Frigidaire GLTF2940ES0, GLTF2940FB - Front Load Washer Datasheet

Washer Tech Data Sheet

P/N 134408500

This information is intended for Qualified Technicians Only.

CAUTION: DISCONNECT ELECTRICAL CURRENT BEFORE SERVICING

Please Return This Sheet to its Envelope in the Product for Future Reference

Contents Page

Error code explanation........................................1-2

Diagnostics ....................................................... ....2

Error Code Chart.............................................. .....3

T est s................................................................ ...4-5

Françis.............................................................. 6-10

Wiring diagram......................................................1 1

The electronic controls of the 3.0 Cu. Ft. horizontal axis washers have self diagnostics codes built in that cover most products

failures.

Model differences:

• Better models have a digital readout display

• Good models do not have a digital readout display

In the Better Models line, the failure codes will appear in the display as an E followed by two numbers, a number and a letter

or two letters. The control will beep and the Door Lock, Wash, Rinse, Final Spin and Control indicator lights will flash.

Example: E14. To stop the flashing and beeping, the customer may touch the Pause Cancel button. The error code remains

stored in the control but once the problem is corrected, it does not effect the operation of the washer . If the failure is something

that the customer can correct (such as the water faucets being turned off), the washer will operate normally the next time it is

started.

In the Good Models line, the control signals the failure code by flashing the five indicator lights of Door Lock, Wash, Rinse,

Final Spin and Control for the first number or letter after the E and the Start indicator light for the second number or letter

after the E. When a failure occurs, the washer stops or pauses and the control beeps and flashes the five indicator light s to tell

the customer that a failure has occurred. T o stop the flashing and beeping, the customer may touch the Pause Cancel button.

The error code remains stored in the control but once the problem is corrected, it does not effect the operation of the washer .

If the failure is something that the customer can correct (such as the water faucets being turned off), the washer will operate

normally the next time it is started.

To recall an error code,

• Wake the machine by pressing any button

• Wait 5 seconds

• Press and hold the Start and Pause Cancel buttons simultaneously

• All LEDs will go blank and after a few seconds the control will signal the stored code using audible beeps and blinking

LEDs. The control will repeatedly signal the code, as long as the Start and Pause Cancel buttons are pressed.

A two-second p ause between repeat s af fords you the ability to make accurate counts to identify the correct error codes.

Please Note the following...... on a small number of washers with serial number prefix XC4,

if the previous procedure does not perform as specified, follow the option below:

• Follow all previous steps but instead of pressing Start and Pause Cancel buttons,

press and hold Options and Pause Cancel buttons.

If the washer is a Better Model, the error code will appear in the display. Troubleshoot problem by using charts on the

following pages.

If the washer is a Good Model, the five indicator lights of Door Lock, Wash, Rinse, Final Spin and Control will flash the

number of times for the first digit of the code and the Start indicator light will flash the number of times for the second digit.

Take separate count s of each indicator light, then repeat to confirm in order to be accurate in identifying the proper error code.

The code is obtained by counting the number of times the lights flash. Example E24: The five indicator lights would flash twice

indicating the 2 and the START indicator light will flash four times indicating the 4. The five indicator lights and the START

indicator light start flashing at the same time.

The control will pause for 2 seconds, then repeat the code as long as the two buttons are pressed and held.

Note: A letter appearing in the code stands for a number higher than nine:

A = 10 B = 11 C = 12 D = 13 E = 14 F = 15

Example Code F1: the first digit would be 15 and the second digit would be 1. If this code would appear on a washer in the

Good model line, the five indicator lights would blink fifteen times and the START indicator light would blink once. Troubleshoot

problem by using charts on the following pages.

Quick Check

If there is no error displayed and the washer momentarily starts then turns back of f:

1. Listen for a relay closure inside the motor control shortly after the START key is pressed. If this happens, the

motor control has power.

2. Check the 5 pin connector wiring between the console control and the motor control.

1

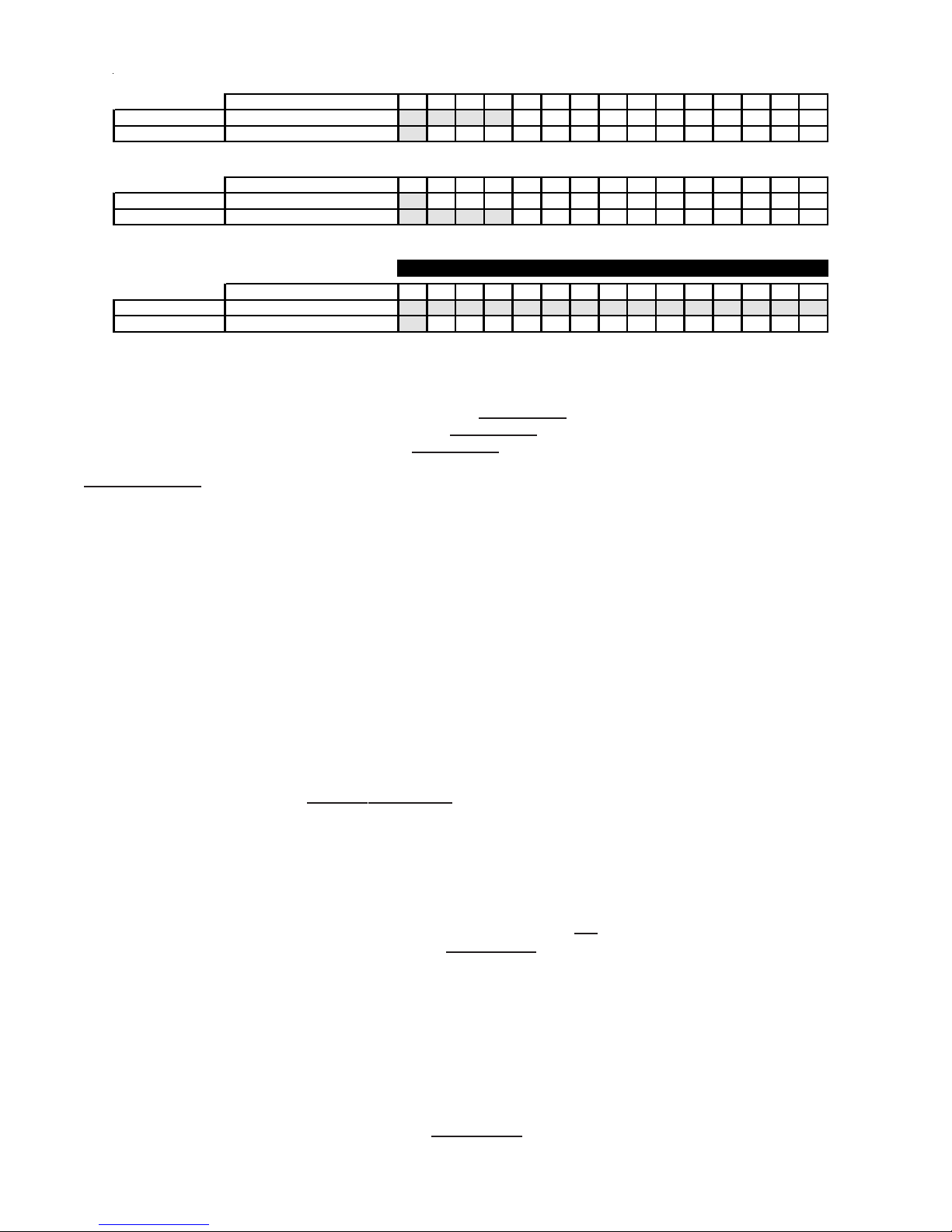

Examples: Identifying Error Codes on non-digital display models:

P/N 134408500

The follo wing LED F lashes and B eeps sign al E4 1 (E rror code

COUNT>>>>>> 123456789ABCDEF

1st C ode Digit 5 Vertical LED Flashes XXXX

2nd Cod e Digit Start LED Fla shes X

The follo wing LED F lashes and B eeps sign al E1 4 (E rror code 14) R e ed S w itc h

COUNT>>>>>> 123456789ABCDEF

1st C ode Digit 5 Vertical LED Flashes X

2nd Cod e Digit Start LED Fla shes XXXX

The follo wing LED F lashes and B eeps sign al EF 1 (E rror code F1) Clogged P um p

1 2 3 4 5 6 7 8 9 101112131415

COUNT>>>>>> 123456789ABCDEF

1st C ode Digit 5 Vertical LED Flashes XXXXXXXXXXXXXXX

2nd Cod e Digit Start LED Fla shes X

) D oor O pen

41

Diagnostic T est:

The diagnostic test is performed by using the Program Knob. To ST A R T THE TEST:

• On non-digital display models, turn the Program Knob to start position, Drain/Spin.

• On digital display models, turn the Program Knob to start position, T ouch Up. (NOTE: If the model has a timer dial that

can be rotated 360°, turn the Program Knob to

start position, Drain/Spin.

• Press Pause Cancel to turn off LEDs.

• Within 5 seconds, press and hold the Option and Pause Cancel buttons until LEDs start sequentially chasing, then

release buttons.

1. All the LEDs will sequentially light. Pressing a button below a light cluster will light all the LEDs in that cluster at one time

to confirm functionality.

2. Turn the program knob (1) click clockwise from the start position. The hot water solenoid will activate and hot water

should enter through the detergent compartment.

3. Turn the program knob (2) clicks from the start position. The bleach water solenoid will activate and cold water should

enter through the bleach compartment.

4. Turn the program knob (3) clicks from the start position. The bleach and the wash water solenoids will activate and cold

water should enter through the softener compartment.

5. Turn the program knob (4) clicks from the start position. The door lock solenoid will activate.

6. Turn the program knob (5) clicks from the start position. The door lock solenoid will deactivate and the loading door can

be opened.

7. Turn the program knob (6) clicks from the start position. The washer will fill and tumble.

8. Turn the program knob (7) clicks from the start position. The washer will fill and spin (leakage test).

9. Turn the program knob (8) clicks from the start position. The drain pump and door lock solenoid will activate and the

washer will operate in high spin.

SAFETY WARNING: If power is removed during this test, the door can be opened. To

prevent injury , DO NOT put your hands inside when the tub is rot ating.

10. T urn the program knob (9) clicks from the st art position. The control will signal the last error code.

Exiting Diagnostic Mode

There are two options for exiting the Diagnostic Test mode and returning the washer to normal operation:

a) Unplug the power cord, wait 5-8 seconds, then reconnect the power cord

OR

b) Turn the program knob clockwise 2 or 3 clicks af ter the Start Position. Press Options and Pause Cancel buttons together

for a few seconds until wash cycle LEDs appear.

If a situation arises where you cannot exit the Diagnostic mode as described above and the bank of 5 LED’s on the

right end remain ON regardless of Program Knob position, a combination of pushed buttons may have caused the

control to enter a special factory test mode. Disconnect power to reset the control to return washer to normal

operation is this occurs.

T o clear latest stored error code:

Place the control into Diagnostic test Mode.

• Turn the program knob clockwise 9 clicks from the Start Position. The control will signal the last error code.

• Press and hold the Options and Pause Cancel buttons for 3 seconds. The code will be cleared.

• Exit Diagnostic Mode to return the washer to normal operation.

2

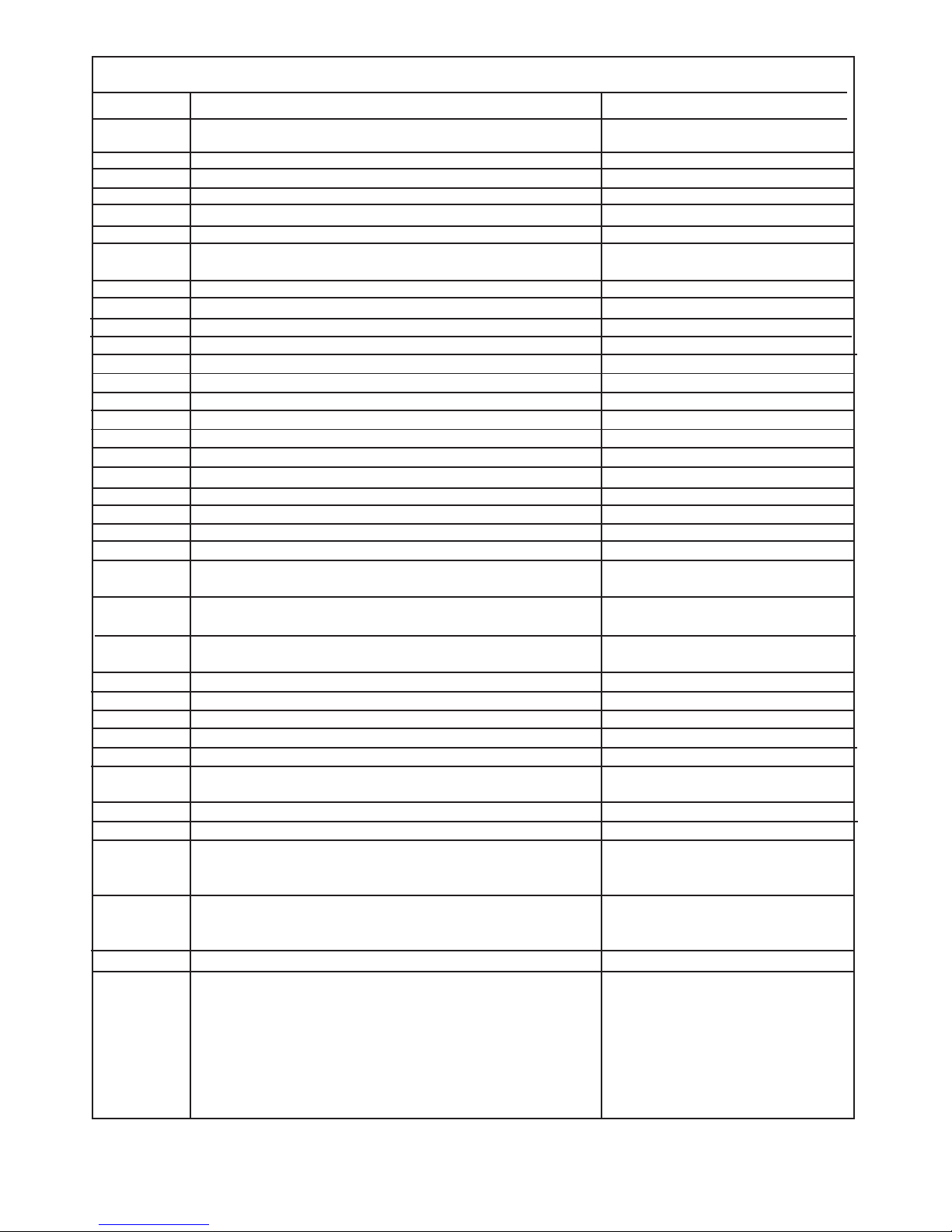

Error code chart

P/N 134408500

Error code Fault condition Check

E11 Fill time too long. Refer to test (1).

E13 Water leak in tub or air leak in air bell. Refer to test (2).

E14 Reed switch. Refer to test (3).

E21 Water not pumping out fast enough. Refer to test (4).

E23 Drain pump relay on control board failed. Replace control board.

E24 Drain pump relay on control board failed. Replace control board.

E31 Better models. Pressure sensor not communicating Refer to test (5).

with control board.

E35 Better models. Pressure sensor indicates water overfill. Refer to test (6).

E41 Control board thinks the door switch is open. Refer to test (7).

E42 Door remains locked after cycle is completed. Refer to test (8).

E43 Control board problem. Replace the control board.

E44 Control board problem. Replace the control board.

E45 Control board problem. Replace the control board.

E46 Control board problem. Replace the control board.

E47 Board thinks the door PTC circuit is open in spin. Refer to test (9)

E48 Board thinks the door PTC circuit is closed. Refer to test (9)

E52 Bad signal from tacho generator. Refer to test (10)

E55 Motor overheating. Refer to test (1 1)

E56 High motor current. Refer to test (1 1)

E57 High current on inverter. Refer to test (11)

E58 High current on motor phase. Refer to test (11)

E59 No tacho signal for 3 seconds. Refer to test (12)

E5A High temperature on heat sink. Replace the speed control

board.

E5B High temperature on heat sink. Replace the speed control

board.

E5C High temperature on heat sink. Replace the speed control

board.

E5D Communication problem. Refer to test (13)

E5E Communication problem. Refer to test (13)

E5F Communication problem. Refer to test (13)

E67 Input voltage on microprocessor incorrect. Replace the control board.

E75 Better models only. Water temperature sensor circuit. Refer to test (14)

E76 Better model only. NTC temperature for the cold water Hot and cold water hoses

valve over the limits. switched.

E95 Communication error. Replace the control board.

EB1 Incoming power frequency out of limits. Refer to test (15)

EB2 Incoming line voltage above 130 V AC. Check voltage at the outlet. If

below 130 V AC, replace the

control board.

EB3 Incoming line voltage below 90 V AC. Check voltage at the outlet. If

above 90 V AC, replace the

control board.

EF1 Clogged drain pump. Unclog the drain pump.

EF2 To much soap. Advise customer to reduce

the amount of soap they are

using.

3

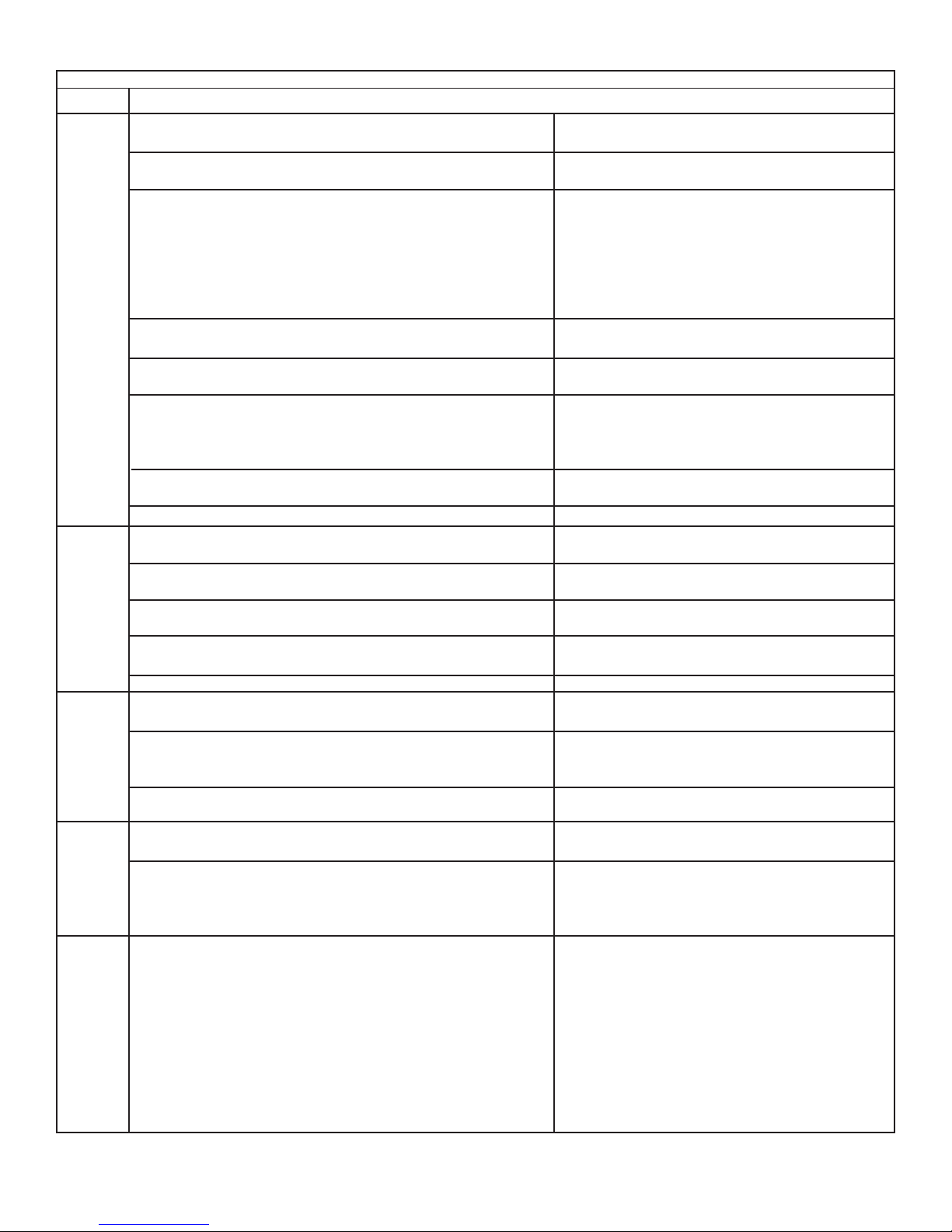

Test

P/N 134408500

Test Check Correction

Test 1:

Test 2:

Test 3:

Test 4:

Test 5:

1. Is the incoming water flow normal?

2. Are the incoming water faucets turned

3. Is the incoming water pressure above (30) psi.

4. Does the fill water continue enter the washer?

5. Remove power from the washer. Did the water fill

stop?

6. Good models, check the pressure switch.

7. Better models, replace the pressure sensor.

8. Replace the control board.

1. Is the washer leaking water?

2. Is there an air leak in the air bell system?

3. Good models, check the pressure switch.

4. Better models, replace the pressure sensor.

5. Replace the control board.

1. Is the dispenser drawer closed?

2. Remove the drawer and check the magnet.

3. Open the console and check the reed switch.

1. Check the drain hose for restrictions.

2. Start the washer and check for 120 VAC at the

drain pump.

Inspect the wiring between the pressure sensor and

the control board.

Yes. Go to step (4).

No. Go to step (2)

No. Turn water faucets on.

Yes. Go to step (3).

No. Have customer correct pressure

problem.

Yes. Check for kinked or blocked

incoming water hoses, clean

the incoming water screens. If

problem still remains, replace the

water inlet valve assembly .

Yes. Go to step (5).

No. Go to step (6)

Yes. Go to step (6)

No. Replace the inlet valve assembly .

Pressure switch checks good.

Go to step (8).

Pressure switch checks bad. Replace

pressure switch.

If this did not correct the problem, go to

step 8.

Y es. Correct water leak.

No. Go to step (2)

Yes. Correct the air leak problem.

No. Go to step (3-4)

Defective. Replace the pressure switch.

Good. Go to step (5)

If this did not correct the problem, go to

step 5.

No. Close the drawer.

Yes. Go to step (2).

Magnet missing or defective. Replace the

magnet.

Magnet good. Go to step (3).

Defective. Replace the reed switch.

Good. Replace the control board.

Restriction. Correct problem.

No restriction. Go to step (2).

Zero. Replace the control board.

120 VAC. Remove the pump and check for

blockage. If blocked, remove the restriction,

if not, replace the pump.

Defective wiring. Correct wiring.

Good wiring. Replace the pressure sensor.

If this does not correct the problem, replace

the control board.

4

Loading...

Loading...