Frigidaire FRRECTWODWMW1 Installation manual

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

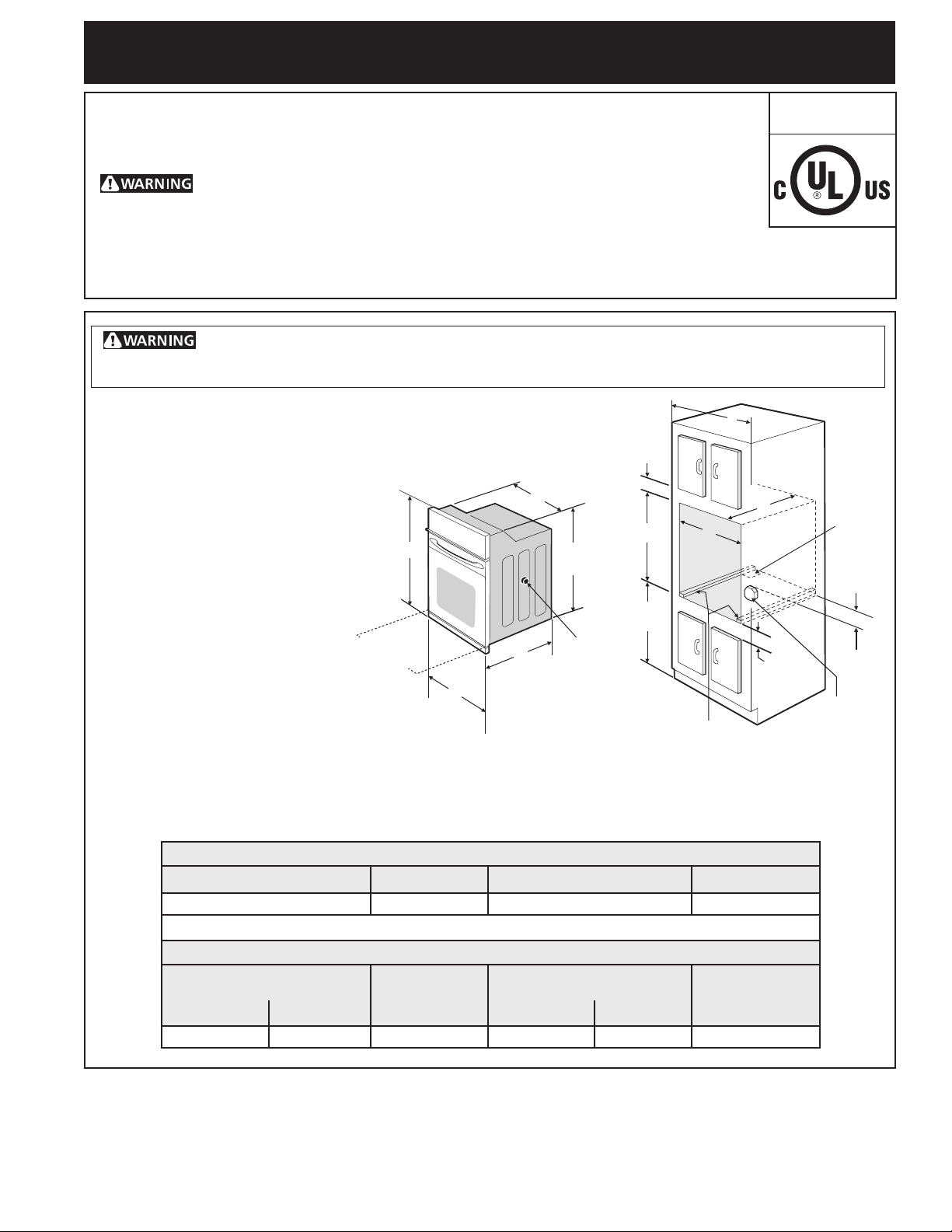

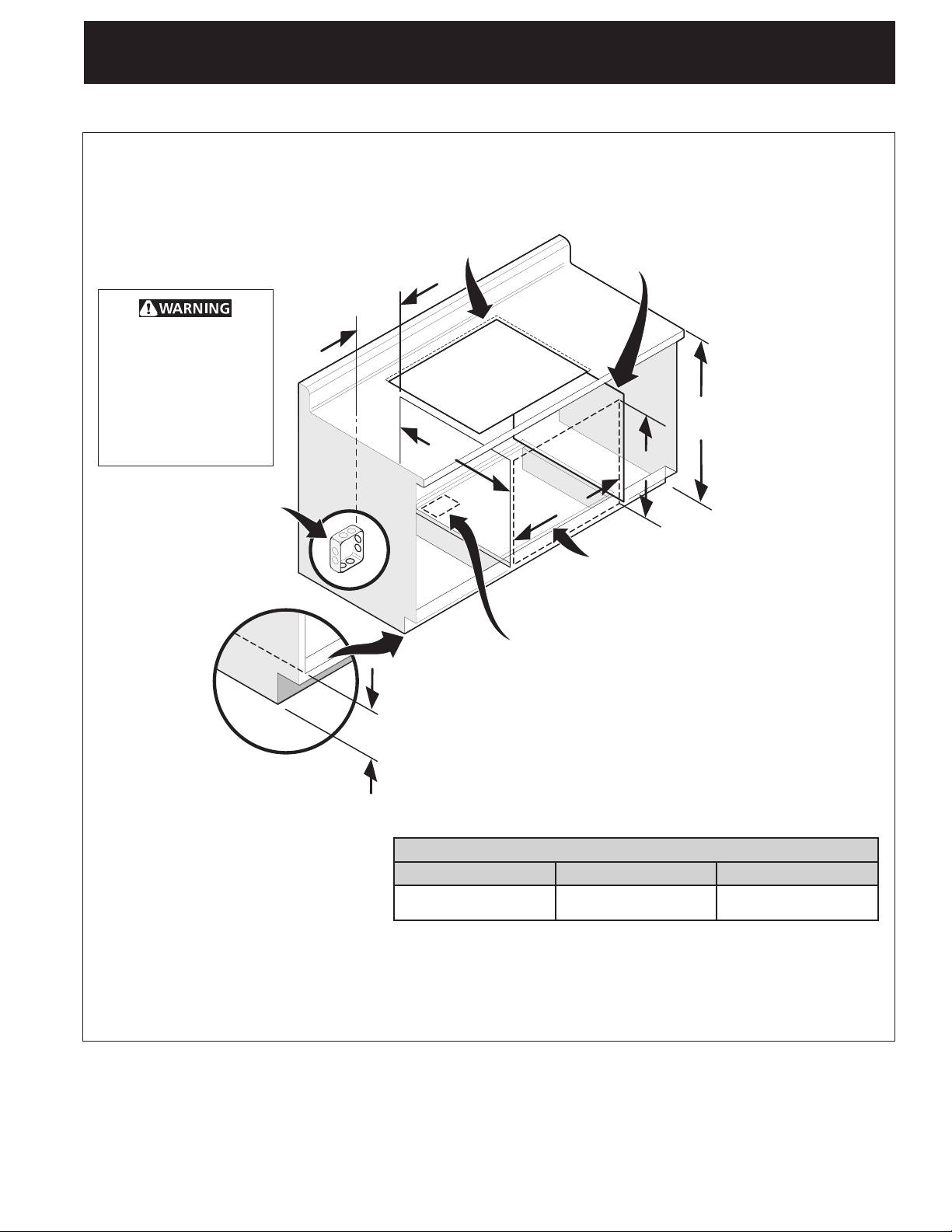

B

A

D

C

H

F

I

G

26 11/16”

(67.8 cm)

2”

(5.1 cm)

Min.

31”*

(78.7 cm)

3”

(7.6 cm)

1½” (3.8 cm)

Min.

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

United States

and Canada

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

FOR YOUR SAFETY: Do not store or use gasoline or other ammable vapors

and liquids in the vicinity of this or any other appliance.

Your new wall oven has been designed to t a limited variety of cutout sizes to make the job of installing easier.

The rst step of your installation should be to measure your current cutout dimensions and compare them to the

cutout dimensions chart below for your model. You may nd little or no cabinet work being necessary.

Do not remove spacers (if equipped) on the side walls of the built-in oven. These spacers

center the oven in the space provided. The oven must be centered to prevent excess heat buildup that may

result in heat damage or re.

NOTES:

1. Base must be capable of supporting 200 pounds (90 kg).

2. Allow at least 21" (53.3 cm) clearance in front of oven for door

depth when it is open.

3. Dimension G (cutout depth) is critical to

the proper installation of the built-in oven.

If the oven decorative trim does not butt

against the cabinet, or if noise is heard

on convection models, verify dimension

G to assure it is the required depth.

4. For a cutout height greater than 28"

(71.1 cm) add one 2"(5 cm)

wide wood shim of appropriate

height to each side of the

opening under the appliance

Door Open

(see note 2)

side rails.

* Suggested distance from oor is 31" (78.7cm).

Minimum required distance is 4 ½" (11.4cm).

Spacer

2" (5 cm) Wide Wood

Spacer if Needed

Hole for

Cord

Electrical

Junction Box

Min. Max. Min.

All dimensions are in inches (cm).

Printed in U.S.A.

281/2 (72.4) 29 (73.7) 231/2 (59.7) 263/4 (67.9) 28 (71.1) 301/8 (76.5) Min

Figure 1

30" Single Wall Ovens (Double ovens see Figure 2)

PRODUCT DIMENSIONS

A B C D

30 (76.2) 29 (73.7) 281/4 (71.8) 243/4 (62.9)

CUTOUT DIMENSIONS AND CABINET WIDTH

F G (Min.)

H. Standard Height

(**Others, see notes 4 & 5)

I

Max.

1

PN 807153704 Rev. A (15/11)

English – pages 1-8

Español – páginas 9-16

Français -pages 17-24

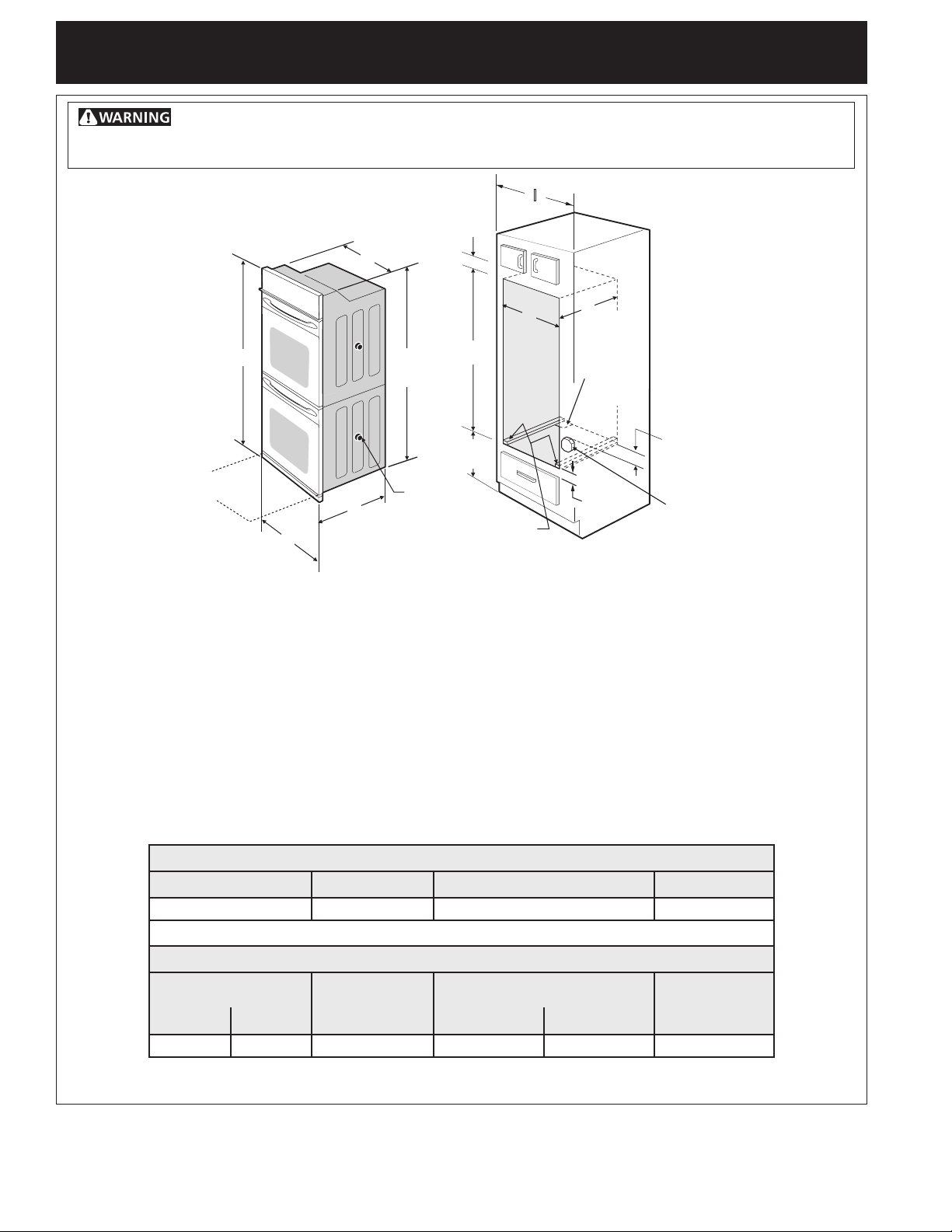

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

)

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

Do not remove spacers (if equipped) on the side walls of the built-in oven. These spacers

center the oven in the space provided. The oven must be centered to prevent excess heat buildup that may

result in heat damage or re.

1½” (3.8 cm)

C

B

Door Open

(see note 2)

48 7/16”

(123 cm)

Spacer

D

A

2" (5 cm) Wide Wood

NOTES:

1. Base must be capable of supporting 375 pounds

(170 kg).

2. Allow at least 21" (53.3 cm) clearance in front of

oven for door depth when it is open.

3. Dimension G (cutout depth) is critical to the

proper installation of the built-in oven. If the oven

decorative trim does not butt against the cabinet,

or if noise is heard on convection models, verify

dimension G to assure it is according to the

required dimension.

Min.

H

11½”

(29.2 cm)

Spacer if Needed

4. For a cutout height greater than 49 3/4" (126.4 cm)

add a 2" (5 cm) wide wood shim of appropriate

height to each side of the opening under the

appliance side rails.

I

F

G

Hole for

Cable

2”

(5.1 cm)

Min.

3” (7.6 cm

Max.

Electrical

Junction Box

A B C D

30 (76.2) 507/16 (128.1) 281/4 (71.8) 243/4 (62.9)

F G (Min.)

Min. Max. Min.

281/2 (72.4) 29 (73.7) 231/2 (59.7) 481/2 (123.2) 493/4 (126.4) 301/8 (76.5) Min

All dimensions are in inches (cm).

Figure 2

30" DOUBLE OVENS (Single Ovens see Figure 1)

PRODUCT DIMENSIONS

CUTOUT DIMENSIONS AND CABINET WIDTH

H. Standard Height

(**Others, see notes 4 & 5)

Max.

2

I

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing the wall oven.

2. Remove all packing material from the oven

compartments before connecting the electrical

supply to the wall oven.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the

consumer.

5. Oven door may be removed to facilitate installation.

6. THESE OVENS ARE NOT APPROVED FOR

STACKABLE OR SIDE-BY-SIDE INSTALLATION.

Important Note to the Consumer

Keep these instructions with your Owner's Guide for the

local electrical inspector's use and future reference.

IMPORTANT SAFETY

INSTRUCTIONS

• Be sure your wall oven is installed and grounded

properly by a qualied installer or service technician.

• This wall oven must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.70latest edition in United Sates, or with CSA Standard

C22.1, Canadian Electrical Code, Part 1, in Canada.

Stepping, leaning or sitting on the door

of this wall oven can result in serious injuries and can

also cause damage to the wall oven.

• Never use your wall oven for warming or heating

the room. Prolonged use of the wall oven without

adequate ventilation can be dangerous.

The electrical power to the oven must be

shut off while line connections are being made. Failure to

do so could result in serious injury or death.

1. Carpentry

Refer to gure 1 or 2 for the dimensions applicable to

your appliance, and the space necessary to receive the

oven. The oven support surface may be solid plywood

or similar material, however the surface must be level

from side to side and from front to rear.

2. Adjusting Oven Height

Oven height can be adjusted with 2" (5cm) wide wood

shims when needed to t into an existing cabinet

cutout opening, when cutout height exceeds 28"

(71.1 cm) for the single wall oven or 493/4" (126.4 cm)

for the double wall oven (see Figure 1 or 2). Place

shims of appropriate height beneath the oven side

rails.

3. Electrical Requirements

This appliance must be supplied with the proper

voltage and frequency, and connected to an individual,

properly grounded branch circuit, protected by a circuit

breaker or fuse. To know the circuit breaker or fuse

required by your model, see the serial plate to nd the

wattage consumption and refer to table A to get the

circuit breaker or fuse amperage.

Appliance

Rating Watts

240V

Less than

4800W

4801W - 7200W

7201W - 9600W

9601W and +

Observe all governing codes and local ordinances

1. A 3-wire or 4-wire single phase 120/240 or 120/208

Volt, 60 Hz AC only electrical supply is required on a

separate circuit fused on both sides of the line (red

and black wires). A time-delay fuse or circuit breaker

is recommended. DO NOT fuse neutral (white wire).

Only certain cooktop models may be installed over

certain built-in electric oven models. Approved

cooktops and built-in ovens are listed by the MFG

ID number (see the insert sheet included in the

literature package).

NOTE: Wire sizes and connections must conform with

the fuse size and rating of the appliance in accordance

with the American National Electrical Code ANSI/NFPA

No. 70-latest edition, or with Canadian CSA Standard

C22.1, Canadian Electrical Code, Part 1, and local

codes and ordinances.

with this appliance. Such use may result in a re,

electrical shock, or other personal injury. If you need a

longer power cord you can purchase a 10' (3 m) power

cord kit #903056-9010 by calling the Service Center.

2. These appliances should be connected to the

fused disconnect (or circuit breaker) box through

exible armored or nonmetallic sheathed cable.

The exible armored cable extending from the

appliance should be connected directly to the

junction box. The junction box should be located

as shown in Figure 1 or Figure 2 and with as much

slack as possible remaining in the cable between

the box and the appliance, so it can be moved if

servicing is ever necessary.

3. A suitable strain relief must be provided to attach

the exible armored cable to the junction box.

Protection

Circuit

Recommended

20A

30A

40A or 50A

50A

An extension cord should not be used

Appliance

Rating Watts

Less than

4101W - 6200W

6201W - 8300W

8301W and +

Table A

208V

4100W

Protection

Circuit

Recommended

20A

30A

40A or 50A

50A

3

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the junction box before

making the electrical connection.

• This appliance must be connected to a grounded,

metallic, permanent wiring system, or a grounding

connector should be connected to the grounding

terminal or wire lead on the appliance.

• Do not use a gas supply line for grounding the

appliance.

Failure to do any of the above could result in a re,

personal injury or electrical shock.

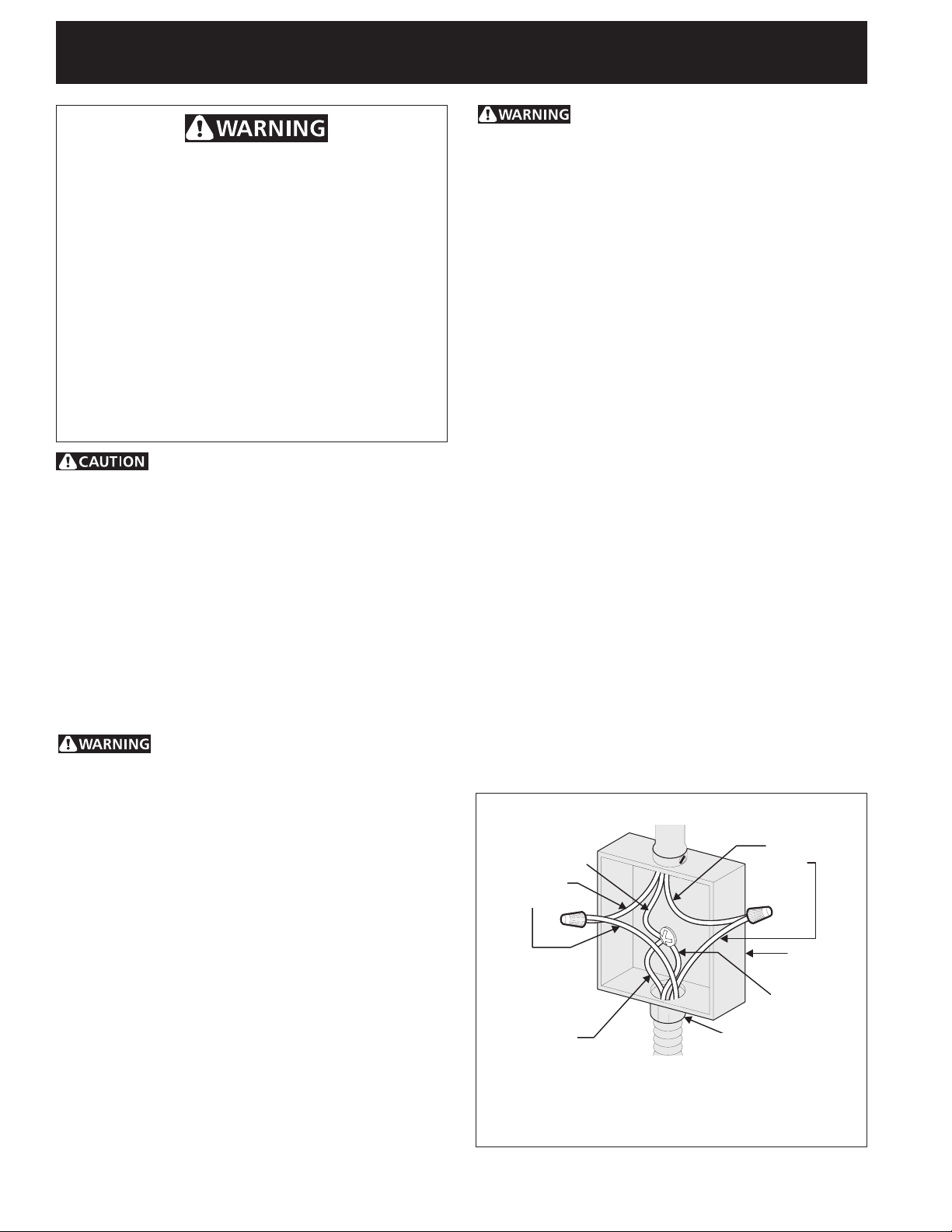

(If your appliance is equipped with a

white neutral conductor.)

This appliance is manufactured with a white neutral

power supply and a frame connected copper wire. The

frame is grounded by connection of grounding lead to

neutral lead at the termination of the conduit, if used in

USA, in a new branch circuit installation (1996 NEC),

mobile home, recreational vehicles, where local code

do not permit grounding trough the neutral (white) wire

or in Canada, disconnect the white and green lead

from each other and use ground lead to ground unit in

accordance with local codes, connect neutral lead to

branch circuit-neutral conductor in usual manner see

Figure 4. If your appliance is to be connected to a 3

wire grounded junction box (US only), where local code

permit connecting the appliance-grounding conductor

to the neutral (white) see Figure 3.

In cold weather shipping and storage

conditions, make sure that oven is in nal location

at least three (3) hours before switching on power.

Switching on power while oven is still cold may

damage the oven controls.

4. Electrical connection

It is the responsibility and obligation of the consumer to

contact a qualied installer to assure that the electrical

installation is adequate and is in conformance

with the National Electrical Code ANSI/NFPA No.

70-latest edition, or with CSA Standard C22.1,

Canadian Electrical Code, Part 1, and local codes and

ordinances.

Risk of electrical shock (Failure to

heed this warning may result in electrocution or

other serious injury.) This appliance is equipped with

copper lead wire. If connection is made to aluminum

house wiring, use only connectors that are approved

for joining copper and aluminum wire in accordance

with the National Electrical Code and local code and

ordinances. When installing connectors having screws

which bear directly on the steel and/or aluminum

exible conduit, do no tighten screws sufciently to

damage the exible conduit. Do not over bend or

excessively distort exible conduit to avoid separation

of convolutions en exposure of internal wires.

NOTE TO ELECTRICIAN: The armored cable leads

supplied with the appliance are UL-recognized for

connection to larger gauge household wiring. The

insulation of the leads is rated at temperatures much

higher than temperature rating of household wiring.

The current carrying capacity of the conductor is

governed by the temperature rating of the insulation

around the wire, rather than the wire gauge alone.

Where local codes permit connecting the appliancegrounding conductor to the neutral (white) wire (US

Only) (see gure 3):

1. Disconnect the power supply.

2. In the junction box:

connect appliance and power supply cable wires as

shown in Figure 3.

Cable from Power Supply

White Wire

(Neutral)

Red

Wires

Black

Wires

Junction

Box

DO NOT ground to a gas supply pipe. DO NOT

connect to electrical power supply until appliance

is permanently grounded. Connect the ground wire

before turning on the power.

Ground Wire

(Bare or Green Wire)

3-WIRE GROUNDED JUNCTION BOX

4

White Wire

(Neutral)

U.L.-Listed Conduit

Connector (or CSA listed)

Cable from appliance

Figure 3

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

IMPORTANT!

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

If oven is used in a new branch circuit installation

(1996 NEC), mobile home, recreational vehicle, or

where local codes DO NOT permit grounding through

the neutral (white) wire, the appliance frame MUST

NOT be connected to the neutral wire of the 4-wire

electrical system. (see gure 4):

1. Disconnect the power supply.

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the junction box:

connect appliance and power supply cable wires as

shown in Figure 4.

Cable from Power Supply

Ground Wire

Red

Wires

Ground Wire

(Bare or Green

Wire)

Junction Box

Cable from appliance

Figure 4

4-WIRE GROUNDED JUNCTION BOX

White Wire

Black

Wires

White Wire

U.L.-Listed

Conduit Connector

(or CSA listed)

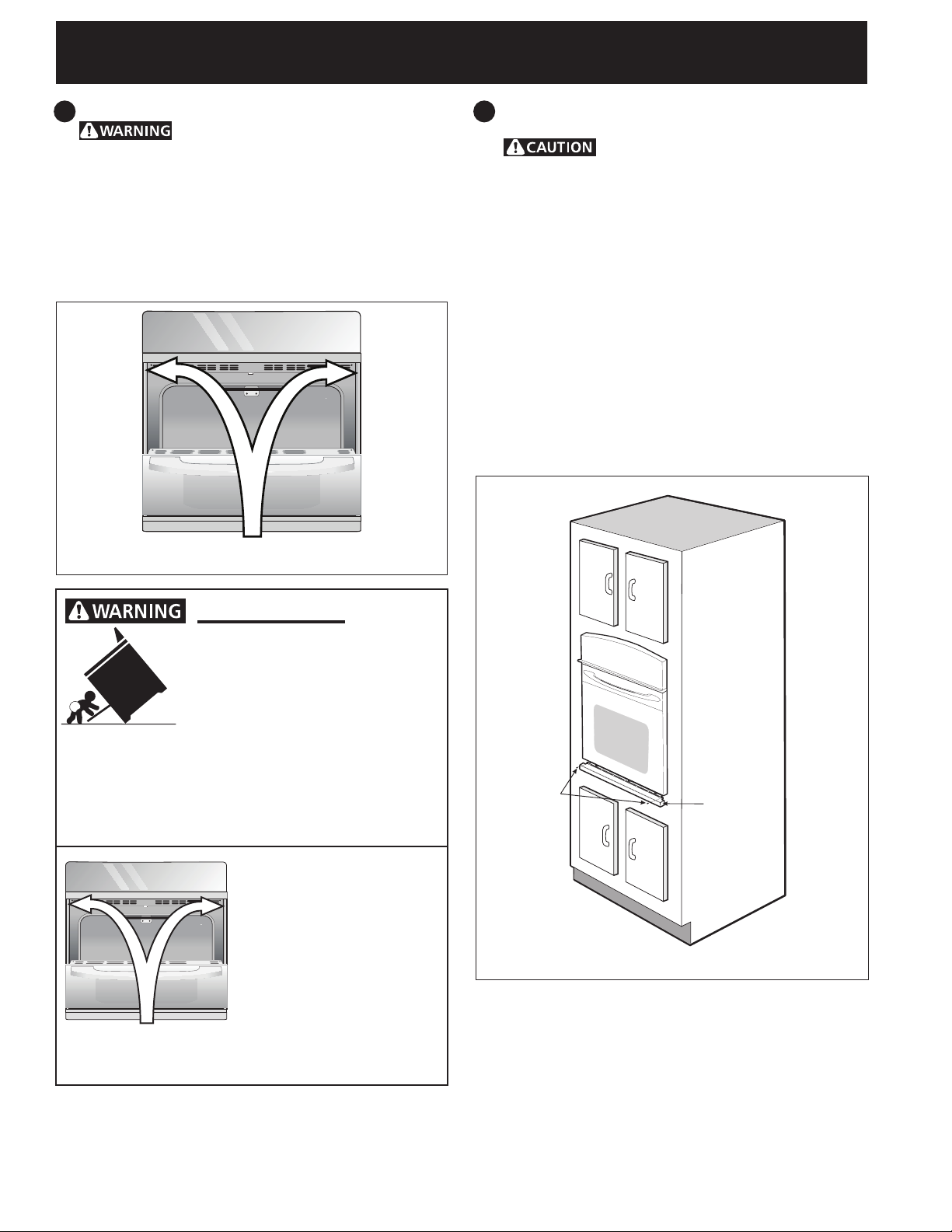

5. Cabinet Installation

Do not lift or manipulate the oven by the door handle

or the control panel.

Heavy Weight Hazard

• Use 2 or more people to move and install wall oven.

• Failure to follow this instruction can result in injury or

damage to the unit.

1 Unpack the wall oven. Remove the bottom trim

taped on the oven top panel.

2 Find the 2 anti-tip mounting screws included in the

literature package.

3 Insert the oven into the cabinet opening. Slide

oven inward leaving 1½" (3.8 cm) clearance

between the oven and front of cabinet (see Figure

5).

4 Pull the armored cable through the hole for it in the

cabinet and toward the junction box while moving

the appliance inward.

5 Push the oven in and against the cabinet.

Model and Serial Number Location

The serial plate is located along the interior side trim of

the oven and visible when the door is opened.

When ordering parts for or making inquires about your

oven, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your oven.

Single Wall Oven

Serial Plate Location

Double Wall Oven

Serial Plate Location

1½" (3.8 cm)

clearance

between unit

and front of

cabinet.

Figure 5

5

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

Tip Over Hazard

• A child or adult can tip the oven

and be killed.

• Install the anti-tip device to oven

and/or structure per installation

instructions.

• Ensure the anti-tip device is re-engaged when the

oven is moved.

• Do not operate the oven without the anti-tip device

in place and engaged.

• Failure to follow these instructions can result in

death or serious burns to children and adults.

Refer to the installation

instructions supplied with your

appliance for proper installation.

Check for proper installation

with a visual check that the

anti-tip screws are present.

Test the installation with light

downward pressure on the

open oven door. The oven

should not tip forward.

Anti-tip mounting holes

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

6 Install the Anti-tip Mounting Screws

The wall oven can tip when the door is

open. The anti-tip mounting screws supplied with the

wall oven must be installed to prevent tipping of the

wall oven and injury to persons.

A. The mounting holes in the side trims may be

used as a template to locate the appliance mounting

screw holes (see gure 6).

B. Use the two screws supplied to x the appliance

to the cabinet.

Anti-Tip Mounting Holes

Figure 6

7 Install the Bottom Trim

Bottom trim must be installed for the

oven to function properly. DO NOT operate the oven

without bottom oven trim installed. Do not use wood

or any other trim that is not manufactured for use

with this model. Operating the appliance without

manufacturer's bottom trim properly installed may

cause personal injury and may damage cabinetry or

the appliance.

Screws to attach the bottom trim are supplied with

the oven. Oven door may be removed to aid bottom

trim installation.

A. Place the top of the bottom trim over the side trim

tabs on each side of the oven below the oven door.

B. Attach the trim using the provided screws (see

Figure 7).

Screws

supplied

Bottom Trim

Figure 7

6

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

For typical under counter installation of an electric built-in oven see Figure below.

Only certain cooktop models may be installed over

certain built-in electric oven models. Approved cooktops

and built-in ovens are listed by the MFG ID number

and product code (see the insert sheet included in the

literature package and cooktop installation instructions

for dimensions).

To reduce the risk of

personal injury and tipping of the wall oven,

the wall oven must be

secured to the cabinet (s) by mounting

screws.

208/240 Volt junction box

for built-in oven.

Approx. 3”

(7.5 cm)

Cabinet side ller panels

are necessary to isolate the

unit from adjoining cabinets.

Cabinet side ller height

should allow for installation of

approved cooktop models

36” Min.

(91.4 cm) Min.

G

H

F

Use 3/4” (1.9 cm) plywood, installed on

two runners, ush with toe plate. Base

must be capable of supporting 200

pounds (90 kg).

* If no cooktop is installed directly over

the oven unit, 5” (12.7 cm) maximum

is allowed above the oor.

Figure 8- TYPICAL UNDER COUNTER INSTALLATION OF A SINGLE ELECTRIC BUILT-IN

OVEN WITH AN ELECTRIC COOKTOP MOUNTED ABOVE

4 1/2” (11.5 cm) Max.*

F.WIDTH G.DEPTH H.HEIGHT

281/2" (72.4 cm) Min.

29" (73.7 cm) Max.

Cut an opening in wood base minimum 9” x

9” (23 X 23 cm), 2” (5 cm) from left side ller

panel, to route armored cable to junction box.

CUTOUT DIMENSIONS

231/2" (59.7 cm) Min. 263/4" (67.9 cm) Min.

28" (71.1 cm) Max.

7

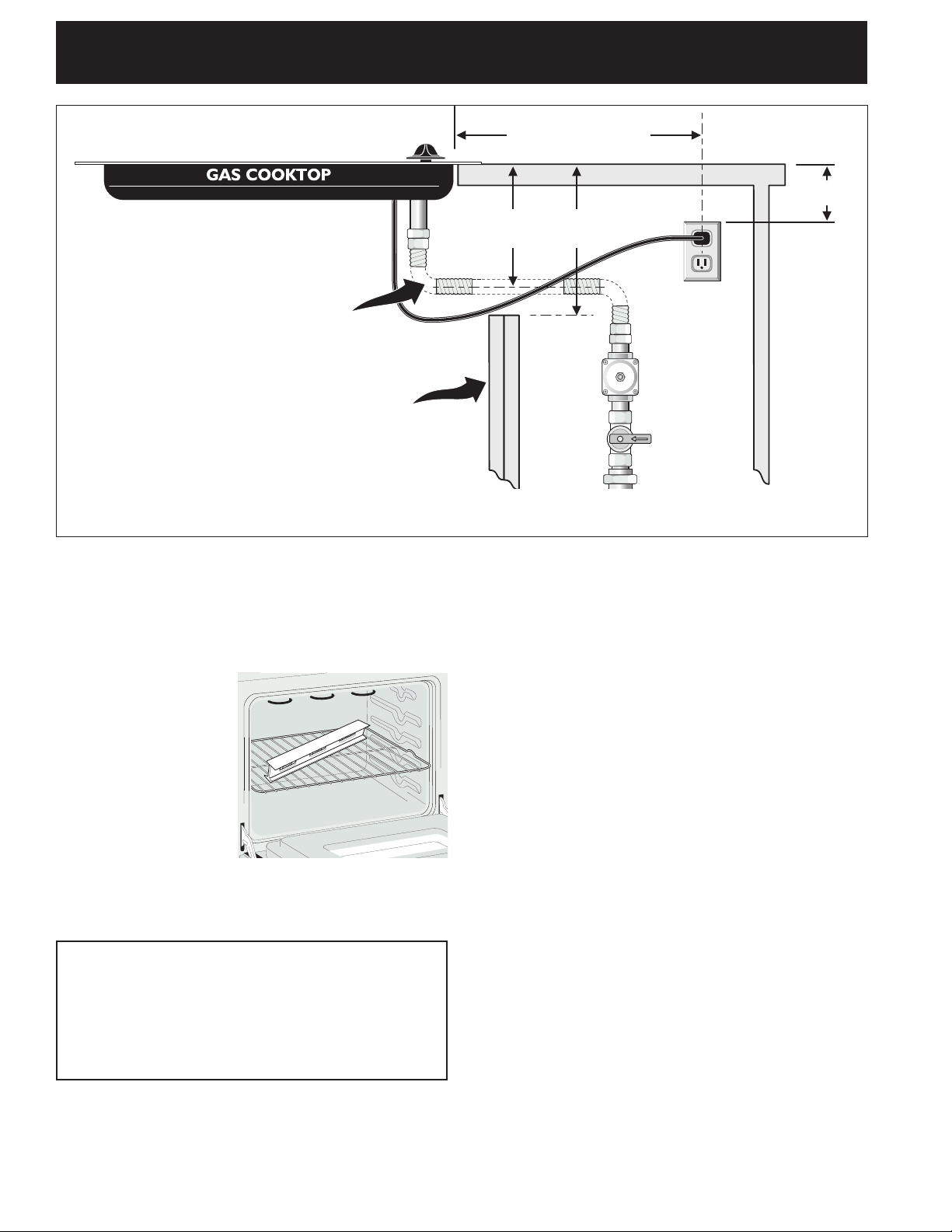

ELECTRIC WALL OVEN INSTALLATION INSTRUCTIONS

(30" 5.1 Capacity Ovens with Optional Electric or Gas Cooktop Combination)

18”(45.7 cm) Max.

4”(10 cm)

Union

Flexible Appliance Conduit

Cabinet sides or

ller panel

Wall Oven Cabinet

Figure 9 - TYPICAL UNDER COUNTER INSTALLATION OF A SINGLE ELECTRIC BUILT-IN OVEN

WITH A GAS COOKTOP ABOVE

6. Leveling the Wall Oven

1. Install an oven rack in the center of the upper oven

(see Figure 10).

2. Place a level on the rack. Take 2 readings with the

level placed diagonally in one direction and then

the other. Use wood shims under the wall oven to

level if necessary.

3. Repeat in the lower

oven if you have a

double cavity wall

oven. If the level

indicates that the rack

is not level, use wood

shims to reach a

compromise for both

ovens.

Figure 10

IMPORTANT NOTE

A cooling fan inside the upper rear part above the

oven (some models) provides cooling of the oven

electrical and electronic components. If the oven

has been operating at high temperatures, the fan

will continue to run after the oven is turned off.

6 1/2” Min.

(16.5 cm)

Flare

Union

120V/60Hz

Grounded

Outlet

Pressure

Regulator

Manual

Shutoff

Valve

Right Side

of Cabinet

accessible

for shut-off

operation)

Flare

5” Max.

(12.7 cm)

7. Checking Operation

Your model is equipped with an Electronic Oven

Control. Each of the functions has been factory

checked before shipping. However, it is suggested

that you verify the operation of the electronic oven

controls once more. Refer to the Use and Care Guide

for operation.

1. Remove all items from the inside of the oven.

2. Turn on the power to the oven (Refer to your Use &

Care Guide.)

3. Verify the operation of the electronic oven controls:

Bake– Verify that this function makes the oven hot.

20 seconds after turning oven on, open the door and

you should feel heat coming from the oven.

Broil– When the oven is set to BROIL, the upper

element in the oven should become red.

Convection (some models)–When the oven is set for

a convection baking or roasting, both elements cycle

on and off alternately and the convection fan will run.

The convection fan will stop running when the oven

door is opened.

Before You Call for Service

Read the "Before You Call for Service Checklist" and

the "Operating Instructions" in your Use and Care

Guide. It may save you time and expense. The list

includes common occurrences that are not the result of

defective workmanship or materials in this appliance.

Refer to your Use and Care Guide for service phone

numbers.

(To be

valve

8

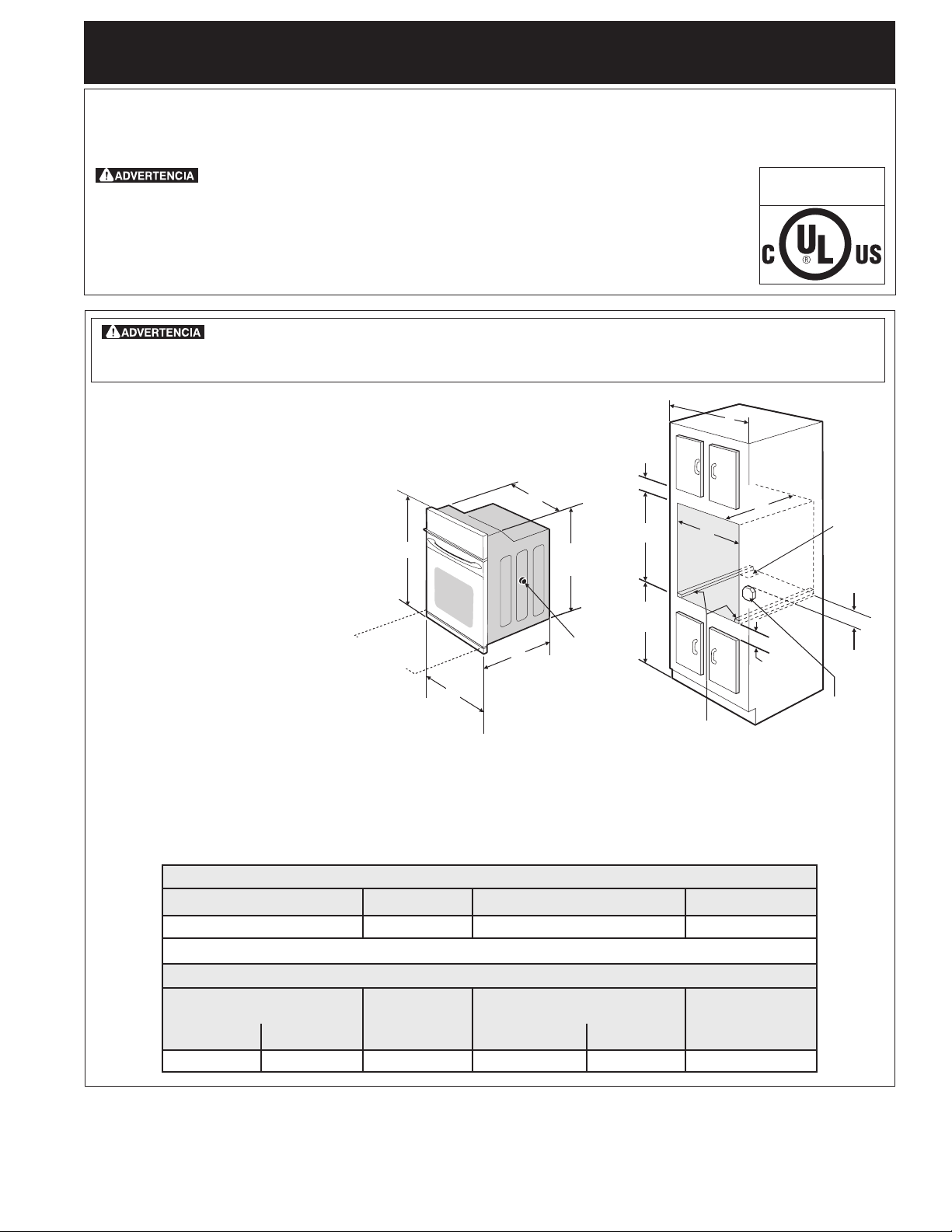

INSTRUCCIONES DE INSTALACIÓN PARA EL HORNO ELÉCTRICO DE PARED

(7.6 cm)

(30" 5.1 capacidad del horno con ombinado con una cocina eléctrica o de gas facultativa)

LA INSTALACIÓN Y EL SERVICIO DEBEN SER EFECTUADOS POR UN INSTALADOR CALIFICADO.

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA USO DEL INSPECTOR LOCAL DE

ELECTRICIDAD. LEA Y GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

PARA SU SEGURIDAD: No almanece ni utilice gasolina u otros vapores y

líquidos inamables en la proximidad de este o de cualquier otro artefacto.

Estados Unidos

y Canadá

El primer paso para su instalación debe de ser el de medir las dimensiones de la apertura

y compararlas con las que se indican en el cuadro de dimensiones del hueco de la gura 1.

Posiblemente encontrará que algún trabajo de carpintería será necesario.

No quite los separadores de los muros laterales del horno empotrado. Estos espaciadores

centran el horno en el espacio provisto. El horno debe estar centrado para prevenir una concentración excesiva

de calor que podría resultar en daños por el calor o un incendio.

NOTAS:

1. La base debe poder sostener 200 libras (90 kg).

2. Deje por lo menos 21" (53.3 cm) de espacio libre para la

profundidad de la puerta cuando esta abierta.

3. La dimensión G (profundidad del

1½” (3.8 cm)

Min.

I

corte) está primordial para instalar

correctamente el horno de pared. Si

el adorno del armazón del horno no

topa contra el armario, o si escuche

un ruido, verique si la dimensión

G está en conformidad con la

B

C

26 11/16”

(67.8 cm)

G

H

F

dimensión requerida.

4. Para un corte de una altura

mayor que 28" (71.1 cm)

agregar una cuña de madera

de 2" (5 cm) de ancho para

lograr la altura apropiada a

cada lado del oricio ubicado

debajo de los rieles laterales

del accesorio.

Puerta Abierta

(vea la nota 2)

Espaciador

D

A

Espaciador de Madera de 2"

(5 cm) de ancho, si es necesario

31”*

(78.7 cm)

2”

(5.1 cm)

Min.

eléctrica

de empalme

* Distancia sugerida desde el suelo es 31" (78.7 cm).

La distancia mínima requerida es 4½" (11.4 cm).

Oricio

para el

Cable

3”

Caja

Hornos simples de Pared de 30" (Para hornos dobles, ver la Figura 2)

DIMENSIONES DEL APARATO

A B C D

30 (76.2) 29 (73.7) 281/4 (71.8) 243/4 (62.2)

DIMENSIONES DEL HUECO Y ANCHURA DEL ARMARIO

F G (Mín.)

Mín. Máx. Mín.

281/2 (72.4) 29 (73.7) 231/2 (59.7) 273/4 (67.9) 28 (71.1) 301/8 (76.5) Mín

Todas las dimensiones se dan en pulgadas (cm).

Imprimido en U.S.A.

Figura 1

9

H. Altura estándar

(**Otras, vea notas 4 & 5)

Máx.

I

P/N 807153704 (15/11) Rev. A

English – pages 1-8

Español – páginas 9-16

Français - pages 17-24

Loading...

Loading...