Frigiking FD350, FD450, FS350, FS450, FD650 Owner's Manual

...

Owner’s Guide

Use and Care Manual

Ducted Cooler Models:

FD350, FD450, FD650

FS350, FS450, FS650

Customer Service

1-800-325-6952

• Safety

• Installation

• Start-up

Congratulations: You have purchased a product of superior performance and design, which will give the best service when

properly installed, operated and maintained.

This guide will provide you with information needed to assemble the unit. It also contains information on how to safely operate,

inspect, maintain and troubleshoot your Frigiking evaporative air cooler.

• Operation

• Maintenance

• Troubleshooting

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

READ AND SAVE THESE IMPORTANT SAFETY INSTRUCTIONS

• Read all instructions carefully before installation.

• Cooler motor, pump, cabinet and junction box must be

grounded in accordance with all local and national codes.

A ground wire must be used between the cooler and the

power source.

• Always disconnect electrical power to the cooler before

working on cooler.

• WARNING To reduce the risk of re or electrical shock

do NOT use this fan with any solid state speed control

device.

• Do NOT remove side panels while cooler is running.

• Do NOT operate with evaporative pad removed.

• Do NOT locate cooler near exhaust or vent pipes as

odors or fumes may be drawn into the unit.

• Be sure cooler is connected to proper line voltage

stamped on blower motor and pump motor specication

plate.

NOTE: IMPROPER VOLTAGE WILL VOID MOTOR

WARRANTY.

• Your warranty does NOT cover shipping damage. Report

all shipping damage at once to store making the delivery.

THE USE OF ANODE DEVICES, CHEMICAL ADDITIVES, OR

COOLER CLEANER TREATMENTS IN THIS COOLER WILL

VOID THE WARRANTY.

• For future reference, record the model and serial number,

date and place of purchase of your evaporative cooler

here:

Model # Serial #

Date of Purchase:

Place of Purchase:

Serial # can be found outside the cabinet.

1-999-1539 REV A09/11/17

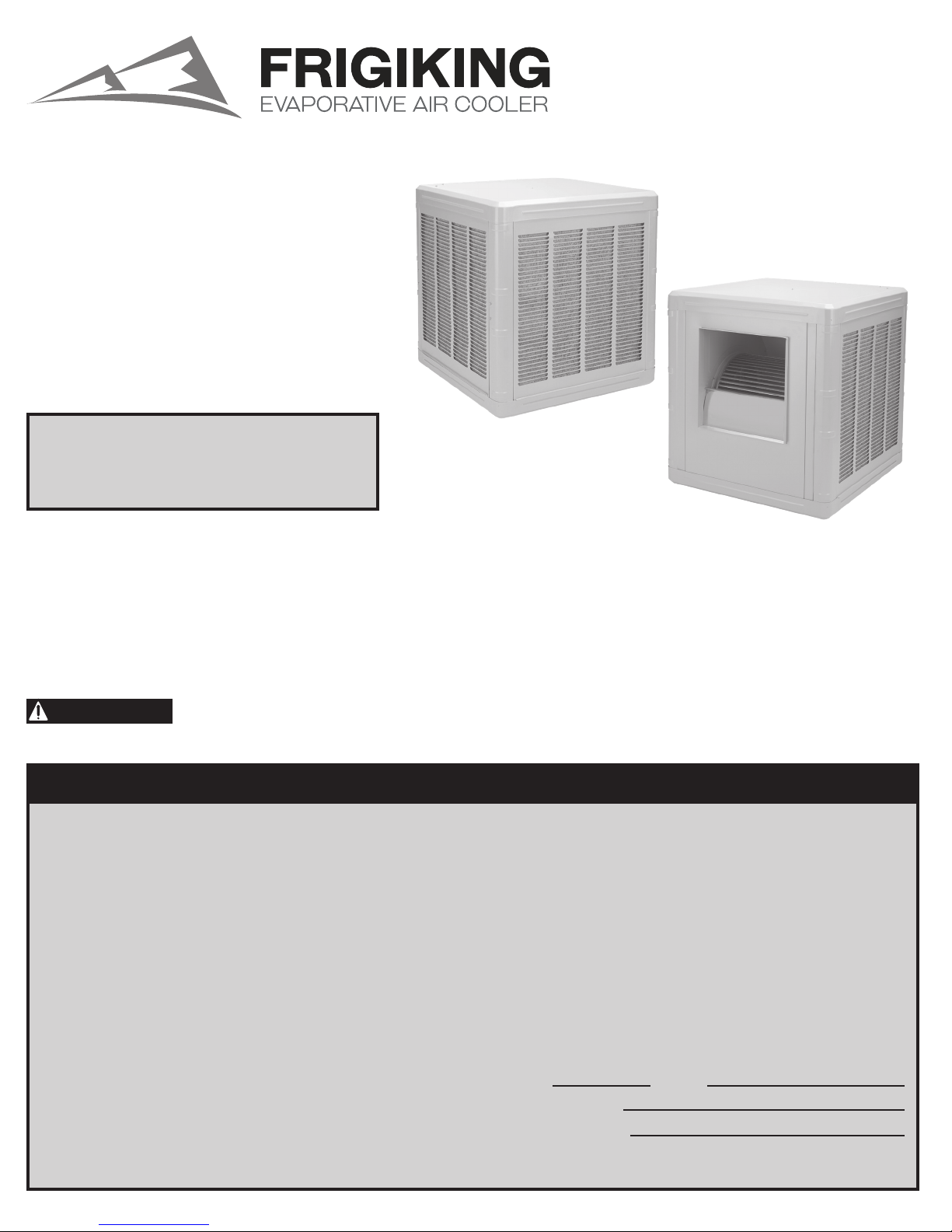

ROOF

DUCT

CEILING

WOOD OR ANGLE

IRON SUPPORT

TYPICAL SIDE DISCHARGE

COOLER

DUCT

WATER CONNECTION Continued

2. Turn water to cooler on and set oat valve to maintain 2 1/2" water depth.

The oat valve is adusted by bending the oat valve rod.

3. Bleed-off: Bleed off is helpful to prevent scale from building up in the

cooler. A bleed-off adapter tee and tube are furnished with the cooler for

this purpose. Run bleed-off line to a proper drain.

Note: Evaporative coolers should not be connected to

a "soft" water system.

ROOF JACK

COOLER STAND

*COLLAR (with ange)

*FLEX DUCT

TYPICAL DOWN DISCHARGE

INSTALLATION

Installation requires connection of blower opening to existing air ducting

system or to a dropper duct with a ceiling diffuser. In either instance, building

modication is necessitated. The bottom discharge cooler is always mounted

on the roof of the structure. This will require a roof stand, roof jack, exible

duct and collar to connect to existing ductwork. If installation is being

made by other than a professional HVAC contractor, it is suggested that the

installation be throughly discussed with a professional sales person familiar

with cooler installation and that printed instructions be requested for the

installation equipment and supplies purchased.

DO NOT DRIVE NAILS OR SCREWS INTO BOTTOM OF

COOLER, THIS WILL CAUSE IT TO LEAK WATER AND

WILL VOID THE WARRANTY.

DRAIN BUSHING

Insert drain bushing through the hole in the cooler bottom pan. Attach nut

securely and hand tighten. Do NOT use a wrench.

WALL SWITCH: For one or two speed (120 ro 240 volt) use switch kit

available from your dealer.

ADJUSTABLE MOTOR PULLEY (SHEAVE): This part is set at

the factory for proper motor load and maximum air delivery of a cooler not

connected duct and register system. When cooler is connected to a duct

system the cooler air capacity and motor amperage decrease due to static

pressure (duct resistance). The adjustable motor pulley is used ONLY to

compensate for duct system resistance by returning cooler and motor to

proper load capacity and should not be adjusted except for that purpose.

CAUTION: AMPERAGE OF MOTOR MUST BE CHECKED

TO MAKE CERTAIN IT DOES NOT EXCEED THE MAXIMUM

ALLOWED AS STAMPED ON MOTOR SPECIFICATION PLATE.

Only persons with proper electrical equipment and thorough knowledge of

adjustable pulleys should attempt adjustment of your cooler.

WARNING: IMPROPER PULLEY ADJUSTMENT CAN

OVERLOAD AND BURN OUT MOTOR AND VOID WARRANTY.

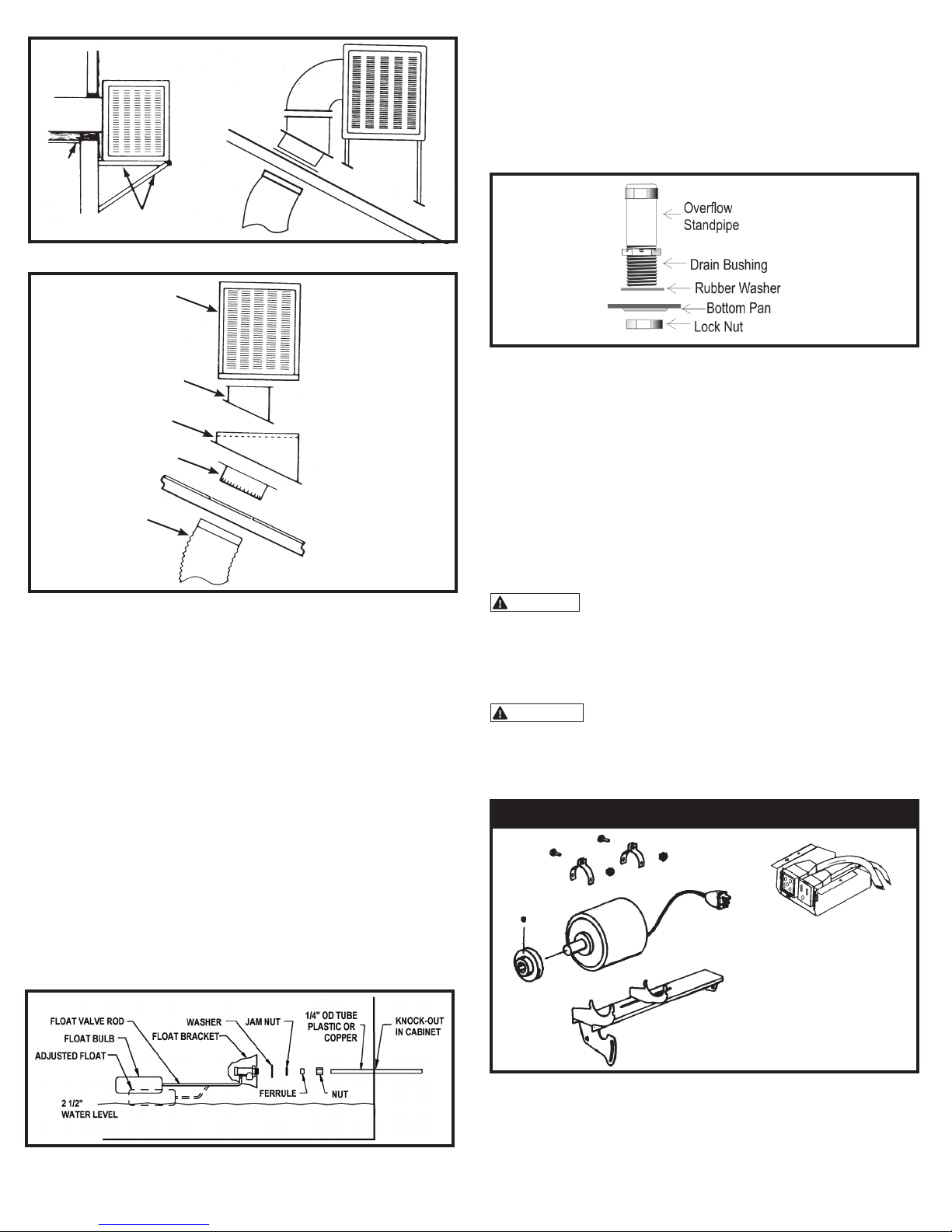

MOTOR KITS

120 VOLT MOTOR KIT

* FOR MOBILE HOME INSTALLATION SEE SEPARATE

INSTRUCTION SHEET IN GRILL KIT BOX.

Whenever the cooler is mounted, the surface must be level. This is necessary

so that the water in the reservoir and in the troughs of the pad frame will be

level when the cooler is operating.

WATER CONNECTION

1. Install oat in hole provided in oat bracket. See parts illustration to route

water line. Connect per above sketch.

INSTALLATION

1. Install the motor in the mounting cradle as shown.

2. Remove the junction box from the cooler.

3. Wire the pump and motor receptacles per the schematic shown below.

4. Place both receptacles in the junction box as shown and re-attach the

junction box to the cooler top.

Page 2

A

B

Green

Black

White

15A 120V

5 Pin

Motor

Recp.

Red

Black

White

Green

Orange

GND

Green

White

Black

Red

Pump

Black

Green

White

Lo

Hi

Com

Power

Supply

3 Pin

A

Orange

5 Pin

Motor

Recp.

Red

Black

Orange

Green

White

GND

Green

Orange

Black

Red

Pump

Black

Green

Orange

Lo

Hi

Com

Power

Supply

3 Pin

B

120 VOLT MOTOR KIT

Green

Black

Green

3 Pin

White

Pump

Black White

15A 120V

Black

Red

Black

White

Green

Lo

Hi

ComRed

White

5 Pin

Green

Orange

A

GND

Motor

Recp.

The orange wire is not used. Double it over and cover the bare end with

A

electrical tape.

The red wire is not used on single speed motors. Double it over and cover

B

the bare end with electrical tape or wirenut.

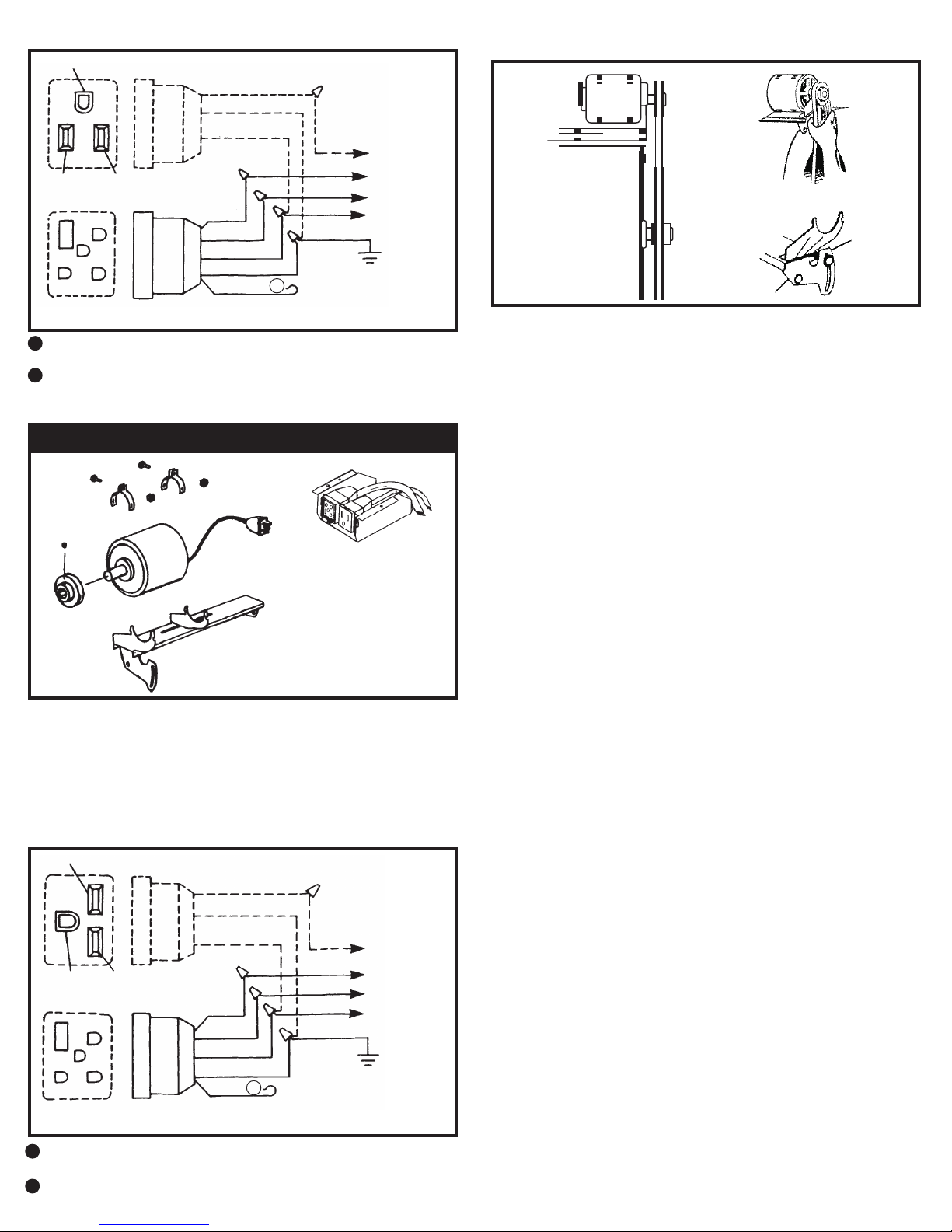

240 VOLT MOTOR KIT

OPERATION

Power

Supply

BLOWER BELT ADJUSTMENT

Correct belt tension adjustment is important. Incorrect adjustment increases

power consumption and shortens belt and motor life.

Install belt over motor and blower pulleys.

(A) check belt tension by squeezing (deecting) belt. Proper tension will allow

deection of 1/2 to 3/4 inch.

(B) To increase or decrease belt tension, loosen bolt in slot of motor support

brcket. Adjust belt to desired tension and re-tighten bolt.

PRE-WET PADS

For maximum cooling efciency, prior to the initial start up of the cooler

remove the pad frame assemblies from the cooler and spray the pad and

frames thoroughly with water from a garden hose.

INSTALLATION

1. Install the motor in the mounting cradle as shown.

2. Remove the junction box from the cooler.

3. Remove 120 volt pump and pump receptacle furnished with cooler and

replace it with the 240 volt LSP-94 pump and pump receptacle. (see

replacement parts list)

4. Wire the pump and motor receptacles per the schematic shown above.

5. Place both receptacles in the junction box as shown and re-attach the

junction box to the cooler top.

Green

Black

Green

3 Pin

Black Orange

15A 230V

Orange

Red

Black

Red

Black

Orange

Green

Pump

Lo

Hi

Com

Orange

5 Pin

Green

White

A

GND

Motor

Recp.

The white wire is not used. Double it over and cover the bare end with

A

electrical tape or wirenut.

The red wire is not used on single speed motors. Double it over and cover

B

the bare end with electrical tape.

Power

Supply

Put the pad frame assemblies back on the cooler and while the pads are still

wet start the cooler with the pump on.

BUILT-IN WINTER CLOSURE (Down discharge units only)

An exclusive feature of your cooler (models in the 4800 to 6800 CFM range)

which is provided is the full closure damper. Your cooler is shipped from the

factory with the damper temporarily fastened to the side of the blower with a

shipping screw. Remove the screw and store the damper for later use during

winter months.

1. For Winter use of a damper, slide damper into cooler below the blower.age.

2. When starting the cooler in the Spring, remove the damper and store in a

safe place.

Page 3

Loading...

Loading...