Frigidaire CFEB27S2FB1, CFEB27S2FB2, CFEB27S2FS1, CFEB27S2FS2, CGEB27S7CB2 Installation Guide

...

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

FOR YOUR SAFETY: Do not store or use gasoJine or other flammabJe vapors and Jiquids in

the vicinity of this or any other appliance.

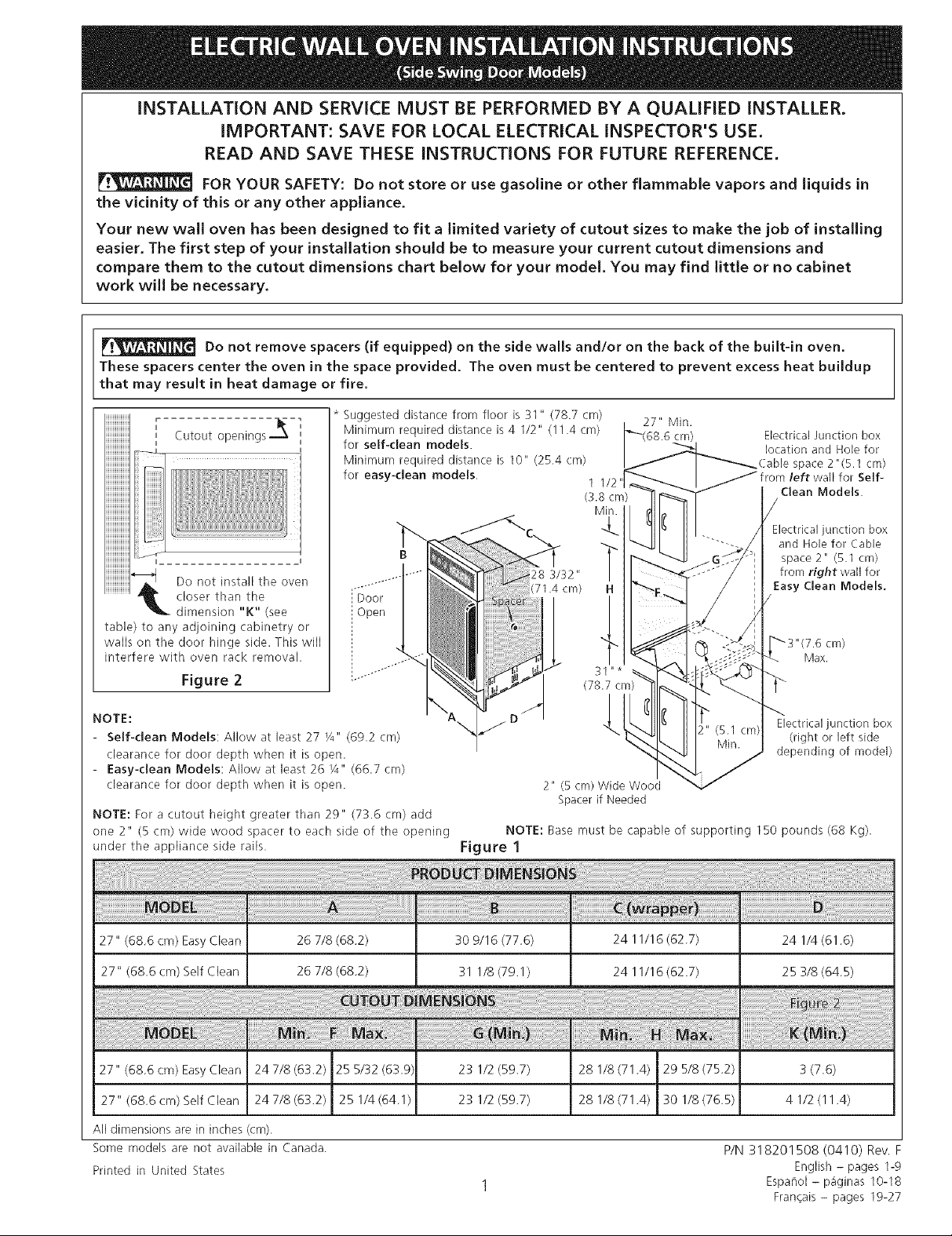

Your new wall oven has been designed to fit a limited variety of cutout sizes to make the job of installing

easier. The first step of your installation should be to measure your current cutout dimensions and

compare them to the cutout dimensions chart beJow for your model You may find httle or no cabinet

work will be necessary.

Do not remove spacers (if equipped) on the side wails and/or on the back of the built-in oven.

These spacers center the oven in the space provided. The oven must be centered to prevent excess heat buildup

that may resuJt in heat damage or fire.

* Suggested distance from floor is 31" (78.7 cm)

[ Cutout openings--_-]

I I

,_Do not install tt_e oven

closer than the

dimension "K" (see

table) to any adjoining cabinetry or

walls on tile door hinge side. This will

interfere with oven rack removal.

Figure 2

NOTE:

- Self-clean Models: Allow at least 27 X" (69.2 cm)

clearance for door depth when it is open.

- Easy-dean Models: Allow at least 26 X" (66.7 cm)

clearance for door depth when it is open.

NOTE: For a cutout height greater titan 29" (73.6 cm) add

one 2" (5 cm) wide wood spacer to each side of the opening

under tt_e appliance side rails.

Minimum required distance is 4 1/2" (11.4 cm)

for self-dean models.

Minimum required distance is 10" (25.4 cm)

for easy-clean models

i Door

::Open

27" Min.

cm}

1 1/2"

(3.8 cm)

Min.

28 3132"

H

31 "*

(78.7

2" (B cm} Wide Wood

Spacer if Needed

Electrical Junction box

location and Hole for

NOTE: Basemust be capable of supporting 150 pounds (68 Kg).

Figure 1

space 2"(5.1 cm)

left wall for Self-

Clean Models.

Electrical junction box

and Hole for Cable

space 2" (5.1 cm}

from right wall for

Easy Clean Models.

cm)

Max.

Electrical junction box

(right or left side

depending of model)

27" (68.6 cm) EasyClears 26 7/8 (68.2)

27" (68.6 cm) Self Clean 26 7/8 (68.2)

27" (68.6 cm) EasyClears 24 7/8 (63.2)

27" (68.6 cm) Self Clean 24 7/8 (63.2)

All dimensions are in inches (cm).

Some models are not available in Canada.

Printed in United States

25 5/32 (63.9}

25 1/4(64.1)

30 9116 (77.6) 24 11/I 6 (62.7) 24 1/4 (61.6)

31 1/8 (79.1) 24 11/I 6 (62.7) 25 3/8 (64.5)

231/2(59.7) 281/8(71.4) 295/8(75.2) 3(7.6)

231/2(59.7) 281/8(71.4) 301/8(76.5) 41/2(11.4)

PIN 318201508 (0410) Rev.

English - pages 1-9

EspaF_ol- paginas 10-18

Fran_ais - pages 19-27

Important Notes to the Installer

I. Read all instructions contained in these installation

instructions before installing the wall oven.

2. Remove all packing material from the oven

compartments before connecting the electrical supply to

the wall oven.

3. Observe all governing codes and ordinances.

4. Be sure to leavethese instructions with the consumer.

5. THESEOVENS ARE NOT APPROVED FOR STACKABLE

OR SIDE-BY-SIDE INSTALLATION.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT AFETY

INSTRUCTIONS

* Be sure your wall oven is installed and grounded

properly by a qualified installer or service

technician.

* This wall oven must be electrically grounded in

accordance with local codes, in their absence,

with the National Electrical Code ANSI/NFPA No.70

- latest edition in the United States, or with CSA

Standard C22.1, Canadian Electrical Code, Part 1, in

Canada

Stepping, leaning or sitting on the

door of this wall oven can result in serious injuries

and can also cause damage to the wall oven.

* Never use your wall oven for warming or heating

the room. Prolonged use of the wall oven without

adequate ventilation can be dangerous.

grounded branch circuit, protected by a circuit breaker or

fuse, having amperage as noted on the rating plate (the

rating plate is located on the oven frame).

Observe all governing codes and local ordinances

I. A 3-wire or 4-wire single phase 120/240 or 120/208

Volt, 60 HzAC only electrical supply is required on

a separate circuit fused on both sides of the line

(time-delay fuse or circuit breaker is recommended).

DO NOT fuse neutral. The fuse size must not exceed

the circuit rating of the appliance specified on the

nameplate. Consideration must be given for a

combination built-in oven and cooktop refer to unit

serial plate of each.

NOTE: Wire sizes and connections must conform with

the fuse size and rating of the appliance in accordance

with the American National Electrical Code ANSI/NFPA

No. 70-latest edition, or with Canadian CSA Standard

C22.1, Canadian Electrical Code, Part I, and local codes

and ordinances.

An extension cord should not be used

with this appliance. Such use may result in a fire,

electrical shock, or other personal injury.

2. The appliance should be connected to the fused

disconnect (or circuit breaker) box through flexible

armored or nonmetallic sheathed cable. The flexible

armored cable extending from the appliance should

be connected directly to the junction box. The

junction box should be located as shown in figure 1

with as much slack as possible remaining in the

cable between the box and the appliance, so it can

be moved if servicing is ever necessary.

3. A suitable strain relief must be provided to attach

the flexible armored cable to the junction box.

The electrical power to the oven must

be shut off while line connections are being made.

Failure to do so could result in serious injury or

death.

1. Carpentry

Refer to figure 1 and 2 for the dimensions applicable to

your appliance, and the space necessary to receive the

oven. The oven support surface may be solid plywood or

similar material, however the surface must be level from

side to side and from front to rear. Leave the bottom of

the cabinet partially opened to permit free air

circulation, otherwise water condensation may appear

inside the control panel when operating the oven.

2. Electrical Requirements

This appliance must be supplied with the proper voltage

and frequency, and connected to an individual, properly 2

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the junction box before

making the electrical connection.

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

• Do not use the gas supply line for grounding

the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

Wait at least three (3) hours after

receivingthisbuilt-inovenbeforeswitchingthepoweron

to preventpossibledamageto thebuilt-inovencontrol

atpoweron.

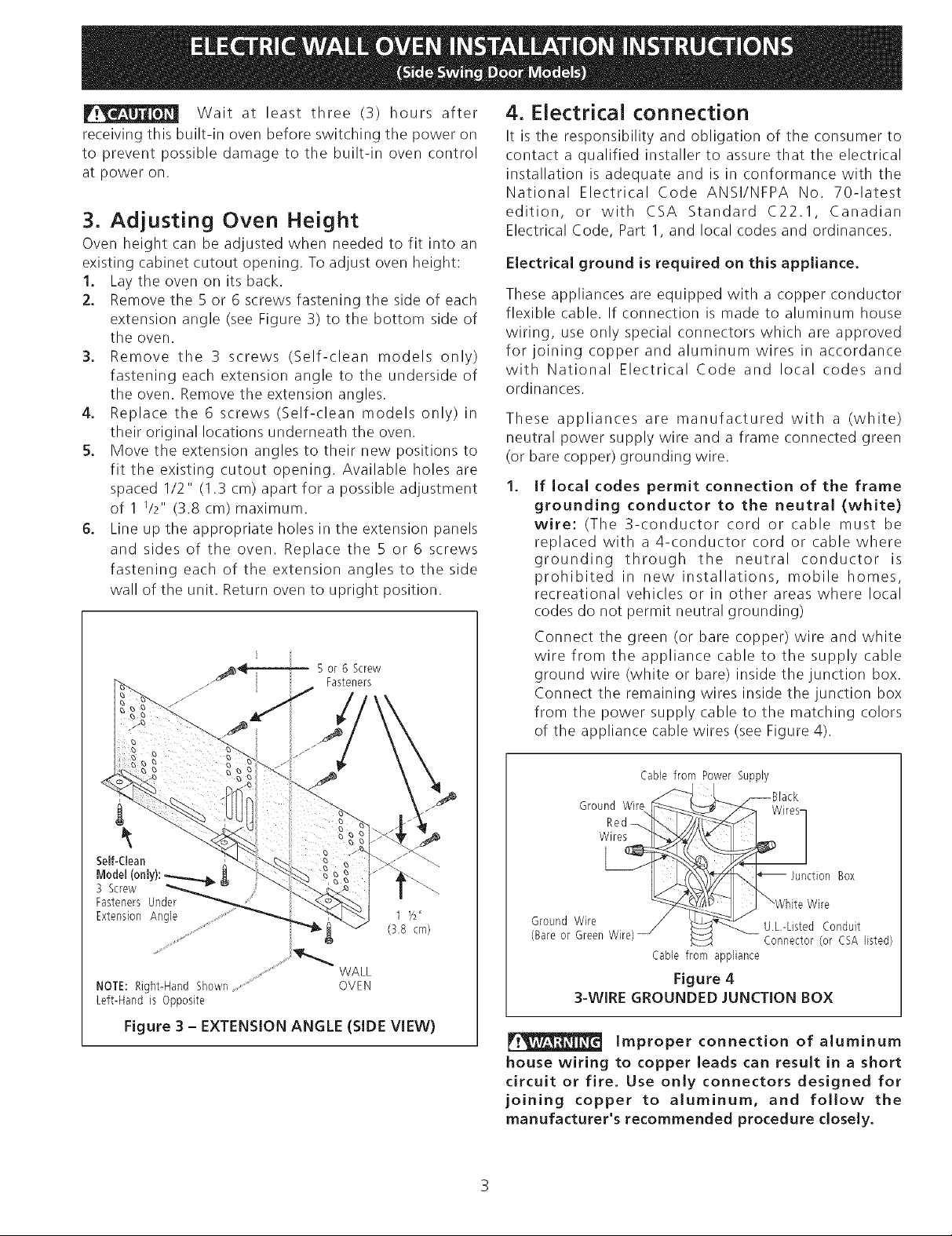

3. Adjusting Oven Height

Oven height can be adjusted when needed to fit into an

existing cabinet cutout opening. To adjust oven height:

1. Lay the oven on its back.

2. Remove the 5 or 6 screws fastening the side of each

extension angle (see Figure 3) to the bottom side of

the oven.

3. Remove the 3 screws (Self-clean models only)

fastening each extension angle to the underside of

the oven. Remove the extension angles.

4. Replace the 6 screws (Self-clean models only) in

their original locations underneath the oven.

5. Move the extension angles to their new positions to

fit the existing cutout opening. Available holes are

spaced 1/2" (I .3 cm) apart for a possible adjustment

of 1 1/2" (3.8 cm) maximum.

6. Line up the appropriate holes in the extension panels

and sides of the oven. Replace the 5 or 6 screws

fastening each of the extension angles to the side

wall of the unit. Return oven to upright position.

5 or 6 Screw

Fasteners

4. Electrical connection

It is the responsibility and obligation of the consumer to

contact a qualified installer to assure that the electrical

installation is adequate and is in conformance with the

National Electrical Code ANSI/NFPA No. 70-latest

edition, or with CSA Standard C22.1, Canadian

Electrical Code, Part I, and local codes and ordinances.

Electrical ground is required on this appliance.

These appliances are equipped with a copper conductor

flexible cable. If connection is made to aluminum house

wiring, use only special connectors which are approved

for joining copper and aluminum wires in accordance

with National Electrical Code and local codes and

ordinances.

These appliances are manufactured with a (white)

neutral power supply wire and a frame connected green

(or bare copper) grounding wire.

If local codes permit connection of the frame

grounding conductor to the neutral (white)

wire: (The 3-conductor cord or cable must be

replaced with a 4-conductor cord or cable where

grounding through the neutral conductor is

prohibited in new installations, mobile homes,

recreational vehicles or in other areas where local

codes do not permit neutral grounding)

Connect the green (or bare copper) wire and white

wire from the appliance cable to the supply cable

ground wire (white or bare) inside the junction box.

Connect the remaining wires inside the junction box

from the power supply cable to the matching colors

of the appliance cable wires (see Figure 4).

Self-Clean

Model (0nly): _

3 Screw

Fasteners Under

Extension Angle

....... WALL

NOTE: Right-Hand Shown.....................................OVEN

Left-Hand is Opposite

Figure 3 - EXTENSION ANGLE (SIDE VIEW)

Cable from Power Supply

Ground Wire

Red

Box

Wire

Ground Wire U.L.-Listed Conduit

(Bare or Green Wire Connector (or CSAlisted)

Cable from appliance

Figure 4

3-WIRE GROUNDED JUNCTION BOX

Improper connection of aluminum

house wiring to copper leads can result in a short

circuit or fire. Use onJy connectors designed for

joining copper to aluminum, and folJow the

manufacturer's recommended procedure doseJy.

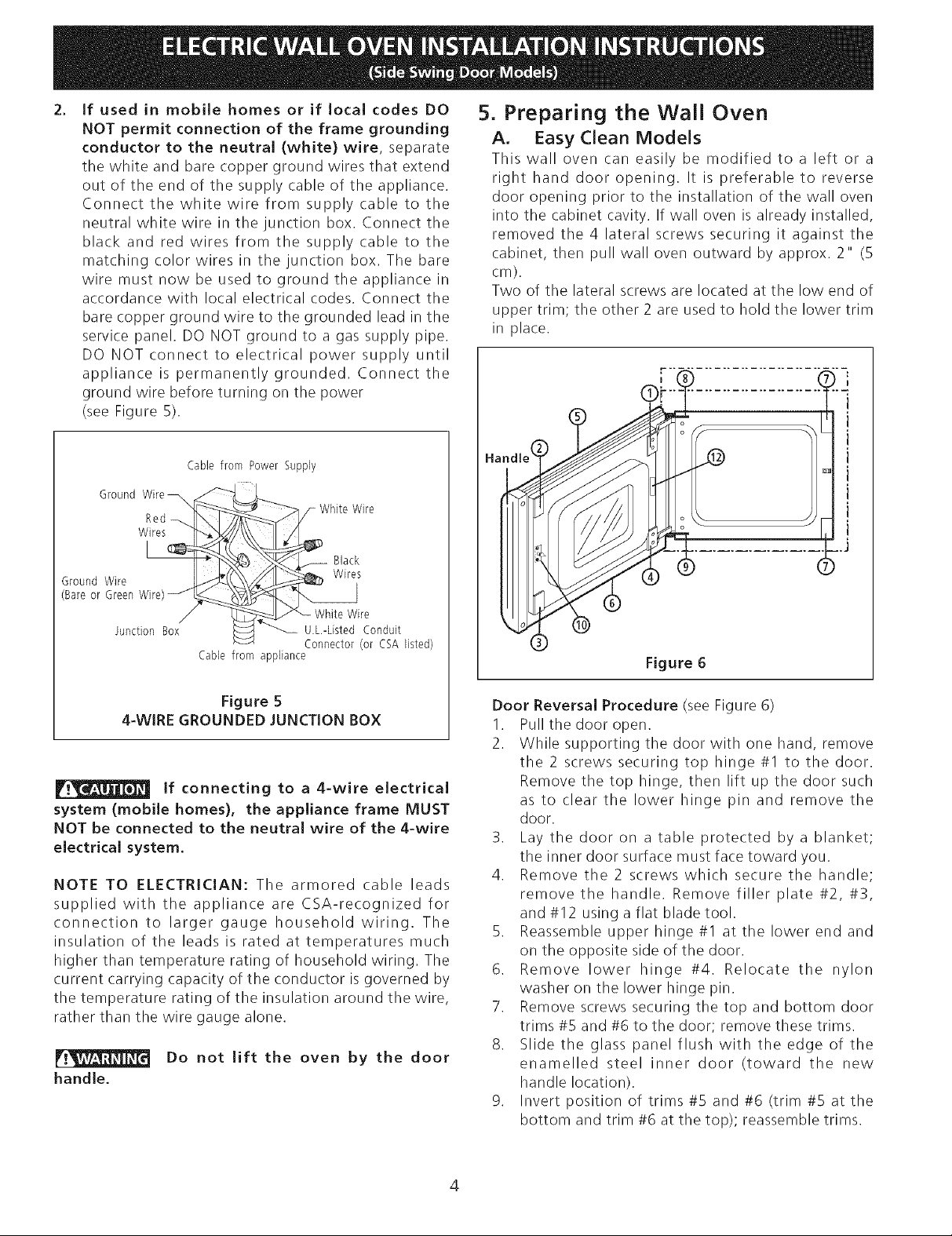

If used in mobile homes or if local codes DO

NOT permit connection of the frame grounding

conductor to the neutral (white) wire, separate

the white and bare copper ground wires that extend

out of the end of the supply cable of the appliance.

Connect the white wire from supply cable to the

neutral white wire in the junction box. Connect the

black and red wires from the supply cable to the

matching color wires in the junction box. The bare

wire must now be used to ground the appliance in

accordance with local electrical codes. Connect the

bare copper ground wire to the grounded lead in the

service panel. DO NOT ground to a gas supply pipe.

DO NOT connect to electrical power supply until

appliance is permanently grounded. Connect the

ground wire before turning on the power

(see Figure 5).

Cable from Power Supply

Ground Wire

Red_l\. _

_White Wire

_ Black

Ground Wire _t_--_ _ W,res

(Bareor Green Wire)_/_

Junction Box _ _ U.L.-Listed Conduit

/

Cable from appliance

rid,,,,,,,,_

White Wire

Connector (or CSA listed)

5. Preparing the Wall Oven

A. Easy dean Models

This wall oven can easily be modified to a left or a

right hand door opening. It is preferable to reverse

door opening prior to the installation of the wall oven

into the cabinet cavity. If wall oven is already installed,

removed the 4 lateral screws securing it against the

cabinet, then pull wall oven outward by approx. 2" (5

cm).

Two of the lateral screws are located at the low end of

upper trim; the other 2 are used to hold the lower trim

in place.

0D

Figure 6

Figure 5

4-WIRE GROUNDED JUNCTION BOX

If connecting to a 4-wire electrical

system (mobile homes), the appliance frame MUST

NOT be connected to the neutral wire of the 4-wire

electrical system.

NOTE TO ELECTRICIAN: The armored cable leads

supplied with the appliance are CSA-recognized for

connection to larger gauge household wiring. The

insulation of the leads is rated at temperatures much

higher than temperature rating of household wiring. The

current carrying capacity of the conductor is governed by

the temperature rating of the insulation around the wire,

rather than the wire gauge alone.

Do not lift the oven by the door

handle.

Door Reversal Procedure (see Figure 6)

1. Pull the door open.

2. While supporting the door with one hand, remove

the 2 screws securing top hinge #1 to the door.

Remove the top hinge, then lift up the door such

as to clear the lower hinge pin and remove the

door.

3. Lay the door on a table protected by a blanket;

the inner door surface must face toward you.

4. Remove the 2 screws which secure the handle;

remove the handle. Remove filler plate #2, #3,

and #12 using a flat blade tool.

5. Reassemble upper hinge #I at the lower end and

on the opposite side of the door.

6. Remove lower hinge #4. Relocate the nylon

washer on the lower hinge pin.

7. Remove screws securing the top and bottom door

trims #5 and #6 to the door; remove these trims.

8. Slide the glass panel flush with the edge of the

enamelled steel inner door (toward the new

handle location).

9. Invert position of trims #5 and #6 (trim #5 at the

bottom and trim #6 at the top); reassemble trims.

I0. Reassemblethehandleandfillerplates#2,#3and

#12ontheoppositesideof thedoor.

11.Removeandrelocatethe filler plates#7on the

oppositesideoftheovenframe.

12.Removethelatchpin#10andrelocatelatchon

theoppositesideoftheovendoor.

13.Invertpositionsof#8and#9hingefixedparts(ex.

fromtopleftsidebottomrightside).

14.Reassemblethedoorontowall oven;insertdoor

intothe fixedlowerhinge,the proceedwith the

reassemblyoftheupperhinge.Aligndoorbyusing

availableplayinthehingeholes.

B. Serf Clean ModeJs

The lower front trim is packed separately and should

not be attached until the oven is in place in the

cabinet cutout.

Removing the Oven Door - Oven Door Reversal

The electrical power to the oven must be shut off

when reversing the door opening. Failure to do so

could result in serious injury or death.

The door on this wall oven is equipped with reversible

hinges, therefore allowing the door to be reversed

from a left hand door (right side opening) as shipped

from the factory to a right hand door (left side

opening).

Tools required: No.2 Phillips@ and No.2 Robertson @

screw drivers, 1/2" open key, small flat-blade screw

driver, long nose pliers.

Procedure for Door Reversal

I. Remove moulding from under the door if installed

(held in place with 2 screws).

2. Keep the door closed and use a 1/2" open key or

a No. 2 Robertson@ screw driver to unscrew and

remove the threaded pin from the lower hinge.

Save the pin for later use.

3. Support the weight of the door with one hand and

open the door about 5" (12.7 cm), then slide the

lower end of the door outside the hinge. Save the

washer of the lower hinge. Grasp the door with

both hands and lower the door off the oven.

The door is heavy; hold it firmly.

4. Gently lay the door on a work table. The door

internal panel should lay face down.

5. Remove the nylon slide (and retainer screw) and

save for use later. Remove the other 2 screws in

the underside of the door plus the 3 screws in the

upper side of the door.

6. Grasp the handle. Lift and remove the outer door

assembly (glass/frame/handle).

7. Unscrew and switch the bumper (with screw and

nut) and the ball screw (and nut).

To reverse the door opening, hire an experienced

technician to prevent any damage to parts or door

alignment problems.

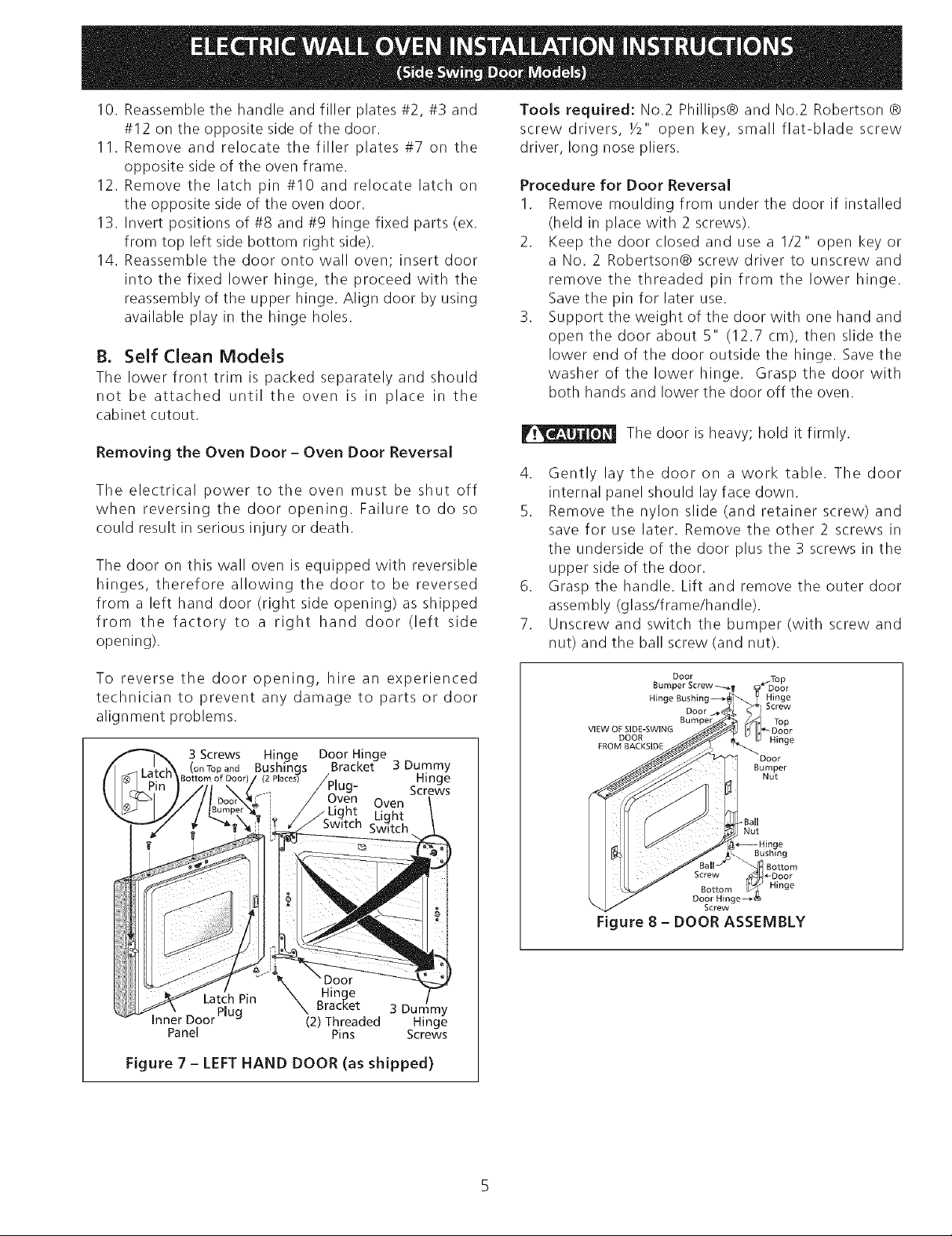

3 Screws

(on Top and

Latch Pin Hinge

Inner Door Plug (2) Threaded Hinge

Panel Pins Screws

Door Hinge

Bracket 3 Dummy

Bracket 3 Dummy

Oven

Light

Sw_tch

Hinge

Screws

Figure 7 - LEFT HAND DOOR (as shipped}

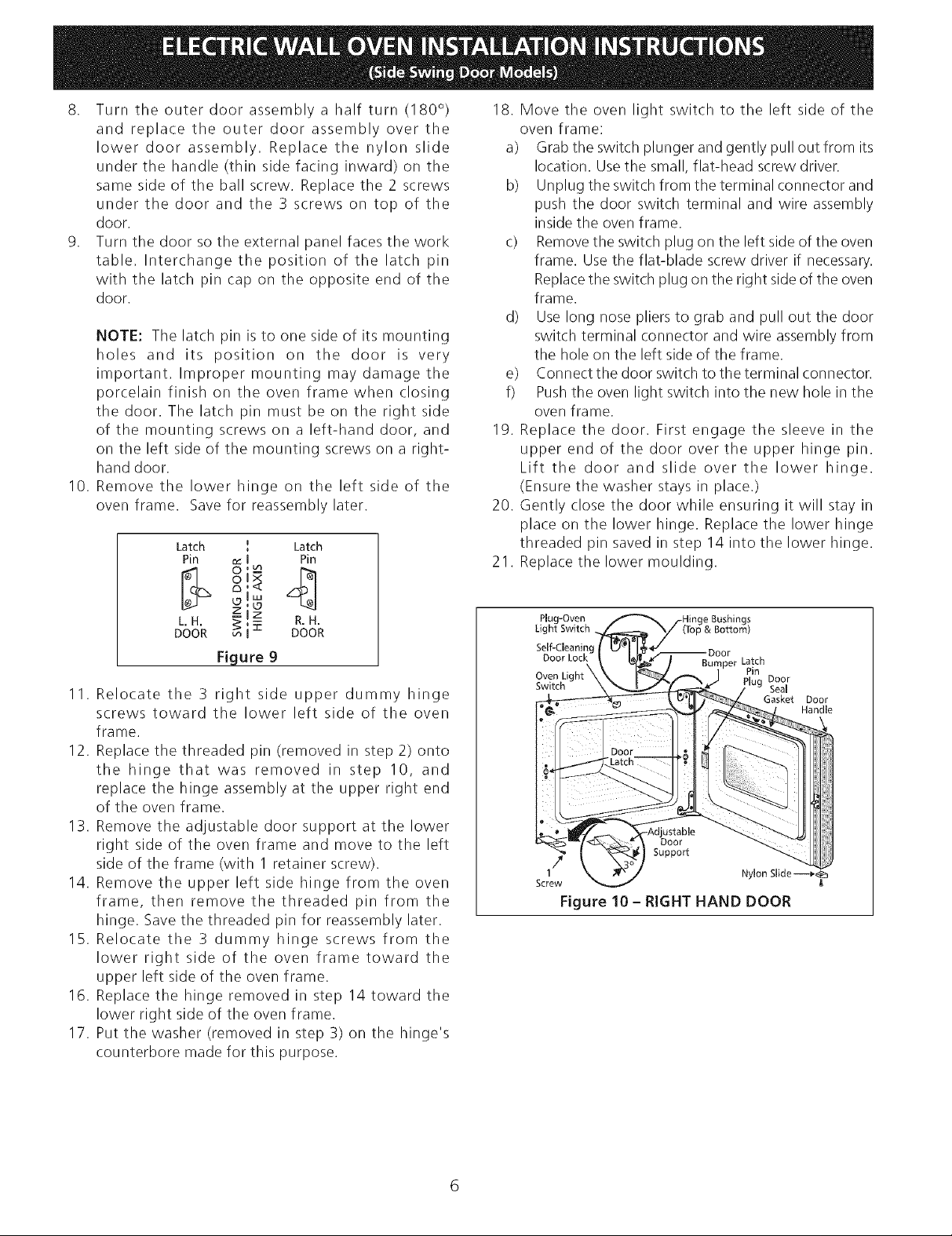

Door Top

Bumper Screw-_-_t _JDoo r

Hinge Bushing_]"_. _ Hinge

DOOR Hinae

FROM BACKSIDE

Door ' _k_. crew,TopViEW OF SIDE-SWING " Door

i Bo,_Nut

_Hinge

k. Bushing

Screw _÷Door

Bottom _ Hinge

Door Hinge_

Screw

Nut

Bumper

Door

"" , Bottom

Figure 8 - DOOR ASSEMBLY

8. Turnthe outerdoorassemblyahalfturn (180°)

andreplacethe outer doorassemblyoverthe

lower door assembly.Replacethe nylonslide

underthehandle(thinsidefacinginward)onthe

samesideofthe ballscrew.Replacethe2 screws

underthe door andthe 3 screwson top of the

door.

9. Turn the door so the external panel faces the work

table. Interchange the position of the latch pin

with the latch pin cap on the opposite end of the

door.

NOTE: The latch pin is to one side of its mounting

holes and its position on the door is very

important. Improper mounting may damage the

porcelain finish on the oven frame when closing

the door. The latch pin must be on the right side

of the mounting screws on a left-hand door, and

on the left side of the mounting screws on a right-

hand door.

10.

Remove the lower hinge on the left side of the

oven frame. Save for reassembly later.

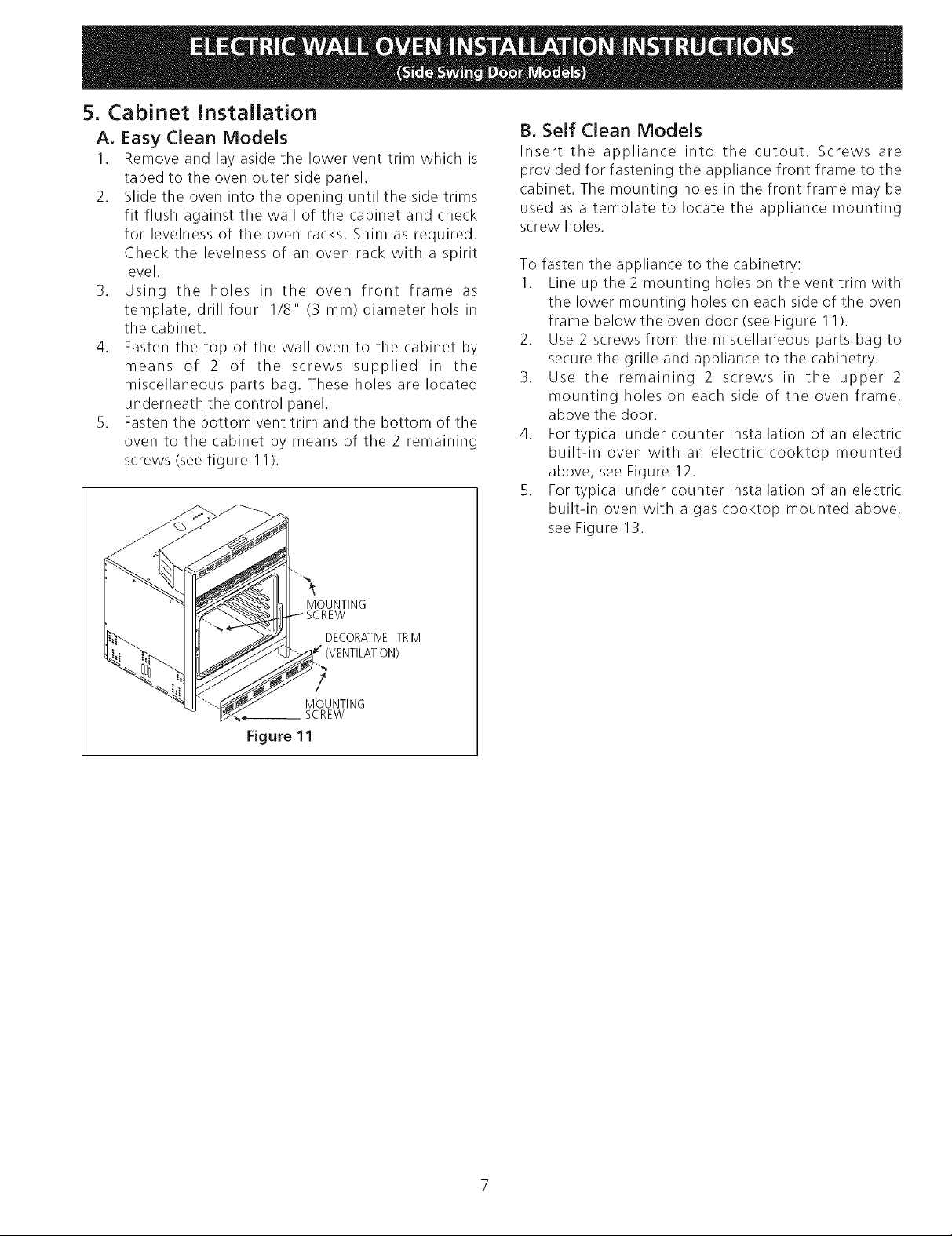

Latch _, Latch

Pin _ I Pin

18. Move the oven light switch to the left side of the

over frame:

a) Grab the switch plunger and gently pull out from its

location. Usethe small, flat-head screw driver.

b) Unplug the switch from the terminal connector and

push the door switch terminal and wire assembly

inside the oven frame.

c) Removethe switch plug on the left side of the oven

frame. Use the flat-blade screw driver if necessary.

Replacethe switch plug on the right sideof the oven

frame.

d) Use long nose pliers to grab and pull out the door

switch terminal connector and wire assembly from

the hole on the left side of the frame.

e) Connect the door switch to the terminal connector.

f) Pushthe oven light switch into the new hole in the

over frame.

19. Replace the door. First engage the sleeve in the

upper end of the door over the upper hinge pin.

Lift the door and slide over the lower hinge.

(Ensure the washer stays in place.)

20. Gently close the door while ensuring it will stay in

place on the lower hinge. Replace the lower hinge

threaded pin saved in step 14 into the lower hinge.

21. Replace the lower moulding.

Iz

L.H. Ri. _ R.H.

DOOR DOOR

Figure 9

11. Relocate the 3 right side upper dummy hinge

screws toward the lower left side of the oven

frame.

12. Replace the threaded pin (removed in step 2) onto

the hinge that was removed in step 10, and

replace the hinge assembly at the upper right end

of the oven frame.

13. Remove the adjustable door support at the lower

right side of the oven frame and move to the left

side of the frame (with 1 retainer screw).

14. Remove the upper left side hinge from the oven

frame, then remove the threaded pin from the

hinge. Save the threaded pin for reassembly later.

15. Relocate the 3 dummy hinge screws from the

lower right side of the oven frame toward the

upper left side of the oven frame.

16. Replace the hinge removed in step 14 toward the

lower right side of the oven frame.

17. Put the washer (removed in step 3) on the hinge's

counterbore made for this purpose.

Plug-Oven

Light Switch

Self-Cleanin_

Oven Lk

Switch

Door

/

1 Nylon

Screw

Support

Figure 10 - RIGHT HAND DOOR

Latch

Gasket Door

Door

Seal

Handle

5. Cabinet Installation

A. Easy Clean Models

I. Remove and lay aside the lower vent trim which is

taped to the oven outer side panel.

2. Slide the oven into the opening until the side trims

fit flush against the wall of the cabinet and check

for levelness of the oven racks. Shim as required.

Check the levelness of an oven rack with a spirit

level.

3. Using the holes in the oven front frame as

template, drill four I/8" (3 ram) diameter hols in

the cabinet.

4. Fasten the top of the wall oven to the cabinet by

means of 2 of the screws supplied in the

miscellaneous parts bag. These holes are located

underneath the control panel.

5. Fasten the bottom vent trim and the bottom of the

oven to the cabinet by means of the 2 remaining

screws (seefigure 1I).

B. Self Clean Models

Insert the appliance into the cutout. Screws are

provided for fastening the appliance front frame to the

cabinet. The mounting holes in the front frame may be

used as a template to locate the appliance mounting

screw holes.

To fasten the appliance to the cabinetry:

1. Line up the 2 mounting holes on the vent trim with

the lower mounting holes on each side of the oven

frame below the oven door (see Figure 11).

2. Use 2 screws from the miscellaneous parts bag to

secure the grille and appliance to the cabinetry.

3. Use the remaining 2 screws in the upper 2

mounting holes on each side of the oven frame,

above the door.

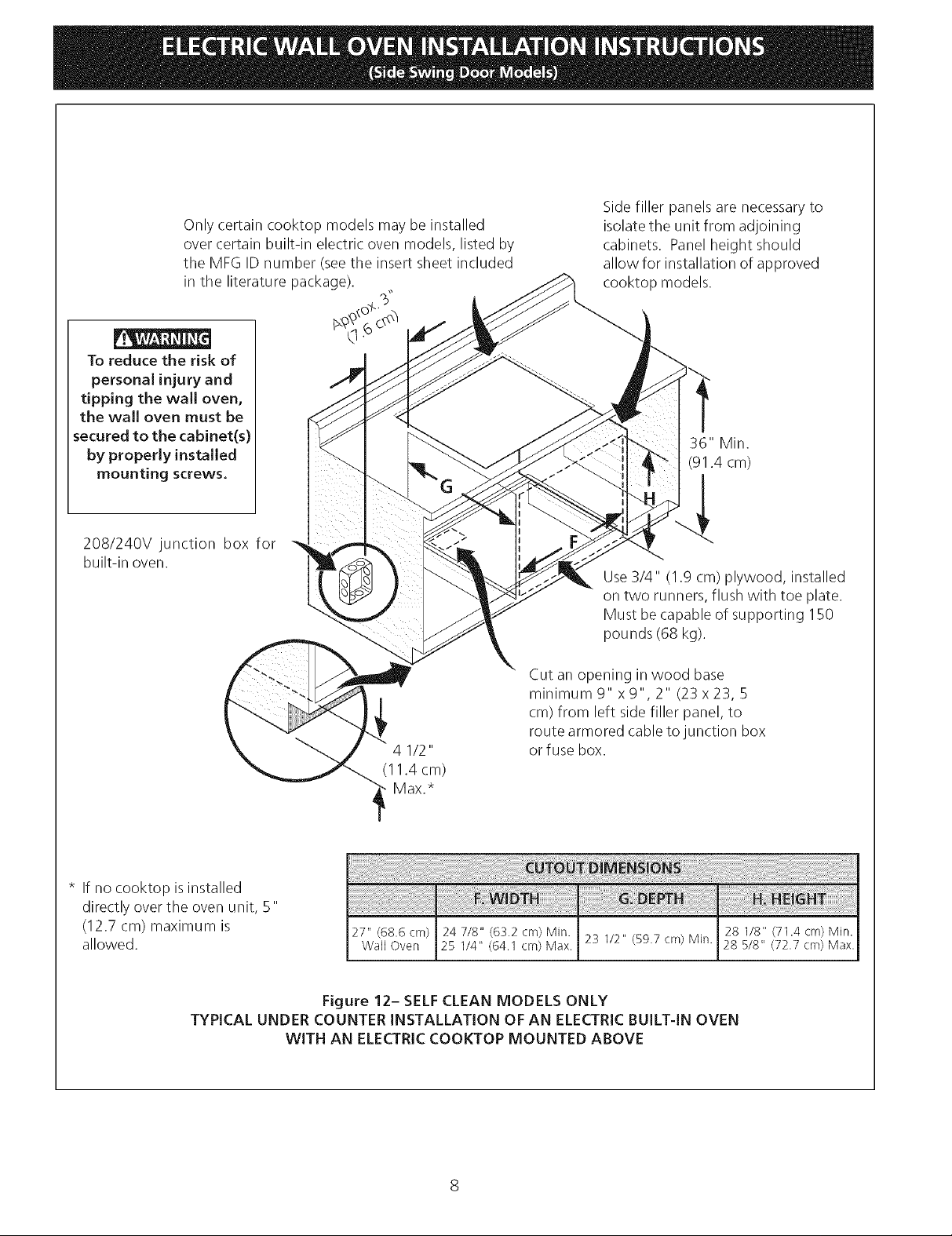

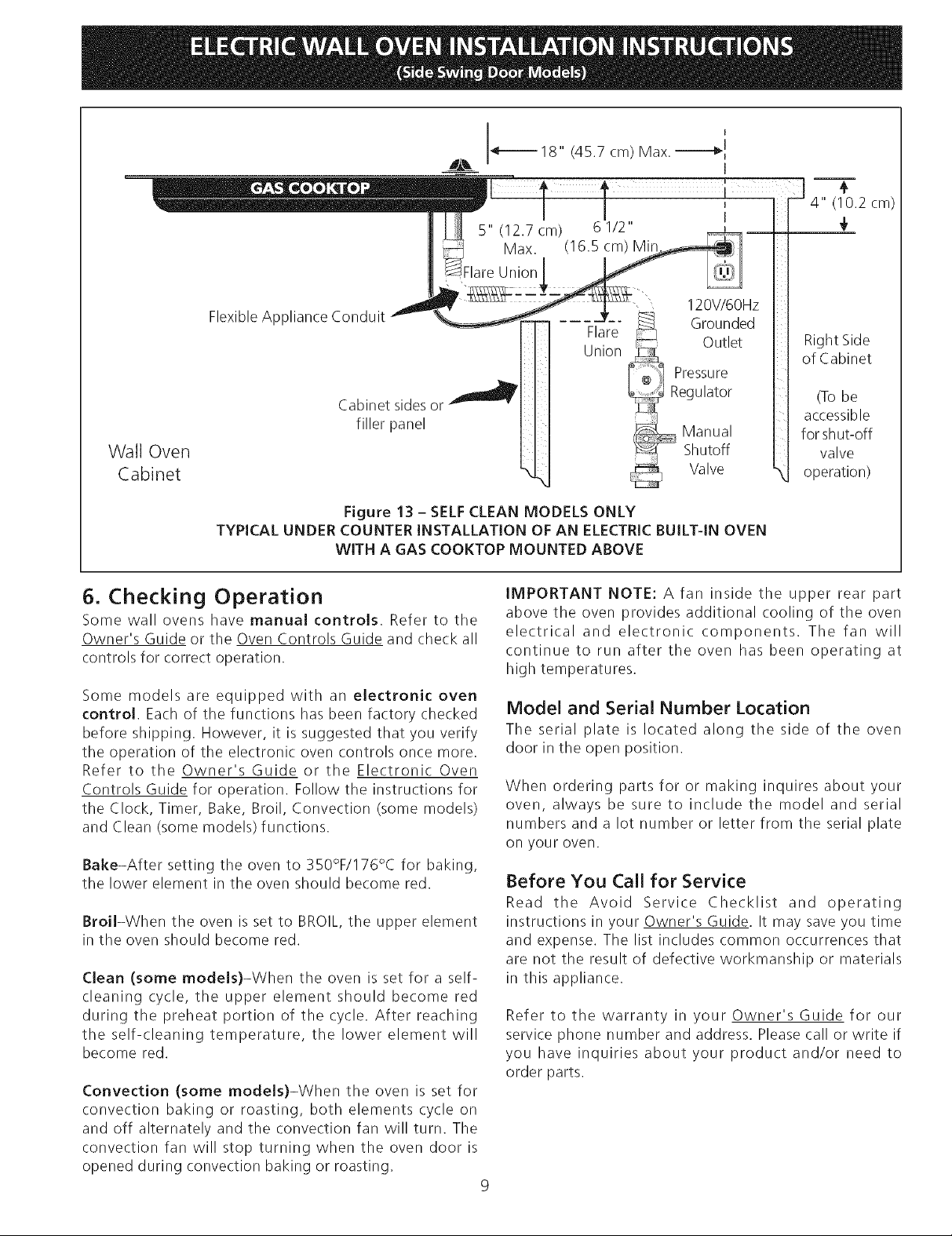

4. For typical under counter installation of an electric

built-in oven with an electric cooktop mounted

above, see Figure 12.

5. For typical under counter installation of an electric

built-in oven with a gas cooktop mounted above,

see Figure 13.

MOUNTING

DECORATIVETRIM

/

MOUNTING

,___ SCREW

Figure 11

)

Onlycertaincooktopmodelsmaybeinstalled

overcertainbuilt-inelectricovenmodels,listedby

theMFGIDnumber(seetheinsertsheetincluded

intheliteraturepackage).

To reduce the risk of

personal injury and

tipping the wall oven,

the wall oven must be

secured to the cabinet(s)

by properly installed

mounting screws.

208/240V junction box for

built-in oven.

Side filler panels are necessary to

isolate the unit from adjoining

cabinets. Panel height should

allow for installation of approved

cooktop models.

s"

36" Min.

(91.4 cm)

Use 3/4" (1.9 cm) plywood, installed

on two runners, flush with toe plate.

Must becapable of supporting 150

pounds (68 kg).

* If no cooktop isinstalled

directly over the oven unit, 5"

(12.7 cm) maximum is

allowed.

TYPICAL UNDER COUNTER INSTALLATION OF AN ELECTRIC BUILT-IN OVEN

Cut an opening in wood base

minimum 9" x 9", 2" (23 x 23, 5

cm) from left side filler panel, to

route armored cable to junction box

4 I/2"

(11.4 cm)

Max.*

27" (68.6 cm) 24 7/8" (63.2 cm) Min. 28 1/8" (71.4 cm) Min.

Wall Oven 2B 1/4" (64.1 cm) Max. 23 1/2" (59.7 cm) Min. 28 5/8" (72.7 cm) Max.

Figure 12- SELF CLEAN MODELS ONLY

WITH AN ELECTRICCOOKTOP MOUNTED ABOVE

or fuse box.

Wall Oven

Cabinet

Flexible ApF

Flare

Union

Cabinet sides or J_-------v

filler panel

Figure 13 - SELFCLEAN MODELS ONLY

TYPICAL UNDER COUNTER INSTALLATION OF AN ELECTRIC BUILT-IN OVEN

WITH A GAS COOKTOP MOUNTED ABOVE

120V/60Hz

Grounded

Outlet

Pressure

Regulator

Manual

Shutoff

Valve

Right Side

of Cabinet

(To be

accessible

for shut-off

valve

operation)

6. Checking Operation

Some wall ovens have manual controls. Refer to the

Owner's Guide or the Oven Controls Guide and check all

controls for correct operation.

Some models are equipped with an electronic oven

control, Each of the functions has been factory checked

before shipping. However, it is suggested that you verify

the operation of the electronic oven controls once more.

Refer to the Owner's Guide or the Electronic Oven

Controls Guide for operation. Follow the instructions for

the Clock, Timer, Bake, Broil, Convection (some models)

and Clean (some models) functions.

Bake-After setting the oven to 350%/176°C for baking,

the lower element in the oven should become red.

Broil-When the oven is set to BROIL,the upper element

in the oven should become red.

Clean (some models)-When the oven is set for a self-

cleaning cycle, the upper element should become red

during the preheat portion of the cycle. After reaching

the self-cleaning temperature, the lower element will

become red.

Convection (some models)-When the oven is set for

convection baking or roasting, both elements cycle on

and off alternately and the convection fan will turn. The

convection fan will stop turning when the oven door is

opened during convection baking or roasting.

IMPORTANT NOTE: A fan inside the upper rear part

above the oven provides additional cooling of the oven

electrical and electronic: components, The fan will

continue to run after the oven has been operating at

high temperatures.

Model and Serial Number Location

The serial plate is located along the side of the oven

door in the open position.

When ordering parts for or making inquires about your

oven, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your oveR.

Before You Call for Service

Read the Avoid Service Checklist and operating

instructions in your Owner's Guide. It may save you time

and expense. The list includes common occurrences that

are not the result of defective workmanship or materials

in this appliance.

Refer to the warranty in your Owner's Guide for our

service phone number and address. Please call or write if

you have inquiries about your product and/or need to

order parts.

9

Loading...

Loading...