Frigidaire CFCS366EB1, CFCS366EB2, CFCS366EB3, CFCS366EC1, CFCS366EC2 Installation Guide

...Page 1

mNSTALLATmONAND SERVICE MUST BE PERFORMED BY A QUAUFBED [NSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL mNSPECTOR'SUSE.

READ AND SAVE THESE [NSTRUCTmONS FOR FUTURE REFERENCE.

IF_ if the information in this manua[ is not followed exactly, a fire

or expJosion may resuJt causing property damage, personaJ injury or death.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other app[iance. Refer to your serial plate for

-- WHAT TO DO JFYOU SMELL GAS: applicable agency certification

• Do not try to Hght any appliance.

• Do not touch any eJectrica[ switch; do not use any phone in your building.

Immediately ca[[ your gas supplier from a neighbor's phone. FoIIow the gas suppIier's instructions,

tf you cannot reach your gas supplier, ca[[ the fire department.

-- Installation and service must be performed by a qualified installer, service agency or the gas supplier,

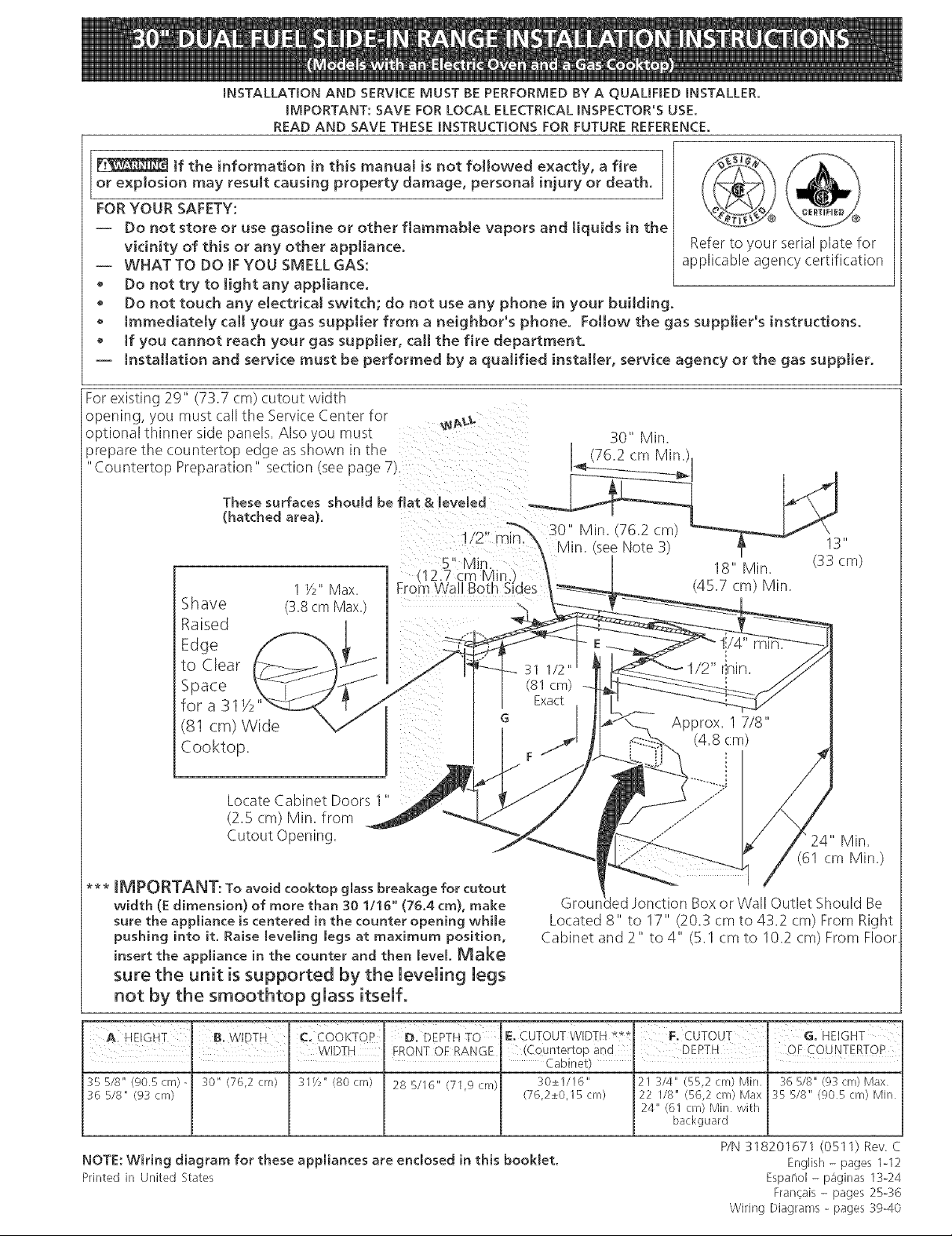

Forexisting 29" (73.7 cm) cutout width

opening, you must call the Service Center for

optional thinner side panels. Also you mus_

prepare the countertop edge as shown in tne

30" Min.

76.2 cm Min.

"Countertop Preparation" section (see page 7/.

These surfaces shouH be fiat & Jeveled

(hatched area).

Shave

(3_8cmMax.)

Raised

Edge

to Clear

Space

for a 31 >2

1 Y2"Max.

(81 cm) Wide

Cooktop.

Approx. 7/8"

(4.8 cm)

Locate Cabinet Doors 1"

(2.5 cm) Min. from

: _24" Mira

Cutout Opening.

i / (61cmMin.)

*** IMPORTANT: To avoid cooktop gmass breakage for cutout

width (E dimension) of more than 30 11!6" (76.4 cm), make

sure the appliance is centered in the counter opening while

pushing into it. Raise leveling legs at maximum position,

insert the appliance in the counter and then [eveL Make

Grour_ed Jonction Box or Wall Outlet Should Be

Located 8" to 17" (20.3 cm to 43.2 cm) From Right

Cabinet and 2" to 4" (5.1 cm to 10.2 cm) From Floor

sure the unit is supported by the leveling legs

not by the smoothtop glass itself.

I I WIDTH FRONT QF RANGE (C0untertop and ' DEATH ' OF COUNTERTOP

355/8" @05cm)- :_0" (76,2 cm) :_1Y2"(80cm) 28 5116" (71,9cm) 30±1116" 21 3/4" {55,2cm) Min, %518"(93cm) Max

36 518" (9_ crn) (76,2±0,15cm) 22 I18" (56,2 cm) Max 35 5/8" (905cm) Min

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

Printed in United States

C. COOKTOP D, DEPTH TO E. CUTOUT WIDTH **g F, CUTOUT G. HEIGHT

' ' Cabinet)

24" {61 cm) Min with

backguard

I

P/N 318201671 (0511) Rev C

English - pages 1-12

Espano[ - p_ginas 13-24

Fran_ais - pages 25-_6

Wiring Diagrams - pages 3g-40

Page 2

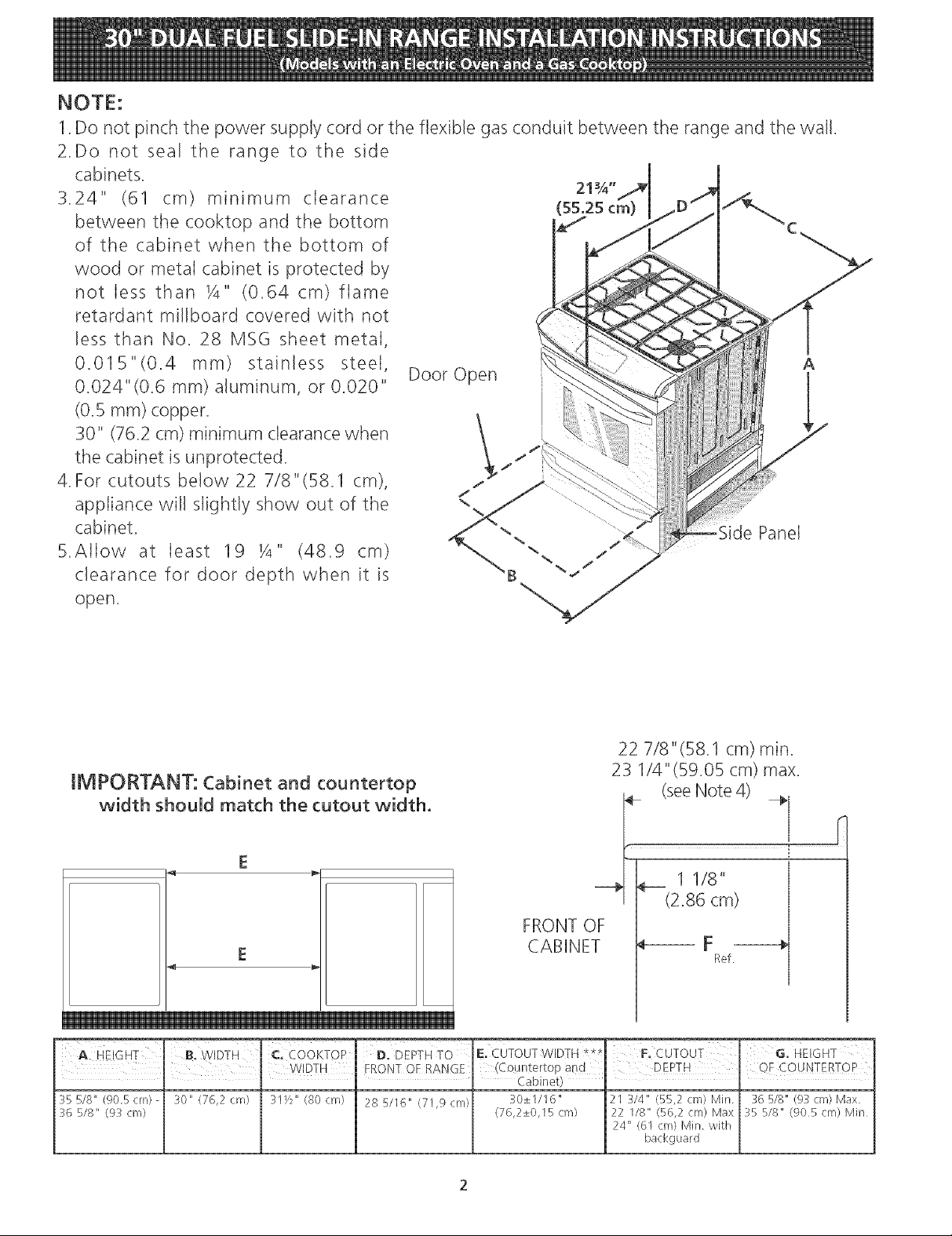

NOTE:

1,Do not pinch the power supply cord or the flexible gas conduit between the range and the wall,

2. Do not seal the range to the side

cabinets.

3.24" (61 cm) minimum clearance

between the cooktop and the bottom

of the cabinet when the bottom of

wood or metal cabinet is protected by

not less than Y4" (0.64 cm) flame

retardant millboard covered with not

less than No. 28 MSG sheet metal,

0.015"(0.4 ram) stainless steel,

0.024"(0.6 ram) aluminum, or 0.020"

(0.5 mm) copper.

30" (762 cm) minimum clearance when

the cabinet is unprotected.

4. For cutouts below 22 7/8"(58.1 cm),

appliance will slightly show out of the

cabinet.

5.Atlow at least 19 Y4" (48.9 cm)

clearance for door depth when it is

open.

Door Open

A

Panel

22 7/8"(58,1 cm) rain,

23 1/4"(59,05 cm) max,

IMPORTANT: Cabinet and countertop

(see Note 4)

width should match the cutout width.

E

1 (2.86 cm)

FRONT OF

E

" Cabinet)

% 5/8" (90,5 crn) - 30" (76,2 crn) :_1Y2"(80 crn) 28 5/I6" (71,9 cm) 30±I/16" 21 W4" (55,2 cnl) Min 36 5/8" (93 cm) Max

36 5/8" (9:_ cm) (76,2±0,15 cm) 22 1/8" (56,2 cm) Max :_ 5/8" (905 cm) Min

2

24" (61 cm) Min with

backguard

Ref.

Page 3

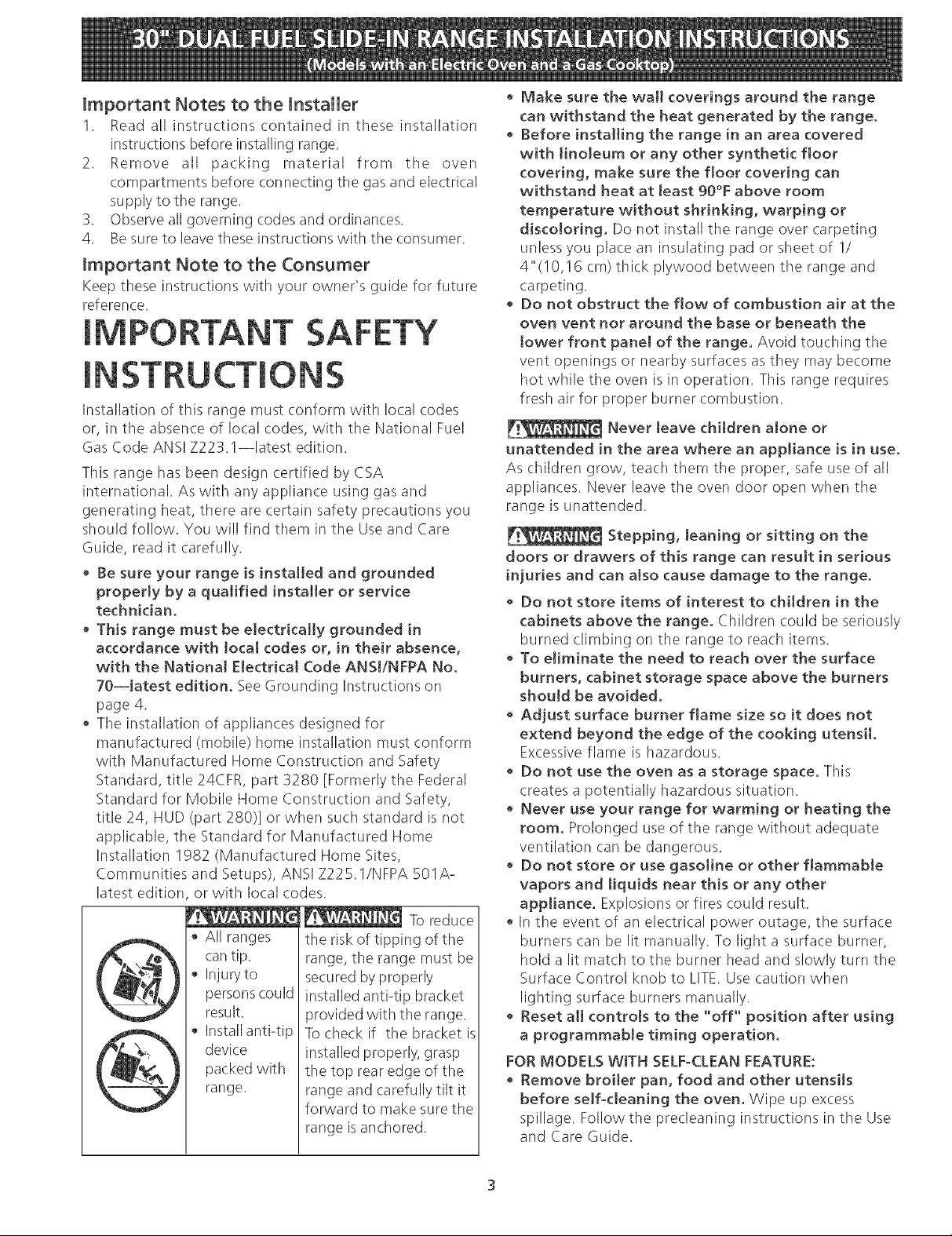

Important Notes to the Installer

1. Readallinstructionscontainedintheseinstallation

instructionsbeforeinstallingrange.

2. Removeall packing material from the oven

compartmentsbeforeconnectingthegasandelectrical

supplytotilerange.

3. Observeallgoverningcodesandordinances.

4. Besureto leavetheseinstructionswithtileconsumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT SAFETY

[NSTRU S

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANS! Z223. l--latest edition.

This range has been design certified by CSA

international. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Useand Care

Guide, read it carefully.

• Be sure your range is instai[ed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with toca[ codes or, in their absence,

with the National EJectrica[ Code ANSJ/NFPA No.

7O--Jatest edition. See Grounding Instructions on

page 4.

• The installation of appliances designed for

manufactured (mobile) home installation must conforra

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard is not

applicable, the Standard for Manufactured Home

Installation 1982 (Manufactured Home Sites,

Communities and Setups), ANSI Z225.1/NFPA 501A-

latest edition or with local (.odes.

To reduce

• All ranges

cantip.

• Injury to

persons could

result.

• Install anti-tip

device

packed with

range.

the risk of tipping of tile

range, the range must be

secured by properly

installed anti-tip bracket

provided with the range.

To check if the bracket is

installed properly, grasp

the top rear edge of the

range and carefully tilt it

forward to make sure the

range is anchored.

Make sure the wal[ coverings around the range

can withstand the heat generated by the range.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at [east 9B°F above room

temperature without shrinking, warping or

discoloring. Do not install tile range over carpeting

unless you place an insulating pad or sheet of 1/

4"(10,!6 cm) thick plywood between the range and

carpeting.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

tower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while tile oven is in operation. This range requires

fresh air for proper burner combustion.

Never leave children alone or

unattended [n the area where an appliance [s [n use.

As children grow, teach them the proper, safe use of all

appliances. Never leave the oven door open when the

range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

shouId be avoided.

Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

Do not use the oven as a storage space. This

creates a potentially hazardous situation.

Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other fJammabIe

vapors and liquids near this or any other

appliance. Explosions or fires could result.

In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control knob to LITE. Use caution when

lighting surface burners manually.

• Reset all controis to the "off" position after using

a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensiJs

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the Use

and Care Guide.

Page 4

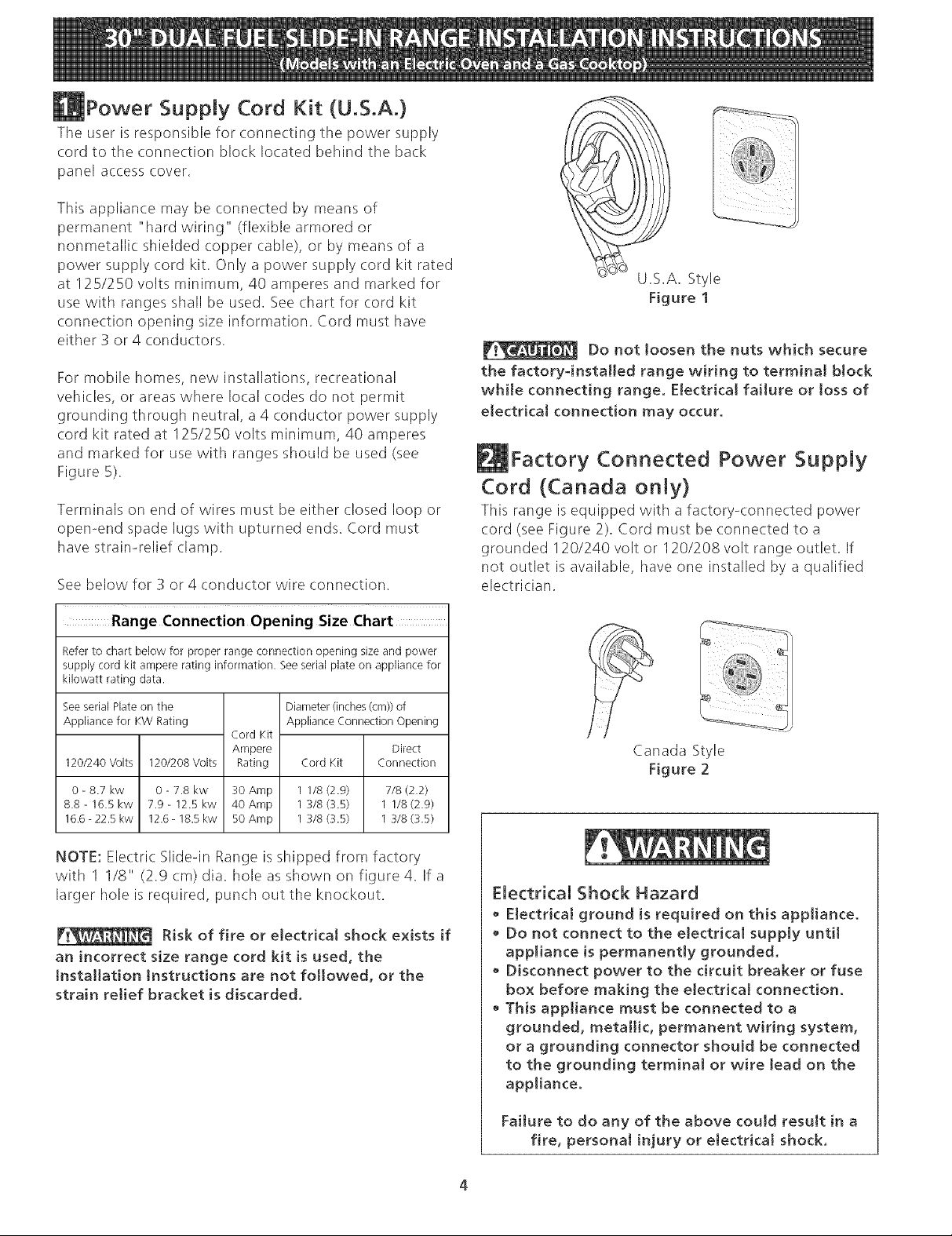

Power Supply Cord Kit (U.S.A.)

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

This appliance may be connected by means of

permanent "hard wiring" (flexible armored or

nonmetallic shielded copper cable), or by means of a

power supply cord kit. Only a power supply cord kit rated

at 125/250 volts minimum, 40 amperes and marked for

use with ranges shall be used. See chart for cord kit

connection opening size information. Cord must have

either 3 or 4 conductors.

For mobile homes, new installations, recreational

vehicles, or areas where local codes do not permit

grounding through neutral, a 4 conductor power supply

cord kit rated at 125/250 volts minimum, 40 amperes

and marked for use with ranges should be used (see

Figure 5).

Terminals on end of wires must be either closed loop or

open-end spade lugs with upturned ends. Cord must

have strain-relief clamp.

See below for 3 or 4 conductor wire connection.

U.S.A. Style

Figure 1

Do not loosen the nuts which secure

the factory-installed range wiring to terminat block

while connecting range. Electrical faiture or toss of

electrical connection may occur.

Factory Connected Power Supply

Cord (Canada only)

This range isequipped with a factory-connected power

cord (see Figure 2). Cord must be connected to a

grounded 120/240 volt or 120/208 volt range outlet. If

not outlet isavailable, have one installed by a qualified

electrician.

Range Connection Opening Size Chart

Refer to chart below for proper range connection opening size and power

supply cord kit ampere rating information. See serial plate on appliance for

kilowatt rating data.

Seeserial Plateon the

Appliance for KW Rating

120/240 Volts 120/208 Volts

0- 8.7 kw 0- 7.8 kw

8.8-16.5kw 7.9- 12.5kw

16.6-22.5kw 12.6-18.5kw

Cord Kit

Ampere

Rating

30 Amp

40 Amp

50 Amp

Diameter (inches (cm)) of

Appliance Connection Opening

Direct

Cord Kit Connection

1 1/8(2.9) 7/8(2.2)

1 3/8 (3.5) 1 1/8 (2.9)

1 318 (3.5) 1 318 (3.5)

NOTE: Electric Slideqn Range is shipped from factory

with 1 1/8" (2.9 cm) dia. hole as shown on figure 4. If a

larger hole is required, punch out the knockout.

Risk of fire or electrical shock exists if

an incorrect size range cord kit is used, the

Installation Instructions are not followed, or the

strain retief bracket is discarded.

Canada Style

Figure 2

Electrical Shock Hazard

Electrical ground is required on this appliance.

• Do not connect to the electrical supply untit

appliance is permanentJy grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

Page 5

EJectricaJ Connection to the Range

(U,S.A.)

This appliance is manufactured with the neutral terminal

connected to the frame.

Note: Refer to the wiring diagram in the center pages of

this manual.

Three Conductor Wire Connection to Range

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power supply

cord (see Figure 4):

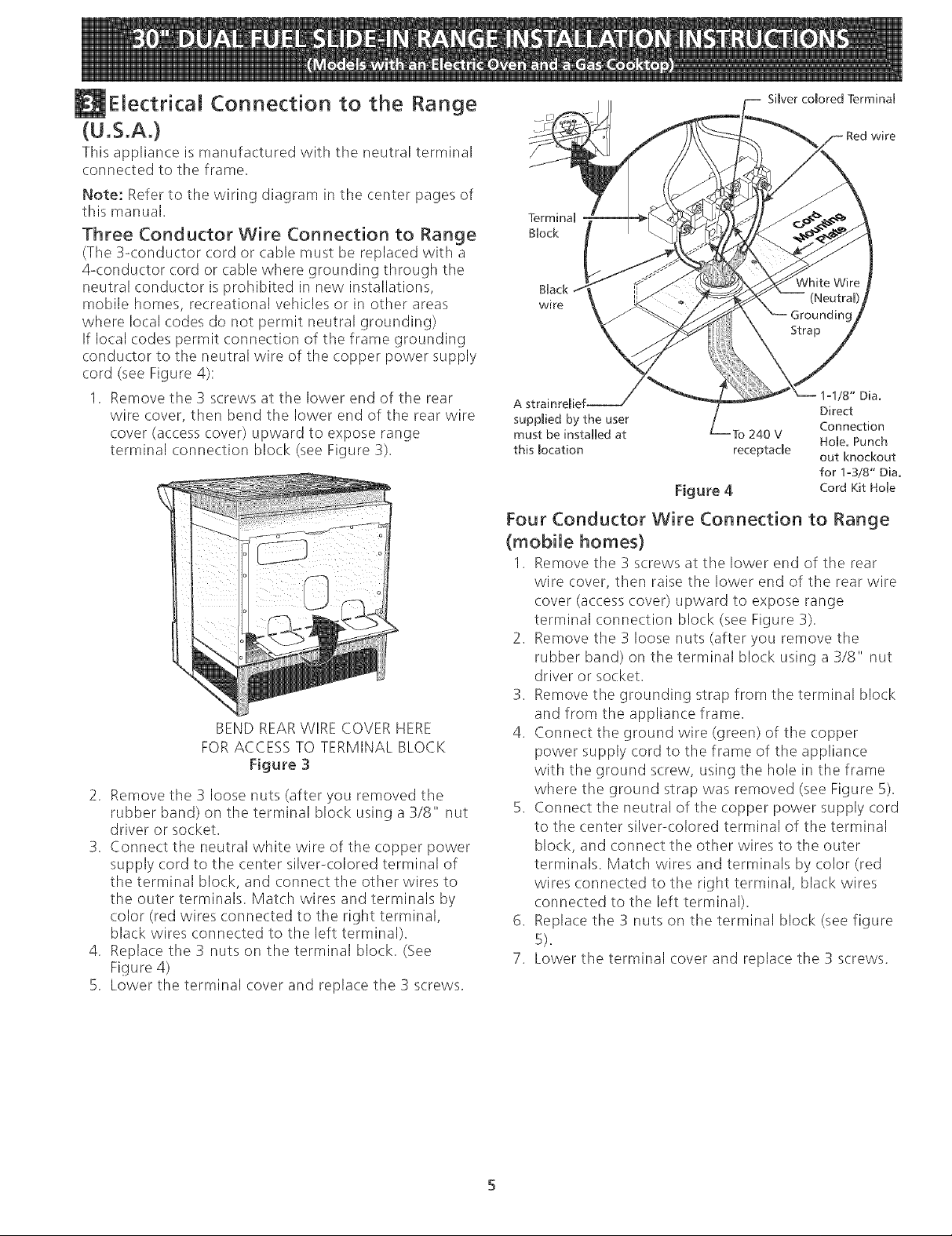

1. Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear wire

cover (accesscover) upward to expose range

terminal connection block (see Figure 3).

BEND REARWIRE COVER HERE

FOR ACCESS TO TERMINAL BLOCK

Figure 3

2. Remove the 3 loose nuts (after you removed the

rubber band) on the terminal block using a3/8" nut

driver or socket.

3. Connect the neutral white wire of the copper power

supply cord to the center silver-colored terminal of

the terminal block, and connect the other wires to

tile outer terminals. Match wires and terminals by

color (red wires connected to the right terminal,

black wires connected to the left terminal).

4. Replace the 3 nuts on the terminal block. (See

Figure 4)

5. Lower the terminal cover and replace the 3 screws.

Simverco[ored TerminaU

Red wire

Terminal

gUock

BUack

wire

suppRied by the user

must be installed at Fo 240 V

this [ocation receptacle out knockout

Figure 4 Cord Kit Hole

Direct

Connection

Hole. Punch

for 1o3/8" Dia.

Four Conductor Wire Connection to Range

(mobile homes)

1. Remove the 3 screws at the lower end of tile rear

wire cover, then raise the lower end of the rear wire

cover (accesscover) upward to expose range

terminal connection block (see Figure 3).

2. Remove the 3 loose nuts (after you remove the

rubber band) on tile terminal block using a 3/8" nut

driver or socket.

3. Remove the grounding strap from the terminal block

and from the appliance frame.

4. Connect the ground wire (green) of the copper

power supply cord to the frame of the appliance

with the ground screw, using the hole in the frame

where the ground strap was removed (see Figure 5).

5. Connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal).

6. Replace the 3 nuts on the terminal block (see figure

5).

7. Lower tile terminal cover and replace the 3 screws.

Page 6

Brock

TerminaF

Red

Wire

1-1/8"

Direct

Connection

HoFe.Punch

out knockout

for 1-3/8" Dia.

Cord Kit Hole

A strainreFief

supplied by the user

must be installed at

this Focation

NOTE: Be sure to remove the supphed

grounding strap

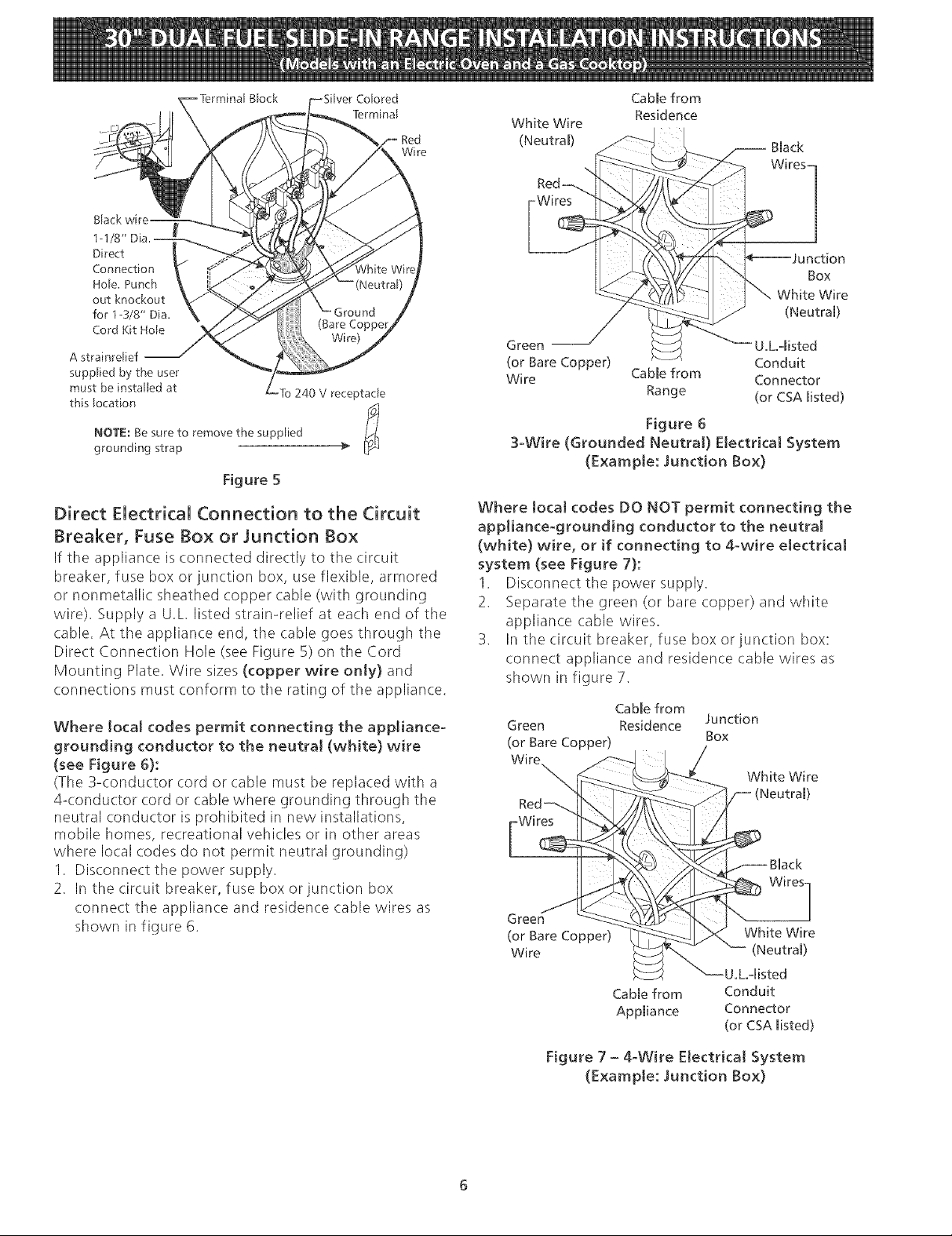

Figure 5

ro 240 v receptacle

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L listed strain-relief at each end of the

cable. At the appliance end, tile cable goes through the

Direct Connection Hole (see Figure 5) on the Cord

Mounting Plate. Wire sizes (copper wire only} and

connections must conform to the rating of the appliance.

Where local codes permit connecting the appliance-

grounding conductor to the neutral (white} wire

(see Figure 6}:

(The 3-conductor cord or cable must be replaced with a

4<onductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

1. Disconnect tile power supply.

2. In the circuit breaker, fuse box or junction box

connect the appliance and residence cable wires as

shown in figure 6.

Cable from

White Wire

(Neutram)

Residence

Black

WiresI

)n

Box

White Wire

(Neutral)

Green U,L,-misted

(or Bare Copper) Conduit

Wire Cable from Connector

Range (or CSA misted)

Figure 6

3-Wire (Grounded Neutral} Electrical System

(Example: Junction Box}

Where tocaJ codes DO NOT permit connecting the

appliance-grounding conductor to the neutral

(white} wire, or if connecting to 4-wire electrical

system (see Figure 7}:

1. Disconnect the power supply.

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the circuit breaker, fuse box or iunction box:

connect appliance and residence cable wires as

shown in figure 7.

Cable from

Green Residence Junction

(or Bare Copper) Box

White Wire

Red_

Wires

ack

Green

(or Bare Copper) White Wire

Wire (Neutram)

U.Loqisted

Cable from Conduit

Appmiance Connector

(or CSA misted)

Figure 7 - 4oWire Electrical System

(Example: Junction Box)

Page 7

Cabinet Construction

To eliminate the risk of burns or fire by

reaching over heated surface units, do not have cabinet

storage space above the range. If there is cabinet

storage space above range, reduce risk by installing a

range hood that projects horizontally a minimum of 5"

(12.7 cm) beyond tile bottom of tile cabinet.

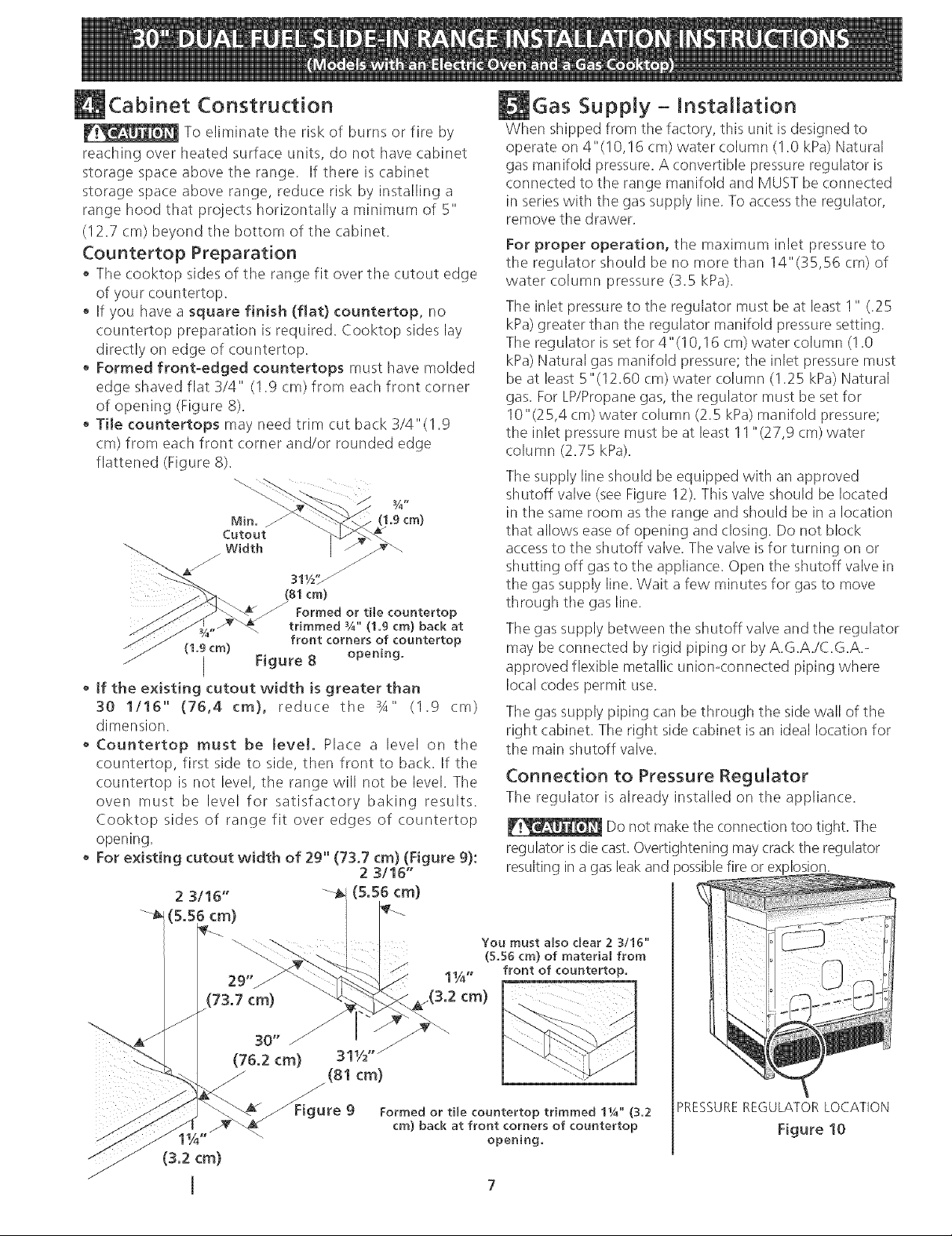

Countertop Preparation

• The cooktop sides of the range fit over the cutout edge

of your countertop.

• If you have a square finish (fiat) countertop, no

countertop preparation isrequired. Cooktop sides lay

directly on edge of countertop.

• Formed front-edged countertops must have molded

edge shaved flat 3/4" (1.9 cm) from each front corner

of opening (Figure 8).

• Tile countertops may need trim cut back 3/4"(1.9

cm) from each front corner and/or rounded edge

flattened (Figure 8).

(1,9cm)

311/2'_

(81cm)

Formed or tile countertop

trimmed ¾" (1.9 cm) back at

(1.9 cm)

• tf the existing cutout width is greater than

30 1/16" (76,4 cm), reduce the 3A" (1.9 cm)

dimension.

Countertop must be level. Place a level on the

countertop, first side to side, then front to back. If the

countertop is not level, tile range will not be level. The

oven must be level for satisfactory baking results.

Cooktop sides of range fit over edges of countertop

opening.

For existing cutout width of 29" (73,7 cm) (Figure g):

front corners of countertop

Figure 8 opening.

2 3/16"

(5.56 cm)

Gas Supply- Installation

When shipped from tile factory, this unit is designed to

operate on 4"(10,16 cm) water column (I .0 kPa)Natural

gas manifold pressure. A convertible pressure regulator is

connected to the range manifold and MUST be connected

in series with tile gas supply line. To accesstile regulator,

remove tile drawer.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm) of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1" (.25

kPa)greater than tile regulator manifold pressure setting.

The regulator issetfor 4" (! 0,16 cm) water column (I .0

kPa) Natural gas manifold pressure; the inlet pressure must

be at least 5"(12.60 cm) water column (!.25 kPa) Natural

gas. For LP/Propanegas, the regulator must be set for

10"(25,4 cm) water column (2.5 kPa)manifold pressure;

the inlet pressure must be at least 11"(27,9 cm) water

column (2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 12). This valve should be located

in tile same room as the range and should be in a location

that allows easeof opening and (:losing. Do not block

accessto the shutoff valve. The valve is for turning on or

shutting off gasto the appliance. Open the shutoff valve in

the gas supply line. Wait a few minutes for gas to move

through tile gas line.

Tile gas supply between the shutoff valve and the regulator

may beconnected by rigid piping or by A.G.A./C.G.A.-

approved flexible metallic uniomconnected piping where

local codes permit use.

The gas supply piping can be through the side wall of the

right cabinet. The right side cabinet isan ideal location for

the main shutoff valve.

Connection to Pressure Regulator

Tile regulator is already installed on the appliance.

Do not makethe connection too tight. The

regulator isdiecast.Overtightening may crack the regulator

resulting in a gasleakand )ossiblefire or explosion.

You must also dear 2 3/16"

(5.56 cm) of material from

29" 1_/_"

front of countertop.

(73.7 cm) _(3.2 cm)

_re Formed or tile countertop trimmed lYg' (3.2

9

cm) back at front corners of countertop

opening,

PRESSURE REGULATOR LOCATION

Figure 10

Page 8

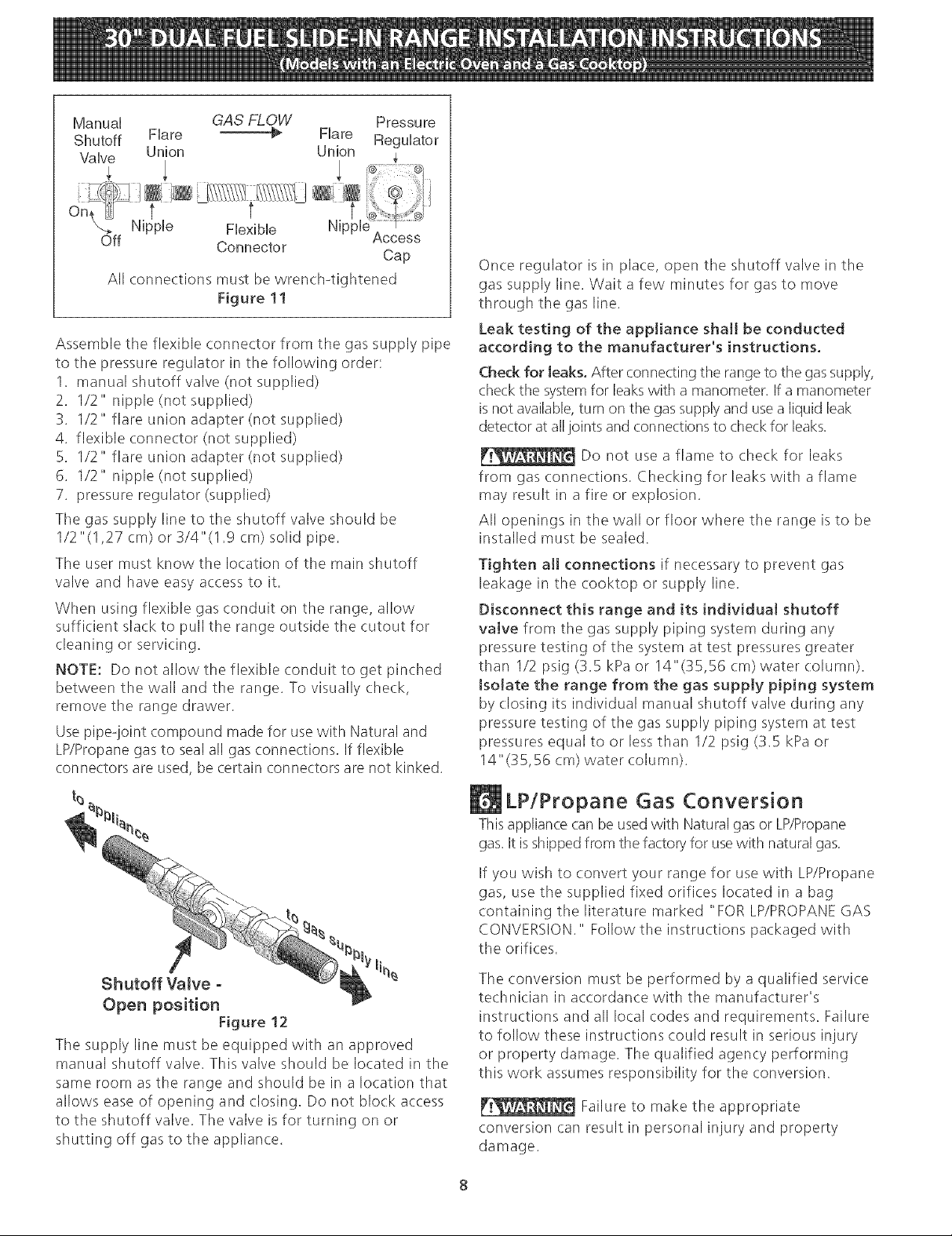

Manual GAS FLOW Pressure

Shutoff Hare _ Hare ReguHator

VaHve Union Union

On, _J t t t

k,_ NippHe FHexibHe NippHe.........................

Off Connector

All connections must be wrench4ightened

Figure 11

Assemble the flexible connecter from the gas supply pipe

to the pressure regulator in the following order:

1. manual shutoff valve (not supplied)

2. 1/2" nipple (not supplied)

3. 1/2" flare union adapter (not supplied)

4. flexible connector (not supplied)

5. 1/2" flare union adapter (not supplied)

6. 1/2" nipple (not supplied)

7. pressure regulator (supplied)

The gas supply line to the shutoff valve should be

1/2"(1,27 cm) or 3/4"(1.9 cm) solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

When using flexible gas conduit on the range, allow

suffi(ient slack to pull the range outside the cutout for

cleaning or servicing.

NOTE: Do not allow the flexible conduit to get pinched

between the wall and the range. To visually check,

remove tile range drawer.

Usepipe-joint compound made for usewith Natural and

LP/Propanegas to seal all gas connections. If flexible

connectors are used, be certain connectors are not kinked.

Access

Cap

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

Leak testing of the appliance shah be conducted

according to the manufacturer's instructions.

Check for leaks. After connecting the range to the gassupply,

checkthe systemfor leakswith amanometer. Ifa manometer

isnot available,turn on tile gassupply and usea liquid leak

detector at alljoints and connections to check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where tile range isto be

installed must be sealed.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Disconnect this range and its individual shutoff

valve from tile gas supply piping system during any

pressure testing of tile system at test pressures greater

than 1/2 psig (3.5 kPa or 14"(35,56 cm) water column).

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of tile gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa or

14"(35,56 cm) water column).

Open position

Figure 12

Tile supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the range and should be in a location that

allows ease of opening and closing. Do not block access

to the shutoff valve. The valve isfor turning on or

shutting off gas to the appliance.

LPiPropane Gas Conversion

This appliance can be usedwith Natural gas or LP/Propane

gas. It isshipped from the factory for usewith natural gas.

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices located in a bag

containing the literature marked "FOR LP/PROPANEGAS

CONVERSION." Follow the instructions packaged with

the orifices.

The conversion must be performed by aqualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in personal injury and property

damage.

Page 9

MOVing the Appliance for

rvicing and Cleaning

Turn off the range line fuse or circuit breakers at the main

power source, and turn off the manual gas shut-off valve.

Make sure the range is(:old. Remove the service drawer

(warmer drawer on some models) and open the oven door.

Lift the range at the front and slide it out of the cut-out

opening without creating undue strain on the flexible gas

conduit. Make sure not to pinch the flexible gas conduit at

the back of the range when replacing the unit into the cut-

out opening. Replace the drawer, closethe door and switch

on the electrical power and gas to tile range.

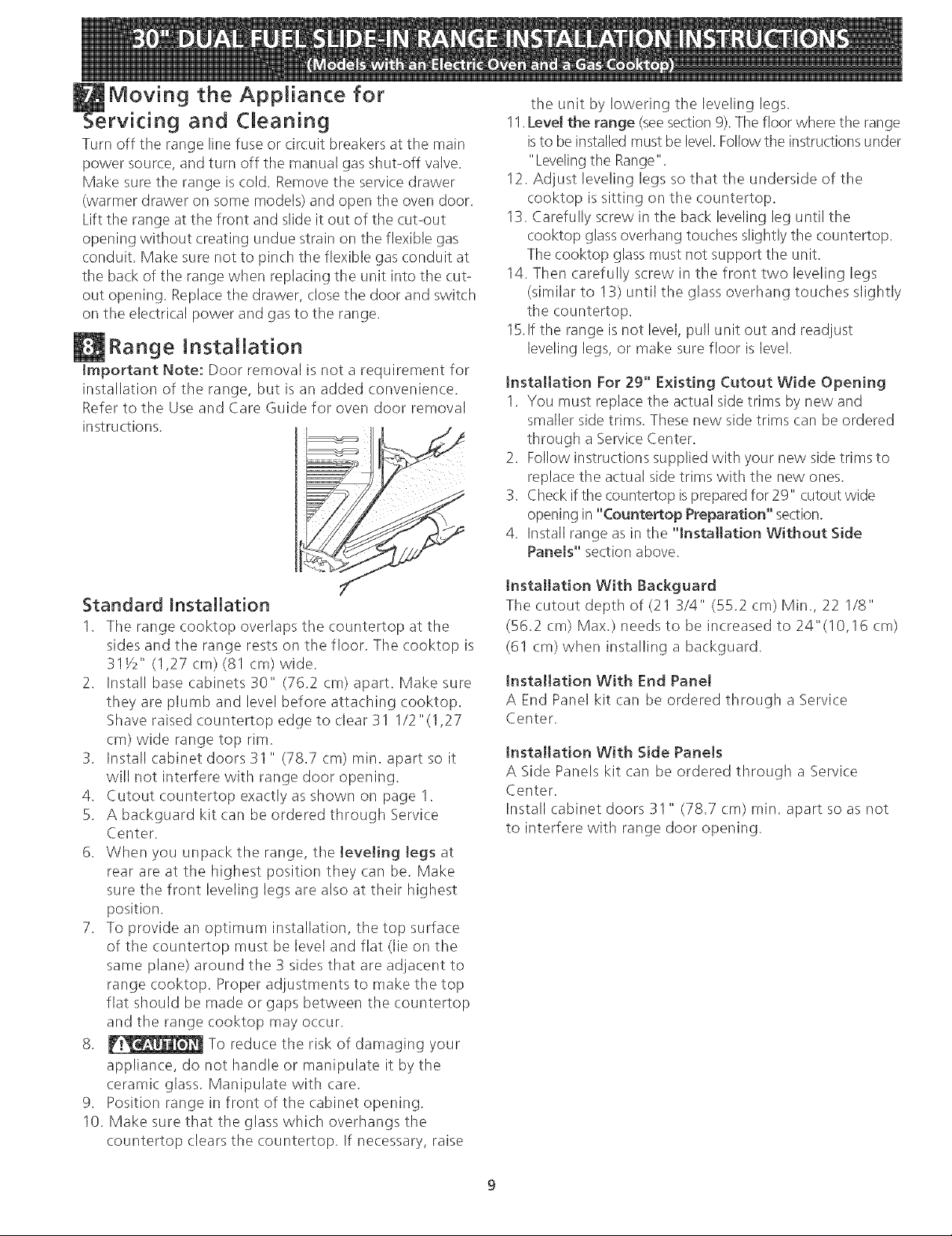

Range Installation

Important Note: Door removal is not a requirement for

installation of the range, but isan added convenience.

Refer to the Use and Care Guide for oven door removal

instructions.

the unit by lowering the leveling legs.

11.Level the range (seesection9). The floor where the range

isto beinstalled must be level.Follow the instructions under

"Levelingtile Range".

12. Adjust leveling legs so that the underside of the

cooktop is sitting on tile countertop.

13. Carefully screw in tile back leveling leg until the

cooktop glass overhang touches slightly the countertop.

The cooktop glass must not support the unit.

14. Then carefully screw in tile front two leveling legs

(similar to !3) until the glass overhang touches slightly

the countertop.

15.1fthe range is not level, pull unit out and readjust

leveling legs, or make sure floor is level.

Installation For 29" Existing Cutout Wide Opening

I. You must replace the actual side trims by new and

smaller side trims. Thesenew side trims can be ordered

through a Service Center.

2. Follow instructions supplied with your new sidetrims to

replace the actual side trims with the new ones.

3. Checkif the countertop isprepared for 29" cutout wide

opening in "Countertop Preparation" section.

4. Install range as in the "installation Without Side

Panels" section above.

f

Standard Installation

1.

The range cooktop overlaps the countertop at the

sides and the range rests on the floor. The cooktop is

31Y_" (1,27 cm) (81 cm) wide.

2. Install base cabinets 30" (76.2 cm) apart. Make sure

they are plumb and level before attaching cooktop.

Shave raised countertop edge to clear 31 1/2 "(I ,27

cm) wide range top rim.

3. Install cabinet doors 31 " (78.7 cm) rain. apart so it

will not interfere with range door opening.

4. Cutout countertop exactly asshown on page I.

5. A backguard kit can be ordered through Service

Center.

6. When you unpack tile range, tile leveling legs at

rear are at the highest position they can be. Make

sure the front leveling legs are also at their highest

position.

7. To provide an optimum installation, the top surface

of the countertop must be level and flat (lie on the

same plane) around the 3 sides that are adjacent to

range cooktop. Proper adjustments to make the top

flat should be made or gaps between the countertop

and the range cooktop may occur.

8. _ To reduce the risk of damaging your

appliance, do not handle or manipulate it by the

ceramic: glass. Manipulate with care.

9. Position range in front of tile cabinet opening.

10. Make sure that the glass which overhangs the

countertop clears the countertop. If necessary, raise

Installation With Backguard

The cutout depth of (21 3/4" (55.2 cm) Min., 22 1/8"

(56.2 cm) Max.) needs to be increased to 24"(!0,16 cm)

(61 cm) when installing a backguard.

Installation With End Panel

A End Panel kit can be ordered through a Service

Center.

Installation With Side Panels

A Side Panels kit can be ordered through a Service

Center.

Install cabinet doors 31 " (78.7 cm) min. apart so as not

to interfere with range door opening.

Page 10

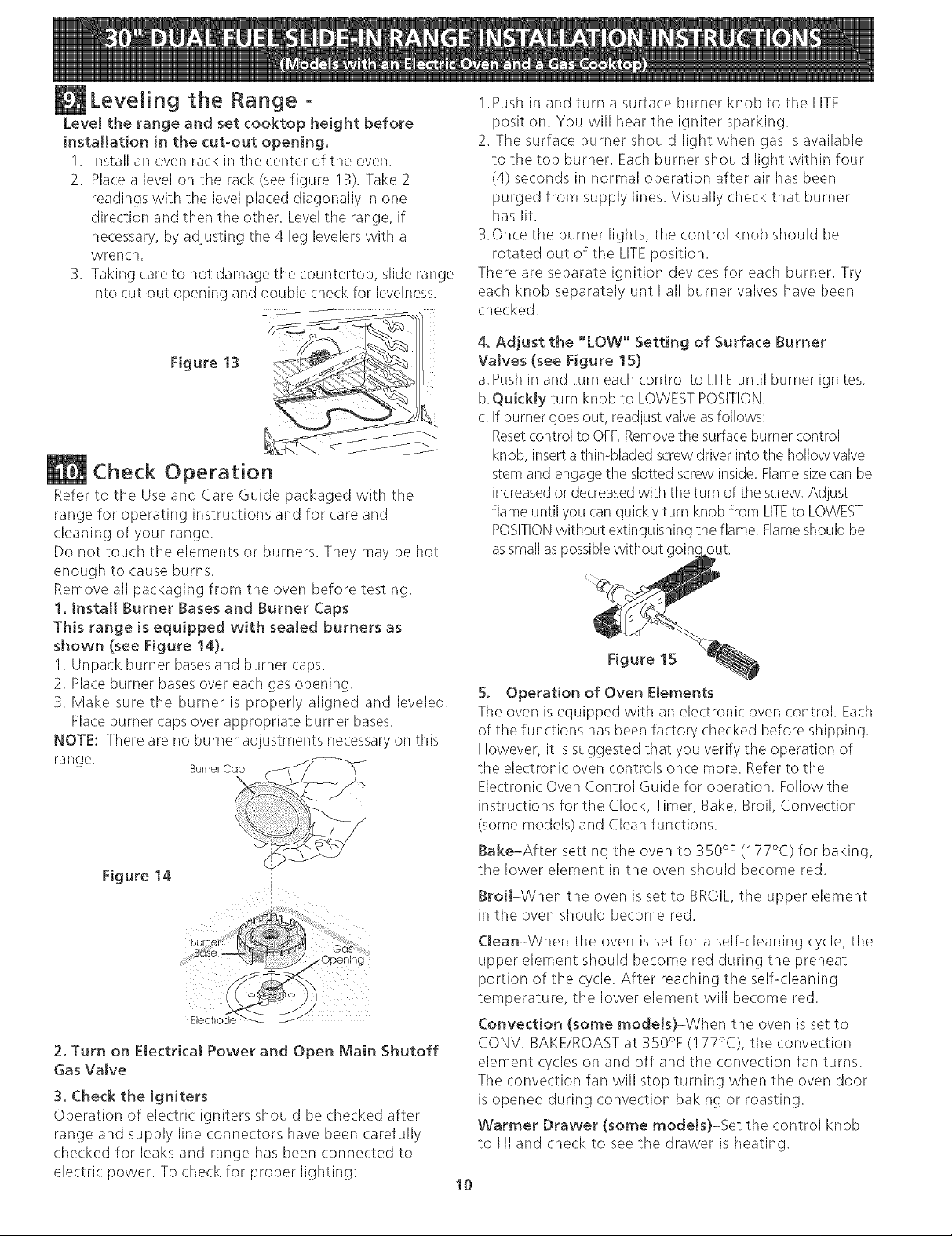

Leveling the Range -

Level the range and set cooktop height before

installation in the cut-out opening,

1. Install an oven rack in the center of tile oven.

2. Place a level on the rack (seefigure 13). Take 2

readings with the level placed diagonally in one

direction and then the other. Levelthe range, if

necessary, by adjusting tile 4 leg levelers with a

wrench.

3. Taking care to not damage the countertop, slide range

into cut-out opening and double check for levelness.

Figure 13

/

Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

(.leaning of your range.

Do not touch the elements or burners. They may be hot

enough to cause burns.

Remove all packaging from tile oven before testing.

1. install Burner Bases and Burner Caps

This range is equipped with sealed burners as

shown (see Figure !@.

1. Unpack burner basesand burner caps.

2. Placeburner basesover each gas opening.

3. Make sure the burner is properly aligned and leveled.

Placeburner caps over appropriate burner bases.

NOTE: There are no burner adjustments necessaryon this

range.

Burner Cap (

Figure 14

1.Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

2. The surface burner should light when gas is available

to the top burner. Each burner should light within four

(4) seconds in normal operation after air has been

purged from supply lines. Visually check that burner

has lit.

3.Once the burner lights, the control knob should be

rotated out of the LITEposition.

There are separate ignition devices for each burner. Try

each knob separately until all burner valves have been

checked.

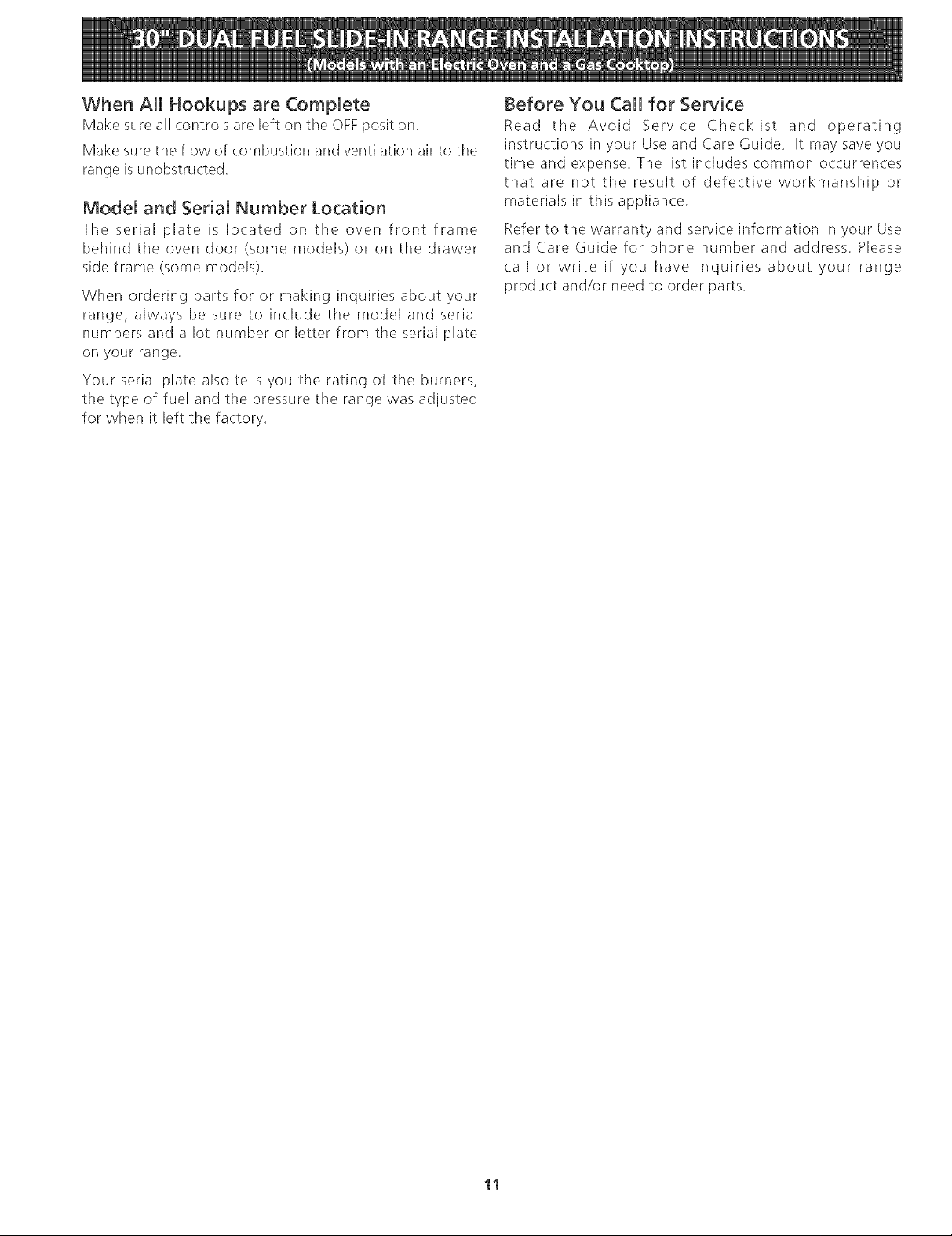

4. Adjust the "LOW" Setting of Surface Burner

Valves (see Figure ! S)

a.Push in and turn each control to LITEuntil burner ignites.

b.QukkJy turn knob to LOWESTPOSITION.

c. If burner goes out, readjust valve asfollows:

Resetcontrol to OFF.Removetile surfaceburner control

knob, insertathin-bladed screwdriver into tile hollow valve

stem and engage the slotted screw inside. Flamesizecan be

increasedor decreasedwith the turn of the screw.Adjust

flame until you can quicklyturn knob from LITEto LOWEST

POSITIONwithout extinguishing tile flame. Flameshould be

assmallaspossiblewithout goin_

Figure 15

5. Operation of Oven Elements

Tile oven is equipped with an electronic: oven control. Each

of the functions has been factory checked before shipping.

However, it issuggested that you verify the operation of

the electronic oven controls once more. Refer to tile

Electronic Oven Control Guide for operation. Follow the

instructions for the Clock, Timer, Bake, Broil, Convection

(some models) and Clean functions.

Bake-After setting the oven to 350% (I 77°C) for baking,

tile lower element in the oven should become red.

Broil-When the oven is set to BROIL, the upper element

in tile oven should become red.

Opening

Electrode

2. Turn on Electrical Power and Open Main Shutoff

Gas Va[ve

3. Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting:

Clean-When the oven is set for a self-cleaning cycle, tile

upper element should become red during the preheat

portion of the cycle. After reaching tile self-cleaning

temperature, tile lower element will become red.

Convection (some models)-When the oven is set to

CONV. BAKE/ROASTat 350% (I 77°C), the convection

element cycles on and off and the convection fan turns.

The convection fan will stop turning when the oven door

is opened during convection baking or roasting.

Warmer Drawer (some mode[s}-Set the control knob

to HI and check to see the drawer is heating.

10

Page 11

When All Hookups are Complete

Make sure all controls are left on the OFFposition.

Make sure the flow of combustion and ventilation air to the

range is unobstructed.

Model and Serial Number Location

The serial plate is located on the oven front frame

behind the oven door (some models or on the drawer

side frame (some models).

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the range was adjusted

for when it left the factory.

Before You Call for Service

Read tile Avoid Service Checklist and operating

instructions in your Use and Care Guide. It may save you

time and expense. The list includes common occurrences

that are not the result of defective workmanship or

materials in this appliance.

Refer to the warranty and service information in your Use

and Care Guide for phone number and address. Please

call or write if you have inquiries about your range

product and/or need to order parts.

11

Page 12

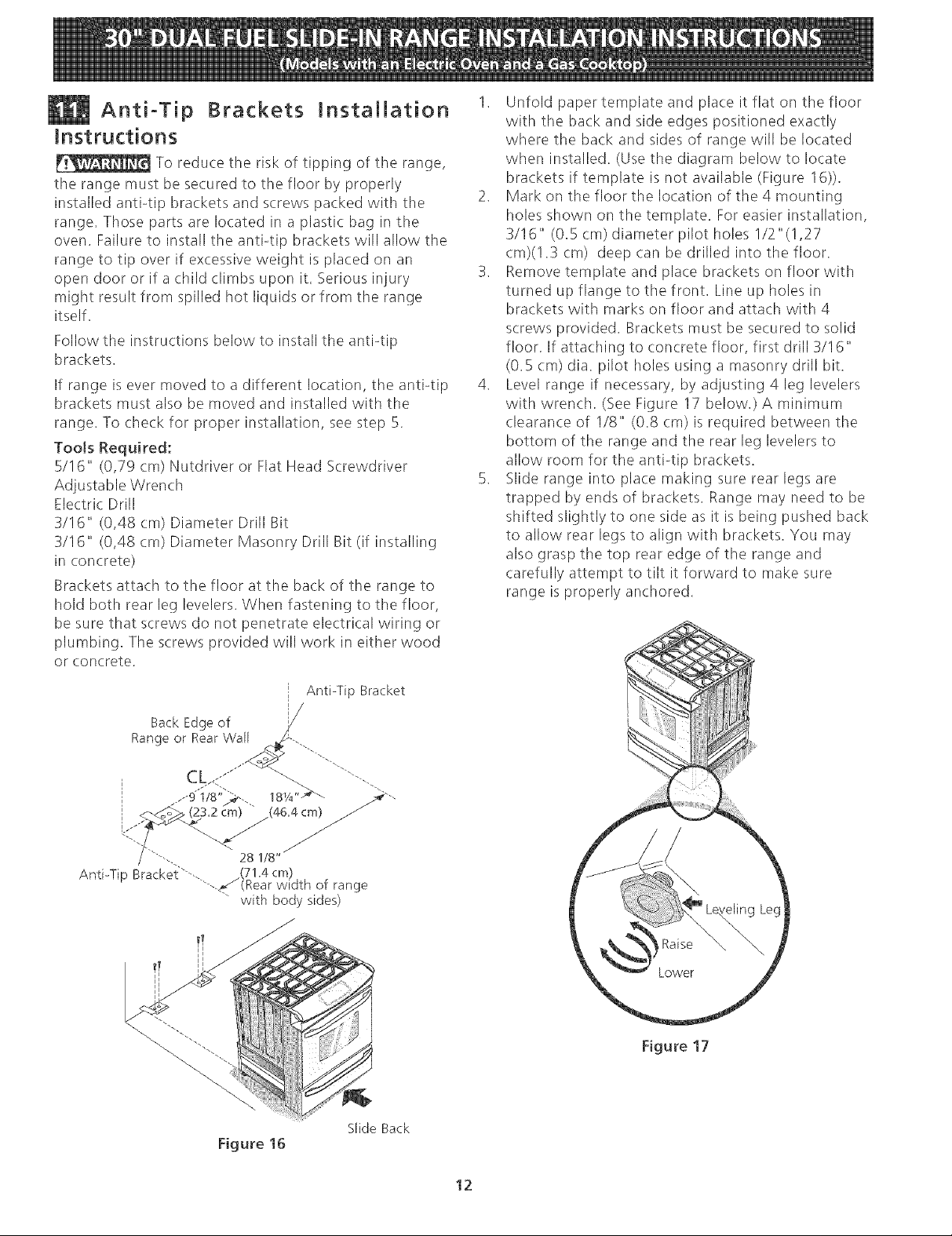

Anti-Tip Brackets JnstaJJation

instructions

To reduce the risk of tipping of the range,

the range must be secured to the floor by properly

installed anti-tip brackets and screws packed with the

range. Those parts are located in a plastic, bag in the

oven. Failure to install the anti-tip brackets will allow the

range to tip over if excessive weight is placed on an

open door or if a child climbs upon it. Serious injury

might result from spilled hot liquids or from the range

itself.

Follow the instructions below to install the anti-tip

brackets.

If range isever moved to a different location, the anti-tip

brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

TooJs Required:

5/16" (0,79 cm) Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16" (0,48 cm) Diameter Drill Bit

3/16" (0,48 cm) Diameter Masonry Drill Bit (if installinc

in concrete)

Brackets attach to the floor at the back of tile range to

hold both rear leg levelers. When fastening to tile floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram below to locate

brackets if template is not available (Figure 16)).

2. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16" (O.S cm) diameter pilot holes I/2"(!,27

cm)(!.3 cm) deep can be drilled into the floor.

3. Remove template and place brackets on floor with

turned up flange to the front. Line up holes in

brackets with marks on floor and attach with 4

screws provided. Brackets must be secured to solid

floor. If attaching to concrete floor, first drill 3/16"

(O.Scm) dia. pilot holes using a masonry drill bit.

4. Level range if necessary, by adjusting 4 leg levelers

with wrench. (See Figure 17 below.)A minimum

clearance of 1/8" (0.8 cm) is required between the

bottom of the range and the rear leg levelers to

allow room for tile anti-tip brackets.

S. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to be

shifted slightly to one side as it is being pushed back

to allow rear legs to align with brackets. You may

also grasp tile top rear edge of tile range and

carefully attempt to tilt it forward to make sure

range is properly anchored.

BackEdgeof /

Range or Rear Wall _,-.. "--.

.,--di/s'M, _s,/4"_'_ _'-,

i _ (23.2 c_m) "" (46.4cm) /

Anti-Tip Bracket"-_.. .(71.4 cm)

"--..<.,_(Rear width of range

" with body sides)

Figure 16

Anti-Tip Bracket

/

Figure 17

Slide Back

12

Page 13

LA [NSTALAaON Y EL SERVIC[O DEBEN SER EFECTUADOS POR UN [NSTALADOR CAUF[CADO°

[MPORTANTE: GUARDE ESTAS [NSTRUCC[ONES PARA USO DEL INSPECTOR LOCAL DE ELECTRIC[DAD.

LEA Y GUARDE ESTAS [NSTRUCC[ONES PARA REFERENC[A FUTURA.

Si [a[nformad6n contenida en este manual no esseguida exactamente, 1

puede ocurrir un incendio o exp[osi6n causandoda_os materiales,[esi6npersonal o [a muerte.

1

PARASUSEGURDAD:

-- No a[maceneni utilke gasolinauotros vaporesy [iquidos inflamables en [aproximidad de

_steo de cua[quier otto artefacto.

m

QUEDEBEHACERSIPERCmBEOLORA GAS:

@

Notrate de encenderningQnartefacto.

@

Notoque n[ngQninterruptor el@trico; no useningQntel_fono en suedifido.

@

Llameasu proveedordegasdesdeelte[_fono deunvedno. Slga[as[nstruccionesdel proveedordegas.

@

Sino [ogra comunicarsecon suproveedor de gas,[lame a[departamento de bomberos.

Refierase a su placa de

serie para la certificaciOn

de la agencia aplicable

Lainstalacibn y el servicio de mantenimiento deben set efectuados pot un instalador califkado, [aagencia de servicio o el

proveedor de gas.

NOTA: Para la abertura amplia ae torte ae

29" (73,7 cm), tiene que Ilamar al Centro de

Servicios y solicitar paneles laterales

opcionales. Despejar el reDorae ancnc ae a

cocina tal como se muestra en la secoon

"Preparaci6n de la Mesada "(ver p_igna gk

___ 30" Min,

1/2" (76,2 cm Min,) \I 3"

Acepille el

(v__a[anota 3) (33 cm)

MJn.5

12.7cm) de la parea,

BI

18" Min

(45,7 cm) Min.

horde

subido a

que deje

espacio

para un

horde 31 1/2" (81 cr

de anchura de estufa

Localise las puertas del

armario I"(2.5 cm) rain del

hueco de la abertura.

***IMPORTANTE: Parael corte a [o ancho (dimensi6n E)de m_S

de 301/16" (76,4 cm) para evitar que se rompa el vidrio, asegurese que

el artefacto est_ centrado en [a abertura de [a mesada mientras [o

presiona. Levante [as patas de nive[aci6n hasta [a posicion m&xima;

inserte el artefacto en [a mesada y [ueqo nive[e. Aseqt_rese de

que la unidad est.eapoyada en [as patas de 5ivelad6n

Lacaja de empalmes o el enchufe (:on puesta a

tierra deberla situarse de 8" a 17" (20.3 cm a

43.2 cm) del armario derecho y de 2" a 4" (5.1

cm a 10.2 cm) del suelo.

y no en ei vmermoimso.

B. ANCHURA C, ANCHURA DEA. ALTURA D. RROFUND[DAD A

35 5/8" (905 cm) 30" (76,2 cm) 31/2" (80 cm) 28 B/16" (71,9 crn) 30±1/16"

:_65/8" (93 cm) (76,2±0, I5 cm)

NOTA: Se adjunta el diagrama de cables de esta cocina al final de este libreta. PIN 318201671 (0510) Rev C

Imprimido en los Estados Unidos English - pages 1-12

E. ANCHURA

DE RECORTADQ*tt

(encima y armario)

F. PROFUNDiDAD DE G. ALTURA DEL

RECORTADO . MOSTRADOR

21 314" (55,2 cm) Min, 36 5/8" @3cm) Max

22 1/8" (56,2 era) Max 35 5/8" (905cm) min

24" (61 cnl) Min con un

protector trasero

Espai_o[ - pBginas 13-24

Fran_ais - pages 25-36

Diagrama de la instalaciOn alambrica - paginas 3%40

Page 14

NOTA:

1.No pelIizque el cord6n el_ctrico o el conducto

flexible de gasentre laestufa y la pared.

No selle la estufa a los armarios de Iado.

3. Un espacio minimo de 24" (61 cm) entre

la superficie de Ia estufa y el fondo deI

armario cuando et fondo deI armario de

madera o metal est,1 protegido pot no menos

de 1/4" (0.64 cm) de madera resistente aI

fuego cubierta por una himina met_Iica de

MSG, nOmero 28, 0.015" (0.4 mm) de acero

inoxidable, 0.024" (0.6 ram) de aluminio, 6

0.02" (0.5 ram) de cobre.

Un espacio mfnimo de 30" (762 cm) cuando

el armario no est_ protegido.

4. Para los recortados menos que 22 7/8", el

etectrodom6stico aparecerla ligeramente en

el exterior deI armario.

Deje pot los 19 Y4" (48.9 cm) de espacio

libre para Ia profundidad de la puerta cuando

esta abierta.

Puerta

abierta

(v_a Ia

nota 5)

21¾"

(55.25 cm

A

Panele

laterale

IMPORTANTE: El ancho de la cubierta

y el armario debe de ser igual al

ancho del torte.

E

E

c SNcHuRADE

' LA PLANCHA DE

COCINAR

35 5/8" (90.5 cm) 30" (76,2 cm) 31Y2" (80 cm}

36 5/8" (9_ cm)

PARTE

DELANTERA

DEL ARMARIO

II). PROFUNDIDAD A' E. ANCHURA

LAFRENTE DELA DE RECORTADO*_

ESTUFA (encima y armario)

28 B/ld" (71,g cm) 30±1/I6"

(76,2±0,15 crn)

14

22 7/8" (58.1 cm) rain.

23 1/4" (59.05 cm) max.

_ (v6a la nota 4)

.... ]

/ 1 1/8"

_| _(2.86 cm)

F

Ref.

F. PROFUNDIDAD DE G. ALTURA DEL

21 :_/4" (55,2 cm) Min 36 5/fi" (g3 cm) Max

22 1/8" (56,2 crn) Max 3B B/8" (g0Bcm}min

24" (6I cm) Min con un

protector trasero

Page 15

Notas importantes para el [nsta[ador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa,

2. Saque todo e! material usado en el embalaje del

compartimiento del homo antes de conectar el

suministro electrico o de gas a la estufa.

3, Observe todos los c0digos y reglamentos pertinentes.

4, Deje estas instrucciones con el comprador.

Nota Importante para el Consumidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

INSTRUCCIONES DE

SEGURIDAD

Instalaci6n de esta estufa debe cumplir con todos los

c6digos locales, o en ausencia de c6digos locales con el

C6digo National de Gas Combustible ANSI Z223,1--

01tima ediciOn,

El diseflo de esta estufa ha sido certificado por la CSA

International, En este comoen cualquierotroartefacto

que use gas y genere calor, hay ciertas precauciones de

seguridad que usted debeseguir. Estasser_in

encontradas en el Manual del Usuario, lea!o

cuidadosamente.

Asegurese de que la estufa sea instalada y

conectada a tierra en forrna apropiada por un

instalador calificado o por un tecnico.

Esta estufa debe ser etectricarnente puesta a tierra

de acuerdo con los c6digos locales, o en su

ausencia, con el Cbdigo Electrico National ANSI/

NFPA No, 70, ultirna edition, Vea las instrucciones

para la puesta a tierra en la pagina 15.

• La instalaci0n de aparatos dise_ados para instalaciOn

en casas prefabricadas (mOviles) debe conformar con el

Manufactured Home Construction and Safety Standard,

titulo 24CFR, parte 3280 [Anteriormente e! Federal

Standard for Mobil Home Construction and Safety,

titulo 24, HUD (parte 280)] o cuando tal estandar no se

aplica, el Standard for Manufactured Home Installation

1982 (Manufactured Home sites, Communities and

Setups), ANSI Z225,1/NFPA 501A-edici0n m_s reciente,

o con los c0digos locales.

• Todas las

estufas

pueden

volcarse.

Esto podria

resultar en

lesiones

personales,

®Instale el

dispositivo

antivuelcos

que se ha

empacado

junto con

esta estufa.

Para reducir el riesgo de

que se vuelque la estufa,

hay que asegurarla

adecuadamente co!o

candole los soportes

antivuelco que se

proporcionan. Para

comprobar si estos estan

instalados y apretados en

su lugar como se debe,

ase el horde trasero

superior de la estufa y

cuidado samente incline la

hacia adelante para

asegurar que la estufa se

ancle.

Antes de instalar la estufa en un Mea cuyo piso

este recubierto con IinSleo u otro tipo de piso

sintetico, asegQrese de que estos puedan resistir

una ternperatura de pot 1o rnenos 90°F sobre la

ternperatura arnbiental sin provocar encogirniento,

deforrnadOnodecoloradOn. No instale laestufa

sobre una alfombra a! menos que coloque una plancha

de material aislante de pot Io menos 1/4 pulgada,

entre la estufa y la alfombra.

AsegQrese de que el material que recubre las

paredes alrededor de la estufa, pueda resistir et

calor generado por la estufa.

No obstruya el flujo del aire de combustion en la

ventilation del homo ni tarnpoco alrededor de la

base o debajo del panel inferior delantero de la

estufa. Evite tocar lasaberturaso a'reascercanas de

la ventilaci0n, ya que pueden estar muy calientes

durante el funcionamiento del horno, La estufa

requiere aire fresco para la combustion apropiada de

los quemadores.

_i_Nunca deje ni_os solos o

desatendidos en un Mea donde un artefacto est_

siendousado, Amedida que los ni_oscrecen,

enseff_eles e! uso apropiado y de seguridad para todos los

artefactos, Nuncadeje la puerta de! homoabierta

cuando la estufa esta" desatendida,

W!_No se pare, apoye o siente en las

puertas o ca jones de esta estufa pues puede resultar

en serias lesiones y puede tambi_n causar da_o a la

estufa.

• No alrnacene articulos que puedan interesar a los

ni_os en los gabinetessobre la estufa. Los nitros

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos articulos.

• Los gabinetes de alrnacenarniento sobre la estufa

deben ser evitados, para elirninar la necesidad de

tenet que pasar sobre los quernadores superiores

de la estufa para Ilegar a ellos,

Ajuste el tarna_o de la llama de los quernadores

superiores de tal rnanera que esta no sobrepase el

bordede los utensilios decocinar. La llama

excesiva es peligrosa.

No use el homo corno espacio de alrnacena]e. Esto

crear_ una situaci0n potencialmente peligrosa.

Nunca use la estufa para calentar el cuarto. El uso

prolongado de la estufa sin la adecuada ventilaci0n

puede resultar peligroso.

No alrnacene ni utilice gasolina u otros vapores y

liquidos inflarnab_es en la proxirnidad de este o de

cualquier otto artefacto etectrico. Puede provocar

incendio o explosion.

En caso de una interruption del servicio electrico, es

pasible de encender los quemadores de superficie a

mano. Para encender un quemador de suoerficie,

acerque un fOsforo encendido del cabezal det

quemador, y gire delicadamente el botOn de control de

superficie a LITE (encendido). Tener cuidado al

encender los quemadores a mano.

A]uste todos los controles a la position "OFF"

(apagada) despues de haber hecho una operacion

con tiernpo prograrnado,

PARA MODELOS AUTOLIMPIANTES:

Saque la asadera, alirnentos o cualquier otto

utensilio antes de usar el ddo de autolirnpieza del

homo, Limpietodoexceso de derrame dealimentos.

Siga las instrucciones de prelimpiado en el Manual del

Usuario.

15

Page 16

Estuche de cable del suministro

emectrico (U.S.A.)

El utilizador es responsable de la conexi6n del cable del

suministro electrico al bloque de conexi6n situado detras

del panel de acceso.

Este electrodomestico puede set conectado pot medio de

una "conexiOn directa" de cablespermanentes (cable

blindado flexible o no metalico recubierto de cobre), o pot

medio de un ensamblaje de cordon de suministro electrico.

Solamente un ensamblaje de (:ordd)nde suministro electrico

con regimen de 125/250 voltios minimo, 40 amperios y

marcado para uso con cocinas debe set utilizado. Vea la

tabla (pagina prc_xima)para information sobre el tama¢io

de abertura de la conexiOn del ensamblaje de cord6n. El

cordon debe de tenet 3 o 4 conductores.

Para lascasassobre ruedas, las nuevas instalaciones, en los

vehkulos de re(reaciOn o en las areas donde los cOdigos

locales no permiten la (onexiOn del conductor a tierra al

neutro, un ensamblaje de suministro electrico de 4

conductores para estufas, clasifi(:ado a 125/250 voltios

minimo, 40 amperios m[nimo, debe de ser utilizado (ver la

figura 5).

Los bornes a la extremidad de los alambres deben set a

curvas cerradas o con extremidades de leng0etas en forma

de U abiertas y curvadas. El cordon debe de tenet una

abrazadera releva de anclaje.

Estilo Estados Unidos

Figura 1

No desajuste las tuercas que

aseguran ta conexiOn de ta codna at bloque

terminat cuando est_ instal_ndola. El corte o ta

perdida de corriente el_ctrica puede ocurrir.

de fuente de energia conectado

de fabrica (Canad8 solamente)

Esta estufa viene de fabrica equipada con un (:ord(m de

fuente de energla (vea a la figura 2). El cordc_n debe de

set conectado a una toma de corriente a tierra de 120/

240 voltios o de 120/208 voltios. Si no hay una toma de

corriente a tierra en la habitaciOn, debe de set instalada

pot un tecnico calificado.

Ver la tabla de arriba para conexion de alambres de 3 o 4

conductores.

Tabla de tamafio de abertura de conexion de cocina

Referirsea la tabla de arriba para el tamaho de abertura de conexiOnde

cocina adecuada,y la informaci0n sobre el regimen de amperios del

ensamblajede cordon de suministro electrico.

Vea la placa deserie de la

cocina para informaci0n sobre

el regimen de kilovatio.

120/240 Volts 120/208 Volts del cordon directa

0 - 8.7 kw 0 - 7.8 kw 30 Amp 1 1/8 (2.9) 7/8 (2.2)

8.8- 16.5 kw 7.9 - 12.5 kw 40Amp 1 3/8 (3.5) 1 1/8 (2.9)

16.6-22.5kw 12.6-18.5kw 50Amp 13/8(3.5) 13/8(3.5)

Regimen

de

amperios

de

ensamblaje

del cordon

Diametro(pulgadas(cm))de

abiertade conexiOndecocina.

Ensemblaje Connect.

NOTA: La cocina corrediza electrica viene de fabrica con

un agujero de diametro 1 I/8" (2.9 cm) come se

muestra en la figura 4. Si un agujero mas largo esta

necesario retire la arandela de la pre-cortada.

_!_ E! riesgo de fuego o de choque

e!_ctrico puede aparecer si usa el tama_o de cable

incorrecto, si tas instrucciones de instataci6n no son

seguidas o si retira ta abrazadera de reteva.

Estilo Canada

Figura 2

Peligro de choque el_ctrico

• La conexiOn a tierra es requerida para este

e[_ctrodom_stico.

• No conecte al suministro el_ctrico hasta que et

el_ctrodom_stico este conectado a tierra de

manera permanente.

• Desconecte e! suministro el_ctrico hacia [a caja

de empalmes antes de hacer [a conexiOn

el_ctrica.

• Este el_ctrodom_stico debe set conectado a un

sistema de alambres permanentes, met_licos,

conectados a tierra o una puesta a tierra debe set

conectada aJterminal de tierra o un emplonbado

al eJ_ctrodom_stico.

EJno seguir ninguna de estas instrucciones podr_a

causar fuego, heridas personales o choques

electricoso

16

Page 17

Cone×ion EN ctrico de [a Estufa

(U.S.A.}

Este aparato se fabrica con el terminal neutro conectado

a! marco.

Refiere al diagrama de alambraje en las paginas de

centro de este manual.

Conexion de tres alambres de conduccibn a

la estufa

(Un cordon flexible o cable de 3 conductores debe de ser

reemplazado con un cordon flexible o cable de 4 conducto-

res donde la conexiOn del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones, las casas sobre

ruedas, los vehlculos de recreation o otras areas donde los

codigos locales no permiten la conexiOn a tierra al neutro.)

Si los c0digos locales permiten la conexi0n del conductor

de tierra del marco con el alambre neutro de! cordon

electrico de cobre (vea Figura 4):

1. Quite los tres torni!los en la parte ma_sbaja del panel

trasero, luego levante la parte m_is baja del panel

trasero (la cubierta de acceso) exponiendo el bloque

de conexiones de los terminales de la estufa.

LEVANTE LA PARTE MAS BAJA DEL PANEL

TRASERO AQU[ PARA TENER ACCESO AL

F[gura 3

2. Quite las tres tuercas desatadas (despues de remover

la cinta de goma) sobre e! b!oque terminal usando

un destornillador o una Ilave de casqui!lo de 3/

8"(0,95 cm).

3. Conecte e! cable neutro del cordon e!#ctrico de

cobre al terminal de color de plata en e! centro de!

b!oque, y conecte los otros cabels a los terminales

laterales, Empareje los cables y los terminales segOn

e! color (cables rojos conectados con el terminal

derecho, cables negros conectados con el terminal

izquierdo,

4. Repone las tres tuercas desatadas sobre el b!oque

terminal,

5. Baje la cubierta del terminal y reinstale los tres (3)

tornillos.

BLOQUE DE CONEXEONES DE LOS

TERMENALES

ue terminal plata

Alambre

Negro

Una arazadera

de rdeva provista debe de estar

instalada a est_ ubicad6n

L Hacia el 240 V conexi6n directa.

recept&culo Retira la arandela

/8" Dia.

Aguiero de la

pre-cortada para

13/8" Dia. Aguiero

Figura 4

ConexiOn de 4 alambres de conduction a la

estufa (casas moviles}

1. Quite los tres tornillos en la parte m_is baja de! panel

trasero, luego levante la parte m_is baja del panel

trasero (la cubierta de acceso) exponiendo e! bloque

de conexiones de los terminales de la estufa,

2. Quite las tres tuercas dasatadas (despues de remover

la cinta de goma) sobre el bloque termianl usando

un destornillador o una Ilave de casquillo de 3/

8"(0,95 cm),

3. Quite la banda de puesta a tierra del bloque de los

terminalesyde! marco delartefacto, Retengael

tornillo de puesta a tierra,

4. Conecte el alambre de puesta a tierra (verde) del

cordon electrico de cobre al marco del artefacto con

el tornillo de puesta a tierra, usando el agujero en el

marco donde se quit0 el tornillo de puesta a tierra

(vea Figura 5).

17

Page 18

Btoque terminal plata

Rojo

Atambre

Negro _/

1-1/8" Dia.

Agujero de ta

conexi6n

directa.Retira

ta arandeta

pre<ortada

para !-3/8" Dia.

Agujero

Una arazadera

de releva provista

debe de estar

instatada a esta

ubicaci6n

@OTA; Asegurese de quitar

ta banda de puesta a tierra provista.

el 240 V receptacu[o

Figura 5

Conexi6n el_ctrica directa al cortadrcuito, a

la caja de fusibles o la caja de empalmes

Si el aparato esta conectado dire(tamente al(ortacircuito,

a la (aja de fusibles o a la cap de empalmes, use un cable

blindado flexible o no metalico recubierto de cobre (con

alambre a tierra). Provee una abrazadera releva de anclaje

homologo UL a cada extremidad del cable. A la

extremidad del electrodom6stico, el cable pase a trav6s del

agujero de la conexion directa (vet Figura 5) en el (:ord6n

de la pla(a de montaje. El tama¢io de los alambres

(alarnbre de cobre solamente) y las (onexiones deben

estar conforme al regim6n del electrodom(_stico.

Donde los c6digos locales permitan conectar e!

conductor de puesta a tierra de[ el_ctrodom_stico a[

neutral (blanco) (vea Figura 6):

(Un cordon flexible o cable de 3 conductores debe de ser

reemplazado con un cord6n flexible o cable de 4 conducto-

res donde la conexic_ndel conductor atierra al neutro esta

prohibida en las nuevas instalaciones, las casassobre

ruedas, los veh[culos de recreaci6n o otras areasdonde los

codigos locales no permiten la conexi6n a tierra al neutro.)

1. Desconecte el suministro electfico.

2. Enel cortacircuito, la caja de fusibles o la caja de

empalmes

a) Conecte el alambre verde (o cobre desnudo), el

alambre blanco del cable del electrodom6stico y el

alambre neutral (blanco)juntos.

b) Conecte losdos alambres negros iuntos.

c) Conecte los dos alambres rqos juntos.

Cable de la fuente

Alambre

Blanco

(Neutro)

Alambres_

rojo

Alambres (Neutro)

desnudos Conductor de

o verdes Cable de la (listadooCSA)

de alimentaci6n

Alambres

negros

Caja de

empaimes

_mbre

B[anco

uni6n I[stadooUL

estufa

Figura 6 oSistema el_ctrico (ejemp[o: caja de

empa[mes) de 3 a[ambres (a tierra neutral)

Donde los c6d[gos locales NO perm[tan conectar el

conductor de puesta a tierra de[ e[_ctrodom_stico a[

neutra[ (bIanco), o si est& conectado con un sistema a

4 aIambres (yea figura 7):

1. Descone(te el suministro electrico

2. Separe el alambre verde (o cobre desnudo) y el

alambre blanco del electrodomestico.

3. En el cortacircuito, la caja de fusibles o la caja de

empalmes.

a. Conecte el alambre blanco del cable del

electrodomestico al alambre neutral (blanco).

b. Conectelos 2 alambres negrosjuntos.

c. Conectelos 2 alambres rojos juntos.

d. Conecte el alambre verde (o de cobre desnudo) de

la puesta a tierra del alambre al alambre de

puesta a tierra del cortacircuito, de la caja de

fusibles o de la caja de empalmes.

Alambre Cable de [a fuente Caja de

desnudo o de alimentaci6n empaimes

verde

Alambres

tO Jog

Alambre

(Neutro)

l

Alambres

negros

Alambres

desnudos o Aiambre

verdes Blanco

Cable de la de

estufa uni6n [istadomU L

(Neutro)

(o listadomCSA)

18

Figura 7 - Sistema el_ctrico de 4 alambres

(ejemplo caja de empaIme)

Page 19

Construcci6n demarmario

Para eliminar el riesgo de quemaduras

o de fuego tratando de alcanzar algo por encima de las

zonas calientes, evite de colocar articulos sobre la

co(ina. Si cree ne(esitar este espa(io, el riesgo puede

disminuir si instala un sombrerete que proteja

horizontalmente un m[nimo de 5" (!2.7cm) sobre la

base del armario.

Preparad6n de[ mostrador

Las extremidades de la cocina sobrepasan el borde de

su raostrador.

Si tiene un mostrador con [as extremidades

cuadradas (planas), no se necesita ninguna

preparacion del mostrador.

• EJ reborde de frente de mostradores moJdeados

deben tener bordes moldeados a 3/4" (1.9cm) a partir

de cada extremidad de la apertura (Figura 8).

• Los mostradores enazulejos deberan necesitar un

recorte de 3/4" (I .9 (m) a partit de cada extremidad

y/o un borde redondeado aplanado (Figura 8).

Anchura_

de hueco

_:_ 311/2,_ "/

(81 cm)

Mostrador moldeado o

o recortado 3/4" (1.9 ¢m)

(1.9 cm) frente de la abertura del

I Figura 8 mostrador.

• Si et ancho de Ja abertura deJ mostrador es m_s

grande que 30 1/!6" (76,4 cm}, ajuste a las

dimensiones como para el 3/4" (! .9).

• El mostrador deber set nivelado. Coloque un

nivelador sobre el mostrador, primero de lado a lado y

luego del frente hacia atras. Si el mostrador no estit

nivelado, la cocina no estara nivelada. El homo debe

set nivelado para tenet resultados satisfactorios al

hornear. Las extremidades de la plancha de la cocinar

sobrepasan los bordes de la abertura del mostrador.

• Para la Anchura existente del Recorte de et

29"(73,7 cm) (Figura 9): 2 3/16"

hada atr_s en las esquinas de

2 3116" (5,56 cm)

, (s.s6cm) i

(1.9 cm)

Quite el 2 3/16" de material

lnstalaci6n de la alimentaci6n de gas

Esta unidad ha sido ajustada para operar con un m01tiple

de admisiOn para gas natural de 4"(10,16 cm) (1.0 kPa).

Un regulador de presiOn convertible esta conectado a la

wilvula distribuidora y DEBE ser conectado en serie con

la tuber[a de suministro de gas.

Para la operaci6n apropiada, la ma'xima presiOn de

entrada al regulador no debe exceder la presiOn de una

columna de agua de 14 pulgadas (3,5 kPa),

La presi6n de entrada al regulador debe ser por !o menos

1 pulgada mas grande que la valvula distribuidora (.25

kPa), El regulador ha sido ajustado para gas natural a 4

pulgadas de presiOn para la wilvula distribuidora (1,0

kPa), La presiOn de entrada debe ser por Io menos de 5

pulgadas (1,25 kPa), Para propano liquido a 10 pulgadas

de presi6n para la wilvula distribuidora (2.5 kPa) la

presi6n de entrada debe ser pot Io menos de 11

pulgadas (2,75 kPa),

La tuberfa deberia set equipada con una v4lvula de

cierre aprobada(vea Figura 12). Estav4lvula debe

ubicarse en la misma habitaci6n que la estufa en un

lugar que permita una una facilidad de abrir y cerrar,

No bloqueee! acceso a lav4lvula de cierre, Lav4lvula

es para abrir o cerrar el suministro de gas al aparato,

Abra la vatvula de cierre en la linea de suministro de

gas. Espere unos minutos a que el gas se mueva pot el

tubo,

E! suministro de gas entre la wilvula de cierre y el

regulador se puede conectar con tuberia rigida o con

tuberfa flexible uni6n meta'lica conectada y aprobada pot

la AGA/CGA donde los c6digos locales permiten,

La tuberia del suministro de gas puede pasar por la

pared lateral delarmario derecho, Elarmario lateral

derecho es un lugar ideal para la wilvula de cierre

pincipal,

Conecte el Regulador de Presi6n

El regulador de presi6n esta ya instalada para la estufa.

No haga que la conexi6n est@

demadiadoapretada, E! reguladorest_ fundidoa

troque!, Apret4ndo!odemasiado podrfa romper el

regulador resultando en escape de gas y posiblemente

un incendio o exp!osi6n.

de frente a [a parte

73.7 cm) _(3.2 cm)

i 30"

(76.2 cm) 31W'/

(81cm)

ostrador moldeado o enazu[ejo

recortado 3/4" (1.9 ¢m) hada atr_s en

las esquinas de frente de la abertura

Figura 9

igura 10

UBICAaON DEL

REGULADOR DE PRESION

19

Page 20

Va!vu!a de FLUJO DEL GAS Regulador

cierre Uni6n Uni6n

manua! ,_

(on) X,_ Boquilla Conector BoquilIa_

Apagado flexible Tapa de

(off) entrada

_@ de presi6n

Todas las conexiones deben ser apretadas con una Ilave

inglesa

Figura 11

ReOnael conector flexible del tubo del suministro de gas

al regulador de la presiOn en la orden siguiente:

1. Valvula de (ierre manual (no incluido)

2. Boquilla de 1/2" (no incluido)

S. 1/2" Adaptador de uni6n (no incluido)

4. Conector flexible (no incluido)

5. 1/2" Adaptador de union (no incluido)

6. Boquilla de 1/2" (no incluido)

7. regulador de presiOn (incluido)

La tuberia de suministro de gas debe ser de 1/2 "(1.27

cm) o 3/4"(1,9 cm) D,I,

El consumidor debe saber la posici6n de la wilvula

principal de cierre y tener acceso f_icil a ello,

Cuando se usa un conducto flexible en la estufa, permita

suficiente flojedad como para sacar la estufa fuera del

recortado para la limpieza y el servicio,

NOTA: No permita quee!conductose pellizqueentre la

pared ylaestufa, Paraverlo, saqueelcajOn,

Use un compuesto para junturas de tuberia hecho para

use con gas natural y de LP/Propano para sellar todas las

conexiones de! gas, Sise usan los conectores flexibles

asegOrese de que no estOn enroscados.

V lvula de cierre -

Abierta

Figura 12

La linea del suministro se debe de ser equipada de una

valvula de cierre manual aprobada. Esta valvula se debe

Iocalizar en el mismo (uarto que la estufa y debe estar

en una IocalizaciOn que permita la facilidad de la

abertura y del cierre. No bloquee el ac.ceso a la v_lvula.

La valvula es para encender o apagar el gas del aparato.

Una vez que regulador esta en su lugar, abra la valvula

enlalineadelsuministrodegas. Esperealgunos

minutos para que el gas pueda moverse a travOs de la

linea de gas.

Para verificar si hay fugas en el electrodomestico

se debe de seguir las instrucdones del fabricante.

Asegurese de que no haya escapes de gas.Despues

de conectar la estufa a! suministro de gas, compruebe el

sistema con un menbmetro. Si no tiene un manOmetro,

abre e! gas y use un detector de fugas liquido en todas

las junturas y conexiones para averiguar si hay escapes

de gas.

No use llama para controlar que no

hayan perdidas de gas, La comprobaciOn de perdidas de

gas con una llama puede resultar en un incendio o

explosi6n,

Se debe sellar todas las aberturas en la pared o el piso

donde la estufa se instala.

Apriete todas las conexiones si hace falta para

prevenir fugas de gas en la superficie de la estufa o en

la linea de suministro,

Desconecte esta estufa y su v_lvula individual de

cierre del sistema de! siministro de gas durante

cualquier prueba de presiOn de ese sistema a presiones

mayores de 1/2 psig (3.5 kPa o 14"(35,56 cm) columna

de agua).

Aisla la estufa del sistema del suministro de gas

cerrando su wilvula manual de cierre individual durante

cualquier prueba de presiOn del suministro del gas a

presiones iguales a menos de 1/2 psig (3.5 kPa o

14"(35,56 cm) columna de agua).

para uso de Propano Liquido

Este aparato puede set usado con gas natural o propano

liquido. Ha sido ajustado en la fa'brica para operar con

gas natural solamente,

Si desea convertir su estufa para uso con propano

liquido, use los orificios provistos ubicados en el bolso

que contiene la literatura titulada "FOR LP/PROPANE

GAS CONVERSION." Siga las instruct!ones que vienen

con los orificios,

La conversion debe ser efectuado por un teen!co de

servicio capacitado, de acuerdo con las instruct!ones del

fabricante y con todos los cOdigos y requisitos de las

autoridades correspondentes, El no seguir las

instruct!ones podria dar como resultado lesiones graves

odaff_osala propiedad, EIorganismoautorizado para

Ilevar a cabo este trabajo asume la responsabilidad de la

conversion.

_!_ La falta de una conversion apropiada

puede resultar en lesiones graves y daf_os a la propiedad.

2O

Page 21

La mudanza de[ aparato para

reparadones o iimpieza

Apague la corriente electrica a la estufa a la fuente de

poder principal, y apague la v41vula de cierre manual de

gas, Aseg0rese de que la estufa este fresca, Quite el cajOn

de servicio (el cajOn calentador en algunos mode!os) y abre

la puerta del homo, Levante la frente de la estufa y

deslicela fuera de la abertura sin crea_ tension desmedida

sobre e! conducto flexible de gas, Aseg0rese de no

pe!lizque el conducto flexible de gas detr_is de la estufa al

reemplazar la unidad en la abertura, Reemplace el cajOn,

cierre la puerta y enciende el gas y la corriente electrica a

la estufa.

lnstalad6n de la estufa

Nota importante: No es necesario, pero si es

conveniente, quitar la puerta para instalar el horno.

Consulte las instrucciones para retirar la puerta en la Guia

de Uso y Cuidado.

lnstalaci6n sin panel(es) lateral(es).

1. La superficie de la estufa se sobrepone al mostrador

por los lados y la estufa descansa sobre el piso, La

estufa es de 31 1/2" (81 cm) de anchura,

2. Instale los gabinetes de base con una separaciOn de

30" (76,2 cm), Aseg0rese de que se aplomen y sean

nivelados antes de juntar la estufa, Acepille la parte

levantada del borde de! mostrador dejando espacio

para la superficie de la estufa de 31 1/2" (81 cm).

3. Instale las puertas de los gabinetes con una separaciOn

minima de 31" (78,7 cm) para que no obstruyan con

la puerta de la estufa al abrirse,

4. Recorte e! mostrador exactamente segOn el dibujo en

la pa'gina 1,

5. Un protector trasero puede pedirse mediante su

negociante,

6. Para una instalaci6n 6ptima, la superficie superior de la

mesada debe estar nivelada y ser plana (sobre el mismo

piano) en los 3 lados adyacentes a la cocina, Se @ben

hacer los ajustes correspondientes para hacer que la

parte superior quede plana, de Io contrario podr_in

quedar espacios entre la mesada y la cocina,o

7. _ Para reducir el riesgo de daflar su

artefacto, no Io manipule cerca del vidrio cer_imico,

Manip@lelo con cuidado,

8. £o!oque la cocina enfrente de la abertura de! armario,

9. Aseg@rese de que el vidrio que est,1 colgado sobre la

mesada deje despejada la mesada, Si es necesario,

levante la unidad bajando las patas de nivelaci6n.

10.Nivele la codna (vea NivelaciOn da la estufa). E! piso

donde se instala la cocina debe estar nivelado, Siga las

instrucciones "nivelaciOn de la estufa - modelos equipado

con las patas niveladoras",

11.Ajuste alas piernas de nivelaci6n de manera que la

parte de abajo de la plancha de cocinar est,1 apoyada

contra el mostrador,

12.Atornille con cuidado en la pata de nivelaciOn trasera

hasta que el vidrio que esta"colgado toque levemente la

mesada. El vidrio debe soportar el peso de la unidad.

13.Luego, atornille con cuidado en lasdos patas de

nivelaci6n anteriores (igual a 12) hasta que el vidrio que

est4 colgado toque levemente la mesada.

14.Si la estufa no est4 nivelada, arranque e! electrodomes-

tico y vuelva a ajustar alas piernas o aseguOreseque el

suelo est4 nivelado.

tnsta[aci6n para ta Anchura existente de[ Recorte de

e[ 29"(73.7 cm) :

1. Usted debe substituir los paneles laterales reales pot los

paneles laterales nuevos y mas pequeFios. Paneles

laterales puede set pedido con su representante.

2. Siga la fuente de las instrucciones (:onsus paneles

laterales nuevos para substituir lospaneles laterales

realespot losnuevos.

3. £ompruebe siel mostrador esta preparadopara la

abertura amplia del recorte de129".

4. Instale la estufa para Instalaci6n sin panel(es)lateral(es).

tnstalaciOn con un protector trasero

La profundidad del recortado de (21 3/4" (55.2 cm)Min.,

22 I/8" (56.2cm) Max.) necesita aumentarse a 24"(61 cm)

al instalar un protector trasero.

tnsta[ad6n con el juego de termino de panel.

Un juego de termino de panel puede ser pedido con su

representante.

tnsta[ad6n con PaneIes LateraJes

PanelesLaterales puede ser pedido con su representante.

Instale las puertas de los armarios a 31 " (78.7 cm) de

espacio entre elias para que no interfieran con la

abertura de la puerta de la cocina.

Niveiad6n de la estufa

Nive[e ta esufa y ajuste [a altura de [a estufa antes de

insta[ar[a en la abertura.

1. £oloque una parilla del homo en el (entro del homo.

2. Ponga un nivel sobre la parrilla (figura 13). Tome dos

lecturas con el nivel puesto diagonalmente en una

direcci6n y despues en la otra. Nivele la estufa, si es

necesario, ajustando las 4 patas niveladoras (.on una

Ilave de tuercas.

3. AsegOrese de no da¢iar al mostrador, desli(e la estufa

dentro de la abertura del hueco y vuelva a verificar a la

nivelaci6n.

Figura 13

21

Page 22

Comprobacion del

Fundonamiento

Consulte el Manua! del Usuario incluido con la estufa

para instrucciones de operaciOn y instrucciones para el

cuidado y limpieza de su estufa,

No toque Ioselementos o quemadores, Pueden estar

bastante calientes para causar quemaduras,

Quite todo el embalaje de la unidad antes de comprobarla,

1, Instale [as tapas de los quemadores y de [as tapas

de los quemadores.

Esta estufa esta equipada con quemadores sellados

como se muestra mas abajo (Figura 14).

1. Desembale las basas de los quemadores y las tapas

de !os quemadores,

2. Coloque una basa de quemador sobre cada abertura

de gas,

3. Asegurese que el quemador esta correctamente

alineado y nivelado, Coloque las tapas de los

quemadores sobre las correctas basas de

quemadores,

NOTA: No hate falta ning0n ajuste de quemador en

esta estufa.

Tapa del

Recogedor i

4,

Ajuste de la Poski6n LOW (BAJA) Para la V_lvula

del Quemador Superior (Flgura 15)

a.

Gire la perilla a la posici0n LITE (encender) hasta que el

quemador encienda.

b,

R_pidamente gire la perilla a la POSIC!ON MAS BAJA.

C.

Si el quemador se apaga, reajuste la v31vula de la

siguiente forma: Mueva el control a la posiciSn OFF

(apagada). Saque la perill ade control del quemador

superior, inserte un destornillador piano pequeho en el

hueco de! w%tago del a v31vula hsta enganchar e!

tornillo interior. El tamaho de la llama puede ser

aumentado o disminuido girando el tornillo. Ajuste el

tamaf_o de la llama hasta que pueda pasar r_ipidamente

de la posiciOn LITE hasta la posiciOn MAS BAJA sin que

se apague la llama. La llama debeser Io m3spequef_a

posible sin que se apague.

Figura 15

5. Fundonamiento de los Elementos del Homo

El homo esta' equipado con un control electrOnico. Cada

funciOn ha sido probada en la fabrica antes del transporte.

Sin embargo, sugerimos que Ud. verifique el

funcionamiento de los controles del homo una vez m_is.

Vease el Manual del Usuario para la operaci6n. Siga las

instrucciones par el Re!oj Minutero, Cooer, Asar,

CovecciOn (algunos modelos) y las funciones de limpieza.

Figura 14

2. Endende [a corriente etectrka y abre [a v_lvula

prff)dpal de derre.

3. Comprobad6n de los Encendedores

El funcionamiento de los encendedores electricos

debe ser comprobado despues de que la estufa y los

conectores a la tuberia de suministro de gas hayan

sido comprobados por escapes y la estufa haya sido

conectada electricamente, Para comprobar que el

encendido sea correcto:

1. Empuje y' gire una perilla del quemador superior hasta