Frigidaire CFGS365EB1, CFGS365EB2, CFGS365EB3, CFGS365EB5, CFGS365ES1 Installation Guide

...Page 1

(NSTALLAT(ON AND SERVICEMUST BEPERFORMEDBY A QUAMF(ED (NSTALLER.

mMPORTANT:SAVE FORLOCAL ELECTRICALINSPECTOR'SUSE.

READ AND SAVE THESEINSTRUCTIONSFORFUTUREREFERENCE.

If the information in this manual is not followed exactty, a

fire or explosion may result causing property damage, personaJ injury

or death.

FOR YOUR SAFETY:

--Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

--WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrkat switch; do not use any phone in your

bui(ding.

• (mmediate[y ca[[ your gas supplier from a neighbor's phone. Follow

the gas suppIier's instructions.

• tf you cannot reach your gas supplier, call the fire department.

--Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

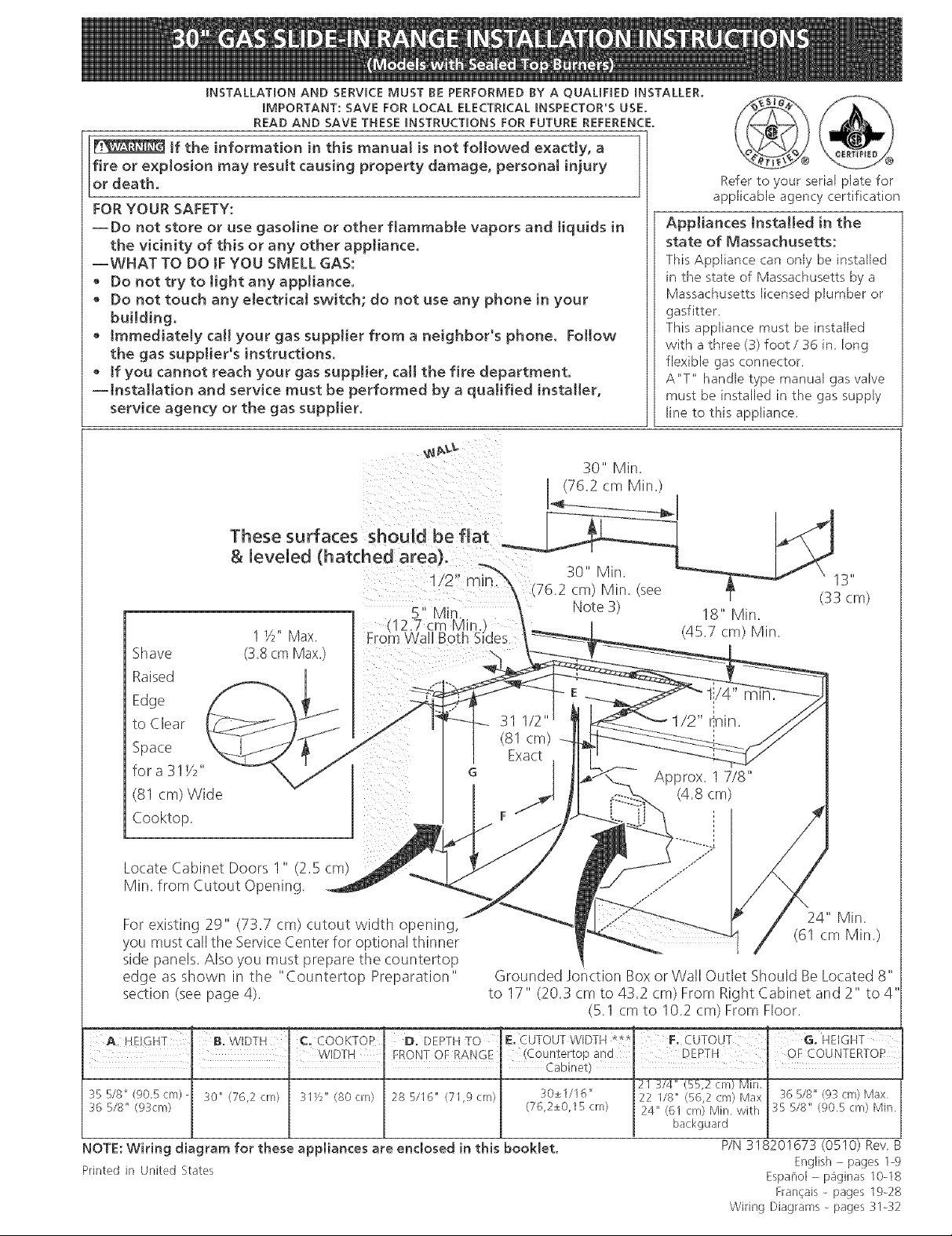

30" Min.

(76.2 cm Min.)

Refer to your serial plate for

applicable agency certificatior

Appliances tnsta!led in the

state of Massachusetts:

This Appliance can only be installed

in the state of Massachusetts by a

Massachusetts licensed plumber or

gasfitter_

This appliance must be installed

with a three (3) foot / 36 in long

flexible gas connector

A"T" handle type manual gas valve

must be installed in the gas supply

line to this appliance

side panels. Also you must prepare the countertop

edge as shown in the "Countertop Preparation"

section (see page 4).

B, WIDTH Co COOKTOP D, DEPTH TO E, CUTOUT WIDTH *t_

I I I Cabinet), •

35 5/8" @0.5cm)- 30" (76,2 cm) 31Y2" (80crn) 28 5/16" (71,9cm)

36 5/8" (93cm)

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

Printed in United States

WIDTH FRONT OF RANGE (Countertop and DEPTH OF COUNTERTOP

Grounded Jonction Box or Wall Outlet Should Be Located 8"

to 17" (20.3 cm to 43.2 cm) From Right Cabinet and 2" to 4'

(76,2±0,I5 cm)

30±1/16"

(5.1 cm to 10.2 cm) From Floor.

21 3/4" (SbT2cm) Min,

22 I18" (56,2 cm) Max 36 5/S" (93 cm) Max

24" (61 cm) Min with 35 5/8" (905cm) Min

bac:kguard

P/N 318201673 (0510) Rev

English - pages 1-9

Espahol - p_ginas 10-18

Francais - pages 19-28

Wiring Diagrams - pages 31-32

Page 2

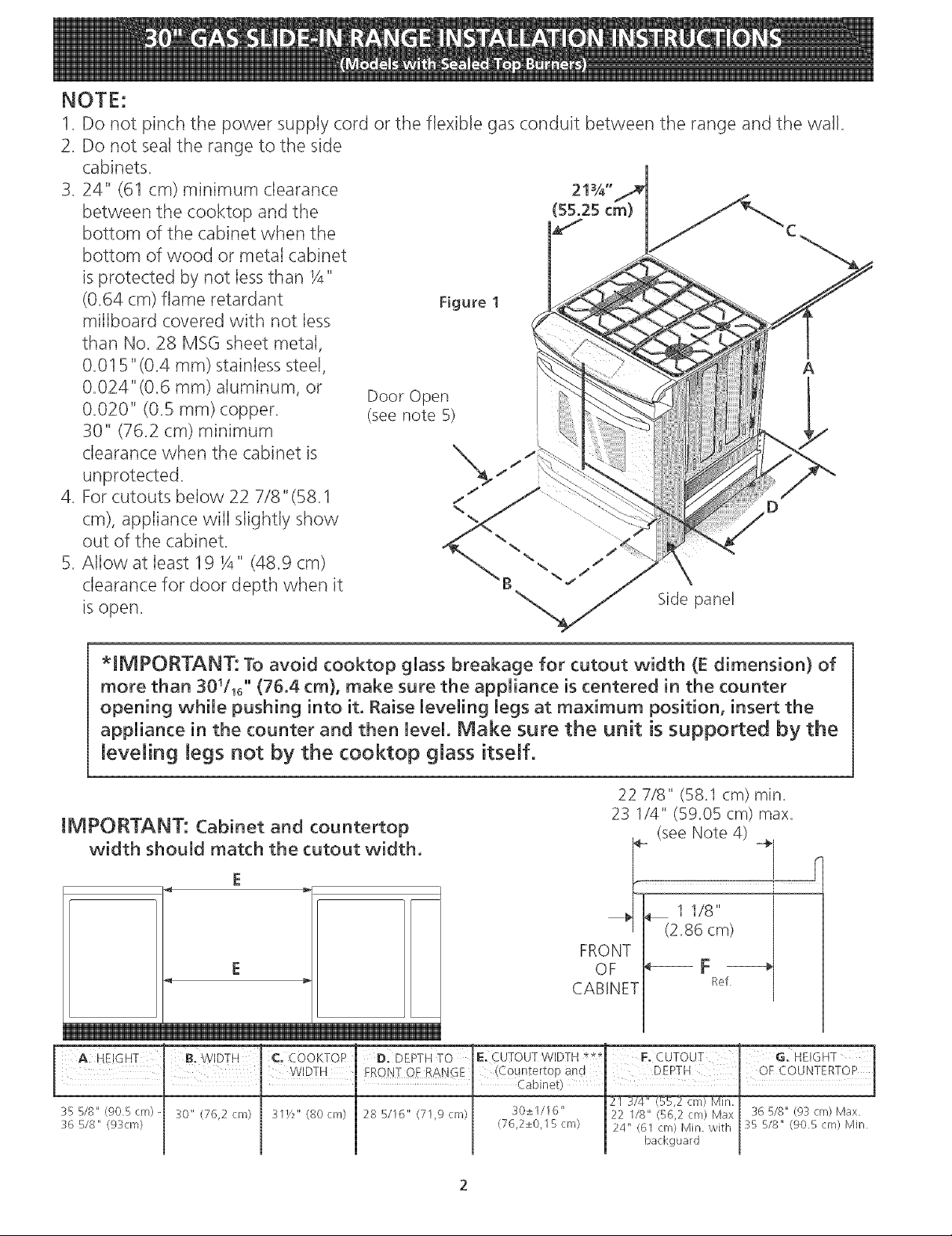

NOTE:

1. Do not pinch the power supply cord or the flexible gas conduit between the range and the wall.

2. Do not seal the range to the side

cabinets.

3.24" (61 cm)minimum clearance

between the cooktop and the

bottom of the cabinet when the

bottom of wood or metal cabinet

is protected by not less than Y4"

(0.64 cm) flame retardant

milIboard covered with not less

than No. 28 MSG sheet metal,

0015"(0.4 ram) stainless steel,

0.024"(0.6 mm) aluminum, or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum

clearance when the cabinet is

unprotected.

4. For cutouts below 22 7/8" (58.1

cm), appliance will slightly show

out of the cabinet.

5. Allow at least 19 V4" (48.9 cm)

clearance for door depth when it

is open.

Figure 1

(see note 5)

Door Open i _/

f

J

"_ ,D

21%"

(55.25 cm

A

Side panel

*IMPORTANT: To avoid cooktop glass breakage for cutout width (E dimension) of

more than 301/16'' (75.4 cm), make sure the appliance is centered in the counter

opening while pushing into it. Raise leveling legs at maximum position, insert the

appliance in the counter and then level. Make sure the unit is supported by the

leveling legs not by the cooktop glass itself.

22 7/8" (58.1 cm) rain.

IMPORTANT: Cabinet and countertop

width should match the cutout width,

E

FA. HEIGHT_CoIOOTKHrOP i D DEPTHTo--ECUTOUTWIDTH*** i F. CUTDUT " G. HEIGHT i

FRONT OF RANGE ] (Countertop and 1 DEPTH I DE CDUNTERTOP I

l Cabinet) ]

28 5/I6" (71,9cm 30+_ / 6" 36 5/8"(93era) Max

23 1/4" (59.05 cm) max.

, (see Note 4) -_

1 118"

/ (2.86 cm)

FRONT

OF _ F

CABINET Ref

Page 3

Important Notes to the Installer

1. Readall instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leavethese instructions with tile consumer.

Make sure the wall coverings around the range

can withstand the heat generated by the range.

Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

Important Note to the Consumer

Keep these instructions with your Use & Care Guide for

future reference.

IMPORTANT SAFETY

INSTRU S

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANS! Z223. I/NFPA .54qatest edition.

This range has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70--latest edition. SeeGrounding Instructions.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering,

make sure the floor covering can withstand heat at

least 90°F above room temperature without

shrinking, warping or discoloring. Do not install the

range over carpeting unless you place an insulating pad

or sheet of 1/4"(I 0,16 cm) thick plywood between the

range and carpeting.

_To

All ranges

cantip.

Injuryto

persons could

result.

InstallantPtip

device

packed with

range.

reduce the risk of tipping

of the range, the range

must be secured by

properly installed antPtip

bracket provided with

the range. To check if

the bracket is installed

properly, grasp the top

rear edge of the range

and carefully tilt it

forward to make sure

the range isanchored.

Never leave children alone or

unattended [n the area where an app!iance [s[n use.

As children grow, teach them the proper, safe use of all

appliances. Never leave the oven door open when the

range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and tiquids near this or any other

appliance. Explosions or fires could result.

• In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control knob to LITE.Use caution when

lighting surface burners manually.

• Reset all controls to the "off" position after using

a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the Use

and Care Guide.

• Unlike the standard gas range, THIS COOKTOP tS

NOT REMOVABLE. Do not attempt to remove the

cooktop.

Page 4

Cabinet Construction

To eliminate the risk of cabinet burns and

fire, do not have cabinet storage space above the range.

If there is cabinet storage space above range, reduce risk

by installing a range hood that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the

cabinet.

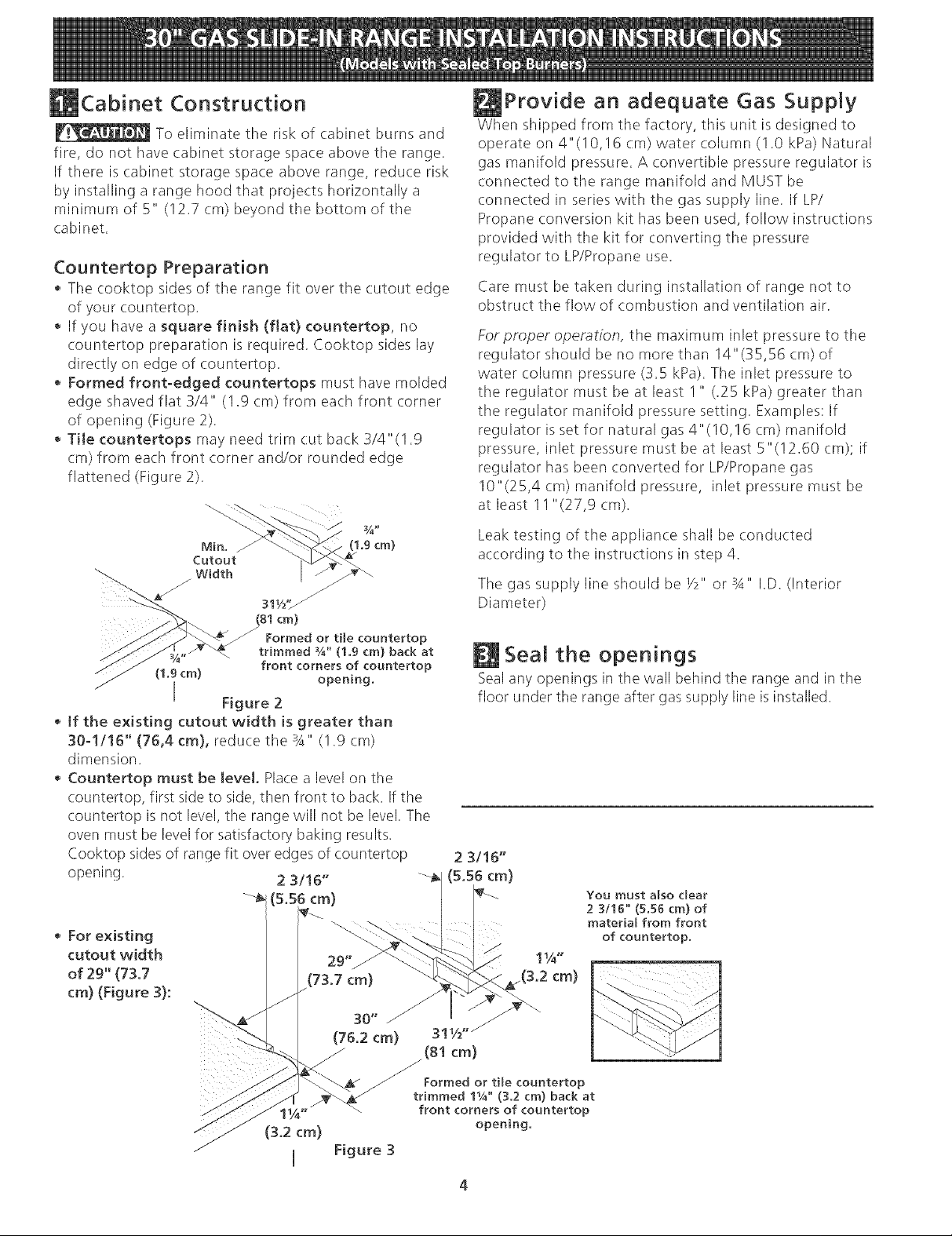

Countertop Preparation

The cooktop sides of the range fit over tile cutout edge

of your countertop.

If you have a square finish (flat} countertop, no

countertop preparation is required. Cooktop sides lay

directly on edge of countertop.

Formed front-edged countertops must have molded

edge shaved flat 3/4" (1.9 cm) from each front corner

of opening (Figure 2).

• Tile countertops may need trim cut back 3/4"(1.9

cm) from each front corner and/or rounded edge

flattened (Figure 2).

Provide an adequate Gas Supply

When shipped from tile factory, this unit is designed to

operate on 4"(10,!6 cm) water column (I.0 kPa) Natural

gas manifold pressure. A convertible pressure regulator is

connected to the range manifold and MUST be

connected in series with the gas supply line. If LP/

Propane conversion kit has been used, follow instructions

provided with the kit for converting the pressure

regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14"(35,56 cm) of

water column pressure (3.5 kPa). Tile inlet pressure to

the regulator must be at least ! " (.25 kPa) greater than

the regulator manifold pressure setting. Examples: If

regulator is set for natural gas 4"(10,!6 cm) manifold

pressure, inlet pressure must be at least 5"(!2.60 cm); if

regulator has been converted for LP/Propane gas

10"(25,4cm) manifold pressure, inlet pressure must be

at least 11 "(27,9 cm).

Min. /

Cutout

311/2'_

(1.9cm)

/

/

(81cm)

Formed or tile countertop

trimmed ¾" (1.9 cm) back at

(1.9 cm) opening.

front corners of countertop

I Figure 2

• tf the existing cutout width is greater than

30-1/16" (76,4 cm}, reduce the 3A" (!.9 cm)

dimension.

Countertop must be level Placea level on tile

countertop, first sideto side, then front to back. If tile

countertop is not level, the range will not be level. The

oven must be level for satisfactory baking results.

Cooktop sides of range fit over edges of countertop

opening. 2 3/!6"

-_ (5.56 cm}

• For existing _- _

cutout width 1 29"/

of 29" (73.7 _73.7 cm)

cm} (Figure 3}:

/

Leak testing of tile appliance shall be conducted

according to the instructions in step 4.

The gas supply line should be Y2" or 3A" I.D. (Interior

Diameter)

Seal the openings

Seal any openings in the wall behind the range and in the

floor under tile range after gas supply line isinstalled.

2 3116"

(5.56 cm)

You must also dear2 3/16" (5.56 cm) of

material from front

of countertop.

.(3.2 cm}

(3.2 cm)

U

(76.2 cm} 311/2"/

/ (81 cm}

_Formed or tile countertop

trimmed lYg' (3.2 cm) back at

front corners of countertop

opening.

Figure 3

Page 5

Connect the range to the gas suppmy

important: Remove all packing material and

literature from range before connecting gas and

electrical supply.

To prevent leaks, put pipe joint sealant on all external

pipe threads.

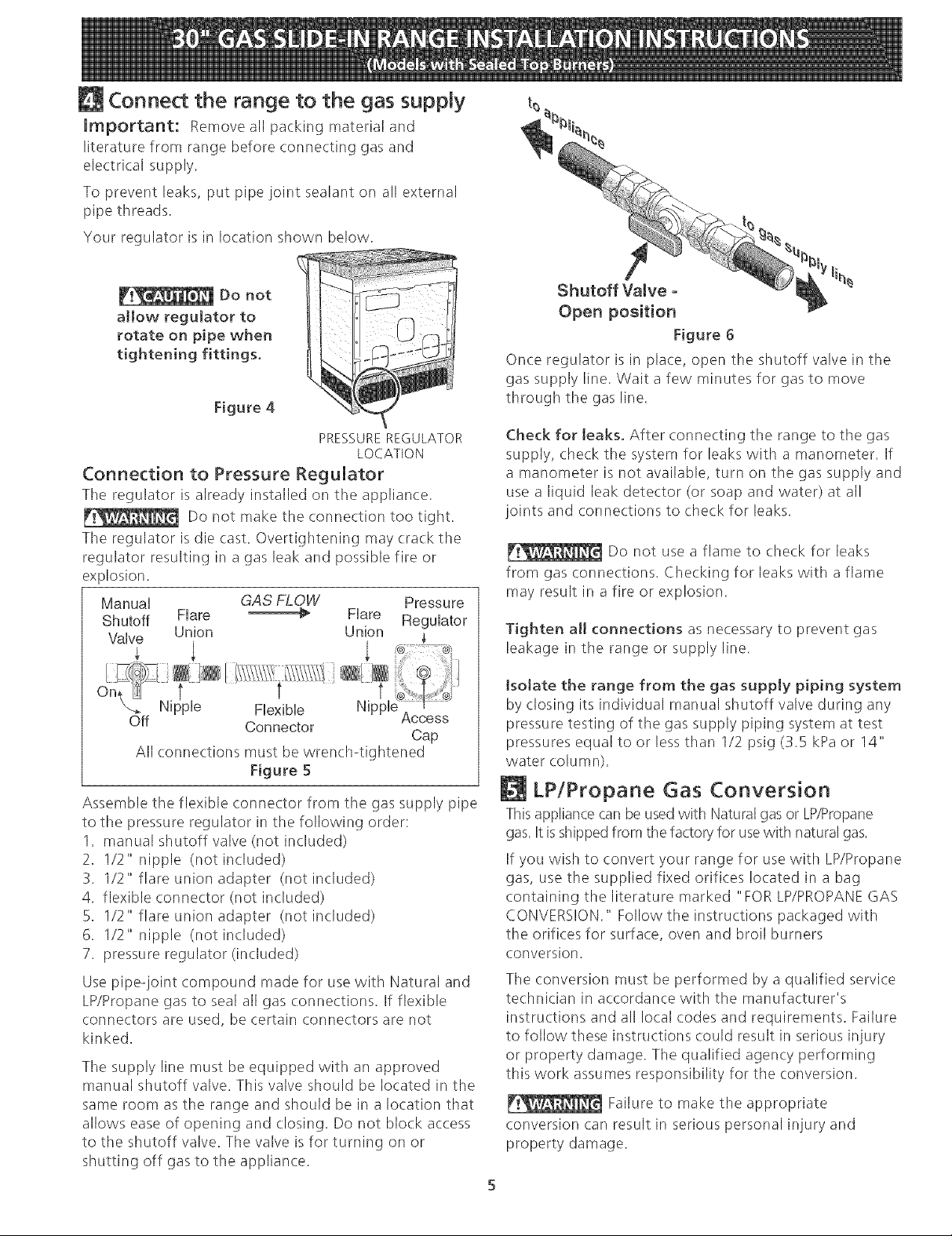

Your regulator isin location shown below.

Do not

allow regulator to

rotate on pipe when

tightening fittings.

Figure 4

Open position

Figure 6

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

PRESSUREREGULATOR

LOCATION

Connection to Pressure Regulator

Tile regulator is already installed on the appliance.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack tile

regulator resulting in a gas leak and possible fire or

explosion.

Manual GAS FLOW Pressure

Shutoff Hare _ Hare Regulator

Valve Union Union

[ ® I

on, t T

_._ Nipple Flexible Access

Off Connector

All connections must be wrench-tightened

Figure 5

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in tile following order:

1. manual shutoff valve (not included)

2. 1/2" nipple (not included)

3. I/2" flare union adapter (not included)

4. flexible connector (not included)

5. 1/2" flare union adapter (not included)

6. 1/2" nipple (not included)

7. pressure regulator (included)

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not

kinked.

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the range and should be in a location that

allows ease of opening and closing. Do not block access

to the shutoff valve. The valve isfor turning on or

shutting off gas to the appliance.

Cap

Check for leaks. After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on tile gas supply and

use a liquid leak detector (or soap and water) at all

joints and connections to check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

Tighten all connections as necessary to prevent gas

leakage in tile range or supply line.

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa or 14"

water column).

LPiPropane Gas Conversion

Thisappliance can be usedwith Natural gasor LP/Propane

gas. It is shipped from the factory for usewith natural gas.

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices located in a bag

containing tile literature marked "FOR LP/PROPANEGAS

CONVERSION." Follow the instructions packaged with

the orifices for surface, oven and broil burners

conversion.

The conversion must be performed by a qualified service

technician in accordance with tile manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

Page 6

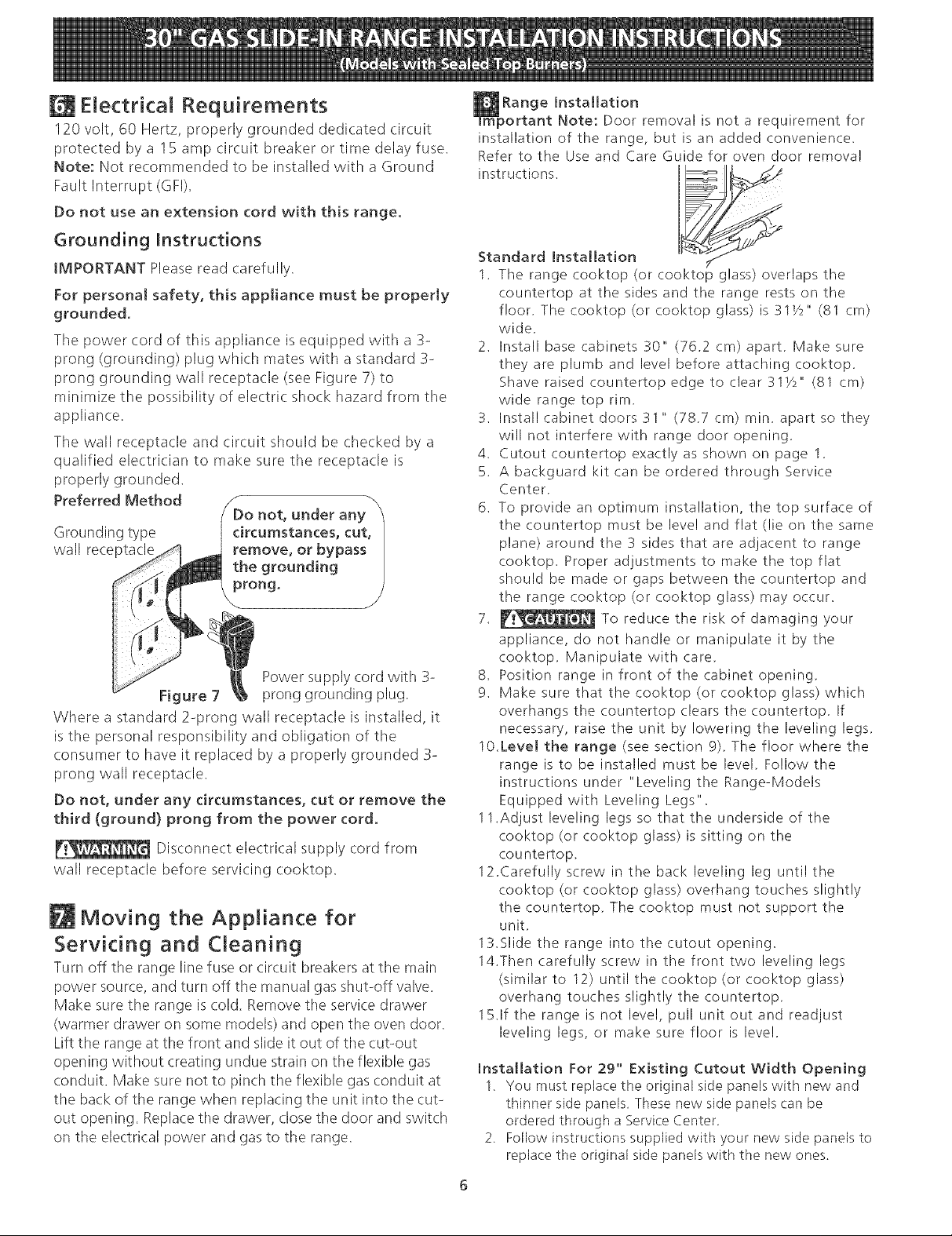

Electrical Requirements

120 volt, 60 Hertz, properly grounded dedicated circuit

protected by a 15 amp circuit breaker or time delay fuse.

Note: Not recommended to be installed with a Ground

Fault Interrupt (GFI).

Do not use an extension cord with this range.

Grounding Instructions

IMPORTANT Please read carefully.

For personal safety, this appliance must be properly

grounded.

The power cord of this appliance is equipped with a 3-

prong (grounding) plug which mates with a standard 3-

prong grounding wall receptacle (see Figure 7) to

minimize tile possibility of electric shock hazard from the

appliance.

The wall receptacle and circuit should be checked by a

qualified electrician to make sure the receptacle is

properly grounded.

Preferred Method /_Do not, under anb/

Grounding type circumstances, cut,

wall rece remove, or bypas_

the grounding [

prong, /

Power supply cord with 3-

Figure 7 prong grounding plug.

Where a standard 2-prong wall receptacle is installed, it

is tile personal responsibility and obligation of the

consumer to have it replaced by a properly grounded 3-

prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord.

Disconnect electrical supply cord from

wall receptacle before servicing cooktop.

Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the main

power source, and turn off the manual gas shut-off valve.

Make sure the range is (:old. Remove the service drawer

(warmer drawer on some models) and open the oven door.

Lift the range at the front and slide it out of the cut-out

opening without creating undue strain on the flexible gas

conduit. Make sure not to pinch the flexible gas conduit at

the back of the range when replacing the unit into the cut-

out opening. Replace the drawer, close the door and switch

on the electrical power and gas to the range.

Range Installation

_ortant Note: Door removal is not a requirement for

installation of the range, but is an added convenience,

Refer to the Use and Care Guide for oven door removal

instructions. __

countertop at the sides and the range rests on the

floor, The cooktop (or cooktop glass) is 31_/2'' (81 cm)

wide.

2. Install base cabinets 30" (76.2 cm) apart, Make sure

they are plumb and level before attaching cooktop,

Shave raised countertop edge to clear 31_/2'' (81 cm)

wide range top rim,

3. Install cabinet doors 31" (78,7 cm) rain, apart so they

will not interfere with range door opening,

4, Cutout countertop exactly as shown on page 1,

5. A backguard kit can be ordered through Service

Center.

6. To provide an optimum installation, the top surface of

the countertop must be level and flat (lie on the same

plane) around the 3 sides that are adjacent to range

cooktop. Proper adjustments to make the top flat

should be made or gaps between the countertop and

the range cooktop (or cooktop glass) may occur.

7. _ To reduce the risk of damaging your

appliance, do not handle or manipulate it by the

cooktop, Manipulate with care,

8. Position range in front of the cabinet opening,

9. Make sure that the cooktop (or cooktop glass) which

overhangs the countertop clears the countertop, If

necessary, raise the unit by lowering the leveling legs,

10.Levet the range (see section 9), The floor where the

range is to be installed must be level, Follow the

instructions under "Leveling the Range-Models

Equipped with Leveling Legs",

11.Adjust leveling legs so that the underside of the

cooktop (or cooktop glass) is sitting on the

countertop.

12.Carefully screw in the back leveling leg until the

cooktop (or cooktop glass) overhang touches slightly

the countertop, The cooktop must not support the

unit,

13,Slide the range into the cutout opening,

14.Then carefully screw in the front two leveling legs

(similar to 12) until the cooktop (or cooktop glass)

overhang touches slightly the countertop,

15.1f the range is not level, pull unit out and readjust

leveling legs, or make sure floor is level.

InstalJation For 29" Existing Cutout Width Opening

1. You must replace the original side pane[swith new and

thinner side panels These new side panels can be

ordered through a Service Center.

2. Follow instructions supplied with your new side panels to

replace the original side panels with the new ones.

Page 7

3 Check if the countertop is prepared for 29" cutout wide

opening at page 3.

4 Install range as in the "Standard Instamlation" section

above.

Installation With Backguard

A backguard kit can be ordered through a Service

Center.

The cutout depth (21 3/4" (55.2 cm) Min., 22 I/8" (56.2

cm) Max.) needs to be increased to 24" (61 cm) when

installing a backguard

I

Installation With End Panel

An end panel kit can be ordered through a Service

Center.

Installation With Side Pane!

A side panels kit (an be ordered through a Service

Center. Install cabinet doors 3! " (78.7 cm) min. apart so

as not to interfere with range door opening.

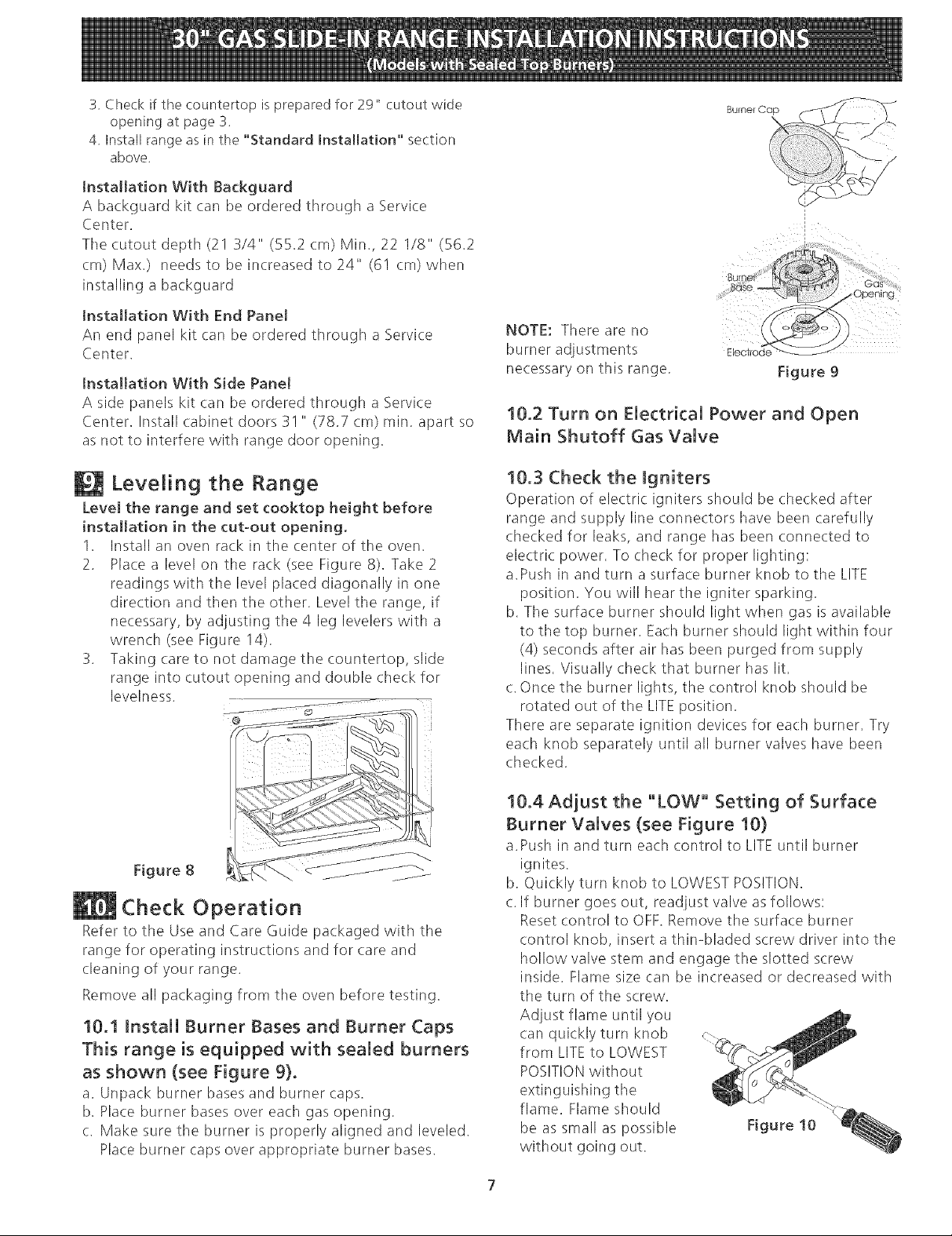

Leveling the Range

Level the range and set cooktop height before

installation in the cut-out opening.

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see Figure 8). Take 2

readings with the level placed diagonally in one

direction and then the other. Level the range, if

necessary, by adjusting the 4 leg levelers with a

wrench (see Figure 14).

3. Taking (are to not damage the countertop, slide

range into cutout opening and double check for

levelness.

@

i

NOTE: There are no

burner adjustments

necessary on this range.

Figure 9

10.2 Turn on Electrical Power and Open

Main Shutoff 6as Valve

10.3 Check the igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power. To check for proper lighting:

a.Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

b. The surface burner should light when gas is available

to the top burner. Each burner should light within four

(4) seconds after air has been purged from supply

lines. Visually check that burner has lit.

c. Once the burner lights, the control knob should be

rotated out of the LITEposition.

There are separate ignition devkes for each burner. Try

each knob separately until all burner valves have been

checked.

Figure 8

Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for (.are and

(.leaning of your range.

Remove all packaging from the oven before testing.

10.1 Install Burner Bases and Burner Caps

This range is equipped with sealed burners

as shown (see Figure 9}.

a. Unpack burner bases and burner caps.

b. Place burner bases over each gas opening.

c. Make sure the burner is properly aligned and leveled.

Place burner caps over appropriate burner bases.

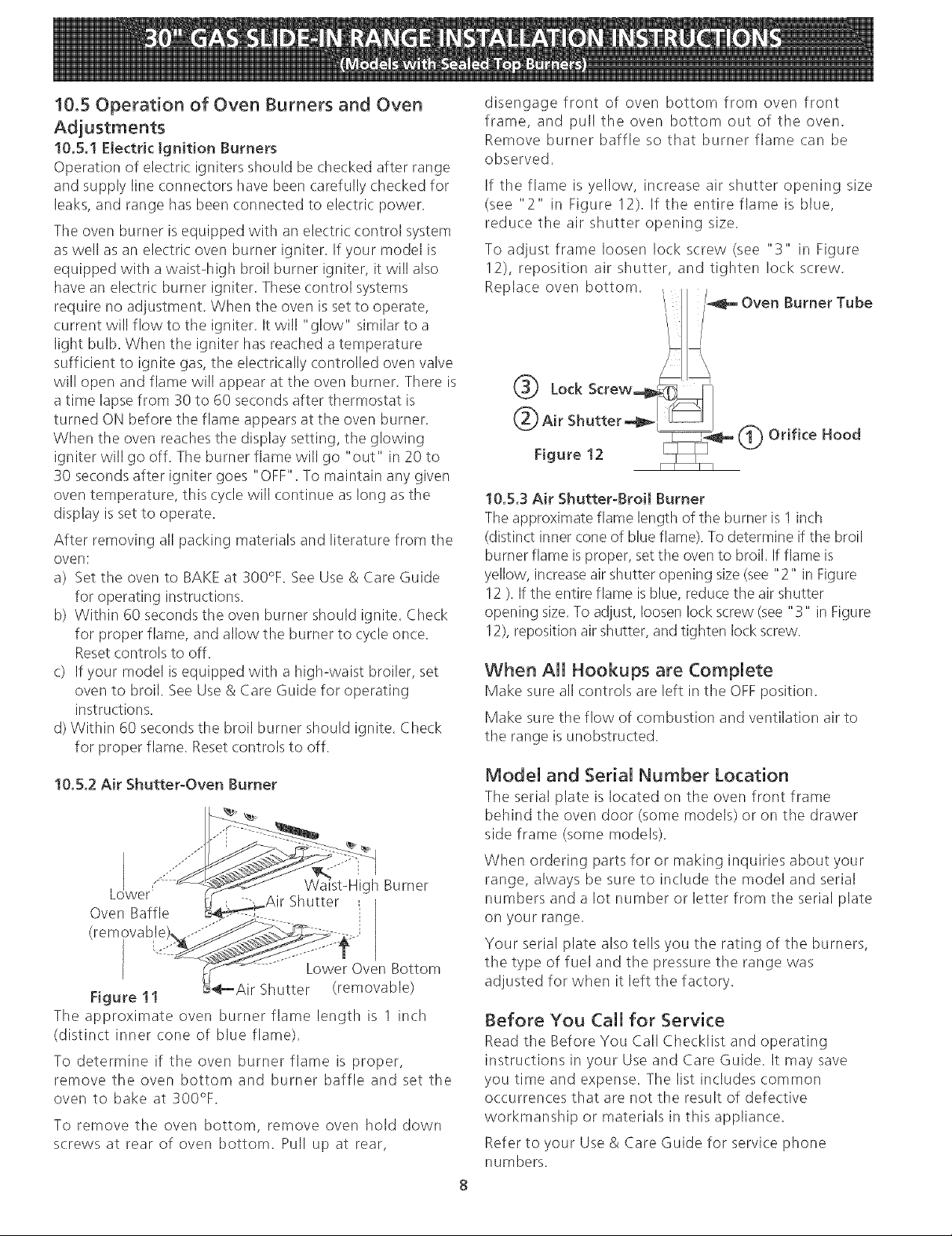

10.4 Adjust the "LOW" Setting of Surface

Burner Valves (see Figure 10}

a.Push in and turn each control to LITEuntil burner

ignites.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, readjust valve asfollows:

Reset control to OFF. Remove the surface burner

control knob, insert a thin-bladed screw driver into the

hollow valve stem and engage the slotted screw

inside. Flame size (:an be increased or decreased with

the turn of the screw.

Adjust flame until you

can quickly turn knob

from LITEto LOWEST

POSITIONwithout

extinguishing the

flame. Flame should

be as small as possible

without going out.

Figure 10

Page 8

10.5 Operation of Oven Burners and Oven

Adjustments

10,5,1 EJectric ignition Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks, and range has been connected to electric power.

The oven burner isequipped with an electric control system

as well as an electric oven burner igniter. If your model is

equipped with a waist-high broil burner igniter, it will also

have an electric burner igniter. Thesecontrol systems

require no adjustment. When the oven is set to operate,

current will flow to the igniter. It will "glow" similar to a

light bulb. When the igniter has reached a temperature

sufficient to ignite gas, the electrically controlled oven valve

will open and flame will appear at the oven burner. There is

a time lapse from 30 to 60 seconds after thermostat is

turned ON before the flame appears at the oven burner.

When the oven reaches the display setting, the glowing

igniter will go off. The burner flame will go "out" in 20 to

30 seconds after igniter goes "OFF". To maintain any given

oven temperature, this cycle will continue as long as the

display is set to operate.

After removing all packing materials and literature from the

oven:

a) Set the oven to BAKE at 300°F. See Use & Care Guide

for operating instructions.

b) Within 60 seconds the oven burner should ignite. Check

for proper flame, and allow the burner to cycle once.

Resetcontrols to off.

c) Ifyour model is equipped with a high-waist broiler, set

oven to broil. See Use & Care Guide for operating

instructions.

d) Within 60 seconds the broil burner should ignite. Check

for proper flame. Reset controls to off.

10,5,2 Air Shutter-Oven Burner

j //.

L wer' gh Burner

Oven Baffle i

(removable

Figure 11 "_,-Air Shutter (removable)

Tile approximate oven burner flame length is 1 inch

(distinct inner cone of blue flame).

To determine if the oven burner flame is proper,

remove the oven bottom and burner baffle and set the

oven to bake at 300°F.

To remove the oven bottom, remove oven hold down

screws at rear of oven bottom. Pull up at rear,

Shutter

Lower Oven Bottom

disengage front of oven bottom from oven front

frame, and pull the oven bottom out of tile oven.

Remove burner baffle so that burner flame can be

observed.

If the flame is yellow, increase air shutter opening size

(see "2" in Figure 12). If the entire flame is blue,

reduce the air shutter opening size.

To adjust frame loosen lock screw (see "3" in Figure

12), reposition air shutter, and tighten lock screw.

10.5.3 Air Shutter-Broil Burner

The approximate flame length of the burner is 1 inch

(distinct inner cone of blue flame). To determine if the broil

burner flame is proper, set tile oven to broil. If flame is

yellow, increase air shutter opening size(see "2" inFigure

12 ). If the entire flame is blue, reduce the air shutter

opening size.To adjust, loosen lock screw (see "3" inFigure

12), reposition air shutter, andtighten lock screw.

When All Hookups are Complete

Make sure all controls are left in the OFFposition.

Make sure tile flow of combustion and ventilation air to

tile range is unobstructed.

Model and Serial Number Location

Tile serial plate is located on the oven front frame

behind the oven door (some models) or on the drawer

side frame (some models).

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from tile serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the range was

adjusted for when it left the factory.

Before You Call for Service

Read the Before You Call Checklist and operating

instructions in your Use and Care Guide. It may save

you time and expense. The list includes common

occurrences that are not the result of defective

workmanship or materials in this appliance.

Refer to your Use & Care Guide for service phone

numbers.

Page 9

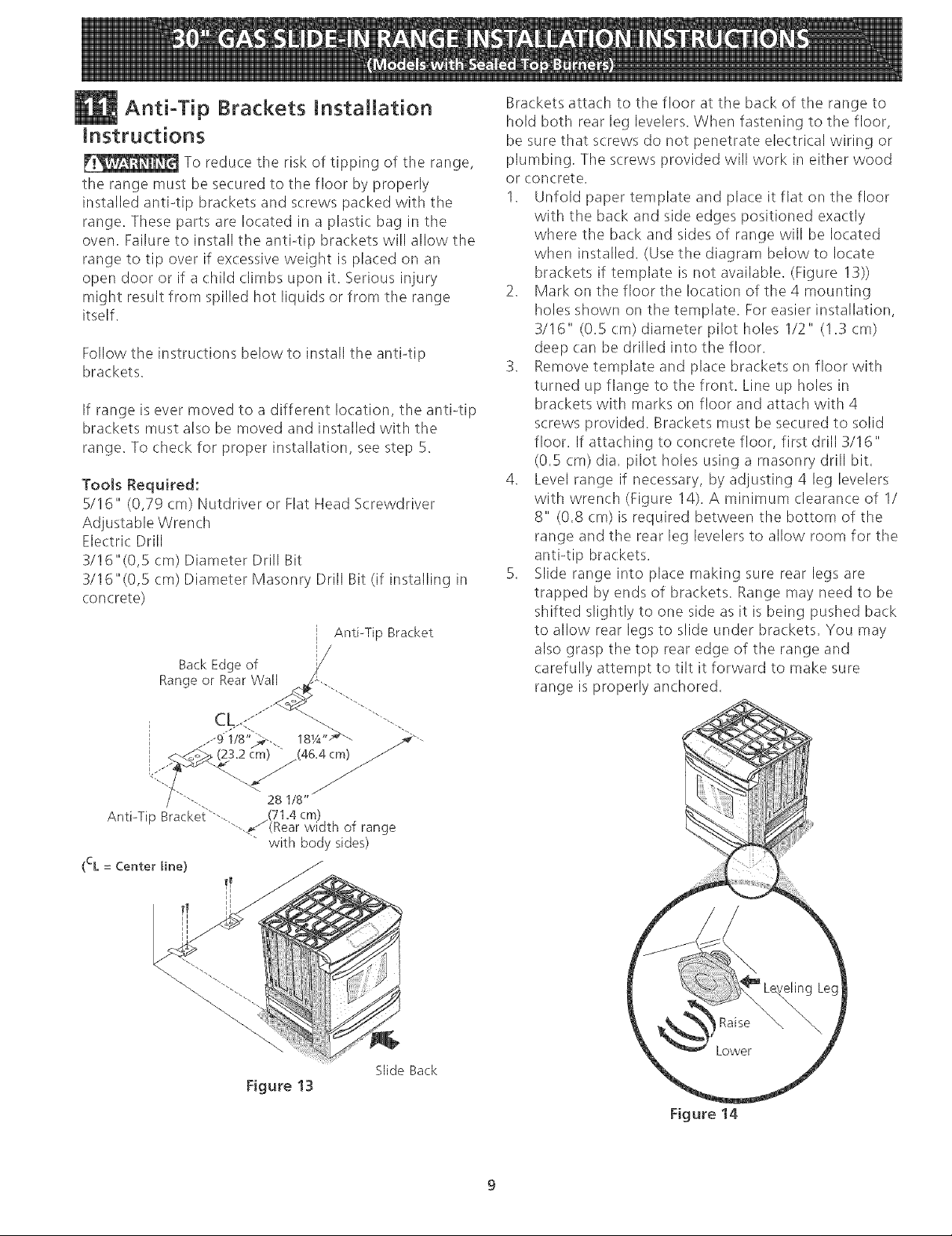

Anti-Tip Brackets JnstaJJation

To reduce the risk of tipping of the range,

the range must be secured to the floor by properly

installed anti-tip brackets and screws packed with the

range. These parts are located in a plastic bag in the

oven. Failure to install the anti-tip brackets will allow the

range to tip over if excessive weight is placed on an

open door or if a child climbs upon it. Serious injury

might result frora spilled hot liquids or from the range

itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the

range. To check for proper installation, see step S.

Tools Required:

5/I 6" (0,79 cm) Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/!6"(0,B cm) Diameter Drill Bit

3/16"(0,B cm) Diameter Masonry Drill Bit (if installing in

concrete)

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with tile back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram below to locate

brackets if template is not available. (Figure 13))

2. Mark on tile floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16" (O.Scm) diameter pilot holes 1/2" (1.3 cm)

deep can be drilled into the floor.

3. Remove template and place brackets on floor with

turned up flange to the front. Line up holes in

brackets with marks on floor and attach with 4

screws provided. Brackets must be secured to solid

floor. If attaching to concrete floor, first drill 3/16"

(0.5 cm) dia. pilot holes using a masonry drill bit.

4. Level range if necessary, by adjusting 4 leg levelers

with wrench (Figure 14). A minimum clearance of I/

8" (0.8 cm) is required between the bottom of the

range and the rear leg levelers to allow room for the

anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to be

shifted slightly to one side as it is being pushed back

to allow rear legs to slide under brackets. You may

also grasp the top rear edge of the range and

carefully attempt to tilt it forward to make sure

range is properly anchored.

Figure lS

Slide Back

Figure 14

Page 10

LAINSTALACIONYELSERVICtODEBENSEREFECTUADOSPORUNtNSTALADORCAUFtCADO.

tMPORTANTE:GUARD[=ESTAStNSTRUCaONESPARAUSODELiNSPECTORLOCALDE ELECTRlaDAD.

LEAY GUARD[=ESTAStNSTRUCaONES PARA REFERENCIAFUTURA_

Si ta informad6n contenida en este manuaJ no es seguida

exactamente, puede ocurrk un incendio o exp[osi6n causando da_os

mateHa[es, [es[6n personal o [a muerte,

PARASUSEGURDAD:

-- Noa[maceneni uti[ke gaso[ina u otros vapores y [iq@dosinf[amab[esen[a proximidad

de _steo de cua[q@erotto artefacto.

-- QUEDEBEHACERS[PERCIBEOLORAGAS:

Notrate de encender ningQnartefacto.

Notoque ningQn interruptor e[&trko; no useningQnte[_fono en suedifido.

, Llamea suproveedor degas desdeel te[_fono de unvedno. Siga [asinstrucdones de[

proveedordegas.

Sino Iogra comunicarsecon su proveedor de gas,[lamea[ departamento de bomberos.

-- La insta[adbn y el servido de mantenimiento deben set efectuados pot un insta[ador

ca[ffkado, [aagenda deservk[o o elproveedor de gas,

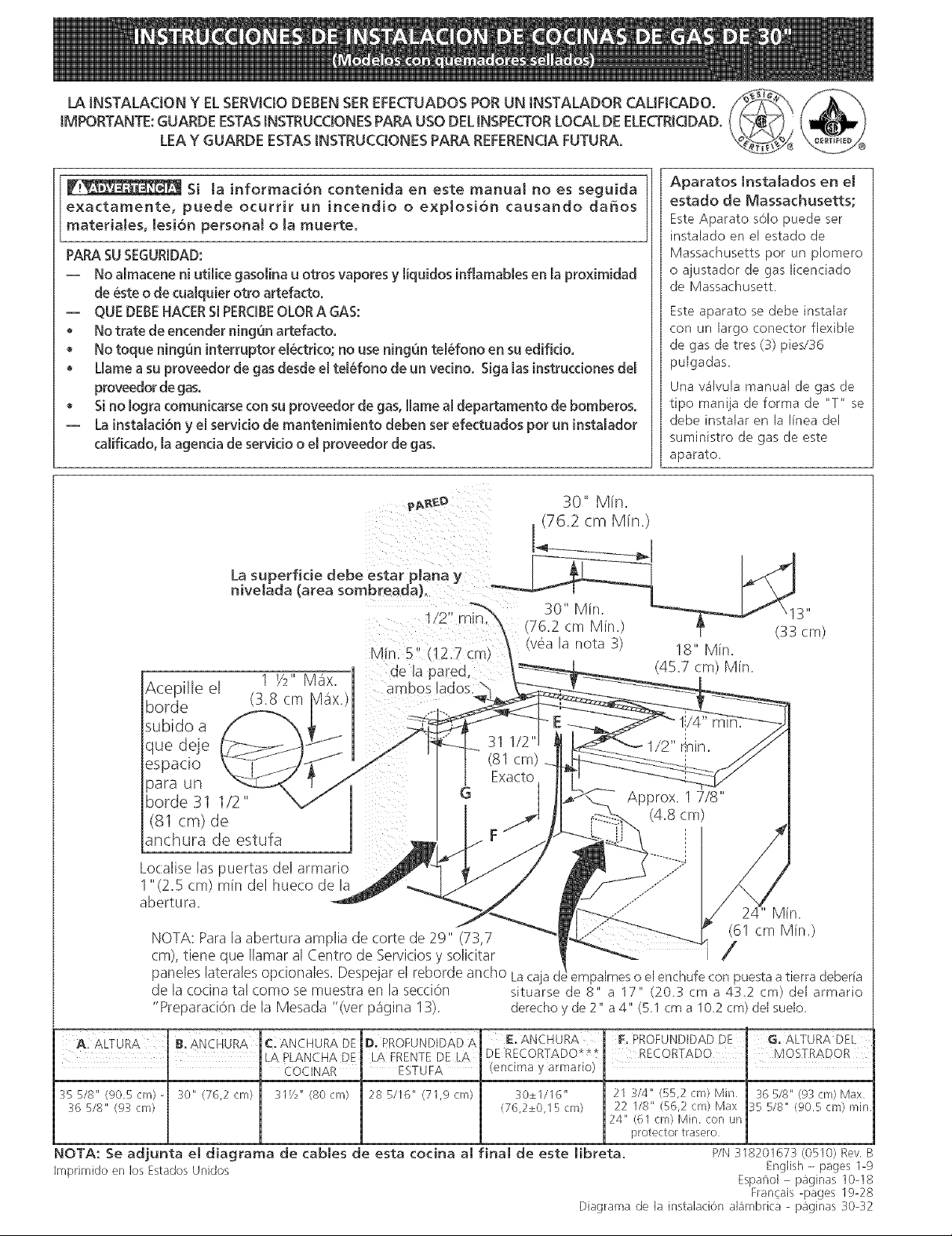

_Agg 30 MIn.

(762 cm Mira)

nivelada (area sombreada). _,_,""_ I ---'_ _

...... _ 30"Min. _ / \13"

m,n,\ Vt! - 133cm>

Min. 5" (12,7 cm) \ tvea la nota J) 18" Mfn.

de la pared__ 1_ (45.7 cm) Min.

Acepille el Y • ambos lados

horde (3.8 cm d_ix.)

subido a / X , £-_L__ _ _ _ ll/4- mln. -_

Aparatos tnsta[ados en el

estado de Massachusetts;

Este Aparato solo puede ser

instalado en el estado de

Massachusetts por un plornero

o ajustador de gas licenciado

de Massachusett

Este aparato se debe insta[ar

con un largo conector flexible

de gas de tres (3) pies!36

pulgadas

Una va'[vu[a manual de gas de

tipo rnanija de forrna de "T" se

debe insta[ar en [a [[nea de[

surninistro de gas de este

aparato,

borde 31 1/2" V ,_->',k Approx. 1 7/8"

@1cm)de tf _.. _ (4,8 cm)

anchura de estufa _, / F" /// _I i /7

?:>, /,

cm>mfndelhuecode / ............ /\ /

NOTA: Parala abertura amplia de torte de 29" (73,7 _4<_ _-----.. _ _ •

crn), tiene que Ilarnar al Centro de ServMos y solicitar __ ___ , , _ !

paneles laterales opcionales, Despeiar el reborde ancho La caD de ernpalrnes o el enchufe con puesta a derra deberfa

de la cocina tal como se muestra en la secciOn situarse de 8" a 17" (20S crn a 433 crn) del arrnario

"Preparation de la Mesada "(ver pagina 13). derecho y de 2" a 4" (5.1 crn a 102 crn) de[ suelo

A ALTURA ' B, ANCHURA ' C, ANCHURA DE' D, PROFUNDIDAD/_ _ IE.ANCHURA F, PROFUNDIDAD DE G, ALTURA DEL

LAPLANCHADE LAFRENTE DE LA DERECORTADO*** RECQRTADO l MOSTRADOR

" " COClNAR ESTUFA (encima y armario) -

_5 5/8" (905cm)- _0" (76,2 cm) :NV/' (80cm) 28 r_/I6" (71,9NTI) _0±1/16" 2I 3/4" (5%2 cm) Min %rWg"@3cm) Max

36 _18" (9:_ cnl) (76,2±0,15 cm) 22 1/8" (56,2 cm) Max _ _/8" (90r_ cnl) rain

NOTA: Se adjunta el diagrama de cables de esta codna al final de este libreta, WN 31820167S (051@ Rev. B

Imprimido en los Estados Unidos Espaflol - paginas 10-I8

, _ (61 cm Min )

24" (6I cm) Min con un

protector tras_ro

English -- pages I@

Franqais -pages 19-28

Diagrama de la instalaci0n alambrica - paginas 30-32

Page 11

NOTAS:

.

No peJJizque el cord6n electrico o el conducto flexible de gas entre [a estufa y [a pared.

2. No selle la estufa a los armarios de

lado.

3. Un espacio mfnimo de 24" (61 cm)

entre la superficie de la estufa y el fondo

del armario cuando el fondo del armario

de madera o metal est,1 protegido por no

menos de 1/4" (0.64 cm) de madera

resistente al fuego cubierta por una

I_imina met_ilica de MSG, nOmero 28,

0.015" (0.4 mm) de acero inoxidable,

0.024" (0.6 mm) de aluminio, 6 0.02" (0.5

mm) de cobre.

Un espacio mfnimo de 30" (762 cm)

cuando el armario no est,1 protegido.

4. Para los recortados menos que 22 7/

8", el electrodomestico aparecerfa

ligeramente en el exterior del armario.

5. Deje por los 19 X" (48.9 cm) de

espado libre para la profundidad de la

puerta cuando esta abierta.

Puerta

abierta

(vea la

nota 5 )

A

*IMPORTANTE: Para el torte a lo ancho (dimensi6n E) de m&s de 30 1/16 °°(76,4 cm) para evitar

que se rompa e[ vidrio, asegurese que e[ artefad{o este centrado en [a abertura de [a mesada

mientras [o presiona. Levante [as patas de nive[ad6n hasta [a posid6n maxima; inserte e[ artefadco

en marnesada y muegoniveme.Asegurese de que ia unidad este apoyada en ias patas

de niveiad6n y no en el vidrio iiso.

22 718" (58.1 cm) rain.

[MPORTANTE: El ancho de [a cubierta

y ei armario debe de ser iguai ai

ancho dei torte.

E

E

A,QLTUR,_B.ANCHURAC.ANCHURA[DED.PROFUN[DDASA

' LA PLANCHA [DE LA FRENTE DE LA

I

35 5/8" (905cm)- 30" (76,2 cm) 31V/' (80cm} 28 5/16" (71,9cm}

:_6 5/8" (9:_ cm)

COCINAR " ESTUFA

DE RECORTADO*** RECORTADO, MOSTRADOB

PARTE DELAN-

TERA DEL ARMARfO

E. ANCHURA JF_PROFUNDIDADDE G, ALTURADEL

(encima y armario) '

30±1/I6" 21 3/4" (55,2 crrl) Min. 36 5/8" (93 cm) Max

(76,2±0,15cm) 22 1/8" (56,2 cm) Max _5 5/8" (905cm) min

23 114" (59.05 cm) max.

(nota 4)

--F

Ref

24" (6I cm) Min. con un

protector trasero

11

Page 12

Notas importantes para e[ [nsta[ador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa.

2. Saque todo el material usado en e! embalaje del

compartimiento de! homo antes de conectar el

suministro electrico o de gas a la estufa.

3, Observe todos los cOdigos y reglamentos pertinentes.

4, Deje estas instrucciones con el comprador.

Nota Importante para el Consumidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

IMPORTANTES

INSTRUCCIONI=S DI=

SI=GURIDAD

Instalaci6n de esta estufa debe cumplir con todos los

c6digos locales, o en ausencia de cOdigos locales con el

COdigo Nacional de Gas Combustible ANSI Z223.1/NFPA

.54--01tima ediciOn,

E! diseflo de esta estufa ha sido certificado por la CSA

Internacional. En este como en cualquier otto artefacto

que use gas y genere calor, hay ciertas precauciones de

seguridad que usted debe seguir. Estas ser_in encontradas

en el Manual de! Usuario, lealo cuidadosamente.

AsegQrese de que la estufa sea instalada y

conectada a tierra en forma apropiada por un

instalador calificado o pot un tecnico.

• Esta estufa debe set eJ(_ctricamente puesta a tierra

de acuerdo con los c6digos locales, o en su

ausenda, con el C6digo Electrico National ANSI/

NFPA No. 70, ultima edici6n. Vea las instrucciones

para la puesta a tierra en la p_igina 4.

• Antes de instalar la estufa en un _rea cuyo piso

este recubierto con linbleo u otro tipo de piso

sintetico, asegurese de que _stos puedan resistir

una temperatura de por Io menos 90°F sobre Ja

temperatura ambiental sin provocar encogimiento,

deformaci6n o decomoradon. No instale laestufa

sobre una alfombra al menos que coloque una plancha

de material aislante de por Io menos 1/4 pulgada,

entre la estufa y la alfombra.

F cge 1 'tr4

• Todas las

estufas

pueden

volcarse.

Esto podria

resultar en

lesiones

personales,

• Instale el

dispositivo

antivuelcos

que se ha

empacado

junto con

esta estufa.

Para reducir el riesgo de

que se vuelque la estufa,

hay que asegurarla

adecuadamente co!o

candole los soportes

antivuelco que se

proporcionan. Para

comprobar si estos estan

instalados y apretados en

su lugar como se debe,

ase el borde trasero

superior de la estufa y

cuidado samente incline la

hacia adelante para

asegurar que la estufa se

ancle.

• AsegQrese de que el material que recubre [as

paredes alrededor de [a estufa, pueda resistir el

calor generado pot [a estufa.

No obstruya eJ flujo dem aire de combustibn en la

ventilation dem homo ni tampoco alrededor de Ja

base o debajo del panel inferior delantero de Ja

estufa. Evite tocar las aberturaso a'reascercanas de

la ventilaci6n, ya que pueden estar muy calientes

duranteelfuncionamientodel homo. Laestufa

requiere aire fresco para la combustion apropiada de

los quemadores.

Nunca deje ni_os solos o

desatendidos en un Mea donde un artefacto est_

siendo usado. A medida que los niCios crecen,

ens6F_eles el uso apropiado y de seguridad para todos los

artefactos. Nunca deje la puerta del homo abierta

cuando la estufa est,1 desatendida.

No se pare, apoye o siente en [as

puertas o cajones de esta estufa pues puede resuJtar

en serias Jesiones y puede tambien causar da5o a Ja

estufa.

,, No almacene articuJos que puedan interesar a los

ni_os en los gabinetes sobre Ja estufa. Los niF_os

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos articulos.

,, Los gabinetes de aJmacenamiento sobre Ja estufa

deben set evitados, para elirninar [a necesidad de

tenet que pasar sobre los quemadores superiores

de Ja estufa para JJegar a eJJos.

• Ajuste el tamaSo de Ja llama de los quemadores

superiores de tal manera que esta no sobrepase el

bordede los utensiJiosdecocinar. La llama

excesiva es peligrosa.

No use el homo como espacio de almacenaje. Esto

crear3 una situaci6n potencialmente peligrosa.

• Nunca use la estufa para caJentar el cuarto. E! uso

prolongado de la estufa sin la adecuada ventilaciOn

puede resultar peligroso.

• No almacene ni utilice gasolina u otros vapores y

Jiquidos inflarnables en la proximidad de este o de

cualquier otto artefacto eJectrico. Puede provocar

incendio o exp!osi6n.

• En caso de una interrupti6n del servicio e!#ctrico, es

posible de encender los quemadores de superficie a

mano. Para encender un quemador de superficie,

acerque un f6sforo encendido del cabezal del

quemador, y gire delicadamente e! bot6n de control de

superficie a LITE (encendido). Tener cuidado al

encender los quemadores a mano,

• Ajuste todos los controJes a la posidbn "OFF"

(apagada) despues de haber hecho una operacion

con tiempo programado.

PARA MODELOS AUTOLIMPIANTES:

,, Saque la asadera, alimentos o cualquier otro

utensiJio antes de usar el ddo de autolimpieza del

homo. Limpietodoexcesode derrame dealimentos.

Siga las instrucciones de prelimpiado en e! Manual del

Usuario.

, A diferenda de Ja gama est&ndar codnas de gas,

ESTA PLANCHA DE COCJNA NO ES MOVIBLE. No

intente quitar la plancha de cocina.

12

Page 13

Construction del armario

r.__ Para eliminar el riesgo de quemaduras o

de fuego tratando de alcanzar algo por encima de las

zonas calientes, evite de colocar articulos sobre la cocina.

Si cree necesitar este espacio, el riesgo puede disminuir si

instala un sombrerete que proteia horizontalmente un

minimo de 5" (12.7cm) sobre la base del armario.

Preparad6n del mostrador

• Las extremidades de la cocina sobrepasan el borde de

su mostrador.

Si tiene un mostrador con tas extremidades

cuadradas (plana$), no se necesita ninguna

preparaci6n del mostrador.

• E[ reborde de frente de mostradores moJdeados

deben tener hordes moldeados a 3/4" (1.9cm) a partir

de cada extremidad de la apertura (Figura 2).

Los mostradores enazuJejos deber_n necesitar un

recorte de 3/4" (1.9 cm) a partit de cada extremidad

y/o un horde redondeado aplanado (Figura 2).

Anchur_

de hueco

311/2'_

(81cm)

/ Mostrador moldeado o

enazulejo recortado 3/4" (1.9 cm)

(1.9 cm) frente de la abertura de[

hada arras en las esquinas de

Figura 2

Si e[ ancho de [a abertura de[ mostrador es m&s

grande que 30 1/16" (76,4 cm), ajuste a las

dimensiones como para el 3/4" (1.9).

• Para [a Anchura existente de[ Recorte de e[

29"(73.7 cm} (F[gura 3):

2 3116"

2 3/16" (5.56 era)

-_(5,56 cm)

i

(1.9cm)

mostrador,

Quite e[ 2 3/16" de

material de frente a [a

parte posteriora.

11/4"

Proporcione un suministro de gas

adecuado

Cu_ndo se env[a de la fabrica, Esta unidad ha sido

ajustada para operar con un mOltiple de admision para

gas natural de 4" (!0.16 cm)(!.0 kPa). Un regulador de

presion convertible esta conectado a la v&lvula

distribuidora y DEBEser conectado con la tuberia del

suministro de gas. 5i eljuego de conversion del propano

LP/Propano se ha utilizado, sigue las instrucciones

proporcionadas el juego para convertir el regulador de

presion al uso de LP/Propano.

se debe de tener cuidado durante la instalaci()n de la

estufa para no obstruir el flujo de aire de combustion y

ventilaci6n

Para la operacion apropriada, la maxima presion de

entrada al regulador no debe execeder la presion de una

columna de agua de 14"(35,56 cm) (3.5 kPa). La presion

de entrada al regulador debe ser por Io menos I " (.25

kPa) m_s grande que la v_lvula distribuidora.Eiemplos: Si

regulador se pone para el gas natural con una presion de

4"(10,16 cm), la presi6n de entrada al regulador debe

ser por Io menos 5"(!2.60 cm); si el regulador se ha

convertido para gas LP/Propane 10"(25,4 cm)la presion

de entrada al regulador debe ser pot Io menos 11"(27,9

cm),

Un examen de detection de fugas del aparato debe ser

realizado segOn las instrucciones en el paso 4.

La linea de fuente de gas debe ser de Y2" o de sA".

Selle las aperturas

sella todas lasaperturas en la pared detras de la estufa y

en el suelo debajo de la estufa despues que la linea del

suministro de gas seainstalada.

L l Conecte la estufa at suministro de gas

Importante: Quite todo el material de embalaje y

literatura de la estufa antes de conectar el gas y la

fuente electrica.

Para evitar fugas, aplique sellador de tuberias en todas

,_jorecortado 3/4" (1.9 cm)

(3,2 cm) frente de la abertura de[

hacia atr_s en las esquinas de

mostrador.

[ Figura 3

• E[ mostrador deber set hive[ado. Coloque un

nivelador sobre el mostrador, primero de lado a lado y

luego del frente hacia atr_s. Si el mostrador no estg

nivelado, la cocina no estar& nivelada. El homo debe

ser nivelado para tener resultados satisfactorios al

hornear. Las extremidades de la plancha de la cocinar

sobrepasan los hordes de la abertura del mostrador.

las partes roscadas

machos (exterior) de la

tuberia. Elregulador se

encuentra en el lugar que

se muestra en la

illustration, (Figura 4)

perm[ta que el

regulador g[re sobre la

tuberi& at apretar tas

un[ones.

13

Figura 4

Ubicacion del regulador

de presiOn

Page 14

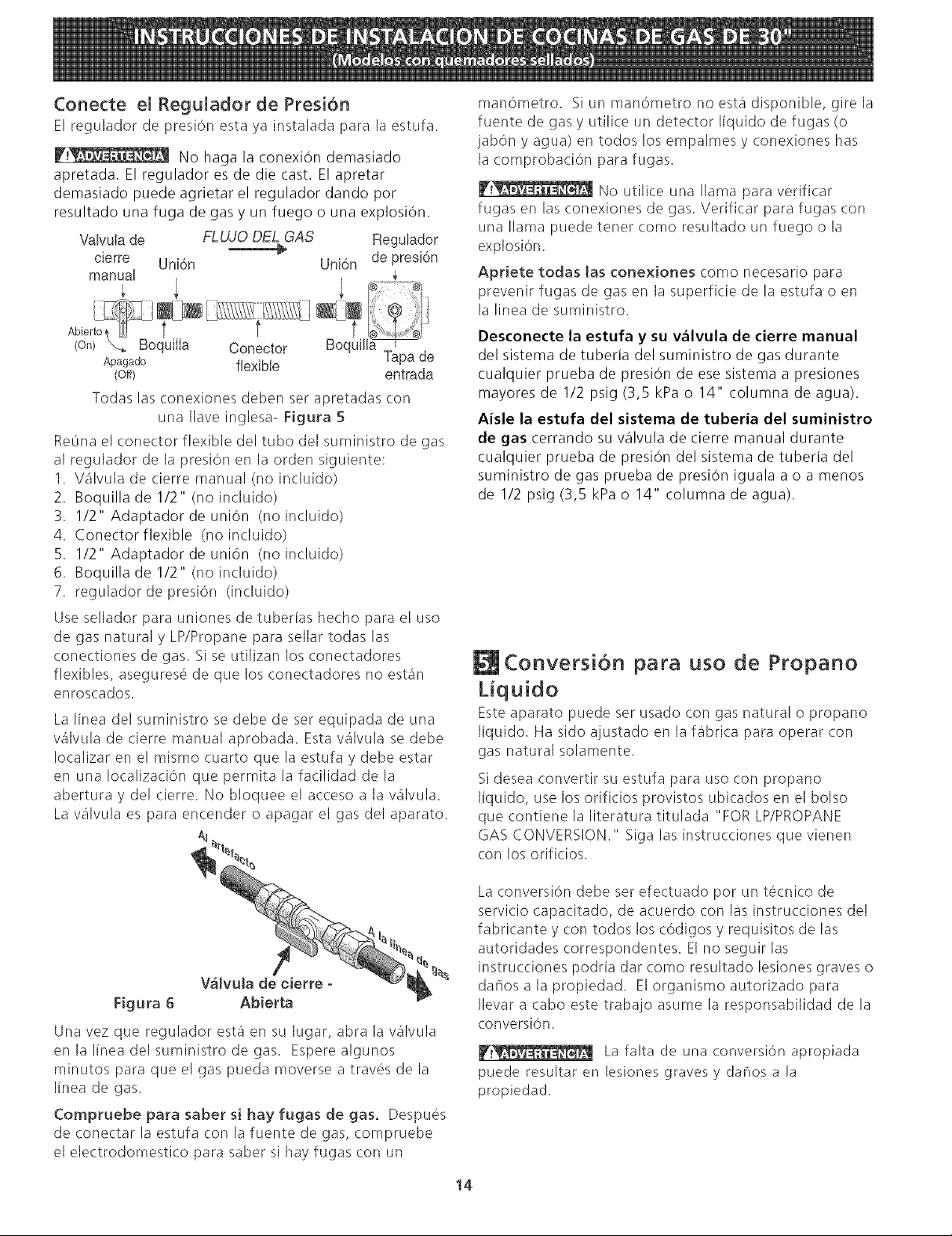

Conecte el Regulador de PresiOn

El regulador de presiOn esta ya instalada para la estufa.

W.__ No haga la conexiOn demasiado

apretada, El regulador es de die cast. El apretar

demasiado puede agrietar el regulador dando per

resultado una fuga de gas y un fuego o una explosion,

Vatvula de FLUJO DEL GAS Regutador

cierre Uni6n Uni6n

manuat

_ de presi6n

manometro, Siunmanometronoestadisponible, girela

fuente de gas y utilice un detector liquido de fugas (o

jabOn y agua) en todos los empalmes y conexiones has

la comprobaciOn para fugas,

W!_ No utilice una llama para verificar

fugas en las conexiones de gas. Verificar para fugas con

una llama puede tenet come resultado un fuego o la

explosi6n.

Apriete todas las conexiones como necesario para

prevenir fugas de gas en la superficie de la estufa o en

la linea de suministro.

(on) _ BoquilIa Conector uitt

Apagade flexible Tapade

(Off) entrada

Todas las conexiones deben set apretadas con

una Ilave inglesa- Figura 5

ReOnael conector flexible del tubo del suministro de gas

al regulador de la presiOn en la orden siguiente:

1. Valvula de cierre manual (no incluido)

2. Boquilla de 1/2" (no incluido)

3. 1/2" Adaptador de union (no incluido)

4. Conectorflexible (no incluido)

5. 1/2" Adaptador de union (no incluido)

6. Boquilla de 1/2" (no incluido)

7. regulador de presiOn (incluido)

Use sellador para uniones de tuber[as hecho para el use

de gas natural y LP/Propane para sellar todas las

conectiones de gas, Si se utilizan los conectadores

flexibles, asegurese de que los conectadores no est&n

enroscados.

La Ilnea del suministro se debe de ser equipada de una

valvula de cierre manual aprobada. Estavalvula se debe

Iocalizar en el mismo cuarto que la estufa y debe estar

en una Iocalizaci6n que permita la facilidad de la

abertura y del cierre. No bloquee el acceso a la v_lvula.

La v_lvula es para encender o apagar el gas del aparato.

Desconecte la estufa y su v_lvula de cierre manual

del sistema de tuberia del suministro de gas durante

cualquier prueba de presiOn de ese sistema a presiones

mayores de 1/2 psig (3,5 kPa o 14" columna de agua),

Aisle la estufa del sistema de tuberia del suministro

de gas cerrando su valvula de cierre manual durante

cualquier prueba de presiOn del sistema de tuberia del

suministro de gas prueba de presion iguala ao a menos

de 1/2 psig (3,5 kPa o 14" columna de agua).

ConversiOn para uso de Propano

Liquido

Este aparato puede ser usado con gas natural o propano

I[quido. Ha sido ajustado en la %brica para operar con

gas natural solamente.

Si desea convertir su estufa para uso con propano

I[quido, use los orificios provistos ubicados en el bolso

que contiene la literatura titulada "FOR LP/PROPANE

GAS CONVERSION." Siga las instrucciones que vienen

con los orificios.

Figura 6 Abierta

Una vez que regulador esta en su lugar, abra la v_lvula

enlallneadelsuministrodegas. Esperealgunos

minutos para que el gas pueda moverse a travOs de la

Ilnea de gas.

Compruebeparasabersihayfugasdegas. Despues

de conectar la estufa con la fuente de gas, compruebe

el electrodomestico para saber si hay fugas con un

La conversi6n debe ser efectuado por un tecnico de

servicio capacitado, de acuerdo con las instrucciones del

fabricante y con todos los cOdigos y requisitos de las

autoridades correspondentes. Elno seguir las

instrucciones podria dar como resultado lesiones graves o

da¢iosalapropiedad. EIorganismoautorizadopara

Ilevar a cabo este trabajo asume la responsabilidad de la

conversi6n.

__ La falta de una conversion apropiada

puede resultar en lesiones graves y darqos a la

propiedad.

14

Page 15

Requisitos eN ctricos

120 voltio, 60 Hertzio, circuito dedicado apropiadamente

puestos a tierra protegido por un circuito de amperio o

fusible de demora de tiempo de 15 amp. Nota: no es

re(omendado instalarlo con un Interruptor (GFI) de

puesta a tierra.

No utilice una extensi6n con esta estufa.

Instrucdones de puesta a tierra

tMPORTANTE Por favor lea con cuidado.

Para Ja seguridad personal, este aparato debe set

puesto a tierra apropiadarnenteo

El cable del suministro electdco de esta estufa est_

equipado con un enchufe de tres patillas (para puesta a

tierra) que coincida con un enchufe de pared est_ndar

con puesta a tierra de tres patillas para minimizar la

posibilidad que se produzcan descargas electdcas.

El cliente debera encargar a un t6cnico para asegurarse

de que el enchufe se encuentra debidemente conectado

a tierra y polarizado.

M_todo refeddo N_i_c°rte'retire° n_

Enchufe de pared Hbe, bajo nmgu

(on toma de _ drcunstanda, Ja ]

tierra _ patiHa de Ja toma del

abledesum n s ro

........... _Np toma de tierra

Figura 7

En lugares en los que aya un enchufe de pared est_ndar

de dos patillas, el cliente tendr_ resposabilidad directa y

la obligation de reemplazado por un enchufe de pared

de tres patillas debidemente cableado a tierra.

Bajo ninguna circunstanda, torte, retire o deribe [a

tercera patHla (de toma de tierra} del cabte del

suministro de energ_a el_ctrica.

F!_ Desenchufa el cable del suministro de

energia electrica del enchufe de pared antes de

mantener la plancha de cocina.

La mudanza de[ aparato para

reparaciones o [impieza

Apague la corriente electrica a la estufa a la fuente de

poder principal, y apague la wilvula de cierre manual de

gas. Aseg0rese de que la estufa este fresca. Quite e! cajOn

de servicio (el caj6n calentador en algunos mode!os) y abre

la puerta de! homo. Levante la frente de la estufa y

deslicela fuera de la abertura sin crear tensi6n desmedida

sobre e! conducto flexible de gas. Aseg0rese de no

pellizque et conducto flexible de gas detr_% de la estufa al

reemplazar la unidad en la abertura. Reemplace el cajOn,

cierre la puerta y enciende el gas y la corriente electrica a

la estufa.

lnstalaci6n de la cocina

Nota importante: No es necesario, pero si es

conveniente, quitar la puerta para instalar el horno.

Consulte las instrucciones para retirar la puerta en la Guia

de Uso y Cuidado.

[nsta[acibn estandard

1. La plancha de cocinar se sobrepone pot encima del

mostrador con sus extremidades y la cocina reposa

sobre el suelo, La plancha de cocinar es 31 1/2" (81

cm) de ancho,

2. Instale la base de los armarios a 30" (76,2 cm) de

espacio entre elias, Aseg0rese que estos esten

verticales y alineados antes de instalar la plancha de

cocinar, Lije el borde de! mostrador para obtener las 31

1/2 (81 cm)" en la parte superior del mostrador,

3. Instale las puertas del armario a 31" (78,7 cm) de

espacio entre elias para que no interfieran con la

abertura de la puerta de la cocina,

4, Corte el mostrador exactamente como en la pa'gina 9.

5. Puede pedir un juego de repuesto con su

representante,

6. Para una instataci6n 6ptima, la superficie superior de la

mesada debe estar nivelada y set plana (sobre el mismo

piano) en los 3 lados adyacentes a la cocina, Se deben

hacer los ajustes correspondientes para hacer que la

parte superior quede plana, de Io contrario podr_in

quedar espacios entre la mesada y la cocina,

7. _ Para reducir el riesgo de daFlar su

artefacto, no Io manipule cerca del vidrio cer4mico.

Manip01elo con cuidado,

8. Coloque la cocina enfrente de la abertura de! armario.

9. Aseg0rese de que el vidrio que est,1 colgado sobre la

mesada deje despejada la mesada, Si es necesario,

levante la unidad bajando las patas de nivelaci6n.

10.Mvele la codna (vea NivelaciOn de la estufa). El piso

donde se instala la cocina debe estar nivelado. Siga las

instrucciones "nivelaciOn de la estufa- modelos

equipado con las patas niveladoras".

11.Ajuste alas piernas de nivelaciOn de manera que la

parte de abajo de la plancha de cocinar est,1 apoyada

contra e! mostrador.

12.Atornille con cuidado en la pata de nivelaciOn trasera

hasta que el vidrio que est,1 colgado toque levemente la

mesada. El vidrio debe soportar el peso de la unidad.

13.Luego, atornille con cuidado en las dos patas de

nivelaciOn anteriores (igual a 12) hasta que el vidrio que

est,1 colgado toque levemente la mesada.

14.Deslice la cocina en la abertura para el corte.

15.Si la estufa no est,1 nivelada, arranque el

electrodomestico y vuelva a ajustar alas piernas o

asegu0rese que el suelo est,1 nivelado.

tnstalaci6n para ta Anchura existente del Recorte de el

29"(73.7 cm) :

1. Usted debe substituir los paneles laterales reales pot los

paneles laterales nuevos y m_s pequdios. Paneles

laterales puede set pedido con su representante.

2. Sigala fuente de lasinstrucciones (:on suspaneles

laterales nuevos para substituir los paneles laterales

15

Page 16

realesporlosnuevos.

3. Compruebesielmostradorestkpreparadoparala

aberturaampliadelrecortede129".

4. Instalelaestufa.

tnstalaci6ncon e[ repuesto.

La profundidad del corte de (21 3/4" (55.2 cm)Min., 22 1/

8" (56.2cm) Max.) necesita ser aumentada a24" (61 cm)

cuando instala el repuesto.

tnstalad6n con el juego de termino de pane[.

Un juego de termino de panel puede ser pedido con su

representante.

tnsta[ad6n con Paneles Laterales Llenos

PanelesLaterales puede ser pedido con su representante.

Instale las puertas de los armarios a 3! " (78.7 cm) de

espacio entre elias para que no interfieran con la abertura

de la puerta de la cocina.

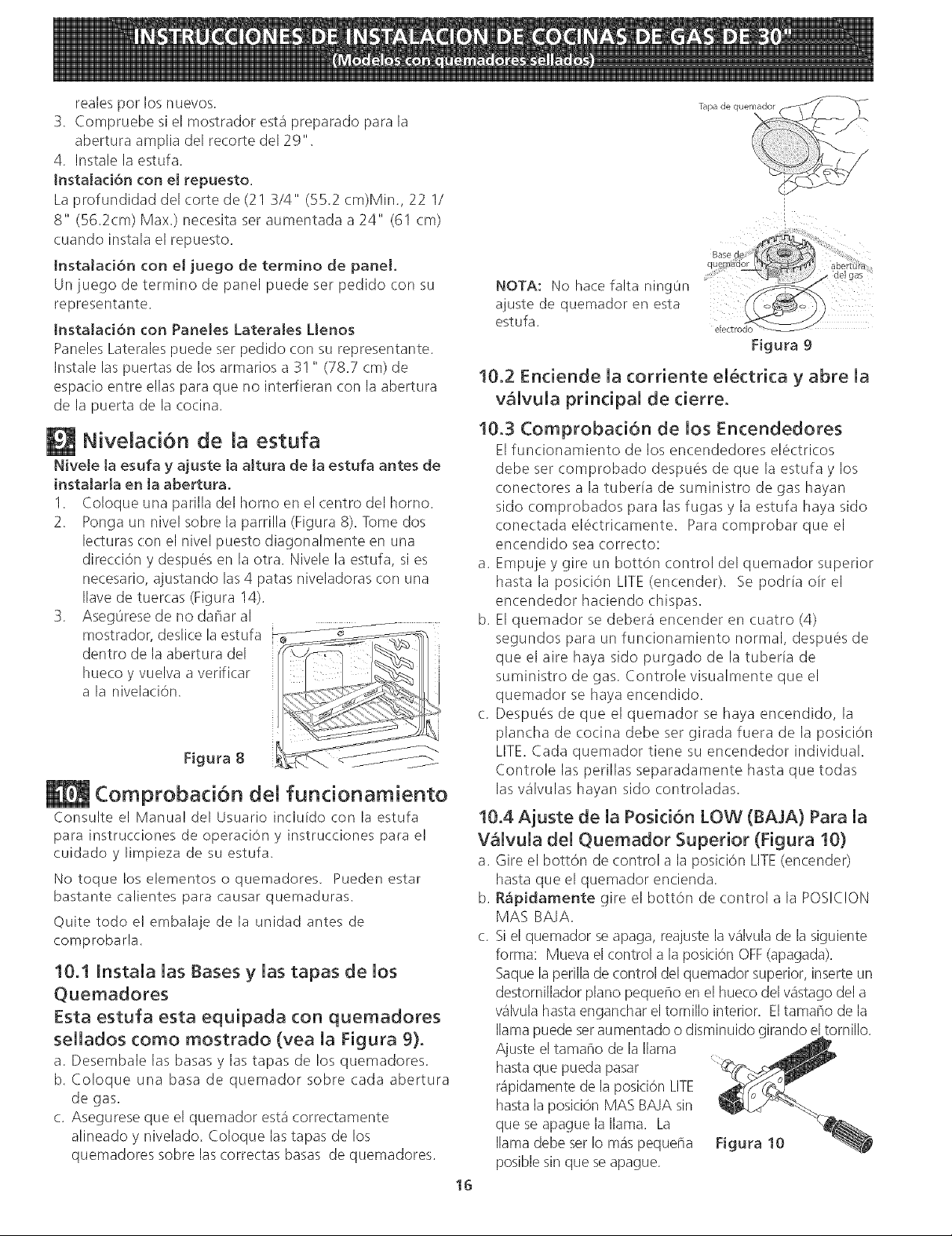

Nivetad6n de la estufa

N[vele [a esufa y ajuste [a a[tura de [a estufa antes de

insta[ar[a en ta abertura.

1. Coloque una parilla del horno en el centro del horno.

2. Ponga un nivel sabre la parrilla (Figura 8). Tome dos

le(turas (:on el nivel puesto diagonalmente en una

direccion y despues en la otra. Nivele la estufa, si es

necesario, ajustando las 4 patas niveladoras con una

Ilave de tuercas (Figura 14).

3. Aseg@resede no dafiaral

mostrador, deslice la estufa __--- _ _.,

dentro de la abertura del S_r-_ J_--.

hueco y vuelva a verificar

a la nivelacion.

F[gura 8

Comprobadon del fundonamiento

Consulte el Manual del Usuario incluido con la estufa

para instrucciones de operaciOn y instrucciones para el

cuidado y limpieza de su estufa.

No toque Ioselementoso quemadores. Pueden estar

bastante calientes para causar quemaduras.

Quite todo el embalaje de la unidad antes de

comprobarla.

10.1 Instala las Bases y las tapas de los

Quemadores

Esta estufa esta equipada con quemadores

sellados coma mostrado (vea la Figura 9}.

a. Desembale las basas y las tapas de los quemadores.

b. Coloque una basa de quemador sabre cada abertura

de gas.

c. Asegurese que el quemador estk correctamente

alineado y nivelado. Coloque lastapas de los

quemadores sabre las correctas basas de quemadores.

I

: i

Base

NOTA: No hace falta ning0n

ajuste de quemador en esta i

estufa.

F[gura 9

10.2 Enciende la corriente el_ctrica y abre la

v&lvula principal de cierre.

10.3 Comprobaci6n de los Encendedores

Elfuncionamiento de los encendedores electricos

debe set comprobado despues de que la estufa y los

conectores a la tuberla de suministro de gas hayan

sido (omprobados para las fugas y la estufa haya sido

conectadaelectricamente. Paracomprobarqueel

encendido sea correcto:

a. Empuje y gire un bott6n control del quemador superior

hastala posici6n LITE(encender). Sepodrlaolrel

encendedor hacienda (hispas.

b. El quemador se debera encender en cuatro (4)

segundos para un funcionamiento normal, despues de

que el aire haya sido purgado de la tuberla de

suministro de gas. Controle visualmente que el

quemador se haya encendido.

c. Despu6s de que el quemador se haya encendido, la

plancha de cocina debe set girada fuera de la posicion

LITE.Cada quemador tiene su encendedor individual.

Controle las perillas separadamente hasta que todas

las valvulas hayan sido controladas.

10.4 Ajuste de la Posici6n LOW (BAJA} Para la

V_lvula del Quemador Superior (Figura 10)

a. Gire el botton de (ontrol a la posici6n LITE(encender)

hasta que el quemador encienda.

b. R_pidamente gire el bott6n de control a la POSIC!ON

MAS BAJA.

c. Siel quemador seapaga, reajuste lav_lvula de la siguiente

farina: Mueva el control a la posi(ion OFF(apagada).

Saque la perilla de (ontrol del quemador superior, inserte un

destornillador piano pequefio en el hue(o del w_stagodel a

%lvula hasta enganchar el tornillo interior. Eltama¢io de la

llamapuede seraumentado o disminuido girando eltomillo.

Ajuste eltama¢io de la llama

hastaque pueda pasar

rkpidamente de la posici6nLITE

hasta la posici6n MAS BAJAsin

que seapague lallama. La

llama debe set Io m& pequdia Figura 10

posiblesin que seapague.

16

Page 17

10.50peradon de Quemadores del Homo y

Ajustes de Homo

10,5,1 Quemadore de ignic6n eJectrica

La operation de los encendores electrJcosdebe de ser

revisada despSesde que lacodna y los conectores de la linea

de sumklJstrohaya sJdocuJdadosamente revJsadapara

descartar fugas y que lacodna hayasido conectada a la

conente electdca.

Elquemador del homo esta equJpado(ion un sJstemade

control electdco asicomo un encendedor de quemador de

homo elOctdco.SJsu moddo esta equJpadocon un

quemador de asadocentral superior, tambJencontara con un

encendedor de quemador electrico. Estossistemasdecontrol

no requieren aiustes. Cuando el homo esta configurado para

operar, B coriente fiuir_ haciael encendedor y tendra un

respBndor de manera similar a una bombi% de luz.Cuando

el encendedor a akanzado una temperatura suficiente para

encender el gas, la%lvula del horno controlada

electricamente seabrira y el fuego aparecera en el quemador

del horno, hay un lapsode tiempo de 30 a 60 segundos

depues de que el termostato seenciende y antes de que la

llama aparezca en el quemador del horno. Cuando el homo

alcanza laconfiguraciOn del dial, el encendedor

resplandeciente se apagara, la llama del quemador

desaparecera por 20 a 30 segundos despuOsde que el

encendedor seapage. Paramantener qualquier temperatura

de homo dada, este ciclo continuara tanto como eldial (o

visualizador)este configurado para operar.

DespuOsde retirar todos los materiales del empaque y la

literatura delhorno:

a) Fiieel homo en HORNEAR(BAKE)a 300°F. Vea la guia de

Usoy Cuidado para conocer lasinstrucciones de

funcionamiento.

b) En60 segundos el quemador del homo seencendera.

Reviseque existaun fuego adecuado, y permita que el

quemador cumpla suciclo una vez. Gire los controladores

haciaoff (APAGADO).

c)Si sumodelo esta equipado con un asadorcentral superior,

fiie el homo en ASAR.Vea la Gu[a de Usoy Cuidado para

conocer lasinstrucciones de funcionamento.

d) En60 segundos el quemador de asardebe de encenderse.

Revisesi existauna llama adecuada. Gire los controles

haciaoff (APAGADO).

10.5.20bturador del Aire ° Quemador del homo

La Iongitud aproximada de la llama del quemador del

homo es 1 pulgada (interior claro, llama azul). Para

determinar si la llama del quemador de homo es la

adecuada, retire elfondodelhomoy el deflectordel

quemador i fiie el homo en la opciOn hornear a 300°F.

Para retirar el fondo del homo, retire los tornillos de

ajuste del homo en la parte posteior del fondo del

horno, jale hacia arriba, desenganche el frente del fondo

del marco anterior del homo, y iale la base hacia a fuera

de 6ste. retire el deflector del quemador de manera que

la llama del quemador pueda ser observada.

Si la llama es de color amarillo, aumente el tamaflo de la

abertura del obturador de aire (Vea el tamaflo "2" en el

grafico de abjo). Si la llama es de azul claro, reduzca el

tamaho de la abertura del obturador de aire. Para ajustar

un tornillo de cierre flojo (Vea el gr_fico "3" de ariba),

vuelva a colocar el obturador de aire, y ajuste el tornillo

de cierre. Reemplace el fondo del horno.

_= Tubos deJ

i quemador

I det homo

Tornillos de

seguridad

@ Obturador ,-¢_J_

de aire _(,11_Tapa

Figura 12

10.5.30bturador de aire - Quemador de asado

La Iongitud aproximada de la llama del quemador de

asado es I pulgada (interior claro, llama azul). Para

determinar si la llama del quemador de asado es la

adecuada, porter el homo en la opciOn asar.

5i la llama es de color amarillo, aumente el tamaflo de

la abertura del obturador de aire (Vea el tamaflo "2"

en el gr_fico de abjo). Si la llama es de azul claro,

reduzca el tamaho de la abertura del obturador de

aire, y ajuste el tornillo de cierre.

de[ o_ificio

Despu_s de Terminar [a _nstalad6n

AsegOresede que todos los controles estOn en la posiciOn

OFF(apagada).

AsegOrese de que e! fhir de! aire de combustion y de

ventilaciOn a la estufa no este obstruido.

Deflector inferior

del horno

(extraible),

}turador altura de la

Quemador a la

aire cintura

Parte nfeior del

_b_Obturador homo (extraible)

deaire Figure 11

Ubicad6n del N0mero de Modelo y de Serie

La placa con e! n0mero de serie esta"ubicada en el

marco delantero del homo detr_%de la puerta de! homo

(algunos modelos) o detr_is del cajOn (algunos modelos).

Cuando haga pedidos de repuestos o solicite informaciOn

con respecto a su estufa, este siempre seguro de incluir

e! n0mero de mode!o y de serie y el n0mero o letra del

Iote de la plata de serie de su estufa.

La placa con e! n0mero de serie tambiOn le da la potencia

nominal de los quemadores, el tipo de combustible y la

presiOn a la cual fue ajustada la estufa en lafiibrica.

17

Page 18

Antes de L[amar a[ Servido

Lea la section Evite Llamadas de Servicio en su Manual del

Usuario. Esto le podr_i ahorrar tiempo y gastos. Esta lista

incluye ocurrencias comunes que no son el resultado de

defectos de materiales o fabricaciOn de este artefacto.

Lea la garantia y la informaciOn sobre e! servicio en su

Manual del Usuario para obtener e! nOmero de te!6fono

gratuito y la direcciOn del servicio.

lnstrucdones de instalad6n de la

fijad6n anti-inclinaci6n

r_ Para reducir el riesgo de inclination de

la cocina, esta debe set asegurada hacia el piso con las

fijaciones de antPinclinaci6n y los tornillos que vienen

con la cocina. Estos componentes se encuentran en el

homo. Si no instala las fijaciones, (orre el riesgo que su

cocina pueda inclinarse si pone demasiado peso en ella

o si un nffio sube sobre esta. Esto podrla ocasionar

graves heridas causadas pot Ilquidos calientes o pot la

propia cocina.

Siga estasinstrucciones para instalar las fijaciones de anti-

inclinacion.

Si lacocina estrasladada a otro lugar, lasfijaciones de anti-

inclinaci_Sndeben tambien ser trasladados (:on la cocina. Rata

controlar la instalaci6n apropiada, yea elpaso n0mero 5.

Herramientas Necesarias:

Llave de tuerca de 5/16"(0,79 cm) o destornillador para

tornillos de (abeza plana

Llave inglesa

Taladro el6ctrico

Broca de 3/16"(0,48 cm) de diametro

Broca para taladro de mamposterla de 3/16"(0,48 cm) de

dla. (si se esta instalando en concreto)

Borde de arras de la

Soporte antivuelco

estufa o pared trasera _..

................

.....9u8 _.. 18,/_"_- _'.

28 118"

Soporte ""-._ _/(71_4 cm)

antivuelco "-.. (Anchuratraserade la

estufa con los lados)

Los soportes sefijan al suelo en la parte trasera de la

estufa para sujetar ambos niveladores de las patas

traseras. Cuando los est6 instalando al piso, aseg0rese de

que los tornillos no penetren el alambrado ele(tri(o o

plomerla. Lostornillos provistos pueden utilizarse en

madera o concreto.

1. Desdoble la plantilla de papel y coloquela plana en

el piso con los bordes laterales y el trasero colocados

exactamente donde la parte trasera y los lados de la

estufa seran colocados cuando sea instalada. (Use el

diagrama siguiente para ubicar los soportes si no se

dispone de la plantilla (Figura 13)).

2. Marque en el piso la ubicacion de los 4 agujeros de

montaje como se muestra en la plantilla. Rata

facilitar la instalacion, se pueden taladrar agujeros

piloto de 3/16" (0.5 cm) de dia. y 1/2" (1.3 cm) de

profundidad en el piso.

3. Saque la plantilla y coloque los soportes en el piso

con la brida hacia arriba dirigida hacia el frente.

Alinee los agujeros en los soportes con las mar(:as en

el piso y sujete (:on los 4 tornillos provistos. Los

soportes deben estar asegurados al piso firme. Si se

va a instalar en piso de concreto, primero debe

taladrar agujeros guia de 3/16" (0.5 cm) de diametro

usando una broca para taladro de mamposteria.

4. Nivele la estufa si es necesario ajustando las cuatro

paras niveladoras (:on una Ilave (Vet la Figura 14

abajo). Se requiere un espacio libre mlnimo de 1/8"

(0.8 cm) entre la parte inferior de la estufa y los

niveladores de las patas traseras para dejar espacio

para los soportes antivuelco.

5. Deslice la estufa a su lugar asegur_ndose de que las

paras traseras esten sujetas pot los extremos de los

soportes. La estufa puede necesitar set movida

ligeramente a un lado cuando est_ siendo empujada

hacia atras para permitir

que las paras se alineen

con los soportes. Usted

tambien puede asir el

borde trasero de la cima

de la estufa y

cuidadosamente intentar

voltearla para asegurarse

de que la estufa sea

adecuadamente

anclada.

Figura 13

eslizar

hacia atras

Figura 14

18

Page 19

UN[NSTALLATEURQUAL[F[EDOlTEFFECTUERL'[NSTALLAT[ONETLESERVICE

iMPORTANT:CONSERVEZCESiNSTRUCTiONSPOURLES[NSPECTEURSLOCAUX.

USEZCESiNSTRUCTiONSETCONSERVEZ-LESPOURR[_F[_RENCESULT[_RJEURES.

__ Si [es instructions de ce manuel ne sont pas suivies & [a [ettre, _ _'_'X

i[ pourrait en r_su[ter un incendie ou une explosion susceptible de causer des

dommages materiels, des b[essures ou m_me [a mort,

POUR VOTRE SIeCUR[T[e:

-- N'entreposez et n'ut[[[sez pas d'essence ou d'autres produ[ts inflammables & Ref6rez-vous _ [a plaque

prox[m[t_ de cet appareH ou de tout autre appare[L signaletique pour la certification

-- QUE FAIRE S! VOUS DitCELEZ UNE ODEUR DE GAZ: d'agence applicable.

• Ne tentez d'a[[umer aucun appareH.

• N'actionnez aucun interrupteur _[ectrique; n'utHisez aucun appareH t_[_phonique de ['_difke.

• Communiquez imm_diatement avec votre foumisseur de gaz en vous servant du t_I_phone d'un voisin.

Suivez [es instructions que [e foumisseur vous donnera.

• S'il vous est impossibJe de rejoindre votre distributeur de gaz, communiquez avec [e service d'incendie.

-- L'instaJIation et ['entretien doivent _tre effectu_s par un instaJIateur qualifi_, un service d°entretien ou de

r_paration accr_dit_ ou [e distributeur de gaz.

30" Min.

panneaux lat6raux plus minces pour ['installation de [a

cuisini_re, Vous devez aussi suivre les instructions pour [a

preparation du dessus de comptoir _h[a section

"Preparation du dessus de comptoir" (voir page 19)

6. LARGEURDE D, PROFONDEUR A E. LARGEUR DE

, LA TABLE DE L'AVANT DE LA

' CUISSON CUISINIERE

:GS/S"(90.5cm 30" (76,2 crn) :_lY2"(g0cm) 28 5/16" (71,9 crn) 30±1116

- :_6 5/8" (9:_cm) (7d,2±0,I5 cm)

NOTE: Le schema de c&blage de ['apparei[ est indus a la fin de ce feui[let.

Imprime aux Etats-Unis

La prise _nurale ou [a bohe de jonction dolt se situer

entre 8" _h17" (203 _h43.2 cm) de ['armoire de droite

et2" _4"(51 & lO,2cm) du plancher

i

m

F. PROFONDEUR G, HAUTEUR DU DESSUS

21 3/4" (55,2 cm) Min. 36 5/8" (93 cm) Max,

22 1/8" (56,2 cm) Max 35 5/8" @05 cm) Min

24" (6I cm) Min siFan

installe un dosseret

PIN 318201673 (0510) Rev

English - pages 1-9

Espano[ - paginas 10-18

Franqais - pages 19-28

Scema de c_blage - pages :_0-:_2

Page 20

NOTE:

1.Necoincez pasIe cordon d'alimentation ou le conduit de gaz entre lemur et I'appareE

ZNe scelIez pas I'appareil aux armoires

Iat6rales.

3.D6gagement minimum de 24" (61 cm)

entre Ia plaque de cuisson et Ia bas de

I'armoire du haut Iorsque Ie dessous de

I'armoire en bois ou en m6tal est prot_g_

par un cetloderme retardateur de flammes

d'un minimum de Y4" (0.64 cm) recouvert

d'une feuilIe de m_taI MSG No. 28, d'acier

inoxydable d'un minimum de 0.015" (0.4

mm), d'aluminium de 0.024" (0.6 mm) ou

de cuivre de 0.020" (0.5 ram).

D6gagement minimum de 30" (76.2 cm)

Iorsque I'armoire n'est pas protegee.

5. Notez que pour les ouvertures de moins de

22 7/8" (58.1 cm), I'appareil d6passera

I6g_rement vers I'avant du comptoir.

6.Allouez au moins 19 Y4" (48.9 cm)

d'espace pour permettre I'ouverture de la

porte du four.

Porte ouverte

(voir la note 5)

"%.

21%"

(55,25 cm

anneau lateral

Figure 1

A

***IM PORTANT:Pour une targeur de d_coupage (dimension E} plus grande que 30 !/16" (76.4

cm) et pour _viter un bris de vitre, au moment d'ins_rer J'appareiJ darts Jecomptoir assurez-vous qu'il

est bien centr_ darts ['ouverture. Levez [es pattes de nive[lement au maximum, ins_rez ['apparel[ darts

te comptoir et ensuite nivelez-le, Assurez-vous que l'appareil est bien supporte par les

pattes de niveHement et non par la surface vitrifiee.

IMPORTANT: La margeurdu comptoir et

de re'armoiredolt _tre _gale a mamargeur

de d_coupage.

22 7/8" (58.1 cm) min.

23 1/4" (59.05 cm) max.

(see note 4)

E

DEVANT

DU

CABINET

1 1/8"

(2.86 cm)

E

F_

A. HAUTEUR B" LARGEUR C. LARGEUR DE

:_5 5/8" (905 cm 30" (76,2 crn) 3I/2" (80 cm) 28 5/16" (71,9 cm)

- 36 5/8" (9_ cm)

m LA TABLE DE L'AVANT DE LA

" " CUISSON CUISINIERE

DECOUPAGE*£*

(Comptoir & armoire)

30_+1116 21 3/4" (5_,2 cm) Min. 36 5/8" (93 cm) Max,

(76,2_+0,I5 c:m) 22 I/8" (56,2 cnl) Max 35 5/8" (90_ cm) Min

DE G. HAUTEUR DU DESSUS

24" (6I cm) Min sil'on

installe un dosseret

!

Ref,

2O

Page 21

Notes importantes a lqnstallateur

1. Lisez toutes les instructions contenues dans ce feuillet

avant d'installer la cuisiniere,

2. Enlevez tout le materiel d'emballage des compartiments

du four avant de connecter I'alimentation de gazet

electrique _] la cuisiniere.

3, Respectez tousles codes et reglements applicables.

4. N'oubliez pas de laisser ces instructions au

consommateur.

Note importante au consommateur

Conservez ces instructions avec le guide de I'utilisateur

pour reference ulterieure.

INSTRUCTIONS DE S¢:CURIT¢:

IMPORTANTES

Cette cuisiniere dolt 6tre insta!lee conformement aux

reglements !ocaux, ou en leurs absences, aux normes

ANSI Z223,1/NFPA ,54- derniere edition.

La conception de cette cuisiniere a ete approuvee par

CSA international, II faut prendre certaines precautions

d'usage Iors de I'utilisation de tout appareil fonctionnant

au gaz naturel ou produisant de la chaleur, Vous

trouverez celles-ci dans votre Guide d'utilisateur, lisez-les

avec attention.

, Assurez-vous que votre cuisiniere est

correctement installee et raise a la terre par un

installateur ou un techniden d'entretien qualifie.

, Le circuit electrique de cette cuisiniere dolt _tre

mis _ la terre conformement aux reglements

Iocaux, ou en leurs absences, au code electrique

ANSI/NFPA No,70oderniere edition. Voir les

instructions de mise _] la terre.

Avant d'installer la cuisiniere & un endroit

recouvert de linoleum ou de tout autre

couvre-plancher synthetique, assurez=vous que

celuFci peut resister a un minimum de 9O°F

(32.2°C) de chaleur au=dessus de la temperature

de la piece sans se rapetisser, se deformer ou se

decolorer. N'installez pas la cuisiniere sur un tapis, _]

moins de placer un tampon isolant ou une feuille de

contreplaque d'une epaisseur de ¼" (0.6 cm) entre la

cuisiniere et le tapis.

Toutes les

peuvent

basculer.

cuisinieres

Des blessures

pourraient

survenir,

Installer les

arnarres qui

accompagnent

la cuisiniere.

Pour prevenir tout risque de

basculement de la cuisiniere,

cet appareil dolt 6tre fixe

correctement au plancher _]

I'aide des amarres qui

I'accompagnent, Pour

verifier si les amarres sont

posees correctement, retirer

le tiroir de rangement et

s'assurer que lesamarres

sont enclenchees.