Page 1

GAS COOKTOP INSTALLATION INSTRUCTIONS

INSTALLATION AND SER VICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SA VE FOR LOCAL ELECTRICAL INSPECT OR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING

If the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

— DO NOT store or use gasoline or other fl ammable vapors

and liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch; DO NOT use any

phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fi re department.

— Installation and service must be performed by a qualifi ed

installer, service agency or the gas supplier.

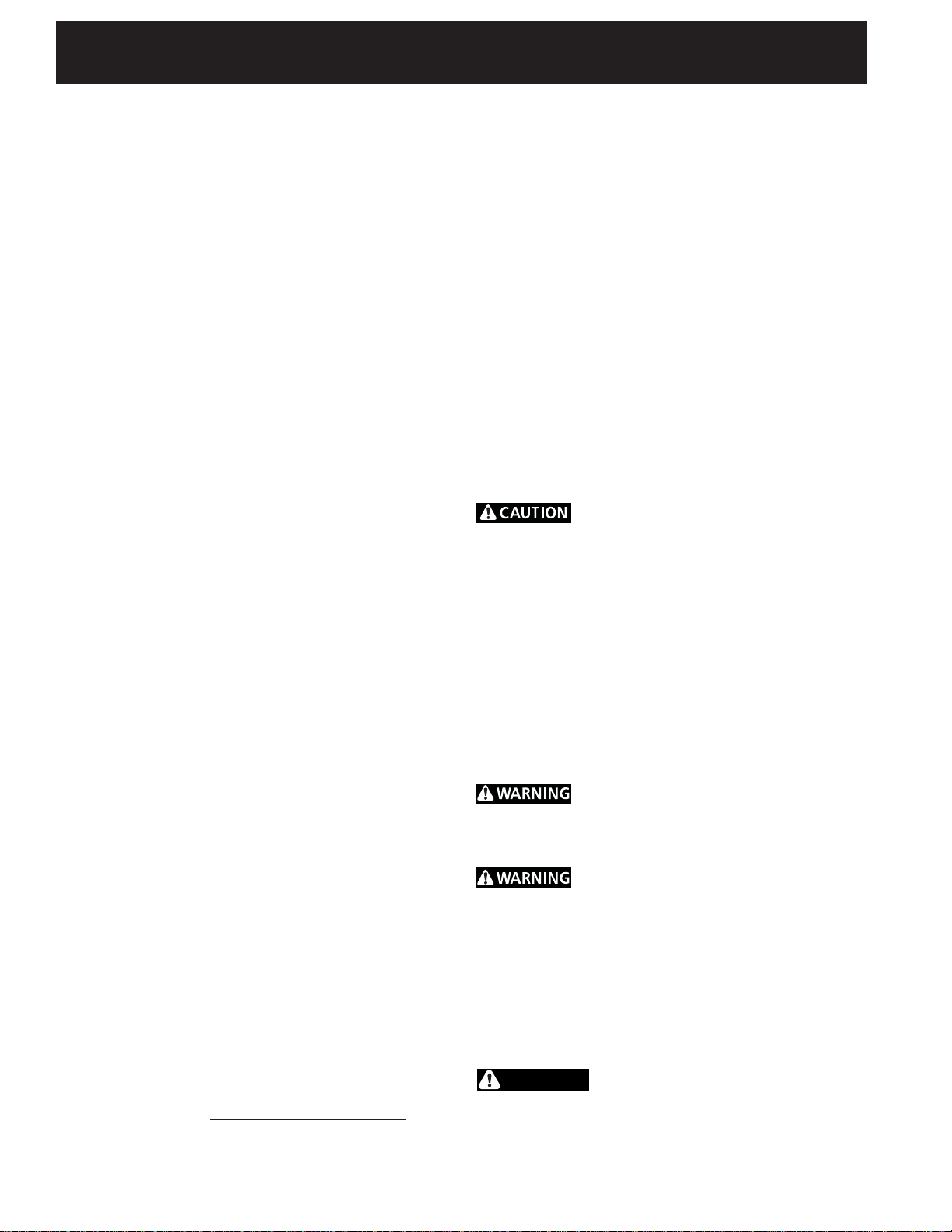

PRODUCT DIMENSIONS

A

A

1

20 1/8”

/

20

8"

51.1 cm

(51.1 cm)

Appliances Installed

in the state of

Massachusetts:

This Appliance can only

be installed in the state

of Massachusetts by a

Massachusetts licensed

plumber or gas fi tter.

This appliance must be

installed with a three (3)

foot / 36 in. long fl exible

gas connector. A "T"

handle type manual gas

valve must be installed

in the gas supply line to

this appliance.

3

23 3/8”

/

23

8"

59.4 cm

(59.4 cm)

C

C

PRODUCT DIMENSIONS

MODEL

A. COOKTOP

WIDTH

30" Gas Cooktop 30" (76.2 cm) 21

36" Gas Cooktop 36" (91.4 cm) 21

All dimensions are stated in inches and (cm).

Printed in U.S.A.

B

B

D

D

B. COOKTOP

DEPTH

13

/

32" (54.4 cm) 26

23

/

32" (55.1 cm) 32

11

/

3 11/16”

3

16"

9.4 cm

(9.4 cm)

13

17 13/16”

/

17

16"

45.2 cm

(45.2 cm)

C. CHASSIS

WIDTH

13

/

16" (68.1 cm) 18

11

/

16" (83.0 cm) 18

318205457 (0613) Rev. B

Figure 1

D. CHASSIS

DEPTH

15

/

16" (48.1 cm)

15

/

16" (48.1 cm)

Page 2

GAS COOKTOP INSTALLATION INSTRUCTIONS

Important Notes to the Installer

1. Read all instructions contained in these

installation instructions before installing

the cooktop.

2. Remove all packing material before

connecting the electrical supply to the

cooktop.

3. Observe all governing codes and

ordinances.

4. Be sure to leave these instructions with

the consumer.

5. Note: For operation at 2000 ft. elevations

above see level, appliance rating shall be

reduced by 4 percent for each additional

1000 ft.

Important Note to the Consumer

Keep these instructions with your Use and

Care Guide for future reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this cooktop must conform

with local codes or, in the absence of

local codes, with the National Fuel Gas

Code ANSI Z223.1/NFPA 54 in the

United States, or in Canada, with the

Canadian Fuel Gas Code, CAN/CGA

B149 and CAN/CGA B149.2.

• When installed in a manufactured

(mobile) home installation must

conform with the Manufactured Home

Construction and Safety Standard,

title 24 CFR, part 3280 [Formerly the

Federal Standard for Mobile Home

Construction and Safety, title 24, HUD

(part 280)] or, when such standard

is not applicable, the Standard for

Manufactured Home Installation, ANSI/

NCSBCS A225.1 or with local codes

where applicable.

This cooktop has been design certifi ed

by Underwriters Laboratories (UL).

As with any appliance using gas and

generating heat, there are certain safety

precautions you should follow. You will

fi nd them in the Use and Care Guide,

read it carefully.

• Be sure your cooktop is installed

and grounded properly by a

qualifi ed installer or service

technician.

• This cooktop must be electrically

grounded in accordance with local

codes or, in their absence, with

the National Electrical Code ANSI/

NFPA No. 70—latest edition in the

United States, or in Canada, with

the Canadian Electrical Code, CSA

C22.1 Part 1.

• The burners can be lit manually

during an electrical power outage.

To light a burner, hold a lit match to

the burner head, then slowly turn

the Surface Control knob to LITE.

Use caution when lighting burners

manually.

DO NOT store items of

interest to children in cabinets

above the cooktop. Children could be

seriously burned climbing on the cooktop

to reach items.

• To eliminate the need to reach over

the surface burners, cabinet storage

space above the burners should be

avoided.

• Adjust surface burner fl ame size so

it does not extend beyond the edge

of the cooking utensil. Excessive

fl ame is hazardous.

Never use your cooktop

for warming or heating the room.

Prolonged use of the cooktop without

adequate ventilation can be hazardous.

Storage on Appliance.

Flammable materials should not

be stored near surface units. This

includes paper, plastic and cloth items,

such as cookbooks, plasticware and

towels, as well as fl ammable liquids.

DO NOT store explosives, such as

aerosol cans, on or near the appliance.

Flammable materials may explode and

result in fi re or property damage.

WARNING

the cooktop must be shut off while

gas line connections are being

made. Failure to do so could result in

2

serious injury or death.

The electrical power to

Page 3

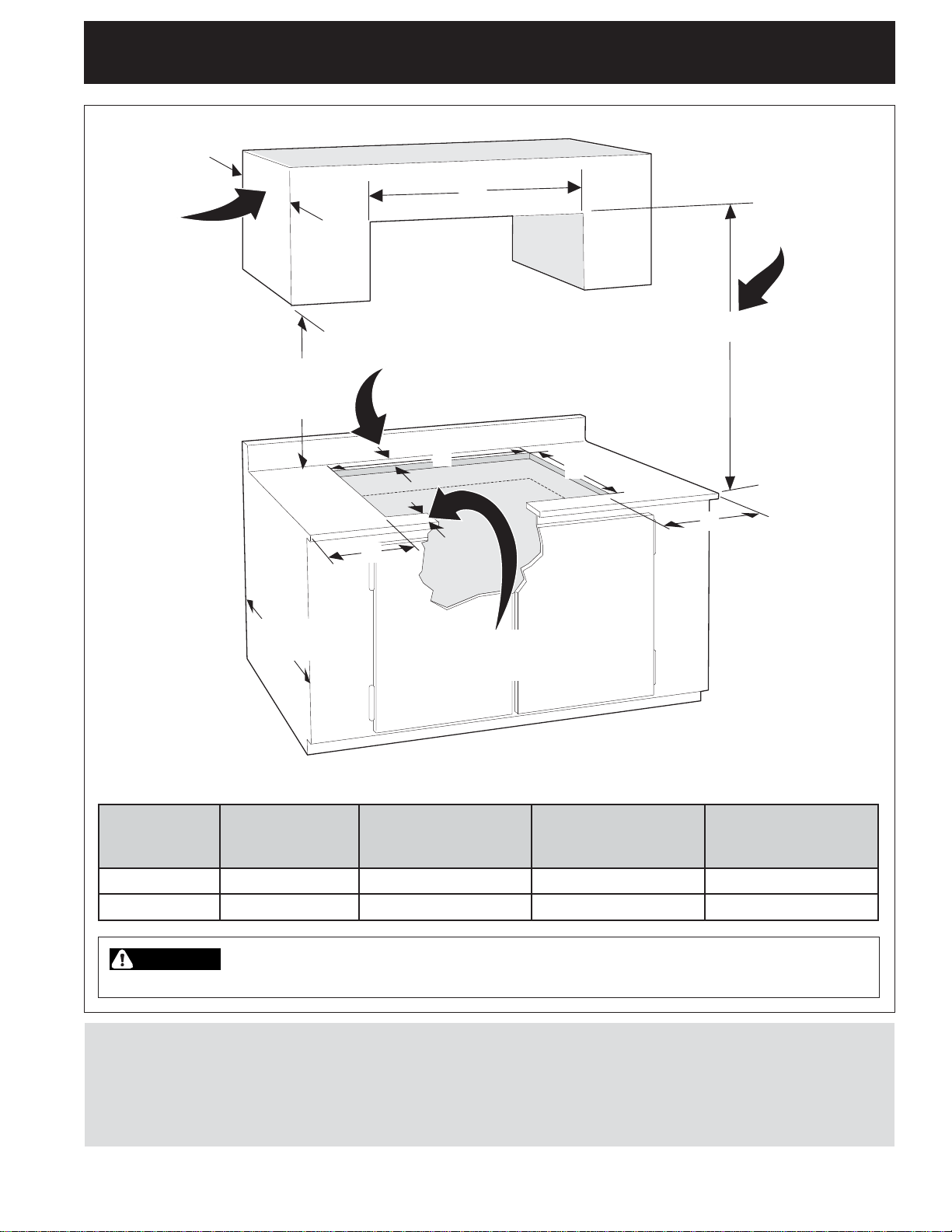

13" (33 cm)

Max. Depth

For Cabinet

Installed

Above

Cooktop.

GAS COOKTOP INSTALLATION INSTRUCTIONS

30" (76.2 cm)

Min. Clearance

Between the Top

of the Cooking

E

Clearance

Platform and

Unprotected

Wood or Metal

Cabinet

18" Min.

(45.7 cm)

24" Min.

(61 cm)

1 ⅜" (3.5 cm) Minimum Flat

Distance from Cutout Edge.

G

H

F

1 ⅜" (3.5 cm) Minimum Flat

Distance from Cutout Edge.

Figure 2 – CABINET DESIGN

F

E. Top Cabinet

MODEL

30" Cooktop 30" (76.2 cm) 9" (22.9 cm) 28" (71.1 cm) 19 ⅛" (48.6 cm)

36" Cooktop 36" (91.4 cm) 9" (22.9 cm)

CAUTION

cabinet storage space located above the cooktop should be avoided.

* For installations involving replacing an existing

cooktop, the cutout depth (H) in the countertop

may be larger than the above recommendation.

A Gap Filller Trim Kit is available which will then

allow for a maximum cutout depth (H) of 21 3/16".

Minimum Side

Clearance

To eliminate the risk of burns or fi re from reaching over heated surfaces,

F. Minimum

Clearance from

Each Side

The Gap Filler Trim Kit part number is

5304488403.

Before beginning installation, refer to the

instructions included with Gap Filler Trim Kit

5304488403 for countertop dimensions, cutout

limitations, and proper location of ductwork.

3

G. Cutout Width

± 1/16" (0.2 cm)

34" (86.4 cm)

H. Cutout Depth

± 1/16" (0.2 cm)

19 ⅛" (48.6 cm)

Page 4

GAS COOKTOP INSTALLATION INSTRUCTIONS

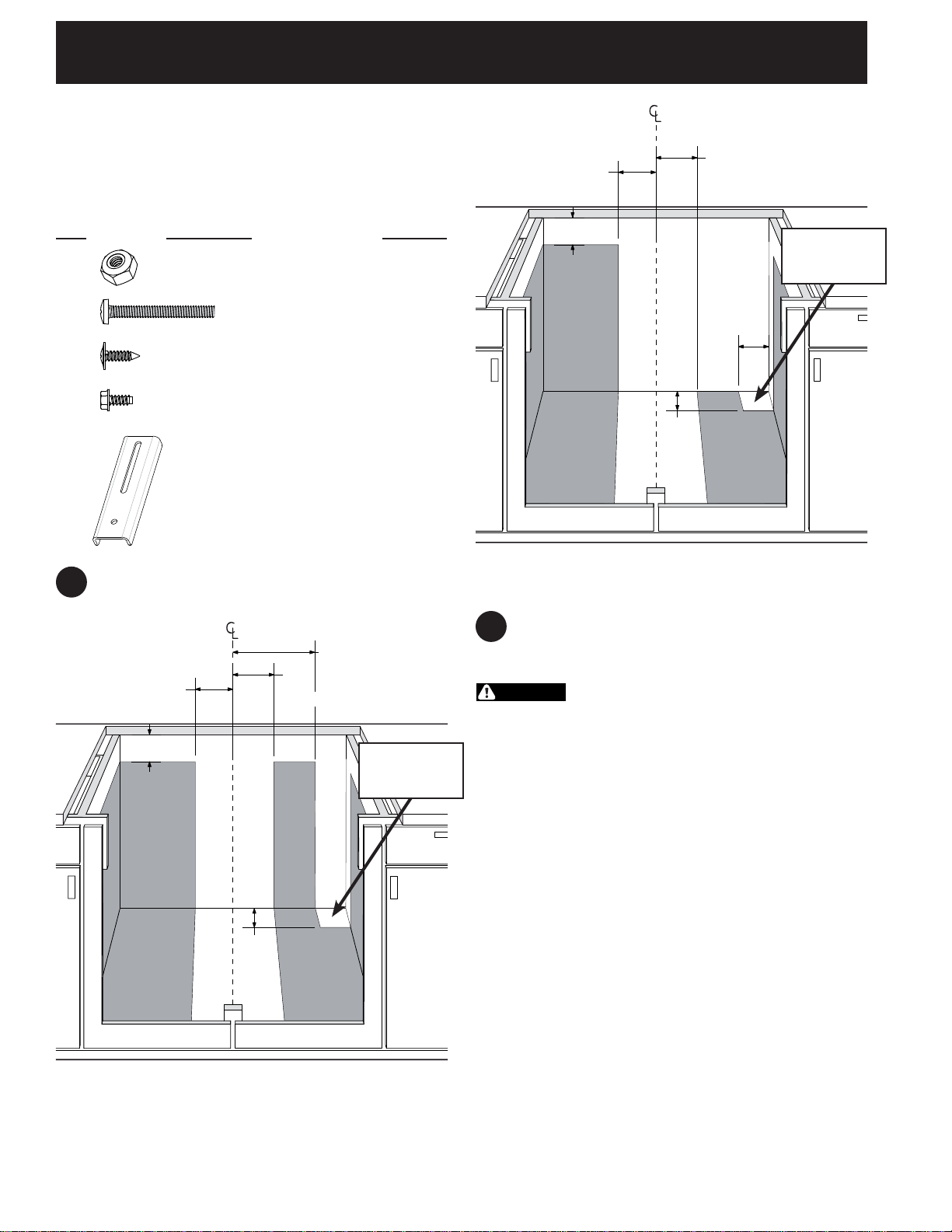

Required Tools for Installation

- Phillips Screwdriver

- ¼" Nut driver / Ratchet

7

/

16" Nut driver / Ratchet

-

Supplied Hardware

Qty. Description Used for

(4)

(2)

(4)

1/4-20 Nylon Insert

7/16" Hex Nut

#10-24 3.5"

Long Phillips

Screw

#8-18 Wide Head

Phillips Screw

Blower (fi g. 20)

Brackets

(fi g. 15 & 16)

Transition Duct

(fi g. 18)

3 1/4”

(8.3 cm)

5 1/2”

(13.9 cm)

11”

(27.9 cm)

Recommended

Gas Supply

Stub Area

4”

(10.2 cm)

(6)

#8-18 Black

¼" Hex Head Screw

Plenum and

Wire Box (fi g.

17 & 21)

(2)

Wall Outlet Location

1

Hold Down Bracket

Countertop

(fi g. 15 & 16)

Install the electric wall outlet within the shaded

area.

11 1/2”

(29.2 cm)

6”

(15.2 cm)

5 1/2”

(13.9 cm)

8 3/4”

(22.2 cm)

Recommended

Gas Supply

Stub Area

4”

(10.2 cm)

4”

(10.2 cm)

Figure 3B - 30” MODEL

ELECTRICAL OUTLET INSTALL DIMENSIONS

2

Provide an Adequate Gas Supply

This cooktop is designed to operate on natural

gas at 4" of manifold pressure only.

WARNING

connected in series with the manifold on the

cooktop and must remain in series with the supply

line.

For proper operation, the maximum inlet

pressure to the regulator must be no more than

14" of water column (W.C.) pressure.

For checking the regulator, the inlet pressure

must be at least 1" (or 2.5 kPa) greater than the

regulator manifold pressure setting. The regulator

is set for 4" of manifold pressure, the inlet

pressure must be at least 5".

The gas supply line to the range should be 1/2" or

3/4" pipe.

A pressure regulator must be

Figure 3A - 36” MODEL

ELECTRICAL OUTLET INSTALL DIMENSIONS

4

Page 5

GAS COOKTOP INSTALLATION INSTRUCTIONS

LP/Propane Gas Conversion

3

This appliance can be used with Natural gas or

LP/Propane gas. It is shipped from the factory for

use with natural gas.

A kit for converting to LP gas is supplied with your

cooktop. The kit is marked "FOR LP/PROPANE

GAS CONVERSION".

The conversion must be performed by a

qualifi ed service technician in accordance with

the kit instructions and all local codes and

requirements. Failure to follow instructions could

result in serious injury or property damage. The

qualifi ed agency performing this work assumes

responsibility for the conversion.

WARNING

conversion can result in serious personal injury

and property damage.

NOTE: Purchase a new fl exible line. DO NOT

USE AN OLD PREVIOUSLY USED LINE.

Important: Remove all packing material and

literature from cooktop before connecting gas and

electrical supply to cooktop.

Model and Serial Number

4

Failure to make the appropriate

Location

The serial plate is located on the underside of the

cooktop.

The wall receptacle and circuit should be checked

by a qualifi ed electrician to make sure the

receptacle is properly grounded.

Where a standard 2-prong wall receptacle is

installed, it is the personal responsibility and

obligation of the consumer to have it replaced by

a properly grounded 3-prong wall receptacle.

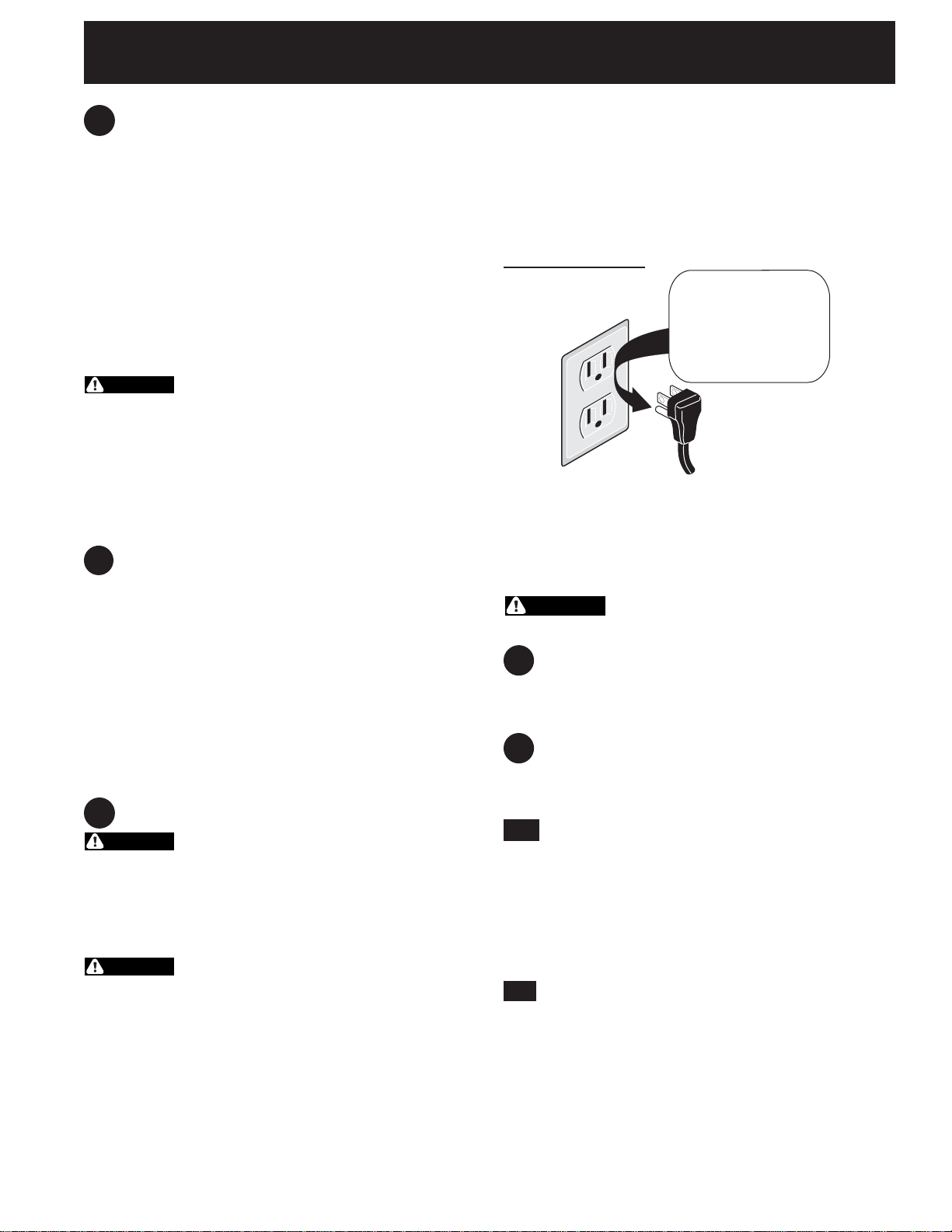

Preferred Method

DO NOT,

Grounding type

wall receptacle

DO NOT, under any circumstances, cut or

remove the third (ground) prong from the

power cord.

WARNING

from wall receptacle before servicing cooktop.

Disconnect electrical supply cord

under any

circumstances,

cut, remove,

or bypass the

grounding prong.

Power supply

cord with 3-prong

grounding plug.

Figure 4

When ordering parts for or making inquires about

your cooktop, always be sure to include the model

and serial numbers and a lot number or letter from

the serial plate of your cooktop.

Your serial plate also tells you the rating of the

burners, the type of fuel and the pressure the

cooktop was adjusted for when it left the factory.

5

Electrical Requirements

WARNING

branch circuit protected by a 15 amp circuit

breaker or time delay fuse. DO NOT use an

extension cord with this cooktop.

120 volt, 60 Hertz, properly grounded

Grounding Instructions

IMPORTANT Please read carefully.

WARNING

must be properly grounded.

The power cord of this appliance is equipped with

a 3-prong (grounding) plug which mates with a

standard 3-prong grounding wall receptacle (see

Figure 4) to minimize the possibility of electric

shock hazard from the appliance.

For personal safety, this appliance

Positioning the Cooktop

6

The exhaust vent from the cooktop must be

located between wall studs or fl oor joists so that

the ductwork may be installed properly

7

Prepare Base Cabinet

This cooktop is designed to fi t easily into a variety

of cabinets. However, some cabinets may require

modifi cations.

7.1

Preparing a Cabinet with Drawers

If the cabinet has drawers, the drawers must be

removed and the drawer fronts attached to the

front of the cabinet.

Verify internal length and width of base cabinet

In some cabinets, the sides or back wall may

need to be cut out, and the corner braces

removed in order to accommodate the unit.

7.2

Countertop Cutout

Countertops with a rolled front edge and radius at

the base of the backsplash may not provide the

fl at surface area required to accommodate the

cooktop.

Cut countertop opening according to the

dimensions shown in Figure 2. The opening must

be cut squarely with sides parallel to each other,

front and rear perpendicular to the sides.

5

Page 6

GAS COOKTOP INSTALLATION INSTRUCTIONS

8

Installing the Ductwork

Use galvanized or aluminum duct in 6” round

or 3¼” x 10" size, or a combination of both.

PVC duct should be used if installing under a

poured concrete slab. Use the shortest and

straightest duct run possible. For satisfactory

performance, the duct run should not exceed 100

feet equivalent length. Refer to the “Calculating

Duct Length” chart for equivalent lengths. (see

page 14). All duct joints should be fastened with a

screw and sealed with tape as shown in Figure 5.

NOTE: Local building code must be followed in

specifying approved type and schedule of ALL

duct used. Always use an appropriate roof or wall

cap with damper.

Duct Tape

Over Seam

and Screw

Air Flow

Screw

Figure 5 – DUCT T APE OVER SEAM AND SCREW

Figure 7 –

Figure 8 –

DUCT THROUGH-THE-FLOOR

DUCT THROUGH-THE-WALL

Figure 6 –

DUCT ON-THE-FLOOR

6

Page 7

GAS COOKTOP INSTALLATION INSTRUCTIONS

Preparing for Ductwork

9

Cut hole in cabinet wall or fl oor as appropriate

for your installation. Make sure exhaust duct is

located between wall studs or fl oor joists. Figure

9, 10, 11 & 12.

NOTE: Ductwork MUST be vented to outside. DO

NOT vent into a wall, ceiling, crawlspace, attic or

any concealed space.

WARNING

ceiling, DO NOT damage electrical wiring and

other hidden utilities.

When cutting or drilling into wall or

CUTOUT

CENTER

CUTOUT

CENTER

CUTOUT

CENTER

CUTOUT

CENTER

1/4"

¼" (0.6cm)

7

4 7/16"

/

4

16" (11.3cm)

5

/

4

16" (11.0cm)

7

Figure 9 – 30" MODEL

BOTTOM DUCTWORK HOLE

CUTOUT

CENTER

CUTOUT

CENTER

5

/

4

16" (11.0cm)

1

/

8" (18.1cm)

8" (20.3cm)

Figure 11 – 36" MODEL

BOTTOM DUCTWORK HOLE

CUTOUT

CENTER

CUTOUT

CENTER

¼" (0.6cm)

1/4"

15

16 15/16"

/

16

16" (43.0cm)

1/4"

¼" (0.6cm)

Figure 12 – 36" MODEL

LEFT OR RIGHT DUCTWORK HOLE

1

/

8

16"

8 1/16"

(20.5cm)

Figure 10 – 30" MODEL

BACK WALL

DUCTWORK HOLE

7

Page 8

GAS COOKTOP INSTALLATION INSTRUCTIONS

Alternate Ducting

9.1

For installations involving

space restrictions for orienting

the blower to connect to the

ductwork a duct adapter, Kit

5304488297 is available.

Dimensions are shown for

locating the duct cutout with

this adapter kit.

CUTOUT

CENTER

(16.2cm)

6"

5

/

22

8"

(57.5cm)

(15.2cm)

Figure 13

ALTERNATE DUCT

TRANSITION KIT

3

/

8"

6

Makeup Air

9.2

Local building codes may require the use of

makeup air systems. Consult local codes to

determine specifi c makeup air requirements for

your installation.

10

Blower to Ductwork Alignment

The use of fl exible ducting is discouraged

because it can severely restrict airfl ow. If the

blower outlet and the fl oor or wall duct location

DO NOT align, then fl exible METAL ducting can

be used to adapt to an offset.

6" MAX.

Center line

To Center

line Offset

Figure 13A - 30" MODEL

ALTERNATE DUCTWORK HOLE

CUTOUT

CENTER

(22.5cm)

1

/

16

8"

(41cm)

1

/

10

8"

(25.7cm)

1

/

8"

10

(25.7cm)

5

/

8"

3

(9.2cm)

(57.5cm)

6"

(15.2cm)

Figure 13B - 36" MODEL

ALTERNATE DUCTWORK HOLE

8

22

Figure 14 –

7

/

8"

5

/

8"

8

DUCTWORK ALIGNMENT

Page 9

GAS COOKTOP INSTALLATION INSTRUCTIONS

11

Installing the Cooktop

Lift the cooktop by the side edges as shown.

Lower the cooktop into the countertop opening,

guiding it into position. Support the underside and

lower slowly. Carefully remove your fi ngers one

corner at a time to lower the cooktop into position.

NOTE: DO NOT use Silicone RTV or caulk to seal

the cooktop to the countertop.

Cooktop

Screws Supplied

Screws Supplied

with Cooktop

with Cooktop

Countertop

Phillips

screw

Phillips

Figure 15 –

12

Installing the installation

LOWERING COOKTOP INTO CUT OUT

brackets

Remove screws from the cooktop chassis and

use to attach the hold down bracket to the bottom

of the chassis. Insert the screw into the bracket

until it contacts the backside of the countertop.

To prevent damage to the countertop, DO NOT

overtighten the screw.

Figure 17 –

13

Installing the blower plenum to the

INSTALLATION BRACKETS

cooktop

With the blower opening on the right slide the plenum

into the opening in the bottom of the cooktop.

Push up on the plenum until the mounting rails

on the sides of the plenum contact the bottom of

the cooktop. Install four #8-18 x 3/8” sheet metal

screws to hold the plenum in place.

Install Four #8-18

Black Hex Head

Screws

One Hold

Down Bracket

One Long

Phillips Screw

Figure 16 –

Figure 18 – 30" MODEL

ATTACH PLENUM TO THE COOKTOP

Two #8-18 Black Hex

Head Screws Attached to

Cooktop

ATTACH THE TWO BRACKETS

9

Page 10

GAS COOKTOP INSTALLATION INSTRUCTIONS

Install Four #8-18

Install 4 Screws

Black Hex Head

Screws

15

Installing the blower to the

plenum

Install four nylon insert nuts to the studs on the

blower, fi nger tighten until resistance is felt.

Position the blower discharge opening to match

the ductwork. Slide the nuts on the side of the

blower housing into the four keyhole openings on

the side of the plenum and allow to slide down

into the slots. Using a wrench or ratchet from the

inside of the plenum tighten the nuts.

Figure 19 – 36" MODEL

ATTACH PLENUM TO THE COOKTOP

14

Installing the transition to the

blower

Attach the transition to the outlet of the blower

using four screws. Tape the joint to seal.

One screw per side

Wide Head Phillips

Screws

Figure 21 –

ATTACH BLOWER TO THE PLENUM

Figure 20 –

ATTACH TRANSITION TO THE

BLOWER

Figure 22 –

10

NUT LOCATIONS INSIDE THE

PLENUM

Page 11

GAS COOKTOP INSTALLATION INSTRUCTIONS

16

Blower electrical connection

Connect the 5-pin plug on the blower assembly

to the matching 5-pin receptacle on the bottom of

the cooktop.

Fold all wires into the wire box on the end of

the blower conduit. Fasten the wire box to the

cooktop with two #8 x 3/8” making sure that no

wires are trapped.

Figure 23 –

17

Connecting the Ductwork

Connect the ductwork prepared in Steps 8, 9 and

10 to the blower transition duct.

CONNECT BLOWER TO COOKTOP

18

Install Pressure Regulator

Install the pressure regulator with the arrow on the

regulator pointing up toward the unit in a position

where you can reach the access cap.

WARNING

tight. The regulator is die cast. Overtightening

may crack the regulator resulting in a gas leak

and possible fi re or explosion.

Manual

Shutoff

Valve

On

Off

All connections must be wrench-tightened

Assemble the fl exible connector from the gas

supply pipe to the pressure regulator in the

following order:

1. manual shutoff valve

2. 1/2" (1.3 cm) nipple

3. 1/2" (1.3 cm) fl are union adapter

4. fl exible connector

5. 1/2" (1.3 cm) fl are union adapter

6. 1/2" (1.3 cm) nipple

7. pressure regulator

Use pipe-joint compound made for use with

Natural and LP/Propane gas to seal all gas

connections. If fl exible connectors are used, be

certain connectors are not kinked.

DO NOT make the connection too

Flare

Union

Nipple Nipple

Figure 24 –

Figure 22 –

GAS FLOW

Flexible

Connector

GAS SUPPLY LINE

GAS SUPPLY LINE

Flare

Union

Pressure

Regulator

Access

Cap

Figure 25 –

11

PHYSICAL ATTACHMENT OF THE

GAS LINE TO THE COOKTOP

Page 12

GAS COOKTOP INSTALLATION INSTRUCTIONS

WARNING

with an approved manual shutoff valve. This

valve should be located in the same room as

the cooktop and should be in a location that

allows ease of opening and closing. DO NOT

block access to the shutoff valve. The valve is for

turning on or shutting off gas to the appliance.

to appliance

Once regulator is in place, open the shutoff valve

in the gas supply line. Wait a few minutes for gas

to move through the gas line.

18.1

Check for leaks. After connecting the

cooktop to the gas supply, check the system for

leaks with a manometer. If a manometer is not

available, turn on the gas supply and use a liquid

leak detector (or soap and water) at all joints and

connections to check for leaks.

WARNING

leaks from gas connections. Checking for leaks

with a fl ame may result in a fi re or explosion.

18.2

Tighten all connections if necessary to

prevent gas leakage in the cooktop or supply line.

The supply line must be equipped

to gas supply line

Shutoff Valve -

Open position

Figure 26 –

DO NOT use a fl ame to check for

SHUTOFF VALVE

19

Electrical Requirements

120 volt, 60 Hertz, properly grounded branch

circuit protected by a 15 amp circuit breaker or

time delay fuse. DO NOT use an extension cord

with this cooktop.

19.1

Grounding Instructions

IMPORTANT Please read carefully.

For personal safety, this appliance must be

properly grounded.

The power cord of this appliance is equipped with

a 3-prong (grounding) plug which mates with a

standard 3-prong grounding wall receptacle (see

Figure 25) to minimize the possibility of electric

shock hazard from the appliance.

The wall receptacle and circuit should be checked

by a qualifi ed electrician to make sure the

receptacle is properly grounded.

Where a standard 2-prong wall receptacle is

installed, it is the personal responsibility and

obligation of the consumer to have it replaced by

Preferred Method

DO NOT,

Grounding type

wall receptacle

Figure 27 –

a properly grounded 3-prong wall receptacle.

under any

circumstances,

cut, remove,

or bypass the

grounding prong.

Power supply

cord with 3-prong

grounding plug.

POWER SUPPLY CORD

18.3

Disconnect this cooktop and its

individual manual shutoff valve

supply piping system during any pressure testing

of that system at test pressures greater than 1/2

psig (3.5 kPa or 14"water column).

18.4

Isolate the cooktop from the gas

supply piping system

manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.5 kPa or 14"

water column).

by closing its individual

from the gas

DO NOT, under any circumstances, cut or

remove the third (ground) prong from the

power cord.

WARNING

from wall receptacle before servicing cooktop.

Install Burner Caps

20

A. Unpack the burner grates.

B. Burners: Unpack the Burner heads and burner

caps. Place the burner heads and caps on the

matching bases.

C. The caps should be level after installation

D. Be sure that all the burner caps burner head

are correctly placed BEFORE using your

cooktop.

12

Disconnect electrical supply cord

Page 13

GAS COOKTOP INSTALLATION INSTRUCTIONS

Install Filter and Grates

21

DO NOT operate the vent without the fi lter in place.

• Place the fi lter diagonally through the vent

chamber.

• Make sure it rests, at an angle, on the supports

in the vent opening.

Vent Chamber

Grease Filter

Vent

Chamber

Figure 28

VENT FILTER LOCATION

–

30" MODEL

• Carefully place vent grate seal over the vent

chamber on the cooktop, with the side marked

FRONT to the front. Make sure the collar on

the bottom of the seal is fully inserted the vent

opening. Secure the seal in place with screw.

• Place the vent grate over the vent opening.

Place the burner grates over the burners.

Vent Grate

Vent Grate

Seal

Figure 30

VENT GRATE AND SEAL LOCATION

–

30" MODEL

Vent Grate

Figure 29

VENT FILTER LOCATION

Grease Filter

Vent

Chamber

–

36" MODEL

Figure 31

VENT GRATE AND SEAL LOCATION

Figure 32

SECURE THE SEAL

Vent Grate

Seal

–

36" MODEL

13

Page 14

GAS COOKTOP INSTALLATION INSTRUCTIONS

22

Check Operation

Refer to the Use and Care Guide packaged with

the cooktop for operating instructions and for care

and cleaning of your cooktop.

21.1

Turn on Electrical Power and Open Main

Shutoff Gas Valve

21.2

Check the Igniters

Operation of electric igniters should be checked

after cooktop and supply line connectors have

been carefully checked for leaks and the cooktop

has been connected to electric power.

To operate the surface burner:

A. Push in and turn a surface burner knob to the

LITE position. You will hear a small ticking

noise; this is the sound of the electric ignitor

which lights the burner.

B. After the burner lights, turn to the desired

fl ame size. The controls DO NOT have to be

set at a particular mark. Use the marks as a

guide and adjust the fl ame as needed.

When All Hookups are Complete

Make sure all controls are left in the OFF position.

Make sure the fl ow of combustion and ventilation

air to the cooktop is unobstructed.

Before You Call for Service

Read the Before You Call for Service Checklist

and operating instructions in your Use and Care

Guide. It may save you time and expense. The

list includes common occurrences that are not the

result of defective workmanship or materials in

this appliance.

Refer to the warranty in your Use and Care

Guide for our service phone number and address.

Please call or write if you have inquiries about

your product and/or need to order parts.

14

Page 15

NOTES

Page 16

GAS COOKTOP INSTALLATION INSTRUCTIONS

Calculating Duct Length Table

For maximum effi ciency, use the shortest and straightest duct possible. Use as few fi ttings as

possible. For best performance, the duct run should not exceed 100 feet of equivalent length.

Calculations are approximate and based on HVAC industry standards.

DUCT PIECES

6" (15.2cm) Round

Straight **

6" (15.2cm) Round Metal Flex

No Bends **

6" (15.2cm)

90° Elbow

6" (15.2cm)

45° Elbow

3¼" x 10" (8.2cm x 25.4cm)

Straight **

3¼" x 10" (8.2cm x 25.4cm)

90° Elbow

3¼" x 10" (8.2cm x 25.4cm)

45° Elbow

3¼" x 10" (8.2cm x 25.4cm)

90° Flat Elbow

EQUIVALENT

LENGTH X

1 Ft. (0.3m) Ft. or m

1.5 Ft. (0.45m) Ft. or m

10 Ft. (3m) Ft. or m

5 Ft. (1.5m) Ft. or m

1 Ft. (0.3m) Ft. or m

10 Ft. (3m) Ft. or m

5 Ft. (1.5m) Ft. or m

10 Ft. (3m) Ft. or m

NUMBER

USED =

EQUIVALENT

LENGTH

3¼" x 10" (8.2cm x 25.4cm) to 6"

(15.2cm) Round Transition 90°

Elbow

6" (15.2cm) Round to 3¼" x 10"

(8.2cm x 25.4cm) Transition

90° Elbow

3¼" x 10" (8.2cm x 25.4cm) to 6"

(15.2cm) Round Transition

6" (15.2cm) Round to 3¼" x 10"

(8.2cm x 25.4cm) Transition

6" (15.2cm) Round Wall Cap with

Damper

3¼" x 10" (8.2cm x 25.4cm) Wall

Cap with Damper

6" (15.2cm) Round Roof Cap 30 Ft. (9m) Ft. or m

** For Straight Round / Rectangular Duct, measure actual linear

feet used and then multiply by Equivalent Length shown.

30 Ft. (9m) Ft. or m

30 Ft. (9m) Ft. or m

5 Ft. (1.5m) Ft. or m

5 Ft. (1.5m) Ft. or m

30 Ft. (9m) Ft. or m

30 Ft. (9m) Ft. or m

TOTAL DUCTWORK Ft. or m

16

Loading...

Loading...