Frigidaire PLGF659ECB, PLGF659GCA Installation Guide

INSTALLATION AND SERVICE MUST BE PERFORMED BY

A QUAUHED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

tf the information in this manua[ is not followed exactly, a fire

or explosion may result causing property damage, personal injury or death,

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IFYOU SMELLGAS:

• Do not try to light any appliance.

• Do not touch any e[ectrka[ switch; do not use any phone in your building,

• immediately ca[[ your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions,

• tf you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

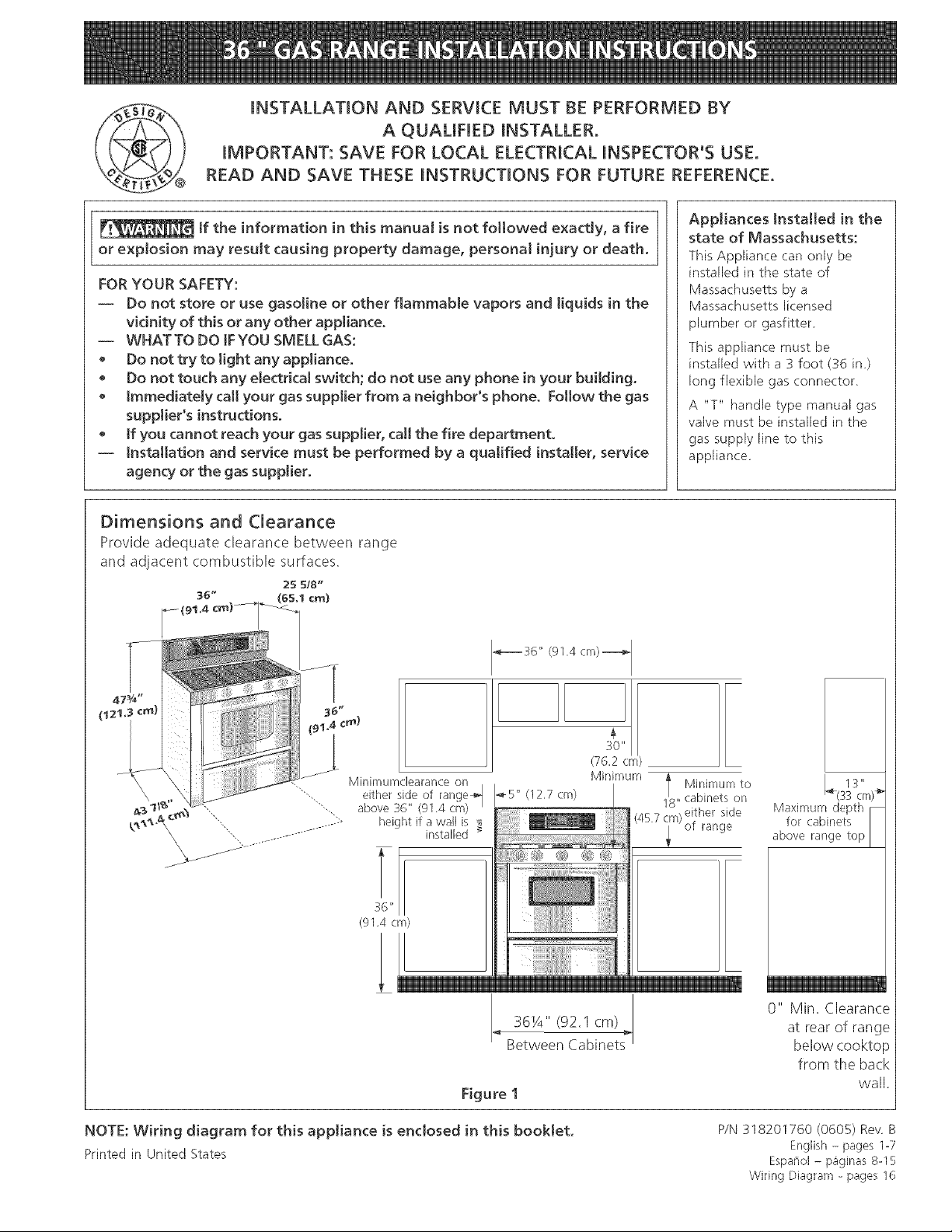

Dimensions and Clearance

Provide adequate clearance between range

and adjacent combustible surfaces.

25 5/8"

36" (65,1 ¢m)

_----36" (91.4 cm)---_

Appliances Installed in the

state of Massachusetts:

This Appliance can only be

installed in the state of

Massachusetts by a

Massachusetts licensed

plumber or gasfitter

This appliance must be

installed with a 3 foot (36 in)

long flexible gas connector,

A "T" handle type manual gas

valve must be installed in the

gas supply line to this

appliance

Minimumclearance on

either side of range_d

above 36" (91 4 cm)

height if a wall is

I

36"

(91,4 cm)

installed _

/

_,5" (12,7 cm) /

__ ___ 18" cabinets on

36V4" (92.1 cm)

Between Cabinets

Figure I

NOTE: Wiring diagram for this appliance is enclosed in this booklet.

Printed in United States

Minimum/ l Minimum to

cm) either side

(45.7 J, of range

0" Min. Clearance

at rear of range

below cooktop

from the back

wall.

P/N 318201760 (0605) Rev B

English - pages 1-7

Espahol - p_ginas 8-15

Wiring Diagram - pages 16

Important Notes to the Installer

1. Readall instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

3. Observe all governing codes and ordinances.

4. Besure to leavethese instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your Use & Care Guide for

future reference.

IMPORTANT SAFETY

JNSTRU S

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANS! Z223. I/NFPA .54datest edition.

This range has been design certified by (SA

International. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

techn[dan.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

7B--latest edition. SeeGrounding Instructions.

• The installation of appliances designed for

manufactures (mobile) home installation must conform

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard is not

applicable, tile Standard for Manufactured Home

Installation 1982 (Manufactured Home Sites,

Communities and Set ups), ANS! Z225.1 latest edition,

or local codes.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering,

make sure the floor covering can withstand heat at

least 90°F above room temperature without

shrinking, warping or discoloring. Do not install tile

range over carpeting unless you place an insulating pad

or sheet of Y4"(! 0,16 cm) thick plywood between the

range and carpeting.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is in use.

As children grow, teach them tile proper, safe use of all

appliances. Never leave the oven door open when the

range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to chiIdren in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

All ranges

can tip

• Injuryto

persons

could result.

Install anti-

tip device

packed with

range.

]b reduce the risk of

tipping ol the range, the

range must be secured by

properly installed anti-tip

bracket (s) provided with

the range. [b check if the

bracket(s) is installed

properly', grasp the top

rear edge of tile range

and carefully tilt it forward

to make sure the range is

anchored.

Do not make any attempt to operate

the electric ignition oven during an electrical power

failure. Resumption of electric power when OVEN TEMP

and OVEN SETcontrols are in any position other than OFF

will result in automatic ignition of the oven or broiler

burner. The oven burner and broil burner on your

range are lighted by electrical ignition. The oven

and broiler cannot be operated in the event of a

power failure.

Intheeventofanelectricalpoweroutage,thesurface

burnerscanbelitmanually.Tolightasurfaceburner,

holdalit matchtotheburnerheadandslowlyturnthe

SurfaceControlknobtoLITE.Usecautionwhen

lightingsurfaceburnersmanually.

• Resetallcontrols to the "off" position whenever

the oven is done cooking.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-deaning the oven, Wipe up excess

spillage. Follow tile precleaning instructions in tile Use

and Care Guide.

Unlike the standard gas range, THIS COOKTOP IS

NOT REMOVABLE. Do not attempt to remove the

cooktop.

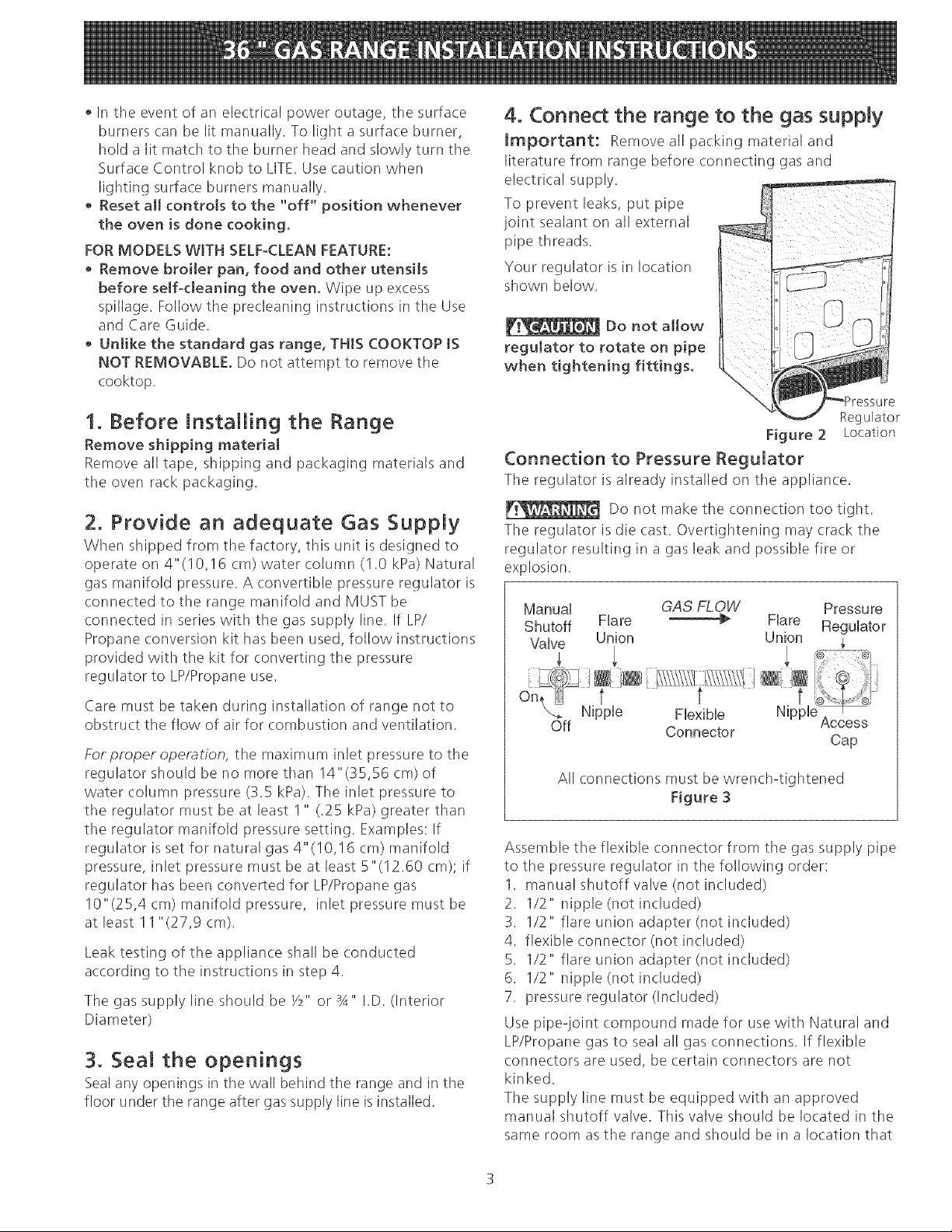

4. Connect the range to the gas supply

Important: Remove all packing material and

literature from range before connecting gas and

electrical supply.

To prevent leaks, put pipe

joint sealant on all external

pipe threads.

Your regulator is in location

shown below.

Do not allow

regulator to rotate on pipe

when tightening fittings.

1. Before Installing the Range

Remove shipping material

Remove all tape, shipping and packaging materials and

the oven rack packaging.

2. Provide an adequate Gas Supply

When shipped from the factory, this unit is designed to

operate on 4"(10,!6 cm) water column (I.0 kPa) Natural

gas manifold pressure. A convertible pressure regulator is

connected to the range manifold and MUST be

connected in series with the gas supply line. If LP/

Propane conversion kit has been used, follow instructions

provided with the kit for converting the pressure

regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct tile flow of air for combustion and ventilation.

For proper operation, tile maximum inlet pressure to the

regulator should be no more than 14"(35,56 cm) of

water column pressure (3.5 kPa). The inlet pressure to

the regulator must be at least I " (.25 kPa) greater than

the regulator manifold pressure setting. Examples: If

regulator is set for natural gas 4"(10,!6 cm) manifold

pressure, inlet pressure must be at least 5"(12.60 cm); if

regulator has been converted for LP/Propane gas

10"(25,4cm) manifold pressure, inlet pressure must be

at least 11 "(27,9 cm).

Leak testing of the appliance shall be conducted

according to the instructions in step 4.

The gas supply line should be _/2"or 3A" I.D. (Interior

Diameter)

3. Seal the openings

Seal any openings in the wall behind the range and in the

floor under tile range after gas supply line isinstalled.

Regulator

Figure 2 Location

Connection to Pressure Regulator

Tile regulator is already installed on tile appliance.

Do not make the connection too tight.

The regulator isdie cast. Overtightening may crack tile

regulator resulting in a gas leak and possible fire or

explosion.

Manual GAS FLOW Pressure

Shutoff Flare _¢_ Flare Regulator

Valve Union Union €

Onj t f t i

_--_ Nipple Flexible Nipple_

Off Connector Access

All connections must be wrench4ightened

Figure 3

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in the following order:

1. manual shutoff valve (not included)

2. 1/2" nipple (not included)

3. 1/2" flare union adapter (not included

4. flexible connector (not included)

5. 1/2" flare union adapter (not included

6. 1/2" nipple (not included)

7. pressure regulator (Included)

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not

kinked.

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as tile range and should be in a location that

Cap

allowseaseofopeningandclosing.Donotblockaccess

totheshutoffvalve.Thevalveisforturningonor

shuttingoffgasto theappliance.

Openposition

Figure4

Onceregulatorisinplace,opentheshutoffvalveinthe

gassupplyline.Waitafewminutesforgasto move

throughthegasline.

Checkfor leaks.Afterconnectingtherangetothegas

supply,checkthesystemforleakswithamanometer.If

amanometerisnotavailable,turnonthegassupplyand

usealiquidleakdetector(orsoapandwater)atall

jointsandconnectionstocheckforleaks.

Donotuseaflameto checkforleaks

fromgasconnections.Checkingforleakswithaflame

mayresultinafireorexplosion.

Tightenal!connectionsasnecessarytopreventgas

leakageintherangeorsupplyline.

Disconnectthis rangefromtile gassupplypiping

systemduringanypressuretestingofthatsystemattest

pressuresgreaterthan1/2psig(3.5kPaor14"water

column).

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

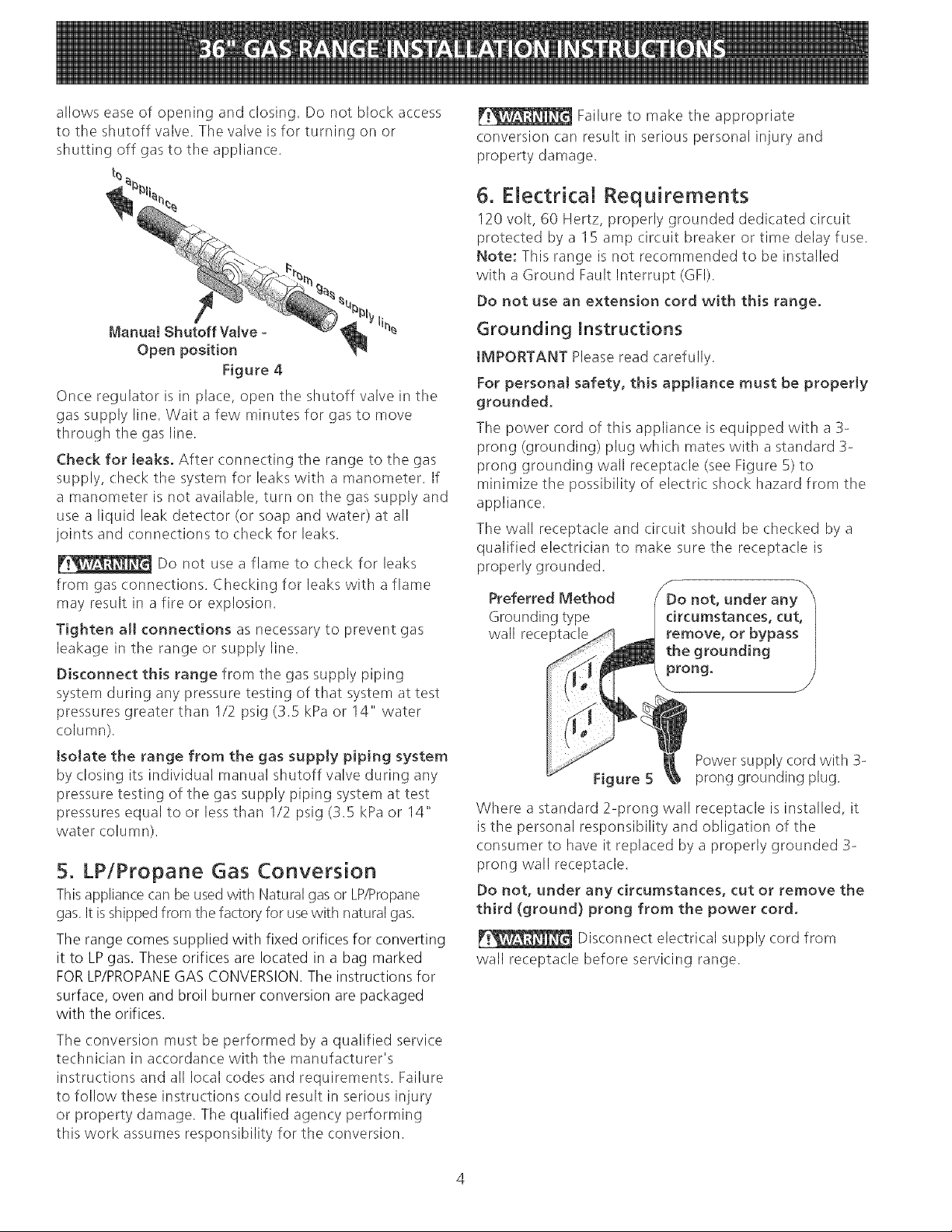

5. Electrical Requirements

120 volt, 60 Hertz, properly grounded dedicated circuit

protected by a 15 amp circuit breaker or time delay fuse.

Note: This range is not recommended to be installed

with a Ground Fault Interrupt (GFI).

Do not use an extension cord with this range.

Grounding Instructions

IMPORTANT Please read carefully.

For personal safety, this appliance must be properly

grounded.

The power cord of this appliance is equipped with a 3-

prong (grounding) plug which mates with a standard 3-

prong grounding wall receptacle (see Figure 5) to

minimize the possibility of electric shock hazard from tile

appliance.

The wall receptacle and circuit should be checked by a

qualified electrician to make sure the receptacle is

properly grounded.

Grounding type

wall rece

Preferred Method /__a_!,l

Isolatetherangefromthe gassupplypiping system

byclosingitsindividualmanualshutoffvalveduringany

pressuretestingofthegassupplypipingsystemattest

pressuresequaltoorlessthan1/2psig(3.5kPaor14"

watercolumn).

5. LP/Propane Gas Conversion

Thisappliance can be used with Natural gasor LP/Propane

gas. It isshipped from the factory for use with natural gas.

The range comes supplied with fixed orifices for converting

it to LPgas. These orifices are located in a bag marked

FORLP/PROPANEGAS CONVERSION.The instructions for

surface, oven and broil burner conversion are packaged

with the orifices.

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for tile conversion.

Power supply cord with 3-

Figure 5

Where a standard 2-prong wall receptacle is installed, it

isthe personal responsibility and obligation of tile

consumer to have it replaced by a properly grounded 3-

prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground} prong from the power cord.

Disconnect electrical supply cord from

wall receptacle before servicing range.

prong grounding plug.

7. Moving the AppNiance for

Servicing and Cmeaning

Turn off the range line fuse or circuit breakers at tile main

power source, and turn off the manual gas shut-off valve.

Make sure the range is (:old. Remove the service drawer

(warmer drawer on some models) and open the oven door.

Lift the range at the front and slide it out of the cut-out

opening without creating undue strain on the flexible gas

conduit. Make sure not to pinch the flexible gas conduit at

the back of the range when replacing the unit into the cut-

out opening. Replace the drawer, closethe door and switch

on the electrical power and gas to the range.

8. Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

Remove all packaging from the oven before testing.

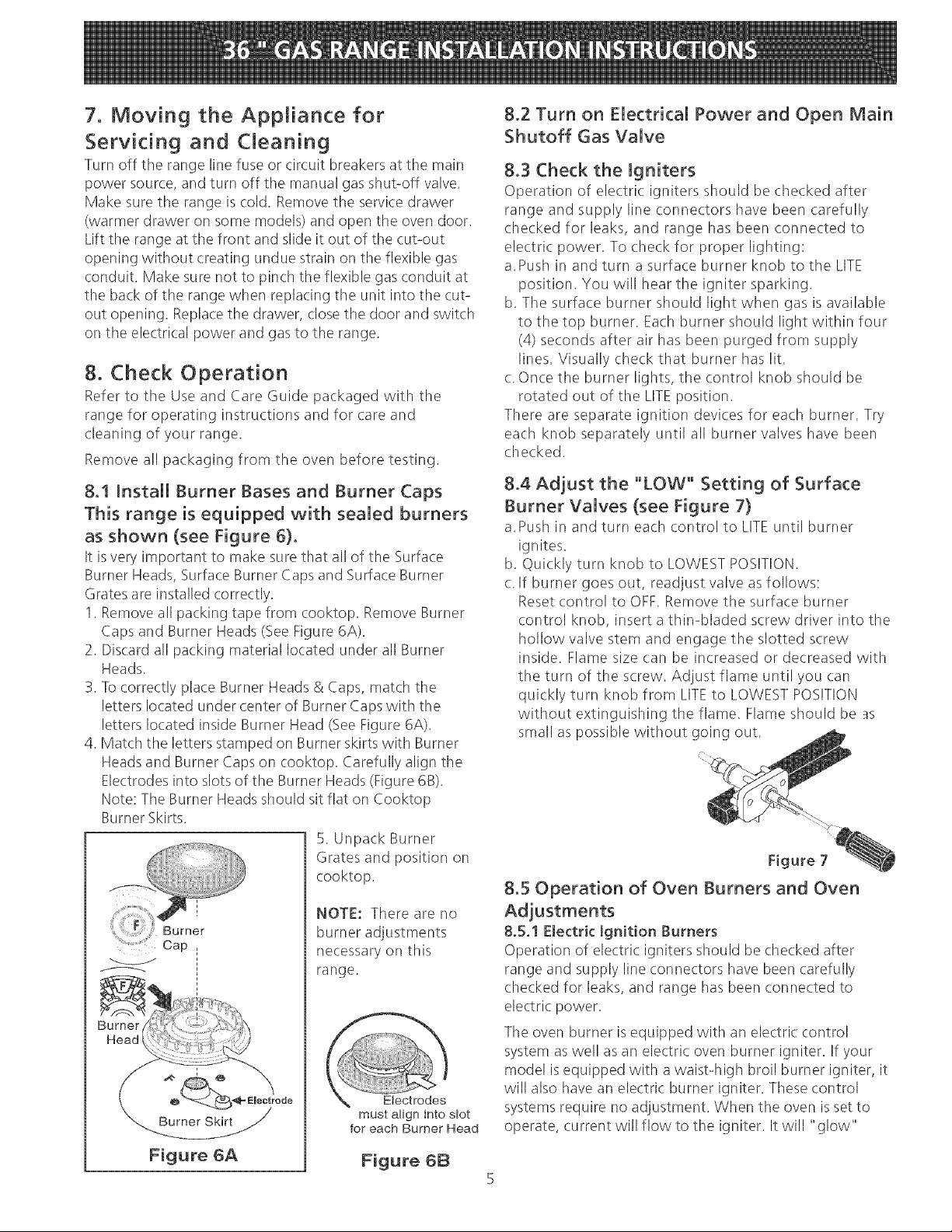

8.1 Install Burner Bases and Burner Caps

This range is equipped with sealed burners

as shown (see Figure 5).

It isvery important to make sure that all of the Surface

Burner Heads, Surface Burner Caps and Surface Burner

Grates are installed correctly.

I. Remove all packing tape from cooktop. Remove Burner

Caps and Burner Heads (See Figure 6A).

2. Discard all packing material located under all Burner

Heads.

3. Tocorrectly place Burner Heads & Caps, match tile

letters located under center of Burner Caps with the

letters located inside Burner Head (See Figure 6A).

4. Match the letters stamped on Burner skirts with Burner

Heads and Burner Caps on cooktop. Carefully align the

Electrodes into slots of tile Burner Heads (Figure 6B).

Note: The Burner Heads should sit flat on Cooktop

Burner Skirts.

5. Unpack Burner

Grates and position on

cooktop.

NOTE: There are no

Burner

Cap

burner adjustments

necessary on this

range.

must align into slot

for each Burner Head

8.2 Turn on Electrical Power and Open Main

Shutoff Gas Valve

8.3 Check the Igniters

Operation of electric: igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric: power. To check for proper lighting:

a.Push in and turn a surface burner knob to tile LITE

position. You will hear the igniter sparking.

b. The surface burner should light when gas is available

to the top burner. Each burner should light within four

(4) seconds after air has been purged from supply

lines. Visually check that burner has lit.

c. Once the burner lights, the control knob should be

rotated out of tile LITEposition.

There are separate ignition devices for each burner. Try

each knob separately until all burner valves have been

checked.

8.4 Adjust the "LOW" Setting of Surface

Burner Valves (see Figure 7}

a.Push in and turn each control to LITEuntil burner

ignites.

b. Quickly turn knob to LOWEST POSITION.

c. lf burner goes out, readjust valve as follows:

Reset control to OFF.Remove the surface burner

control knob, insert a thin-bladed screw driver into tile

hollow valve stem and engage the slotted screw

inside. Flame size can be increased or decreased with

the turn of the screw. Adjust flame until you can

quickly turn knob from LITEto LOWEST POSITION

without extinguishing the flame. Flame should be _s

small as possible without going out.

Figure 7

8.5 Operation of Oven Burners and Oven

Adjustments

8.5.1 Electric Ignition Burners

Operation of electric: igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power.

The oven burner is equipped with an electric control

system aswell asan electric oven burner igniter. If your

model is equipped with awaist-high broil burner igniter, it

will also have an electric burner igniter. These control

systems require no adjustment. When the oven is set to

operate, current will flow to tile igniter. It will "glow"

Figure 6A

Figure 6B

5

Loading...

Loading...