INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, persona njury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

®

• ALL RANGES

CAN TIP

• INJURYTO PERSONS

COULD RESULT

• INSTALL ANTI-TIP

DEVICE PACKED WITH

RANGE

• SEE INSTALLATION

INSTRUCTIONS

department.

-- Installation and service must be performed by aqualified

installer, service agency or the gas supplier.

RANGE

OVERALL 253/4"

O,MENS,ONi

DoorOpen,, 29

Clearances and Dimensions

1, Location_hecklocationwhere

the ranoe will be installed. Check

for proper electrical and gas

supply, and the stability of the

floor.

2. Dimensionsthatare shown must

be used, Given dimensions

provide minimum clearance,

Contact surface must be solid

and level,

PIN 316259309(0108)

..... [ I _ FRONT

HI ii

Minimum to

Wall on Eit 0

Sideof Range

Above 36 ]e 1_---3 0" -_1_

Height, _ I I I i

* Note; 3" _ 30 ....

Clearance

with 11000 or 2" *_

greater BTU Burners.

L

Minimum

.....

Minimum to

. Lau.ie_s un Maximum Depth

18 Either Side for Cabinets /-_

of Range. Above Range Top.

_r _25'!_

SIDE

VIEW

o

36" _

I

r

4_ 30" _ O'ClearanceBelowCookingTopandatRearofRange.

Provide Proper Fuel Type

Before Proceeding: Your range is preset to operate on LP/Propane Gasonly.

1

c _ ..........

H ........ i

!!

Fran;ais - Pages 9-16

Espafiol - Paginas 17-24

Important Notes to the Installer

1. Readallinstructionscontainedin theseinstallation

instructionsbeforeinstallingrange.

2. Removeallpackingmaterialfromtheovencompartments

beforeconnectingthegasandelectricalsupply to the

range.

3. Observe allgoverning codes and ordinances.

4. Be sureto leave these instructionswith the consumer.

Important Note to the Consumer

1. Keep these instructions with your owner's guide for

futurereference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation ofthisrange mustconformwithlocal codesor,in

the absence of local codes, with the National Fuel Gas Code

ANSI Z223.1--1atest edition when installed in the United

States.

This range has been design certifiedby CSA International.

As with any appliance using gas and generating heat, there

are certain safety precautions you should follow. You will find

them in the Use & Care Manual. read it carefully.

Besureyour rangeisinstalled andgrounded properly

by a qualified installer or service technician.

This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical CodeANSI/NFPA No .70.--

latest edition when installed in the United States.

See GroundingInstructionson page 5.

Before installing the range in an area covered with

linoleum or any other synthetic floor covering, make

sure the floor covering can withstand heat at least

90°F above room temperature without shrinking,

warping or discoloring. Do not installthe range over

carpetingunless you placean insulatingpad or sheet of

1/4-inchthickplywoodbetweentherangeandcarpeting.

Make sure the wall coverings around the range can

withstand the heat generated by the range.

Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the lower

front panel of the range. Avoid touching the vent

openings or nearby surfacesas they may become hot

whiletheoven is inoperation.Thisrange requiresfresh

air for properburnercombustion.

Never leave children alone or unattended

inthe area where an appliance is inuse. Aschildrengrow,

teach them the proper, safe use of all appliances. Never

leavethe oven dooropen when the range isunattended.

Stepping, leaning or sitting on the doors

or drawers of this range can result in serious injuries and

can also cause damage to the range.

Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

Do not use the oven as a storage space. This creates

a potentially hazardous situation.

Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

Reset all controls to the "off" position after using a

programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils before

self-cleaning the oven. Wipe upexcessspillage.Follow

the precleeninginstructionsin the Owner'sGuide.

Unlike the standard gas range, THIS COOKTOP IS

NOT REMOVABLE, Do not attempt to remove the

cooktop.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING AN

ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes ifthe oven thermostat control

was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

Duringa power outage, the surface burners can be litwith

a match. Hold alighted match to the burner, then slowly turn

the knob to the LITE position. Use extreme caution when

lighting burners this way.

Before Starting

Tools You Will Need

For leveling legs and Anti-Tip Bracket:

Adjustablewrench or channel lock pliers

5/16" Nutdriveror FlatHead Screw Driver

ElectricDrill&1/8"Diameter DrillBit(5/32"MasonryDrill

Bit if installingin concrete)

For gas supply connection:

Pipe wrench _

For burner flame adjustment:

Phillipshead _ and

blade-type screwdrivers

For gas conversion (LP/Propane or Natural):

Open endwrench - 1/2"

Additional Materials You Will Need

Gas line shut-offvalve I_

Pipe joint sealant that resists action of LP/Propane gas

A new flexiblemetal appliance conduit(1/2" NPTx 3/4"

or1/2"I.D.) mustbedesign certifiedbyCSAInternational.

Because solid pipe restricts moving the range we

recommend usinga new flexible conduit (4 to 5 foot

length) for each new installation and additional

reinstallations.

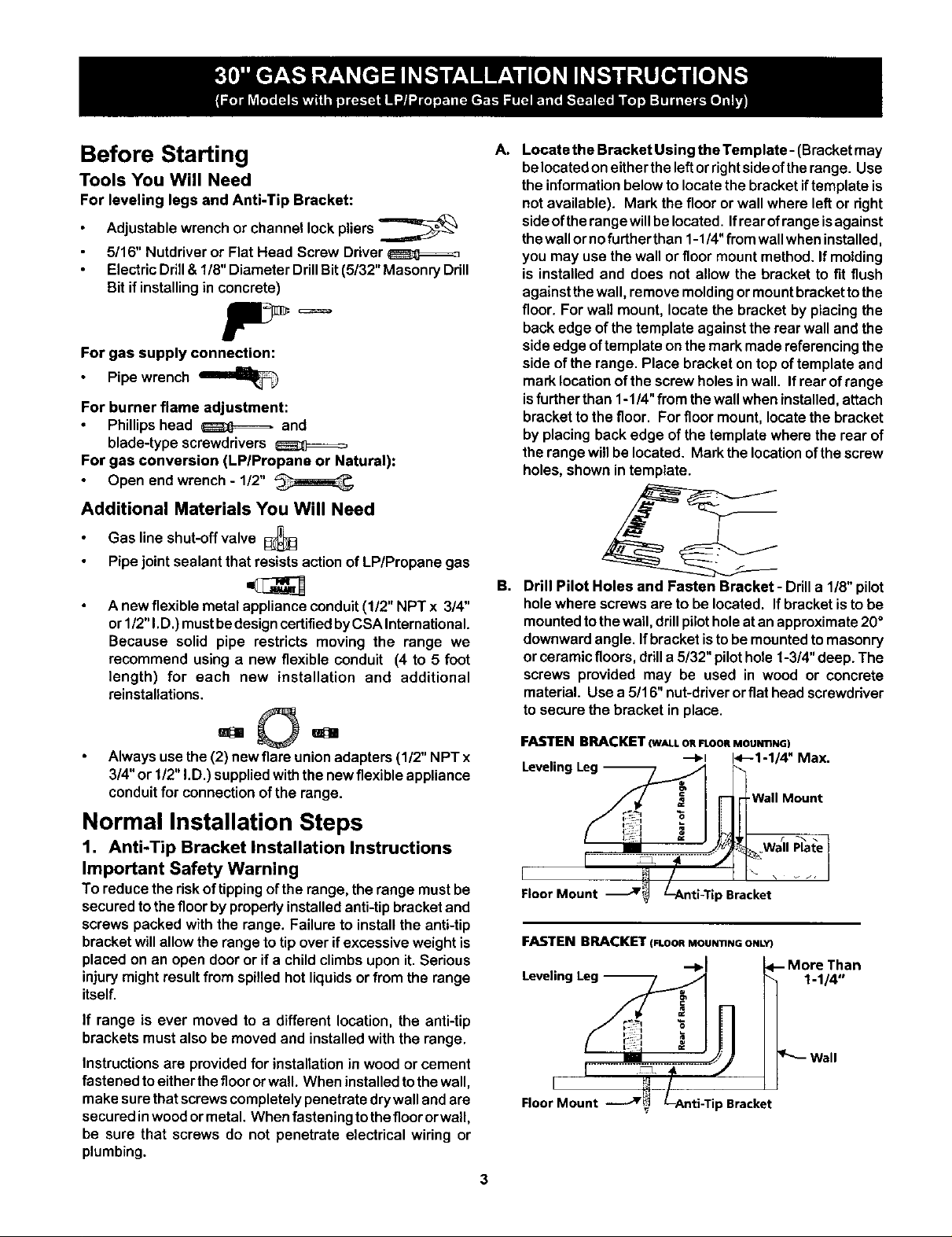

A°

Locate the Bracket Using the Template- (Bracketmay

belocatedoneithertheleftorrightsideoftherange. Use

the informationbelowtolocatethe bracketiftemplate is

notavailable). Mark the flooror wall where leftor right

sideof therangewillbelocated. Ifrearof rangeisagainst

thewallornofurther than 1-1/4"from wallwheninstalled,

you may use thewall orfloor mountmethod. If molding

is installed and does not allow the bracket to fit flush

againstthe wall, removemoldingormountbrackettothe

floor. For wall mount, locate the bracketby placingthe

backedge ofthe template against the rearwalland the

sideedge oftemplate onthe markmadereferencingthe

side of the range. Place bracketontop of template and

marklocationof the screw holes inwall. Ifrear of range

isfurtherthan 1-1/4"from the wallwhen installed,attach

bracketto thefloor. Forfloor mount,locatethe bracket

by placing back edge of the templatewhere the rearof

therangewillbe located. Mark the locationofthescrew

holes, shown intemplate.

B,

Drill Pilot Holes and Fasten Bracket- Ddll a 1/8" pilot

hole where screws are to be located. If bracket is to be

mounted to the wall, drill pilot hole at an approximate 20 °

downward angle. If bracket is to be mounted to masonry

or ceramic floors, drill a 5/32" pilot hole 1-3/4" deep. The

screws provided may be used in wood or concrete

material. Use a 5/16" nut-driver or flat head screwdriver

to secure the bracket in place.

Always use the(2) newflare unionadapters (1/2" NPT x

3/4"or 1/2"I.D.) suppliedwiththenewflexibleappliance

conduitfor connectionofthe range.

Normal Installation Steps

1, Anti-Tip Bracket installation Instructions

Important Safety Warning

To reducethe riskof tippingofthe range,the range mustbe

securedto the floorby properlyinstalledanti-tipbracketand

screwspacked withthe range. Failure to installthe anti-tip

bracketwillallowthe rangeto tip over if excessive weight is

placedon an open dooror if a childclimbs upon it.Serious

injurymight result from spilled hotliquidsorfromthe range

itself.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

Instructionsare provided for installation in wood or cement

fastenedtoeitherthefloororwall. When installedtothe wall,

make surethatscrewscompletelypenetratedrywallandare

securedinwoodor metal. When fasteningto thefloororwall,

be sure that screws do not penetrate electrical wiring or

plumbing.

FASTENBRACKET(WALLORFLOORMOUN'nNG)

--_1 1<--'1"1/4"Max.

Leveling Leg _._ _

I wa''°°u°t

[ ...........! I i

L_._ _t / I1"- , _. i

Floor Mount -_'_'_ L-Anti-Tip Bracket

FASTEN BRACKET(FLOORMOUNTINGONLY)

--,I

Leveling Leg --

Floor Mount =Bracket

C. Level and Position Range - Level range by adjusting

the (4) leveling legs with a wrench. Note: A minimum

clearance of 1/8" is required between the bottomof the

rangeandthe leveling legto allow roomfor the bracket.

Usea spiritlevelto check youradjustments. Slide range

backintoposition.Visuallycheckthat rear levelingleg is

insertedintoand fullysecuredbytheAnti-TipBracketby

removinglowerpanelorstoragedrawer. Formodelswith

a warmer drawer or broilercompartment, graspthe top

rear edge of the range and carefully attempt to tilt it

forward.

(17ram)

%

Range Side _"

3. Seal the openings.

Sealanyopeningsinthewallbehindthe rangeandinthe floor

underthe range aftergas supplyline is installed.

2. Provide an adequate gas supply.

Thisunitis pre-settooperateon10"LP/Prepanagas manifold

pressure.Aconvertiblepressureregulatorisconnectedtothe

manifold and MUST be connected in series with the gas

supply line.

Care mustbetaken dudnginstallationofrangenotto obstruct

theflow ofcombustionand ventilationair.

For proper operation, the maximum inlet pressure to the

regulatorshouldbe nomorethan 14 inchesofwatercolumn

pressure.The inletpressureto the regulatormust beat least

1inchgreaterthan regulatormanifoldpressure.Examples; If

regulatorhas beensetfor LP/Propane gas 10 inch manifold

pressure, inletpressure mustbe atleast 11 inches.

Leaktesting ofthe applianceshallbeconducted according to

the instructions in step 4g.

The gas supplyline should be 1/2" or 3/4" I.D.

4. Connect the range to the gas supply.

To preventleaks, puta pipejointsealantonallmale (outside)

pipethreads,

Your regulator isin the locationshown below.

Do not allow regulator to turn on pipe when

tightening fittings.

aa_

Regulatel

Regulator

Gas

Service

Gas Shut-OffValve

shown in the

Manual Flare Flexible Flare Union Pressure

Shu_vOff Union AcPoP/ic_ncte Adaptor Regulator

(ShowninON Position).

Besureleverisinthe "On"position when

installationiscomplete

a) Install an externalmanual gas shut-off valve to gas supply

line inan easily-accessible location outside of the range.

Be sure you know how and where to shut-off the gas

supply to the range.

b) Install 1/2" flare union adapter to pressure regulator.

c) Attach appliance conduit to flare union on regulator.

d) Install flare union adapter to external manual shut-off

valve.

e) Attach appliance conduitto flare union on shut-offvalve.

f) Make sure service shut-offvalve on pressure regulator is

in "ON" position.

g) Check for leaks. Turn the gas supply on to the renge and

use a liquid leak detector at all joints and conduits to

check for leaks in the system.

Do not use a flame to check for gas leaks.

Checking Manifold Gas Pressure

Disconnectthe range and its individualshut-offvalve from

thegas supply piping system duringany pressuretestingof

that system at test pressures greater than 14" of water

columnpressure (approximately 1/2"psig).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve dudng

any pressure testing of the gas supply piping system at test

pressures equal to or less than 14"of water column pressure

(approximately 1/2" psig).

Ifit should be necessary to check the manifoldgas pressure,

connect manometer (water gauge) orother pressure device

to the top burner right rear orifice. Using a rubber hose with

inside diameter ofapproximately 1/4," hold tubing down tight

over orifice. Turn burner valve on.

For an accurate pressure check have at leasttwo (2) other

top burners burning. Be sure the gas supply (inlet) pressure

is at least one inch above specified range manifold pressure.

The gas supply pressure should never be over 14" water

column. When propedy adjusted for LP/Propane Gas the

manifold pressure is 10".

5. Read electrical connection details below and

connect electricity to range,

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric Reouirements: Anindividual,propedy grounded and

polarized branch circuit protected by a 15amp. circuit breaker

or time delay fuse. See serial plate for proper voltage.

ExtensionCord Precautions:

Becauseofpotential safety hazards under certainconditions,

we strongly recommend against the use of any extension

cord. However, ifyou still elect to use an extension cord, it is

absolutely necessary that it bea UL listed 3-wire grounding

type appliance extension cord and that the current carrying

rating of the cord in amperes be equivalent to orgreater than

the branch circuit rating. Such extension cords are obtainable

through your local service organization.

PLEASE READ CAREFULLYI Forpersonal

safety, thisproduct must be properly grounded.

Grounding Instructions

The power cord ofthis applianceis equippedwith a

3-prong(grounding)plugwhich mateswith a standard

3-pronggroundingwallreceptacletominimizethepossibility

ofelectricshockhazard from thisappliance. The customer

should have the wall receptacle and circuit checked by a

qualifiedelectricianto make sure the receptacleis properly

groundedand polarized.

Preferred Method ./I /f Do Not, Under

Grounding Cord with

Type 3-Prong

Wall Grounding

Receptacle Plug

/ I _J Any Circumstances, I

/._: I _ Cut, Remove, |

Power Supply

___ _s;hPeOng" j)

Where a standard two-prongwallreceptacleisencountered,

itisthepersonal responsibilityandobligationofthe customer

tohaveitreplaced witha propedygroundedthree-prongwall

receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM THE

POWER CORD.

Operation of Surface Burners

6. Installation of Burner Cap Assembly

Your range isequipped with any combinationofthe sealed

burners. Refer to the chart to find yoursurface burner and

surfaceburnercapconfiguration.Besureto placethecorrect

burnercap at onall four surfaceburners,

PossibleSurfaceBurnerandCap configurations:

Install the parts shown below at all four surface burner

locations:

1st- Install the surface burner pans (if equipped); 2nd -install

the surface burner heads; 3rd- install thesurface burnercaps

and 4th; install the burner grates.

Surface

Burner

Grate

7. Electric Ignition Surface Burners

Operation of electric igniters should bechecked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

a. To check for proper lighting, push in and turn a surface

burner knob counterclockwise to the LITE position.

You willhear the ignitersparking.

b,

The surface burner should light whengas is available to

the top burner. Purge air from supply lines by leaving

knob in the LITE position until burner ignites. Each

burner should light within four (4) seconds in normal

operation after air has been purged from supply lines.

c. Visually check that burner has lit. Once the burner lights,

the control knob should beturned out of the LITE position.

d. There are separateelectrodes(igniters) for each burner.

Try each knob separately until all burner valves have

been checked.

Note: Knob styles may vary from those pictured below.

Surface

(_Burner

_._d) Surface

Orifice

Hold_ Electrode _e models)

Cap

Burner

Head

Removable

Burner

Drip Pan

I OFF ..LITE..hi 6 5 4 3 2 Io ]

8. Adjust the "LOW" Setting of Surface Burner

Valve (Linear Flow Valves Only):

To

Surface

Burner

Test to verify if "LOW"settingshouldbe adjusted

a. Push in and turn control to LITE until burner ignites.

b. Push in and auickty turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Removethe surface burner control knob.

e. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased with theturn ofthe screw.

Turn counterclockwise to increase flame size. Turn

clockwise to decrease flame size.

BurnernameSize -_1 5/8' t_

After removing all packing materials and literature from the

oven:

a) Set oven to BAKE at 300°F. See Use& Care Manual for

operating instructions.

b) Within 60 seconds the oven burner should ignite. Check

for proper flame, and allow the burner to cycle once.

Reset controls to off.

c) If your model is equipped with a waist-high broiler, set

oven to BROIL. See Use & Care Manual for operating

instructions.

d) Within 60 seconds the broil burner should ignite. Check

for proper flame. Reset controls to off.

10. Air Shutter-Oven Burner

Waist-High Burner

(SelfClean Models)

i

_Air Shutter

Adjust flame until you can quickly turn knob from LITE to

LOWEST POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

Operation of Oven Burners and

Oven Adjustments

9, Electric Ignition Burners

Operationofelectricignitersshouldbe checked after range

and supplylineconnectorshave been carefullycheckedfor

leaks and range has been connectedto electricpower,

The oven burner is equippedwithan electriccontrolsystem

as well as an electric oven burner igniter. If your model is

equipped with a waist-highbroilburner, itwill alsohave an

electnc burner igniter, These control systems require no

adjustment.When the oven issettooperate, currentwillflow

to the igniter.It will"glow" similarto a lightbulb. When the

igniterhas reached a temperaturesufficientto ignitegas,the

electrically controlled oven valve will open and flame will

appear at theoven burner.There ise time lapse from 30 to

60 seconds after the thermostat is turned ON before the

flame appears at the oven burner. When the oven reaches

the dial setting,the glowing igniterwill go off. The burner

flame willgo "out" in20 to 30 secondsafterthe ignitergoes

"OFF." To maintain any given oven temperature,this cycle

willcontinueas longas thedial(ordisplay) isset to operate.

Lower Oven Bottom

Air Shutter

(Removable)

The approximate flame length of the oven burner is 1 inch

(distinct inner, blue flame).

To determine ifthe oven burner flameis proper, removethe

oven bottomand burner baffle and set the oven to bake at

3OO°F.

To remove the ovenbottom, remove ovenhold down screws

atrearofoven bottom.Pullupatrear,disengagefrontofoven

bottomfrom oven front frame, and pullthe oven bottomout

ofthe oven. Remove burnerbaffle so that the burnerflame

can be observed.

If the flame is yellow in color, increase air shutteropening

size. (See "2" in illustrationbelow.) If theflame is a distinct

blue, reduce the air shutter openingsize.

To adjust loosen lock screw (see "3" illustration below),

reposition air shutter, and tighten lock screw. Replace oven

bottom.

Oven

Tube

® ®

(_Air Shutter Orifice

11. Air Shutter-Broil Burner

The approximateflame length of the broilburner is 1 inch

(distinctinner, blue flame).

To determine if the broil burner flame is proper, set the oven

to broil.

Before You Call for Service

Readthe "Before YouCall" and operating instruction sections

in your Use & Care Manual. It may save you time and

expense. The list includes common occurrences that are not

the result of defective workmanship or materials in this

appliance.

Refer to the warranty in yourUse& Care Manual for our toll-

free service number and address. Please call or write if you

have inquiries about your range product and/or need to order

parts.

i

If the flame is yellow in color,increase air shutter opening

size. (See "2" in illustration above.) If the flame is adistinct

blue, reduce the air shutter opening size.

To adjust, loosen lock screw (see "3" in illustration above),

reposition air shutter, and tighten lock screw.

12,Make Sure Range is Level.

Level the range by placing a level horizontally on an oven

rack. Check diagonally from front to back, then level the

range by either adjusting the leveling legs orby placing shims

under the corners of the range as needed,

13.After installation is complete, make sure all

controls are left in the OFF position,

Model and Serial Number Location

For sealed burner ovens, the serial plate is locatedon the

right-handsurface ofthe oven front frame at the storageor

warmer drawer;or the lowerpanel area.

When ordering parts for ormakinginquiresabout your range,

always be sure to include the model and serial numbers and

a lot number or letter from the sedal plate on your range.

n n _

60 O©

Your serial plate also tells youthe rating of the burners, the

type offuel andthe pressure the range was adjusted for when

it left the factory.

Care, Cleaning and Maintenance

Refer tothe Use & Care Manual for cleaning instructions.

If removing the range is necessary for cleaning or

maintenance, shut off gas supply. Disconnect the gas and

electrical supply. Ifthe gasor electrical supply isinaccessible,

lift the unitslightly at thefront and pull out away from the wall.

Pull only as far as necessary to disconnect the gas and

electrical supply. Finish removing the unit for servicing and

Serial plate location

Open storage or warmer drawer

or remove lower panel

(on some models)

Loading...

Loading...