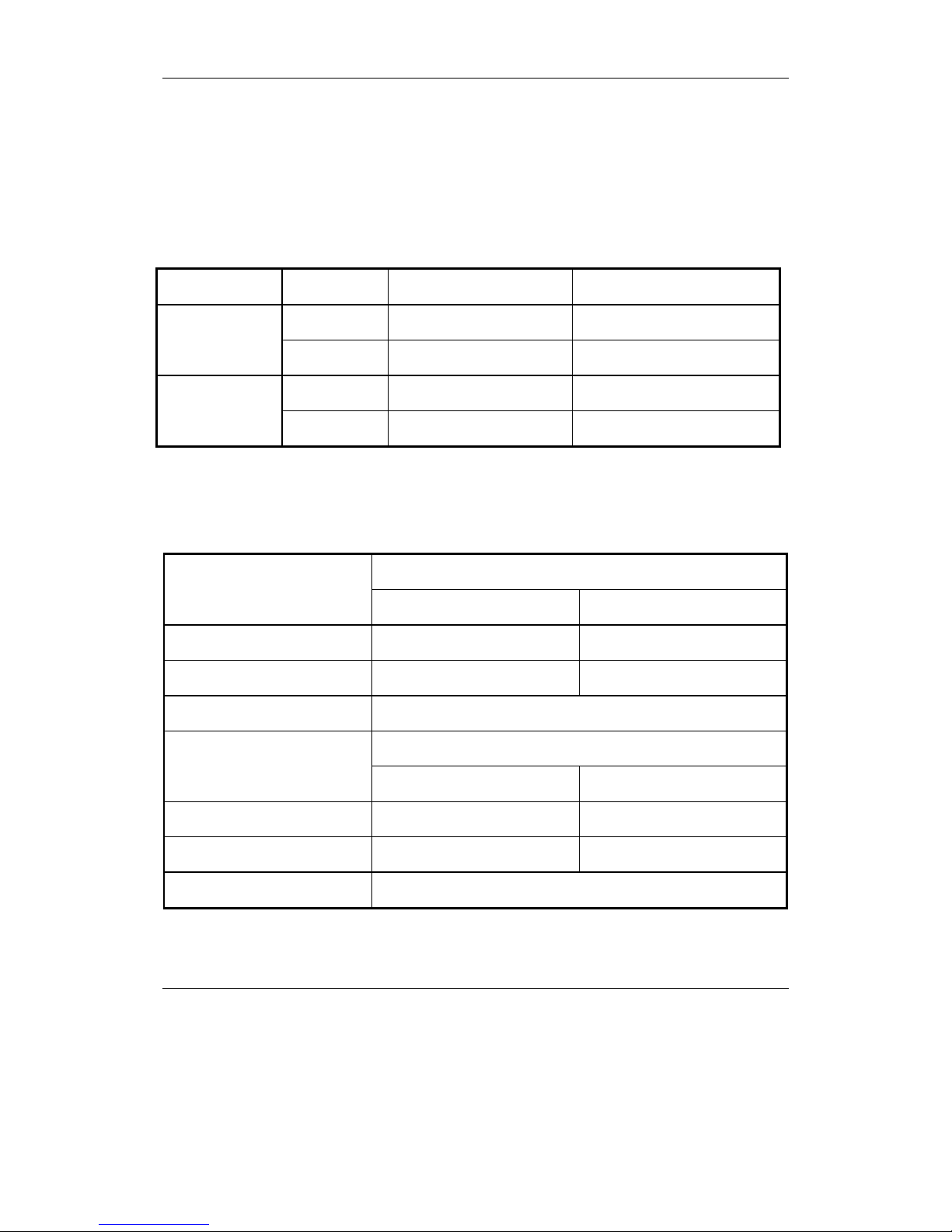

Operating Modes Temperature Indoor Temperature Outdoor Temperature

Max.

32℃ DB/23℃ WB 43℃ DB

Cooling

Min.

21℃ DB/15℃ WB 21℃ DB

Max.

27℃ DB 24℃ DB/18℃ WB

Heating

Min.

5℃ DB -7℃ DB/-8℃ WB

1.2 Operating Conditions

Rated Operating Conditions

Indoor Temperature Outdoor Temperature

Cooling

27℃ DB/19℃ WB 35℃ DB/24℃ WB

Heating

20℃ 7℃ DB/6℃ WB

Tubing Length (m) 4.0

Max. Operating Value

Indoor Temperature Outdoor Temperature

Cooling

32℃ DB/23℃ WB 43℃ DB

Heating

27℃ 24℃ DB/18℃ WB

Tubing Length (m) 4.0

DB: Dry-bulb temperature

WB: Wet-bulb temperature

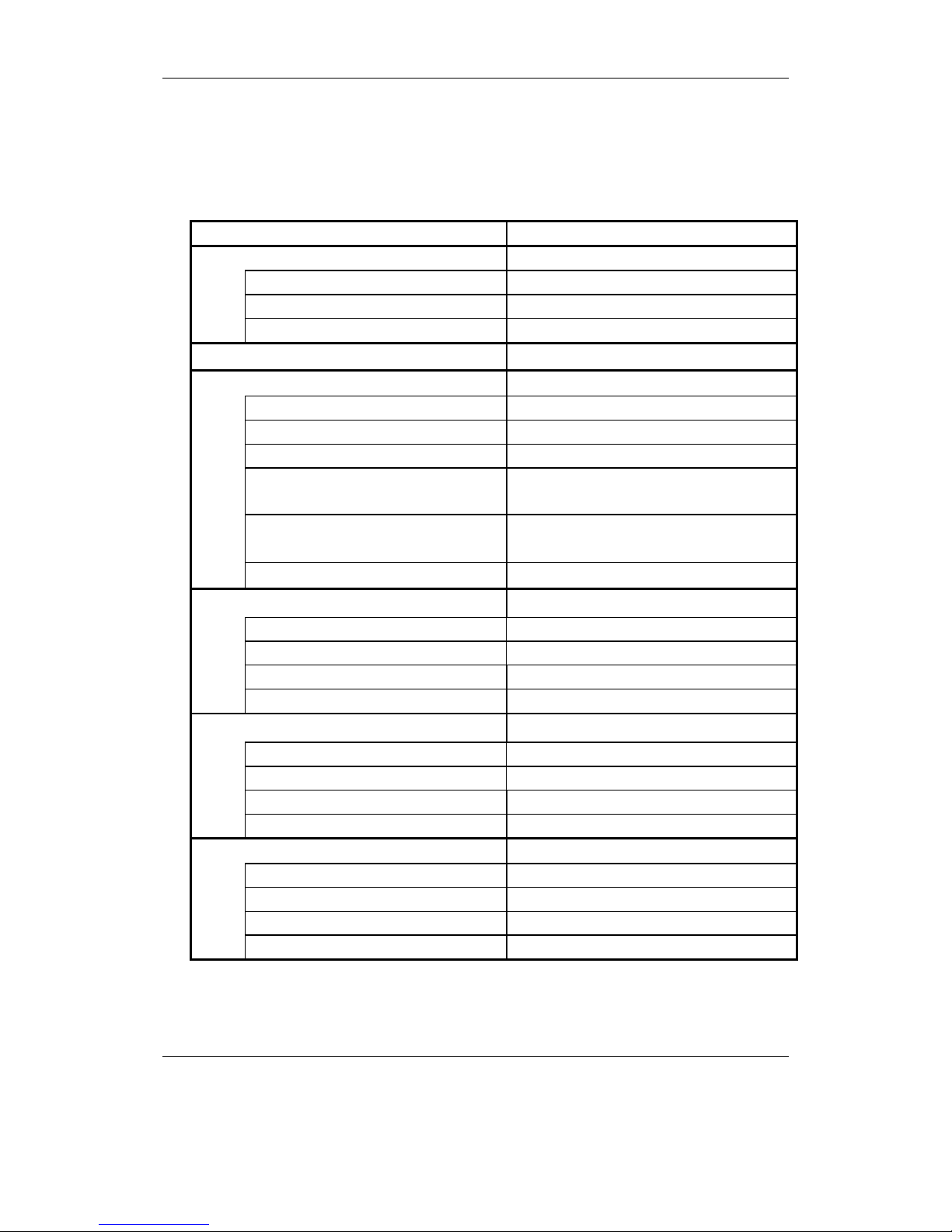

Type

Cooling kW

Heating kW

Cooling kW

Heating kW

kW

COOL

HEAT

Ph-V-Hz

I.U. ~ O.U.

A

A

A

A

n°

Liquid side mm(inch)

Gas side mm(inch)

m

m

Kg

m

g/m

°C

°C

Dimension (W*H*D) mm 918 291 180 918 291 180

Packing (W*H*D) mm 977 357 252 977 357 252

Net/Gross weight Kg

dB(A) 37 35 33 40 38 36

dB(A) 29 27 25 32 30 28

Litres/h

m3/h 430 - - 500 - -

n°

Pa

mm

mm

type

Dimension (W*H*D) mm 786 530 305 786 530 305

Packing (W*H*D) mm 925 617 380 925 617 380

Net/Gross weight Kg

dB(A)

dB(A)

m3/h

Indoor Unit Model

Outdoor Unit Model

Capacity

Input

EER

COP

Annual Consumption (500h/Y)

ENERGY CLASS

Power supply

Current (Cooling)

Current (Heating)

Max. current

Starting current

Wiring cables i.u./o.u. (without ground)

Refrigerant

Refrigerant Pipe

Splitting distance indoor/outdoor

Splitting level difference (out.-ind./ind.-out.)

Refrigerant Precharge

MAX Splitting with Refrigerant Precharge

Additional Refrigerant Charge

Refrigerant Control

Temperature range cooling

Temperature range heating

Indoor unit

Indoor Noise level 1 m (Hi/Mi/Lo)

Indoor Noise level 2,5 m (Hi/Mi/Lo)

Moisture Removal

Indoor air flow (Hi/Mi/Lo)

Fan Speeds

Available static pressure

MAX Drain up (from the bottom of the I.U.)

Drain hose diameter

Remote Controller (st. equipment)

Outdoor unit

Outdoor Noise level 1 m (MAX)

Outdoor Noise level 2,5 m (MAX)

Outdoor Air flow

HKEJ 261 G

HCNJ 261 G

Constant speed

2,60

2,70

0,78

0,73

3,33

3,70

390

A

A

1-220~240V-50HZ

I.U.

4,23

4,22

-

-

4

R410A

6.35(1/4’)

9.52(3/8’)

10

5/5

0,80

5

15

Capillary

+18°C ~ +43°C

-7°C ~ +24°C

11/13,5

1,1

3

-

-

16

Wireless IR

33/37

51

43

1400

HKEJ 351 G

HCNJ 351 G

Constant speed

3,60

4,00

1,12

1,15

3,21

3,48

560

A

B

1-220~240V-50HZ

I.U.

5,31

5,49

-

-

4

R410A

6.35(1/4’)

12.70(1/2’)

10

5/5

1,00

5

15

Capillary

+18°C ~ +43°C

-7°C ~ +24°C

11/13,5

1,5

3

-

-

16

Wireless IR

36/39

54

46

1600

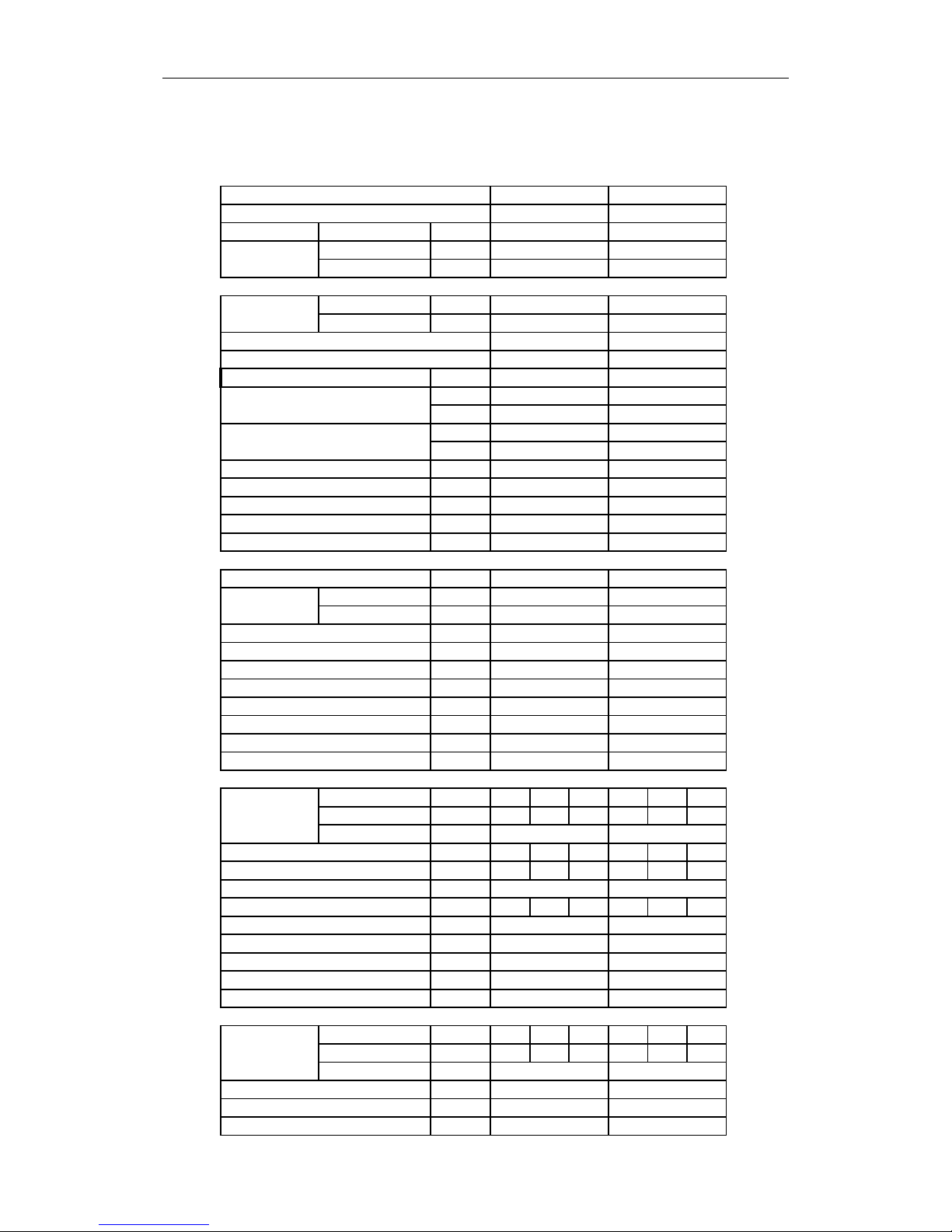

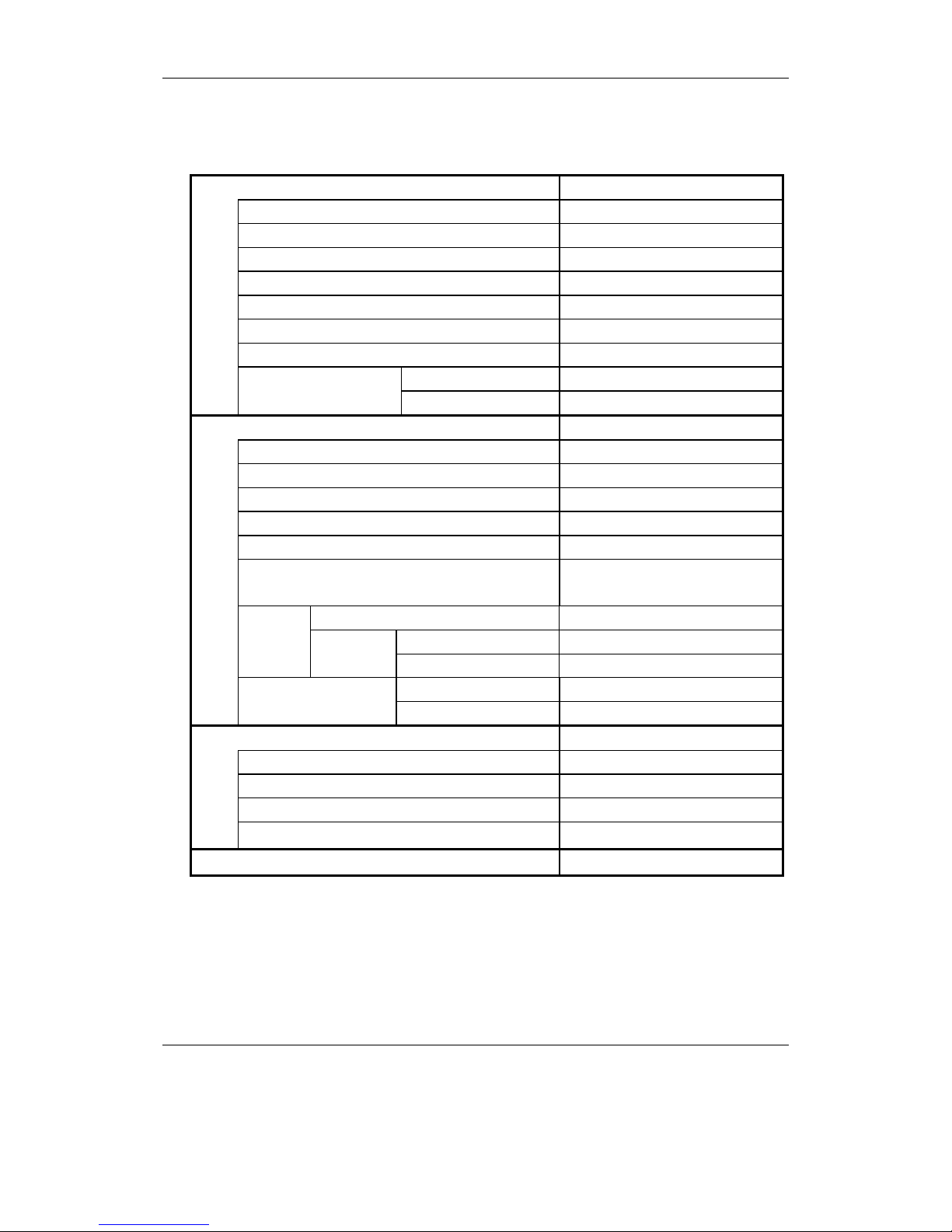

2.2 Specifications of main parts

2.2.1 Indoor unit

Controller

Part No. JUK6.672.512/507/508

Controller Microprocessor

Fuse 250V a.c. / 3.15A/15

Remote controller

KK10A

& Fan motor

Type Cross-flow fan

Quantity / Diameter / Length mm

1/ф86/ 720.5

Fan motor model Wolong: YYW16-4-561

Pole / Rotation of motor

(rpm, 220V High speed)

----

Coil resistance

Ambient temp 20℃ Ω

Wolong: Red-purple: 267.2

purple-White: 494

Fan

Operating capacitor

1μF / 450 VAC

Louver motor

Type Step motor

Model 24BYJ48-FII

Rated voltage (d.c.) V 12

Coil resistance (Ambient temp 25℃) Ω 300Ω±7%

Front panel motor

Type Step motor

Model 35BYJ412B-26

Rated voltage (d.c.) V 12

Coil resistance (Ambient temp 25℃) Ω 200Ω±7%

Heat exchanger

Fin Aluminum fin / Copper tube

Rows 2

Fin pitch mm 1.4

Face area m

2

0.182

Data subject to change without notice

Compressor

Type Rotary(Hermetic)

Compressor model Huarun: C-1RV113H1A

Compressor power input W 800

Compressor oil / Amount CC PVE(FV-68S)/ 350

Overload protector (external) B165-145-241E

Compressor locked rotor amperes A 21.5

Coil resistance (Ambient temp 20℃) Ω

C-R: 3.650 C-S: 5.380

μF

25

Operating capacitor

VAC 450

Fan & Fan motor

Type Propeller fan

Amount / Diameter mm

1/ф400

Fan motor model Welling:YDK17-6G

Pole / Rotation of motor (220V,High speed) rpm 6…720

Rated power output W 20

Coil resistance (Ambient temp 20℃) Ω

White – Gray: 426

Brown–White:214

Type Internal protector

Open ℃ 130±8

Safety

device

Operating

temp

Close ℃ 90±15

μF

2.5

Operating capacitor

VAC 450

Heat exchanger

Fin Aluminum fin / Copper tube

Rows 1.5

Fin pitch mm 1.4

Face area m2 0.375

External coating

Powder-spraying coating

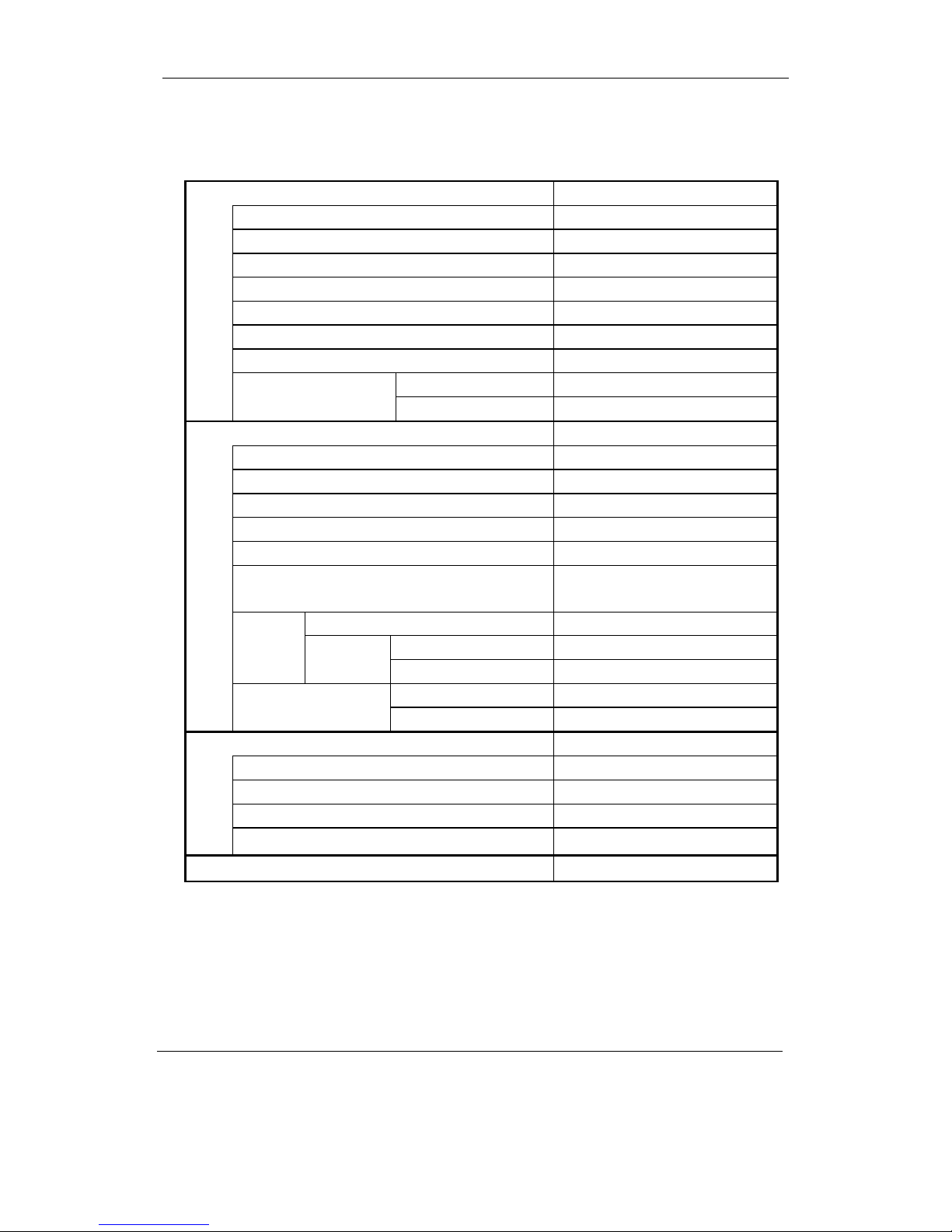

Data subject to change without notice

Compressor

Type Rotary(Hermetic)

Compressor model Huarun: C-RV146H1AB

Compressor power input W 1000

Compressor oil / Amount CC PVE(FV-68S)/ 500

Overload protector (external) B230-150-241E

Compressor locked rotor amperes A 28

Coil resistance (Ambient temp 20℃) Ω

C-R: 2.355 C-S: 5.600

μF

25

Operating capacitor

VAC 450

Fan & Fan motor

Type Propeller fan

Amount / Diameter mm

1/ф400

Fan motor model Welling:YDK40-6H

Pole / Rotation of motor (220V,High speed) rpm 6…880

Rated power output W 40

Coil resistance (Ambient temp 20℃) Ω

White – Gray: 211

Brown–White: 258

Type Internal protector

Open ℃ 130±8

Safety

device

Operating

temp

Close ℃ 90±15

μF

2.5

Operating capacitor

VAC 450

Heat exchanger

Fin Aluminum fin / Copper tube

Rows 2

Fin pitch mm 1.4

Face area m2 0.375

External coating

Powder-spraying coating

Data subject to change without notice

2.3 Specifications of other parts

Indoor unit

Transformer (TR)

DB-08-05B

Thermal resistor

KTM-41-C9(Copper), KTEC-41-C12(Plastic)

Resistance( KΩ)

0℃ 32.97KΩ 10℃ 20.00KΩ

20℃ 12.51KΩ 25℃ 10.00KΩ

30℃ 8.048KΩ

Power relay (PR)

G4A-1A-E 12VDC Or

JQX-102F-012

JZC-43F-012-HS

Coil rated voltage

Coil resistance Ω(20℃)

12V d.c

Ω

12V d.c

Ω

Outdoor unit

Four-way reversing valve

Coil rated value

Coil resistance Ω(20℃)

AC 220V/240 50Hz 6W

1450±10%

Data subject to change without notice

Power supply

JUK6.604.1743

16A/ 250Va.c

3. Control Specifications

3.1 System source

3.1.1 Signal input

Temperature sensor signal (indoor temperature, indoor coiled temperature, outdoor coiled

temperature); remote control signal; emergency switch input; auto diagnosis/ time-shortening input; fan

speed (high/medium/low/breeze) input; (capacity, heating or cooling) input; AC zero p assage;PG feedback.

3.1.2 Signal output

Display signals (SI, SCK, RCK); louver motor (1a, 1b, 1c, 1d); step motor(2a, 2b, 2c, 2d); anion/

Electronic dust collector; ultraviolet,Auxiliary electric heating; PG output; buzzer & buzzer power;

compressor; outdoor fan motor; 4-way reversing valve.

3.2 Control functions

3.2.1 Switches input:

Press on / off button when the air conditioner is in the off mode. The unit turns on and works at 24℃

in AUTO mode automatically. Press this button when the unit is running or in TEST RUN mode, air

conditioner is turned off.

Press the button for four seconds until the buzzer beeps twice. Air conditioner enters the TEST RUN

mode. During the period of test run, the air conditioner is controlled by remote controller. The air conditioner

will start the normal operation automatically if the test running time is for more than 15minutes. Air

conditioner will be stopped and exit the test running mode when users press on / off button which is on the

indoor unit or on the remote controller.

3.2.2 Timing on/off and program control

3.2.2.1 Turn on the air conditioner on timer

The air conditioner will start operation at the set time. “Timing on” function is only effective for one

time in 24 hours. If user turns on the air conditioner by pressing ON/OFF button on the remote controller

before the set time, then “Timing on” function will be cancelled. If user select “Timing on” when the air

conditioner is in on status, the unit will be turned off and it will be turned on at the set time. The original

display of “Timing on” is 12:00.

3.2.2.2 Turn off the air conditioner off timer

The air conditioner will exit running at the set time. “Timing off ” function is only effective for one time

in 24 hours. If user selects “Timing off” function when the air conditioner is in the off status, the unit will be

turned on and it will be turned off at the set time. If user turns off the air conditioner by hand before the set

time, then “Timing off” function will be cancelled. The original display of “Timing off” is 12:00.

3.2.2.3 Program control

The air conditioner will be turned on/off at the set time everyday. If user turns off the air conditioner

by hand before the set time, then “Timing off” function will be cancelled; but “Timing on” function is still

effective. If user turns on the air conditioner by hand before the set time, then “Timing on” function will be

cancelled; but “Timing off” function is still effective.

3.2.3 Temperature control:

There is 3℃ temperature comprehension in HEAT mode. Not available for COOL, AUTO or DRY

modes.

3.2.4 Sleep mode:

Temperature will be adjusted automatically when the sleep mode is set. The set temperature will

increase 1℃ after running 1 hour in Cooling or dehumidifying mode. Temperature will decrease 1℃ after

running 1 hour in heating mode. The set temperature will be controlled between 16℃ and 32℃.

When the air conditioner runs in sleep mode, the Max. indoor fan speed is set at medium level.

Indoor fan motor will stop running after stopping the compressor for 30 seconds. (In cool mode, indoor fan

motor will not stop).

3.2.5 The front panel

The front panel will be opened either the air conditioner is started running or air refres h function is

started; or it will be closed.

Indoor fan motor will be started running only the front panel is opened completely.

3.3 Operating mode

3.3.1 Auto-operating mode: (not available for cooling-only type air conditioner)

When air conditioner stars running or the set temperature is adjusted under this mode, Master

controller can select running mode (cooling or heating) automatically by the D-value between indoor

temperature and set temperature. It runs in cooling mode when Tr≥Ts (Tr: Room temperature, Ts: Set

temperature) and in heating mode when Tr<Ts.

In heating mode, When Tr≥Ts+3℃ lasts for 15 minutes. It turns into cooling mode.

In cooling mode, when Tr≤Ts-2℃ lasts for 15 minutes. It turns into heating mode.

When Ts-2℃< Tr < Ts+3℃, it keeps original operating mode.

Temperature control range: 16℃-32℃; Original value: 24℃;

Temperature control precision: ±1℃;

3.3.2.Cooling:

Temperature control range: 16℃-32℃; Original value: 24℃;

Temperature control precision: ±1℃;

Characters on control:

4-way reversing valve closes:

When Tr≥Ts+1℃, compressor runs; When Tr≤Ts-1℃, compressor stops; The control circuit will

stop compressor only after it has run at least 5 minutes. The compressor can be restarted 3 minutes later

the turn-off.

Fan speed control:

Auto: When Tr>Ts+2℃, high speed;

When T s+1℃≤Tr<T s+2℃, medium speed;

When Tr< Ts+1℃, low speed.

Manual: Users can select the fan speed of high, medium or low level as n e eded when the air conditioner is

1

2

3

5

4

Fig.1

6

in the turn-on status.

Louver adjustment:

Manual (vertical direction): Set the blades position as needed. (Position 1-6 in figure 1.)

Auto (vertical direction): The range of sweeping is in position 2-5.

3.3.3. Dehumidification:

Temperature control range: 16℃-32℃; Temperature control precision: ±1℃;

Characters on control:

4-way reversing valve closes.

When Tr≥Ts+2℃,the running mode is the same to the cooling operation;

When Ts-1℃< Tr < Ts+2℃, compressor and outdoor fan motor run continuously. And indoor fan

motor runs at low fan speed

When 15℃< Tr < Ts-1℃, compressor and outdoor fan motor are working according to 3 minutes

working alternating with 9 minutes stopping. Indoor fan motor runs at low fan speed when compressor is

running, and it runs at breeze level for 30 seconds later the turn-off of compressor. 30 seconds later, fan

motor will turn off.

When Tr≤15℃, indoor and outdoor fan motor will stop running, louver blades (vertical direction)

can’t be controlled.

Louver adjustment (vertical direction): The range of sweeping is in position 2-5.

3.3.4. Heating (not available for cooling-only type air conditioner)

Temperature control range: 16℃-32℃; Original value: 24℃;

Temperature control precision: ±1℃;

Characters on control:

4-way reversing valve opens.

When Tr≤Ts-1℃, compressor, 4-way reversing valve and outdoor fan motor all open.

When Tr≥Ts+1℃, compressor and outdoor fan motor both close; Indoor fan motor is running at

breeze. When Trc (Trc: The indoor coiled temperature) <F℃ , the air conditioner will enter into

cool-airflow-prevention operation, the PAUSE indicator will light.

Indoor Fan motor control:

Manual: Users can select the fan speed of high, medium or low level as needed.

Auto: When Tr< Ts-2℃, high speed; When Tr≥Ts-2℃,medium speed;

Louver adjustment:

Manual (vertical direction): Set the blades position as needed. (Position 1-6 in figure 1.)

Auto (vertical direction): The range of sweeping is in position 1-4.

Compressor control:

The control circuit will stop compressor only after it has run at least 5 minutes. Compressor can be

restarted 5 minutes later the turn-off.

3.3.5. Sweep Mode

In sweep mode, compressor, 4-way reversing valve and outdoor fan motor are all stops;

Indoor fan motor can be adjusted at high, medium low speed and breeze.

Louver adjustment:

Manual: Users can set the position as needed. (Positions 1-6 in figure 1)

Auto: The range of sweeping is in position 1-5.

3.4 Protection function

3.4.1 Delay-starting protection for the compressor

Compress will restart working 3 minutes(5 minutes in HEAT mode) later the turn-of f of compressor or

power-off to keep the pressure balance of the cooling system.

3.4.2 Freeze-prevention: To prevent indoor heat exchanger freezing in COOL and DRY

operation.

When Trc≤3℃ for 2 minutes, the air conditioner will enter into freeze-prevention operation. If

indoor fan speed is at low or breeze level, it will turn to medium speed automatically; if indoor fan speed is

at medium speed, it will turn to high speed;, The air conditioner will exit Freeze-prevention op eration when

Trc>8℃, indoor fan motor runs at the set fan speed. Compressor will stop running when it runs at least 10

minutes and Trc≤-2℃. If the off-time of compressor is for more than 6 minutes or Trc≥8℃, and the

compressor stops running for more than 3 minutes. Compressor and outdoor fan motor will restart working.

The air conditioner will exit Freeze-prevention operation, and indoor fan motor is running at the set speed.

3.4.3 Cooling overload working: To prevent the temperature of indoor heat

exchanger is too high (not available for cooling-only type air conditioner)

When Toc≥60℃, the air conditioner will enters into cooling overload protection, and indoor fan

speed will drop a gear. When Toc≥75℃, compressor will stop, indoor fan motor goes on running. When

Toc≤55℃ and the time of indoor fan exchange is for more than 5 minutes, the air c onditioner will exit

cooling overload protection; indoor fan motor and compressor will restore normal operation.(compressor

has a delay protection function)

3.4.4 Cool-airflow-prevention: (not available for cooling-only type air conditioner)

In heating operation, if Trc<F℃, and the running time of compressor is for less than 5 minutes, air

conditioner stays in the cool-airflow prevention, Louver blades will move to position 6 and can’t be

controlled; Indoor fan motor will stop and PAUSE (red) indicator will light.

3.4.5 Heating overload working: (not available for cooling-only type air conditioner)

When Trc≥A℃, the unit enters into heating overload protection. If indoor fan speed is set at lo w or

breeze level, it will turn to medium speed automatically; if indoor fan speed is set at medium speed, it will

turn to high speed; When Trc≥B℃, outdoor fan motor stops. When Trc≤D℃, outdoor fan motor will restart

working. Air conditioner will exit overload protection when Trc drops blow E℃, compressor restarts working,

Indoor fan motor runs at the set fan speed.

When Trc≥C℃and the build-up time of compressor running is for more than 5 minutes, compressor

will be stopped.

3.4.6 Defrosting: (not available for cooling-only type air conditioner)

3.4.6.1 Defrost entry conditions

After the compressor running for more than 10 minutes.

A. Indoor unit enters into overload prevention and outdoor unit stops. When outdoor fan motor runs for more

than 10 minutes, and the build-up time of compressor running is for more than 50 minutes, Trc≤A-1℃

and Toc≤-2℃( Toc: The outdoor coil temperature.)

B. Not overload, but Toc≤-17℃ for 30 seconds. The build- up time of compressor runnin g is for more than

25 minutes.

C. The build-up time of compressor running is for more than 3 hours. And Toc≤-2℃ for 5 minutes. Trc≤

G-2℃ and Trc≤(Tr+H)℃.

D. The build-up time of compressor running is for more than 3 / 2 hours. And it reaches the condition of the

unit stopping. Toc drops blow -2℃ for 3 minutes(overload).or Toc≤ -2℃ and Trc≤G+2℃ (not

overload).

E. The build-up time of compressor running is for more than 50minutes.Toc ≤-2℃, Trc drops at least 3℃

and Trc≤G℃, Trc≤(Tr+H) ℃.

F. Toc ≤-2℃, the temperature decreases 1℃ every 6 minutes (repeat for 3 times). The build-up running

time is for more than 25 minutes.

The air conditioner will defrost only one of the conditions is meet.

3.4.6.2 Defrosting:

Compressor, indoor and outdoor fan motor will stop working after the unit entering into defrost running.

55 seconds later, 4-way reversing valve will close. Another 5 seconds, compressor starts running. When the

time of the compressor running is for more than 10 minutes or Toc≥20℃, and defrosting time is for more

than 3 minutes, Compressor stops. 55 seconds later, 4-way reversing valve will open. Another 5 seconds

later, compressor and outdoor fan motor will restart working and exit defrosting operation. In defrosting

operation, the time of compressor running is at least 3 minutes. Cool-airflow-prevention and blow ing residue

heat are both efficient.

3.4.7 Testing codes

code 1: to set test run; code 2: to set fast testing;

code 3: to set auto-diagnosis; code 4: to cancel the above setting;

3.4.8 Temperature and failure code display

The defining of code refers to the following:

Code 11: room temperature code 12: indoor coil pipe temperature

Code 13: outdoor coil pipe temperature code 14: abnormal information

E0: Normal operation P1: Cooling overload

P2: Heating overload F4: PG motor is abnormal

F1: The circuit of room temperature sensor is damaged or abnormal

F2: The circuit of indoor coiled temperature sensor is damaged or abnormal

F3: The circuit of outdoor coiled temperature sensor is damaged or abnormal

When temperature sensor or PG motor is damaged or abnormal, RUN indicator will flash.

3.5 Other functions

3.5.1 Auto-diagnosis

Test terminal on the main panel is shorted. The Auto-diagnosis functions are in the following steps

when the power is turned on.

Buzzer beeps 1s →Runni ng indicator on 0.5s →Pause indicator on 0.5 s → Timer indicator on

0.5s →air refresh indicator on 0.5s →breeze indicator on 0.5s→low fan speed indicator on 0.5s →medium

fan speed indicator on 0.5s →high fan speed indicator on 0.5s →air refres h indicator on 0.5s →ultraviolet

indicator on 0.5s →auxiliar y electric heating indicator on 0.5s →step motor for louver(1a,1b,1c,1d)on 0.5s

→step motor for front panel(2a,2b,2c,2d)on 0.5s→ 4-way reversing valve 0.5s→Outdoor fan motor run

0.5s → compressor run 0.5s→ no output for 0.5s→ all signal output for 1s→ Buzzer beeps 1s

During the period of auto-diagnosis, LED display “11,22,33,44,55,66,77,88,99,00” circularly, and

each display for 0.5s. Indoor fan motor runs at medium fan speed.

During the period of auto-diagnosis, buzzer will keep beep if temperature sensor is abnormal.

3.5.2 Timer saving:

The time-shortening terminal on the main panel is shorted when the unit is powered on. The buzzer

beeps twice and the master controller CPU run as 61 times as the former speed.

3.5.3 Auxiliary electric heating: (not available for cooling-only type air conditioner)

The starting conditions of auxiliary electric heating:

A. Received the signal for remote controller to start this function;

B. Air conditioner runs in heat mode;

C. Compressor runs for more than 1 minute.

D. Tr≤14℃.

E. Ts-Tr≥6℃

F. Indoor fan runs at high or medium fan speed.

Auxiliary electric heating will be closed under the one of the following conditions.

A. Tr≥18℃;

B. Ts-Tr≤2℃;

C. Trc≥A-2℃;

D. Indoor fan runs at low or breeze fan speed;

E. Defrost operation;

F. Received the signal for remote controller to stop this function;

3.5.4 LCD display

The LCD doesn’t display symbols if air conditioner is in off status. Timer indicator will light if ON

TIMER function set before. The LCD will display the set temperature and running mode when air

conditioner is running but air refresh doesn’t functioned. And it will display index of air refresh when air

conditioner and air refresh are running. The index will display “6” if air refresh runs for more than 50 minutes;

“7” for 2 hours running; “8” for 3 hours running; and “9” for 4 hours running. T his index range is 1~9. if set

temperature is changed during the period of air refresh, the LCD will display the set temperature for 1

minutes, and then return to display the index of air refresh. LCD will not display the index if air refresh

function is stopped running. Only run indicator lights If SLEEP function is set for 30 seconds later; and it will

display all setting if remote control signal is received.

3.5.5 Air refresh function

Press air refresh button when the unit doesn’t run, air refresh and run indicators will light (display the

index of air refresh), air conditioner will be turned on and runs at the set fan speed; in ion mode, anio n are

working according to 10 minutes working alternating with 5 minutes stopping. When air refresh function is

turned off, the unit will turn back to the original mode. Press air refresh button if Air conditioner is runnin g,

air refresh will be functioned and the indicator will light too.

3.5.6 Quiet Operation

Press quiet button when air conditioner is in SWEEP mode, the indoor fan will run at breeze;

Press air refresh button if air conditioner doesn’t run, the indoor fan will run at breeze if the setting fan

speed is breeze.

Quiet function is not effective for other status.

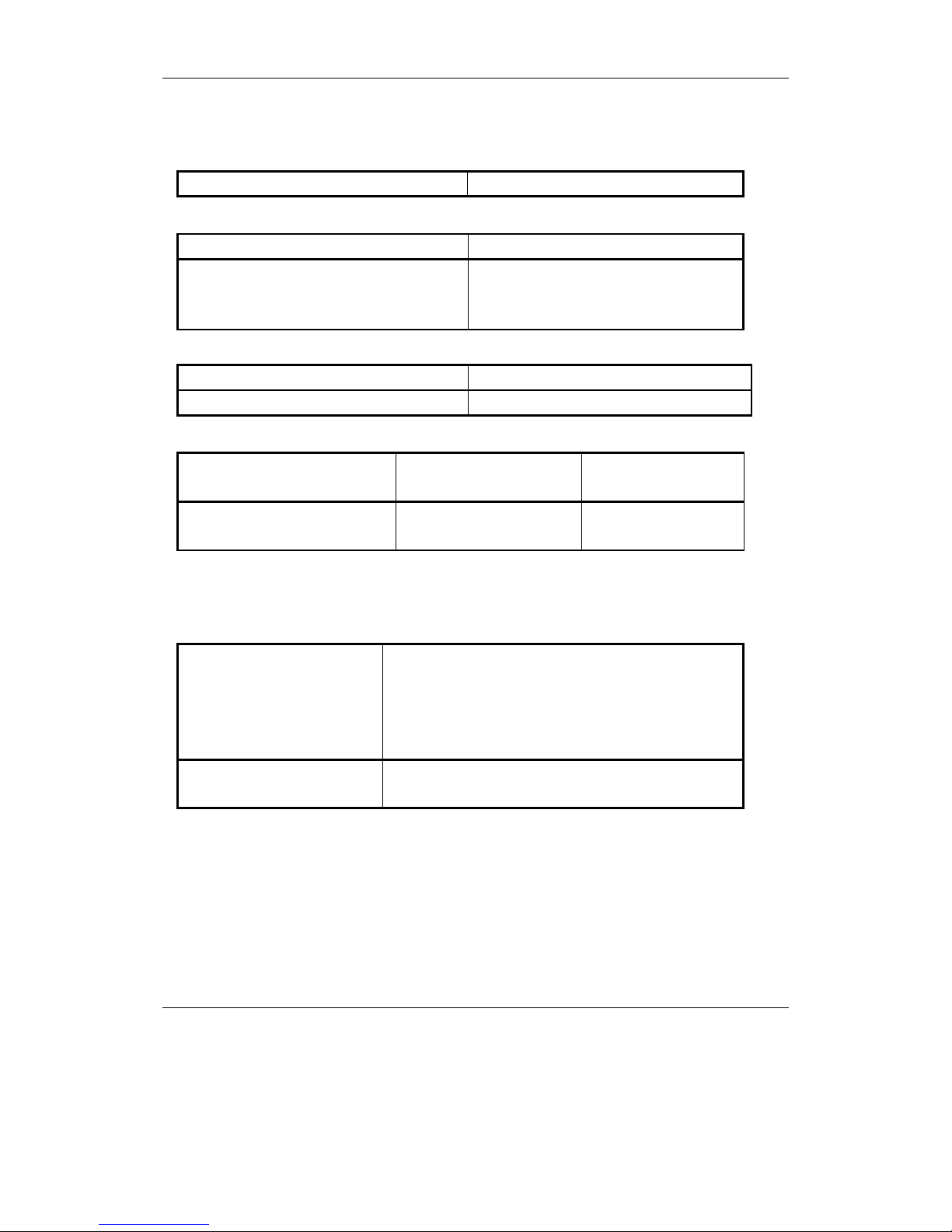

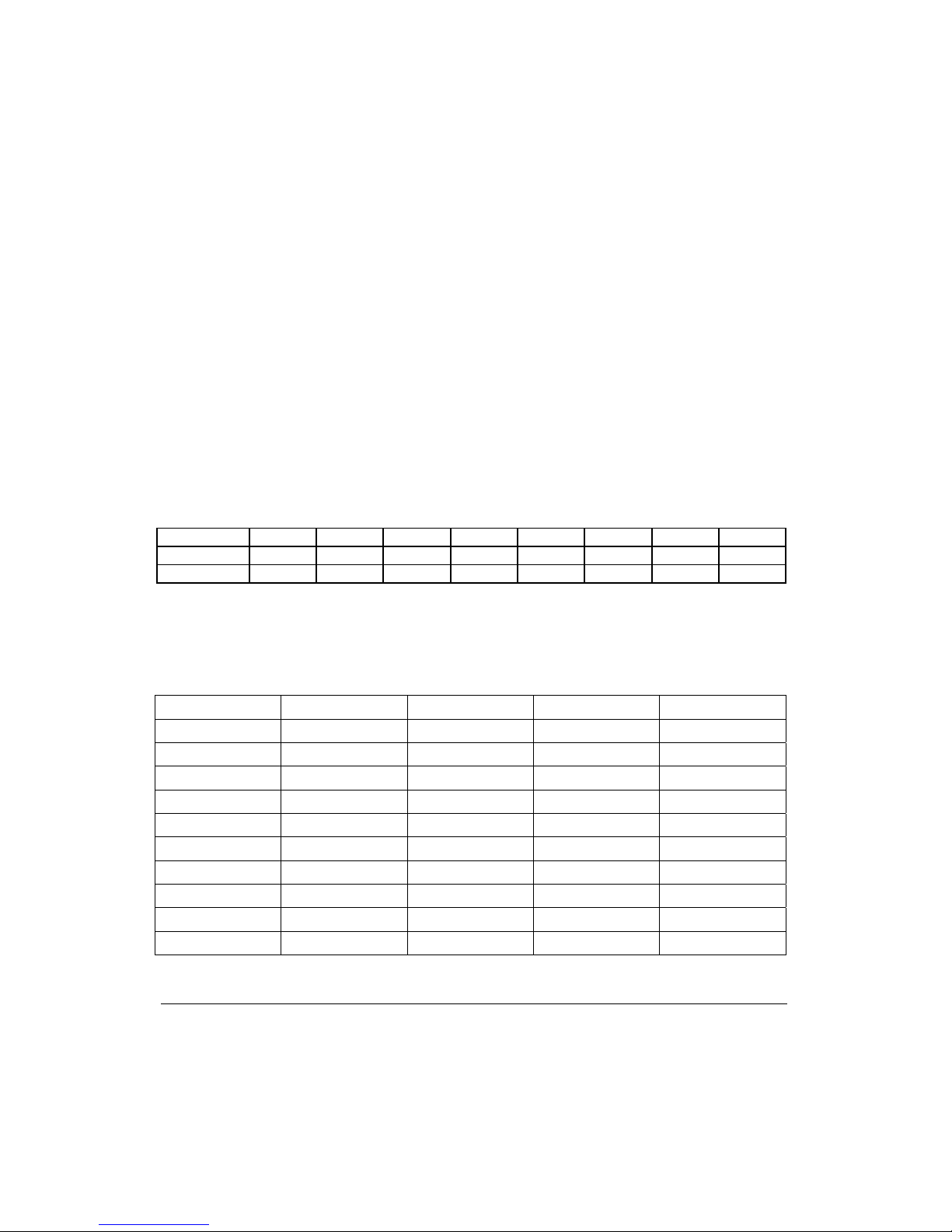

3.6 Parameter table

Temperature table of protecting point

The type of remote controller for heat-pump air conditioner is KK10A.

The type of remote controller for cooling-only air conditioner is KK9B.

Fan motor rotation

Voltage High fan speed Medium fan speed Low fan speed Breeze

0.5 1080 980 880 760

1.0 1110 1010 910 770

1.5 1140 1040 940 780

2.0 1170 1070 970 790

2.5 1200 1100 1000 800

3.0 1230 1130 1030 810

3.5 1260 1160 1060 820

4.0 1290 1190 1090 830

4.5 1320 1220 1120 840

5.0 1350 1250 1150 850

Model

A

B C D E F G H

HKEJ 261 G 49 52 65 44 42 32 39 22

HKEJ 351 G 54 57 70 48 46 34 43 26

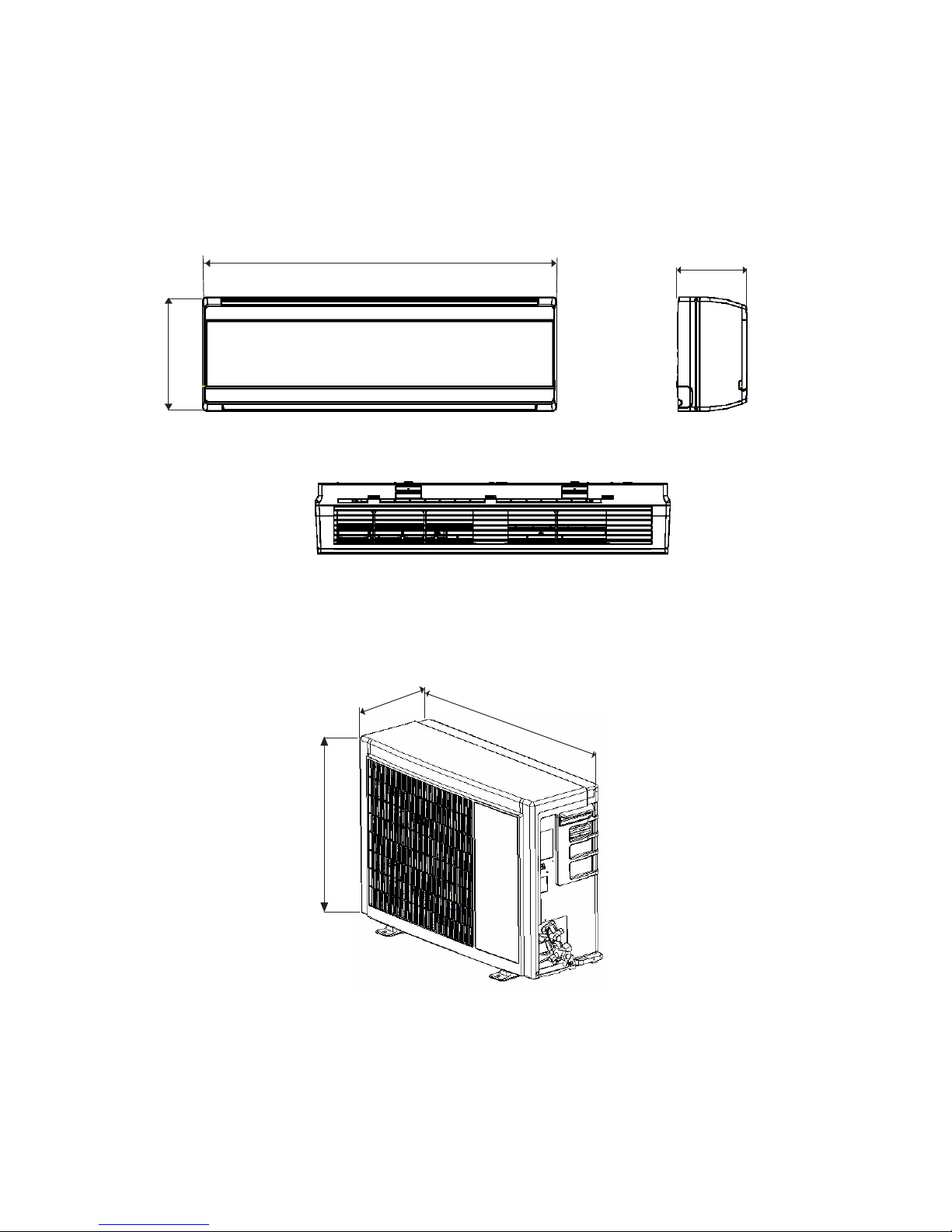

4. Dimensional data

Indoor Unit

Outdoor Unit

918

291

180

786

305

530

Unit: mm

The above figures are only schematic, and they may be slightly different from

the actual appliance you bought.

Monosplit ON/OFF models:

HCNJ 261 G, 351 G

Outdoor Unit

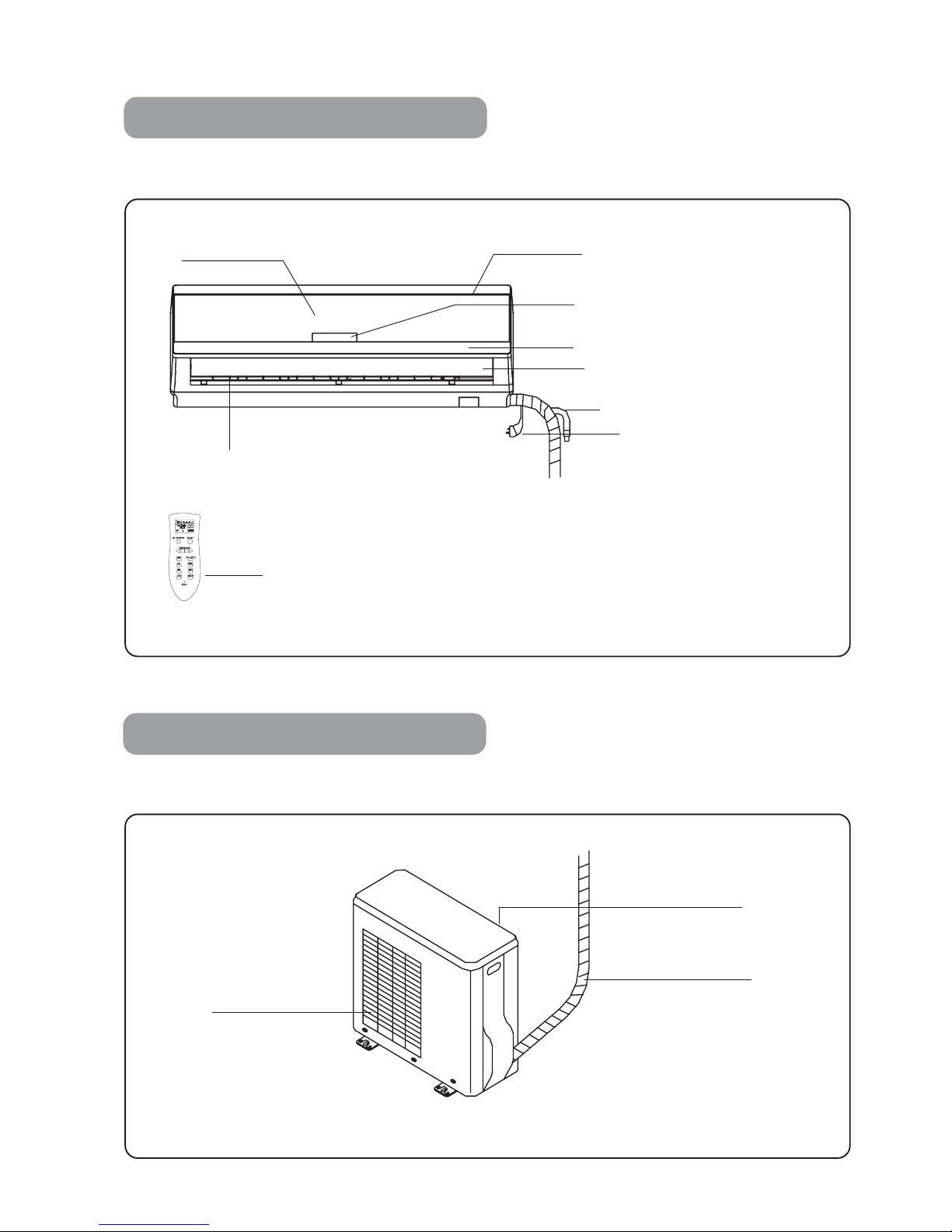

OUTLINE OF PARTS AND FUNCTIONS

Indoor Unit

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

NOTE: The figure above is for explanation purpose only; the actual appliance may be slightly different.

NOTE: The figure above is for explanation purpose only; the actual appliance may be slightly different.

Power cord

Condensate drain hose

Motorized horizontal flap

Remote controller receiver and Display

Air inlet

Vertical louvers

(manual adjusting)

Front panel

Decorated board (removable)

Infrared remote controller

Refrigerant piping

and electrical wiring

Air inlet

(sideways and rear)

Air outlet

LED display panel on the Indoor Unit

OUTLINE OF PARTS AND FUNCTIONS

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

Front panel

Air filter

Decorated board

Motorized flap

(for vertical distribution)

Manual louvers

(for horizontal distribution)

"PAUSE" Indicator

"RUN" Indicator

It lights up to indicate that the

unit is operating:

AUTO (Automatic)

HEAT (Heating)

COOL (Cooling)

SWEEP (Fan only)

DRY (Dehumidifying).

It lights up during automatic

defrosting, or when the preheating function for the indoor

heat exchanger is active (i.e.

when operation in Heating

mode starts).

ON/OFF Switch

For emergency operation in AUTO mode (if

the remote controller

is not available). Press

it again to stop the

unit.

"TIMER" Indicator

It lights up to indicate

that the unit's operation

has been programmed

by the Timer.

"AIR REFRESH" Indicator

It refers to a function which

is unavailable on these models.

Set temperature display

The desired temperature value is

displayed, as set by the User

through the infrared remote

controller.

Current indoor fan speed setting indicator

Indoor fan is set at "HIGH" speed

Indoor fan is set at "MEDIUM" speed

Indoor fan is set at "LOW" speed

NOTES:

If the current indoor fan speed setting indicator is flashing, this means that

"AUTO" fan speed has been selected.

1. Do not put fingers or sticks into the air inlet or air outlet of the indoor unit.

2. Touching the indoor fan which rotates at high speed, may result in serious injuries. Moreover the

aluminium fins on the heat echanger are sharp-edged. As a consequence, particular attention must

be observed when the front panel of the indoor unit has been opened for maintenance or air filters

cleaning. It is strongly adviced to switch off the main power line and wait some minutes before

carrying on the inspection work.

3. If the "RUN" indicator flashes, this means that a malfunction has occurred. In such cases, it is

required to contact a Service Agent.

NO. NAME CODE

1 Pressure plate for tube

2 Electrical motor lid

3 Fan electromotor

4 Flap motor

5 Flap

6 Crank shaft

7 Connecting bar

8 Media frame

9 Electric control assembly

10 Electric control cover

11 Air filter (right side)

12 Front panel assembly

13 Display window assembly

14 Decorative slat

15 Air filter (left side)

16

NM-potocatalyst deodorant

net

17 Cover for step motor

18 Step motor

19 Air guiding frame assembly

20 Axile bush

21 Fan

22 Supporter (left side)

23 Evaporator assembly

24 Real panel assembly

25 Installation board

26

27

28

6. Refrigerant Flow Diagram

Thermal insulating of refrigerant pipeline

To prevent heat loss and condensed water from dropping on the floor, the wide and narrow tube of

air conditioner should be wrapped with thermal insulating materials. For using capillary tube, and the

tubes are in low temperature, the thickness of thermal insulating materials shall be more than 8 mm.

Narrow tube

Ф6.35 mm(1/4”)

Ф9.52 mm(3/8”)

Wide tube

Ф12.7 mm(1/2”)

7. Circuit Diagram

7.1 Electrical wiring diagram for outdoor unit

To avoid electrical shock hazard, be sure to disconnect power before

checking, servicing and/or cleaning any electrical parts.

Warning

7.2 Electrical wiring diagram for indoor unit

To avoid electrical shock hazard, be sure to disconnect power before

checking, servicing and/or cleaning any electrical parts.

Warning

7.3 Electrical Schematic wiring diagram

8. Troubleshooting

8.1 Check before troubleshooting

8.1.1 Check power line

To check whether the power line is connected correctly to the terminal No 1 which is on the

terminal block of the indoor unit

8.1.2 Check unit wiring

To check whether the inter-unit wires are connected correctly in accordance with the wiring

diagram.

8.1.3 Check power supply

To check whether the power supply is in the specified range (220±10%).

To check whether the power supply is being supplied.

8.1.4 Check connector and lead wire of indoor and outdoor units.

To check whether the insulating cover of the lead wire is damaged.

To check whether the lead wire and the connector are connected well

High-voltage will result in electric shock or death.

Always cut off the power before checking and maintaining.

Warning:

To check wires.

8.1.5 Poor cooling or heating phenomena.

Poor cooling

(heating)

performance

Is the temperature

set properly?

Change the set temperature.

The heating (cooling)

load is too large.

Reduce heat (cool) source or change

the air conditioner with large power.

Refrigerant

flow is not

enough

Refrigerant is not enough.

Filling it

Capillary tube is blocked.

Replace it.

Compressor is in error.

Replace it.

Service valve is not open

completely.

Open it

completely.

Air circulating

capacity is

not enough.

The air filter is blocked.

Clean it.

4-way reversing valve fails.

Replace it

Fan running speed

is at “low”.

Change it to “high’ or

“medium”.

Connection between indoor

and outdoor units is in poor

thermal-insulated.

Wide and narrow tubes

are thermal-insulated

separately.

Cooling air -flow

4-way reversing valve is defective.

Replace it

Cooling airflow

protector is no use.

The pause indicator is on.

Replace the electric

controller of indoor unit.

Temperature sensor of

indoor coil is defective.

Replace the sensor.

No

Yes

8.1.6 Compressor does not run.

8.1.7 Only outdoor fan motor does not run.

8.2 Electrical Troubleshooting

8.2.1 Check before or after repairing the units.

8.2.1.1 Check whether the connection of the units is in good condition.

8.2.1.2 Check whether the connection of the units is in good condition.

8.2.1.3 Check whether the lead wire and connector of the units are in good condition.

8.2.1.4 Check power circuit.

8.2.2 The air conditioner do not run

8.2.2.1 Check the switch power.

① Without 30V DC output from two ends of the capacitor C405 (the indicator does not light).

A. Check 240V power supply, power socket → power cord → fuse(3.15A /220V) → high voltage

capacitor C410 (whether there is 280 ~ 300V DC or not)

B. Check the capacitor C405

Check the relay of the compressor

motor for normality.

Check the winding resistor of the

compressor.

Replace the compressor.

Replace the relay

Yes

Abnormal

Check the fan rotation Check if foreign matter is in

the fan cover.

Check if fan motor is broken

or foreign matter in bearing.

Measure the resistance of motor coil.

Check the capacitor of the fan motor.

Ok

Ok

C. Check the switch transformer for sounding. If the transformer sounds, remove the load on the power

supplies of 30V DC and 12V DG. If still without 30V DC output after removal, then the switch power is

defective. If with 30V DC output, the load is short – circuited but the switch power is good. Then check

the secondary load circuit.

D. Check D 401, D402, C408 and D403 for PWM (66KHz) output.

E. Check VD405 and VD406 for breakdown.

② With voltage output (much different from 30V DC)from two ends of the capacitor C405 (the indicator

lights).

A. Remove the power load.

B. If without 30V DC output but with stable voltage, check R401 and R403.

8.2.2.2 Power supply is OK.

① Check the power supply connected to D300 (MCU) for normality.

② Check whether the toggle switch (XS310) buzzes when the switch inputs.

③ The sensor gives an alarm.

④ Over-current alarms (check the switch power for correct installation and check the compressor current

detector.)

8.2.3 The indoor fan does not run.

Check the fan for being in protection.

8.2.4 the louver motor does not run or runs improperly.

8.2.4.1 Check the power supply 12V.

8.2.4.2 Check the motor for being in protection.

8.2.4.3 Check the PCB (XS301 and D300) for welding loosely or welding jointly.

8.2.4.4 Replace the step motor.

8.2.5 Sensor alarm, units stop.

8.2.5.1 Check the 5V power supply.

8.2.5.2 Check PCBs for welding loosely.

8.2.5.3 Check the sensor for being damaged.

8.2.6 The outdoor compressor, fan and four-way valve do not run.

8.2.6.1 Check input and output of relay K301 for fan. Check input and output of relay K302 for four-way

valve.

8.2.6.2 Check input and output of relay K303 for compressor.

8.2.6.3 Check 12V power supply.

8.2.6.4 Check the connection wiring.

8.2.6.5 Check the relay and start - up capacitor.

8.2.6.6 Check whether the compressor, fan and four – way valve are in good condition.

8.2.7 No signal, indicators does not light.

8.2.7.1 Check the remote control for being damaged or the batteries for being exhausted.

8.2.7.2 check for obstacles between the unit and remote controller.

8.2.7.3 Check C305 on the indicator and 5V power supply.

8.2.7.4 Check IC10,D20 and D30 on the indicator.

8.2.7.5 Check the connection wire.

8.2.8 The switch board is defective.

8.2.8.1 Check the toggle switch and 5V power supply.

8.2.8.2 Check the connection wire.

9. Checking Electrical Components

9.1 Measure insulation resistance

The insulation is in good condition if the resistance

exceeds 2 MΩ.

9.1.1 Power supply wires

Clamp the ground pins of the power plug with the lead clip

of the insulation resistance tester and measure the

resistance by placing a probe on either of the power wires.

(Fig. 1)

Then measure the resistance between the

ground wire and the other power wire. (Fig. 1)

9.1.2 Indoor unit

Clamp an aluminum plate fin or copper tube with the lead

clip of the insulation resistance tester and measure the

resistance by placing a probe on each terminal screw on the terminal plate. (Fig. 2)

Note that the ground line terminal should be skipped for the check.

9.1.3 Outdoor unit

Clamp a metallic part of the unit with the lead

clip of the insulation resistance tester and

measure the resistance by placing a probe on each terminal

screw where power supply lines are connected on the

terminal plate. (Fig. 2)

9.1.4 Measurement of Insulation Resistance for Electrical Parts

Disconnect the lead wires of the desired electric part from terminal plate. Capacitor, etc.

Similarly disconnect the connector. Then measure the insulation

resistance. (Fig. 3 and 4)

9.2 Checking continuity of fuse on PCB ass”y

Remove the PCB ass’ y from the electrical component box. Then

pull out the fuse from the PCB ass’ y. (Fig. 5)

Check for continuity using a multimeter as shown in Fig. 6

9.3 Checking motor capacitor

Remove the lead wires from the capacitor terminals, and then

place a probe on the capacitor terminals as shown in Fig. 7.

Observe the deflection of the pointer setting the resistance

measuring range of the multimeter to the maximum value.

The capacitor is “good” if the pointer bounces to a great extent

and then gradually returns to its original position.

The range of deflection and deflection time differ according to

the capacity of the capacitor.

Refer to electric wiring diagram.

If the probe can’ t enter the p oles because

the hole is too narrow then use a probe with

a thinner pin.

Note:

INSTALLATION INSTRUCTION FOR SPLIT TYPE AIR CONDITIONER

Model: HKEJ- HCNJ 261 G - HKEJ - HCNJ 351 G

INSTALLATION GUIDE

• This air conditioner needs standard safety and operation promulgated by the Nation.

• You need to invite professional air conditioner service and maintenance personnel to

install or remove the air conditioner. Problems may occur and you may suffer losses if

non-professional install the air conditioner.

• User shall provide the power that meets installation and operation and requirements.

The voltage for this product is 198-253V~. Voltage exceeding this scope will affect the

normal operation of the air conditioner.

• Separate line that is installed with delay fuse protector or automatic breaker should

be used for the air conditioner.

• The air conditioner must be correctly and reliably grounded, or it may cause electric

shock or fire.

• Do not connect the power of the air conditioner before well connecting and carefully

checking the tubing and wires.

• The appliance shall not be installed in laundry or bathroom.

• The air conditioner can be connected only to a supply with system impedance no

more than 0.35 ohm (0.16 ohm for HKEJ-HCNJ 351 G). If necessary, please consult

your supply authority for system impedance information.

• The instruction is subject to change without notice.

INSTALLATION OF ACCESSORIES

• Examine carefully the attached packing list and check whether the accessories are

complete.

• Users may need to buy at their own expenses the articles not included in the packing

list and may be needed in installing.

10. Installation

Fig.12

CONNECTION OF WIRES

1. Indoor Unit

• Push the decorated board downward and move it away,

open the front panel by pushing it upward.

• Detach the electric control cover and pressure plate of

lead wire.

• Connect the connecting wires of the unit separately to

the corresponding terminals, and fix the terminals (Fig. 13).

• Butt the signal control wire.

• Press tightly the connecting wires of the units with pressure

plate of lead wire.

• Close the connection lid and screw it tightly.

• Close the front panel and reinstall the decorated board.

• For the details, please refer to "How to clean the air

filters" in the "User's Manual".

2. Outdoor Unit

• Loose off the screws and remove the electronic

device lid.

• Dismantle the pressure plate of wire fastener.

• Connect the connecting wires of the unit to the

corresponding terminal, and fix the terminals (Fig. 13).

• Butt the signal control wire.

• Press tightly the connecting wires of the unit with

pressure plate.

• Remount the electronic device lid to the original

position.

• RW type lead wire is used for power cord.

• If User wants to prolong or replace the power wire,

please do it according to the table.

• Ensure that wire connections are carried out according

to the wiring diagram of the air conditioner.

HKEJ 261 G

HKEJ 351 G

Fig.11

Fig.13

TUBE STRAPPING

• Strap with PVC Protective tapes the tubes, discharge pipes, connecting wires.

• Strapping should start from the lower part of the outdoor unit to the tube bundle

wall inlet.

• Fix the PVC protection tapes with plastic adhesive tapes to prevent loosing.

• Fix the tube bundle with tube clamps on the wall.

• Seal the external wall holes with sealing gum or putty.

• Do not strap too tightly, otherwise it will affect the insulation effects.

• For appropriate dripping location, strapping should be such that there is a

sufficient length of exposed discharge hose. Do not insert the drain hose into the

ditch.

• When indoor unit is lower than outdoor unit, please bent the pipe to prevent

water from dropping.

Wall

Clamp

PVC protective tape

Drainage outlet

Fig. 14

Now the installation for air conditioner is finished. Please operate the air

conditioner correctly according to the User's Manual.

Thanks for purchasing our products. Contact us if necessary, and we'll offer

you excellent service promptly.

INFRARED REMOTE CONTROLLER

Buttons on the infrared remote controller

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

MODE

A

IR REFRESH

ON/OFF

TEMPERATURE

FAN SPEED

A

UH

FAN SWEEP

TIME

TIMER

HOUR

MINUTE

RESET

SET TEMP

AUTO

LCD Display

It displays current operation

settings.

"Air Refresh" Button

"MODE" Button

To select the operating mode:

"AUTO" (Automatic)

"HEAT" (Heating)

"COOL" (Cooling)

"DRY" (Dehumidifying)

"SWEEP" (Fan only)

"AUH" Button

"TIME" Button

To adjust the current time, set

the TIMER mode (On/Off) and

the "SLEEP" function (night

softening mode).

"HOUR" Button

To adjust the current time or

adjust the Timer (HOURS).

"ON/OFF" Button

To start or stop the air conditioner.

"TEMPERATURE" Buttons

Press " " to increase the set

temperature by 1˚C.

Press " " to decrease the set

temperature by 1˚C.

!

"

"FAN SPEED" Button

To set the rotation speed of the

indoor fan:

"AUTO" fan speed

"HIGH" fan speed

"MEDIUM" fan speed

"LOW" fan speed

"FAN SWEEP" Button

To set the vertical angle of the

motorized flap (6 fixed stop positions or continuous swinging

of the flap).

"TIMER" Button

To display (in sequence) the

settings related to : ON Timer

(programmed start), Timer OFF

(programmed stop) and set the

PROGRAM (programmed start

and stop or vice versa).

"MINUTE" Button

"RESET" Button

To restore the factory settings for

the remote controller (e.g. after

replacing the batteries).

NOTES:

1) Temperature can be set in the following range: 16˚C ~ 32˚C.

2) "AIR REFRESH" and "AUH" buttons refer to functions which are unavailable on these models.

AUTO

PROGRAM

It refers to a function which is

unavailable on these models.

It refers to a function which is

unavailable on these models.

To adjust the current time or adjust the Timer (MINUTES).

INFRARED REMOTE CONTROLLER

LCD screen on the infrared remote controller

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

AUTO

SET TEMP

PROGRAM

AUTO

Operating mode symbols

"AUTO" (Automatic)

"HEAT" (Heating)

"COOL" (Cooling)

"DRY" (Dehumidifying)

"SWEEP" (Fan only)

Fan speed symbols

"AUTO" fan speed

"HIGH" fan speed

"MEDIUM" fan speed

"LOW" fan speed

Transmission Indicator

It indicates that the remote

controller is sending signals

to the infrared receiver on

the indoor unit.

"PROGRAM" Indicator

It indicates that the programmed timing operation

mode (air conditioner start

and stop or vice versa) is

active or it can be set.

"ON Timer" Indicator

It indicates that the programmed startup of the

air conditioner is active

or it can be set.

"Timer OFF" Indicator

It indicates that the programmed stop of the air

conditioner is active or it

can be set.

Time Indicator

It displays the current time or the set time for the

Timer functions (programmed operation or stop).

"AIR REFRESH" Indicator

"SET TEMP" Indicator

It shows the current set temperature value.

"SLEEP" Mode Indicator

It is shown when the "night softening" mode is

active; this means timed operation with automatic control over the set temperature.

It refers to a function which is not

available on these models.

Additional information about the remote controller

How to insert batteries in the remote controller

1

2

3

4

Remove the lid on the batteries'

compartment.

Open the lid of the batteries'

compartment, placed on the rear side

of the remote controller.

Insert the dry batteries.

Make sure both dry batteries are set

in the right directions as marked inside

the hollow.

Press the RESET button on the remote controller.

Use a pointed object.

Reattach the lid.

Follow in the reverse way the same

proceeding described for removal.

Note:

• Use two new dry batteries of the same brand

and type ("AAA").

• Remove the batteries from the remote controller

when it is not used for 1 month or more.

• When the remote controller does not work

after batteries' replacing, remove and reinsert

both of them after 30 seconds or more, or

press several times the ON/OFF button on

the remote controller with no batteries inside.

Correct handling of the remote controller

• When operating, point the signal

transmitter toward the remote signal

receiver of the Indoor Unit. Maximum

distance for operation is 8 m.

• Make sure there are no obstacles

between the remote controller and the

receiver.

• The signal receiver may not get the

signals in a room with electro-lighting type

fluorescent lamps or cordless phones.

• Handle the remote controller with care.

Do not drop, throw or immerse in water

the remote controller.

• Do not expose the remote controller to

direct sunlight or heating sources.

Infrared remote controller:

The battery compartement's lid

is on the remote controller's rear.

OPERATING THE AIR CONDITIONER

Available options for the operating modes

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

# Additional information about the various operating modes:

MODE

AIR REFRESH

ON/OFF

TEMPERATURE

FAN SPEED

AUH

FAN SWEEP

AUT

O

SET TEMP

3

6

2

1

4

5

AUTO

Automatic

High

Medium

Low

Select the operating mode ("MODE")

AUTO

HEAT.

SWEEP

COOL.

DEHUMIDIFYING

Adjust the set temperature value

Press " " to increase the value by 1˚C.

Press " " to decrease the value by 1˚C.

!

"

Press the "ON/OFF" button

When the air conditioner is OFF, press this

button to switch ON the air conditioner.

Press the "FAN SWEEP" button

To adjust up and down the vertical direction

of the airflow.

Press the "FAN SPEED" button

To select the desired indoor fan speed.

Press the "ON/OFF" button

1. If the "AUTO" (Automatic) mode has been selected, the air conditioner will perform the most

appropriate operation according to the difference between the room temperature and the temperature

value set by the User through the remote controller.

2. If the "AUTO" (Automatic) mode has been selected, the "SLEEP" (i.e. night softening) function is not

available.

3. If the "DRY" (Dehumidifying) mode has been selected, the appliance will operate discontinuously in

Cooling mode, with automatic control of the indoor fan speed, to reduce the humidity degree inside the

room. For this reason the indoor fan speed could not be modified manually.

4. If the "SWEEP" mode (Fan only) has been selected, adjusting the room temperature value is not

available. The indoor fan speed can be only set between: "HIGH", "MEDIUM" or "LOW"; in "SWEEP"

mode, the"AUTO" (Automatic) option for the indoor fan is not available.

When the air conditioner is ON, press this

button to switch OFF the air conditioner.

OPERATING THE AIR CONDITIONER

Adjusting the airflow direction

At startup, the front panel opens

automatically as shown in the figure

on the left. Under all operating

modes, the indoor fan rotation is

allowed only if the front panel has

opened previously.

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

• Horizontal adjusting

To adjust the horizontal direction of the airflow blown by the air conditioner, you can manually set the

louvers to the left or right, according to the actual comfort needs. For safety reasons, the air conditioner

must be switched off before, to avoid touching the indoor fan while it is rotating at high speed.

• Vertical adjusting

Louvers (left/right adjusting)

1

2

3

6

4

5

Press repeatedly the "FAN SWEEP" button on the remote

controller, to adjust the vertical direction of the airflow blown

by the air conditioner.

It is possible to select one among 6 available stop angles

for the motorized flap (see picture on the right), or also to

activate the automatic swinging for the flap ("AUTO

SWING" option): up/down and vice versa. The swinging

angles depend on the current operating mode:

- In COOL and DRY mode, swinging is between 2 and 5 .

- In HEAT mode, swinging is between 1 and 4 .

- In SWEEP mode, swinging is between 1 and 5 .

Automatic opening of the front panel

OPERATING THE AIR CONDITIONER

SLEEP Mode (Night Softening)

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

1.

2.

Notes:

a.

c.

d.

e.

f.

g.

SET TEMP

While the air conditioner is operating, hold the "TIME" button pressed, until the symbol is shown

on the LCD screen of the remote controller, this indicates that the "SLEEP" function (which allows

relevant energy saving) is now enabled.

To disable the "SLEEP" function, hold the "TIME" button pressed, until the symbol

disappears from the LCD screen of the remote controller; this indicates that the "SLEEP" function is

now disabled.

The "SLEEP" function cannot be enabled when the current operating mode is "AUTO" (Automatic) or

"SWEEP" (Fan only).

When the "SLEEP" function is enabled, during operation in Cooling and Dehumidifying modes, the

set temperature will be increased by 1˚C one hour later; during operation in Heating mode, the set

temperature will be decreased by 1˚C one hour later. The set temperature will be controlled between

16˚C and 32˚C.

When the "SLEEP" function is enabled, the indoor fan speed is automatically set to "MEDIUM"

(middle speed), but this setting can be modified by the User through the remote controller.

When the "SLEEP" function is enabled, the LED display on the indoor unit will turn off 30 seconds

after a signal from the remote controller was received.

When the "SLEEP" function is enabled, only the "RUN" indicator will light up to show that the air

conditioner is operating.

When the "SLEEP" function is enabled, the buzzer on the indoor unit will not beep when a signal is

received from the remote controller, but, if the operation settings are changed, the relevant lamps on

the indoor unit will light up for about 30 seconds. After this time has elapsed, only the "RUN" indicator

will light up to show that the air conditioner is operating.

If the "TIME" button is hold pressed while the "SLEEP" function is enabled, the function itself will be

disabled; in this case the buzzer on the indoor unit will beep and the relevant indicators on the indoor

unit's display will light up as during normal operation.

b.

OPERATING THE AIR CONDITIONER

Firstly adjusting the current time

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

1

2

3

MODE

AIR REFRESH ON/OFF

TEMPERATURE

FAN SPEED

AUH

FAN SWEEP

TIME

TIMER

HOUR

MINUTE

RESET

SET TEMP

# Important:

The above described current time setting proceeding must be performed BEFORE any TIMER function's

setting.

Press the "TIME" button;

the symbol is displayed

on the LCD screen and the

current time indication keeps

flashing.

Press the "HOUR" button to

adjust the current time

(HOUR) shown on the LCD

screen.

If you hold the button pressed, the relevant indication

changes quickly.

Press the "MINUTE" button to adjust the current

time (MINUTES) shown

on the LCD screen.

If you hold the button

pressed, the relevant indication changes quickly.

After adjusting is correct,

wait 10 seconds until the

current time indication

stops flashing. The current

time setting is now complete.

OPERATION UNDER TIMER MODE

Programmed Start (ON Timer)

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

1

2

3

MODE

AIR REFRESH ON/OFF

TEMPERATURE

FAN SPEED

AUH

FAN SWEEP

TIME

TIMER

HOUR

MINUTE

RESET

SET TEMP

Perform the current time

setting proceeding, as described on the previous page. Press the "TIME" button

twice: the symbol is

displayed on the LCD screen

and the time indication keeps

flashing.

ON

Adjust the desired time for

programmed start through

the "HOUR" and "MINUTE"

buttons. The desired time

can be set by 10 minutes steps.

Press the "TIMER" button to confirm the

setting.

ON

Notes:

1.

After the time for the programmed start (ON Timer) is set, the air conditioner will stop and the

symbol will be shown on the LCD screen of the remote controller; the air conditioner will restart

operating at the set time, and the symbol will disappear from the remote controller's LCD

screen. If the set time for the programmed start is the same as the current time, the air conditioner

will restart operating on the following day at the same time.

If the ON/OFF button on the remote controller is pressed, the programmed start function will be

cancelled and the air conditioner will start operating.

2.

ON

ON

OPERATION UNDER TIMER MODE

Programmed Stop (Timer OFF)

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

1

2

3

MODE

AIR REFRESH ON/OFF

TEMPERATURE

FAN SPEED

AUH

FAN SWEEP

TIME

TIMER

HOUR

MINUTE

RESET

SET TEMP

Perform the current time

setting proceeding, as described on the previous page. Press the "TIME" button

3 times: the symbol is

displayed on the LCD screen

and the time indication keeps

flashing.

Adjust the desired time for

programmed stop through

the "HOUR" and "MINUTE"

buttons. The desired time

can be set by 10 minutes steps.

Press the "TIMER" button to confirm the

setting.

Notes:

1.

After the time for the programmed stop (Timer OFF) is set, the air conditioner will start and the

symbol will be shown on the LCD screen of the remote controller; the air conditioner will stop

operating at the set time, and the symbol will disappear from the remote controller's LCD

screen. If the set time for the programmed stop is the same as the current time, the air conditioner

will stop operating on the following day at the same time.

If the ON/OFF button on the remote controller is pressed, the programmed stop function will be

cancelled and the air conditioner will stop operating.

2.

OFF

OFF

OFF

OFF

OPERATION UNDER TIMER MODE

“PROGRAM” Mode (Programmed start and stop)

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

MODE

AIR REFRESH ON/OFF

TEMPERATURE

FAN SPEED

AUH

FAN SWEEP

TIME

TIMER

HOUR

MINUTE

RESET

SET TEMP

PROGRA

M

1

2

1.

2.

Perform the current time

setting proceeding as

previously explained.

Please refer to the

setting to adjust the time

for programmed start.

Please refer to the

setting to adjust the time

for programmed stop.

ON

OFF

Press the "TIMER" button

repeatedly until the symbol

shown below is displayed

on the LCD screen of the

remote controller:

PROGRAM

ON

PROGRAM

OFF

PROGRAM

According to the programmed time

settings, the air conditioner will start

operating and then stop or vice versa.

For your reference, the symbols

displayed on the LCD screen of the

remote controller are the following:

If it is not disabled, each program set

for start and stop will be repeated

everyday.

If the air conditioner is switched OFF

manually before the programmed time

for stop is reached, the setting for

programmed start will remain valid all

the same.

If the air conditioner is switched ON

manually before the programmed time

for start is reached, the setting for

programmed stop will remain valid all

the same.

NOTES:

Emergency operation

OPERATION WITHOUT THE REMOTE CONTROLLER

• Emergency operation allow the air conditioner to be started or stopped when the infrared remote controller is not available or the batteries are low.

• To access the emergency button, you have to remove the decorated board (the one with the

"HOKKAIDO" logo on it) before: holding it on both sides, let it slide downwards.

• When the air conditioner is OFF, shortly press the emergency button to turn ON the appliance.

• Operation will start in “AUTO” mode, and the set temperature value will be 24°C.

• When the air conditioner is ON, shortly press the emergency button to turn OFF the appliance.

• The position of the emergency operation (also for "TEST RUN mode) switch is pointed out in

the picture above.

“TEST RUN” Mode

• To start operation in "TEST RUN" mode, the emergency run switch (see above) must be hold

pressed for more than 4 seconds; the buzzer on the indoor unit will beep twice to indicate that

the air conditioner has entered the "TEST RUN" mode.

• The "TEST RUN" mode will last for no more than 15 minutes; after this time has elapsed, the air

conditioner will automatically switch to normal operation.

• During "TEST RUN" mode operation, the indoor unit can receive signals from the infrared

remote controller.

• You can also stop operation in "TEST RUN" mode before 15 minutes have elapsed: shortly

press the emergency run switch on the indoor unit, or press the ON/OFF button on the infrared

remote controller.

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

Monosplit ON/OFF models:

HKEJ 261 G, 351 G

Emergency operation button

(also for "TEST RUN" mode)

Loading...

Loading...