Page 1

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

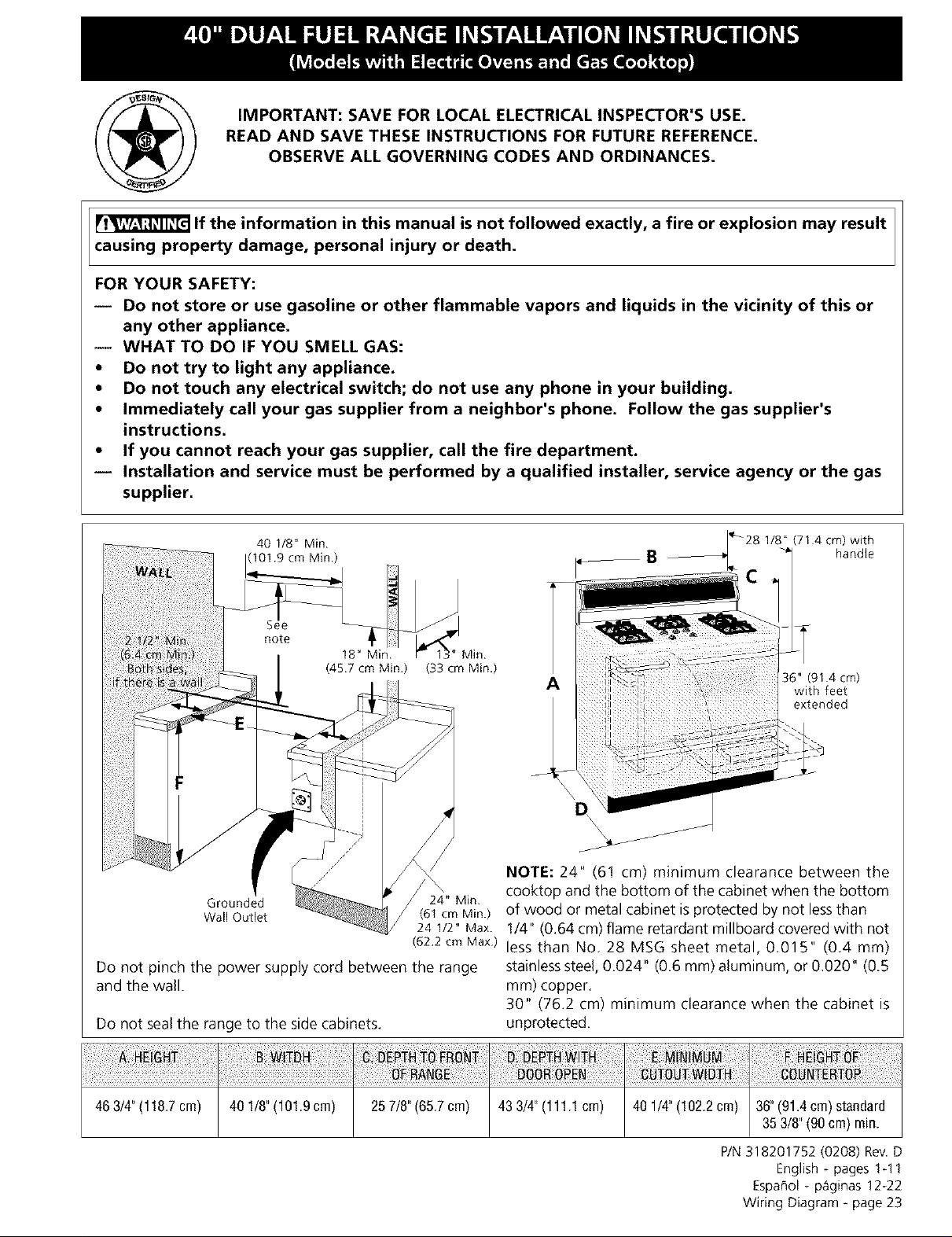

40 1/8" Min (71 4 cm) with

101.9crnMin.) _ B _ handle

note

18" Min _" Min

(457 cm Min.) (33 cm Min.)

A 36" (91 4 cm)

NOTE: 24" (61 cm) minimum clearance between the

Grounded 24" Min

Wall Outlet (61 em Min.)

24 1/2" Max.

(622 cm Max)

Do not pinch the power supply cord between the range

and the wall.

Do not seal the range to the side cabinets, unprotected.

cooktop and the bottom of the cabinet when the bottom

of wood or metal cabinet is protected by not lessthan

1/4" (0.64 cm) flame retardant millboard covered with not

less than No. 28 MSG sheet metal, 0.015" (0.4 ram)

stainless steel, 0.024" (0.6 mm) aluminum, or 0.020" (0.5

mm) copper.

30" (76.2 cm) minimum clearance when the cabinet is

with feet

extended

D

46 3/4"(118.7cm) 40 1/8"(101.9crn) 257/8"(65.7cm) 43 3/4"(111.1crn) 40 1/4"(102.2crn) 36"(91.4crn)standard

35 3/8"(90crn) rnin.

P/N 318201752 (0208) Rev.

English - pages 1-11

Espar_ol- p_iginas 12-22

Wiring Diagram _ page 23

Page 2

Important Notes to the Installer

1. Readall instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the electrical supply

to the range (see "Preparation ", page 8).

3. Install the 4 shipping bolts from range

packaging as range leveling legs (see "Leveling the

Range", page 8).

4. Two anti-tip brackets MUST be removed from

lower back of range and MUST be installed (see

"Anti-Tip Bracket Installation ", page 10).

5. Observe all governing codes and ordinances.

6. Besure to leavethese instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1-latest edition.

This range has been designed certified by the American

Gas Association. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

_To

All ranges

can tip.

®

Injuryto

persons

could result.

Install anti-tip

device

®

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70--1atest edition (See grounding Instructions on

page 4).

• The installation of appliances designed for

manufactured (mobile) home installation must conform

with Manufactured Home Construction

and Safety Standard, title 24CFR, part 3280 [Formerly

the Federal Standard for Mobile Home Construction

and Safety, title 24, HUD (part 280)] or when such

reduce the risk of tipping

of the range, the range

must be secured by

properly installed anti-tip

bracket (s) provided with

the range. To check if the

bracket (s) is installed

properly, remove the

lower panel or storage

standard is not applicable, the Standard for

Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Setups), ANSI Z225.1/

NFPA 501A-latest edition, or with local codes.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F/32°C above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of 114" (6.4

mm) thick plywood between the range and carpeting.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

_'l_Wl_,_:l_lh_[elNever leave children alone or

unattended in the area where an appliance is in use.

As children grow, teach them the proper, safe use of all

appliances, Never leave the oven door open when the

range is unattended

Stepping, leaning or sitting on the

door(s) or drawer of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

units, cabinet storage space above the units

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessiveflame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control knob to Lite. Use caution when lighting

surface burners manually.

• Reset all controls to the "off" position after using

a programmable timing operation.

2

Page 3

Power Supply Cord Kit

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

This appliance may be connected by means of

permanent "hard wiring" (flexible armored or

nonmetallic shielded copper cable), or by means of a

power supply cord kit. Use only a power supply cord kit

rated at 125/250 volts minimum, 40 amperes minimum

and marked for use with ranges. See chart (below) for

cord kit connection opening size and rating information.

Cord must haveeither 3 or 4 conductors.

For mobile homes, new installations, recreational

vehicles, or areas where local codes do not permit

grounding through neutral, a 4 conductor power supply

cord kit rated at 125/250 volts minimum, 40 amperes

and marked for use with ranges should be used (see

Figure 4).

Terminals on end of wires must either be closed loop or

open-end spade lugs with upturned ends. Cord must

have strain relief clamp.

[l,'_vf_,IH_ll_[el Risk of fire or electrical shock exists if

an incorrect size range cord kit is used, if the

Installation Instructions are not followed, or if the

strain relief bracket is discarded.

Range Connection Opening Size Chart

Refer to chart below for proper range connection opening size

and power supply cord kit ampere rating information See serial

plate on range for kilowatt rating data

Range Kilowatt Rating

(See Serial Plate on Range)

120/240 Volts I20/208 Volts

0-16.5 kW 0-125 kW

166-22.5kW 126-18.5kW

Minimum Diameter (inches) of Range

Cord kit Connection Opening

Ampere Direct

Rating Cord Kit Connection

40 Amp 1-3/8 in 1-1/8 in

50 Amp 1-3/8 in 1-3/8 in

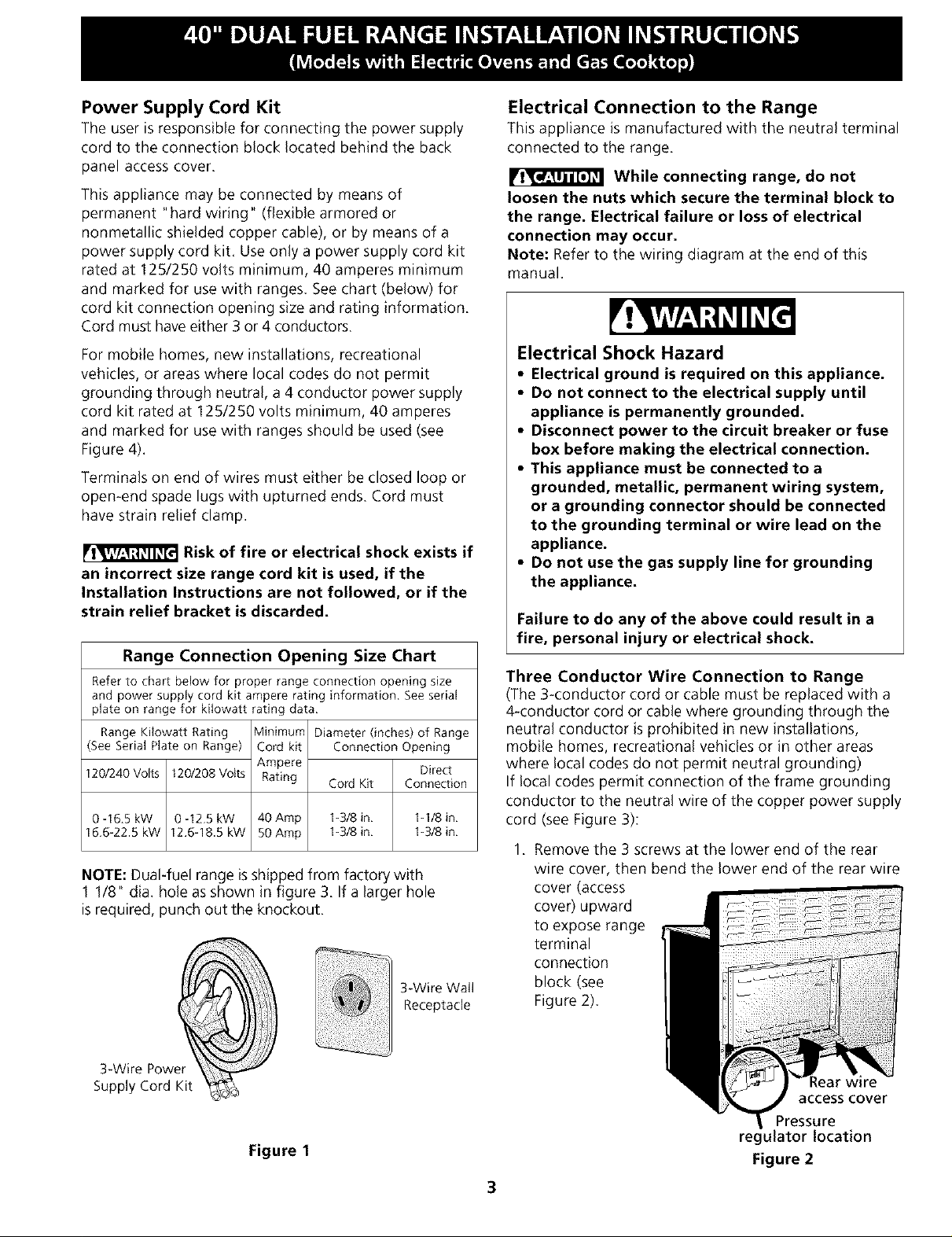

NOTE: Dual-fuel range isshipped from factory with

1 1/8" dia. hole asshown in figure 3. If a larger hole

isrequired, punch out the knockout.

3-Wire Wall

Receptacle

Electrical Connection to the Range

This appliance is manufactured with the neutral terminal

connected to the range.

While connecting range, do not

loosen the nuts which secure the terminal block to

the range. Electrical failure or loss of electrical

connection may occur.

Note: Refer to the wiring diagram at the end of this

manual.

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

• Do not use the gas supply line for grounding

the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

Three Conductor Wire Connection to Range

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power supply

cord (see Figure 3):

1.

Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear wire

cover (access

cover) upward

to expose range

terminal

connection

block (see

Figure 2).

3-Wire Power

Supply Cord Kit

Figure 1

3

Page 4

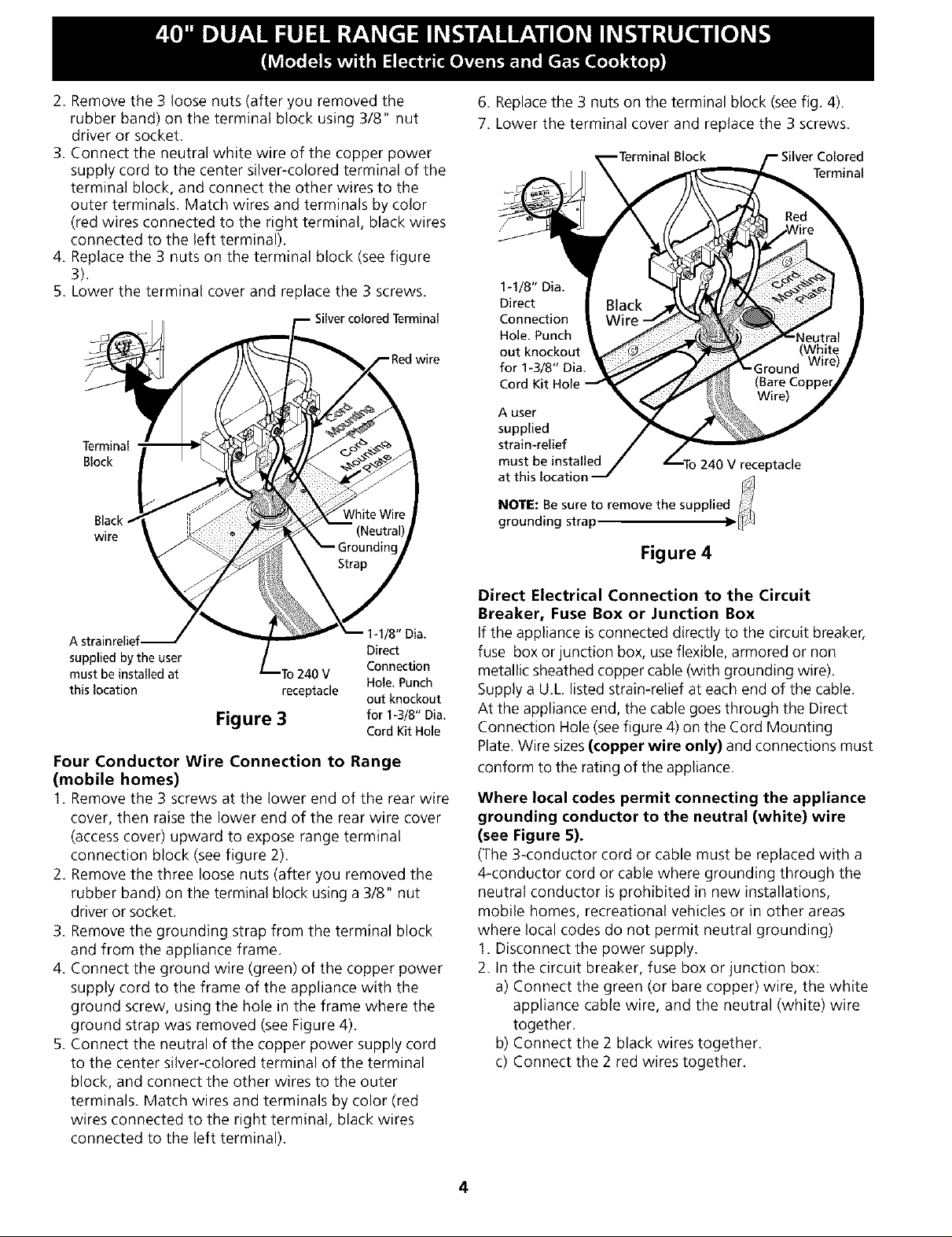

2.Removethe3loosenuts(afteryouremovedthe

rubberband)ontheterminalblockusing3/8"nut

driverorsocket.

3.Connecttheneutralwhitewireofthecopperpower

supplycordtothecentersilver-coloredterminalofthe

terminalblock,andconnecttheotherwiresto the

outerterminals.Matchwiresandterminalsbycolor

(redwiresconnectedtotherightterminal,blackwires

connectedtotheleftterminal).

4.Replacethe3nutsontheterminalblock(seefigure

3).

5.Lowertheterminalcoverandreplacethe3 screws.

Terminal

Block

Black

wire

6. Replace the 3 nuts on the terminal block (see fig. 4).

7. Lower the terminal cover and replace the 3 screws.

I-I/8" Dia.

Direct

Connection

Hole. Punch

out knockout

for I-3/8" Dia,

Cord Kit Hole

A user

supplied

strain-relief

must be installed

NOTE: Be sure to remove the supplie

at this location d

grounding strap

Figure 4

A strainrelief I/8" Dia.

supplied by the user

must be installed at To 240 V

this location receptacle out knockout

Figure 3 for I-3/8" Dia,

Direct

Connection

Hole, Punch

Cord Kit Hole

Four Conductor Wire Connection to Range

(mobile homes)

1. Remove the 3 screws at the lower end of the rear wire

cover, then raise the lower end of the rear wire cover

(access cover) upward to expose range terminal

connection block (see figure 2).

2. Remove the three loose nuts (after you removed the

rubber band) on the terminal block using a 3/8" nut

driver or socket.

3. Remove the grounding strap from the terminal block

and from the appliance frame.

4. Connect the ground wire (green) of the copper power

supply cord to the frame of the appliance with the

ground screw, using the hole in the frame where the

ground strap was removed (see Figure 4).

5. Connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal).

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance isconnected directly to the circuit breaker,

fuse box or junction box, use flexible, armored or non

metallic sheathed copper cable (with grounding wire).

Supply a U.L listed strain-relief at each end of the cable.

At the appliance end, the cable goes through the Direct

Connection Hole (see figure 4) on the Cord Mounting

Plate. Wire sizes (copper wire only) and connections must

conform to the rating of the appliance.

Where local codes permit connecting the appliance

grounding conductor to the neutral (white) wire

(see Figure 5).

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

1. Disconnect the power supply.

2. In the circuit breaker, fuse box or junction box:

a) Connect the green (or bare copper) wire, the white

appliance cable wire, and the neutral (white) wire

together.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

4

Page 5

WhiteWire

(Neutral)

Cablefrom

Residence

Wires 1

Junction Box Location

Locate junction box as shown in Figure 7.

If a service cord is used, the wall receptacle should be

located in accordance with the dimensions below.

Center

Line of

Range

Box

(Neut_l)

Green U.L.-listed

(or RareCopper) Conduit

Wire Cablefrom Connector

Range (orCSAlisted)

Figure 5

3-Wire (Grounded Neutral) Electrical System

(example: Junction Box)

Where local codes DO NOT permit connecting the

appliance grounding conductor to the neutral

(white) wire or if connecting to 4-wire electrical

system (see Figure 6).

1. Disconnect the power supply.

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the circuit breaker, fuse box or junction box:

a) Connect the white appliance cable wire to the

neutral (white) wire.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

d) Connect the green (or bare copper) grounding

wire to the grounding wire of the circuit breaker,

fuse box or junction box.

Cablefrom

Green Residence

(or BareCopper)

Junction

Box

$25.4 cm)

(so!O.cm)_- .wALL

7" Max.

(17.8cm Max

"_ Center

Locate Electrical Hook-up Range

Inside Shaded Area

Line of

Figure 7

Range Placement

To eliminate the risk of burns or fire by

reaching over heated surface units, cabinet storage

space located above the range should be avoided. If

cabinet storage space isto be provided, the risk can be

reduced by installing a range hood that projects

horizontally a minimum of 5" (12.7 cm) beyond the

bottom of the cabinet.

Center

Line of

Range

Wire

Red_

rwir

(or Bare Copper)

Wire

4-Wire Electrical System

(example: Junction Box)

Cable from Conduit

Appliance Connector

(or CSA listed)

Figure 6

Follow instructions for

the type of installation you have

Figure 8

If range will be installed with a cabinet on both

sides, draw a center line on the floor between the

cabinets (see figure 8). If back of range will not be

flush with the wall (the location of the outlet may not

allow the range to be positioned against the wall), draw

a line on the floor where the back edge of the range will

be. Now install anti-tip brackets (see "Anti-Tip Brackets

Installation", page 10).

If range will be installed with a cabinet on one side

only, move the range into final position. Draw a line on

the floor along the side of the range that is not against

5

Page 6

the cabinet. If back of range will not be flush with

the wall (the location of the outlet may not allow the

range to be positioned against the wall), draw a line on

the floor where the back edge of the range will be. Now

install anti-tip brackets (see "Anti-Tip Brackets

Installation", page 10).

If range will not be installed against a cabinet,

move range into final position. Draw a line on the floor

along both sides of the range. If back of range will not

be flush with the wall (the location of the outlet may

not allow the range to be positioned against the wall),

draw a line on the floor where the back edge of the

range will be. Now install anti-tip brackets (see "Anti-Tip

Brackets Installation", page 10).

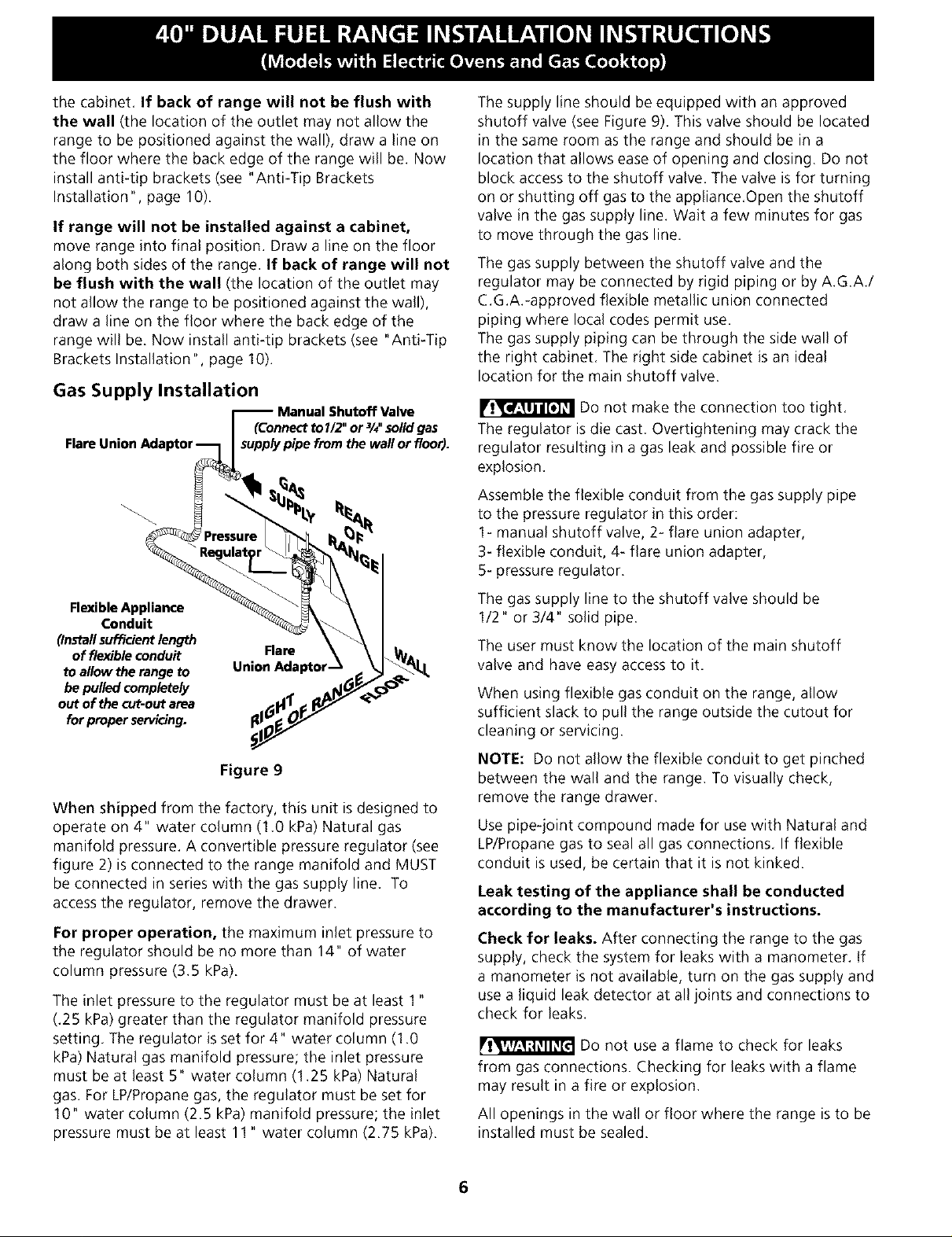

Gas Supply Installation

-- Manual ShutoffValve

(Connectto112"or3/,/,solidgas

FlareUnion Supply pipe fromthe wallor floor).

The supply line should be equipped with an approved

shutoff valve (see Figure 9). This valve should be located

in the same room as the range and should be in a

location that allows ease of opening and closing. Do not

block access to the shutoff valve. The valve is for turning

on or shutting off gas to the appliance.Open the shutoff

valve in the gas supply line. Wait a few minutes for gas

to move through the gas line.

The gas supply between the shutoff valve and the

regulator may be connected by rigid piping or by A.G.A./

C.G.A.-approved flexible metallic union connected

piping where local codes permit use.

The gas supply piping can be through the side wall of

the right cabinet. The right side cabinet is an ideal

location for the main shutoff valve.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Assemble the flexible conduit from the gas supply pipe

to the pressure regulator in this order:

1- manual shutoff valve, 2- flare union adapter,

3- flexible conduit, 4- flare union adapter,

5- pressure regulator.

Flexible Appliance

Conduit

(Install sufficient length

of flexible conduit

to allow the range to

be pulled completely

out of the cut-out area

for proper servicing.

L

Figure 9

When shipped from the factory, this unit isdesigned to

operate on 4" water column (1.0 kPa) Natural gas

manifold pressure. A convertible pressure regulator (see

figure 2) is connected to the range manifold and MUST

be connected in series with the gas supply line. To

access the regulator, remove the drawer.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14" of water

column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1"

(.25 kPa) greater than the regulator manifold pressure

setting. The regulator is set for 4" water column (1.0

kPa) Natural gas manifold pressure; the inlet pressure

must be at least 5" water column (1.25 kPa) Natural

gas. For LP/Propane gas, the regulator must be set for

10" water column (2.5 kPa) manifold pressure; the inlet

pressure must be at least 11 " water column (2.75 kPa).

The gas supply line to the shutoff valve should be

1/2" or 3/4" solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

When using flexible gas conduit on the range, allow

sufficient slack to pull the range outside the cutout for

cleaning or servicing.

NOTE: Do not allow the flexible conduit to get pinched

between the wall and the range. To visually check,

remove the range drawer.

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

conduit is used, be certain that it is not kinked.

Leak testing of the appliance shall be conducted

according to the manufacturer's instructions.

Check for leaks. After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector at all joints and connections to

check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where the range is to be

installed must be sealed.

6

Page 7

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Check alignment of valves after connecting the

cooktop to the gas supply to be sure the manifold pipe

has not been moved.

Disconnect the range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of the system at test pressures greater

than 1/2 psig (3.5 kPa or 14" water column).

LP/Propane Gas Conversion

This appliance can be used with Natural Gas or Propane

Gas. It is shipped from the factory for usewith natural gas.

If you wish to convert your range for use with LP/Propane

gas, usethe supplied fixed orifices; they are contained in a

special bag along with instructions marked "FOR LP/

PROPANEGAS CONVERSION", located on the back of

the range, close to the appliance regulator valve.

The conversion must be performed by a qualified installer,

LPsupplier or service technician in accordance with the

installation instructions furnished with this range and all

codes and requirements of all local codes and

requirements. Failure to follow instructions could result in

serious injury or property damage. The qualified agency

performing this work assumes responsibility for the

conversion.

Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer and open the oven door. Lift the range at the

front and slide it out of the cut-out opening without

creating undue strain on the flexible gas conduit.

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or lessthan 1/2 psig (3.5kPa or 14"

water column).

Make sure not to pinch the flexible gas conduit at the

back of the range when replacing the unit into the cut-

out opening. Replace the drawer, close the door and

switch on the electrical power and gas to the range.

If the pressure regulator is connected to rigid piping, the

regulator must be disconnected before moving the

appliance.

Reassemble in reverse order (see figure 9).

Failure to make the appropriate conversion

can result in personal injury and property damage.

Any additions, changes or conversions

required in order for this appliance to satisfactorily meet

the application needs must be made by an authorized

Sears Service Center, Distributor or Qualified Agency.

7

Page 8

Range Installation

When unpacking the range, do not

discard the 4 shipping bolts. These are to be replaced on

the unit for use as leveling legs and height adjustments.

NOTE:

1. The back of the range may be installed directly

against the wall.

2. To reduce possible scorching of vertical walls and to

minimize potential fire hazards under abnormal

surface unit use conditions such as high heat or no

pans and to conform to A.G.A. requirements, a

minimum of 2 1/2" (6.4 cm) spacing should be

provided on both sides of the cooktop.

.

Slide range into cut-out opening and double check

for levelness. If the range is not level, pull unit out

and readjust leveling legs, or make sure floor is

level.

Preparation

Excessive Weight Hazard

* Use 2 or more people to move and install

range.

* Failure to follow this instruction can result in

back or other injury.

1. Put on safety glasses and gloves. Remove oven racks

and parts package from inside the oven. Remove

shipping materials, tape and protective film from the

range.

2. Take 4 cardboard corners from the carton. Stack one

on top of another. Repeat with other 2 corners.

Place corners lengthwise on the floor in back of the

range to support range.

3. Firmly grasp the range and gently lay it on its back

on the cardboard corners.

4. Remove and save the 4 shipping bolts from the skid.

Discard skid.

5. Install 4 shipping bolts as leveling legs.

6. Lay a large piece of cardboard in front of the range.

Carefully stand the range upright on cardboard.

7. Adjust the leveling legs to a point where the range

base does not touch the floor.

Leveling the Range

Level the range and set cooktop height before

installation in the cut-out opening (if applicable).

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see fig. 10). Take 2

readings with the level placed diagonally in one

direction and then the other. Level the range, if

necessary, by adjusting the 4 leveling legs with a

wrench (see Figure 14).

Figure 10

Check Operation

Refer to the Use and Care Guide and the Electronic Oven

Control Guide packaged with the range for operating

instructions and for care and cleaning of your range.

Remove all packaging from the oven before testing.

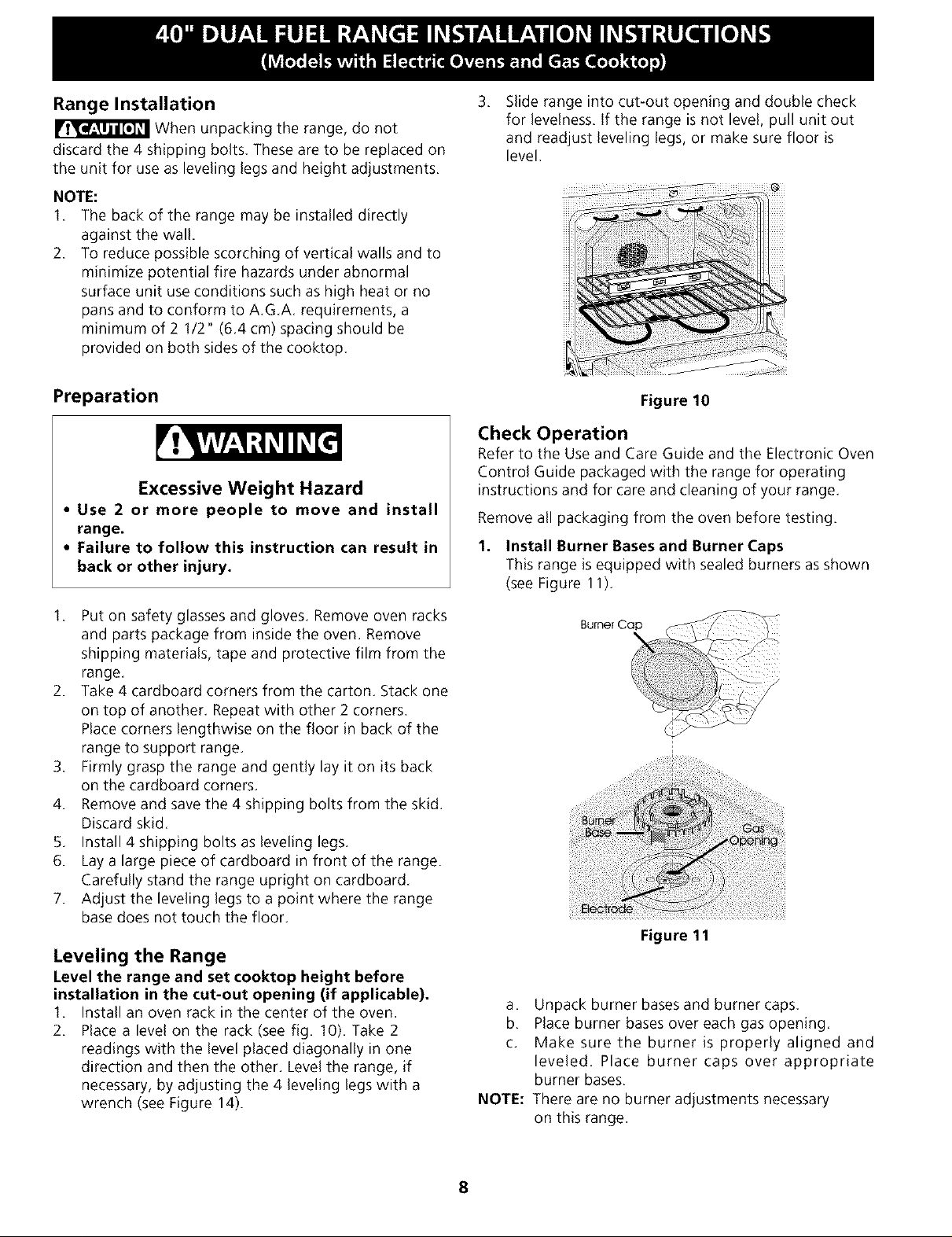

1. Install Burner Bases and Burner Caps

This range is equipped with sealed burners as shown

(see Figure 11).

Figure 11

a. Unpack burner bases and burner caps.

b. Place burner bases over each gas opening.

c. Make sure the burner is properly aligned and

leveled. Place burner caps over appropriate

burner bases.

NOTE: There are no burner adjustments necessary

on this range.

8

Page 9

2.

Turn on Electrical Power and Open Main Shutoff

Gas Valve

3.

Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting:

a. Push in and turn a surface burner knob to the

LITEposition. You will hear the igniter sparking.

b. The surface burner should light when gas is

available to the top burner. Each burner should

light within four (4) seconds in normal operation

after air has been purged from supply lines.

Visually check that burner has lit.

c. Once the burner lights, the control knob should

be rotated out of the Life position.

There are separate ignition devices for each burner.

Try each knob separately until all burner valves have

been checked.

4.

Adjust the "LOW" Setting of Surface Burner

Valves (see Figure 12)

a. Push in and turn each control to LITEuntil burner

ignites.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, readjust valve as follows:

Reset control to OFF. Remove the surface burner

control knob, insert a thin-bladed screwdriver

into the hollow valve stem and engage the

slotted screw inside. Flame size can be increased

or decreased with the turn of the screw. Adjust

flame until you can quickly turn knob from LITE

to LOWESTPOSITIONwithout extinguishing the

flame. Flame should be as small as possible

without going out.

5. Operation of Oven Elements

The oven is equipped with an electronic oven control. Each

of the functions has been factory checked before shipping.

However, it issuggested that you verify the operation of

the electronic oven controls once more. Referto the Use

and Care Guide for operation. Follow the instructions for

the Clock, Timer, Bake, Broil, Convection (some models)

and Clean (some models) functions.

When checking oven element operation,

do not touch the elements. They will be hot enough to

cause serious burns.

Bake-After setting the oven to 350°F (177°C) for baking,

the lower element in the oven should become red.

Broil-When the oven is set to BROIL,the upper element

in the oven should become red.

Clean (some models) When the oven is set for a self-

cleaning cycle, the upper element should become red

during the preheat portion of the cycle. After reaching

the self-cleaning temperature, the lower element will

become red.

Convection (some models)-When the oven is set to

CONV. BAKE/ROAST at 350°F (177°C), both elements

cycle on and off alternately and the convection fan will

turn. The convection fan will stop turning when the oven

door isopened during convection baking or roasting.

When All Hookups are Complete

Make sure all controls are left in the OFFposition.

Model and Serial Number Location

The serial plate is located on the drawer side frame.

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your range.

Figure 12

Before You Call for Service

Read the Avoid Service Checklist and operating

instructions in your Use and Care Guide. It may save you

time and expense. The list includes common occurrences

that are not the result of defective workmanship or

materials in this appliance.

Refer to the warranty and service information in your Use

and Care Guide for our phone number and address.

Pleasecall or write if you have inquiries about your

range product and/or need to order parts.

9

Page 10

Important Safety Warning

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed anti-tip

brackets and screws packed with the range. Those parts

are located in a plastic bag in the oven. Failure to install

the anti-tip brackets will allow the range to tip over if

excessive weight is placed on an open door or if a child

climbs upon it. Serious injury might result from spilled

hot liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" (8 mm) Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16" (4.8 mm) Diameter Drill Bit

3/16" (4.8 mm) Diameter Masonry Drill Bit (if installing

in concrete)

Anti-Tip Bracket Installation

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram in figure 13 to

locate brackets if template is not available.)

2. Mark on the floor the location of the 4 mounting

holes (2 holes per bracket) shown on the template.

For easier installation, 3/1 6" (4.8 mm) diameter pilot

holes 1/2" (1.3 cm) deep can be drilled into the

floor.

3. Remove template and place brackets on floor with

turned up flanges to the outside (see figure 13). Line

up holes in brackets with marks on floor and attach

with 4 screws provided (2 screws per bracket).

Brackets must be secured to solid floor. If attaching

to concrete floor, first drill 3/16" (4.8 mm) dia. pilot

holes using a masonry drill bit.

4. Level range if necessary, by adjusting the 4 leveling

legs with a wrench. (See Figure 14 below.) A

minimum clearance of 1/8" (3.2 mm)is required

between the bottom of the range and the rear

leveling legs to allow room for the anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to be

shifted slightly to one side as it is being pushed back

to allow rear legs to align with brackets.

6. After installation, verify that the anti-tip bracket is

engaged. Open and remove drawer and check to

make sure the anti-tip bracket is engaged.

Anti-Tip Bracket

Figure 13

Back

3A*'(1.9 cm) Typ.

Figure 14

10

Page 11

NOTES:

11

Page 12

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA USO DEL

INSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

OBSERVE C_DIGOS TODO GOBERNANTES Y ORDENANZAS,

_Si la informacibn contenida en este manual no es seguida exactamente, puede

ocurrir un incendio o explosibn causando dahos materiales, lesibn personal o la muerte,

PARA SU SEGURIDAD:

-- No almacene ni utilice gasolina u otros vapores y liquidos inflamables en la proximidad de _ste

o de cualquier otro artefacto.

-- QUE DEBE HACER SI PERCIBE OLOR A GAS:

• No trate de encender ningt_n artefacto.

• No toque ning_n interruptor el_ctrico; no use ningt_n tel_fono en su edificio.

• Llame a su proveedor de gas desde el tel_fono de un vecino. Siga las instrucciones del

proveedor de gas.

• Si no Iogra comunicarse con su proveedor de gas, Ilame al departamento de bomberos.

-- La instalacibn y el servicio de mantenimiento deben ser efectuados pot un instalador calificado,

la agencia de servicio o el proveedor de gas.

40 I/8" Min.

1019 cm Min)

Nota

(457 cm Min)

_ 28 1/8" (71 4 cm) con

13" Min 36"

(33 cm MIn.) A (91 4 cm)

extendida

tirador

piecRa

D

**NOTA: Un espacio minimo de 24" (61 cm) entre la

superficie de la estufa y el fondo del armario cuando el

Tomacorrientede 24" Min. fondo del armario de madera o metal est_ protegido pot

pared puestoa tierra (61 cm Min)

No pellizque el cord6n electrico entre la estufa y la aluminio, 6 0.02" (0.5 mm) de cobre.

pared. Un espacio minimo de 30" (76.2 cm) cuando el armario no

No selle la estufa a los armarios de lado. est_ protegido.

24 1/2" M_x no menos de 1/4" (0.64 cm) de madera resistente al fuego

(622 cmM_x.)cubierta por una I_imina met_ilica de MSG, nOmero 28,

0.01 5" (0.4 mm) de acero inoxidable, 0.024" (0.6 mm) de

463/4"(11&7cm) 40 1/8"(101.9cm) 257/8"(65.7cm) 43 3/4"(111.1cm) 401/4"(102.2crn) 36"(91.4crn)standard

35 3/8"(90cm) rain.

P/N 318201752 (0208) Rev.D

English _ pages 1_11

Espa_ol _ p_iginas 12-22

Diagrama de la instalad6n al_mbrica _p_gina 23

Page 13

Notas importantes para el Instalador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento del homo antes de conectar el

suministro el_ctrico a la estufa.

3. Guarde los 4 pernos del empaque de la estufa

para usarlos como patas niveladoras.

4. Dos soportes antivuelco DEBEN quitarse de la

parte de inferior trasera de la estufa y DEBEN ser

instalados. Para detalles, vea instrucciones en la

pagina 10.

5. Observe todos los c6digos y reglamentos pertinentes.

6. Deje estas instrucciones con el comprador.

Nota Importante para el Consumidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

IMPORTANTES

INSTRUCCIONES DE

SEGURIDAD

Instalaci6n de esta estufa debe cumplir con todos los

c6digos locales, o en ausencia de c6digos locales con el

C6digo Nacional de Gas Combustible ANSI Z223.1--

Oltima edici6n.

El dise_o de esta estufa ha sido certificado por la

Asociaci6n de Gas Americana. En_stecomoen

cualquier otro artefacto que use gas y genere calor, hay

ciertas precauciones de seguridad que usted debe seguir.

Estas seroin encontradas en el Manual del Usuario, l_alo

cuidadosamente.

• La instalaciOn de aparatos disehados para instalaciOn

en casas prefabricadas (mOviles) debe conformar con

el Manufactured Home Construction and Safety

Standard, titulo 24CFR, parte 3280 [Anteriormente el

Federal Standard for Mobil Home Construction and

Safety, titulo 24, HUD (parte 280)] o cuando tal

est4ndar no se aplica, el Standard for Manufactured

Home installation 1982 (Manufactured Home sites,

Communities and Setups), ANSI Z225.1/NFPA 501A-

edici6n m_is reciente, o con los cOdigos locales.

• Asegurese de que el material que recubre las

paredes alrededor de la estufa, pueda resistir el

calor generado por la estufa.

• Antes de instalar la estufa en un area cuyo piso

este recubierto con lin61eo u otro tipo de piso

sintdtico, asegt_rese de que dstos puedan resistir

una temperatura de por Io menos 90°F sobre la

temperatura ambiental sin provocar

encogimiento, deformaci6n o decoloraci6n. No

instale la estufa sobre una alfombra al menos que

coloque una plancha de material aislante de por lo

menos 1/4 pulgada, entre la estufa y la alfombra.

• No obstruya el flujo del aire de combusti6n en la

ventilaci6n del homo ni tampoco alrededor de la

base o debajo del panel inferior delantero de la

estufa. Evite tocar las aberturas o 4reas cercanas de

la ventilaciOn, ya que pueden estar muy calientes

durante el funcionamiento del horno. La estufa

requiere aire fresco para la combustion apropiada de

los quemadores.

Nunca deje ni_os solos o

desatendidos en un area donde un artefacto estE

siendo usado. A medida que los ni_os crecen,

ense_eles el uso apropiado y de seguridad para todos los

artefactos. Nuncadejela puertadel hornoabierta

cuando la estufa est.1 desatendida.

• Asegt_rese de que la estufa sea instalada y

conectada a tierra en forma apropiada pot un

instalador calificado o pot un t_cnico.

• Esta estufa debe ser eldctricamente puesta a

tierra de acuerdo con los c6digos locales, o en su

ausencia, con el C6digo Eldctrico Nacional ANSI/

NFPA No. 70, (_ltima edici6n.

®

• Todas las

estuffas

pueden

volcarse.

• Esto podria

resultar en

lesiones

personales.

• Instale el

dispositivo

antivuelcos que

seha

empacado

junto con esta

estufa.

Para reducir el riesgo de

que se vuelque la estufa,

hay que asegurarla

adecuadamente

colocandole Los soportes

antivuelco que se

propordonan. Para

comprobar si estos estan

instaiados yapretados en

su lugar como se debe, ase

el borde trasero superior de

la estufa y cuidadosamente

inclinela hada

adelante para asegurar

que la estufa se ancle.

No se pare, apoye o siente en las

puertas o cajones de esta estufa pues puede

resultar en serias lesiones y puede tambien causar

da_o a la estufa.

• No almacene articulos que puedan interesar a los

nihos en los gabinetes sobre la estufa. Los niEos

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos articulos.

• Los gabinetes de almacenamiento sobre la estufa

deben set evitados, para eliminar la necesidad de

tener que pasar sobre los elementos superiores de

la estufa para llegar a ellos.

• Ajuste el tama_o de la llama de los quemadores

superiores de tal manera que dsta no sobrepase el

borde de los utensilios de cocinar. La llama

excesiva es peligrosa.

• No use el homo como espacio de almacenaje. Esto

crear4 una situaciOn potencialmente peligrosa.

• Nunca use la estufa para calentar el cuarto. El uso

prolongado de la estufa sin la adecuada ventilaciOn

puede resultar peligroso.

13

Page 14

• No almacene ni utilice gasolina u otros vapores y

liquidos inflamables en la proximidad de dste o

de cualquier otro artefacto electrico. Puede

provocar incendio o explosion.

• En caso de una interruption del servicio electrico, es

pasible de encender los quemadores de superficie a

mano. Para encender un quemador de suoerficie,

acerque un fOsforo encendido del cabezal del

quemador, y gire delicadamente el bot0n de control de

superficie a LITE(encendido). Tener cuidado al

encender los quemadores a mano.

• Ajuste todos los controles a la posici6n "OFF" (apagada)

despudsde haber hecho una operacion con tiempo

programado.

rl1_;i;:_:_u[_[o],,i AI realizar la conexion de la estufa, no

desaprete las tuercas que aseguran el alambraje de la estufa al

bloque terminal instalado en la f_ibrica. Se puede ocurrir corte de

energia o p_rdida de conexiOn electrica.

Juegode CordOr_

de Suministro \_

El_ctricode 3

Alambres Figura 1

Juego de Cordbn Eldctrico

Elconsumidor tiene la responsabilidadde conectar el cordon

el_ctdco al bloque de conexiOn ubicado detr_s de la cubierta

de accesodel panel trasero.

Este artefacto puede ser conectado mediante "cableado

rigido" permanente (un cable fexible escudido o un cable de

cobre escudido no met_lico) o un "juego de cordon

el_ctdco". Se usar_i solamente un juego de cordon electrico

para 125/250 voltios minimo, 40 amperios minimo y marcado

para uso con estufas. Eljuego de cordon electrico debe tener

3 o 4 conductores.

Para las casas sobre ruedas, las nuevas instalaciones, en los

vehiculos de recreation o en las _ireas donde los cOdigos

locales no permiten la conexiOn del conductor a tierra al

neutro, un ensamblaje de suministro el_ctrico de 4

conductores para estufas, clasificado a 125/250 voltios

minimo, 40 amperios minimo, debe de ser utilizado (vea

Figura 4).

Los terminales en las puntas de los alambres deben ser de

drcuito cerrado o de orejeta de pala punta abierta y con las

puntas vueltas hacia ardba. El cordon debe tener un anclaje

del cable.

Puede ocurrir riesgo de incendio o

choque el_ctrico si se usa un juego de cordbn de estufa de

tamafio incorrecto, si las instrucciones de instalacibn no

son seguidas o si no se usa el andaje del cable.

Tabla de tamafio de abertura de conexibn de cocina

Referirse a la tabla de arriba para et tama_o de abertura de

connexidn de codna adecuada, y la information sobre el regimen

de amperios del ensamblaje de corddn de suministro el_ctdco

Vea la placa de serie de la

cocina para informaciOn

sobre el regimen de

ki_ovatio

120/240 Volts I20/208 Volts

0-165 Kw 0-125 Kw 40 Amp

I6 6-22.5 Kw 12.6-18 5 Kw 50Amp

Minimo

regirnOn de

amperios

de

ensamblaje

del cordon

Diametro (pulgadas) de

abierta de conexiOn de

codna

DimensiOn ConexiOn

agujero directo

ConnexiOn

3/8 pulg 1 1/8 pulg

3/8 pulg 1 3/8 pulg

Conexibn Eldctrica de la Estufa

Este aparato se fabrica con el terminal neutro conectado

al marco.

Refiere al diagrama de alambraje de esta cocina al final

de este libreta.

Riesgo de Choque Eldctrico

• Una puesta a tierra est& requerido en este

aparato.

• No Io conecte a la corriente eldctrica hasta que

el aparato haya sido puesto a tierra

permanentemente.

• Desconecte la corriente eldctrica a la caja de

empalmes antes de hacer la conexibn eldctrica.

• Este aparato debe estar conectado con un

sistema de alambres puesto en tierra, metElico

y permanente o un conector de puesta a tierra

debe conectarse al terminal de puesta a tierra

o el alambre conductor en el aparato.

La falta de hacer cualquier de las cosas arriba

podria resultar en un incendio, choque

el_ctrico o lesiones personales.

Conexibn de tres alambres de conduccibn a la

estufa

(Un cordon flexible o cable de 3 conductores debe de set

reemplazado con un cordon flexible o cable de 4 conducto-

res donde la conexi0n del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones, las casas sobre

ruedas, los vehiculos de recreaci0n o otras _ireasdonde los

c0digos locales no permiten la conexi0n a tierra al neutro.)

Si los c0digos locales permiten Ia conexi0n del conductor

de tierra del marco con el alambre neutro del cordon

electrico de cobre (vea Figura 3):

NOTA: La estufa bi*energi_i viene de f_ibrica preparada para

funcionar con un hueco de 1 1/8" de diametro come se muestra

en la figura 3. Encaso de necesitarse un hueco m_s grande retire

la cubierta.

Figura 2

14

del alambre trasero

de acceso

Ubicacibn del

regulador de presibn

Page 15

1. Quite los tres tornillos en la parte m_s baja del panel

trasero, luego levante la parte m_s baja del panel

trasero (la cubierta de acceso) exponiendo el bloque

de conexiones de los terminales de la estufa (vea

Figura 2).

2. Quinte las tres tuercas desatadas (despu_s de

remover la cinta de goma) sobre el bloque terminal

usando un destornillador o una Ilave de casquillo de

3/8".

3. Conecte el cable neutro del cordon el_ctrico de cobre

al terminal de color de plata en el centro del bloque,

y conecte los otros cabels a los terminales laterales.

Empareje los cables y los terminales segOn el color

(cables rojos conectados con el terminal derecho,

cables negros conectados con el terminal izquierdo).

4. Baje la cubierta del terminal y reinstale los tres (3)

tornillos.

5. Baje la cubierta del terminal y reponga los 3 tornillos.

de terminal

5. Conecte el alambre neutro (blanco) del cordon

electrico de cobre al terminal de color de plata en el

centro del bloque y conecte los otros alambres al los

terminales laterales. Conecte los alambres y

terminales emparejando los colores (los alambres rojos

conectsdos al terminal derecho, los alambres negros

conectados al terminal izquierdo).

6.Reponga las 3 tuercas sobre el bloque terminal (vea

figura 4).

7. Baje la cubierta de acceso y vuelva a porter los 3

tornillos.

- Bloqueterminal f-Terminal

plata

• . ,,egro _

dlrecta.Retlra -" _ u r

e t 0

,a arandela _(_AlernU_ /

pre-cortada _'_ _ II_ _ Blanco)/

para.1-318"Dia .... "Puesta a tierra _'

Agujero_ _ J_ I_!/_ (cablede _"

Una arazaaera _,. _,_L_

__!_ cobre)

de relevaprovist__

debedeestar - _

instalada aest_ _ Hacian_:)2d40V

ubicaciOn recept_culo

Una arazaden

de releva

provista debe de

estar instalada a

est_ ubicaci6n

Conexi6n de 4 alambres de conducci6n a la

Haciael 240 V conexi6n directa.

recept_culo Retirala arandela

Figura 3 I-3/8" Dia. Agujero

I/8" Dia.

Agujero de la

pre-cortada para

estufa (casas m6viles)

1. Quite los tres tornillos en la parte m_s baja del panel

trasero, luego levante la parte m_s baja del panel

trasero (la cubierta de acceso) exponiendo el bloque

de conexiones de los terminales de la estufa (vea

figura 2).

2. Retire las 3 tuercas (despu_s de haber removido la

banda de goma) sobre el bloque terminal usando un

manguito o destornillador de casquillo de 3/8"

pulgadas.

3. Quite la banda de puesta a tierra del bloque de los

terminalesydelmarcodelartefacto. Retengael

tornillo de puesta a tierra.

4. Conecte el alambre de puesta a tierra (verde) del

cordon electrico de cobre al marco del artefacto con

el tornillo de puesta a tierra, usando el agujero en el

marco donde se quit0 el tornillo de puesta a tierra

(yea figura 4).

NOTA: Aseguresede quitar la banda depuesta a tierra'--]_/_/

provista.

Figura 4

Conexi6n el_ctrica directa al cortacircuito, a la caja

de fusibles o la caja de empalmes

Si el aparato est,1conectado directamente al cortacircuito,

a la caja de fusibles o a lacaja de empalmes, use un cable

blindado flexible o no met_lico recubierto de cobre (con

alambre a tierra). Provee una abrazadera releva de andaje

homologo ULa cada extremidad del cable. A la

extremidad del el_ctrodom_stico, el cable pase a trav_s del

agujero de la conexiOn directa (vea figura 4) en el cable de

la placa de montaje. Eltama_o de los alambres (alambre

de ¢obre solamente) y lasconexiones deben estar

conforme al regimen del el_ctrodom_stico.

Donde los c6digos locales permitan conectar el

conductor de puesta a tierra del electrodomestico al

neutral (blanco) (vea figura 5):

(Un cord6n flexible o cable de 3 conductores debe de set

reemplazado con un cord6n flexible o cable de 4 conducto-

resdonde la conexiOn del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones, las casassobre

ruedas, los vehiculos de recreaciOno otras _Ireasdonde los

c6digos locales no permiten la conexi6n atierra al neutro.)

1. Desconecteelsuministro el_ctrico.

15

Page 16

2.

En el cortacircuito, la caja de fusibles o la caja de

empalmes

a) Conecte el alambre verde (o cobre desnudo), el

alambre blanco del cable del electrodomestico y el

alambre neutral (blanco) juntos.

b) Conecte los dos alambres negros juntos.

c) Conecte los dos alambres rojos juntos.

Cablede lafuente

_amb_

de alimentacibn

_Alambres

.2

Situaci6n de caja de uni6n

CL

dela

estufa

_'----- _a de

eml_lm_

_ A]ambre

Blanco

(Neutro)

Conductorde

overdes Cablede la (listado_SA)

Figura 5 - Sistema electrico(ejemplo: caja de

empalmes) de 3 alambres (a tierraneutral)

Donde los cbdigos locales NO permitan conectar el

conductor de puesta a tierra del el_ctrodomestico al

neutral (blanco), o si est& conectado con un sistema a

4 alambres (vea figura 6):

1. Desconecte el suministro electrico

2. Separe el alambre verde (o cobre desnudo) y el

alambre blanco del electrodom_stico.

3. En el cortacircuito, la caja de fusibles o la caja de

empalmes.

a. Conecte el alambre blanco del cable del

el_ctrodom_stico al alambre neutral (blanco).

b. Conecte los 2 alambres negros juntos.

c. Conecte los 2 alambres rojos juntos.

d. Conecte el alambre verde (o de cobre desnudo) de

la puesta a tierra del alambre al alambre de

puesta a tierra del cortacircuito, de la caja de

fusibles o de la caja de empalmes.

Alambre Cable de la fuente Caja de

desnudo o de alimentacibn empalmes

AlambVerde Alambrelanco

eutr°)rolos

Alambres

desnudos o Alambre

verdes Blanco

estufa

estufa unibn listado-UL

uni6nlistado-UL

Alambres

negros

(o listado-CSA)

Figura 6 - Sistema el_ctrico de 4 alambres

(ejemplo caja de empalme)

Localice la caja de empalmes como se ve en la Figura 7.

Si se usa un cordon de servicio, el recept_culo de pared

debe estar localizado seg0n las medidas que se indican

abajo.

sombreada

Figura 7

Estufa - Emplazamiento

Para eliminar el riesgo de quemaduras

e incendios al tocar superficies sobrecalentadas, se debe

evitar colocar espacio para armarios de almacenamiento

sobre las estufas con elementos al descubierto. Si se

instalan armarios sobre la estufa, se pueden reducir tales

riesgos instlando una campana purificadora que se

proyecta horizontalemente un mfnimo de 5" (12.7 cm)

m_s afuera de la parte inferior de los armarios.

I

Siga las instrucciones

para el tipo de instalaci6nque usted tenga

Figura 8

Si la estufa se va a instalar con un armario a ambos

lados, marque el centro de la abertura del armario en el

piso. Si la parte trasera de la estufa no estara a ras

con la pared (la ubicaci6n del tomacorriente puede que

no permita que la estufa se pegue a ras con la pared),

marque el piso donde estar_ el border trasero de la

estufa. Pongaelpatr0nenel piso, alineandolalinea

del centro del patron con la marca en el centro de la

aberturadelarmario. Pongael bordetraserodelpatr0n

a ras contra la pared trasera o la Ifnea marcada para la

parte de atr_s de la estufa.

Si la estufa se va a instalar con un armario a sblo un

lado, mueva la estufa a su posici_n final. Marque el piso

por el lado de la estufa que no estar_ contra el armario.

Si la parte trasera de la estufa no estara a ras con la

pared (la ubicaci6n del tomacorriente puede que no

permita que la estufa se pegue a ras con la pared),

marque el piso donde el borde trasero de la estufa estar_.

Ponga el patron en el piso y alinie el lado del patron con

la Ifnea marcada en el piso. Alinie la parle trasera del

patron con la pared trasera o la linea marcada para la

parte de atr_s de la estufa.

16

Page 17

Si la estufa no sera instalada junta contra un armario,

mueva la estufa a su posicioonfinal. Marque el piso por los

dos lados de la estufa. Si la parte trasera de la estufa

no estara a ras con la pared (la ubicacioondel

tomacorriente puede que no permita que la estufa se

pegue a ras con la pared), marque en el piso donde el

borde trasero de la estufa estar_. Ponga el patroonen el

piso y alinie los lados del patrooncon las lineas marcadas

en el piso. Alinie la parte trasera del patrooncon la pared

trasera o la linea marcada para la parte trasera de la

estufa (vea Instalacioondel Soporte Antivuelco p_igina 10).

Instalacibn de la alimentacibn de gas

V._lvulaManual Externa deCierre

(Conecte a un conducto s61idode

Adaptor de gas

Conector Flexible

para Artefactos

(Instale un conducto

Io suficientemente

largo para poder sacar la

estufa totalmente fuera

de la _irea recortada

para un servicio satisfactorio.)

Esta unidad ha sido ajustada para operar con un mOltiple

de admisioon para gas natural de 4" (1.0 kPa). Un

regulador de presioonconvertible esta conectado a la

wilvula distribuidora y DEBEset conectado en serie con

la tuberia de suministro de gas.

Para la operacibn apropiada, la m<ixima presioonde

entrada al regulador no debe exceder la presioonde una

columna de agua de 14 pulgadas (3.5 kPa).

La presioonde entrada al regulador debe set pot Io

menos 1 pulgada m_s grande que la wilvula distribuidora

(.25 kPa). El regulador ha sido ajustado para gas natural

a 4 pulgadas de presioonpara la wilvula distribuidora (1.0

kPa). La presioonde entrada debe set por Io menos de 5

pulgadas (1.25 kPa). Para propano liquido a 10 pulgadas

de presioonpara la v_lvula distribuidora (2.5 kPa) la

presioonde entrada debe ser por Io menos de 11

pulgadas (2.75 kPa).

La tuberia deberia ser equipada con una v_lvula de

cierre aprobada (vea Figura 6). Esta wilvula debe

ubicarse en la misma habitacioon que la estufa en un

lugar que permita una una facilidad de abrir y cerrar.

No bloqu_e el acceso a la v_lvula de cierre. La wilvula

es para abrir o cerrar el suministro de gas al aparato.

surninistrode gasde I/2" o %").

Adaptor de gas-

Figura 9

Abra la v_lvula de cierre en la linea de suministro de

gas. Espere unos minutos a que el gas se mueva por el

tubo.

El suministro de gas entre la wilvula de cierre y el

regulador se puede conectar con tuberia rigida o con

tuberia flexible unioon met_ilica conectada y aprobada por

la AGA/CGA donde los coodigos locales permiten.

La tuberia del suministro de gas puede pasar pot la

pared lateraldelarmarioderecho. Elarmariolateral

derecho es un lugar ideal para la wilvula de cierre

pincipal.

Fl_lr.I;l=(@;]l/=.][,],'lNo haga que la conexiooneste

demadiado apretada. El regulador esta fundido a

troquel. Apretandolo demasiado podria romper el

regulador resultando en escape de gas y posiblemente

un incendio o explosioon.

Monte el conector flexible desde el tubo de suministro

de gas hasta el regulador de presioonseg0n este orden:

1- wilvula de cierre manual, 2- adaptor de gas, 3-

conector flexible, 4- adaptor de gas, 5- regulador de

presioon.

Latuberia de suministro de gas debeset de 1/2" o 3/4" D.I.

El consumidor debe saber la posicioonde la v_lvula

principal de cierre y tener acceso f_icil a ello.

Cuando se usa un conducto flexible en la estufa, permita

suficiente flojedad como para sacar la estufa fuera del

recortado para la limpieza y el servicio.

NOTA: No permita que el conducto se pellizque entre la

pared y la estufa. Para verlo, saque el cajoon.

Use un compuesto para junturas de tuberia hecho para

uso con gas natural y de LP/Propano para sellar todas las

conexiones del gas. Si se usan los conectores flexibles

aseg_3resede que no esten enroscados.

Para verificar si hay fugas en el electrodomestico se

debe de seguir las instrucciones del fabricante.

Asegdrese de que no haya escapes de gas.Despues

de conectar la estufa al suministro de gas, compruebe el

sistema con un menoometro. Si no tiene un manoometro,

abre el gas y use un detector de fugas liquido en todas

las junturas y conexiones para averiguar si hay escapes

de gas.

rl _l'_'J'_==l_'_ No use llama para controlar que no

hayan perdidas de gas. La comprobacioon de perdidas de

gas con una llama puede resultar en un incendio o

explosioon.

Se debe sellar todas las aberturas en la pared o el piso

donde la estufa se instala.

Apriete todas las conexiones si hace falta para

prevenir fugas de gas en la superficie de la estufa o en

la linea de suministro.

Aseg_rese del alineamiento de las v&lvulas despues

de conectar la superficie de la estufa con el suministro

del gas para cerciorarse de que el tubo de escape no se

haya movido.

17

Page 18

Desconecte esta estufa y su valvula individual de

cierre del sistema del siministro de gas durante

cualquier prueba de presi0n de ese sistema a presiones

mayores de 1/2 psig (3.5 kPa o 14" columna de agua).

Conversibn para uso de Propano Liquido

Este aparato puede ser usado con gas natural o propano

liquido. Ha sido ajustado en la fabrica para operar con

gas natural solamente.

Si desea convertir su estufa para uso con propano

Ifquido, use los orificios provistos ubicados en el bolso

que contiene la literatura titulada "FOR LP/PROPANE

GAS CONVERSION", Iocalizado en la parte posteriora

del horno, cerca de la valvula del regulador del

homo. Siga las instrucciones que vienen con los

orificios.

La conversion debe ser efectuado por un tecnico de

servicio capacitado, de acuerdo con las instrucciones del

fabricante y con todos los c0digos y requisitos de las

autoridades correspondentes. El no seguir las

instrucciones podria dar como resultado lesiones graves

o da_os a la propiedad. El organismo autorizado para

Ilevar a cabo este trabajo asume la responsabilidad de la

conversion.

La mudanza del aparato para reparaciones o

limpieza

Apague la corriente electrica a la estufa a la fuente de

poder principal, y apague la wilvula de cierre manual de

gas. Aseg0rese de que la estufa este fresca. Quite el cajOn

de servicio y abre la puerta del homo. Levante la frente de

la estufa y deslicelafuera de la abertura sin crear tension

desmedida sobre el conducto flexible de gas.

Aisla la estufa del sistema del suministro de gas

cerrando su v_lvula manual de cierre individual durante

cualquier prueba de presi0n del suministro del gas a

presiones iguales a menos de 1/2 psgi (.5 kPao 14"

columna de agua).

Aseg0rese de no pellizque el conducto flexible de gas

detr_is de la estufa al reemplazar la unidad en la abertura.

Reemplaceel caj0n, cierre la puerta y enciende el gas y la

corriente electrica a la estufa.

El regulador debe desconectarse antes de mover el

aparato, si el regulador de la estufa se conecta a una

caheria rigida.

Reensamble en orden inverso (consulte Figura 9).

r!_ La falta de una conversion apropiada

puede resultar en lesiones graves y da_os a la

propiedad.

La instalaci0n y el servicio de

mantenimiento deben ser efectuados por un instalador

calificado, la agencia de servicio o el proveedor de gas.

18

Page 19

Instalacibn de laestufa

ris-_:_,_:_l[_[._l Mientras se desembala la estufa, ne

deseche los cuatro (4) pernos de embabalaje.

Reempl_celos como patas niveladoras y para ajustar la

altura de la unidad.

NOTA:

1. La parte trasera de la estufa puede ser directamente

instalada a ras con la pared trasera de la estructura.

2. Para reducir posibles marcas o rayas de las paredes

verticales y minimizar los riesgos de choques electricos

en caso de condiciones de uso anormales como alto

calor o no cazuelas, y para conformar a los requisitos

de A.G.A, un espacio mfnimo de 2 Y2" (6.4 cm) debe

de set provisto en ambos lados de la plancha de

cocinar.

Preparacibn

Peligro de Peso Excesivo

• Use 2 personas o m&s para mover e instalar la

estufa.

eSi no cumple con esta instrucci6n, puede

resultar en da_o a la espalda u otra lesi6n.

1. P_ngase guantes y anteojos de seguridad. Quite las

parrillas del homo y paquete de piezas de adentro del

homo. Quite materiales de empaque, cinta y pelfcula

protectiva de la estufa.

2. Tome las 4 esquinas de cart6n de la caja de empaque.

Col6quelas una encima de otra. Repita esta operaci_n

con las otras 2 esquinas. Coloque las esquinas

Iongitudinalmente en el piso detr_s de la estufa, para

apoyarla.

3. Sujete firmemente la estufa y suavamente recu_stela

en su respaldo, en las esquinas de cart6n.

4. Quite y guarde los 4 pernos de empaque de la

corredera. Descarte la corredera.

5. Instale los 4 pemos de transporte como patas de

nivelaci6n.

6. Ponge el carton delante de la estufa. Cuidadosamente

pare la estufa en el cart6n.

7. Ajuste la patas de nivelaci6n al punto en que la base

de la estufa no toque el piso.

2. Ponga un nivel sobre la parrilla. Tome dos lecturas con

el nivel puesto diagonalmente en una direcci6n y

despu_s en la otra. Nivele la estufa, si es necesario,

ajustando las 4 patas niveladoras con una Ilave de

tuercas (Figura 10).

3. Deslice la estufa en la abertura y verifique la nivelaci6n

otra vez. Si la estufa no es nivelada, tire la unidad

hacia afuera y reajuste las patas niveladoras, o verifique

que el piso sea niveIado.

Figura 10

Comprobaci6n del Funcionamiento

Consulte el Manual del Usuario incluido con la estufa

para instrucciones de operaci6n y instrucciones para el

cuidado y limpieza de su estufa.

Quite todo el embalaje de la unidad antes de

comprobarla.

1.1nstale las tapas de los quemadores y de las

tapas de los quemadores.

Esta estufa esta equipada con quemadores sellados

como se muestra mEs abajo (Figura 11).

a. Desembale las basas de los quemadores y las tapas

de los quemadores.

b. Coloque una basa de quemador sobre cada

abertura de gas.

c. Asegurese que el quemador est_ correctamente

alineado y nivelado. Coloque las tapas de los

quemadores sobre las correctas basas de

quemadores.

NOTA: Nohacefalta ning0najustedequemadoren

esta estufa.

Nivelacibn de la estufa

Nivele la estufa y ajuste la altura de la estufa antes

de instalarla en la abertura.

1. Coloque una parrilla del homo en el centro del homo.

Recogedor

Base del Abertura

quemador de gas

Etectrodo

Figura 11

19

Page 20

2,

Enciende la corriente eldctrica y abre la vElvula

principal de cierre.

3.

Comprobacibn de los Encendedores

El funcionamiento de los encendedores electricos

debe ser comprobado despu_s de que la estufa y los

conectores a la tuberia de suministro de gas hayan

sido comprobados por escapes y la estufa haya sido

conectada electricamente. Para comprobar que el

encendido sea correcto:

a. Empuje y gire una perilla del quemador superior

hasta la posici6n LITE (encender). Se podrfa oir

el encendedor haciendo chispas.

b. El quemador se deber_ encender en cuatro (4)

segundos para un funcionamiento normal, luego

de que el aire haya sido purgado de la tuberia

de suministro de gas. Controlevisualmenteque

el quemador se hay encendido.

c. Luego que el quemador se haya encendido, la

perilla debe ser girada fuera de la posici6n LITE.

Cada quemador tiene su encendedor individual.

Controle las perillas separadamente hasta que todas

las voilvulas hayan sido controladas.

4. Ajuste de la Posici6n LOW (BAJA) Para la

V_lvula del Quemador Superior (Figura 12)

a. Gire la perilla a la posici6n LITE (encender) hasta

que el quemador encienda.

b. R,_pidamente gire la perilla a la POSICION MAS

BAJA.

c. Si el quemador se apaga, reajuste la wilvula de

lasiguienteforma: Muevaelcontrolala

posici6n OFF (apagada). Saque la perill ade

control del quemador superior, inserte un

destornillador piano pequeho en el hueco del

wistago del a voilvula hsta enganchar el tornillo

interior. EItamahodela llama puedeser

aumentado o disminuido girando el tornillo.

Ajuste el tama_o de la llama hasta que pueda

pasar r_ipidamente de la posici6n LITE hasta la

posiciOn MAS BAJA sin que se apague la llama.

La llama debe ser Io m_is peque_a posible sin

que se apague.

Figura 12

S. Funcionamiento de los Elementos del Homo

El horno est_ equipado con un control electr6nico. Cada

funci6n ha sido probada en la f_ibrica antes del transporte.

Sin embargo, sugerimos que Ud. verifique el

funcionamiento de los controles del horno una vez m_is.

Vease el Manual del Usuario para la operaci6n. Siga las

instrucciones par el Reloj, Minutero, Cocer, Asar,

CovecciOn (algunos modelos) y las funciones de limpieza

(algunos modelos).

_l'l_-J;_:lu[_[.],,u AI verificar el funcionamiento de

elemento de homo, no toque los elementos. Ellos tendr_n

el calor bastante para causar las quemaduras serias.

Cocer/Bake-Despu_s de poner el homo a 350°F (177°C)

para cocer, el element inferior debe ponerse rojo

Asar/BroiI-Cuando est_ puesto para BROIL, el elemento

superior se debe poner rojo.

Limpieza/Clean (algunos modelos)-Cuando el horno

est,1 puesto para un ciclo de auto-limpieza, el element

superior se pondr_i rojo durante el periodo de

precalentamientodelciclo. Despu_sdealcanzarla

temperatura de auto-limpieza , el elemento inferior se

pondr_ rojo.

Convecci6nlConvection (algunos modelos)-Cuando

el homo se pone a CONV. BAKE/ROAST a 350°F

(177°C), los dos elementos se enciendan y se apagan

alternando en un ciclo y el ventilador se pone en

marcha. El ventilador de convecci6n se parar_i cuando

se abre la puerta del horno durante el cocido o el asado

por convecci6n.

Despu_s de Terminar la Instalacibn

Aseg0rese de que todos los controles est_n en la posici6n

OFF (apagada).

Ubicaci6n del N_mero de Modelo y de Serie

La placa con el n0mero de serie est_ ubicada en el

marco delantero del horno detr_s de la puerta del horno

grande.

Cuando haga pedidos de repuestos o solicite informaci6n

con respecto a su estufa, este siempre seguro de incluir

el n0mero de modelo y de serie y el n0mero o letra del

Iote de la placa de serie de su estufa.

Antes de Llamar al Servicio

Lea la secci6n Lista de control de averias en su Manual

del Usuario. Esto le podroi ahorrar tiempo y gastos. Esta

lista incluye ocurrencias comunes que no son el

resultado de defectos de materiales o fabricaci6n de

este artefacto.

Lea la garantia y la informaciOn sobre el servicio en su

Manual del Usuario para obtener el n0mero de telefono

gratuito y la direcciOn del servicio. Por favor Ilame o

escriba si tiene preguntas acerca de su estufa o necesita

repuestos.

2O

Page 21

Importante Advertencia de Seguridad

Para reducir el riesgo de que la estufa se vuelque, es

necesario asegurarla al piso instalando los soportes

antivuelco y los tornillos suministrados con la estufa. Las

piezas se encuentran en un saco de plastic6 en el horno.

Si no se instalan los soportes antivuelco, la estufa se

puede volcar si se coloca exceso de peso en una puerta

abiertaosiun nihosesubeaella. Sepuedenocasionar

lesiones graves causadas por los Ifquidos calientes

derramados o por la estufa misma.

Siga las instrucciones que mas abajo se indican para

instalar los soportes antivuelco.

Si la estufa es movida a otro lugar, los soportes

antivuelco deben tambien set movidos e instalados en la

estufa. Para controlar la instalaci6n apropiada, vea el

paso nOmero 5.

Herramientas Necesarias:

Llave de tuerca de 5/16" (8 mm) o destornillador para

tornillos de cabeza plana

Llave inglesa

Taladro electrico

Broca de 3/16" (4.8 mm) de di_imetro

Broca para taladro de mamposteria de 3/16" (4.8 mm)

de diam. (si se est_ instalando en concreto).

Instrucciones de Instalacibn del Soporte

Antivuelco

Los soportes se fijan al suelo en la _artetrasera de la

estufa para sujetar ambos niveladores de las patas

traseras. Cuando los este instalando al piso, aseg0rese de

que los tornillos no penetren el alambrado electrico o

plomerfa. Los tornillos provistos pueden utilizarse en

madera o concreto.

1. Desdoble la plantilla de papel y colOquela plana en

el piso con los bordes laterales y el trasero colocados

exactamente donde la parte trasera y los lados de la

estufa ser_n colocados cuando sea instalada. (Use el

diagrama figura 13 para ubicar los soportes si no se

dispone de la plantilla).

2. Marque en el piso la ubicaci6n de los 4 agujeros de

montaje como se muestra en la plantilla. Para

facilitar la instalaci6n, se pueden taladrar agujeros

piloto de 3/16" (4.8 mm) de di_im, y 1/2" (1.3

cm)de profundidad en el piso.

3. Saque la plantilla y coloque los soportes en el piso

con la brida hacia arriba dirigida hacia el frente.

Alinee los agujeros en los soportes con las marcas en

el piso y sujete con los 4 tornillos provistos. Los

soportes deben estar asegurados al piso firme. Si se

va a instalar en piso de concreto, primero debe

taladrar agujeros gufa de 3/16" (4.8 mm) de

di_metro usando una broca para taladro de

mamposteria.

4. Nivele la estufa si es necesario ajustando las cuatro

patas niveladoras con una llave (Ver la Figura 14

abajo). Se requiere un espacio libre minimo de 1/8"

(3.2 mm) entre la parte inferior de la estufa y los

niveladores de las patas traseras para dejar espacio

para los soportes antivuelco.

5. Deslice la estufa a su lugar asegur_ndose de que las

patas traseras esten sujetas pot los extremos de los

soportes. La estufa puede necesitar set movida

ligeramente a un lado cuando est_ siendo empujada

hacia atr_is para permitir que las patas se alineen con

los soportes.

6. Despues de haber realizado la instalacibn verifique

que la fijaciOn anti-inclinacibn est<iempotrada. Abra

la gaveta, retire la gaveta y verifique para

asegurarse que est,1empotrada.

Soporte antivuelco

Figura 13 Figura 14

Deslice hacia

atras

3A*'(1.9 cm) Typ.

21

Page 22

NOTAS:

22

Page 23

TOP BURNER [ON]TEA _ COOKTOP CIRCUIT

ION S_

@__ RIGHT REAR

IUEMABOR BE ENCENDIO0 £UPER]OR _RLANCHA DE COC I NAR

TOP BURNER ]GN]TER

OUEMROOR OE ENCENO[IO SUPER]OR

__LEFT REAR

_ TR_SERO

TOP BURNER [GN]TER

_ aUEMAOOR BE ENCENOIBO___SUPER]OR

TOP BURNER [GN[TER

___IQUEMAOOR OE ENCENDIO0 SUPER[OR

TOP BURNER [GN]TER _g-_

OUEMABOR BE ENCENB[DO SUPERIOR _CENTRE REAR

INT. ENC

TRASERO

,ON

; RBFB LF FENCE,B,OO

NOTE

SERV]CE:]F REPLACEMENT OF TERM]NALS BECOMES NECESSARYCOHPARABLE WIRE TYPE AND

GAGE AND COMPARABLE TERHINALS MUST BE USED.

NOTA:

EN CASO QUE SEA NECESARIO DE REEMPLAZAR LOS BORNESES NECESARIO DE UT]L]ZAR

EL N]SMO T[PO DE ALAHBRE Y BE MEDIDOR Y EL N[SNO T]PO DE BORNES

CAUT[ON

LABEL ALL WIRES PR]OR TO D]SCONNECT[ON XHEN SERVIC]NG CONTROLS.W[R[NG ERROR CAN ERROR

AN CAUSE [MPROPER AND DANGEROUS OPERAT[ON VERIFY PROPER OPERAT]ON AFTER SERV[CI

RV]_O:

ET[QUETE TO°O$ LOS ALANBRES ANTES DE °ESCONECTAR PAR REAL]ZAR EL NANTEN[H[ENTO BE LOS

CONTROLESERROR DE ALANBRAJE PUEDE CAUSAR UN FUNCIONAM]ENTO [NCORRECTO Y PEL[GROSO.

VER]F]QUE S] ELFUNC[ONAH[ENTO ESTA CORRECTO DESPUES DEL HANTENIN]ENTO.

WARN]NO:

D]SCONNECT PO#ER BEFORE SERVICING UNIT.

AVISO:

DESCONECTE LA ENERG[A MRNTENIM]ENTO °EL ELECTRODOMESTOCO.

I BK BLACK/NEGRO I G GREEN/VERDE ICODE

0 2

V 5

B/W BLACK/_HITE /

OR/BL ORANGE/BLUE / NARANJA/AZUL 7

COLOR CODE / CODIGOS DE COLOR 9

3AUGE TEMP."C STYLE UL

F[L

4EDIDA qOOO UL

?

10 150 3321

12 150 3321

3

14 150 3321

4

16 150 3321

18 150 3321

I_ IP_ 3173

18 200 3122

8

ig 105 1015

ig 200 3304

LI

O00H LATCH SWITCH

]NT OE CERROJO OE PUERTA

SW._

tK 3 I

.4l

]NTERRUPTOR BE PUERTA BE HORNO [Z_U[ER°O (f_h_

EFT OVEN THERMOSTAT S_ LEFT OVEN BROIL ELEMENT

[NTERRUPTOR BE TERMOSTATO ELEMENTO DE ASA°O BE HORNO [ZOUIERDD

HORNO ]ZDU]ERBO

o 5 THERMAL C]RCU[T BREAKER

RELAY

RELE

240 V

AUTO BOOR S_[TCH LOCK MOTOR/MOTDR OE CERROJO

]NT DE PUERTA AUTO I BK 5 BK 6

BK • _NO

BK 5

FAN S_./INTI BE VENT]LADOR

B/# 5 B/# B

BK S _o BR 5

BK 5 o BK 5 W 5

OVEN LIGHT SWITCH ONE SHO_N,T_O REOU]RED

]NTERRUPTOR OE LUZ UNO MOSTRAOO OOS REOU]R]O0

LEFT OVEN O00R S_]TCH LEFT OVEN LAMP

BL 4 BL 4 u uu_ BL 4

EFT OVEN ]ND LEFT OVEN B_KE ELEMENT

OVEN CIRCUIT

C]RCUITO DE HORNO