Page 1

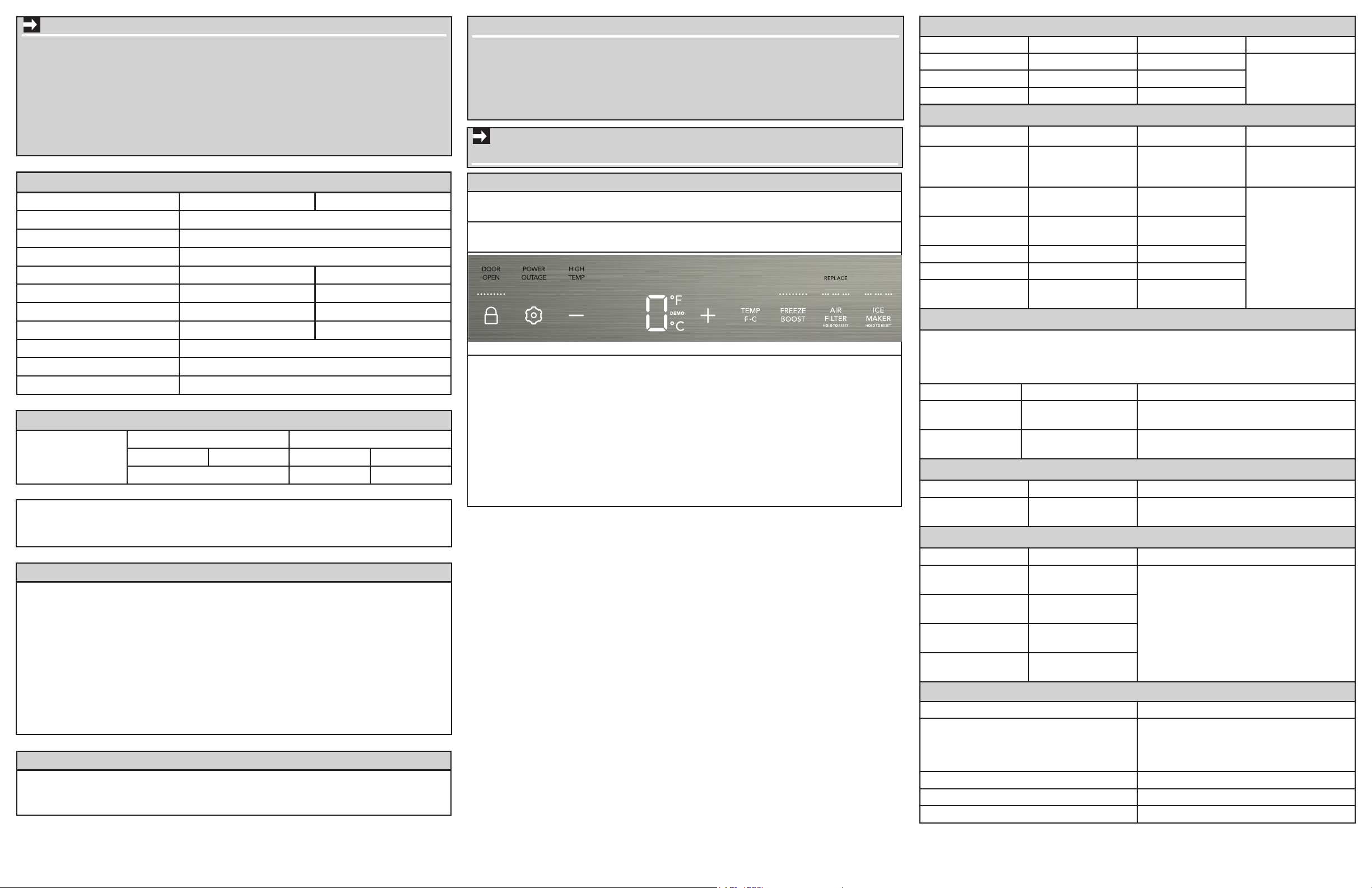

DEFROST CONTROL

IMPORTANT SAFETY NOTE

ICE MAKER INFORMATION

The information provided herein is designed to assist qualified repair

personnel only. Untrained persons should not attempt to make repairs due to

the possibility of electrical shock. Disconnect power cord before servicing this

appliance.

IMPORTANT

If any green/yellow grounding wires are removed during servicing, they

must be returned to their original position and properly secured.

PERFORMANCE AT FACTORY SETTING

Ambient Temperature 70°F 90°F

Operating Time 100%

Freezer Temperature 4 to -4°F

Low Side Pressure (Cut-in) ——

Low Side Pressure (Cut-o) -9.8 to -4.4 psig -7.8 to -4.4 psig

High Side Pressure 35 to 47 psig 51 to 56 psig

Wattage 35W 54W

Amps 0.50 0.68

Base Voltage 115

Refrigerant Charge 50g

Defrost Heater 206W

DEFROST SPECIFICATIONS

Thermal Cutout Heater

Cabinet Size: 19´

Specifications subject to change without notice. For complete performance

data by model, refer to service manual. Options shown are not necessarily

part of model.

The defrost period will vary dependent on the heater on time, with a maximum of 60 minutes. There is a 5 minute idle (drip time) time after the heater

turns o before the evaporator fan and compressor will turn on. During the

defrosting period a temperature sensor monitors the evaporator temperature

and the main control board turns the defrost heater o after the frost on the

evaporator has melted.

A manual defrost can be activated by simultaneously pressing and holding +

and AIR FILTER for 10 seconds. The temperature display will show dF for a

few seconds indicating manual defrost is activated and a beep will be heard.

Then the unit will display the last set point. There may be up to a 3 minute

delay before the defrost heater is energized.

Adjust Water Fill Setting: Press and hold FREEZER BOOST and ICE MAKER

together for 10 seconds. Use + and — to select water fill setting.

Display switches back to normal mode in 10 seconds.

Open Closed Watts Ohms

n/a 206 n/a

SERVICE DATA SHEET

A16331302

AUTOMATIC DEFROST

UPRIGHT FREEZER - R600A

IMPORTANT: PLEASE RETURN THIS SHEET TO

ITS ORIGINAL LOCATION.

SERVICE MODE DIAGNOSTIC TESTS

Allows technicians to step through available tests to diagnose individual

electrical circuits.

To Enter and Exit Service Mode: Press and hold — and +

simultaneously for 10 secs

Controls:

Upon entering Service Mode the User Interface illumination test begins.

1. All of the LEDs on the User Interface will illuminate.

2. Press and release + and all of the LEDs on the User Interface will turn o.

3. Press and release + to move to the Output Loads test. Press and release

FREEZE BOOST to energize load.

4. Pressing and releasing + moves through the Output Loads test, input

tests and information display phase. Press and release — to go back to

previous tests.

5. The table provides the test description, test number that is displayed to

identify the specific test being performed and the displayed info when

the test output or input is activated.

Software Code Streaming

During this phase all software parameters and codes which are programmed

into the Main Control Board and User Interface board will be displayed in the

following order:

1. Main Control Board parameters code (8 characters)

2. Main Control Board software name code (8 characters)

3. User Interface software name code (8 characters)

The User Interface displays each character for 1 second, and then the buzzer

emits a short beep and displays the next character.

• Between the 3 dierent sets of code displays, the User Interface displays a

horizontal bar.

• Pressing and releasing + before the software streaming phase is completed

the Service Mode goes straight to the lifetime information display phase.

• After the software code streaming phase is complete the test automatically

goes to the lifetime streaming phase.

Lifetime Display

During this phase the display shows the total number of days the appliance has

been powered up.

• Each number is shown on the display starting from the most significant

one. Pressing and releasing + makes the buzzer emit a short beep and then

display the next digit.

• Pressing and releasing + when the fourth digit is displayed makes the

Service Mode go straight to the final phase.

Final Phase

During this phase the User Interface shows a 1-sec upcounting timer.

This phase communicates Service Mode has come to an end. To return to

normal mode, press and hold — and + simultaneously for 10 secs.

120 VAC OUTPUT LOAD TESTS

Test Number Load Display

Defrost Heater 2 120 VAC, ≈206 W

Primary Water Valve 56 120 VAC, ≈15 W

oF (OFF)/

on (ON)Condenser Fan 12 120 VAC, ≈3.1 W

DIGITAL OUTPUT TESTS

Test Number Load Display

oF (OFF)

DC Evaporator Fan 15 +12 VDC, ≈1 W

Freezer LED Lights 20

Compressor Inverter Speed Control

Ice Maker Fan 62 +12 VDC, ≈2.5 W

Fill Tube Heater 67 +12 VDC, ≈0.9 W

Ice Maker Filtered

Water Fill Output

38 12 V Square Wave

81 +12 VDC

+12 VDC,

≈21.6 W Total

ՈI (MID SPEED)

on (FULL SPEED)

oF (OFF)/

on (ON)

TWIST TRAY ICE MAKER TESTS

This phase is to test the ice maker twist tray motor and bail arm. When this mode is

entered the twist tray motor moves to the home position. Pressing and releasing ICE

MAKER makes the twist tray cycle (flashes I while cycling). Pressing and releasing ICE

MAKER again makes the bail arm cycle, checking if the ice bucket is empty or full.

Test Number Display

Twist Tray Motor 50

Bail Arm 78

GO (HOME)/I (FLASHING)/

GO (CYCLE COMPLETED)

EՈ (EMPTY)/ I (FLASHING)/ EՈ (EMPTY) or

FU (FULL)

DIGITAL INPUT TESTS

Test Number Display

Freezer Magnetic

Door Switch

24 OP (OPEN)/CL (CLOSED)

TEMPERATURE SENSOR TESTS

Test Number Display

Freezer Cabinet

Temp Sensor

Main Board Ambient

Temp Sensor

Evaporator Defrost

Temp Sensor

Ice Maker Twist

Tray Temp Sensor

30

33

OP (OPEN)/SH (SHORT)

39

45

ERROR CODES

Error Type Digit Display

Communication error (communication

was never achieved at power up or lost

communication between main board and

UI board during normal system run)

Freezer Cabinet NTC T1

Freezer Defrost NTC T2

Freezer Icemaker NTC T6

CE

Page 2

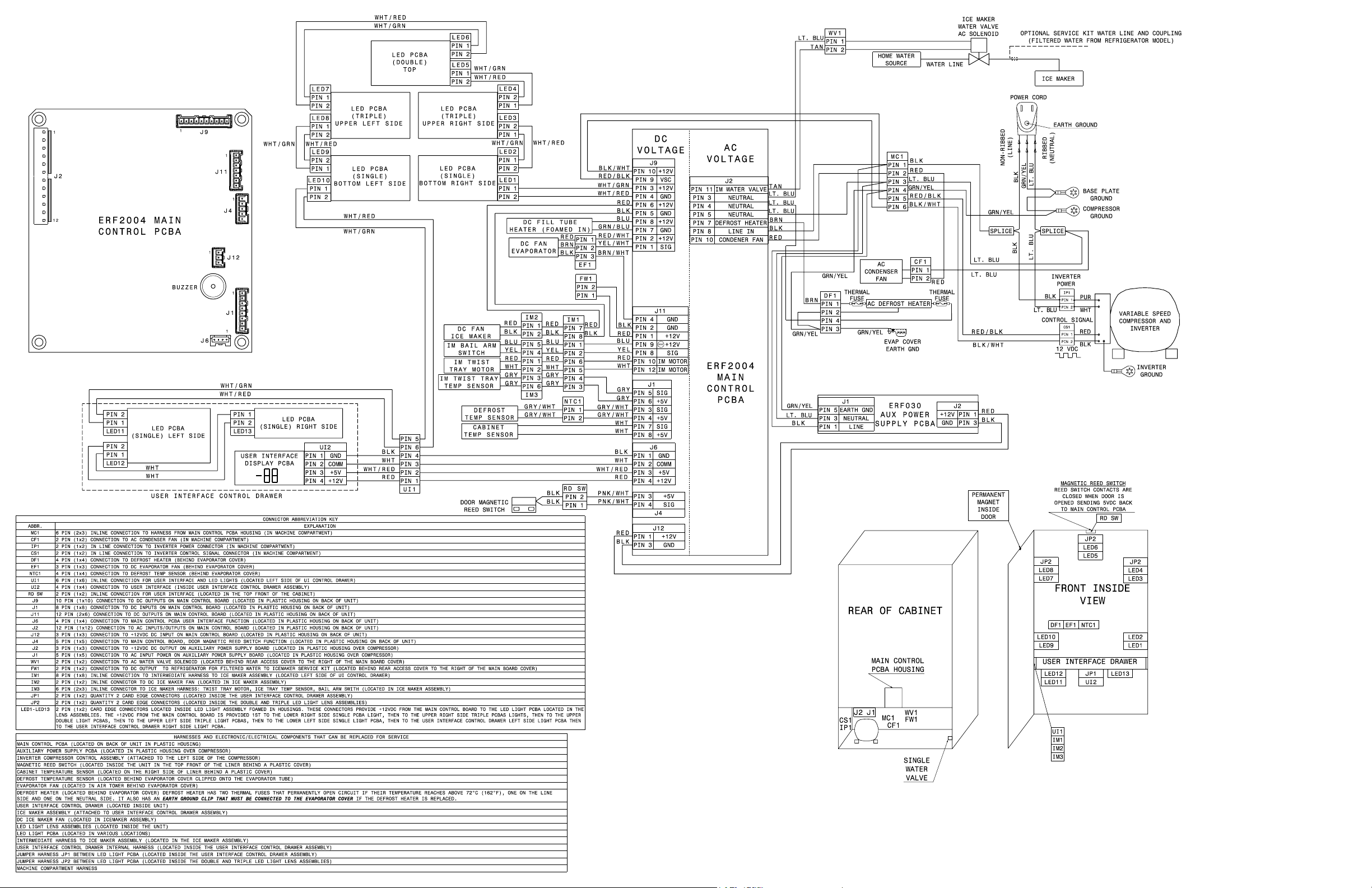

Wiring Diagram A19239201

Loading...

Loading...