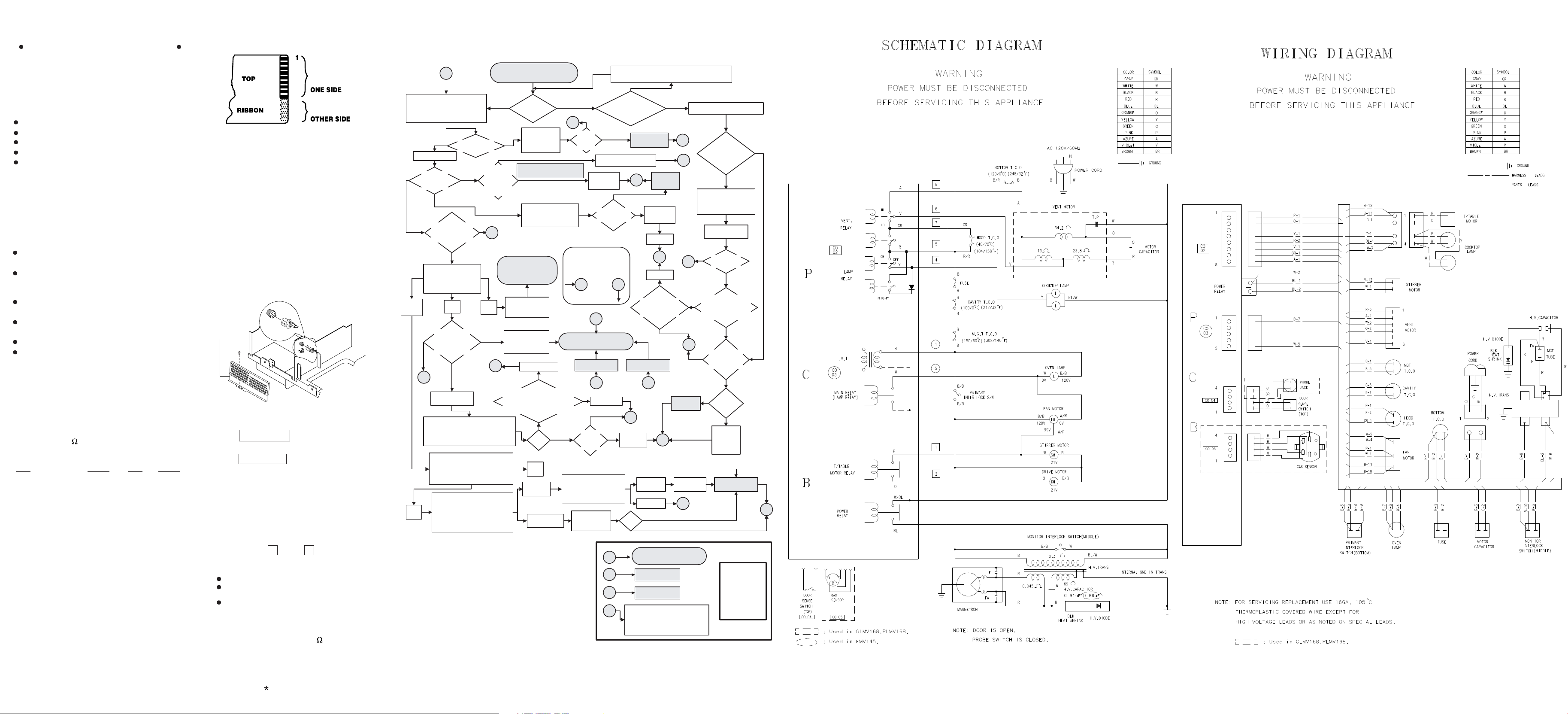

Frigidaire FMV145KS3 Wiring Diagram

TECHNICAL DATA SHEET

MWO TROUBLESHOOTING FLOW CHART

SMART BOARD

The SMART BOARD contains the power relay,

LVT, vent blower triac, surface light relays, and

other components to perform the proper

switching circuits. Several disconnect plugs are

also located on the SMART BOARD:

CON 01 - Ribbon Connector

CON 02 - Vent Blower Connector

CON 03 - Primary L.V.T & Main Relay

CON 04 - Door Sensing & Probe Connector

CON 05 - Gas Sensor Connector

(PLMV168, GLMV168)

Many diagnostic circuit tests can be made at the

disconnect plugs. (Refer to diagnosis flow chart

and simplified schematic in mini-manuals.)

CONTROL PERFORMANCE TEST

Set Clock-Touch clock pad, enter time of day,

AM/PM touch start pad.

Alternately touch each function pad and enter

time or temperature selection for the function.

Also change power levels.

Touch Clear-Off after each function test to

clear that function.

Repeat procedure for each function to

exercise each pad.

Control and display should respond to each entry.

Display should revert to Time-Of-Day after each

Clear-Off. Refer results to Diagnostic Flow Chart.

KEY PANEL TEST

If necessary the key panel pads can be verified

by a continuity test. For ease of handling the key

panel should be removed and placed on a flat

surface.

Check continity between connections at end of

ribbon (Use high scale).

RIBBON

PAD CONN. PAD CONN.

ADD 30SEC 4-11 REHEAT 8-11

BEVERAGE 9-11

POWER LEVEL 3-14 TIMER 4-13

DEFROST START 3-11

4-15

BEEPER VOLUME 9-12

AUTO NITE LIGHT 6-12 POTATO 6-10

AM/PM 9-13 1 9-16

SURFACE LIGHT

7-12 2 8-16

VENT FAN 8-12 3 7-16

TURNTABLE 5-12 4 6-16

REMINDER 5-13 5 5-16

TIME COOK 5-15 6 4-16

DELAY START 6-13 7 9-15

CLEAR 3-12 8 8-15

POPCORN 7-11

TEMPCOOK/ROAST 3-15

GROUND MEATS 3-10

VEGETABLE 9-10

- FMV145 -

BEVERAGE 6-11

REHEAT 9-11

POPCORN 5-11

PUB. NO. 31-40015

CLOCK 7-13

HELP 4-12

9 7-15

0 6-15

1~9

9

10

10~16

16

ERROR MESSAGE

Display Signal

• F1 Open thermal sensor(convection)

• F2

• F3

Shorted thermal sensor(convection)

Keypanel shorted for > 60seconds

• F4 Open humidity sensor

• F5

Shorted humidity sensor

* Error sound will beep for 3 cycles (2 second on,

1 second off) loudey in upper condition.

SENSOR COOKING

The Sensor Cooking function uses a special gas

sensor which detects both humidty (steam) and

hydrocarbons (food odors) during the cooking

process, The sensor is a plug-in device located in

the vent area at the top left hand corner of the

cavity behind the grille.

Bracket Barrier

SENSOR COOKING TEST

1. Place 1/3 cup tap water in oven.

2. Touch

3. Control Beeps and shuts off.

4. Touch

VEGETABLE

CLEAR/OFF

A) Test OK - Normal

B) Test Fails - Check Sensor

C) Test Fails - See Sensor Test Below

Condition

(PLMV168, GLMV168)

(PLMV168, GLMV168)

, the oven starts immediately.

SENSOR TEST (QUICK TEST)

(PLMV168, GLMV168)

1. With 2 fingers touch and hold the following

pads at the same time:

and

87

2. Observe diagnostic number in display

(numbers approximate)

15-185 (Normal-verify with "detection test")

213 or Higher (sensor failed to open, sensor

unplugged, wiring or smart board)

Less than 6 (shorted sensor, or smart board).

NOTE:

Only heater terminals (H : Black

and Red leads) can be checked

with ohmmeter (30 ).

CAUTION :

DO NOT ATTEMPT TO CHECK

SENSOR TERMINALS(White

and Orange leads).

CAN DAMAGE SENSOR.

D

1. SET CLOCK (IF NEEDED)

2. PLACE CUP OF WATER AND

NEON LIGHT TESTER IN UNIT

3. PROGRAM UNIT TO COOK

YES

UNIT ABLE TO

PRESS START

SERVICE

BREAKER

TRIPS?

NO

WATER HEATS /

NEON TESTER

INSTALL CLAMP ON

AMMETER TO MWO's

INTERNAL FUSE

ABOUT

5A

BLOWER AND

CAVITY LIGHT

NO

B

CHECK VOLTAGE ACROSS POWER

RELAY ON PCB (DOOR CLOSED,

NO COOKING PROGRAMMED) -

CMO ONLY - IF AN OTR, GO TO

INSTALL CLAMP ON AMMETER

1. UNPLUG UNIT

2. DISCHARGE HVC

> 8A

3. SET DVM ON 2K OHM SCALE

4. MEASURE HVD SIDE OF HVC

TO GROUND

PROGRAM?

IMMED

AFTER A

FEW SEC

LIGHTS?

NO

LEAD

< 2A

MAGNETRON

ON?

YES

PRIMARY

SWITCH OK

SHOULD GET ABOUT 120V

"OTR START" BLOCK

TO A MAGNETRON LEAD

OTR START

START - VERIFY MWO POWER

CORD PLUGGED INTO OUTLET

YES

IS DISPLAY

LIT?

NO

MONITOR

DOOR

SWITCH

OK?

A

YES

PROBLEM - CALL TAG

> 8A

CAVITY

LIGHT

ONLY ON

B

YES

PERFORM

KEY PANEL

"*" REFER TO FRONT

PAGE FOR MORE INFO

NO

CHECK RESISTANCE

OF HVC - 2K OHM

INTERMITTENT

TEAM FOR

RESOLUTION

MAGNETRON &

HV COMPTS

ARE GOOD

REPLACE

PRIMARY DOOR

SWITCH

ABOUT 120V

PROGRAM UNIT FOR

COOKING AND START -

CHECK VOLTAGE AT RELAY

INFINITE

(OPEN)

RESISTANCE

SCALE ON DVM

AGAIN

120V?

< 1A

DVM - DIGITAL VOLT METER

HVC - HIGH VOLTAGE CAPACITOR

HVD - HIGH VOLTAGE DIODE

HVT - HIGH VOLTAGE TRANSFORMER

LVT - LOW VOLTAGE TRANSFORMER

TCO

- THERMAL CUT OUT

(TEMPERATURE SENSOR)

PCB - PRINTED CIRCUIT BOARD

TEST

SOME

NO

B

PANEL

CIRCLE NODES:

ARROWS - EXAMPLE:

RETEST & REASSEMBLE -

REPLACE PCB REPLACE HVT

YES

CHECK RESISTANCE

OF SECONDARY SIDE

OF HVT (SINGLE LEAD

REPLACE HVD

& HVC AND

VERIFY OUTLET

VOLTAGE PRESENT

YES

KEY

OK?

FOLLOW THE

A A

NO

HVT IS GROUNDED

REPAIR /

REPLACE

YES

RESISTANCE

< 2K OHMS?

THEN

GO TO

A

END

B

ABOUT 0V

YES

WIRING

TO HVT

RETEST

OK?

TO HVC)

NONO

A

B

C

D

CHECK FUSE/CIRCUIT BREAKER - RESET

BREAKER/REPLACE FUSE IF NEEDED

NO

UNPLUG & DISASSEMBLE

A

C

INSTALL SERVICE

BREAKER ACROSS

YES

D

SERVICE BREAKER

TRIPPED BEFORE

YES

NO

B

YES

IS INTERNAL

MWO 15A/20A

FUSE OK?

NO

FUSE HOLDER

PLUG IN UNIT

IS DISPLAY

PROGRAMMING

FOR COOK?

VOLTAGE AT

LVT ON PCB?

REPLACE

KEY PANEL

REPLACE

A

NO

HVC IS

MISWIRED

REPAIR

REPAIR

ANY SHORTED

OR PINCHED

WIRING?

YES

HVC

A

YES

C

REPLACE

TCO(s)

C

REPAIR

OK?

1. SET CLOCK (IF NEEDED)

2. PLACE CUP OF WATER AND

NEON LIGHT TESTER IN UNIT

3. PROGRAM UNIT TO COOK

A

70 - 150

OHMS

OTHER

NO

YES

RETEST & REASSEMBLE -

END

REPLACE PCB

REPLACE HVT

OPEN

HVT IS OK

C

LIT?

NO

NO

HAVE

NO

CHECK

TCO(s)

CLOSED

CHECK/

REPAIR

TCO

WIRING

REPLACE

MAGNETRON

THIS IS A

LEGEND -

FIND

THESE

ON MAIN

CHART

YES

MODULARITY-OTR-FRIGIDAIRE

MODEL NO. :

PLMV168KC4, GLMV168KB4,

GLMV168KQ4, GLMV168KS4,

FMV145

A

MODULARITY-OTR-FRIGIDAIRE

MODEL NO. :

PLMV168KC4, GLMV168KB4,

GLMV168KQ4, GLMV168KS4,

FMV145

Printed in Malaysia

DE99-00140B

MICROWAVE OVEN HOODS

IMPORTANT SAFETY NOTICE

THIS INFORMATION IS INTENDED FOR USE

BY INDIVIDUALS POSSESSING ADEQUATE

BACKGROUNDS OF ELECTRICAL, ELECTRONIC

AND MECHANICAL EXPERIENCE. ANY

ATTEMPT TO REPAIR A MAJOR APPLIANCE

MAY RESULT IN PERSONAL INJURY AND

PROPERTY DAMAGE. THE MANUFACTURER OR

SELLER CANNOT BE RESPONSIBLE FOR THE

INTERPRETATION OF THIS INFORMATION, NOR

CAN IT ASSUME ANY LIABILITY IN

CONNECTION WITH ITS USE.

E. BEFORE TURNING ON MICROWAVE

F. ANY DEFECTIVE OR MISADJUSTED

DISCONNECT POWER BEFORE SERVICING

IMPORTANT · RECONNECT

ALL GROUNDING DEVICES

ALL PARTS OF THIS APPLIANCE CAPABLE OF

CONDUCTING ELECTRICAL CURRENT ARE

GROUNDED. IF GROUNDING WIRES, SCREWS,

STRAPS, CLIPS, NUTS OR WASHERS USED TO

COMPLETE A PATH TO GROUND ARE REMOVED

FOR SERVICE, THEY MUST BE RETURNED TO

THEIR ORIGINAL POSITION AND PROPERLY

FASTENED.

G.

GROUNDING SPECIFICATIONS

PRECAUTIONS TO BE

OBSERVED BEFORE AND

Leakage Current 0.5 mA. (Max.)

Ground Path Resistance 0.14 ohms (MAX.)

DURING SERVICING TO

AVOID POSSIBLE

EXPOSURE TO

EXCESSIVE MICROWAVE

ENERGY

A.

IF OVEN IS OPERATIVE PERFORM

MICROWAVE EMISSION CHECK

PRIOR TO.

B. DO NOT OPERATE OR ALLOW THE

OVEN TO BE OPERATED WITH THE

DOOR OPEN.

C. IF THE OVEN OPERATES WITH THE

DOOR OPEN :

1) INSTRUCT THE USER NOT TO

OPERATE THE OVEN AND

2) CONTACT THE MANUFACTURER

AND THE CENTER FOR DEVICES

RADIOLIGICAL HEALTH

IMMEDIATELY.

D.

CHECK THE FOLLOWING SAFETY

ITEMS ON ALL MICROWAVE OVENS

(MWO) BEFORE ACTIVATING THE

MAGNETRON. MAKE REPAIRS AS

NECESSARY :

1. INTERLOCK OPERATION

2. PROPER DOOR CLOSING

3. SEAL AND SEALING SURFACES

(CHECK FOR ARCING, WEAR, AND

OTHER DAMAGE)

4. DAMAGE TO OR LOOSENING OF

HINGES AND LATCHES

5.

EVIDENCE OF DROPPING OR ABUSE

PUB. NO. 31-40014

INSTALLATION REQUIREMENTS

ELECTRICAL

MWO Power 950 Watts

Power Source 120 VAC, 60 Hz.

Line Current 13.5 Amps. (1580Watts)

Over Current Protection 20 Amps *

* Requires 120 Volt, 20 Amp. parallel,

grounded separate circuit.

Working Voltage 105-130 VAC.

MICROWAVE LEAKAGE TEST

1. Place 275 ml. water in 600 ml. beaker

2. Place beaker in center of oven shelf.

3. Set meter to 2450 MHz scale.

4. Turn oven "on" for 5 minute test.

5. Hold probe perpendicular to surface being

6. Maximum leakage 4 MW/CM

7. Record data on service invoice and

NOTE :

Inform the manufacturer of any oven found to

have emission in excess of 5 MW/CM

repairs to bring the unit into compliance at no

cost to owner and try to determine cause.

Instruct owner not to use oven if it has not

been brought into compliance.

POWER FOR ANY SERVICE TEST OR

INSPECTION WITHIN THE MICROWAVE

GENERATING COMPARTMENTS,

CHECK THE MAGNETRON, WAVE

GUIDE, AND CAVITY FOR PROPER

ALIGNMENT, INTEGRITY, AND

CONNECTIONS.

COMPONENTS IN THE INTERLOCK,

MONITOR, DOOR SEAL, AND

MICROWAVE GENERATION AND

TRANSMISSION SYSTEMS SHALL BE

REPAIRED, REPLACED, OR ADJUSTED

BY PROCEDURES DESCRIBED IN THIS

MANUAL BEFORE THE OVEN IS

RELEASED TO THE OWNER.

A MICROWAVE LEAKAGE CHECK TO

VERIFY COMPLIANCE WITH THE

FEDERAL PERFORMANCE STANDARD

SHOULD BE PERFORMED ON EACH

OVEN PRIOR TO RELEASE TO THE

OWNER.

(WB64X5010)

tested and scan surfaces at rate of one

inch/sec.

Test the following areas:

Entire perimeter of door and control panel

Viewing surface of door window

Exhaust vents

microwave leakage report.

Maximum allowable leakage is 5 MW/

2

. 4 MW/CM2is used to allow for

CM

measurement and meter accuracy.

2

2

. Make

WARNING!

TO PREVENT ELECTRICAL SHOCK, USE

EXTREME CAUTION WHEN DIAGNOSING

OVEN WITH OUTER CASE REMOVED AND

POWER "ON". THE HIGH VOLTAGE SECTION

OF THE POWER SUPPLY, INCLUDING

FILAMENT LEADS HAVE THE POTENTIAL

WITH RESPECT TO GROUND TO REACH

4000 VOLTS!

HIGH VOLTAGE CAPACITOR

The high voltage capacitor has an internal shunt

resistor to automatically discharge the capacitor

when the oven turns "off". Under normal

operation the capacitor should fully discharge

within 30 seconds.

WARNING!

Always be certain the capacitor is

discharged before servicing.

Discharge by placing an insulated handle

screw driver between the diode connection of

the capacitor and oven chassis ground.

PERFORMANCE TEST

1. Measure line voltage (loaded). This test is based

on normal voltage variations of 105V to 130V.

Low voltage will lower output power and

temperature rise.

2. Place WB64 X0073 beaker containing one liter

water (1000ml, 59

F~75 F) on turn table and

record the starting water temperature with

an accurate thermometor.

(DO NOT USE ANY OTHER LOAD OR DISH AS

RESULTS WILL VERY FROM STANDARD!)

3. Set at HIGH power for 2 minutes, and 3 sec.

4. Turn on the oven.

5. Record end water temperature.

The minimum difference between the initial

and ending temperature should be:

40 F @ 120 V

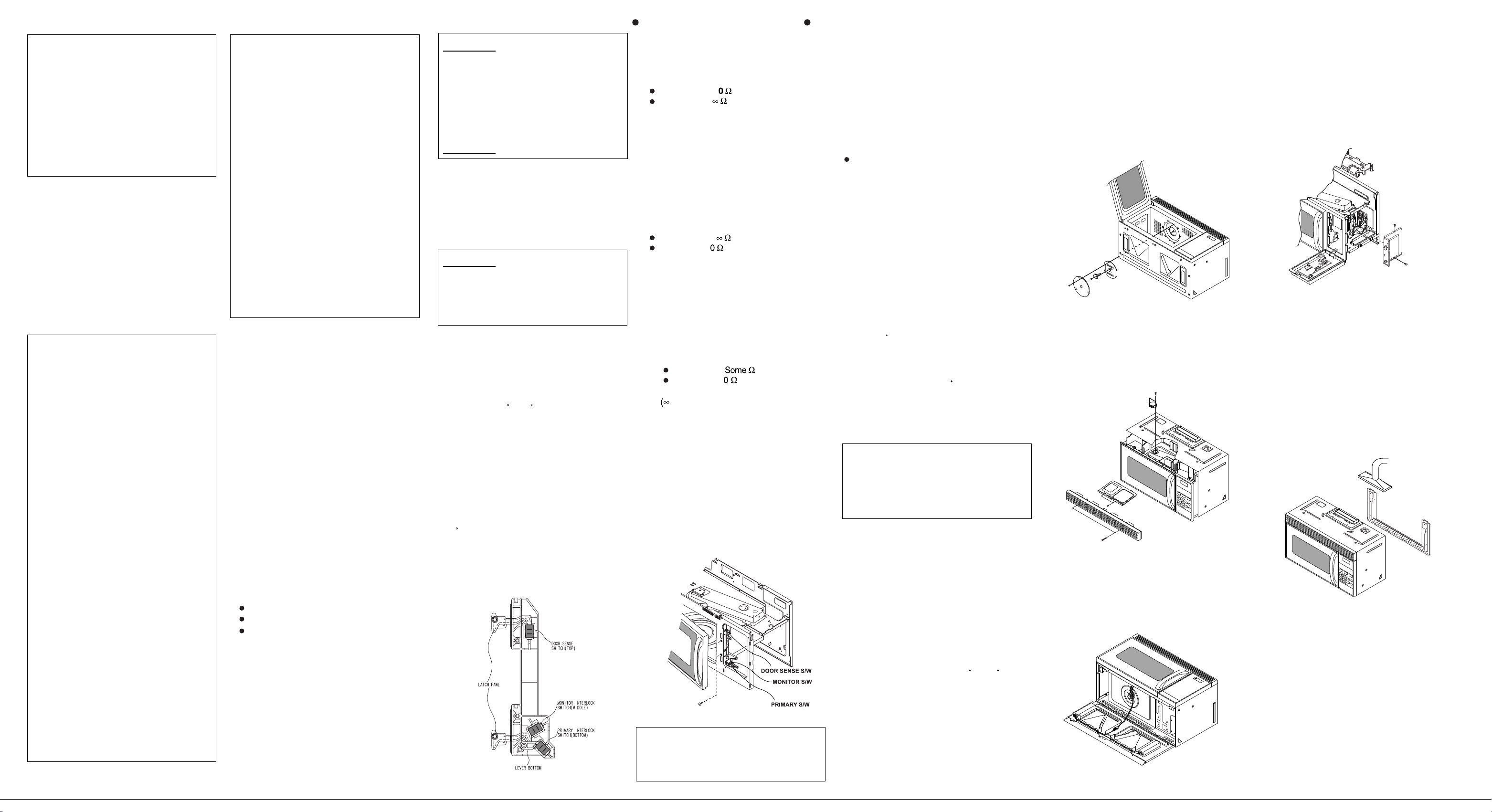

INTERLOCKS (DOOR Latch Switches)

Interlocks are designed as follows:

Primary - Bottom switch operated by bottom

latch pawl connected to line (L) leg.

TECHNICAL DATA SHEET

HOW TO TEST INTERLOCKS

1. Disconnect power, open control panel,

and discharge capacitor.

Primary

2. Check Continuity of Com and N.O. :

Door Closed –

Door Open –

MONITOR SWITCH

The monitor switch is located between the top

and bottom interlocks. The monitor switch is

operated indirectly by the bottom latch pawl.

HOW TEST MONITOR

1. Disconnect power, open control panel, and

discharge capacitor.

2. Disconnect monitor switch leads, and test at

terminals:

Door Closed –

Door Open –

3. Reconnect switch wiring.

4. Test Circuit Operation:

A) Connect temporary jumper across relay

contacts and primary switch to simulate

shorted switch contacts. Locate

convenient connections in circuit to be

certain COM and N.O. terminals are used.

B) Connect OHM meter (Low Scale) across

the two line terminals of appliance power

cord.

Continuity must show:

Door Close –

Door Open –

C) Remove 20 Amp. Fuse

Ohms). If not check wiring of monitor

and interlock circuits.

D)

WARNING!

jumper leads from interlocks and relay.

Reconnect monitor switch leads, replace

fuse.

E)

Replacement of any parts in monitor

After test remove temporary

– Circuit must open

circuit requires repeating this entire

test procedure.

IMPORTANT

Door, Interlock

:

Check for microwave leakage

after replacing or adjusting

switches or

brackets.

FUSE

WARNING!

to operation of the monitor switch, the monitor

switch must be replaced. Also replace relays

and / or interlock switches when continuity

check shows contacts shorted.

When 20 Amp. fuse is blown due

INTERLOCK REPLACEMENT

The switch housing is not adjustable. It is fixed

on the front cavity with 2 screws.

IMPORTANT - CHECK FOR MICROWAVE

LEAKAGE AFTER REPLACING OR

ADJUSTING DOOR, INTERLOCK

SWITCHES OR BRACKETS.

CAUTION !

When safety interlocks and monitor switches are

repaired or replaced, check microwave leakage.

Perform microwave leakage check, if leakage

does not exceed 4 MW/CM it is performing

properly.

2

AUTOMATIC FAN FEATURE

Exhaust fan turns "ON" automatically during

some surface unit heavy use conditions.

(Cannot be turned off manually - will turn off

automatically.) May stay on up to 15 mins.

after range and lower oven controls are

turned off.

HOOD THERMOSTAT

Single pole thermostat mounted ON R.H. side

duct in control compartment. Contacts close at

approx. 158 F.

BOTTOM THERMOSTAT

Single pole thermostat mounted on base plate.

Contacts open at approx. 248 F.

DOOR ASSEMBLY (NOT ADJUSTABLE)

The door assembly is serviceable as an

assembly or with parts.

MICROWAVE LEAKAGE TEST

A microwave leakage test must be performed

any time a door is removed, replaced,

disassembled, or adjusted for any reason.

THE MAXIMUM LEAKAGE IS

4 MW/CM

2

MICROWAVE OVEN HOODS

WARNING

NEVER TOUCH OR SERVICE THE

HIGH VOLTAGE CIRCUIT WITHOUT

DISCHARGING CAPACITOR BY

SHORTING ACROSS ITS TERMINALS.

TO AVOID POSSIBLE ELECTRICAL

SHOCK.

OVEN THERMAL CUTOUT

(FLAME SENSOR)

The Oven Thermal Cutout is located on the top

side of the Oven Cavity beside Exhaust duct

with a temperature rating of 212 F.(100 C.) The

cutout is tightly held to the top of the oven cavity

by a spring clip.

NOTE :

If cutout cannot be removed from clip

oven will have to be removed from

installation and outer case removed.

ANTENNA

The antenna is motor driven and located on the

upper side of the cavity. The oven uses a top

feed wave guide. The antenna blade is located in

the wave guide and the motor is located on the

wave guide.

To Service Antenna Blade

1. Disconnect power and open the door.

2. Remove the clip and turn the antenna cover

left.

3. Remove antenna cover and the antenna will

come with it.

To Service Antenna Motor

1. Disconnect power and remove grille

screws(2).

2. Remove grille and the bracket duct upper

screw.

3. Remove the bracket duct upper and

disconnect the antenna motor wire.

4. Remove antenna motor screws(2) and pull the

antenna motor.

To Service Turntable(on/off) Motor

1. Disconnect power and remove bottom plate

screws(7).

2. Remove bottom plate and disconnect the

turntable motor wire.

3. Remove turntable motor screws(2) and pull

the turntable motor.

CAPACITOR AND DIODE REMOVAL

The high voltage capacitor and diode can be

serviced through Control Panel after removing

grille.

1. Disconnect power and discharge capacitor.

2.

Disconnect capacitor leads and remove 1 screw.

3. Remove bracket-capacitor.

MAGNETRON, MAGNETRON FAN, VENT

BLOWER AND POWER TRANSFORMER

Oven must be removed from wall.

REMOVING OVEN FROM WALL

(2 PEOPLE REQUIRED)

Oven hooked on metal tabs at bottom of wall

mounting plate and fastened to cabinet by (3)

top cabinet bolts.

CAUTION :Oven weights about 62 lbs.

Requires 2 people for removal.

1. Disconnect Power Cord, Top vented models disconnect duct and remove damper assembly.

2. Remove top cabinet bolts(3).

3. Pull unit forward slowly, providing adequate

support to prevent dropping unit during

removal of last top cabinet bolt.

Loading...

Loading...