FNG576CFSWB

FNG576CFSSB

User Manual

TABLE OF CONTENTS

www.frigidaire-intl.com

Safety information ...............................2

Safety instructions ...............................3

Daily use .......................................7

Maintenance .....................................16

Troubleshooting ....................................18

Instal lation Instructions .....................21

Environment concerns .....................29

222D5749P024

Care and cleaning .................................12

2

IMPORTANT SAFETY INFORMATION.

READ ALL ISTRUCTIONS BEFORE USING.

WARNING

If the information in this manual is not followed exactly, a fire or explosion

may result, causing property damage, personal injury or death.

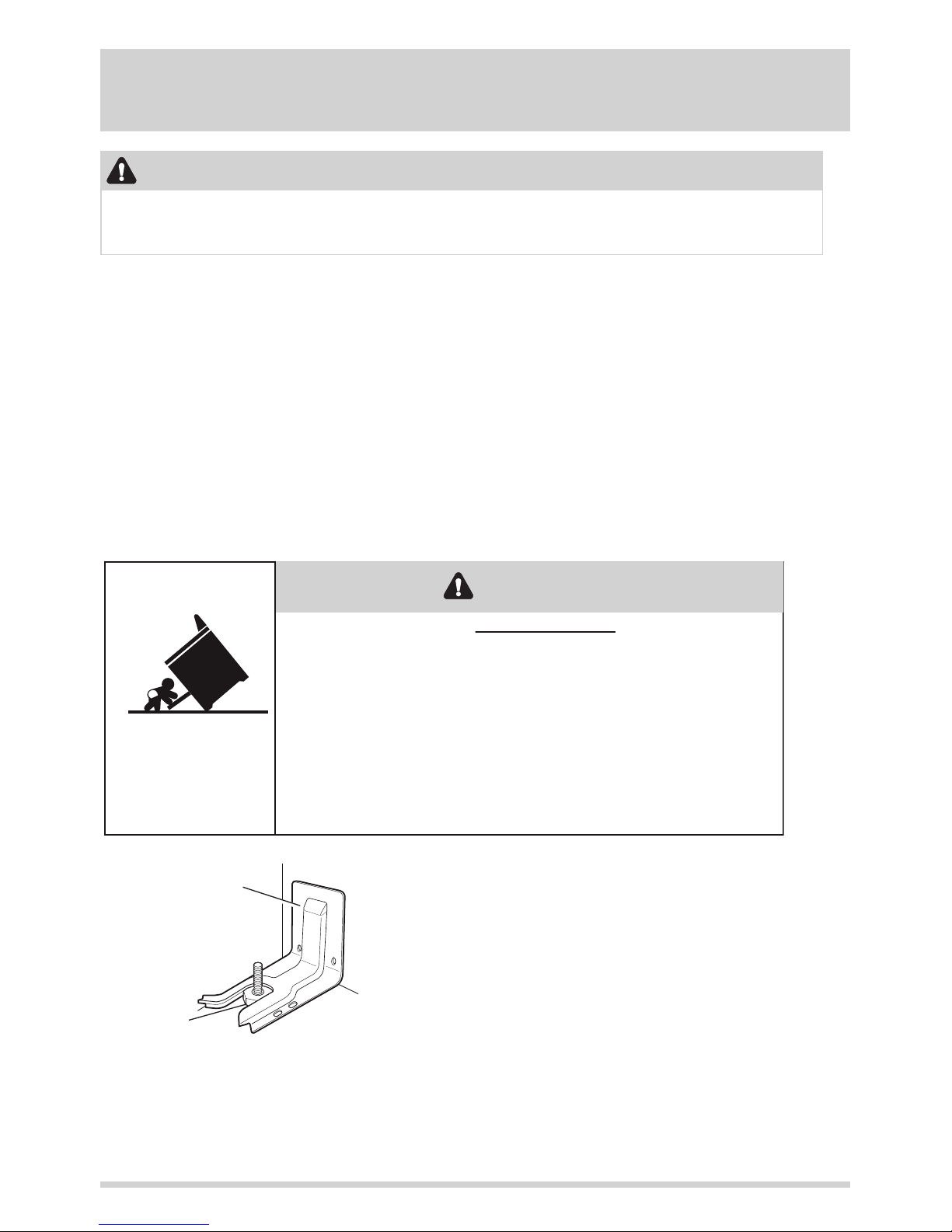

ANTI-TIP DEVICE.

For Freestanding and Slide-In Cookers. To

check if the bracket is installed and engaged

properly, loo

k underneath the cooker to see

that the rear leveling leg is engaged in the

bracket. On some models, the storage drawer

or kick panel can be removed for easy inspection.

If visual inspection is not possible, slide the

cooker forward, confirm the anti-tip bracket is

securely attached to the floor or wall, and slide

the cooked back so the rear leveling leg is under

the anti-tip bracket.

Freestanding and Slide-In Cookers

Anti-Tip

Bracket

Leveling Leg

A child or adult can tip the cooker and be killed.

Verify the anti-tip bracket has been properly installed

and engaged.

Ensure the anti-tip bracket is re-engaged when the cooker

is moved.

Do not operate the cooker without the anti-tip bracket in

place and engaged.

Failure to follow these instructions can result in death or

serious burns to children or adults.

Tip-Over Hazard

- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

WARNING

3

I

f the cooker is pulled from the wall for any reason, always repeat this procedure

to verify the cooker is properly secured by the anti-tip bracket.

Never completely remove the leveling legs or the cooker will not be secured

to the anti-tip device properly.

GENERAL SAFETY INSTRUCTIONS

NEVER use this appliance as

a space heater to heat or warm

the room. Doing so may result in

carbon monoxide poisoning and

overheating of the oven.

WARNING

CAUTION

with broken glass. Shock, fire or cuts

may occur.

• Do not leave children alone—children

should not be left alone or unattended

in an area where an appliance is in use.

They should never be allowed to climb,

sit or stand on any part of the appliance.

• Do not store items of

interest to children in cabinets above

an oven-children climbing on the oven

to reach items could be seriously injured.

• Do not allow anyone to climb, stand or

hang on the oven door, drawer or

hob. They could damage the cooker

or tip it over causing severe injury or death.

• Never block the vents (air openings) of

the cooker. They provide the air inlets and

outlets that are necessary for the cooker

to operate properly with correct combustion.

Air openings are located at the rear of

the hob, at the top and bottom of the oven

door, and at the bottom of the cooker

under the warming drawer, lower oven

drawer or kick panel.

• Use only dry pot holders—moist or damp

pot holders on hot surfaces may result

in burns from steam. Do not let pot

holders touch surface burners, burner

grate, or oven heating element. Do not

use a towel or other bulky cloth in place

of pot holders.

• Do not touch the heating elements or

the interior surface of the oven. These

surfaces may be hot enough to burn

even though they are dark in color.

During and after use, do not touch, or

let clothing or other flammable materials

contact any interior area of the oven;

allow sufficient time for cooling first.

• Use this appliance for its intended purpose

as described in this owner’s manual.

• Have your cooker installed and properly

grounded by a qualified installer in

accordance with the provided installation

instructions. Any adjustment and service

should be performed only by a qualified

gas cooker installers or service technicians.

Do not attempt to repair or replace any

part of your cooker unless it is specifically

recommended in this manual.

• Your coo

ker is shipped from the factory set

for use with natural gas. It can be converted

for use with LP gas. If required, these

adjustments must be made by a qualified

technician in accordance with the installation

instructions and local codes. The agency

performing this work assumes responsibility

for the conversion.

• Have the installer show you the location of

the cooker gas shut-off valve and how to

turn it off if necessary.

• Before performing any service, unplug the

cooker or disconnect the power supply at the

household distribution panel by removing

the fuse or switching off the circuit breaker.

• Be sure all packing materials are removed

from the cooker before operating to prevent

ignition of these materials.

• Avoid scratching or impacting glass doors,

hob or control panels. Doing so may lead

to glass breakage. Do not cook on a product

4

KEEP FLAMMABLE MATERIALS AWAY FROM THE OVEN

Failure to do so may result in fire or personal injury.

Other surfaces of the appliance may become

hot enough to cause burns. Potentially hot

surfaces include the burners, grates, oven

vent opening, surfaces near the opening

and crevices around the oven door.

• Do not heat unopened food containers.

Pressure could build up and the container

could burst, causing an injury.

WARNING

• Do not store or use flammable materials

in an oven or near the hob, including

paper, plastic, pot holders, linens, wall

coverings, curtains, drapes and gasoline

or other flammable vapors and liquids.

• Never wear loose-fitting or hanging

garments while using the appliance. Avoid

storing commonly used items in cabinets

above the cooker and be careful when

reaching over the cooker. Clothing in

close proximity to burners or hot surfaces

may ignite causing severe burns.

• Do not let cooking grease or other flammable

materials accumulate in or near the cooker.

Grease in the oven or on the hob may ignite.

• Clean ventilating hoods frequently. Grease

should not be allowed to accumulate on

the hood or filter.

IN THE EVENT OF A FIRE, TAKE THE FOLLOWING

STEPS TO PREVENT INJURY AND FIRE SPREADING

WARNING

• Do not use water on grease fires. Never

pick up a flaming pan. Turn the controls

off. Smother a flaming pan on a surface

burner by covering the pan completely

with a well-fitting lid, cookie sheet or flat

tray. If necessary, use a multi-purpose dry

chemical or foam-type fire extinguisher.

• If there is a fire in the oven during baking,

turn the oven off and keep the door closed

until the fire goes out. If necessary, use

a multi-purpose dry chemical or foam

type fire extinguisher.

• If there is a fire in the oven during self

-clean, turn the oven off and wait for

the fire to go out. Do not force the door

open. Introduction of fresh air at self-clean

temperatures may lead to a burst of flame

from the oven. Failure to follow this

instruction may result in severe burns.

• Do not use any type of foil or liner to

cover the oven bottom, drip pans or

anywhere in the oven, except as described

in this manual. Oven liners can trap heat

or melt, resulting in damage to the product

and risk of shock, smoke or fire.

5

HOB SAFETY INSTRUCTIONS

WARNING

• Never leave the surface burners unattended

at medium or high heat settings. Foods,

especially oily foods, may ignite resulting

in fire that could spread to surrounding

cabinets.

• Never leave oil unattended while frying.

If allowed to heat beyond its smoking point,

oil may ignite resulting in fire that may

spread to surrounding cabinets. Use a deep

fat thermometer whenever possible to

monitor oil temperature.

• To avoid oil spillover and fire, use a minimum

amount of oil when shallow pan-frying and

avoid cooking frozen foods with excessive

amounts of ice.

• Use proper pan size and avoid pans that

are unstable or easily tipped. Select

cookware that is matched to the size of

the burner. Burner flames should be adjusted

so that they do not extend beyond the

bottom of the pan. Excessive flame may

be hazardous.

• Always use the LITE position when igniting

the top burners and make sure the burners

have ignited.

• When using glass/ceramic cookware, make

sure it is suitable for hob service; others may

break because of sudden change in

temperature.

• To minimize the possibility of burns, ignition

of flammable materials and spillage, the

handle of a container should be turned

toward the center of the cooker without

extending over nearby burners.

• When preparing flaming foods under a

hood, turn the fan on.

• Do not use a wok with a round metal

support ring. The ring may trap heat and

block air to the burner resulting in a carbon

monoxide hazard.

• Do not attempt to lift the hob. Doing

so may damage the gas tubing to the

surface burners resulting in a gas leak and

risk of fire.

• When disabling Lock Control (on some

models), make sure the surface controls

are set to the OFF position. This will prevent

unintended gas flow from the burners.

• Do not use aluminum foil to cover the

grates or line any part of the hob.

Doing so may result in carbon monoxide

poisoning, overheating of the hob

surfaces, or a potential fire hazard.

OVEN SAFETY INSTRUCTIONS

WARNING

escapes can cause burns to hands, face

and/or eyes.

• Keep the oven free from grease buildup.

Grease in the oven may ignite.

• Place oven racks in desired location while

oven is cool. If rack must be moved while

oven is hot, be careful to avoid touching

hot surfaces.

• Pull the oven rack to the stop-lock position

when loading and unloading food from the

oven. This helps prevent burns from touching

hot surfaces of the door and oven walls.

• Do not leave items such as paper, cooking

utensils or food in the oven when not in

use. Items stored in an oven can ignite.

NEVER cover any slots, holes, or

passages in the oven bottom or cover

an entire rack with materials such as

aluminum foil or oven liners. Doing

so blocks air flow through the oven

and may cause carbon monoxide

poisoning. Never place foil or oven liners

on the oven bottom. They can trap heat

causing risk of smoke or fire.

WARNING

• Use this appliance for its intended purpose

as described in this owner’s manual.

• Stand away from the cooker when opening

the oven door. Hot air or steam which

SELF-CLEANING OVEN SAFETY INSTRUCTIONS

WARNING

The self-cleaning feature

operates the oven at temperatures high

enough to burn away food soils in the oven.

Follow these instructions for safe operation.

• Do not touch oven surfaces during self-clean

operation. Keep children away from the

oven during self-cleaning. Failure to follow

these instructions may cause burns.

• Before operating the self-clean cycle,

remove pans, shiny metal oven racks and

other utensils from the oven. Only porcelain

-coated oven racks may be left in the oven.

Do not use self-clean to clean other parts,

such as grates.

• Before operating the self-clean cycle, wipe

grease and food soils from the oven.

Excessive amount of grease may ignite

leading to smoke damage to your home.

• If the self-cleaning mode malfunctions, turn

the oven off and disconnect the power

supply. Have it serviced by a qualified

technician.

• Do not use oven cleaners. No commercial

oven cleaner or oven liner protective coating

of any kind should be used in or around any

part of the oven.

6

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

• Do not leave items on the hob near the

oven vent which is in the center of

the backguard. Items may overheat

resulting in a risk of fire or burns.

• When using cooking or roasting bags in the

oven, follow the manufacturer’s directions.

• Never broil with door open. Open-door

broiling is not permitted due to overheating

of control knobs.

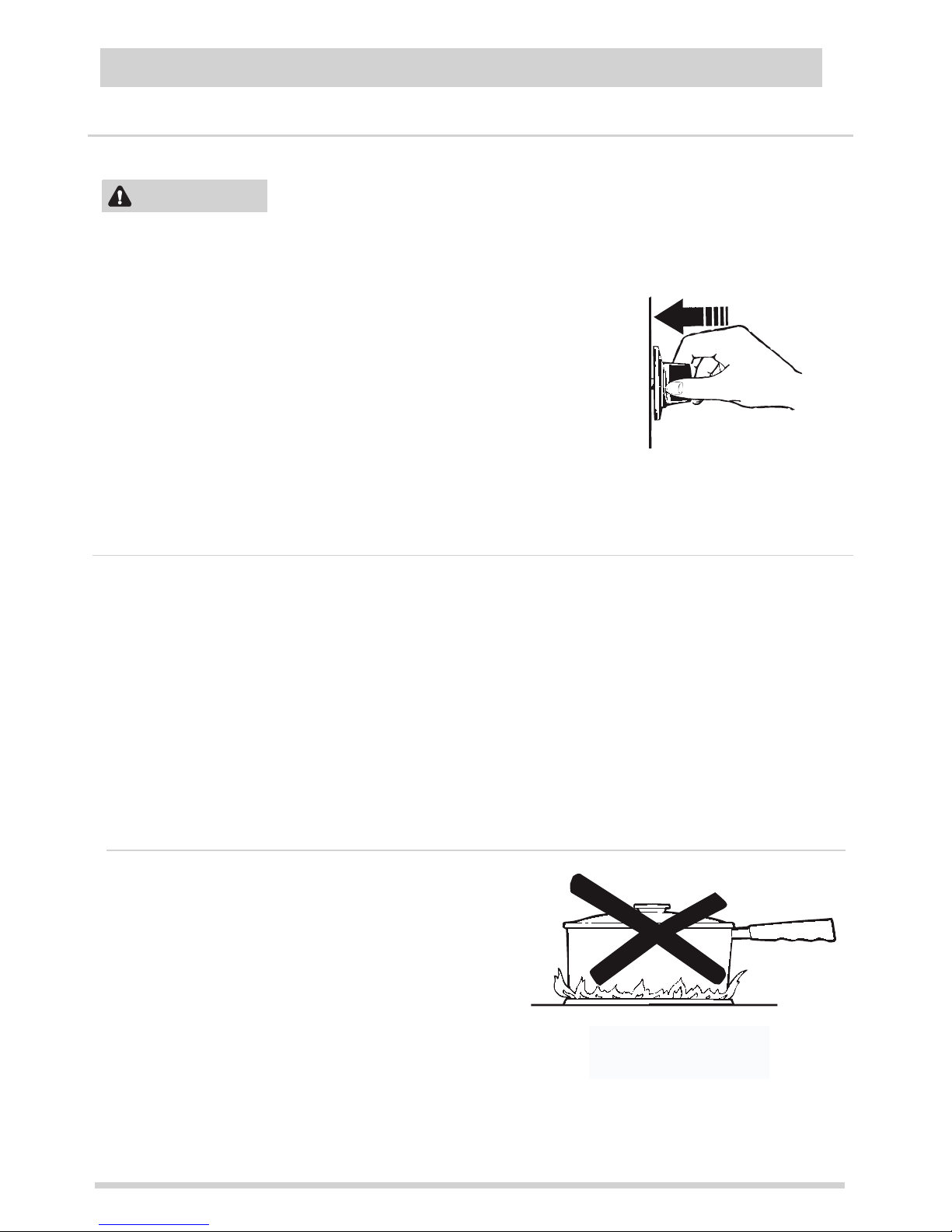

How to Remove Protective Shipping Film and Packaging Tape

Carefully grasp a corner of the protective

shipping film with your fingers and slowly

peel it from the appliance surface. Do not

use any sharp items to remove the film.

Remove all of the film before using the

appliance for the first time.

To assure no damage is done to the

finish of the product, the safest way to

remove the adhesive from packaging

tape on new appliances is an application

of a household liquid dishwashing detergent.

Apply with a soft cloth and allow to soak.

NOTE: The adhesive must be removed

from all parts. It cannot be removed if

it is baked on.

7

These flames are too

large for the pot

Burners should be

Push the control knob in and

turn it to the LITE position.

Surface Burners

DAILY USE

How to Light a Surface Burner

WARNING

operated only when covered by

cookware. Burner flames not covered

by cookware present a risk of fire or

clothing ignition. Never let flames

extend beyond the sides of the

cookware. Failure to comply may result

in serious injury.

Make sure all burners are in their correct

locations and

fully assembled before

attempting to operate any burner. Select

a burner and find its control knob. Push

the knob in and turn it to the LITE position.

You will hear a clicking noise—the sound

of the electric spark igniting the burner.

When one burner is turned to LITE, all

burners will spark.

Sparking will

continue as

long as the

knob remains

at LITE. Once

gas is ignited,

turn the knob

to adjust the

flame size.

After Lighting a Burner

• Do not operate the burner for an extended

period of time without cookware on the

grate. The finish on the grate may discolor

or chip without cookware to absorb the

heat.

• Do not attempt to disassemble any burner

while another burner is on. An electric

shock may result, which could cause

you to knock over hot cookware.

• Be sure the burners and grates are cool

before you place your hand, a pot holder

or cleaning materials on them.

How to Select Flame Size

Watch the flame, not the knob, as you adjust

heat. When rapid heating is desired, the

flame size on a burner should match the

size of the cookware you are using. Flames

larger than the bottom of the cookware will

not heat faster and may be hazardous.

8

Top-of-Cooker Cookware

Aluminum: Medium-weight cookware is

recommended because it heats quickly and

evenly. Most foods brown evenly in an

aluminum skillet. Use saucepans with tightfitting lids when cooking with minimum

amounts of water.

Stainless Steel: This metal alone has poor

heating properties and is usually combined

with copper, aluminum or other metals for

improved heat distribution. Combination

metal skillets usually work satisfactorily if

they are used with medium heat as the

manufacturer recommends.

Cast-Iron: If heated slowly, most skillets

will give satisfactory results.

Enamelware: Under some conditions,

the enamel of some cookware may melt.

Follow cookware manufacturer’s

recommendations for cooking methods.

Glass: There are two types of glass

cookware—those for oven use only and

those for top-of-cooker cooking (saucepans,

coffee and teapots). Glass conducts heat

very slowly.

Heatproof Glass Ceramic: Can be used

for either surface or oven cooking. It

conducts heat very slowly and cools very

slowly. Check cookware manufacturer’s

directions to be sure it can be used on

gas cooker.

(on some models)

1 3 7 6

4 852

10

Non Convection

Oven Controls

9

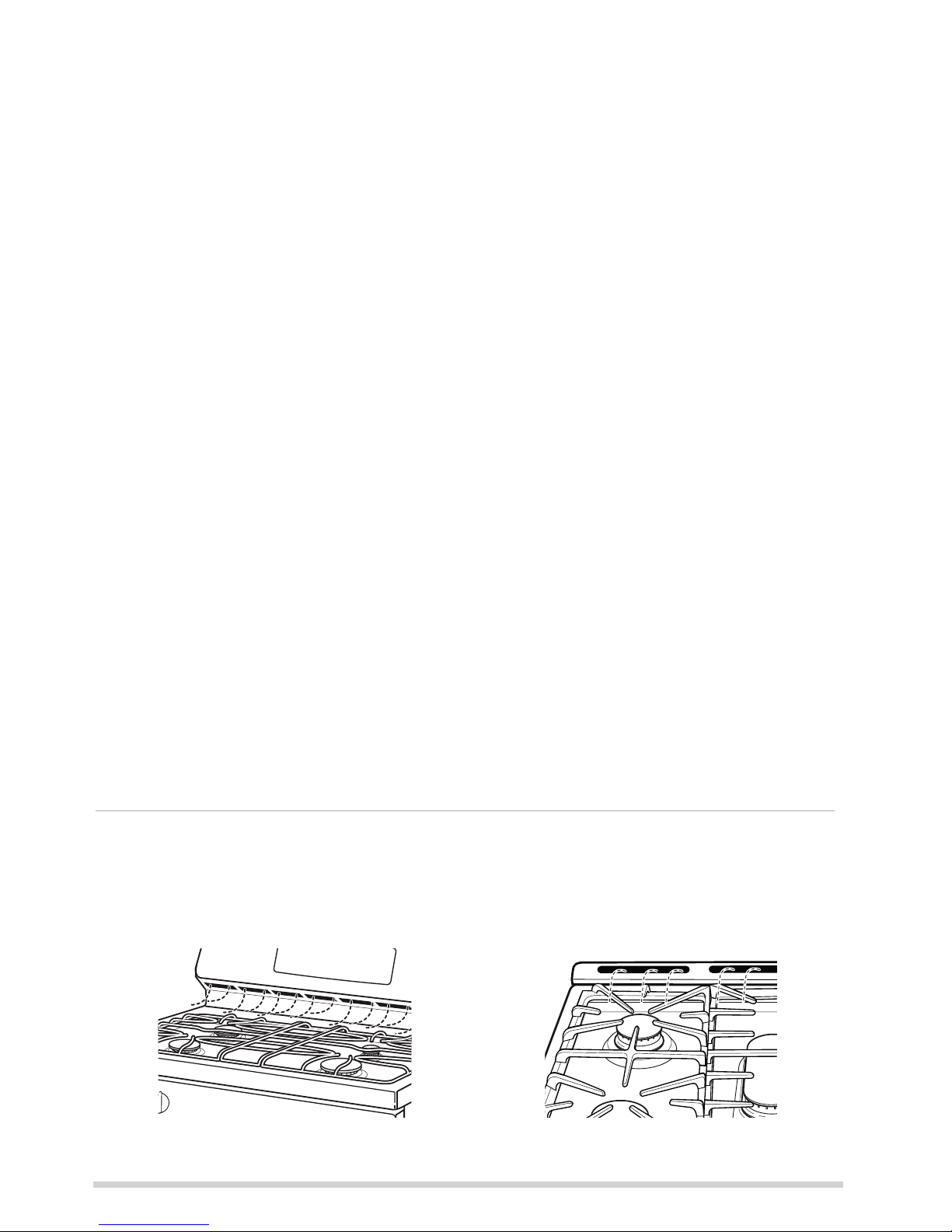

Oven Air Vents

Vent appearance and location vary.

9

Oven Controls

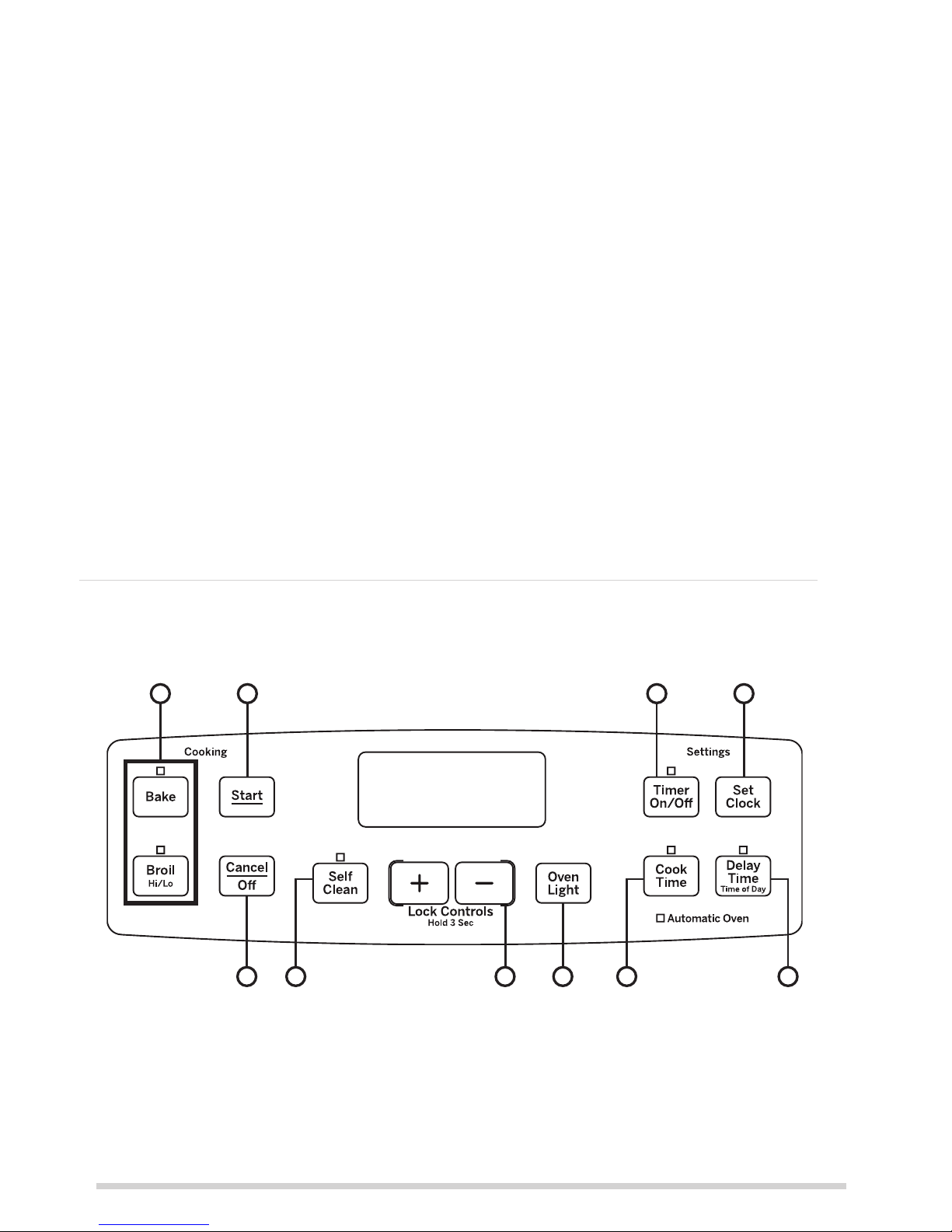

1. Traditional Cooking Modes: Your

oven has the following traditional cooking

modes: Bake, Broil Hi and Broil Lo. See the

Cooking Modes section for more information.

2. Clean See the Cleaning the Oven section

for important information about using these modes.

3. Start: Must be pressed to start any

cooking, cleaning, or timed function.

4. Cancel/Off: Cancels ALL oven operations

except the clock and timer.

5. Cook Time: Counts down cooking time

and turns off the oven when the cooking

time is complete. Press the Cook Time pad,

use the number pads to program a cooking

time in hours and minutes, then press Start.

This can only be used with Traditional Bake,

Convection Bake, Convection Bake Multi,

and Convection Roast.

6. Clock: Sets the oven clock time. Press

the + and - pads and hold for 3 seconds or

press Set Clock pad (on some models). Use

the + and - pads to program the clock. Press

Start to save the time.

7. Timer: Works as a countdown timer.

Press the Timer pad and the + and - pads

to program the time in hours and minutes.

Press the Start pad. The oven will continue

to operate when the timer countdown is

complete. To turn the timer off press the

Timer pad.

8. Delay Time: Delays when the oven

will turn on. Use this to set a time when

you want the oven to start. Press the

Delay

Time pad and use the + and - pads

to program the time of day for the oven

to turn on. Press the desired cooking mode

and temperature then press Start. A cook

time may also be programmed if desired.

This can only be used with Traditional Bake,

and Self-Clean

9. Oven Light(s): (on some models)

Turns the oven light(s) on or off.

10. Lock Controls: (on some models)

Locks out the control so that pressing

the pads does not activate the controls.

Press and hold the Lock Controls pad or

press + and - pads and hold for 3 seconds

to lock or unlock the control. Cancel/Off

is always active, even when the control

is locked.

Never block the vents (air openings) of the

cooker. They provide the air inlet and outlet

that are necessary for the cooker to keep cool

and operate properly with correct combustion.

Air openings are located at the rear of

the hob, at the top and bottom of the oven

door, and at the bottom of the cooker.

Special Features

Adjust the Oven Temperature

This feature allows the oven baking temperature to be adjusted up to 35ºF hotter or down

to 35ºF cooler. Use this feature if you believe your oven temperature is too hot or too cold

and wish to change it. Press the Bake pad, then use the + and - pad to increase or decrease

your oven temperature. Press the Start pad to save the change.

Oven Racks

Main Oven

Your oven has six rack positions in the

main oven. Adjusting rack position is one

way to impact cooking results. For example,

if you would prefer darker tops on cakes,

muffins, or cookies, try moving food one rack

position higher. If you find foods are too

brown on top try moving them down next time.

When baking with multiple pans and on

multiple racks, ensure there is sufficient space

between pans to allow air to flow.

Oven Racks

When placing and removing cookware, pull

the rack out to the bump (stop position) on

the rack support. To remove a rack, pull it

toward you, tilt the front end up and pull it out.

To replace, place the curved end of the rack

(stop-locks) onto the oven supports, tilt up

the front of the rack and push the rack in.

Racks may become difficult to slide, especially

after a self-clean. Put some vegetable oil on

a soft cloth or paper towel and rub onto the

left and right edges.

10

There are special features on your oven. To change the settings of these special features,

press the BAKE and BROIL pads at the same time and hold for three seconds. "SF" will

appear in the display. Select the feature you want to change. When the change has been

made, press the START key to save the change and return to the time of day.

Your new oven has a variety of cooking modes to help you get the best results. These

modes are described below. Remember, your new oven may perform differently than the

oven it is replacing.

Bake

The bake mode is for baking and roasting.

This mode uses heat only from the lower

burner. Follow recipe recommendations for

food placement. If no guidelines are provided

center food in the oven. To use this mode

press the Bake pad, enter a temperature,

and then press Start.

Broiling Modes

Always broil with the main oven and broil

drawer doors closed. Monitor food closely

while broiling. Use caution when broiling on

upper rack positions as placing food closer to

the broil burner increases smoking, spattering,

and the possibility of fats igniting.

Try broiling foods that you would normally

grill. Adjust rack positions to adjust the

intensity of the heat to the food. Place foods

closer to the broil burner when a seared

Broil Hi

The Broil Hi mode uses intense heat from the

upper burner to sear foods. Use Broil Hi for

thinner cuts of foods you prefer less done on

the interior. To use this mode press the Broil

pad once and then press Start. It s not

necessary to preheat when using this mode.

Broil Lo

The Broil Lo mode

uses less intense heat from

the upper burner to cook food thoroughly

while also browning the surface. Use Broil Lo

for thicker cuts foods that you would like

cooked all the way through. To use this mode

press the Broil pad twice and then press Start.

It is not necessary to preheat when using

this mode.

Cookware

Cookware Guidelines

The material, finish, and size of cookware

affect baking performance.

Dark, coated and dull pans absorb heat more

readily than light, shiny pans. Pans that absorb

heat more readily can result in a browner,

crisper, and thicker crust. If using dark and

coated cookware check food earlier than

minimum cook time. If undesirable results

are obtained with this type of cookware

consider reducing oven temperature by 25º F

next time.

Shiny pans can produce more evenly cooked

baked goods such as cakes and cookies.

Glass and ceramic pans heat slowly but retain

heat well. These types of pans work well for

dishes such as pies and custards.

Air insulated pans heat slowly and can reduce

bottom browning.

Keep cookware clean to promote even heating.

Cooking Modes

11

surface and rare interior is desired. Thicker

foods and foods that need to be cooked

through should be broiled on a rack position

farther from the burner or by using Broil Lo.

CAUTION: Do not use any type of foil or oven liner to cover the oven bottom.

Aluminum Foil and Oven Liners

Be sure electrical power is off and all surfaces are cool before cleaning any part of the oven.

Control Panel and Knobs

Wipe the control panel after each use of the

oven with a damp cloth. For cleaning, use

mild soap and water or a 50/50 solution of

vinegar and water. Rinse with clean water.

Polish dry with a soft cloth.

Do not use abrasive cleansers, strong liquid

cleansers, plastic scouring pads or oven

cleaners on the control panel—they will

damage the finish.

Do not try to bend knobs by pulling them up

or down or by hanging a towel or other such

loads. This can damage the gas valve shaft.

The control knobs may be removed for easier

cleaning.

With knobs in the OFF position pull them

straight off the stems.

The knobs can be washed by hand with

soap and water or in a dishwasher.

Surface burner knob

CARE AND CLEANING

12

These items can block airflow or melt, resulting in damage to the product and

risk of carbon monoxide poisoning, smoke or fire. Damage from improper use

of these items is not covered by the product warranty.

Foil may be used to catch spills by placing a sheet on a lower rack, several inches below

the food. Do not use more foil than necessary and never entirely cover an oven rack with

aluminum foil. Keep foil at least 1-1/2” from oven walls to prevent poor heat circulation.

Oven Exterior and Hob Surface

Do not use oven cleaners, abrasive cleansers,

strong liquid cleansers, steel wool, plastic

scouring pads, or cleaning powders on the

interior or exterior of the oven. Clean with

a mild soap and water or a 50/50 solution

of vinegar and water. Rinse with clean water

and dry with a soft cloth. When cleaning

surfaces, make sure that they are at room

temperature and not in direct sunlight.

If a stain on the door vent trim is persistent,

use a mild abrasive cleaner and a spongescrubber for best results.

Spillage of marinades, fruit juices, tomato

sauces and basting liquids containing acids

may cause discoloration and should be wiped

up immediately. Let hot surfaces cool, then

clean and rinse.

Oven Interior

The interior of your new oven can be cleaned

manually or by using the Self Clean modes.

Spillage of marinades, fruit juices, tomato

sauces and basting liquids containing acids

may cause discoloration and should be

wiped up as soon as hot surfaces cool, then

clean and rinse.

Manual Cleaning

Do not use oven cleaners, abrasive cleaners,

strong liquid cleansers, steel wool, scouring

pads, or cleaning powders on the interior of

the oven. Clean with a mild soap and water

or 50/50 solution of vinegar and water. Rinse

with clean water and dry with a soft cloth.

When cleaning surfaces, make sure that

they are at room temperature and not in

direct sunlight.

Self Clean Mode

Read Self-Cleaning Oven Safety Instructions

at the beginning of this manual before using

Self Clean Mode. Self clean uses very high

temperatures to clean the oven interior. Wipe

Stainless Steel Surfaces (on some models)

Do not use a steel wool pad; it will scratch

the surface.

To clean the stainless steel surface, use

warm sudsy water or a stainless steel

cleaner or polish. Always wipe the surface

inner black door before self clean. Remove

all items from the oven other than enameled

(dark color) racks. Shiny or silver racks, and

any cookware before initiating a self-clean

cycle. Close the door. Latch the door. If the

oven is too hot, you will not be able to slide

the latch. Wait until the oven is cool to slide

the latch. Press the Clean pad once and a

default self-clean time is displayed. Press the

START pad or use the number pads to enter

any clean time between 3 and 5 hours and

press start. For heavily soiled ovens 5 hours is

recommended. The oven will turn off automatically

when the self-clean cycle is complete. The

door will stay locked until the oven has cooled

down. After the oven has cooled down wipe

any ash out of the oven.

IMPORTANT: The health of some birds

is extremely sensitive to the fumes given

off during the self-cleaning cycle of any

cooker. Move birds to another well-

ventilated room.

13

in the direction of the grain. Follow the

cleaner instructions for cleaning the stainless

steel surface.

All oven racks may be cleaned by hand with an abrasive cleaner or steel wool. Black

porcelain-coated oven racks may remain in the oven during the self-cleaning cycle without

being damaged. If nickel-plated oven racks remain in the oven during the self-cleaning

cycle, they will lose their luster and become hard to slide. It will be necessary to grease

all oven rack side edges with a light coating of vegetable oil after cleaning them by hand

or in the oven. This will help maintain the ease of sliding the racks in and out of the oven.

Oven Racks

Removal of Surface Burners for Cleaning

Turn all controls OFF.Allow hob to cool before removing grates and burner parts.

When removing the burner caps and heads, remember their size and location. Replace

them in the same location after cleaning.

Cleaning The Hob

Round Burner

The burner caps and burner heads can be

lifted off the hob.

Round Burner Cap

(Removable)

Cleaning The Burners

Burner Caps

Wash burner caps in hot, soapy water and

rinse with clean water. You may scour with

a plastic scouring pad to remove burned-on

food particles. The round caps may also be

cleaned in your dishwasher.

Burner Heads

Wash the burner heads routinely, especially

after bad spillovers, which could clog the

openings. Lift burners off when cool. Use

hot, soapy water. Rinse with clean water.

For more stubborn stains, use a brush

with plastic bristles.

NOTE: Do not use steel wool or scouring

powders to clean the burner parts as these

may clog the parts. Never wash burner heads

in your dishwasher as dishwasher detergents

will discolor your burners. The ports in the

burner heads must be kept clean at all times

for an even, unhampered flame. Clogged or

dirty burner ports or electrodes will not allow

the burner to operate properly.

For proper ignition, make sure the small hole

in the notch that fits over the electrode is

kept open. A sewing needle or wire twist-tie

works well to unclog it

After cleaning

Before putting the burner caps, shake out

excess water and allow them to dry thoroughly.

Replacing Burner Heads

Replace burner heads in the correct locations

according to size.

Burner Caps

Replace burner caps on burner heads. Make

sure each cap fits securely and sits flat on

its corresponding burner head.

Round hole in

burner head must

be kept clear

14

Burner cap is

properly seated.

Burner cap is

NOT properly seated.

Burner cap is

NOT properly seated.

Any spill on or around an electrode must be

carefully cleaned. Take care to not hit an

electrode with anything hard or it could be

damaged.

Electrode

The electrode of the spark igniter is

exposed when the burner head is removed.

When one burner is turned to LITE, all

the burners spark. Do not attempt to

disassemble or clean around any burner

while another burner is on. An electric

shock may result, which could cause

you to knock over hot cookware.

Burner Grates

Grates should be washed in hot, soapy water

and rinsed with clean water. To soften

burned-on food, place grates in a plastic

bag containing ¼-cup of household ammonia

for several hours. Afterward, scrub grates

with a plastic scouring pad soaked in hot,

soapy water. Rinse well and dry.

15

CAUTION

Do not operate the

hob without all burner parts and

grates in place.

When replacing the grates, be sure to locate

them correctly on the hob. Grate should fit

securely into the hob. Grates will gradually

lose their shine due to their continual

exposure to high temperatures.

Cleaning The Door and Drawer

The gasket is designed with a gap at the bottom to

allow for proper air circulation.

extremely low resistance to abrasion.

If you notice the gasket becoming worn, frayed or

damaged in any way or if it has become displaced on

the door, you should have it replaced.

To clean the inside of the door

Do not allow excess water to run into any

holes or slots in the door. Wipe dishwashing

detergent over any baked-on spatters on

the glass. Use a single sided safety razor

blade to clean it off. Then wipe over the

glass with a soapy cloth to remove any

residue and dry off.

The area outside the gasket can be cleaned

with a soap-filled plastic scouring pad.

Removable Storage Drawer (on some models)

The storage drawer is a good place to store

cookware and bakeware. Do not store plastics

and flammable material in the drawer.

The storage drawer may be removed for

cleaning under the cooker. Clean the storage

drawer with a damp cloth or sponge. Never

use harsh abrasives or scouring pads.

To remove storage drawer:

1. Pull drawer straight out until it stops.

2. Tilt the front of the drawer up and free

of the cooker.

To replace storage drawer:

1. Set the stops on the back of the drawer

over the stops in the cooker.

2. Slide drawer evenly and straight back, so

that the rails

The storage drawer may be removed for cleaning

under the cooker.

16

MAINTENANCE

SHOCK OR BURN HAZARD: Before replacing oven light bulb,

disconnect the electrical power to the oven at the main fuse or circuit

breaker panel. Failure to do so may result in electric shock or burn.

BURN HAZARD: The glass cover and bulb should be removed when cool.

Touching hot glass with bare hands or a damp cloth can cause burns.

Oven Light Replacement

WARNING

CAUTION

Oven Light Bulb

NOTE: The glass cover should be removed

only when cold. Wearing latex gloves may

offer a better grip.

Before replacing the bulb, disconnect electrical

power to the oven at the main fuse or circuit

breaker panel. Let the bulb cool completely

before removing it. For your safety do not

touch a hot bulb with a damp cloth. If you

do the bulb may break.

To remove:

Turn the glass cover counterclockwise 1/4

turn until the tabs of the glass cover clear

the grooves of the socket. Remove the bulb.

To replace:

Put in a new 40-watt appliance bulb. Place

the tabs of the glass cover into the grooves

of the socket. Turn the glass cover clockwise

1/4 turn.

NOTE:

A 40-watt appliance bulb is smaller than a

standard 40-watt household bulb.

Reconnect electrical power to the oven once

the new bulb is installed.

For improved lighting inside the oven, clean

the glass cover frequently using a wet cloth.

This should be done when the oven is

completely cool.

Bulb

Socket

Tab

3

1

2”

Max

length

Glass cover

To Remove the Door:

1. Fully open the oven door.

2. On each hinge, slide the hinge lock up,

making sure it snaps into its fully raised

position.

3. Firmly grasp both sides of the door at

near the top.

4. Close door until the top of the door is

approximately 3” from the cooker frame.

5. Lift door up and away from the cooker until

both hinge arms are clear of the slots in

the cooker frame.

Pull hinge locks up to unlock

Notch

Push hinge locks down to lock

Removal position

Lift-Off Oven Door

The door is very heavy. Be careful when removing and lifting the door. Do not lift door by

the handle.

If improperly removed, oven door hinges may suddenly open and can

17

WARNING

cause personal injury to appendages near the hinge. Follow instructions below to avoid a

risk of injury when removing and re-installing the oven door.

To Replace the Door:

1. Firmly grasp both sides of the door near

the top.

2. With the door at the same angle as the

removal position, rest the notch in the

bottom of the left hinge arm on the

bottom edge of the left hinge slot. The

notch in the hinge arm must be fully

seated onto the bottom of the slot.

Repeat for the right side.

Save time and money! Review the charts on the following pages first and you may not

need to call for service.

oD oT tahWesuaC elbissoPmelborP

My new oven doesn't

cook like my old one.

Is something wrong

with the temperature

settings?

Your new oven has a different cooking system

from your old oven and therefore may cook

differently than your old oven.

For the first few uses, follow your recipe times

and temperatures carefully. If you still think

your new oven is too hot or too cold, you can

adjust the temperature yourself to meet your

specific cooking preference.

Food does not bake

properly

Oven controls improperly set. See the Cooking Modes section.

Rack position is incorrect or rack is not level. See the Cooking Modes section.

Incorrect cookware or cookware of improper

size being used.

See the Cookware section.

Oven temperature needs adjustment. See the Special Features section.

Ingredient substitution Substituting ingredients can change the recipe

outcome.

Food does not broil

properly

Oven controls improperly set. Make sure you select the appropriate broil

mode.

Improper rack position being used. See Oven Racks / Main Oven section for

rack location suggestions.

Food being cooked in a hot pan. Make sure cookware is cool.

Cookware not suited for broiling. Use a pan specifically designed for broiling.

Aluminum foil used on the broiling pan and

grid has not been fitted properly and slit as

recommended.

If using

aluminum foil conform to pan slits.

In some areas the power (voltage) may be low. Preheat the broil element for 10 minutes.

Oven temperature too

hot or too cold

Oven temperature needs adjustment. See the Special Features section.

Oven does not work or

appears not to work

A fuse in your home may be blown or the

circuit breaker tripped.

Replace the fuse or reset the circuit breaker.

Oven controls improperly set. See the Using the Oven section.

“Crackling” or

“popping” sound

This is the sound of the metal heating and

cooling during both the cooking and cleaning

functions.

This is normal.

TROUBLESHOOTING TIPS ... Before you call for service

18

3. Fully open the door. If the door will not

fully open, the notches in the bottoms

of the hinge arms are not seated correctly

onto the bottom edge of the slot. Lift the

door off the cooker and repeat Step 2.

4. Push the hinge locks down to the locked

position.

5. Close the oven door.

19

oD oT tahWesuaC elbissoPmelborP

Why is my cooker

making a "clicking"

noise when using my

oven?

Your cooker has been designed to maintain

a tighter control over your oven's temperature.

You may hear your oven's heating elements

"click" on and off more frequently than in

older ovens to achieve better results during

baking, broiling, and self-clean cycles.

This is normal.

Clock and timer do not

work

A fuse in your home may be blown or the

circuit breaker tripped.

Replace the fuse or reset the circuit breaker.

Sometimes the

oven takes longer to

preheat to the same

temperature

Cookware or food in oven The cookware or food in the oven will cause

the oven to take longer to preheat. Remove

items to reduce preheat time.

Number of racks in oven Adding more racks to the oven will cause the

oven to take longer to preheat. Remove some

racks.

Oven light does not

work

Light bulb is loose or defective. Tighten or replace bulb.

Pad operating light is broken. Call for service.

Oven will not self-clean The temperature is too high to set

a self-clean operation.

Allow the oven to cool and reset the controls.

Oven controls improperly set. See the Cleaning the Oven section.

Excessive smoking

during clean cycle

Excessive soil or grease. Press the Cancel/Off pad. Open the windows

to rid the room of smoke. Wait until the LOCKED

light goes off. Wipe up the excess soil and

reset the clean cycle.

Excessive smoking

during broiling

Food too close to burner element. Lower the rack position of the food.

Oven door will not

open after a clean cycle

Oven too hot. Allow the oven to cool below locking

temperature.

Oven not clean after a

clean cycle

Oven controls improperly set. See the Cleaning the Oven section.

Oven was heavily soiled. Clean up heavy spillovers before starting the

clean cycle. Heavily soiled ovens may need to

self-clean again or for a longer period of time.

"LOCK DOOR" flashes

in the display

The self-clean cycle has been

selected but the door is not closed.

Close the oven door.

LOCKED light is on

when you want to cook

The oven door is locked because

the temperature inside the oven

has not dropped below the locking

temperature.

Press the Cancel/Off pad. Allow the oven

“F— and a number

or letter” flash in the

display

You have a function error code. Press the Cancel/Off pad. Allow the oven to

cool for one hour. Put the oven back into operation.

If the function code repeats. Disconnect all power to the oven for at least

30 seconds and then reconnect power. If the

function error code repeats, call for service.

to cool.

Display goes blank A fuse in your home may be blown

or the circuit breaker tripped.

Replace the fuse or reset the circuit breaker.

The clock is turned off. See the Special features section.

Power outage, clock

flashes

Power outage or surge Reset the clock. If the oven was in use, you

must reset it by pressing the Cancel/Off pad,

setting the clock and resetting any cooking

function.

“Burning” or “oily”

odor emitting from the

vent

This is normal in a new oven and

will disappear in time.

To speed the process, set a self-clean cycle

for a minimum of 3 hours. See the Cleaning

the Oven section. This is temporary.

Lock Controls or

Control Lockout

feature is activated

If LOC ON appears in the display, the cooker

control is locked. Turn this feature off to use

the cooker. See the Lock Control feature in the

Oven Controls section.

Lever is

shown closed.

PULL TO OPEN.

Sealed burner models

Thumb screws

Lower oven drawer models

20

oD oT tahWesuaC elbissoPmelborP

Strong odor An odor from the oven insulation

is normal for the first few times the

oven is used.

This is temporary and will go away after

several uses or a self-clean cycle.

My oven door glass

appears to be "tinted"

or have a "rainbow"

color. Is this defective?

No. The inner oven glass is coated

with a heat barrier to reflect the

heat back into the oven to prevent

heat loss and keep the outer door

cool while baking.

This is normal. Under certain light or angles,

you may see this tint or rainbow color.

Top burners do

not light or do not

burn evenly. (The

front right burner

is designed to have

slightly smaller

flames between

the 6 and 9 o’clock

positions. This is

normal.)

Plug on cooker is not completely

inserted in the electrical outlet.

Make sure electrical plug is plugged into a live,

properly grounded outlet.

Burner slits on the side of the burner

may be clogged.

Remove the burners and clean them. Check

the electrode area for burned-on food or grease.

See the Care and cleaning of the cooker section.

Improper burner assembly. Make sure the burner parts are installed correctly.

See the Care and cleaning of the coocker section.

Burner flames very

large or yellow

Improper air to gas ratio. If cooker is connected to LP gas, contact the

person who installed your cooker or made the

conversion.

Surface burners

light but oven does

not

The oven gas shut-off valve may

have accidentally been moved

during cleaning or moving.

To check the oven gas shut-off valve, remove

the drawer (see the Care and cleaning of the

cooker section). For lower oven drawer models,

remove the rear access panel by unscrewing

the thumb screws in the upper left and right

corners. Look for the gas shut-off lever at the

back of the cooker.

Burners do not

light

Lock Controls feature is activated. Allow the cooker to cool down and touch and

hold the Lock Controls pad (on some models)

for 3 seconds until the display shows LOC OFF.

Plug on cooker is not completely

inserted in the electrical outlet.

Make sure electrical plug is plugged into a live,

properly grounded outlet.

Gas supply not connected or

turned on.

See the Installation Instructions.

A fuse in your home may be blown

or the circuit breaker tripped.

Replace the fuse or reset the circuit breaker.

Burner parts not replaced correctly. See the Care and Cleaning of the cooker section.

Drawer does not slide

smoothly or drags

The drawer is out of alignment. Fully extend the drawer and push it all the

way in. See the Care and cleaning of the

cooker section.

Drawer is over-loaded or load is

unbalanced.

Reduce weight. Redistribute drawer contents.

INSTALLATION INSTRUCTIONS

FIRE OR EXPLOSION HAZARD

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

Installation must be performed by a

qualified installer.

Read these instructions completely and

carefully.

Installation of this cooker must conform

with local codes, or in the absence of local

codes, with the National Fuel Gas Code,

ANSI Z223.1/ NFPA.54, latest edition.

When installing a gas appliance the use of

old flexible connectors can cause gas leaks

and personal injury. Always use a NEW

flexible connector.

Leak testing of the appliance shall be conducted

according to the manufacturer instructions.

The cooker must be electrically grounded in

accordance with local codes or, in the absence

of local codes, in accordance with the National

Electrical Code (ANSI/NFPA 70, latest edition).

See Electrical Connections in this section.

Do not install this product with an air curtain

hood or other cooker hood that operates by

blowing air down on the hob. This airflow may

interfere with operation of the gas burners

resulting in fire or explosion hazard.

FOR YOUR SAFETY:

• A child or adult can tip the cooker and be killed.

• Install the anti-tip bracket to the wall or floor .

• Engage the cooker to the anti-tip bracket by sliding

the cooker back such that the foot is engaged.

• Re-engage the anti-tip bracket if the cooker is moved.

• Failure to do so can result in death or serious burns

to child ren or adults.

Tip-Over Hazard

WARNING

Before beginning

the installation, switch power off at

service panel and lock the service

disconnecting means to prevent power

from being switched on accidentally.

When the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a

tag, to the service panel.

Anti-Tip Bracket

Kit Included

21

WARNING

WARNING

TOOLS YOU WILL NEED

MATERIALS YOU MAY NEED

Gas line shut-off valve

Pipe joint sealant or UL-approved pipe thread

tape with Teflon* that resists action of natural

and LP gases

Flexible metal appliance connector (1/2” I.D.).

A 5-foot length is recommended for ease of

installation but other lengths are acceptable.

Never use an old connector when installing a

new cooker.

Flare union adapter for connection to gas

supply line (3/4” or 1/2” NPT x 1/2” I.D.)

Flare union adapter for connection to pressure

regulator on cooker (1/2” NPT x 1/2” I.D.)

Liquid leak detector or soapy water.

*Teflon: Registered trademark of DuPont

Flat-blade

screwdriver

Pipe wrenches (2)

(one for backup)

Phillips

screwdriver

Open-end or

adjustable wrench

Pencil and ruler

Level

Drill, awl or nail

IMPORTANT — Save these instructions for

local inspector’s use.

IMPORTANT — Observe all governing

codes and ordinances.

IMPORTANT — Remove all packing

material and literature from oven before

connecting gas and electrical supply to cooker.

IMPORTANT — To avoid damage to your

cabinets, check with your builder or cabinet

supplier to make sure that the materials used will

not discolor, delaminate or sustain other damage.

This oven has been designed in accordance with

the requirements of UL and CSA International

and complies with the maximum allowable wood

cabinet temperatures of 194°F (90°C).

Note to Installer – Be sure to leave these

instructions with consumer.

Note to consumer – Keep these instructions for

future reference.

Servicer – The electrical diagram is in an

envelope attached to the back of the cooker.

Proper installation is the responsibility of the

installer.

Product failure due to improper installation is not

covered under warranty.

Before installing your cooker on linoleum or any

other synthetic floor covering, make sure the

floor covering can withstand 180°F without

shrinking, warping or discoloring. Do not install

the cooker over carpeting unless a sheet of 1/4”

thick plywood or similar insulator is placed

between the cooker and carpeting.

22

BEFORE YOU BEGIN

Provide adequate clearances between the

cooker and adjacent combustible surfaces. These

dimensions must be met for safe use of your

cooker.

Allow 30” (76.2 cm) minimum clearance between

burners and bottom of unprotected wood or

metal cabinet, or allow a 24” (61 cm) minimum

when bottom of wood or metal cabinet is

protected by no less than 1/4” (6.4 mm) thick

flame-retardant millboard covered with no less

than No. 28 MSG sheet metal (.015” [.38 mm]

thick), .015” (.38 mm) thick stainless steel, .025”

(0.64 mm) aluminum or .020” (0.5 mm) copper.

Installation of a listed microwave oven or

cooking appliance over the hob shall conform

to the installation instructions packed with

that appliance.

For island installation, maintain 2-1/2” minimum

from cutout to back edge of countertop and

3” minimum from cutout to side edges of

countertop.

To cabinets

below hob

and at the

cooker back

Minimum to

cabinets on

either side

of the cooker

30”

30”

Minimum

15”

3”

Minimum

clearance to

right wall

Maximum

depth for

cabinets above

countertops

Front edge

of the cooker

side panel

forward from

cabinet

0”

To cabinets

below hob

and at the

cooker back

1/4”

3”

Minimum

clearance

to left

wall

0”

18”

30"

46 3/8 "

28 3/4 "

w/ handle

26 1/4 "

w/o handle

10 7/8 "

36 1/4 " ± 1/4

23

DIMENSIONS AND CLEARANCES

CONVERTING TO LP GAS

(OR CONVERTING BACK TO

NATURAL GAS FROM LP)

This cooker leaves the factory set for use with

natural gas. If you want to convert to LP

gas, the conversion must be performed by a

qualified LP gas installer.

The conversion orifices and instructions can be

found on back of the cooker.

Keep these instructions and all orifices in case

you want to convert back to natural gas.

GAS PIPE AND ELECTRICAL OUTLET LOCATIONS

Rear of Cooker

Orifice Strip

(location

may vary)

Recommended area for

220-240V outlet on rear wall and

area for through-the-wall

connection of pipe stub and

shut-off valve.

Recommended area

for through-the-floor

connection of pipe stub

and shut-off valve.

CAUTION To prevent drafts

from affecting burner operation, seal

all openings in floor under appliance

and behind appliance wall.

24

CONNECTOR HOOKUP

Pressure

regulator

Gas Flow into Cooker Gas Flow into Cooker

Flex

connector

(6 ft. max.)

Adapter

Installer: Inform the consumer of the location of the gas shut-off valve.

1/2” or 3/4”

Gas pipe

Adapter

Gas

shut-off

valve

Pressure

regulator

Elbow

Elbow

Nipple

Union

Nipple

Gas

shut-off

valve

1/2” or 3/4”

Gas pipe

Flexible

Option

Rigid Pipe

Option

1

GAS SUPPLY

Fire Hazard: Do not use a

flame to check for gas leaks.

Explosion Hazard: Do not

exceed 25 ft-lbs of torque when making gas

line connections. Overtightening may crack

the pressure regulator resulting in fire or

explosion hazard.

Gas Pressure Regulator

You must use the gas pressure regulator supplied

with this cooker. For proper operations the inlet

pressure to the regulator should be as follows:

Natural Gas:

Minimum pressure: 6” of Water Column

Maximum pressure: 13” of Water Column

LP Gas:

Minimum pressure: 11” of Water Column

Maximum pressure: 13” of Water Column

If you are not sure about the inlet pressure

contact local gas supplier.

Shut off the main gas supply valve before

disconnecting the old cooker and leave it off

until the new hook-up has been completed.

Don’t forget to relight the pilot on other gas

appliances when you turn the gas back on.

Because hard piping restricts movement of

the cooker, the use of a CSA Internationalcertified flexible metal appliance connector is

recommended unless local codes require a hardpiped connection.

If the hard piping method is used, you must

carefully align the pipe; the cooker cannot be

moved after the connection is made.

To prevent gas leaks, put pipe joint compound on,

or wrap pipe thread tape with Teflon* around, all

male (external) pipe threads.

A. Install a manual shut-off valve in the gas line

in an easily accessed location outside of the

cooker. Make sure everyone operating the

cooker knows where and how to shut off the

gas supply to the cooker.

B. Install male 1/2” flare union adapter to the 1/2”

NPT internal thread at inlet of regulator. Use a

backup wrench on the regulator fitting to avoid

damage.

C. Install male 1/2” or 3/4” flare union adapter to

the NPT internal thread of the manual shut-off

valve, taking care to back-up the shut-off valve

to keep it from turning.

D. Connect flexible metal appliance connector

to the adapter on the cooker. Position cooker to

permit connection at the shut-off valve.

E. When all connections have been made, make

sure all cooker controls are in the off position

and turn on the main gas supply valve.

Use a liquid leak detector at all joints and

connections to check for leaks in the system.

When using pressures greater than 1/2 psig

to pressure test the gas supply system of the

residence, disconnect the cooker and individual

shut-off valve from the gas supply piping. When

using pressures of 1/2 psig or less to pressure

test the gas supply system, simply isolate the

cooker from the gas supply system by closing the

individual shut-off valve.

When checking for proper operation of the

regulator, the inlet pressure must be at least 1”

greater than the operating (manifold) pressure as

given on rating label of product.

*Teflon: Registered trademark of DuPont

25

WARNING

WARNING

2

ELECTRICAL CONNECTIONS

Shock Hazard: This

appliance must be properly grounded.

Failure to do so can result in electric shock.

Electrical Requirements - 220-240 V, 50/60 Hz.

properly grounded dedicated circuit protected by a

15-amp or 20-amp circuit breaker or time delay fuse.

Note: Use of automatic, wireless, or wired external

switches that shut off power to the appliance are

not recommended for this product.

Grounding

The power cord of this appliance is equipped with

a three-prong (grounding) plug which plugs into a

standard three-prong grounding wall receptacle

to minimize the possibility of electric shock hazard

from this appliance.

The customer should have the wall receptacle

and circuit checked by a qualified electrician to

make sure the receptacle is properly grounded.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with

a properly grounded three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

THE POWER CORD. DO NOT USE AN ADAPTER.

DO NOT USE AN EXTENSION CORD.

3

SURFACE BURNERS

Fire or Explosion Hazard:

Do not operate the burner without all burner

parts in place.

A.

Burners - Place surface burners into

corresponding positions on hob.

B.

Caps - Place caps on proper size burner..

C.

Single Grates - Place the oval (center) head/

cap assembly over the electrode on the hob.

Make sure the notch in the

burner head is positioned

over the electrode.

Electrode

Notch

Cap

Burner

Locator Bumps

26

WARNING

WARNING

4

CHECK SURFACE BURNERS

Push and turn knob to LITE position. You will hear

a clicking sound indicating proper operation of

the spark module. Once the air has been purged

from the supply lines, burners should light within

4 seconds. After burner lights, rotate knob out of

the LITE position. Try each burner in succession

until all burners have been checked.

Quality of Flames

The flame quality of the burners needs to be

determined visually.

If burner flames look like (A), call for service.

Normal burner flames should look like (B)

or (C), depending on the type of gas you use

With LP gas, some yellow tipping on outer cones

is normal.

5

CHECK BAKE AND BROIL

BURNERS

To remove the oven bottom:

A. Remove the screws holding down rear of the

oven bottom.

B. Grasp the oven bottom at rear slots on each

side.

C. Lift the rear of the oven bottom and slide it

back until it clears the lip of the cooker frame

at the front. Then lift bottom up and out.

Set Bake function to 350°F. Burner should

light in 30 to 90 seconds.

Check Flame Quality.

•

Flames should have approximately 1” blue

cones.

• Natural gas should burn with no yellow

flames.

• LP gas flames have slight yellow tips

• After warming up, the flame should not lift

off the burner.

Check broil burner using the same method

as the bake burner.

6

ADJUST BAKE AND BROIL

AIR SHUTTER IF NECESSARY

To adjust the flow of air to either burner, loosen

the Phillips head screw and rotate the shutter

as needed.

A. If the flames are yellow, open shutter more

than the original setting.

B. If the flames lift off the burner, close the air

shutter more than the original setting.

Check flames again and adjust further if

necessary. Replace oven bottom.

Loosen

Air

shutter

Air

shutter

Loosen

Oven bottom

Slots

Broil BurnerBake Burner

27

(C) Soft blue flames—

Normal for natural gas

(B) Yellow tips on

outer cones—

Normal for LP gas

(A) Yellow flames—

Call for service

WHEN ALL HOOKUPS ARE

COMPLETED

Make sure all controls are left in the off position.

Make sure the flow of combustion and ventilation

air to the cooker is unobstructed.

Check that all packing materials and tape have

been removed. This will include tape on metal

panel under control knobs (if applicable), adhesive

tape, wire ties, cardboard and protective plastic.

Failure to remove these materials could result in

damage to the appliance once the appliance has

been turned on and surfaces have heated.

7

INSTALL AND CHECK

ANTI-TIP DEVICE

Never completely remove

the leveling leg as the cooker will not be

secured to the anti-tip device properly.

Follow instructions supplied with ANTI-TIP bracket

8

LEVEL THE COOKER

Never completely remove the

leveling leg as the cooker will not be secured to

the anti-tip device properly.

A. Plug in the unit.

B. Measure the height of your countertop at the

rear of the opening (X).

C. Adjust two rear leveling legs so that the rear of

hob is at the same height as the counter (Y).

D. Slide unit into place.

E. Install oven shelves in the oven and position the

cooker where it will be installed.

F. Check for levelness by placing a spirit level on

one of the oven shelves. Take two readings—with

the level placed diagonally first in one direction

and then the other.

G. Adjust front leveling legs until the cooker is level.

H. Look under the unit and verify that the rear leg

is fully engaged with the anti-tip device. If not,

remove the unit and adjust the height of the

rear leg so that it is properly engaged.

Anti-Tip Bracket

Kit Included

Spirit level

X

Y

28

WARNING

WARNING

29

Recycle the materials with the symbol .

Put the packaging in applicable containers

to recycle it.

Help protect the environment and human

health and to recycle waste of electrical

and electronic appliances. Do not dispose

appliances marked with the symbol

with

the household waste. Return the product to

your local recycling facility or contact your

municipal

ENVIRONMENT CONCERNS

NOTES

30

NOTES

31

Loading...

Loading...