Frigidaire Fully Integrated Direct FeedModel Dishwashers, PLD4555RFC, PLD4375RFC, LEDB500FEE Service Manual

Dishwasher

Service Manual

Fully Integrated Direct Feed

Model Dishwashers

5995477345 October 2006

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe

Servicing Practices be observed. The following are some limited examples of

safe practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

• Remove the power cord from the electrical outlet, trip the circuit breaker to

the OFF position, or remove the fuse.

• Turn off the gas supply.

• Turn off the water supply.

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY

STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN,

or GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a hazard.

6. Prior to returning the product to service, ensure that:

• All electrical connections are correct and secure

• All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts

• All non-insulated electrical terminals, connectors, heaters, etc. are

adequately spaced away from all metal parts and panels

• All safety grounds (both internal and external) are correctly and securely

connected

• All panels are properly and securely reassembled

ATTENTION!!!

This service manual is intended for use by persons having electrical and mechnical

training and a level of knowledge of these subjects generally considered acceptable in the

appliance repair trade. Electrolux Home Products, Inc. cannot be responsible, nor assume

any liability, for injury or damage of any kind arising from the use of this manual.

© 2006 Electrolux Home Products, Inc.

2

TABLE OF CONTENTS

Safe Servicing Practices ------------------------------------------------------------------------------------------- 2

The Design and Operation of the Fully Integrated Dishwasher --------------------------------------- 5

PLD4555RFC ----------------------------------------------------------------------------------------------------- 5

PLD4375RFC ----------------------------------------------------------------------------------------------------- 5

LEDB500FEE ----------------------------------------------------------------------------------------------------- 5

Cycle Selections ------------------------------------------------------------------------------------------------------ 6

Ulimate Scrub---------------------------------------------------------------------------------------------------- 6

Maxx Clean ------------------------------------------------------------------------------------------------------- 6

Speed Clean ------------------------------------------------------------------------------------------------------ 6

Normal Wash----------------------------------------------------------------------------------------------------- 6

China/Crystal ---------------------------------------------------------------------------------------------------- 6

Eco Wash --------------------------------------------------------------------------------------------------------- 6

Top Rack, Glasses and Party Glasses ------------------------------------------------------------------- 6

Rinse Only -------------------------------------------------------------------------------------------------------- 6

Favorite Cycle --------------------------------------------------------------------------------------------------- 6

Option Selections ---------------------------------------------------------------------------------------------------- 7

Wash Pressure -------------------------------------------------------------------------------------------------- 7

Wash Temperature --------------------------------------------------------------------------------------------- 7

Sanitize Rinse --------------------------------------------------------------------------------------------------- 7

Dry------------------------------------------------------------------------------------------------------------------- 7

Delay Start -------------------------------------------------------------------------------------------------------- 7

Control Lock ----------------------------------------------------------------------------------------------------- 8

Digital Display --------------------------------------------------------------------------------------------------- 8

Status Indicators ----------------------------------------------------------------------------------------------------- 8

WASHING --------------------------------------------------------------------------------------------------------- 8

DRYING ------------------------------------------------------------------------------------------------------------ 8

CLEAN ------------------------------------------------------------------------------------------------------------- 8

SANITIZE ---------------------------------------------------------------------------------------------------------- 8

Rinse Agent LOW ----------------------------------------------------------------------------------------------- 8

Wash System ----------------------------------------------------------------------------------------------------------- 8

The Alternating Wash System -------------------------------------------------------------------------------------- 9

Part in the Wash System--------------------------------------------------------------------------------------------- 10

Wash Pump ------------------------------------------------------------------------------------------------------- 10

Stainless Steel Filter --------------------------------------------------------------------------------------------- 10

Lower Spray Arm ------------------------------------------------------------------------------------------------- 11

Center Spray Arm ------------------------------------------------------------------------------------------------ 11

Upper Spray Arm ------------------------------------------------------------------------------------------------- 11

Drain Pump -------------------------------------------------------------------------------------------------------- 11

Drying System ---------------------------------------------------------------------------------------------------------- 12

Fan/Vent Assembly ---------------------------------------------------------------------------------------------- 12

Heater--------------------------------------------------------------------------------------------------------------- 13

Door Baffles ------------------------------------------------------------------------------------------------------- 13

Dispensing System ---------------------------------------------------------------------------------------------------- 13

Dispenser Operation -------------------------------------------------------------------------------------------- 13

Door Latch Assembly ------------------------------------------------------------------------------------------------- 14

Fill System --------------------------------------------------------------------------------------------------------------- 14

Door Hinge and Spring ----------------------------------------------------------------------------------------------- 14

3

The Control System --------------------------------------------------------------------------------------------------- 15

Soil Sensing ------------------------------------------------------------------------------------------------------- 15

Temperature Controls ------------------------------------------------------------------------------------------- 15

Service Tests ------------------------------------------------------------------------------------------------------ 16

Water Temperature Test ----------------------------------------------------------------------------------- 16

To Activate the Water Temperature Test --------------------------------------------------------- 16

Water/Service Test------------------------------------------------------------------------------------------ 16

To Start the Test ---------------------------------------------------------------------------------------- 16

To Exit the Water/Service Test --------------------------------------------------------------------- 16

Chart for the Water/Service Test ------------------------------------------------------------------- 17

Relay/Triac and Sensor Test ----------------------------------------------------------------------------- 17-18

Control Codes----------------------------------------------------------------------------------------------------- 19

Disassembly and Service -------------------------------------------------------------------------------------------- 20

Safety Precautions ----------------------------------------------------------------------------------------------- 20

Control Panel------------------------------------------------------------------------------------------------------ 20

Electronic Control ------------------------------------------------------------------------------------------- 20

Display --------------------------------------------------------------------------------------------------------- 20

Door Latch --------------------------------------------------------------------------------------------------------- 21

Door Strike --------------------------------------------------------------------------------------------------------- 21

Detergent/Rinse Aid Dispenser ------------------------------------------------------------------------------- 21

Door Hinge--------------------------------------------------------------------------------------------------------- 21

Door Seal ---------------------------------------------------------------------------------------------------------- 22

Bottom Door Seal ------------------------------------------------------------------------------------------- 22

Upper Rack -------------------------------------------------------------------------------------------------------- 22

Tub Roller Assembly -------------------------------------------------------------------------------------------- 22

Center Spray Arm ------------------------------------------------------------------------------------------------ 22

Upper Spray Arm ------------------------------------------------------------------------------------------------- 22

Lower Spray Arm, Spray Arm Support and Filter --------------------------------------------------------- 23

Heating Element-------------------------------------------------------------------------------------------------- 23

Float Switch and Mount Bracket ------------------------------------------------------------------------------ 23

Water Valve -------------------------------------------------------------------------------------------------------- 23

Drain Pump -------------------------------------------------------------------------------------------------------- 24

Replacing the Drain Pump -------------------------------------------------------------------------------- 24

Pump and Motor Assembly ------------------------------------------------------------------------------------ 24

Remove motor from sump -------------------------------------------------------------------------------- 24

Delivery Tube ----------------------------------------------------------------------------------------------------- 25

Vent and Fan Assembly ---------------------------------------------------------------------------------------- 25

Exploded Views -------------------------------------------------------------------------------------------------------- 26-34

Control Panel------------------------------------------------------------------------------------------------------ 26

Door - model LEDB500FEE0 --------------------------------------------------------------------------------- 27

Door - models PLD4375RFC0 & PLD4555RFC0 -------------------------------------------------------- 28

Tub ------------------------------------------------------------------------------------------------------------- 29

Motor & Pump ---------------------------------------------------------------------------------------------------- 30

Frame ------------------------------------------------------------------------------------------------------------- 31

Racks - model LEDB500FEE0-------------------------------------------------------------------------------- 32

Racks - model PLD4375RFC0 ------------------------------------------------------------------------------- 33

Racks - model PLD4555RFC0 ------------------------------------------------------------------------------- 34

Service Data Sheet ---------------------------------------------------------------------------------------------------- 35-36

4

Fully Integraded Direct Feed

Model Dishwashers

PLD4555RFC

Figure 1

The Design and Operation of the

Fully Intergraded Dishwasher.

The fully integrated control places all cycle selection

and options on top of the console out of sight with

the door closed. With the controls under the counter

top while in operation, the cycle selection needs to

be accomplished with the door opened. First select

a wash cycle and any options, then press the Start/

Cancel pad or a Delayed Start pad and close the

door the cycle begins. A display mounted in the front

of the console shows the time remaining of the delay

or the time remaining in the cycle. While in operation,

the dishwasher control monitors the progress of the

cycle to determined if changes need to be made to

improve the cycle performance. Changes to the

cycle can start as early as the first fill, if food soils in

the water deems it necessary. If the user wishes to

make a change to the cycle, it needs to be done

before the completion of the first fill. After that time

any changes to a wash cycle will require a Cancel/

Drain before a new wash cycle can be selected.

While in operation, the control monitors all aspects of

the cycle with the use of sensors mounted in the

sump. These sensors enable the control to adjust

the length of the cycle based on soil level and water

temperature and are made as needed.

As stated earlier, a wash cycle can not be changed

after the first fill without a Cancel/Drain, options to

the wash cycle can be changed at any time up to

the point they are to be applied. If at any time after

the cycle has been started, the door is opened the

unit will stop, by closing the door the operations will

resume without pressing the Start/Cancel pad. If a

cycle needs to be terminated after the first fill has

started touching the Start/Cancel pad once sends

the unit into a Cancel/Drain for 90 seconds, this

terminates this selection. If while in a Cancel/Drain

the Start/Cancel pad is pressed a second time the

drain action stops immediately. At the completion of

a wash cycle the control lights the Clean indicator;

this indicator remains on until the door is opened.

After the wash cycle is completed and the door

opened when the Start/Cancel pad is pressed for a

new load the control will repeat the previous run

cycle, including all of the previously selected

options.

Added to the fully integrated control, the new design

offers, a new control console which is decreased in

height. The vent and door latch release handle that

had added to the height have been redesigned. The

towel bar handle once decoration now becomes the

door opening handle.

PLD4555RFC This is a 5 speed Professional

model with 6 wash cycles and a Rinse only cycle.

This model has preprogrammed wash pressure,

water temperatures, and dry options for each of the 6

different wash cycles. The user has the option to

change these setting to accommodate their desires.

See Figure 1

PLD4375RFC This is a 3 speed Professional

model with 6 wash cycles and a Rinse only cycle.

This model has preprogrammed wash pressure,

water temperatures, and dry options for each of the

6 different wash cycles.

LEDB500FEE This is a 5 speed Elements model

with 5 wash cycles, a Favorite cycle, and a Rinse

only cycle. This model has preprogrammed settings

for motor speed , water temperature and dry for each

of the wash cycles with the option to change these if

the user wishes. The Favorite Cycle selection allows

the user to program a wash cycle with any options to

their liking, then hold this cycle in memory by press-

ing one pad the designed cycle is repeated.

5

Cycle Selections

PLD4555RFC

PLD4375RFC

Normal Wash

This cycle is for normally soiled dishes. The control

automatically selects the Normal speed for the wash

motor, an assured water temperature of 135°in the

main wash and 140° in the final rinse. All of the

options are available and soil sensing will be used.

China/Crystal

This cycle is for delicate crystal or china. The control

automatically selects the Delicate speed for the wash

motor, an assured water temperature of 130°in both

the main wash and the final rinse. Only the Air Dry

and the Delay Start options are available. Soil

sensing will not be used.

LEDB500FEE

Figure 2

To better understand these different wash cycles the

following are each cycle, the settings and what

options are available.

Ultimate Scrub

This cycle is used for heavily soiled dishes. The

control automatically selects the High speed for the

wash motor, an assured water temperature of 140°in

the main wash and 155° in the final rinse, and dry is

a default to Sahara. All of the options are available

and soil sensing will be used.

Maxx Clean

This cycle is used for heavily soiled dishes. The

control automatically selects the Maxx wash speed

for the wash motor, an assured water temperature of

140°in the main wash, 155° in the final rinse, and dry

is default to Maxx. All of the options are available

and soil sensing will be used.

Eco Wash

This cycle is for lightly soiled dishes The control

automatically selects the Normal speed for the wash

motor, an assured water temperature of 135°in the

main wash and 140° in the final rinse. All Wash

Pressures, Dry Options, and Delay Start options are

available. The Wash Temperature option is not

available and soil sensing will not be used.

Top Rack, Glasses, or Party Glasses

This cycle is used for small loads of glassware or

cups. The control automatically selects the Normal

speed for the wash motor only an assured water

temperature of 135° is set for the final rinse. The

water temperature options, dry options, and Delay

Start are available. Soil sensing will not be used.

Rinse Only

This cycle is intended to rinse dishes that will be

washed at a later time. There are no options

availably with the exception of a Delay Start.

Favorite Cycle

Speed Clean

This cycle is used for a small dish load or lightly

soiled. The control automatically selects a High /

Maxx wash speed on the wash motor, an assured

water temperature of 125° in the main wash and

128° in the finial rinse. Only the Dry Option and

Delay Start options are available. Soil sensing is

used.

This is a cycle programmed by the user and gives

them a short cut to a cycle they use frequently. To

program the Favorite Cycle make the selection of a

wash cycle and all of the desired options, press and

hold the Favorite Cycle pad for three seconds.

Once the Favorite Cycle has been set the following

indicators will flash Time remaining, Favorite Cycle,

the user’s selected cycle and all options selected.

These lights will flash for 2 seconds. The Favorite

cycle can now be set as a wash cycle with the Start/

Cancel pad.

6

Option Selections

The display will flash an HO on models so equipped.

This option will increase the water temperature to

140°. There is a time override for this option of not

more then 10 minute.

PLD4555RFC

PLD4375RFC

LEDB500FEE

Figure 3

Option selections allow the user flexibility to alter a

wash cycle to their desires. These options are the

speed of the wash motor this will increase water

pressure sprayed on the load, the temperature of

water in both the main wash and finial rinse segment of a cycle, the dry can be a no heat dry or on

some models the heated dry can actually be

extended for a longer time. This section cover

these and a delay start option.

Wash Pressure

This option allows the user to raise or lower the

speed of the wash motor which increases or decreases the pressure of the water used to clean the

dishes. The control will not allow this change in all

cycles because of the intent of the cycle. This

change in water pressure will effect all of the washes

and rinses in this selected cycle.

Sanitize Rinse

The Sanitize rinse increases the finial rinse segment

to a temperature of 155° on select wash cycles. On

models PLD4555RFC and LRDB500FEE when the

sanitize rinse option is selected this selects the High

Temp wash as well, for that reason, both the Sanitize

and Hi temp wash indicators will light. On other

models, this is a separate option. There can be up to

30 minutes delay for the Sanitize rinse when selected. On models with a display, an HO will flash

during this delay period. Once the wash cycle is

completed, the Sanitize light and the Clean light are

light and remain on until the door is opened. If the

155° was not reached in the allotted time, the

Sanitize light will not come on informing the user the

criteria for this setting was not met.

Dry

This option, on all models, can disable the heating

element which gives only an air dry. There is an

active vent and fan assembly located in the top right

back corner of the tub that will be activated at the

end of all wash cycles. On select models, the Dry

option also offers a Max or a Sahara dry, this setting

lengths the dry cycle by 20 minutes to insure a dry

load. If when the dishwasher is in the dry cycle the

door is opened and stays open for more then one

minute the remainder of the dry cycle will cancel out.

Delay Start

Depending on model, the option could read either

“High” or “Maxx” speed. This selection will

substitute the speed of the motor to 3400 rpm when

spraying from the lower spray arm and 3200 rpm

from the upper and center arms. This overrides the

variable speed function of the selected cycle.

Delicate Pressure limits all wash and rinse speeds

to 2800 rpm only for the selected cycle.

Wash Temperature

This option allows for the selection of a high temperature wash in select cycles. The high temperature wash occurs at the end of the main wash

segment of the cycle.

This option allows for a wash cycle to be pro-

grammed into the control and the start delayed for a

set number of hours. A cycle can be delayed from 1

to 24 hours in 1 hour increments. To set a Delay

Start a wash cycle with options is selected followed

by pressing the Delay Start pad. Each time the Delay

Start pad is pressed in 3 second intervals the number

of hours to delay will increase by one hour up to 24

hours. Once the delay begins, time is decreased in

one hour segments until one hour remains, then the

count down changes to minutes. After the count

down starts pressing the Start/Cancel pad will have

no effect on the delay start, if the Start/Cancel pad is

a second time in succession this will cancel the delay

and start the selected cycle.

7

Control Lock

The control lock disables the keypad so that the

settings entered into the control can not be changed.

To activate the control lock press and hold the Delay

Start pad for 3 seconds with the dishwasher door

closed. The Control Lock indicator will illuminate

when the lock is set. To remove the control lock

press and hold the Delay Start pad for 3 seconds

until the light goes out. If the control lock is used, it

should be turned off after the cycle is completed and

before the door is opened.

If the control lock was used and not turned off before

the dishwasher door is opened the light will go out

with the control still locked, resulting in a non functioning dishwasher. This can be corrected by

removing power from the unit this will reset the

control.

Digital Display

The digital display is to indicate the current status of

the cycle. The display is a two digit display so time

will read from 1 to 99 minutes. If a cycle length is

over 99 minutes, the display will have a plus sign (+)

to the right of the numbers. This plus sign (+) will

stay light until the cycle time drops below 99 minutes. The display may also have codes appear to

indicate the status of the cycle or the condition of the

dishwasher. The most common of these codes is an

HO code which may appear and flash in the display,

this indicates that the control has delayed the cycle

to increase the water temperature. Another of these

codes is a flashing CL indicates of an open door.

This code can appear if the control is programmed

and the Start/Cancel pad is pressed before the door

is closed. Close the door and the cycle will start.

The last of the common codes is a PF code. This

will flash in the display on initial power up of the

dishwasher or any time power to the dishwasher has

been interrupted. There are fault codes that can

appear in the display as well; these will be listed as

failure codes in the control test section of this

manual.

The CLEAN indicator is energized at the end of all

wash cycles with the exception of a Rinse and hold

cycle. The clean indicator will remain on until the

door is opened. After the door is open, ALL indicators

will be extinguished with the exception of the “Rinse

aid low” if applicable.

The SANITIZE indicator is shown in the front display

as an “S” and will be energized at the end of any

cycle that the Santi option has been selected. The

sanitize criteria must be completed correctly for this

indicator to come on. This indicator will be extin-

guished when the door is opened.

The Rinse Agent LOW indicator on the keypad will

be on any time the rinse aid level in the dispenser is

low. This light will stay on until the dispenser is filled.

The indicator can also be extinguished after 5

successive cycles have been run with out filling the

dispenser. On select models an Lo will appear in the

front display to indicate the rinse aid dispenser is low

on agent.

Wash System

The wash system consists of wash pump and motor

assembly to provide water under pressure for the

three spray arms used to clean the dishes. These

three spray arms will alternate operation starting with

the lower spray arm. After a predetermined time the

spray will change to the center and upper spray arms

simultaneously.

Status Indicators

The WASHING indicator is energized at the begin-

ning of any wash cycle and will remain on as long as

the vent actuator is not energized.

The DRYING indicator is energized when the vent

actuator is energized and remains on until the end of

the cycle regardless of which drying option is se-

lected.

Figure 4

Below the lower spray arm is the filter and soil

director this covers the complete sump. The filter is

intended to block loosened food particles from

entering the wash sump area as they fall to the

bottom from the spray action. See Figure 4

8

On the underside of the filter is a soil director which

directs the loosened food particles to the lower left

side of the sump to a stainless steel food macerator

used to pulverize the soil so it can pass through the

drain hose. See Figure 5

Figure 5

The remaining parts in the wash system are the

sump assembly that acts as a reservoir for clean

water being supplied to the wash pump and the

delivery tube to supply water to the upper two spray

arms.

Figure 7

The check ball rests at the end of a ramp molded

into the sump partially blocking the rear hole. As

water under pressure enters the volute cover, the

check ball is held tightly into the rear hole restricting

water flow from this opening. Water can only leave

the remaining hole from the top of the volute cover

into the lower spray arm. See Figure 7

The Alternating Wash System

This wash system is designed to spray from only one

arm or one set of arms at a time. The advantage of

this is that it reduces the amount of water needed in

the tub. The way this system operates is explained

as follows.

Alternating the spray is achieved with a check ball

moving between two holes in the sump. One hole is

located in the rear of the sump used to supply water

to the upper two spray arms; the second is located

out the top of the volute cover onto which is mounted

the lower spray arm.

Bypass opening

Ball covering back hole

Figure 6

Volute cover

Opening to

lower spray

arm

Figure 8

The force of the water entering and leaving the arm

causes it to turn by the positioning of the hole in the

spray arm. The rear hole which is molded in the

sump has a small section removed above where the

check ball sets, this section allows a small amount of

water to by-pass the check ball and enter the delivery

tube mounted up the out side rear of the tub. Water

by-passing the check ball will fill the delivery tube at a

rate of approximately four inches a second. This

water will be used to change the spray from bottom

to the upper two spray arms. All wash and rinse

cycles will start by spraying from the lower wash arm.

Changing spray from bottom to upper spray arms is

accomplished with the control stopping the wash

pump for not more then .6 of a second. This pause

removes water pressure from the rear of the check

ball, water that had accumulated in the delivery tube

now reenter the sump, which moves the check ball

away from the hole and up the ramp.

9

Ball at the top of ramp

opening hole to center arm

The pump restarts the

water pressure in back

of the ball forces the

check ball up into the top

hole in the volute cover

blocking water tothe

lower spray arm. Water

exits the rear hole into

the delivery tube supplying water to the upper

spray arms.

Water in the delivery tube is divided with 80% going

to the center spray arm and 20% to the upper arm.

Water spray will continue from the upper spray arms,

after a predetermined time the control will again

pause the pump this time the pause will be for 3

seconds. This longer time allows for the delivery

tube to completely drain then the check ball returns

to the bottom of the ramp. The pump restarts with

spray from the lower spray arm completing a spray

arm change cycle.

Figure 9

The speed of the motor is determined by the elec-

tronic control based on the cycle selected. The

control continually monitors motor speed with input

from a Hall Effect sensor mounted to the rear of the

wash motor. Input voltage for operating the motor

will be 120VAC with the motor changing this to VDC

with a built-in rectifier.

Stainless Steel Filter

The stainless steel filter covers the entire sump area.

The filter is intended to remove all food particles from

the water so only clean water reenters the sump.

There is a fine mesh polyester screen housing in the

center of the stainless steel filter to house a lift out

basket to catch larger items, this basket can be

removed for cleaning. On the bottom of the inner

screen housing there is a soil director used to direct

food soil removed from the dishes to the left side of

the sump to be removed first when the water is

drained from the tub. The lower spray arm support

is also used as a lock for the filter to insure it is down

tight to the sump. See figure 11

Parts in the wash System

Wash Pump

These model dishwashers use a variable speed DC

motor. The variable speed motor is used to improve cleaning by varying the water pressure

depending on the cycle selected. An Ultimate

Scrub and Maxx cycle intended for heavily soiled

dishes will have a high pressure speed to better

remove baked on food where a China/Crystal cycle,

for very delicate items will have a very low water

pressure setting. The user has an option to change

the motor speed on some models. There is an

added advantage of quieter operation when the

lower speed is used. The motor and wash pump

are supplied as a one piece assembly.

Figure 11

Figure 10

10

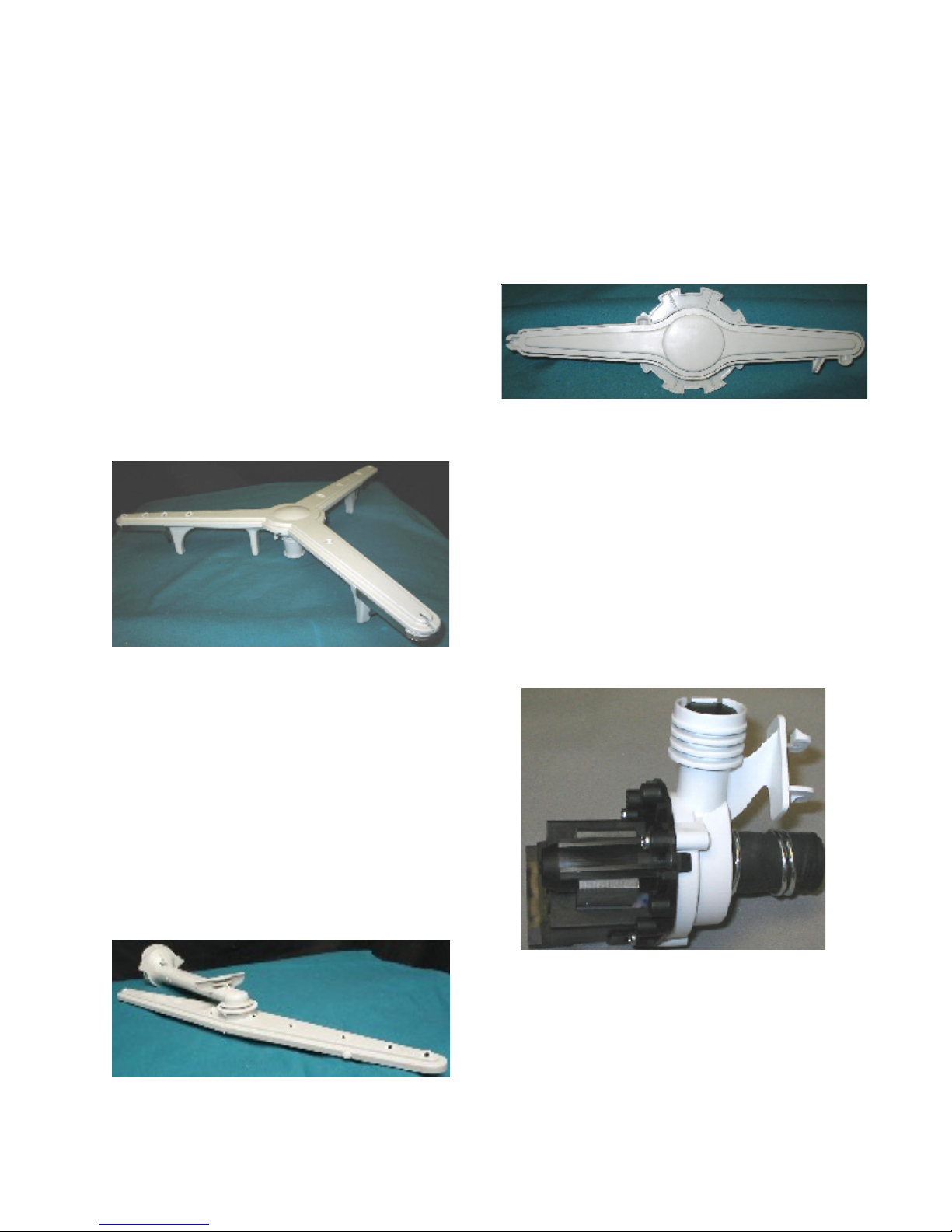

Lower Spray Arm

Upper Spray arm

This spray arm is designed using three spray arms to

spray water up into the lower rack. There are also

on the underside of this spray arms 4 legs used for

cleaning the soil from the stainless steel filter. Three

of the legs have spray openings pointed toward the

center these will spray water across the top of the

filter forcing the loosen soil to the center. The forth

leg is mounted closer to the center of the spray arm,

with a spray opening pointed straight down forces

food collected in the center basket down into the soil

director for removal in the drain segment of the wash

cycles. Turning of the arm is accomplished by water

under pressured sprayed from holes molded on top

of the arm these force the arm to turn in a clockwise

direction. The lower spray arm turns periodically in

all cycles, this to keep the filter clean, and reduce

chances of redeposit. See Figure 12

This arm is located in the top of the tub and turns in

a counter clockwise direction, and sprays simultaneously with the center spray arm. The mount for

the upper spray arm serves as the lock nut for the

delivery tube and is only available as an assembly.

The spray arm will turn at approximately 40 rpm.

See Figure 14

Figure14

Drain Pump

The only function of the drain pump is to remove

water from the dishwasher. The drain pump is

mounted directly to the front of the sump. The

motor for this pump is rated a 1/25th hp drive motor.

The drain pump only comes as an assembly. The

front cover of the pump can be removed for cleaning

if needed.

Figure 12

Center Spray arm

This spray arm is mounted on a short delivery tube

to the under side of the upper rack. This arm rotates

clockwise at approximately 20 rpm. The center

spray arm and delivery tube will move in and out with

the upper rack. There is a bellows mounted to the

back end of this short delivery tube which forms a

seal against the back wall of the tub when the spray

arm is in operation. This delivery tube is also de-

signed for the adjustable upper rack. See Figure 13

Figure 13

Figure15

With the drain pump mounted in this location it is

accessible by removing both the outer door and the

toe kick panels. The drain pump connector hose

from the pump to the sump are supplied as an

assembly. See Figure 15

11

Loading...

Loading...