Page 1

IMPORTANT:SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

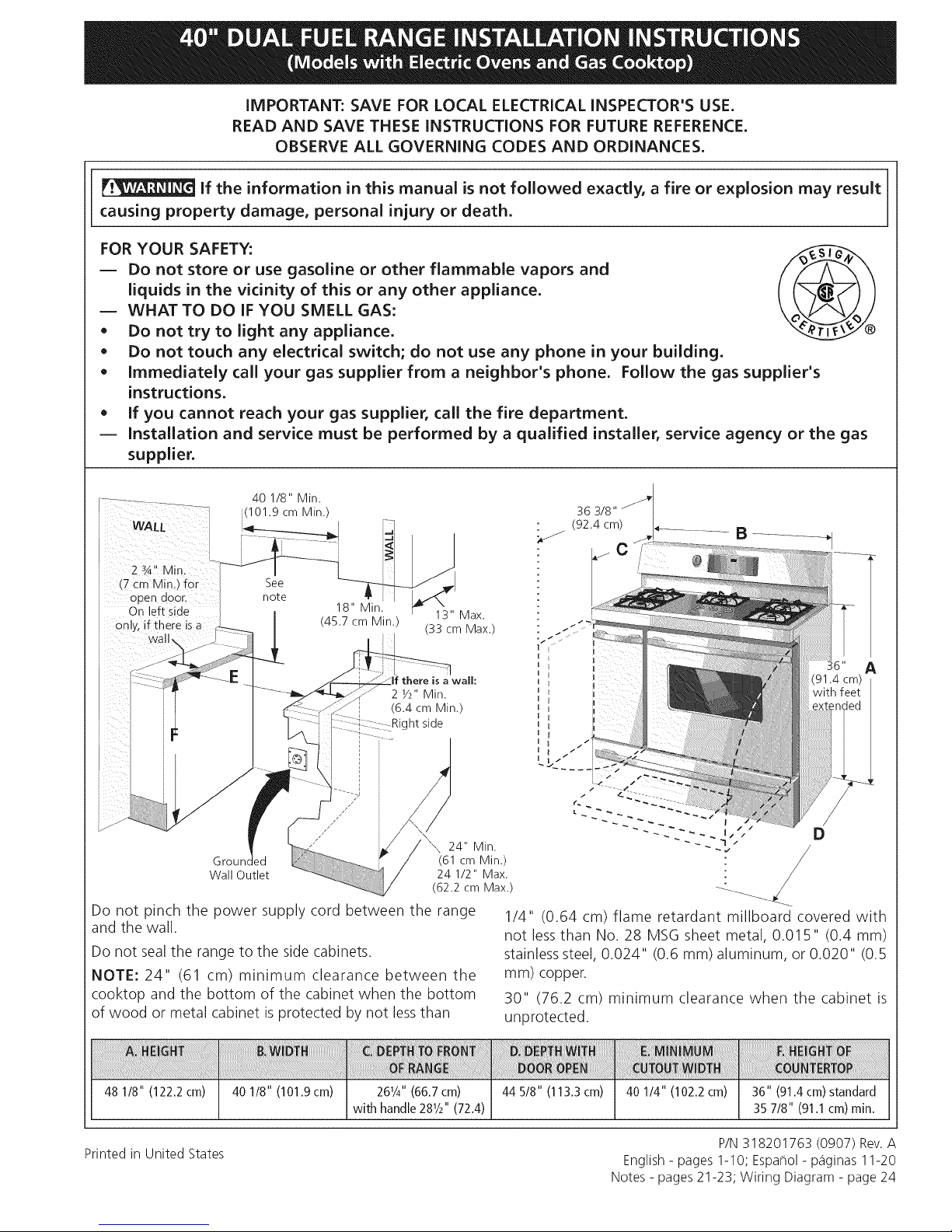

40 1/8" Min.

_(101.9 cm Min.)

WAIL

i (7 cm Min.) for

i open door_

i On left side

0nlyl if there is a

wall,

i

Groun, (61 cm Min.)

Wall Outlet 24 1/2" Max.

See

note

18" Min.

(45.7 cm Min.)

(6.4 cm Min.)

I

I

I

I

I

/"

,/

,/'// 24" Min.

13" Max.

(33 cm Max.)

a wall:

2 Y2" Min.

ht side

(62.2 cm Max.)

Do not pinch the power supply cord between the range

and the wall.

Do not sealthe range to the side cabinets.

NOTE: 24" (61 cm) minimum clearance between the

cooktop and the bottom of the cabinet when the bottom

of wood or metal cabinet is protected by not less than

36 3/8"

(92.4 cm) .÷ .......... B

D

/

1/4" (0.64 cm) flame retardant millboard covered with

not less than No. 28 MSG sheet metal, 0.015" (0.4 mm)

stainless steel, 0.024" (0.6 mm) aluminum, or 0.020" (0.5

ram) copper.

30" (76.2 cm) minimum clearance when the cabinet is

unprotected.

48 1/8" (122.2cm)

40 1/8" (10119cm) 2@/4"(66.7cm) 44 5/8" (113.3 cm) 40 1/4" (102.2 cm)

Printed in United States

with handle 28Y2"(72.4)

36" (91.4cm)standard

35 7/8" (91.1cm) min.

P/N318201763 (0907) Rev.A

English- pages 1-10; Espa_ol- p_Sginas11-20

Notes - pages 21-23; Wiring Diagram - page 24

Page 2

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the electrical supply

to the range (see "Preparation", page 8).

3. Two anti-tip brackets, located inside the oven cavity MUST

be installed (see "Anti-Tip BracketInstallation", page 8).

4. Observe all governing codes and ordinances.

5. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT SAFETY

INSTRUCTION

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223. l-latest edition.

This range has been designed certified by the American

Gas Association. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

o All ranges can

tip.

Injury to

persons could

result.

Install anti-tip

device packed

with range.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70--latest edition (See grounding Instructions on

page 4).

The installation of appliances designed for

manufactured (mobile) home installation must conform

with Manufactured Home Construction

and Safety Standard, title 24CFR, part 3280 [Formerly

To reduce the risk of tipping

of the range, the range

must be secured by properly

installed anti-tip bracket(s)

provided with the range.

To check if the bracket(s) is

installed properly, remove

the lower panel or stor-

age drawer and verify that

the anti-tip bracket(s)is

engaged.

the Federal Standard for Mobile Home Construction

and Safety, title 24, HUD (part 280)] or when

such standard is not applicable, the Standard for

Manufactured Home Installation 1982 (Manufactured

Home Sites, Communities and Setups), ANSI Z225.1/

NFPA 501A-latest edition, or with local codes.

Make sure the wall coverings around the range

can withstand the heat generated by the range.

Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F/32°C above room

temperature without shrinking, warping or

discoloring, Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/4"

(6.4 ram) thick plywood between the range and

carpeting.

Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range, Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is in

use, As children grow, teach them the proper, safe use

of all appliances. Never leave the oven door open when

the range is unattended.

Stepping, leaning or sitting on the

door(s) or drawer of this range can result in serious

injuries and can also cause damage to the range.

Do not store items of interest to children in

the cabinets above the range, Children could be

seriously burned climbing on the range to reach items.

To eliminate the need to reach over the surface

units, cabinet storage space above the units

should be avoided,

Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil,

Excessiveflame is hazardous.

Do not use the oven as a storage space, This

creates a potentially hazardous situation.

Never use your range for warming or heating the

room, Prolonged use of the range without adequate

ventilation can be dangerous.

Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance, Explosions or fires could result.

In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn

the Surface Control knob to Lite. Use caution when

lighting surface burners manually.

Reset all controls to the OFF position after using a

programmable timing operation.

Page 3

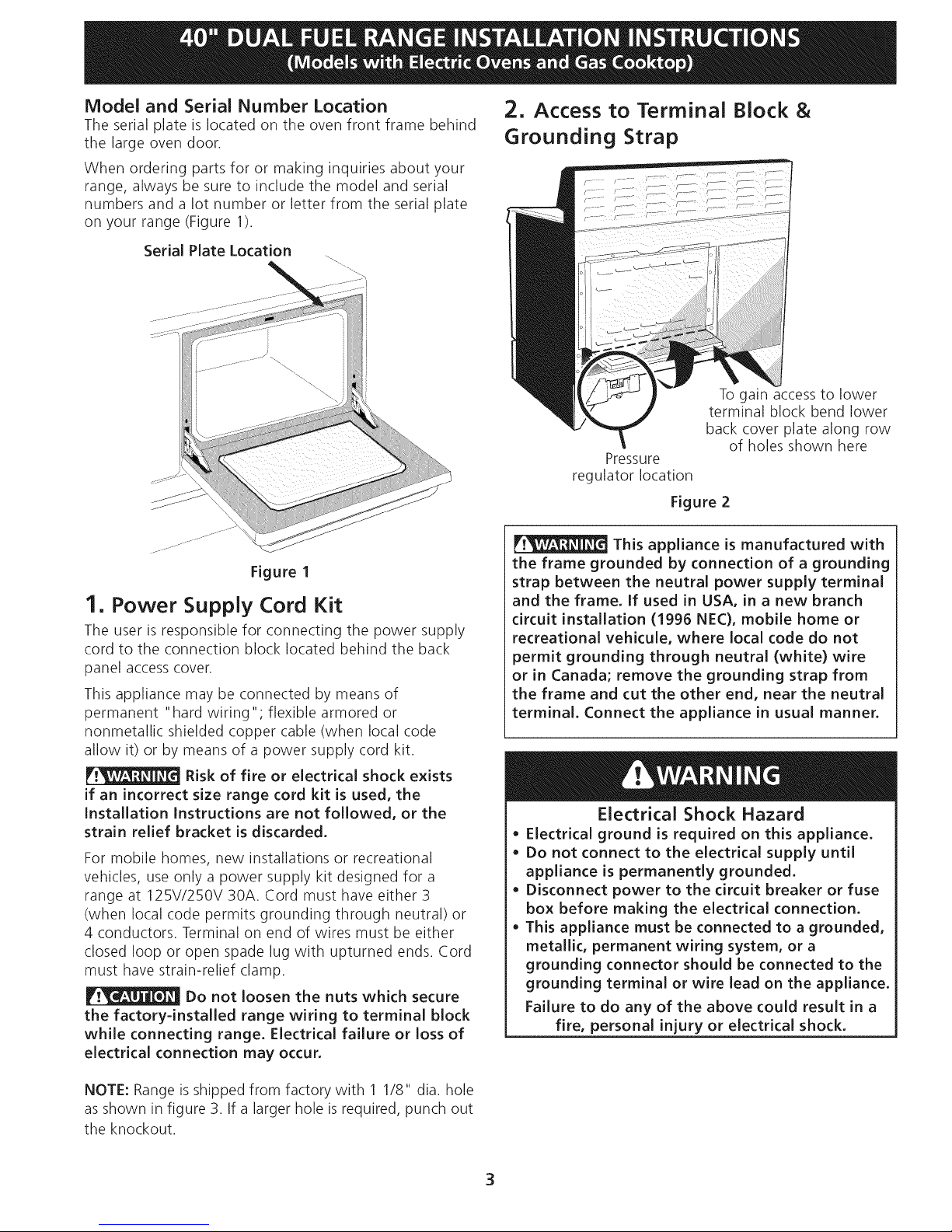

Model and Serial Number Location

Theserialplateislocatedontheovenfrontframebehind

thelargeovendoor.

Whenorderingpartsforormakinginquiriesaboutyour

range,alwaysbesuretoincludethemodelandserial

numbersandalotnumberorletterfromtheserialplate

onyourrange(Figure1).

SerialPlateLocation

Figure 1

1. Power Supply Cord Kit

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

This appliance may be connected by means of

permanent "hard wiring"; flexible armored or

nonmetallic shielded copper cable (when local code

allow it) or by means of a power supply cord kit.

Risk of fire or electrical shock exists

if an incorrect size range cord kit is used, the

Installation Instructions are not followed, or the

strain relief bracket is discarded.

For mobile homes, new installations or recreational

vehicles, use only a power supply kit designed for a

range at 125V/250V 30A. Cord must have either 3

(when local code permits grounding through neutral) or

4 conductors. Terminal on end of wires must be either

closed loop or open spade lug with upturned ends. Cord

must have strain-relief clamp.

Do not loosen the nuts which secure

the factory=installed range wiring to terminal block

while connecting range. Electrical failure or loss of

electrical connection may occur.

2. Access to Terminal Block &

Grounding Strap

To gain access to lower

terminal block bend lower

back cover plate along row

of holes shown here

Pressure

regulator location

Figure 2

This appliance is manufactured with

the frame grounded by connection of a grounding

strap between the neutral power supply terminal

and the frame. If used in USA, in a new branch

circuit installation (1996 NEC), mobile home or

recreational vehicule, where local code do not

permit grounding through neutral (white) wire

or in Canada; remove the grounding strap from

the frame and cut the other end, near the neutral

terminal. Connect the appliance in usual manner.

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appliance must be connected to a grounded,

metallic, permanent wiring system, or a

grounding connector should be connected to the

grounding terminal or wire lead on the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

NOTE: Range is shipped from factory with 1 1/8" dia. hole

as shown in figure 3. If a larger hole is required, punch out

the knockout.

3

Page 4

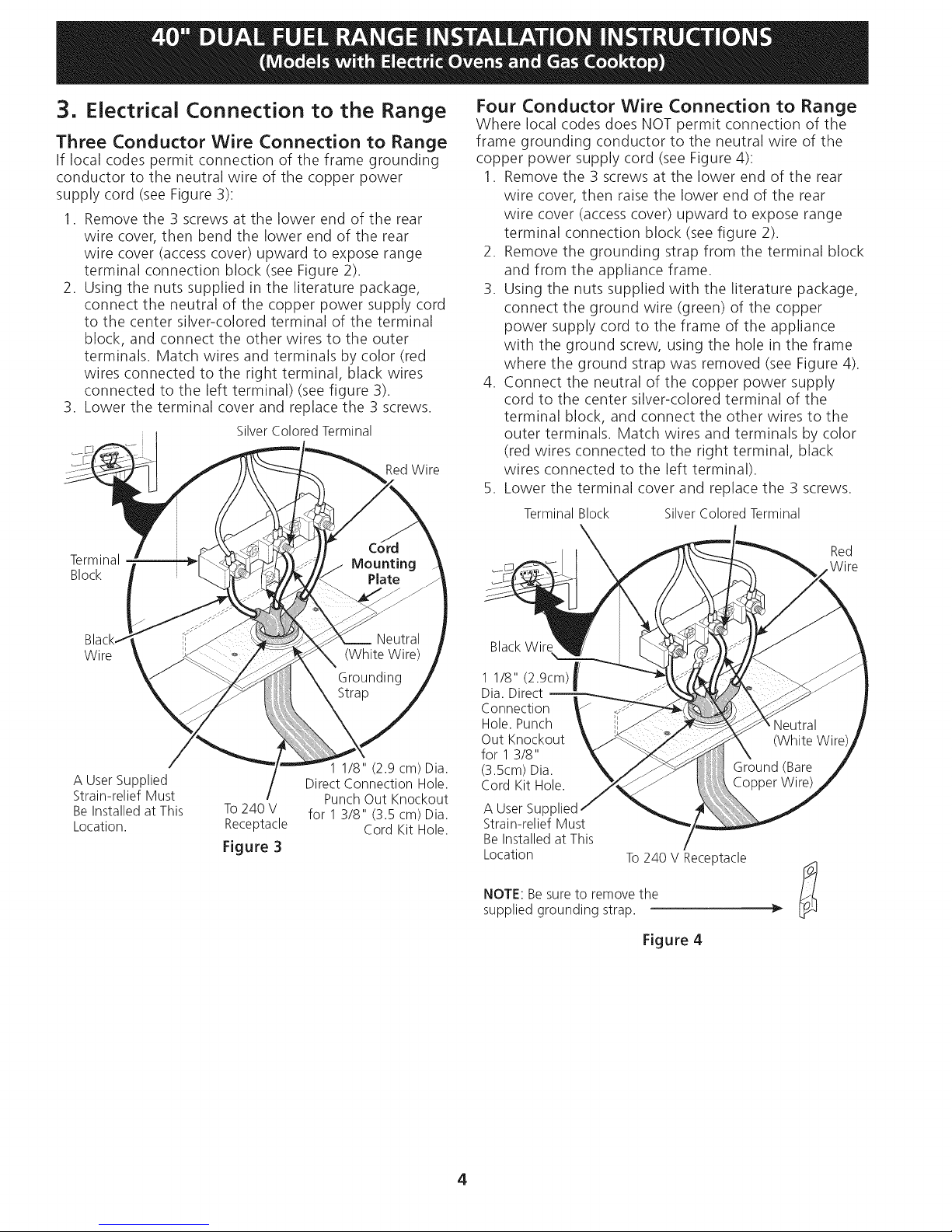

3, Electrical Connection to the Range

Three Conductor Wire Connection to Range

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power

supply cord (see Figure 3):

1. Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear

wire cover (access cover) upward to expose range

terminal connection block (see Figure 2).

2. Using the nuts supplied in the literature package,

connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal) (see figure 3).

3. Lower the terminal cover and replace the 3 screws.

Silver Colored Terminal

RedWire

Four Conductor Wire Connection to Range

Where local codes does NOT permit connection of the

frame grounding conductor to the neutral wire of the

copper power supply cord (see Figure 4):

1. Remove the 3 screws at the lower end of the rear

wire cover, then raise the lower end of the rear

wire cover (access cover) upward to expose range

terminal connection block (see figure 2).

2. Remove the grounding strap from the terminal block

and from the appliance frame.

3. Using the nuts supplied with the literature package,

connect the ground wire (green) of the copper

power supply cord to the frame of the appliance

with the ground screw, using the hole in the frame

where the ground strap was removed (see Figure 4).

4. Connect the neutral of the copper power supply

cord to the center silver-colored terminal of the

terminal block, and connect the other wires to the

outer terminals. Match wires and terminals by color

(red wires connected to the right terminal, black

wires connected to the left terminal).

5. Lower the terminal cover and replace the 3 screws.

Terminal Block Silver Colored Terminal

Terminal

Block

Wire

A User Supplied

Strain-relief Must

Be Installed at This

Location.

To240 V

Receptacle

Figure 3

1 1/8" (2.9 cm) Dia.

Direct Connection Hole.

Punch Out Knockout

for 1 3/8" (3.5 cm) Dia.

Cord Kit Hole.

BlackWire

1 1/8" (2.9cm)_s

Dia. Direct

m

Connection

Hole.Punch

Out Knockout

for 1 3/8"

(3.5cm)Dia.

Cord Kit Hole.

A User Supl

Strain-relief Must

Be Installed at This

Location

NOTE: Be sure to remove the

supplied grounding strap.

To 240 V Receptacle

Red

Wire

Figure 4

4

Page 5

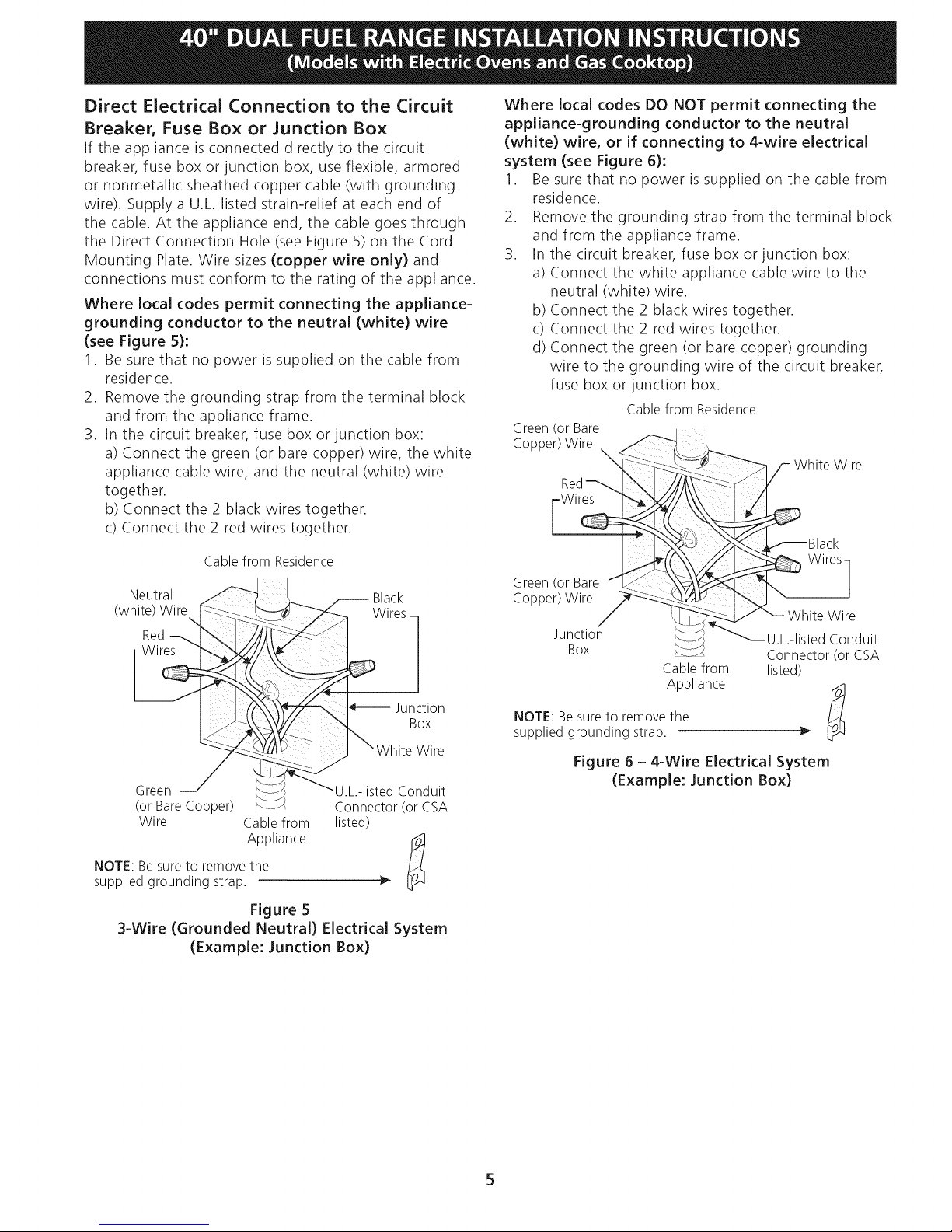

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L. listed strain-relief at each end of

the cable. At the appliance end, the cable goes through

the Direct Connection Hole (see Figure 5) on the Cord

Mounting Plate. Wire sizes (copper wire only) and

connections must conform to the rating of the appliance.

Where local codes permit connecting the appliance-

grounding conductor to the neutral (white) wire

(see Figure 5):

1. Be sure that no power is supplied on the cable from

residence.

2. Remove the grounding strap from the terminal block

and from the appliance frame.

3. In the circuit breaker, fuse box or junction box:

a) Connect the green (or bare copper) wire, the white

appliance cable wire, and the neutral (white) wire

together.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

Where local codes DO NOT permit connecting the

appliance-grounding conductor to the neutral

(white) wire, or if connecting to 4-wire electrical

system (see Figure 6):

1. Be sure that no power is supplied on the cable from

residence.

2. Remove the grounding strap from the terminal block

and from the appliance frame.

3. In the circuit breaker, fuse box or junction box:

a) Connect the white appliance cable wire to the

neutral (white) wire.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

d) Connect the green (or bare copper) grounding

wire to the grounding wire of the circuit breaker,

fuse box or junction box.

Cablefrom Residence

Green(or Bare

Copper)Wire \ _

/- White Wire

Red '!!

I

Wires ' _

_glack

Cable from Residence

Neutral "-'_--'_ _ Black

(white) Wire [_ :::._:-..,..,_-_'_ --_ Wires

, Wile_,_ \,,_I _ZIRed ::*:-1::::_;i_:--/

_ _ _" whiteB_ire

Green J _:'_-__UL listedConduit

(or BareCopper) ; ::- Connector(or CSA

Wire Cablefrom listed)

NOTE:Besureto removethe

suppliedgrounding strap.

Appliance

Figure 5

3-Wire (Grounded Neutral) Electrical System

(Example: Junction Box)

Grepepne(r_i_ i

Junction _:7-'S

Box

Cablefrom

Appliance

NOTE: Be sure to remove the

supplied grounding strap.

Figure 6 - 4-Wire Electrical System

(Example: Junction Box)

Wires]

White WirJe

_U L-listed Conduit

Connector(or CSA

listed)

Page 6

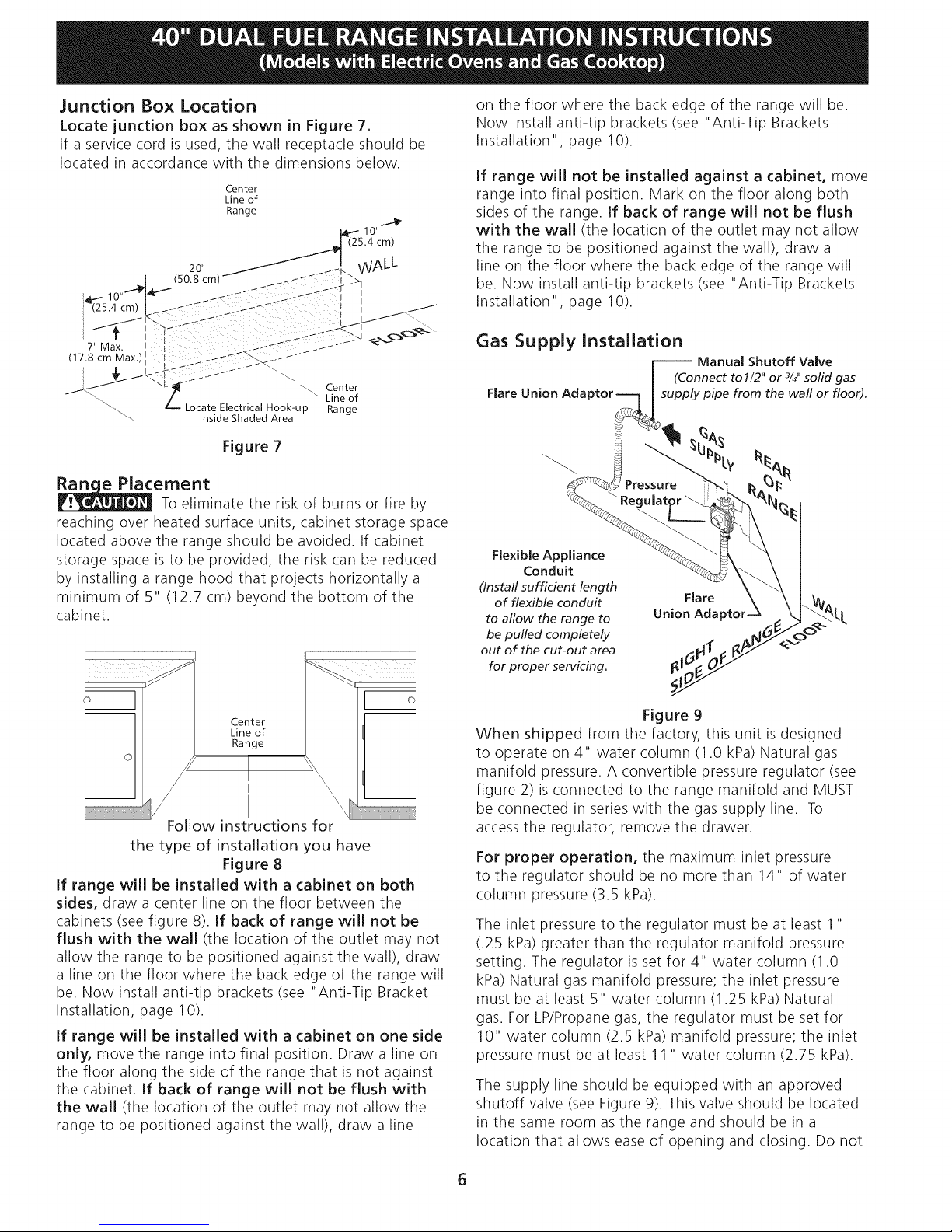

Junction Box Location

Locate junction box as shown in Figure 7.

If a service cord is used, the wall receptacle should be

located in accordance with the dimensions below.

Center

Line of

Range

ALL

"--. Center

Locate Electrical Hook-up

Inside Shaded Area

" Line of

Range

Figure 7

ement

To eliminate the risk of burns or fire by

reaching over heated surface units, cabinet storage space

located above the range should be avoided. If cabinet

storage space is to be provided, the risk can be reduced

by installing a range hood that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the

cabinet.

on the floor where the back edge of the range will be.

Now install anti-tip brackets (see "Anti-Tip Brackets

Installation" page 10).

If range will not be installed against a cabinet, move

range into final position. Mark on the floor along both

sides of the range. If back of range will not be flush

with the wall (the location of the outlet may not allow

the range to be positioned against the wall), draw a

line on the floor where the back edge of the range will

be. Now install anti-tip brackets (see "Anti-Tip Brackets

Installation", page 10).

Gas Supply Installation

l Manual Shutoff Valve

I (Connect to 1/2" or 3/4"solid gas

Flare Union Adaptor-----] I supply pipe from the wall or floor).

F leXlbcl:nA_p_a nee ___

(Install sufficient length

offlexibleconduit ... . \ \1%,

to allow the range to Union Adaptor _' _. k,_ "_ LL

be pulled completely . . _J_/__ < _

out of the cut-out area .,g_1,1_11_ _/_/ _<_

©

Center

Line of

Range

I

Follow instructions for

the type of installation you have

Figure 8

If range will be installed with a cabinet on both

sides, draw a center line on the floor between the

cabinets (see figure 8). If back of range will not be

flush with the wall (the location of the outlet may not

allow the range to be positioned against the wall), draw

a line on the floor where the back edge of the range will

be. Now install anti-tip brackets (see "Anti-Tip Bracket

Installation, page 10).

If range will be installed with a cabinet on one side

only, move the range into final position. Draw a line on

the floor along the side of the range that is not against

the cabinet. If back of range will not be flush with

the wall (the location of the outlet may not allow the

range to be positioned against the wall), draw a line

Figure 9

When shipped from the factory, this unit is designed

to operate on 4" water column (1.0 kPa) Natural gas

manifold pressure. A convertible pressure regulator (see

figure 2) is connected to the range manifold and MUST

be connected in series with the gas supply line. To

access the regulator, remove the drawer.

For proper operation, the maximum inlet pressure

to the regulator should be no more than 14" of water

column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1"

(.25 kPa) greater than the regulator manifold pressure

setting. The regulator is set for 4" water column (1.0

kPa) Natural gas manifold pressure; the inlet pressure

must be at least 5" water column (1.25 kPa) Natural

gas. For LP/Propane gas, the regulator must be set for

10" water column (2.5 kPa) manifold pressure; the inlet

pressure must be at least 11 " water column (2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 9). This valve should be located

in the same room as the range and should be in a

location that allows ease of opening and closing. Do not

Page 7

blockaccesstotheshutoffvalve.Thevalveisforturning

onorshuttingoffgastotheappliance.Opentheshutoff

valveinthegassupplyline.Waitafewminutesforgas

tomovethroughthegasline.

Thegassupplybetweentheshutoffvalveandthe

regulatormaybeconnectedbyrigidpipingor byC.S.A.

approvedflexiblemetallicunionconnectedpipingwhere

localcodespermituse.

Thegassupplypipingcanbethroughthesidewall

oftherightcabinet.Therightsidecabinetisanideal

locationforthemainshutoffvalve.

Donotmaketheconnectiontootight.

Theregulatorisdiecast.Overtighteningmaycrackthe

regulatorresultinginagasleakandpossiblefireor

explosion.

Assembletheflexibleconduitfromthegassupplypipe

tothepressureregulatorinthisorder:

1-manualshutoffvalve,2-flareunionadapter,

3-flexibleconduit,4-flareunionadapter,

5-pressureregulator.

Thegassupplylinetotheshutoffvalveshouldbe

1/2"or3/4"solidpipe.

Theusermustknowthelocationofthemainshutoff

valveandhaveeasyaccesstoit.

Checkalignmentof valvesafterconnectingthe

cooktopto thegassupplytobesurethemanifoldpipe

hasnotbeenmoved.

Disconnectthe rangeandits individualshutoff

valvefromthegassupplypipingsystemduringany

pressuretestingofthesystemattestpressuresgreater

than1/2psig(3.5kPaor 14"watercolumn).

LP/PropaneGasConversion

ThisappliancecanbeusedwithNaturalGasorPropane

Gas.Itisshippedfromthefactoryforusewithnaturalgas.

IfyouwishtoconvertyourrangeforusewithLP/Propane

gas,usethesuppliedfixedorifices;theyarecontainedin

aspecialbagalongwithinstructionsmarked"FORLP/

PROPANEGASCONVERSION",locatedonthe backof

therange,closeto theapplianceregulatorvalve.

Theconversionmustbeperformedbyaqualifiedinstaller,

LPsupplieror servicetechnicianin accordancewith the

installationinstructionsfurnishedwith thisrangeandall

codesandrequirementsofalllocalcodesandrequirements.

Failuretofollowinstructionscouldresultinseriousinjuryor

propertydamage.Thequalifiedagencyperformingthiswork

assumesresponsibilityfortheconversion.

Failuretomaketheappropriateconversion

canresultinpersonalinjuryandpropertydamage.

Whenusingflexiblegasconduit

sufficientslackto pulltherange

ontherange,allow

outsidethecutoutfor

cleaningorservicing.

NOTE:Donotallowtheflexible

betweenthewallandtherange.

conduittogetpinched

Tovisuallycheck,

removetherangedrawer.

Usepipe-jointcompoundmadeforusewithNaturaland

LP/Propanegastosealallgasconnections.Ifflexible

conduitisused,becertainthatit isnotkinked.

Leaktestingof the applianceshallbeconducted

accordingto the manufacturer'sinstructions,

Checkfor leaks.Afterconnectingtherangetothegas

supply,checkthesystemforleakswithamanometer.If

amanometerisnotavailable,turnonthegassupplyand

usealiquidleakdetectoratalljointsandconnectionsto

checkforleaks.

Donotuseaflameto checkforleaks

fromgasconnections.Checkingforleakswithaflame

mayresultinafireorexplosion.

Allopeningsinthewallorfloorwheretherangeisto be

installedmustbesealed.

Tightenallconnectionsif necessaryto preventgas

leakageinthecooktoporsupplyline.

Anyadditions,changesorconversions

requiredinorderforthisappliancetosatisfactorilymeet

theapplicationneedsmustbemadebyanauthorized

SearsServiceCenter,DistributororQualifiedAgency.

Moving the Appliance for Servicing and

Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer and open the oven door. Lift the range at the

front and slide it out of the cut-out opening without

creating undue strain on the flexible gas conduit.

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5kPa or 14"

water column).

Make sure not to pinch the flexible gas conduit at the

back of the range when replacing the unit into the cut-

out opening. Replace the drawer, close the door and

switch on the electrical power and gas to the range.

If the pressure regulator is connected to rigid piping,

the regulator must be disconnected before moving the

appliance.

Reassemble in reverse order (see figure 9).

7

Page 8

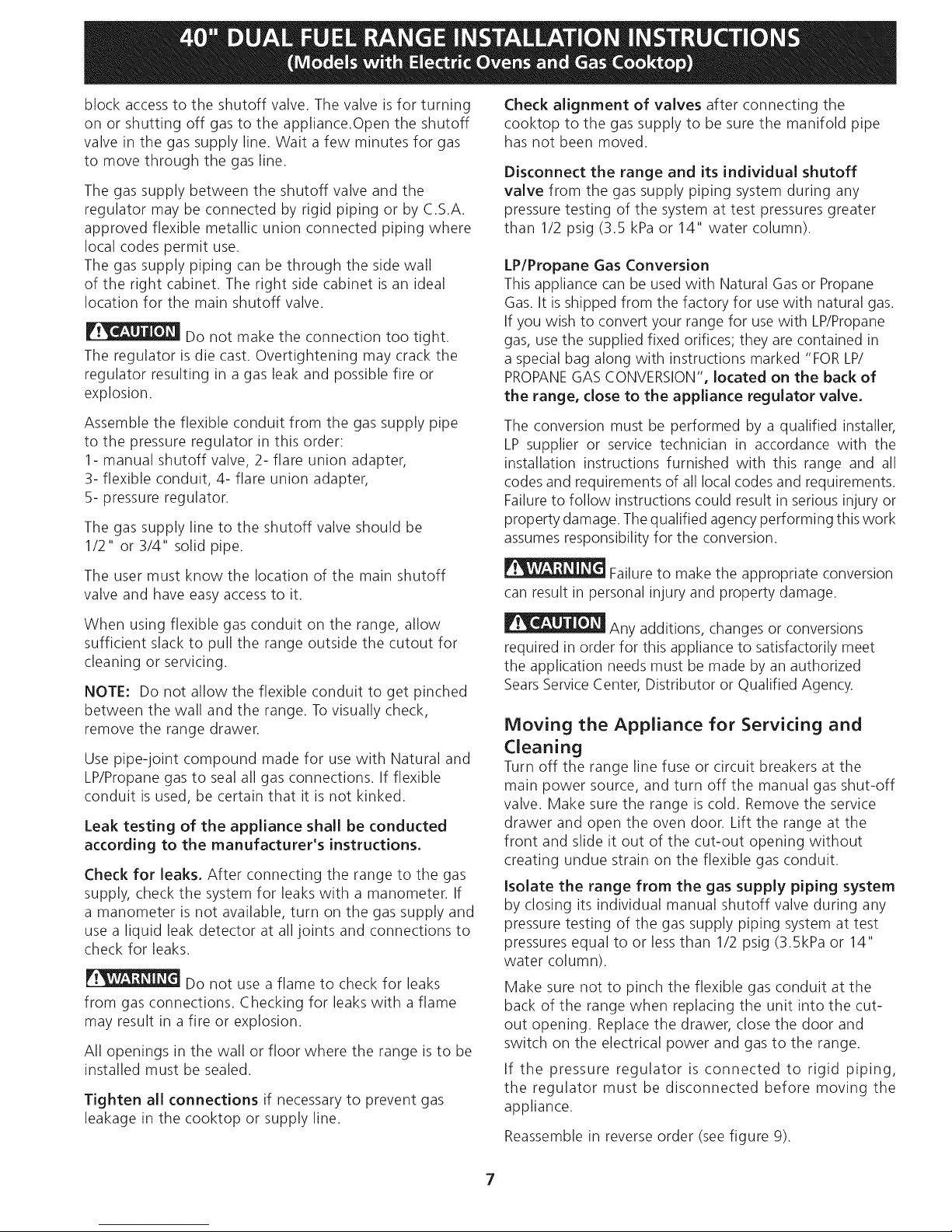

Range Installation

NOTE:

1. The back of the range may be installed directly

against the rear wall of the structure.

2. To reduce possible scorching of vertical walls and

to minimize potential fire hazards under abnormal

surface unit use conditions such as high heat or

no pans and to conform to C.S.A. requirements,

a minimum of 21/2"(6.4 cm) spacing should be

provided on both sides of the cooktop.

3. If a wall is present on the left side of range, allow

a minimum of 2 3/4" (7 cm) to open the auxiliary

door.

Excessive Weight Hazard

• Use 2 or more people to move and install range.

• Failure to follow this instruction can result in

back or other injury.

Preparation

1. Put on safety glasses and gloves. Remove oven racks

and parts package from inside the oven. Remove

shipping materials, tape and protective film from the

range.

2. Take 4 cardboard corners from the carton. Stack

one on top of another. Repeat with other 2 corners.

Place corners lengthwise on the floor in back of the

range to support range.

3. Firmly grasp the range and gently lay it on its back

on the cardboard corners.

4. Remove the 4 shipping bolts from the skid. Discard

skid.

5. Lay a large piece of cardboard in front of the range.

Carefully stand the range upright on cardboard.

6. Adjust the leveling legs to a point where the range

base does not touch the floor.

Figure 10

Check Operation

Refer to the Use and Care Guide and the Electronic Oven

Control Guide packaged with the range for operating

instructions and for care and cleaning of your range.

Remove all packaging from the oven before testing.

.

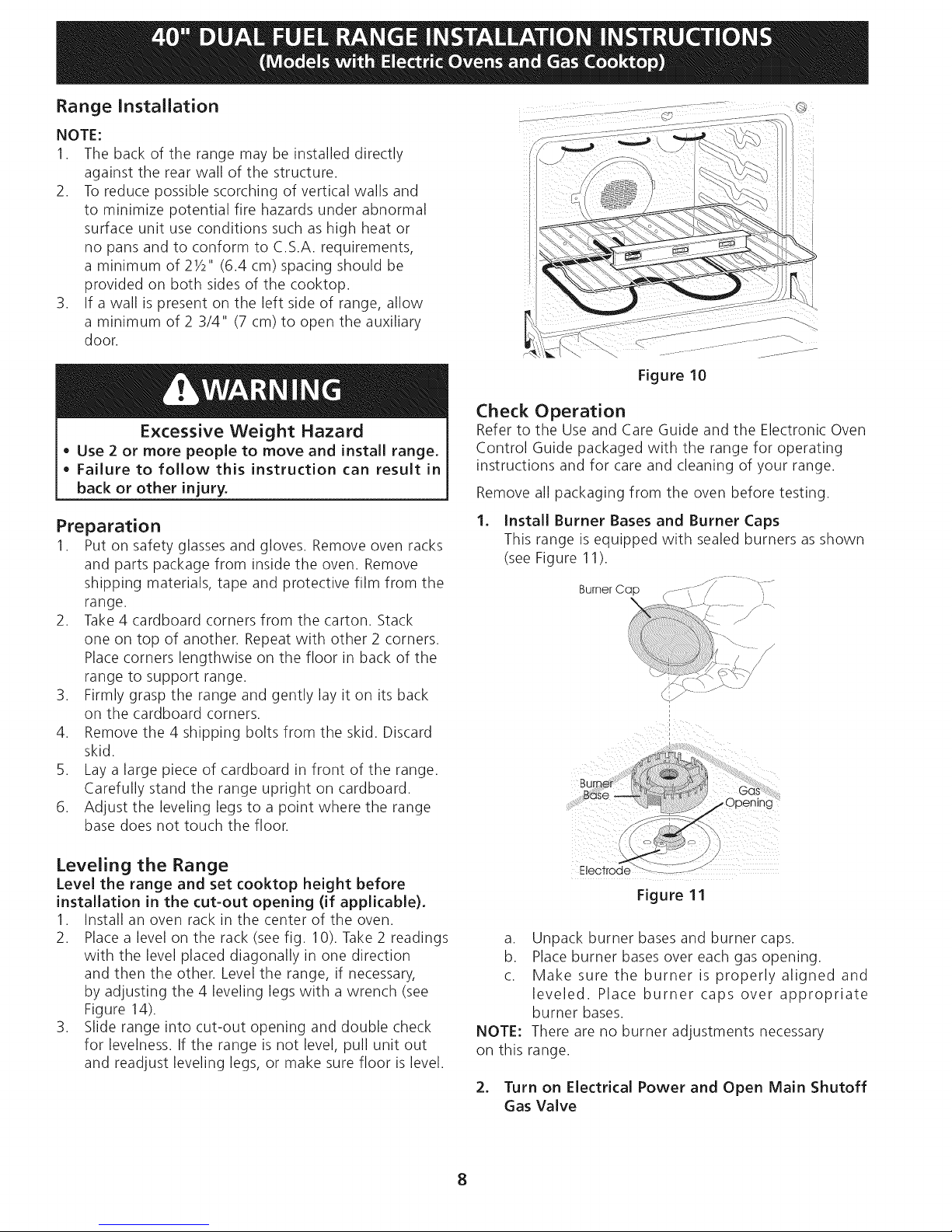

Install Burner Bases and Burner Caps

This range is equipped with sealed burners as shown

(see Figure 11).

Burner Cap _i_.---1,----i_..... " "

.............._. _. _ "_';_,-,/

\.;/

I

Burner

Base _ .

_t LTOS

_Jpen_ng

Leveling the Range

Level the range and set cooktop height before

installation in the cut=out opening (if applicable).

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see fig. 10). Take 2 readings

with the level placed diagonally in one direction

and then the other. Level the range, if necessary,

by adjusting the 4 leveling legs with a wrench (see

Figure 14).

3. Slide range into cut-out opening and double check

for levelness. If the range is not level, pull unit out

and readjust leveling legs, or make sure floor is level.

Electrode ......._ _ ......_/

Figure 11

a. Unpack burner bases and burner caps.

b. Place burner bases over each gas opening.

c. Make sure the burner is properly aligned and

leveled. Place burner caps over appropriate

burner bases.

NOTE: There are no burner adjustments necessary

on this range.

2. Turn on Electrical Power and Open Main Shutoff

Gas Valve

8

Page 9

3_

Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting:

a. Push in and turn a surface burner knob to the

LITEposition. You will hear the igniter sparking.

b. The surface burner should light when gas is

available to the top burner. Each burner should

light within four (4) seconds in normal operation

after air has been purged from supply lines.

Visually check that burner has lit.

c. Once the burner lights, the control knob should

be rotated out of the LITEposition.

There are separate ignition devices for each burner.

Try each knob separately until all burner valves have

been checked.

5. Operation of Oven Elements

The oven is equipped with an electronic oven control. Each

of the functions has been factory checked before shipping.

However, it is suggested that you verify the operation of

the electronic oven controls once more. Refer to the Use

and Care Guide for operation. Follow the instructions for

the Clock, Timer, Bake, Broil, Convection (some models)

and Clean (some models) functions.

When checking oven element operation,

do not touch the elements. They will be hot enough to

cause serious burns.

Bake-After setting the oven to 350°F (177°C) for

baking, the lower element in the oven should become

red.

Broil-When the oven is set to BROIL,the upper element

in the oven should become red.

4_

Adjust the "LOW" Setting of Surface Burner

Valves (see Figure 12)

a. Push in and turn each control to LITEuntil

burner ignites.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, readjust valve as follows:

Reset control to OFE Remove the surface burner

control knob, insert a thin-bladed screwdriver

into the hollow valve stem and engage the

slotted screw inside. Flame size can be increased

or decreased with the turn of the screw. Adjust

flame until you can quickly turn knob from LITE

to LOWEST POSITIONwithout extinguishing

the flame. Flame should be as small as possible

without going out.

Clean-When the oven is set for a self-cleaning cycle, the

upper element should become red during the preheat

portion of the cycle. After reaching the self-cleaning

temperature, the lower element will become red.

Convection-When the oven is set to CONV. BAKE/

ROAST at 350°F (177°C), both elements cycle on and

off alternately and the convection fan will turn. The

convection fan will stop turning when the oven door is

opened during convection baking or roasting.

When All Hookups are Complete

Make sure all controls are left in the OFFposition.

Before You Call for Service

Read the Avoid Service Checklist and operating

instructions in your Use and Care Guide. It may save you

time and expense. The list includes common occurrences

that are not the result of defective workmanship or

materials in this appliance.

Refer to the warranty and service information in your

Use and Care Guide for our phone number and address.

Please call or write if you have inquiries about your range

product and/or need to order parts.

Figure 12

9

Page 10

Important Safety Warning

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed anti-tip

brackets and screws packed with the range. Those parts

are located in a plastic bag in the oven. Failure to install

the anti-tip brackets will allow the range to tip over if

excessive weight is placed on an open door or if a child

climbs upon it. Serious injury might result from spilled

hot liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-

tip brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" (8 mm) Nutdriver

Adjustable Wrench

Electric Drill

3/16" (4.8 mm) Diameter Drill Bit

3/16" (4.8 mm) Diameter Masonry Drill Bit (if installing in

concrete)

Anti-tip Bracket Installation

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram in figure 13 to

locate brackets if template is not available.)

2. Mark on the floor the location of the 4 mounting

holes (2 holes per bracket) shown on the template.

For easier installation, 3/1 6" (4.8 mm) diameter pilot

holes 1/2" (1.3 cm) deep can be drilled into the

floor.

3. Remove template and place brackets on floor with

turned up flanges to the outside (see figure 13).

Line up holes in brackets with marks on floor and

attach with 4 screws provided (2 screws per bracket).

Brackets must be secured to solid floor. If attaching

to concrete floor, first drill 3/1 6" (4.8 mm) dia. pilot

holes using a masonry drill bit.

4. Level range if necessary, by adjusting the 4 leveling

legs with a wrench. (See Figure 14 below.) A

minimum clearance of 1/8" (3.2 mm)is required

between the bottom of the range and the rear

leveling legs to allow room for the anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to be

shifted slightly to one side as it is being pushed back

to allow rear legs to align with brackets.

6. After installation, verify that the anti-tip bracket is

engaged. Open and remove drawer and check to

make sure the anti-tip bracket is engaged.

Anti-tip Bracket

Figure 13 Figure 14

Slide Back

Leveling Leg

Lower

10

Page 11

IMPORTANTE:GUARDEESTASINSTRUCCIONESPARA USO DEL INSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

OBSERVE C6DIGOS TODO GOBERNANTES Y ORDENANZAS.

Si la informad6n contenida en este manual no es seguida exactamente, puede

ocurrir un incendio o explosi6n causando dafios materiales, lesi6n personal o la muerte.

PARA SU SEGURIDAD: /_o_-\,

-- No almacene ni utilice gasolina u otros vapores y liquidos inflamables

en la proximidad de este o de cualquier otto artefacto.

-- QUE DEBE HACER SI PERCIBE OLOR A GAS:

• No trate de encender ningQn artefacto.

• No toque ningQn interruptor el_ctrico; no use ningQn tel_fono en su edifido.

• Llame a su proveedor de gas desde el tel_fono de un vedno.

Siga las instrucdones del proveedor de gas.

• Si no Iogra comunicarse con su proveedor de gas, Ilame al departamento de bomberos.

-- La instalad6n y el servicio de mantenimiento deben ser efectuados pot un instalador calificado,

la agenda de servido o el proveedor de gas.

36 3/8"

(92.4 cm) _-......... B

ill ii

23A"Min.

(7 cmMin.)

Sihayuno

pared,lado

izqu!

Vea

Nota

13" Max.

(45.7 cm Min.) (33 cm Max.)

O

uno pared:

2V2" Min.

(6.4 cm M[n.)

lado derecho

Tomacorriente d, (61 cm M[n.)

puesto a tierra 24V2" Max.

(62.2 cm Max.)

No pellizque el cordOn electrico entre la estufa y la pared.

No selle la estufa a los armarios de lado.

**NOTA: Un espacio mmimo de 24" (61 cm) entre la

superficie de la estufa y el fondo del armario cuando el

fondo del armario de madera o metal est,1 protegido pot

no menos de 1/4" (0.64 cm) de madera resistente al fuego

48 1/8" 40 1/8"

(122.2cm) (101.9cm)

26Y4" (66.7 cm) 44 5/8" (113.3 cm)

con la manilla 28Y2" (72.4)

24" M[n.

D

cubierta por una I_imina met_ilica de MSG, nOmero 28,

0.015" (0.4 ram) de acero inoxidable, 0.024" (0.6 mm) de

aluminio, 6 0.02" (0.5 mm) de cobre.

Un espacio m[nimo de 30" (76.2 cm) cuando el armario no

est,1protegido.

40 1/4" (102.2 cm) 36" (91.4 cm)standard

35 7/8" (91.1cm) min.

Imprimido en los Estados Unidos

P/N318201763 (0907) Rev.A

English- pages 1-10; Espa_ol- p_iginas 11-20

Notes- pages 21-23; Wiring Diagram - page 24

Page 12

Notas importantes para el Instalador

1.Lea todas las instrucciones contenidas en este manual antes

de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento del homo antes de conectar el suministro

electrico a la estufa.

3.Dos soportes antivuelco DEBEN quitarse en el homo y

DEBEN set instalados. Para detalles, vea instrucciones en

la p_igina 20.

4. Observe todos los codigos y reglamentos pertinentes.

5. Deje estas instrucciones con el comprador.

Nota Importante para el Consurnidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

IMPORTANTES INSTRUCCIONES

DE SEGURIDAD

Instalacion de esta estufa debe cumplir con todos los codigos

locales, o en ausencia de codigos locales con el Codigo

Nacional de Gas Combustible ANSI Z223.1--01tima edicion.

El diseho de esta estufa ha sido certificado pot la

Asociacion de Gas Americana. En este como en cualquier

otto artefacto que use gas y genere calor, hay ciertas

precauciones de seguridad que usted debe seguir. Estas

set,in encontradas en el Manual del Usuario, lealo

cuidadosamente.

Todaslasestufas

pueden volcarse.

Estopodria

resultaren lesiones

personales.

Instaleel

dispositivo

antivuelco que

sehaempacado

junto con esta

estufa.

• Asegurese de que la estufa sea instalada y conectada

a tierra en forma apropiada pot un instalador

calificado o pot un tecnico.

• Esta estufa debe set electricamente puesta a tierra

de acuerdo con los cOdigos locales, o en su ausenda,

con el C6digo Electrico National ANSI/NFPA No. 70,

ultima ediciOn.

• La instalaciOn de aparatos disehados para instalaciOn

en casas prefabricadas (moviles) debe conformar con el

Manufactured Home Construction and Safety Standard,

t[tulo 24CFR, parte 3280 [Anteriormente el Federal Standard

for Mobil Home Construction and Safety, t[tulo 24, HUD

(parte 280)] o cuando tal est_indar no se aplica, el Standard

for Manufactured Home Installation 1982 (Manufactured

Home sites, Communities and Setups), ANSI Z225.1/NFPA

501A-ediciOn m_is reciente, o con los cOdigos locales.

Para reducir el riesgo de que

se vuelque la estufa, hay que

asegurarla adecuadamente

coloc_indole Los soportes

antivuelcoqueseproporcionan.

Paracomprobar si estos est_in

instalados y apretados en su

lugarcomosedebe,aseelborde

trasero superior de la estufa y

cuidadosamenteinclinela hacia

adelante para asegurarque la

estufaseancle.

• Asegurese de que el material que recubre las

paredes alrededor de la estufa, pueda resistir el

calor generado pot la estufa.

• Antes de instalar la estufa en un _rea cuyo piso

este recubierto con lin61eo u otto tipo de piso

sintetico, asegurese de que estos puedan resistir

una temperatura de pot Io menos 90°F sobre la

temperatura ambiental sin provocar encogimiento,

deformation o decoloradOn. No instale la estufa sobre

una alfombra al menos que coloque una plancha de

material aislante de pot Io menos 1_ pulgada, entre la

estufa y la alfombra.

• No obstruya el flujo del aire de combusti6n en la

ventilaci6n del homo ni tampoco alrededor de la

base o debajo del panel inferior delantero de la

estufa. Evite tocar las aberturas o _ireas cercanas de la

ventilacion, ya que pueden estar muy calientes durante el

funcionamiento del homo. Laestufa requiere aire fresco

para la combustion apropiada de los quemadores.

Nunca deje ni_os solos o

desatendidos en un _rea donde un artefacto est_

siendo usado. A medida que los nihos crecen, enseheles

el uso apropiado y de seguridad para todos los artefactos.

Nunca deje la puerta del homo abierta cuando la estufa

est,1 desatendida.

No se pare, apoye o siente en las

puertas o cajones de esta estufa pues puede resultar

en serias lesiones y puede tambien causar da_o a la

estufa.

• No almacene articulos que puedan interesar a los

ni_os en los gabinetes sobre la estufa. Los nihos

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos art[culos.

• Los gabinetes de almacenamiento sobre la estufa

deben set evitados, para eliminar la necesidad de

tenet que pasar sobre los elementos superiores de la

estufa para Ilegar a ellos.

• Ajuste el tama_o de la llama de los quemadores

superiores de tal manera que esta no sobrepase el

borde de los utensilios de cocinar. La llama excesiva es

peligrosa.

• No use el homo como espacio de almacenaje. Esto

create1una situacion potencialmente peligrosa.

• Nunca use la estufa para calentar el cuarto. El uso

prolongado de la estufa sin la adecuada ventilacion puede

resultar peligroso.

No almacene ni utilice gasolina u otros vapores y

liquidos inflamables en la proximidad de este o de

cualquier otto artefacto electrico. Puede provocar

incendio o explosion.

En caso de una interrupcion del servicio electrico, es posible

de encender los quemadores de superficie a mano. Para

encender un quemador de superficie, acerque un fosforo

encendido del cabezal del quemador, y gire delicadamente

el boton de control de superficie a LITE (encendido). Tenet

cuidado al encender los quemadores a mano.

• Ajuste todos los controles a la posici6n "OFF"

(apagada) despues de haber hecho una operaci6n

con tiempo programado.

12

Page 13

Ubicacion del Nurnero de Modelo y de Serie

La placa con el n0mero de serie est,1ubicada en el marco

delantero del homo detr_is de la puerta del homo grande.

Cuando haga pedidos de repuestos o solicite informacion

con respecto a su estufa, este siempre seguro de incluir el

n0mero de modelo y deserie y el n0mero o letra del Iote de

la placa de serie de su estufa (figura 1).

La placa de serie

est_ ubicada aqui. _ ...... .

........ Figura I

1, Estuche de cable del suministro electrico

El utilizados es responsable de la conexiOn del cable del

suministro el_ctrico al bloque de conexi6n situado detr_is

del panel de acceso.

El electrodom_stico se puede conectar a trav_s de un

cableado permanente "cableado duro"; cable de cobre

blindado armado o cable no-met_ilico flexible (cuando el

c6digo local Io permite) o pot medio de un kit de cable de

alimentaciOn.

NOTA: La cocina corrediza el6ctrica viene de fabrica con

un agujero de di_imetro 1 1/8" (2.9 cm) come se muestra

en la figura 4. Si un agujero mas largo est,1 necesario

retire la arandela de la pre-cortada.

F_ El riesgo de fuego o de choque

el6ctrico puede aparecer si usa el tamafio de cable

incorrecto, si las instrucdones de instalaci6n no son

seguidas o si retira la abrazadera de releva.

Para casassobre ruedas, nuevas instalaciones, en los

vehiculos de recreativos o en las lugares donde los c6digos

locales no permiten la conexi6n del conductor de tierra

al neutro, un ensamble de suministro el6ctrico de 4

conductores para estufas, calificado a 125/250 voltios

minimo, 30 Amperes minimo, debe de set utilizad.

IF.t_ No desajuste las tuercas que aseguran

[a conexi6n de la cocina a[ bloque terminal cuando

est6 instal,indola. El corte o la perdida de corriente

el6ctrica puede ocurrir.

2. Acceso a la terminal del bloque y

la correa de tierra

Cubierta de

acceso del

alarnbre trasero

Ubicad6n del

regulador de

presi6n

Figura 2

Este electrodom_stico fue fabricado

con el marco aterrizado a traves de una correa

de conexi6n entre el neutral de la fuente de

alimentaci6n y el marco. Si es utilizado en los E.E.

U.U., con un circuito nuevo de instalaci6n (1996

NEC), en casa sobre ruedas o vehiculo recreativo,

donde el codigo local no permite el atterizaje

a trav_s del cable neutro (blanco) o en Canada,

remueva la correa de aterrizaje del marco y corte

el otro extremo, cerca de la terminal de neutral.

Conecte el electrodom_stico de la forma usual

Peligro de choque el_ctrico

• Laconexion a tierra es requerida para este

electrodomestico.

Noconecte al suministro electrico hasta que el

electrodomestico este conectado atierra de rnanera

permanente.

• Desconecteel suministro electrico hacia la caja de

empalmes antes de hacer la conexion electrica.

• Esteelectrodomestico debe set conectado aun sistema

de alambres permanentes, metalicos, conectados a tierra

o una puesta a tierra debe set conectada al terminal de

tierra o un emplomando al electrodomestico.

Elno seguir ninguna de estasinstruccionespodria causar

fuego, heridas personaleso choques electricos.

13

Page 14

3. Conexion electrica a la cocina

Conexi6n del cable a tres alambres ia cocina

Si los c6digos locales permiten la conexi6n del conductor a

tierra del armaz6n al alambre neutral del cable de bronce

del suministro el@ctrico(vea figura 3).

1. Retire los 3 tornillos de la parte baja de la cubierta del

cable trasero (cubierta de acceso), luego levante la

cubierta hacia arriba para tener acceso al bloque de

conexi6n del borne terminal (vea figura 2).

2. Utilizar los tuercas suministraron en el paquete de la

literatura para conectar la parte neutral del cable de

bronce de suministro el_ctrico al terminal plateado que

se encuentra al centro del bloque terminal y, conectar

los otros alambres a los terminales externos. Aparee

los alambres y los terminales segOn el color (alambres

rojos conectados al terminal derecho, alambres negros

conectados al terminal izquierdo) (vea figura 3).

3. Baje la cubierta del terminal y vuelva al colocar los 3

tornillos.

Terminalplata

Alambre

rojo

Bloque

terminal

Conexi6n del cable de cuatro conductores a

ia cocina.

1. Retire los 3 tornillos de la parte baja de la cubierta

del cable trasero, luego levante la cubierta hacia

arriba para tener acceso (cubierta de acceso) al

bloque de conexi6n del borne terminal (vea figura 2).

2. Retire la correa de la base del bloque terminal y del

armaz6n del electrodom@stico. Retenga el tornillo de

la base.

3. Utilizar los tuercas suministraron en el paquete de la

literatura para conectar el alambre de tierra (verde)

del cable de bronce del suministro el@ctrico al

armaz6n del electrodom@stico con el tornillo de la

base, usando el hoyo del armaz6n por donde retir6

la correa de la base (vea figura 4).

4. Conecte el alambre neutral (blanco) del cable de

cobre del suministro el@ctrico al terminal plateado

del centro del bloque terminal y, conecte los otros

alambres a los terminales externos.

5. Baje la cubierta del terminal y vuelva al colocar los 3

tornillos.

Bloque terminal

Terminal plata

Alambre

'0

Alambre

Negro

Una arazadera de

releva provista debe

de estar instalada a

est,1ubicaci6n.

1 1/8" cm) Agujero

de la conexi6n directa.

Retira la arandela pre-

Hacia el 240 V cortada para 1 3/8" (3.5

Recept_iculo. cm) Dia. agujero.

Figura 3

Alambre

Ne(

1 1/8" (2.9 cm)

Dia. A,

de la conexi6n

directa. Retira

la arandela pre-

cortada para 1

318" (3.5 cm)

dia. agujero.

Una arazadera de

releva provista debe de

estar instalada a est,1

ubicaci6n.

NOTA: AsegOrese de quitar

la banda de puesta a tierra

provista.

Haciael 240V recept_iculo

/

Figura 4

14

Page 15

Conexion electrica directa ai cortacircuito, a

ia caja de fusibles o ia caja de empalmes

Si el aparato est_Sconectado directamente al cortacircuito,

a la caja de fusibles o a la caja de empalmes, use un cable

blindado flexible o no met_qlicorecubierto de cobre (con

alambre a tierra). Provee una abrazadera releva de anclaje

hom61ogo UL a cada extremidad del cable. A la extremidad

del electrodom_stico, el cable pase a trav_s del agujero

de la conexi6n directa (vet figura 5) en el cord6n de la

placa de montaje. El tamaho de los alambres (alambre de

cobre solamente) y las conexiones deben estar conforme

al r_gimen del electrodom_stico.

Donde los c6digos locales permitan conectar el

conductor de puesta a tierra del electrodom_stico al

neutral (blanco) (vea figura 5):

1. Desconecte el suministro el_ctrico.

2. Quite la banda de puesta a tierra de la caja de

empalmes y del marco de la estufa.

3. En el cortacircuito, la caja de fusibles o la caja de

empalmes:

a) Conecte el alambre verde (o cobre desnudo), el

alambre blanco del cable del electrodom_stico y el

alambre neutral (blanco)juntos.

b) Conecte los dos alambres negros juntos.

c) Conecte los dos alambres rojos juntos.

Cable de la fuente de

alimentaciOn

Alambre neutro _ Alambres

(blanco) negros

Alambres

rojos

Caja de

empalmes

Alambre blanco

Alambre

desnudos

overdes

Cable de la

estufa

Conductorde

uni6n listado-UL

(listado-CSA)

Donde los c6digos locales NO permitan conectar el

conductor de puesta a tierra del electrodom_stico al

neutral (blanco), o si est_ conectado con un sistema a

4 alambres (vea figura 6):

1. Desconecte el suministro el_ctrico.

2. Separe el alambre verde (o cobre desnudo) y el

alambre blanco del electrodom6stico.

3. En el cortacircuito, la caja de fusibles o la caja de

empalmes:

a. Conecte el alambre blanco del cable del

electrodom6stico al alambre neutral (blanco).

b. Conecte los 2 alambres negros juntos.

c. Conecte los 2 alambres rojos juntos.

d. Conecte el alambre verde (o de cobre desnudo) de

la puesta a tierra del alambre al alambre de puesta

a tierra del cortacircuito, de la caja de fusibles o de

la caja de empalmes.

Alambre

desnudo

o verde

Alambres

rojos

Cable de la fuente de

alimentaciOn

Alambre blanco

1

-- Alambres

Alambre

desnudo

o verde

Caja de

empalmes

Cablede la

estufa

NOTA: Asegurese de quitar

la banda de puesta a tierra provista.

Figura 6

Sistema El_ctrico a 4 Alambres

(Ejemplo: Caja de empalmes)

negros

Alambre blanco

Conductorde

uni6n listado-UL

(o listado-CSA)

NOTA: Aseg0rese de quitar

la banda de puesta a tierra

provista.

Figura 5

Sistema El_ctrico a 3 Alambres (Neutral puesta a tierra)

(Ejemplo: Caja de empalmes)

.S

15

Page 16

Situacion de caja de union

Localice la caja de ernpalmes como se ve en la Figura 7.

Si se usa un cord6n de servicio, el recept_iculo de pared

debe estar Iocalizado seg0n las medidas que se indican

abajo.

Construcci6n de los Armarios

Center

DELA ESTUFA

20" _ __. PARED

/ (50.8cm)f ! j_ _-- __:

10,,_14 -'_ <!<< _ L_<, T- i

(17.8 cm Max.) I I _._ <" \-._ _

_,,jff \ L-:_ _ Center

....................L UBIQUE LO ELECTRICO DE LA

incendios al tocar superficies sobrecalentadas, se debe evitar

colocar espacio para armarios de almacenamiento sobre

las estufas con elementos al descubierto. Si se instalan

armarios sobre la estufa, se pueden reducir tales riesgos

instalando una campana purificadora que se proyecta

horizontalmente un minimo de 5" (12.7 cm) m_is afuera de

la parte inferior de los armarios.

Si la estufa se va a Jnstalar con un arrnarJo a arnbos

lados, marque el centro de la abertura del armario en el piso.

DENTRO DEL AREA ESTUFA

SOMBREADA

Figura 7

Para eliminar el riesgo de quemaduras e

Center

Line of

Range

parte trasera de la estufa no estar_ a ras con la pared

(la ubicacion del tomacorriente puede que no permita que la

estufa se pegue a ras con la pared), marque el piso donde el

borde trasero de la estufa estate1. Ponga el patron en el piso y

alinee el lado del patron con la I[nea marcada en el piso. Ali-

nee la parte trasera del patron con la pared trasera o la I[nea

marcada para la parte de atr_is de la estufa.

SJla estufa no ser_ Jnstalada junta contra un armarJo,

mueva la estufa a su posicion final. Marque el piso pot los

dos lados de la estufa. Si la parte trasera de la estufa no

estar,_ a ras con la pared (la ubicacion del tomacorriente

puede que no permita que la estufa se pegue a ras con la

pared), marque en el piso donde el borde trasero de la estufa

estate1.Ponga el patron en el piso y alinee los lados del patron

con las I[neas marcadas en el piso. Alinee la parte trasera del

patron con la pared trasera o la I[nea marcada para la parte

trasera de la estufa (vea instalacion del Soportes Antivuelco

p_igina 20).

Instalaci6n de ia alimentaci6n de gas

V_lvula Manual Externa de Cierre

(Conecte a un conducto sOlido de

Adaptor de gas suministro de gas de 1/2" o 3/4").

Reguladol

presi6n

Conector Flexible

para Artefactos

(Instale un conducto

Io suficientemente

largo para poder sacar la

estufa totalmente fuera

de la _rea recortada

para un servicio satisfactorio.)

Adaptor de gas.

I

I

Siga las instrucciones para el tipo de

instalaci6n que usted tenga

Figura 8

Si la parte trasera de la estufa no estar_ a ras con la

pared (la ubicacion del tomacorriente puede que no permita

que la estufa se pegue a ras con la pared), marque el piso

donde estate1el borde trasero de la estufa. Ponga el patron

en el piso, alineando la linea del centro del patron con la

marca en el centro de la abertura del armario. Ponga el borde

trasero del patron a ras contra la pared trasera o la linea mar-

cada para la parte de atr_is de la estufa.

Si la estufa se va a instalar con un armarJo a s6lo un

lado, mueva la estufa a su posicion final. Marque el piso pot

el lado de la estufa que no estate1contra el armario. Si la

Figura 9

Esta unidad ha sido ajustada para operar con un m01tiple de

admision para gas natural de 4" (1.0 kPa). Un regulador de

presion convertible esta conectado a la wilvula distribuidora

y DEBE set conectado en serie con la tuber[a de suministro

de gas.

Para la operaci6n apropiada, la m_ixima presiOn de

entrada al regulador no debe exceder la presion de una

columna de agua de 14 pulgadas (3.5 kPa).

La presion de entrada al regulador debe set pot Io menos 1

pulgada m_is grande que la wilvula distribuidora (.25 kPa).

El regulador ha sido ajustado para gas natural a 4 pulgadas

de presion para la wilvula distribuidora (1.0 kPa). La presion

de entrada debe ser pot Io menos de 5 pulgadas (1.25

kPa). Para propano I[quido a 10 pulgadas de presion para la

wilvula distribuidora (2.5 kPa) la presion de entrada debe set

pot Io menos de 11 pulgadas (2.75 kPa).

16

Page 17

La tuberfa deberfa set equipada con una wilvula de cierre

aprobada (vea Figura 6). Esta wilvula debe ubicarse en la

misma habitacion que la estufa en un lugar que permita

una facilidad de abrir y cerrar. No bloque el acceso a

la wilvula de cierre. La wilvula es para abrir o cerrar el

suministro de gas al aparato.

Abra la wilvula de cierre en la Ifnea de suministro de gas.

Espere unos minutos a que el gas se mueva pot el tubo.

El suministro de gas entre la wilvula de cierre y el regulador

se puede conectar con tuberfa rfgida o con tuberfa flexible

union met_ilica conectada y aprobada pot la C.S.A. donde

los codigos locales permiten.

La tuberfa del suministro de gas puede pasar pot la pared

lateral del armario derecho. El armario lateral derecho es un

lugar ideal para la wilvula de cierre principal.

No haga que la conexion este demasiado

apretada. El regulador est,1 fundido a troquel. Apret_indolo

demasiado podrfa romper el regulador resultando en escape

de gas y posiblemente un incendio o explosion.

Monte el conector flexible desde el tubo de suministro

de gas hasta el regulador de presion seg0n este orden:

1- wilvula de cierre manual, 2- adaptar de gas, 3-conector

flexible, 4- adaptar de gas, 5- regulador de presion.

La tuberfa de suministro de gas debe set de 1/2" o 3/4" D.I.

El consumidor debe saber la posicion de la wilvula principal

de cierre y tenet acceso f_icil a ello.

Cuando se usa un conducto flexible en la estufa, permita

suficiente flojedad como para sacar la estufa fuera del

recortado para la limpieza y el servicio.

NOTA: No permita que el conducto se pellizque entre la

pared y la estufa. Para verlo, saque el cajon.

Use un compuesto para junturas de tuberfa hecho para

uso con gas natural y de LP/Propano para sellar todas las

conexiones del gas. Si se usan los conectores flexibles

aseg0rese de que no esten enroscados.

Para verificar si hay fugas en el electrodomestico se

debe de seguir [as instrucciones de[ fabricante.

Asegurese de que no haya escapes de gas. Despues

de conectar la estufa al suministro de gas, compruebe el

sistema con un manometro. Si no tiene un manometro,

abre el gas y use un detector de fugas Ifquido en todas las

junturas y conexiones para averiguar si hay escapes de gas.

No use llama para controlar que no

hayan perdidas de gas. La comprobacion de perdidas de gas

con una llama puede resultar en un incendio o explosion.

Se debe sellar todas las aberturas en la pared o el piso donde

la estufa se instala.

Apriete todas las conexiones si hace falta para prevenir

fugas de gas en la superficie de la estufa o en la linea de

suministro.

Asegurese del alineamiento de las v&lvulas despues

de conectar la superficie de la estufa con el suministro del

gas para cerciorarse de que el tubo de escape no se haya

movido.

Desconecte esta estufa y su v&[vu[a individual de

cierre del sistema del suministro de gas durante cualquier

prueba de presion de ese sistema a presiones mayores de

1/2 psig (3.5 kPa o 14" columna de agua).

ConversiOn para uso de Propano Liquido

Este aparato puede set usado con gas natural o propano

Ifquido. Ha sido ajustado en la f_ibrica para operar con gas

natural solamente.

Si desea convertir su estufa para uso con propano Ifquido,

use los orificios provistos ubicados en el bolso que contiene

la literatura titulada "FOR LP/PROPANE GAS CONVERSION",

[ocaHzado en [a parte posterior de[ homo, cerca de [a

v_[vu[a de[ regu[ador del horno, Siga las instrucciones

que vienen con los orificios.

La conversion debe set efectuado pot un tecnico de servicio

capacitado, de acuerdo con las instrucciones del fabricante

y con todos los codigos y requisitos de las autoridades

correspondientes. El no seguir las instrucciones podrfa dar

como resultado lesiones graves o dahos a la propiedad. El

organismo autorizado para Ilevar a cabo este trabajo asume

la responsabilidad de la conversion.

La falta de una conversion apropiada

puede resultar en lesiones graves y dahos a la propiedad.

La instalacion y el servicio de manteni-

miento deben set efectuados pot un instalador calificado, la

agencia de servicio o el proveedor de gas.

La mudanza de[ aparato para reparaciones o

[impieza

Apague la corriente electrica a la estufa a la fuente de poder

principal, y apague la wilvula de cierre manual de gas. Aseg0-

rese de que la estufa este fresca. Quite el cajon de servicio y

abre la puerta del homo. Levante la frente de la estufa y deslf-

cela fuera de la abertura sin crear tension desmedida sobre el

conducto flexible de gas.

Ais[a [a estufa de[ sisterna de[ surninistro de gas cerran-

do su wilvula manual de cierre individual durante cualquier

prueba de presion del suministro del gas a presiones iguales a

menos de 1/2 psgi (.5 kPa o 14" columna de agua).

Aseg0rese de no pellizque el conducto flexible de gas detr_is

de la estufa al reemplazar la unidad en la abertura. Reem-

place el cajon, cierre la puerta y enciende el gas y la corriente

electrica a la estufa.

El regulador debe desconectares antes de mover el aparato,

si el regulador de la estufa se conecta a una caherfa rigida.

Re ensamble en orden inverso (consulte Figura 9).

17

Page 18

InstalaciOn de ia estufa

NOTA:

1. La parte trasera de la estufa puede set directamente

instalada a ras con la pared trasera de la estructura.

2. Para reducir posibles marcas o rayas de las paredes

verticales y minimizar los riesgos de choques electricos en

caso de condiciones de uso anormales como alto calor o

no cazuelas, y para conformar a los requisitos de C.S.A.,

un espacio mfnimo de 2 Y2" (6.4 cm) debe de set provisto

en ambos lados de la plancha de cocinar.

3. Si una pared se encuentra en el lado izquierdo de la estu-

fa, dejar 2 3/4" (7 cm) mfn. par abrir la puerta auxiliar.

Peligro de Peso Excesivo

. Use 2 personas o mas para mover e instalar [a estufa.

• Si no cump[e con esta instrucciOn, puede resu[tar en

daffo a la espaida u otra lesi6n,

PreparatiOn

1. Pongase guantes y anteojos de seguridad. Quite las parri-

Ilas del homo y paquete de piezas de adentro del homo.

Quite materiales de empaque, cinta y pelfcula protectiva

de la estufa.

2. Tome las 4 esquinas de carton de la caja de empaque.

Col0quelas una encima de otra. Repita esta operacion

con las otras 2 esquinas. Coloque las esquinas Iongitudi-

nalmente en el piso detr_is de la estufa, para apoyarla.

3. Sujete firmemente la estufa y suavemente recuestela en

su respaldo, en las esquinas de carton.

4. Quite los 4 pernos de empaque de la corredera. Descarte

la corredera.

5. Ponga el carton delante de la estufa. Cuidadosamente

pare la estufa en el carton.

6. Ajuste la patas de nivelacion al punto en que la base de

la estufa no toque el piso.

Figura 10

ComprobaciOn de[ Funcionamiento

Consulte el Manual del Usuario incluido con la estufa para

instrucciones de operacion y instrucciones para el cuidado y

limpieza de su estufa.

Quite todo el embalaje de la unidad antes de comprobarla.

1. InstaladOn de las tapas de quemadores

Esta plancha de cocinar est.1equipada con quemadores

sellados como se muestra (Figura 11)

A. Desembale lastapas de los quemadores y las bases.

B. Coloque las basas de quemador sobre cada tubo de

abertura de gas.

C. Aseg0rese que el quemador est.1correctamente

alineado y nivelado. Coloque cada tapa del

quemador debajo de cada base del quemador.

Tapa del

quemador

/

/

NivelaciOn de [a estufa

Nive[e [a estufa y ajuste [a a[tura de [a estufa antes de

insta[ar[a en [a abertura,

1. Coloque una parrilla del homo en el centro del homo.

2. Ponga un nivel sobre la parrilla (vea figura 9). Tome dos

lecturas con el nivel puesto diagonalmente en una direc-

cion y despues en la otra. Nivele la estufa, si es necesario,

ajustando las 4 patas niveladoras con una Ilave de tuercas

(Figura 11).

3. Deslice la estufa en la abertura y verifique la nivelacion otra

vez. Si la estufa no es nivelada, tire la unidad hacia afuera

y reajuste las patas niveladoras, o verifique que el piso sea

nivelado.

Figura 11

NOTA: No es necesario realizar ajustes en los quemadores

de esta plancha de cocinar.

18

Page 19

2. Endende la corriente electrJca y abre la v&lvula

principal de cJerre.

3_

Comprobaci6n de los Encendedores

El funcionamiento de los encendedores electricos

debe set comprobado despues de que la estufa y los

conectores a la tuber[a de suministro de gas hayan

sido comprobados pot escapes y la estufa haya sido

conectada electricamente. Para comprobar que el

encendido sea correcto:

a. Empuje y gire una perilla del quemador superior

hasta la posicion LITE (encender). Se podr[a o[r el

encendedor haciendo chispas.

b. El quemador se deber_i encender en cuatro (4)

segundos para un funcionamiento normal, luego

de que el aire haya sido purgado de la tuber[a de

suministro de gas. Controle visualmente que el

quemador se hay encendido.

c. Luego que el quemador se haya encendido, la

perilla debe set girada fuera de la posicion LITE.

Cada quemador tiene su encendedor individual.

Controle las perillas separadamente hasta que todas las

wilvulas hayan sido controladas.

4_

Ajuste de la Posici6n LOW (BAJA) Para la V_ilvula

del Quernador Superior (FJgura 12)

a. Gire la perilla a la posici6n LITE (encender) hasta

que el quemador encienda.

b. Rapidamente gire la perilla a la POSICION MAS

BAJA.

c. Si el quemador se apaga, reajuste la wilvula de la

siguiente forma: Mueva el control a la posicion

OFF (apagada). Saque la perilla de control del

quemador superior, inserte un destornillador piano

pequeho en el hueco del wistago del a wilvula

hasta enganchar el tornillo interior. El tamaho de la

llama puede set aumentado o disminuido girando

el tornillo. Ajuste el tamaho de la llama hasta que

pueda pasar r_ipidamente de la posicion LITE hasta

la posicion MAS BAJA sin que se apague la llama.

La llama debe set Io m_is pequeha posible sin que

se apague.

5. Funcionamiento de los Elementos del Horno

El homo est,1 equipado con un control electronico. Cada

funcion ha sido probada en la f_ibrica antes del transporte.

Sin embargo, sugerimos que Ud. verifique el funcionamiento

de los controles del homo una vez m_is. Vease el Manual del

Usuario para la operacion. Siga las instrucciones par el Reloj,

Minutero, Cocer, Asar, Conveccion (algunos modelos) y las

funciones de limpieza (algunos modelos).

' " "" " Alverificarelfuncionamientode

elemento de homo, no toque los elementos. EIIos tendr_in el

calor bastante para causar las quemaduras serias.

Cocer/Bake-Despues de poner el homo a 350°F (177°C)

para cocer, el elemento inferior debe ponerse rojo

Asar/BroiI-Cuando est,1 puesto para BROIL, el elemento

superior se debe poner rojo.

Limpieza/Clean-Cuando el homo est,1 puesto para un

ciclo de auto-limpieza, el elemento superior se pondr_i rojo

durante el perfodo de precalentamiento del ciclo. Despues

de alcanzar la temperatura de auto-limpieza, el elemento

inferior se pondr_i rojo.

Convecd6n/Convection-Cuando el homo se pone a

CONV. BAKE/ROAST a 350°F (177°C), los dos elementos se

enciendan y se apagan alternando en un ciclo y el ventilador

se pone en marcha. El ventilador de conveccion se parar_i

cuando se abre la puerta del homo durante el cocido o el

asado por conveccion.

Despues de Terminar ia Instalaci6n

Aseg0rese de que todos los controles esten en la posicion OFF

(apagada).

Antes de Llamar al Servicio

Lea la secciOn Lista de control de averfas en su Manual del

Usuario. Esto le podr_i ahorrar tiempo y gastos. Esta lista

incluye ocurrencias comunes que no son el resultado de

defectos de materiales o fabricacion de este artefacto.

Lea la garant[a y la informacion sobre el servicio en su

Manual del Usuario para obtener el n0mero de telefono

gratuito y la direccion del servicio. Por favor Ilame o escriba

si tiene preguntas acerca de su estufa o necesita repuestos.

b

Fi r 12

19

Page 20

Importante Advertencia de Seguridad

Para reducir el riesgo de que la estufa se vuelque, es

necesario asegurarla al piso instalando los soportes

antivuelco y los tornillos suministrados con la estufa. Las

piezas se encuentran en un saco de plastic0 en el homo. Si

no se instalan los soportes antivuelco la estufa se puede

volcar si se coloca exceso de peso en una puerta abierta o si

un niflo se sube a ella. Se pueden ocasionar lesiones graves

causadas pot los Ifquidos calientes derramados o pot la

estufa misma.

Siga las instrucciones que m_is abajo se indican para instalar

los soportes antivuelco.

Si la estufa es movida a otto lugar, los soportes antivuelco

deben tambien set movidos e instalados en la estufa. Para

controlar la instalacion apropiada, vea el paso n0mero 5.

Herramientas Necesarias:

Llave de tuerca de 5/16" (8 mm) Llave inglesa

Taladro electrico

Broca de 3/16" (4.8 mm) de di_imetro

Broca para taladro de mamposterfa de 3/16" (4.8 mm) de

di_i. (si se est,1 instalando en concreto).

Instrucciones de Instalaci6n del Soporte

Antivuelco

Los soportes se fijan al suelo en la parte trasera de la estufa

para sujetar ambos niveladores de las patas traseras. Cuando

los este instalando al piso, aseg0rese de que los tornillos

no penetren el alambrado electrico o plomerfa. Los tornillos

provistos pueden utilizarse en madera o concreto.

1. Desdoble la plantilla de papel y coloquela plana en

el piso con los bordes laterales y el trasero colocados

exactamente donde la parte trasera y los lados de la

estufa set,in colocados cuando sea instalada. (Use el

diagrama figura 13 para ubicar los soportes si no se

dispone de la plantilla).

2. Marque en el piso la ubicacion de los 4 agujeros de montaje

como se muestra en la plantilla. Para facilitar la instalacion,

se pueden taladrar agujeros piloto de 3/16" (4.8 ram) de

di_i. y 1/2" (1.3cm) de profundidad en el piso.

3. Saque la plantilla y coloque los soportes en el piso con

la brida hacia arriba dirigida hacia el frente. Alinee los

agujeros en los soportes con las marcas en el piso y

sujete con los 4 tornillos provistos. Los soportes deben

estar asegurados al piso firme. Si se va a instalar en

piso de concreto, primero debe taladrar agujeros gufa

de 3/16" (4.8 mm) de di_imetro usando una broca para

taladro de mamposterfa.

4. Nivele la estufa si es necesario ajustando las cuatro

patas niveladoras con una Ilave (Vet la Figura 14 abajo).

Se requiere un espacio libre mfnimo de 1/8" (3.2 mm)

entre la parte inferior de la estufa y los niveladores de

las patas traseras para dejar espacio para los soportes

antivuelco.

5. Deslice la estufa a su lugar asegur_indose de que

las patas traseras esten sujetas pot los extremos de

los soportes. La estufa puede necesitar set movida

ligeramente a un lado cuando ester siendo empujada

hacia atr_is para permitir que las patas se alineen con los

soportes.

6. Despues de haber realizado la instalacion verifique que

la fijacion de montaje est,1 empotrada. Abra la gaveta,

retire la gaveta y verifique para asegurarse que est,1

empotrada.

Anti-tip Bracket

Figure 13 Figure 14

Slide Back

2O

Page 21

Notes/Notas

21

Page 22

Notes/Notas

22

Page 23

L2

R-7

w_s

W-5

BR-14

W-I4

W-5

w-s '_ 2

[

• 7 •

OVEN ClRCUIT//CIRCUITO DE HORNO//CIRCUIT FOUR

CONVECTION FAN/

VENTILAOOR BE CONVECDTON/

VENTI[ATEUR CONVECTION

LATCH MOTOR/

MOTOR CERROJO/

MOTEURVERROU

OVEN LAMP]

LUZDEHORNO/

LUMIERE FOUR

OVEN LAMP/

LUZ DE HORNOI

LUMIERE FOUR

COOLING FAN/VENTILADOR DE ENFRIAMIENTO/

VENTILATEUR DE REFROtDIBBEMENT I

) / / - =

BR-14 Z

BR-14

RIGH/ALTA/HAUTE

\y

SOME MODELS/ALGUNOS MODELOS/

',, CERTAINS MODELES

J

L1 ELECTRONIC OVEN CONTROL/

BK-7 CONTROL DE HORNO ELECTRONICO/

CONTROLE ELECTRONIQUE FOUR

JJJiiJilliJJilliJilliJJilliJJJJJJJilliJJilliJJilil

J3

[]

[]

==

BR 14 Z

BR-14==

1

R-5:

BK-5

[]

[]

[]

[]

[]

ES 5XX

CONV []

BR[]

Plt

[]

[]

[]

L2 OUT Z

== BK-2O

==

== BK-2O

=

== BK-14

==

; BK 20

== BK-14

==0-6

==

==

==BL_8

TEMPERATURE PROBE/

SONDA OR TEMPERATURA/

SONDE THERMIQUE

DOOR SWITCH/

1NTERRUPTOR DE PUERTA/

INTERRUPTEUR PORTE

_--. BK-20 .........

MOTOR SWITCH LATCH/

INTERRUPTOR MOTOR DE LOQUETA DE PUERTA

INTERRUPTEUR MOTEUR VERROU

_---...<> BK-14

NO C

CONVECTION ELEMENT/

ELEMENTO DE OONVECCION/

ELEMENT CONVECTION

BAKE ELEMENT/

ELEMENTODE RORNO/

ELEMENT CUISSON

BROIL ELEMENT/

ELEMENTO DE ASADO/

El EMENT GRIt t AGE

BL-7

THERMAL CIRCUIT BREAKER/ I

INTERRMPTOR DE CZROUITO

TERMICO/BZSJONCTEUR THERMZQUEI

L •

AUXILIAIRY OVEN // HORNO

L1

LEFi OVEN DOOR SWlFCH/

INTERRUPTOR DE PUERTA DE HORNO IZQUIERDO/

INTERRUPTEUR DE PORTE DE FOUR GAUCHE

BK_lO

LEFT OVEN THER_JSTAT SW./ LEFT OVEN BROIL ELEMENT/

TNTENRUPTOR DE TERMOGTATO EtEMENTO bE ASAO0 DE BORHO IZQU[ERDO/

DE HORNO IZOBIERBO/ ELEMENT DE GRIllAGE FOUR GAUCHE

INTENRUPTEUR THERMOSTAT

DE FOUR GAUCHE BL-5 BL 5 BL 5

BK 5 INDI AT R _E H RN ELEMBNTO BE NORNEO

_ F R A HE ELEMENT BE CUIBBON TERMOSTATO DE £EGUR.DAD/

CAUTION:DISCONNECT POWER BEFORE SERVICING UNIT.

ATENCION:CORTAR LA CORRIENTE ANTES DE REALIZAR EL MANTENIMIENTO DEL ELECTRODOMESTICO.

ATTENTION;COUPEZ L'ALIMENTATION AVANT B'EFFECTUER LA REPARATION,

A LEFT OVEN_,)_R/J-NOICATOR/ LEFT OVEN BAKE ELEMENT/ENT/

- C u O_ll u ORNO IZQUIERO0/ SAFETY THERMOSTAT/

OUG UC

p W'_ FOUR GAUCHE _/_ mHER.OBTAT BE SURETE 5

_?Y_5 5 Y 5 1 ^_ 2 R-5 ^__

B

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

WIRINGS ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING,

ETIQUETE TODOS LOB CABLES ANTES DE DESCONECTAR CUANDO NASA EL SERVICIO A LOS CONTROLES,

ERRORES AL VOLVER A ENSAMBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERACIOMES PELIGROSAS.

VERIFTQUE IA CORRPCTA OPFRACION DESPUPS DEl SERVICIO.

IDENTIFIEZ TOBS LEG FILS AVAMT DE LED DEBRANCHER OUAND L'APPAREIL EST MORB SERVICE.

LEG ERREURS DE CONNECTION DE FILS PEUVENT CAUSER UN #AL FONCTIONNEMENT ET UN DANGER

D'USAGE DE L'APPAREIL. VERIFIEZ LE DON FONCTIONNEMENT DE L'APPAREIL APRES LE SERVICE.

LATERAL // FOUR AUXILIAIRE

LEFT OVEN LAdP/

LUZ DE RORNO £ZGUIERDO/

LAMPE DE FOUR 6AUCNE

BR 10 W_l

LEFT OVEN THERMOSTAT/

TERMOSTATO DE HORNO IZQUIERBO/

THERMOSTAT DE FOUR GAUCHE

=

= =

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIF

N

L2 EN =

L2

CONNECTOR/

CONECTOR/

CONNECTEUR

A_

DOOR LA]CR 8WI1CH

INI_RRUPIOR CERROJO

BE FUERTA/INTERRUPTEUR

DE PORTE VERROU \ /

COLOR CODE/CODI60S DE COLOR

CODE DE COULEUR

GY, GREY/GRID/BRIG

G, GREEN/VERDE/VENT

i W* WHITE/BLANCO/BLANC

i R, RED/ROJO/ROUBE

i O, ORANGE/NARANJA/DRANGE

i Y, YELLOW/AMARILLO/JAUNE

i _R* BROWB/CAFE/BRUN

i BL, BLBE/AZUL/BLEU

i BK, BLACK/NEGRO/NO_R

CODE GAUGE TEMP.'C CSA UL

COBIGO MEDIBA

CODE CALIBRE

1 18 125 0L1251 3173

2 IB 125 CL1251 3173

3 14 125 0L1251 3173

4 12 125 CL1251 3173

5 18 150 EXL-150 3321

6 18 150 EXL-150 3321

7 14 150 EXL-150 3321

8 12 150 EXL 150 332t

9 10 150 EXL 150 3321

10 18 200 SEW 1 3122

11 16 200 SEW 1 3122

12 12 250 3252

13 16 250 3252

14 20 150 EXL-150 3321

15 B 150 EXI-150 332t

16 B 60

17 10 60

1018 200 SEW-1 3122

19 20 125 0L1251 3173

20 20 200 SEW-1 3122

21 22 125 3266

22 22 150 10109

23 18 200 3573