Page 1

installation

instructions

Ful! Size Tumble Action Washers

Before beginning installation, carefully read these instructions. This will simpfify the

installation and ensure the washer is installed correctly and safely. Leave these instructions

near the washer after installation for future reference.

NOTE: The electrical service to the washer must conform with local codes and ordinances

and the latest edition of the National Electrical Code, ANS!/NFPA 70.

Contents

For your safety the information in

this manual must be followed to minimize the risk

of fire or explosion or to prevent property damage,

personal injury or loss of life.

- Do not store or use gasoline or other flammable

vapors and liquid in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Clear the room, building or area of all

occupants.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas suppliers

instructions.

• If you cannot reach your gas supplier, call

the fire department.

SUBJECT PAGE

Pre-lnstallation Requirements 2

Electrical Requirements 2

Grounding Requirements 2

Water Supply Requirements 2

Drain Requirements 2

Rough-In Dimensions 3

Location Of Your Washer 4

Unpacking 4

Installation 5-6

Replacement Parts 6

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Printed in U.S.A.

P/N 134850100 (0701)

Page 2

PRE-INSTALLAT!ON REQUIREMENTS

Tools Required for Installation:

I. Phillips screwdriver

2. 10 mm socketwith ratchet.

3. Channel-lock adjustable pliers.

4. Carpenter's level.

absence of local codes, with the National Electrical

Codes, ANSI/NFPA 70 (latest edition). If in doubt,

call a licensed electrician. DO NOTcut off or alter

the grounding prong on the power supply cord. In

situations where a two-slot receptacle is present,

it is the owner's responsibility to have a licensed

electrician replace it with a properly grounded

three prong grounding type receptacle.

ELECTRICAL REQUIREMENTS

CIRCUIT- Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY- 2 wire, with ground, 120 volt, single

phase, 60 Hz, Alternating Current. NOTE: Becauseof

potential inconsistent voltage capabilities, the useof this

washer with power created by gas powered generators,

solar powered generators, wind powered generators or

any other generator other than the local utility company

isnot recommended.

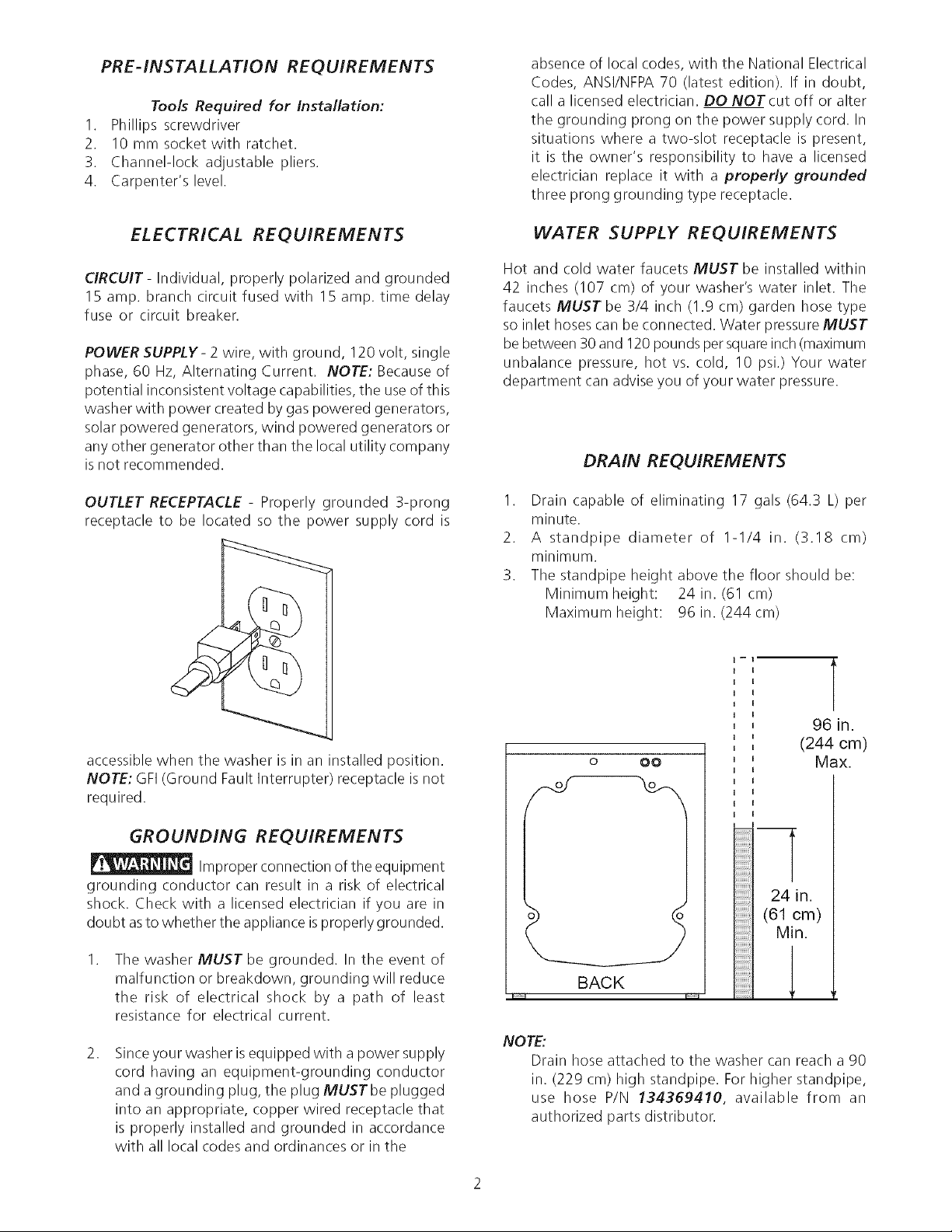

OUTLET RECEPTACLE - Properly grounded 3-prong

receptacle to be located so the power supply cord is

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within

42 inches (107 cm) of your washer's water inlet. The

faucets MUST be 3/4 inch (1.9 cm) garden hose type

so inlet hoses can be connected. Water pressure MUST

be between 30 and 120pounds per squareinch (maximum

unbalance pressure, hot vs. cold, 10 psi.) Your water

department can advise you of your water pressure.

DRAIN REQUIREMENTS

I. Drain capable of eliminating 17 gals (64.3 L) per

minute.

2. A standpipe diameter of I-I/4 in. (3.18 cm)

minimum.

3. The standpipe height above the floor should be:

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244cm)

accessible when the washer is in an installed position.

NOTE: GFI (Ground Fault Interrupter) receptacle is not

required.

GROUNDING REQUIREMENTS

Improper connection of the equipment

grounding conductor can result in a risk of electrical

shock. Check with a licensed electrician if you are in

doubt asto whether the appliance isproperly grounded.

.

The washer MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce

the risk of electrical shock by a path of least

resistance for electrical current.

.

Sinceyour washer isequipped with a power supply

cord having an equipment-grounding conductor

and a grounding plug, the plug MUSTbe plugged

into an appropriate, copper wired receptacle that

is properly installed and grounded in accordance

with all local codes and ordinances or in the

o OO

T

24 in.

(61 cm)

Min.

BACK

I I

NOTE:

Drain hose attached to the washer can reach a 90

in. (229 cm) high standpipe. For higher standpipe,

use hose P/N 134359410, available from an

authorized parts distributor.

l

r

96 in.

(244 cm)

Max.

Page 3

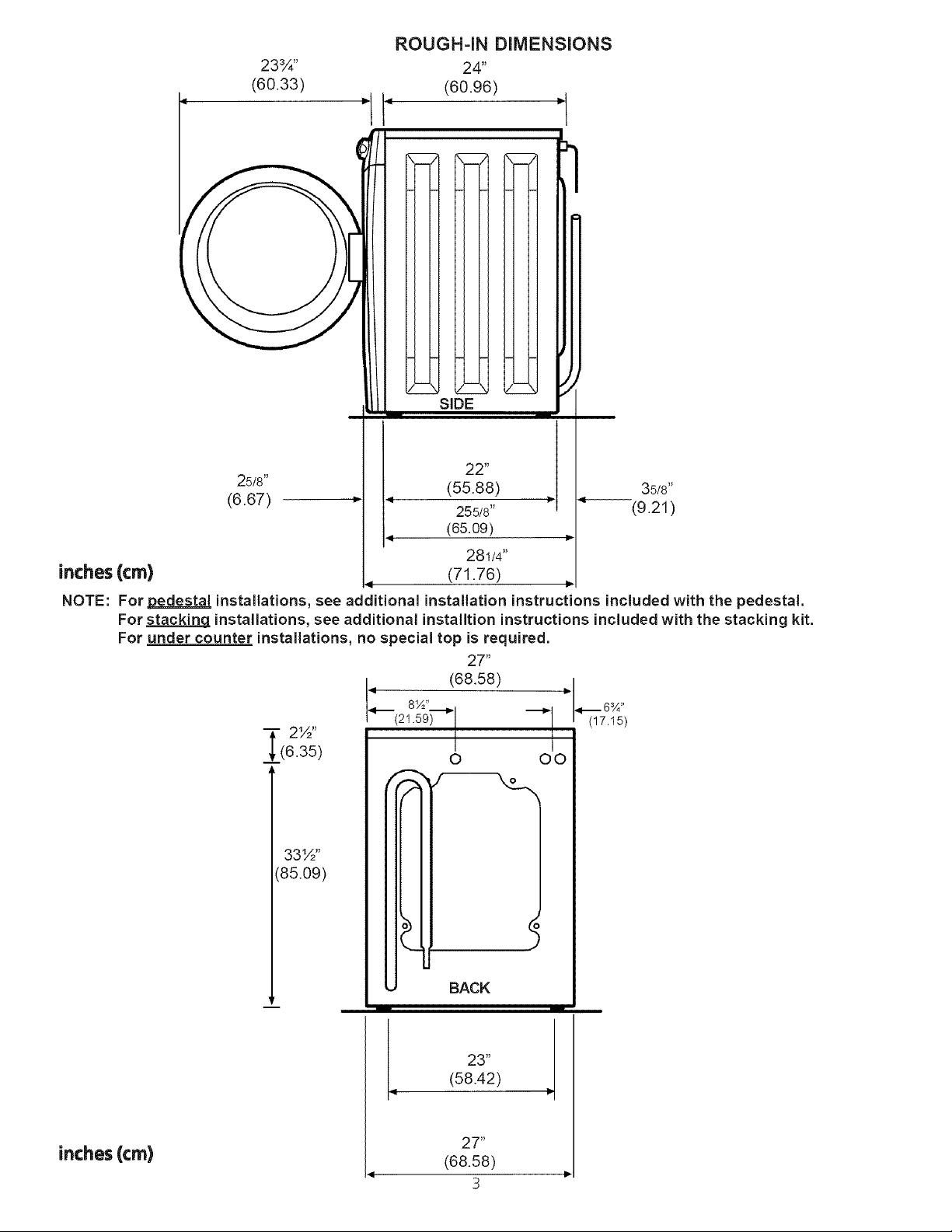

23¾"

(60.33)

ROUGH-iN DiMENSiONS

24"

(60.96)

ID 4 ID

m m m

i i i

i i i

- SLOE- -

25/8"

(6.67)

Ii, _9

22"

(55.88)

255/8"

35/8"

(9.21)

(65.09)

281/4"

inches(cm)

q (71.76)

NOTE: For pedestal installations, see additional installation instructions included with the pedestal.

For stacking installations, see additional installtion instructions included with the stacking kit.

For under counter installations, no special top is required.

27"

4

___ (68.58)

-- 2½"

(6.35)

8½"

I(21.59)

0 O0

--6¾"

(17.15)

33½"

(85.09)

inches(cm)

BACK

23"

(58.42)

27"

(68.58)

3

Page 4

LOCATION OF YOUR WASHER

DO NOTINSTALL YOUR WASHER:

1. In an area exposed to dripping water or outside weather 4.

conditions. The ambient temperature should never be below

60 ° F(15.6 ° C) for proper washer (detergent breakdown) 5.

operation.

2. In an area where it will come in contact with curtains or

drapes. 6.

3. Inan area (garage or garage-type building) where gasoline

of other flammables are kept or stored (including

automobiles).

4. On carpet. Floor MUST be solid with a maximum slope of

1/2 in. per foot (I .27 cm per 30.5 cm). Toensure vibration 7.

or movement does not occur, reinforcement of the floor

may be necessary.

IMPORTANT

MINIMUM INSTALLATION CLEARANCES

When installed in alcove or closet:

Sides, Rear = 0 in. (0 cm)

Top = 0 in. (0 cm)

When installed in closet: Front = I in. (2.54 cm)

Closet door ventilation required: 2 Iouvered openings each 60

in2(387 cm2), 3 in. (7.6 cm) from top and bottom of door.

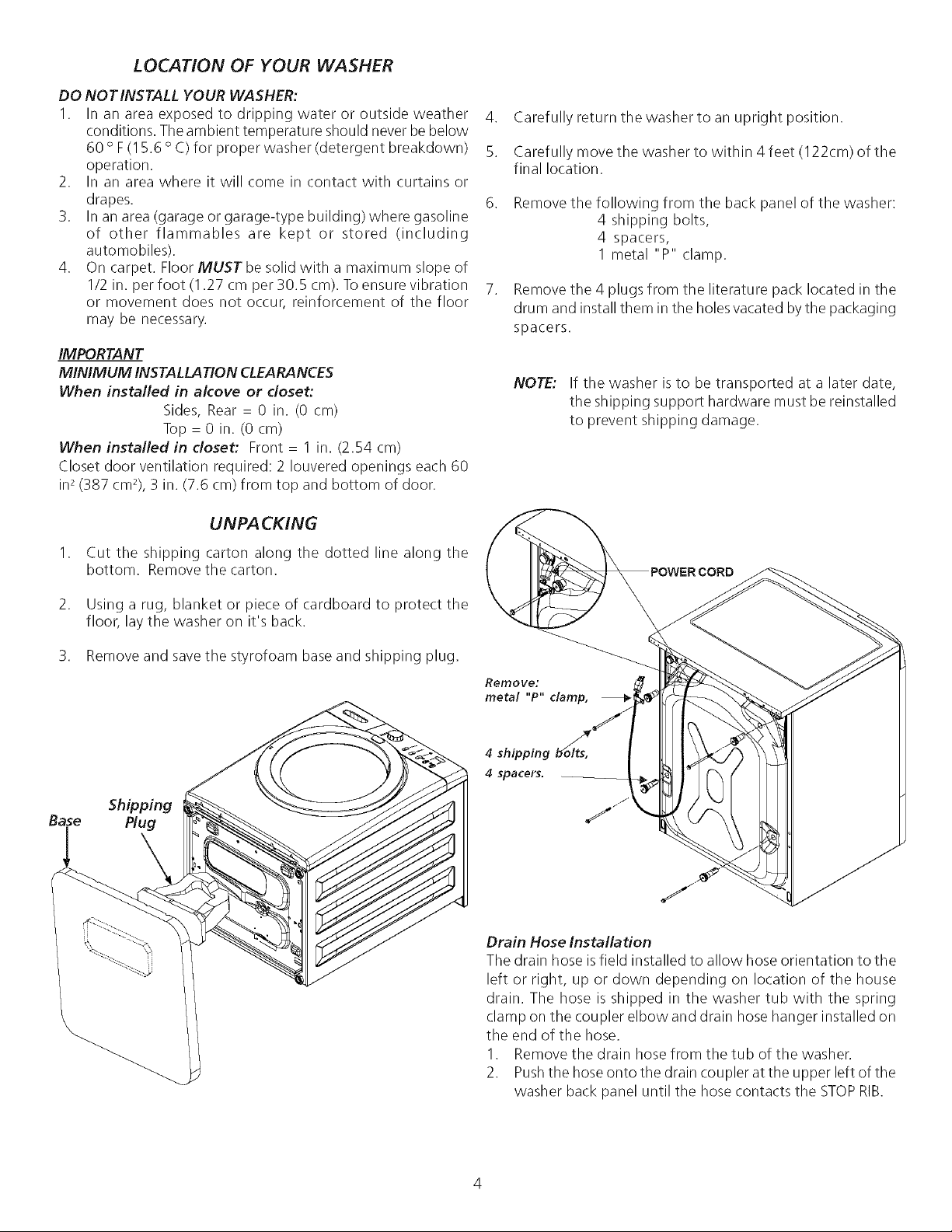

Carefully return the washer to an upright position.

Carefully move the washer to within 4 feet (122cm) of the

final location.

Remove the following from the back panel of the washer:

4 shipping bolts,

4 spacers,

1 metal "P" clamp.

Remove the 4 plugs from the literature pack located in the

drum and installthem in the holesvacated bythe packaging

spacers.

NOTE: If the washer is to be transported at a later date,

the shipping support hardware must be reinstalled

to prevent shipping damage.

UNPACKING

1. Cut the shipping carton along the dotted line along the

bottom. Remove the carton.

2. Using a rug, blanket or piece of cardboard to protect the

floor, lay the washer on it's back.

3. Remove and savethe styrofoam base and shipping plug.

Shoping

Base Plug

Remove:

metal "P" clamp,

4 shipping bolts,

4 spacers.

Drain Hose Installation

The drain hose isfield installed to allow hose orientation to the

left or right, up or down depending on location of the house

drain. The hose is shipped in the washer tub with the spring

clamp on the coupler elbow and drain hose hanger installed on

the end of the hose.

1. Remove the drain hose from the tub of the washer.

2. Pushthe hose onto the drain coupler at the upper left of the

washer back panel until the hose contacts the STOPRIB.

Page 5

STOP RIB-

PUSH HOSE ONTO

COUPLER TO STOP RIB

HOSE TABS

SPRING

CLAMP

PROVIDED

ON HOSE

INSTALLATION

Leve/ing the !_/asher

Excessive noise and vibration can be prevented by properly

leveling the washer.

For free standing installation and with the washer in it's

final position, place a level on top of the washer. Adjust

the leveling legs so the washer is level front-to-rear and

side-to-side, and stable corner-to-corner.

Press down on alternate corners and sides and feel for

the slightest movement. Adjust the appropriate leg sothe

washer is SOLID on the floor on ALL four legs. Keep the

leveling legextension at a minimum for best performance

of the washer.

.

Using pliers, squeeze the ears of the spring clamp

and position the clamp so the clamp ears @ with

and contact the tabs on the drain hose. This assures

proper location of the clamp to prevent leaks.

ALIGN SPRING

CLAMP EARS WITH

TABS ON HOSE

\

i

!

J

/

\

/

/

/

/

2. For pedestal installations Seeadditional installation

instructions included with the pedestal.

Washer Connections

I. Run sornewater from tile hot and cold

faucets to flush the water lines and

remove particles that might clog up the

water valve screens.

. Remove the inlet hoses and rubber

washers from the plastic bag located in

the drum of the washer and install the

rubber washers in each end of the inlet

hoses.

.

Carefully connect the inlet hose marked "HOT" to the

outside "H" outlet of the water valve. Tighten by hand, then

tighten another 2/3 turn with pliers. Carefully connect the

other inlet hose to the inside "C" outlet of the water valve.

Tighten by hand, then tighten another 2/3 turn with pliers.

Do not crossthread or over-tighten these connections.

. Connect the inlet hose ends to the HOT and COLD water

faucets tightly by hand, then tighten another 2/3 turn with

pliers. Turn the water on and check for leaks.

NOTE: Use only new hoses.

Page 6

INSTALLATION (CON'T)

Placethe hook end of the drain hose in the drain opening.

Secure the drain hose with the cable tie (provided in the

enclosure package) to the standpipe, inlet hose, laundry

tub, etc. so the hose does not pull out from the force of

the water.

.

Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at a circuit

breakedfuse box before plugging the power cord

into an outlet.

7. Turn on the power at a circuit breaker/fuse box.

8. Read the Operating Instructions and Owner's Guide

provided with the washer. They contain valuable and helpful

information that will save you time and money.

l

Cable Tie

Cable Tie

Cable Tie

9. Runthewasherthrough a complete cycle. Checkforwater

leaks and proper operation.

I 0. If you r washer does not operate, please review the "Avoid

Service Checklist" in your Owner's Guide before calling

for service.

11. Placethese instructions in a location near the washer for

future reference.

NOTE: Awiring diagram and technical data sheet are located

in an envelope attached to the left hand side panel on

the inside of the washer.

Pedestal

A pedestal accessory, Model No. APWD15W (White),

APWD15GB (Glacier Blue), APWD15P (Platinum) and

APWD15E (Black), specifically designed for this washer may

be used when elevating the washer for ease of use. Failure to

use accessories certified by the manufacturer could result in

personal injury, property damage or damage to the washer.

REPLACEMENTPARTS

If replacements parts are needed for your washer, contact the

sourcewhere you purchased your washer, call 1-800-944-9044,

or visit our website, www.frigidaire.com, for the Frigidaire

Company Authorized Parts Distributor nearest you.

Destroy the carton and plastic bags after the

washer isunpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plastic sheets can become

airtight chambers causing suffocation. Place all materials in

a garbage container or make materials inaccessible to

children.

The instructions in this manual and all other

literature included with this washer are not meant to cover

every possible condition and situation that may occur. Good

safe practice and caution MUST be applied when installing,

operating and maintaining any appliance.

Maximum benefits and enjoyment are achieved when all

the Safety and Operating instructions are understood and

practiced asa routine with your laundering tasks.

Page 7

_ Sujetacables

InstaladOn (Con't)

5. Ponga el extremo del gancho de la tubo de drenaje en la

abertura del dren. Asegure la tubo de drenaje con laatadura

de cables (proporcionada en el paquete del recinto) a la

columna de alimentaciOn, la tuberia de la entrada, la tina

del lavadero, el etc. asique la tubo no se saca de lafuerza

del agua.

6. Enchufe el cable en un tomacorrientes con toma de tierra.

NOTA: Aseg0rese de que la corriente est_ cortada en el

disyuntor/caja de fusibles antes de enchufar elcable

en el tomacorrientes.

7. Encienda la corriente en eldisyuntor/caja defusibles.

8. Lea las Instrucciones para el funcionamiento y la Guia del

propietario incluidas con la lavadora. Contienen informaciOn

valiosa y 0til que leahorrara tiempo y dinero.

9. Haga funcionar la lavadora durante un ciclo completo.

Compruebe que no haya fugas de agua y que funcione

correctamente.

10.

Sisulavadora no funciona, leala "Lista de comprobaci6n para

evitar el servicio" que seencuentra en laGuia del propietario,

antes de Ilamar al servicio t_cnico.

11.

Guarde estas instrucciones en un lugar cercano a la lavadora

para poder referirse a eliasen elfuturo.

j!

Sujetacables

NOTA: Dentro de la lavadora, en el panel de servicio, se

encuentra un diagrama de cableado.

Pedestal

Un accesorio del pedestal diseh6, N{Jmero de Modelo

APWD 15W (Blanco), APWD 15P(Platino), APWD 15GB

(Azul Glaciar) o APWD 15E(Negro), especificamente para

esta lavadora puede ser utilizado al elevar la lavadora para

lafacilidaddeempleo. Lafaltadeutilizarlosaccesorios

certificados por elfabricante podia dar lugar a dahos corpo-

rales, a dahos materiales, o a daho a lalavadora.

PIEZAS DE REPUESTO

Si necesita piezas de repuesto para su lavadora, acuda al

establecimiento dondelacompr6 Ilameal1-800-944-9044,ovisite

nuestroweb sitio,www.frigidaire.

com,para ladigan Distribuidor autorizada de laspiezasdeFrigidaire

Iomas cerca posible usted.

IF.__ Deseche la caja de carton y las bolsas de

plastico una vez que haya desembalado la lavadora. Los niflos

podrian usarlas para jugan Las cajas de carton tapadas con

alfombras, colchas u hojas de plastico pueden convertirse en

camaras herm_ticas, causando asfixia. Coloque todos los

materiales en el basurero o evite que los nihos tengan acceso a

ellos.

Lasinstrucciones que aparecenen estemanual

y lasdemas guiasincluidas con esta lavadora no pretenden cubrir

todas las condiciones y situaciones posibles que pueden ocurrir.

DEBE tenerse sentido com0n y cuidado al instalar, operar y

mantener cualquier electrodom_stico.

Se obtiene el maximo de beneficios y resultados cuando

todas las instrucciones de seguridad y de funcionamiento

son comprendidas y puestas en practica de forma rutinaria

cada vez que se lava la ropa.

Page 8

COSTILLA DE LA PARADA.

/

/

EMPUJE LA TUBO SOBRE EL

ACOPLADOR PARA

PARARLACOSTILLA.

.

Quite la tubo de

OREJAS DE TUBO DE DRENAJE.

LA ABRAZADERA DEL

" RESORTE PROPORCION6

_\_,\ E _, TUBO.

drenaje de la tina

de la lavadora.

.

Empuje la tubo sobre el

acoplador del dren en el

alto a la izquierda del

panel de la lavadora

\

detras hasta que la tubo

entra en contacto

con la COSTILLA de la

PARADA.

.

Con los alicates, exprima los oidos de la abrazadera del

resorte y coloque la abrazadera asi que los oidos de

abrazadera alinean con y entran en contacto con las orejas

en la de tubo de drenaje. Esto asegura la Iocalizaci6n

apropiada de la abrazadera para prevenir los escapes.

ALINEE LOS OIDOS DE ABRAZADERA DEL RESORTE

CON LAS OREJAS EN LA TUBO.

\

'\,

L

J

i

/

,/

/'

/

ORIENTE LA TUBO A

DERECHO, A

OREJA$

LA IZQUIERDA, ENCIMA

DE O.ABAJO

SEGUN LO NECESITADO

ANTES

DE COLOCAR LA

ABRAZADE ,RAEN

LA POSICION.

INSTALAION

La nivelaci0n del ruido y de la vibraci6n excesivos de la

lavadora puede ser prevenida correctamente nivelando la

lavadora.

I. Para la instalaci6n derecha libre y con la lavadora en ella

esta la posici6n final, pone un nivel encima de la lavadora.

Ajuste las piernas de nivelaci6n asi que la lavadora es, y

esquina-a-esquina estable de adelante hacia atras y de lado

aladollana. Presioneabajoenesquinasyladosalternosy

si_ntase para el movimiento mas leve. Ajuste la pierna

apropiada asi que la arandela es SOLIDA en el piso en las

cuatro piernas. Guarde la extensi6n de nivelaci6n de la pierna

en un minimo para el mejor funcionamiento de la lavadora.

2. Para las instalaciones del pedestal, vea las instrucciones de

instalaci6n adicionales incluidas con el pedestal.

\\

\

\

CONEX!ONES DE LA LAVADORA

1. Deje correr un poco agua de lasIlavesde agua

caliente y fria para vaciar las lineas y eliminar las

particulas que pueden obstruir las rejillas de las

valvulas de agua.

2. Examine los tubos de entrada de agua para

asegurarse de que lasarandelas de caucho est_n

instaladas en cada extremo.

3. Conecte con cuidado lostubos de entrada a lavalvula

de agua (en la lavadora)CALIENTEcon de salida "H ",

apriete a mano y luego apriete 2/3 de vuelta con unosalicates.

Conecte con cuidado lostubos de entrada a lavalvula de agua

(en la lavadora)FRIAcon de salida "C ", apriete a mano y luego

apriete 2/3 devuelta con unos alicates.

4. Conecte los extremos del tubo de entrada a las Ilaves de

agua CALIENTE y FRIA apretando bien a mano, y apriete

otros 2/3 devuelta con los alicates. Abra el agua y compruebe

que no haya fugas.

NOTA: Utilice solamente las nuevas mangueras provistas con

_ste dectrodomestico.

ALINEE SIEMPRE LOS OIDOS DE ABRAZADERA

DEL RESORTE

CON LAS OREJAS EN LA TUBO,

Page 9

UBICA OON DE SU LAVADORA

NO INSTALE SU LAVADORA:

I. En un area expuesta a goteos de qgua o a la

intemperie. Latemperature ambiente nunca debera

estar por debajo de los 60 grados F (15,6 C) para

que su lavadora funcione correctamente.

2. En un area donde estara en contacto con persianas

o cortinas.

3. En un area (garaje o construcciOn similar) donde

haya o se almacene gasolina u otros productos

inflamables (inclusive automOviles).

4. Sobre una alfombra. Elpiso DEBE ser duro con una

inclinaciOn maxima de I/2 pulgaga por pie (1,27 cm

por cada 30,5 cm). Paraasegurarse de que no existan

vibraciones ni ruidos, puede ser necesario reforzar

el piso.

IMPORTANTE

DESPEJES MINIMOS DE INSTALACION

InstalaciOn en una alcoba: Lados, Parte Trasera, Parte

Superior = 0 cm (0 pulg.)

InstalaciOn en un armario: Lados, Parte Trasera, Parte

Superior = 0 cm (0 pulg.), Parte Delantera = 2.54 corn

(1 pulg.)

Aberturas de ventilaciOn requeridas en la puerta del

armario: Dos rejillas de ventilaciOn cada 387 cm2 (60

pulg/) - 7.6 cm (3 pulg.) desde la parte inferior ysuperior

de la puerta.

DESEMPAQUE

4. Con cuidado, vuelva a colocar la lavadora en posiciOn

vertical y saque la caja.

5. Con cuidado, mueva la lavadora a unos4 pies (122cm)

de su ubicaciOn definitiva.

.

Saque Io siguiente de laparte posterior de lalavadora:

• 4 pernos

4 separadores

I abrazaderas de presiOna liberar cordon del

servicio

.

Quite los 4 tapOns pequehos del agujero del

paquete de la literatura e instalelos en los agujeros

del panel lateral desocupados por el fijacione de

empaquetado.

NOTA: En caso de que la lavadora tiene que estar

transportada en elfuturo, es necesario que vuelva a instalar

la quincalla de lafijaciOn de expediciOn paraempedir dahos

a la lavadora durante la expediciOn.

CabJe

EJ_ctrico

1. Corte la caja de carton a Io largo de la linea

punteada al fondo de la caja. Retire la caja de

carton.

2. Usando una manta, cobija o cubierta de cart6n

para proteger el piso, recueste la lavadora sobre

su parte trasera.

3. Retire y conserve la base de plastico del empaque

de envio y su extensi6n que sujeta y va hasta el

tambor de la lavadora.

Empaque

Base de Envio

,1 \

Quite:

abrazaderas

de "P'.

4 pernos,

4 separadores,

Instalacion el Tubo de Drenaje

La tubo de drenajees campo instalado para permitir la

orientaciOn de la tubo el al izquierdo o derecho, encima o

abajo dependiendo de la IocalizaciOn del dren de la casa.

La tubo se envia en la tina de la lavadora con la abrazadera

del resorte en lasuspension de latubo del codo y de drenaje

del acoplador instalada en el extremo de la tubo.

Page 10

DIMENS!ONES PARA LA INSTALACION

23%"

(60.33)

l I- 1

m m __

i i i

- LA50 -

25/8"

(6.67)

Po (cM)

22"

(55.88)

255/8"

(65.09)

281/4"

35/8"

(9.21)

q (71.76)

Nota: Para instalaciones de pedestal, yea las instrucciones adicionales de instalaci6n incluidas con el pedestal.

Para instalaciones apiladas, yea las instrucciones adicionales de instalaci6n incluidas en el paquete para apilar (stacking kit)

Para instalaciones debajo de una mesa o base, no se requiere ninguna tapa o cubierta especial.

27"

/ t-.. ¢,_ t-- ,,-3 \

__6¾"

-_- 2½"

,(6.35)

_'_(218. 5Y29"_ "_

O OO

(17.15)

33½"

:85.09)

PO(cM)

PARTE POSTERIOR

q 23"

(58.42)

27"

(68.58)

Page 11

REQUISITOS ANTES DE LA INSTALA aON

Herramientas necesarias para la instalad6n:

1. Destornillador Phillips

2. Casquillo con trinquete de 10ram

3. AlicatesajustablesChannel-lock

4. Niveldecarpintero

REQUISITOS ELECTRICOS

CIRCUITO - Circuito derivado individual, correctamente

polarizado ycon toma de tierra, de 15amperios con fusible

de 15 amperios con retardo o disyuntor.

ALIMENTACION ELECTRICA - Corriente alterna

monofasica, 60 Hz, 120 voltios, bifilar, con toma de tierra.

NOTA:Elusodel lavadora con energia de generador de gas,

generador de solar, generador de viento, o cualquier otros

generador con excepci6n de le central el_ctrica no es

recornendai_

hilos de cobre, que este instalado y conectado a tierra segOn

todos los c6digosy ordenanzas locales,o sino existenc6digos

locales, con losNational Electrical Codes (C6digos El6ctricos

Nacionales),ANSI/NFPA70(laedici6n masreciente). Sino esta

seguro, Ilameaun electricistalicenciado.NO torte nimodifique

laclavija detoma de tierra del cable el6ctrico. Encasosen que

s61ohaya un tomacorrientes de dos orificios, sera responsa-

bilidad del propietario hater que un electricista licenciado Io

cambie por un tomacorrientes de 3 orificios con la toma de

tierra adecuada.

REQUISITOS PARA EL

SUMINISTRO DE AGUA

LasIlaves de agua caliente y fria DEBEN estar instaladas a

menos de 42 pulgadas (107 cm) de la toma de agua de la

lavadora. LasIlavesDEBENserdel tipo manguera dejardin de

3/4 de pulgada (1,9 cm) para que se les puedan conectar los

tubos de entrada de aguaLa presi6ndelagua DEBEestar entre

10 y 120 libras por pulgada cuadrada (presi6n maxima de

desequilibrio, caliente contra fria, 10 libras por pulgada

cuadrada). Sucompahia de suministro de aguapuede decirle

cual esla presi6n del agua.

REQUISITOS PARA EL DRENAJE

TOMACORRIENTES - Eltomacorrientes con 3 orificios y

toma detierra correcta, debe estarubicado de manera que

el cable el_ctrico sea accesible cuando la lavadora este

instalada.NOTA:GFI(GroundFaultInterrupter) receptaculo

no esrequerido.

REQUISITOS PARA LA TOMA DE TIERRA

La conexi6n incorrecta del

conductor de toma de tierra deeste equipo puede causar

un riesgo de descargas el6ctricas. Consulte a un

electricista licenciado si no esta seguro si el

electrodom6stico esta bien conectado a tierra.

. La lavadora DEBE ser conectada a una toma de

tierra. Encasode un realfuncionamiento o una falla,

la toma de tierra reduce el riesgo de descargas

electricas proporcionando a la corriente el6ctrica

una via con menos resistencia.

.

Ya que su lavadora esta equipada con un cable

el6ctrico que Ilevaun conductor paratoma de tierra

y un enchufe para toma de tierra, el enchufeDEBE

ser insertado en un tomacorrientes adecuado, con

.

Drenajequepuedaeliminar 7galones(64,3 L)por

mlnuto.

2.

Diametro de la tu beria vertical de I-1/4 puIgadas (3,18

cm) como minimo.

3.

Laaltura de latuberia vertical porencima delpisodebeser:

Altura minima: 24 pulgadas (61 cm)

Altura maxima: 96 pulgadas (244 cm)

96pulg

(244 cm)

Max.

T

24pulg

PARTE ({

I 1 II 1

NOTA:

Eltubo de drenajeconectado alalavadorapuede Ilegar

a una tuberia vertical de 90 pulgadas (229 cm). Para

una tuberia vertical mas alta, use el tubo con N° de

pieza 134369410, disponible en

distribuidores autorizados de piezas.

(61 cm)

Min.

Page 12

m

Instrucc

e$

para la instalad6n

Lavadora de acci6n giratoria de tama o grande

Antes de comenzar la instalad6n, lea estas instrucdones con atenci6n. Le fadlitar2n la

instalaci6n y asegurar2n que la lavadora sea instalada correctamente y de manera segura.

Guarde estas instrucciones cerca de la lavadora una vez terminada la instalaci6n para

referirse a elias en el futuro.

NOTA: el suministro el_ctrico de su lavadora debe estar conforme con los c6digos y

ordenanzas locales y la edici6n m2s redente del National Electrical Code (C6digo Electrico

Nacional), ANS!/NFPA 70.

Indice

r_J__! Para su seguridad, siga la

informaci6n contenida en este manual para

minimizar el riesgo de incendio o explosi6n o

para evitar daNos materiales, lesiones

personales o la muerte.

- No guarde ni utilice gasolina u otros vapores y

liquidos inflamables en las cercanias de este

ni cualquier otto electrodom_stico.

- QUE HACER SI NOTA UN OLOR A GAS:

• No trate de encender ningOn

electrodom_stico.

. No toque ningOn interruptor el_ctrico; no

use ningOn tel_fono de su edificio.

• Haga que todo el mundo salga del cuarto,

edificio o _irea.

. Llame inmediatamente al proveedor del

gas desde el tel_fono de un vecino. Siga

las instrucciones del proveedor del gas.

. Si no puede ponerse en contacto con el

proveedor del gas, Ilame a los bomberos.

1"!TU L 0 PA GINA

Requisitos antes de la instalaci6n 2

Requisitos el_ctricos 2

Requisitos para la toma de tierra 2

Requisitos para el suministro de agua 2

Requisitos para el drenaje 2

Dimensiones para la instalaciOn 3

Ubicaci6n de su lavadora 4

Desempaque 4

Instalaci6n el Tubo de Drenaje 4-5

Instalaci6 5-6

Piezasde repuesto 6

La instalaci6n y el servicio deben set hechos pot

un instalador capacitado, una agencia de servi-

cios o el proveedor del gas.

Impreso en los EE.UU.

P/N 134850100 (0701)

Loading...

Loading...