Page 1

LAUNDRY CENTER

use

Introduction .......................................................2

Important Safety Information ....................3

Features ..............................................................8

Pre-Installation Requirements ....................9

Installation ....................................................... 17

Controls And Settings ................................ 25

&

Operating Instructions ...............................30

Operating Instructions ............................... 32

Stain Removal Guide...................................33

Stain Removal Guide...................................34

Troubleshooting .......................................... 37

Limited Warranty .........................................43

care

A11271204 (January 2020)

Frigidaire.com USA 1-800-374-4432 Frigidaire.ca Canada 1-800-265-8352

Page 2

2

Welcome to our

Thank you for bringing Frigidaire into

your home! We see your purchase as the

beginning of a long relationship together.

This manual is your resource for the Use

& Care of your product. Please read it

before using your appliance. Keep it

handy for quick reference. If something

doesn’t seem right, the troubleshooting

section will help you with common issues.

FAQs, helpful tips and videos, cleaning

products, and kitchen and home accessories

are available at www.frigidaire.com.

We are here for you! Visit our website,

chat with an agent, or call us if you need

help. We may be able to help you avoid

a service visit. If you do need service, we

can get that started for you.

Let’s make it ocial! Be sure to register

your product.

INTRODUCTION

family

Keep your product info here so it’s easy

to find.

Model Number

Serial Number

Purchase Date

Serial Number Location

Page 3

IMPORTANT SAFETY INFORMATION

3

WARNING

FIRE or explosion hazard

Failure to follow safety warning exactly could

result in serious injury, death, or property damage.

DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS:

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch; DO NOT

use any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

NOTE

The instructions appearing in this

possible condition and situation that may occur. Common sense and caution must

be practiced when installing, operating and maintaining any appliance.

Use & Care Guide

are not meant to cover every

Page 4

4

IMPORTANT SAFETY INFORMATION

WARNING

Please read all instructions before using

this laundry center.

This

Use & Care Guide

operating instructions for your laundry

center. It also contains information about

features for several other models. Your

model may not have every feature included.

Use the laundry center only as instructed

in this

Use & Care Guide

This book contains valuable information

about operation, care and service. Keep it

in a safe place.

provides general

.

CAUTION

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have more

than one person move or lift the appliance.

Product record

Record Your Model and Serial Numbers

The model and serial numbers of your

laundry center are found on the dryer serial

plate located inside the door opening.

Record and retain these numbers.

Model Number

Serial Number

Recognize safety symbols,

words and labels

Safety items throughout this manual are

labeled with a WARNING or CAUTION

based on the risk type as described below:

Definitions

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety messages

that follow this symbol to avoid possible

injury or death.

DANGER

DANGER indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

CAUTION indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Purchase Date

Child safety

Destroy or recycle the carton, plastic

bags, and any exterior wrapping material

immediately after the laundry center is

unpacked. Children should never use

these items to play. Cartons covered with

rugs, bedspreads, plastic sheets or stretch

wrap may become airtight chambers, and

can quickly cause suocation.

Proper disposal

Child entrapment and suocation are

not problems of the past. Junked or

abandoned washers/dryers are still

dangerous – even if they will sit for “just

a few days”. If you are getting rid of your

old washer/dryer, please follow the Risk

of

Child Entrapment

instructions to help prevent accidents.

section of the safety

IMPORTANT

IMPORTANT indicates installation,

operation or maintenance information

which is important but not hazard-related.

WARNING

ELECTRIC SHOCK HAZARD

Certain internal parts are intentionally

not grounded and may present a risk

of electrical shock if contacted during

installation. Do not contact the following

parts while the appliance is energized:

• Pump

• Drive Motor

• Electronic control boards

• Water valve

Page 5

IMPORTANT SAFETY INFORMATION

WARNING - risk of fire

To reduce the risk of fire, electrical

shock, or injury to persons when using

this laundry center, comply with the

basic warnings listed below. Failure

to comply with the Important Safety

Information and WARNINGS could result

in serious personal injuries or death.

Prevent re

• DO NOT wash or dry items that have

been previously cleaned in, soaked

in, or spotted with gasoline, cleaning

solvents, kerosene, cooking oils, waxes,

etc. DO NOT store these items on or

near the washer. These substances

give o vapors or chemical reactions

that could ignite or explode.

• DO NOT put oily or greasy rags or

clothing on top of the laundry center.

These substances give o vapors that

could ignite the materials.

• DO NOT add gasoline, cleaning

solvents, or other flammable or

explosive substances to the wash

water. These substances give o

vapors that could ignite or explode.

• Under certain conditions, hydrogen

gas may be produced in a hot water

system that has not been used for 2

weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system

has not been used for such a period,

turn on all hot water faucets and let

the water flow from each for several

minutes BEFORE using the washer.

This will release any accumulated

hydrogen gas. Hydrogen gas is

flammable; DO NOT smoke or use an

open flame during this time.

• DO NOT store or use gasoline, or

other flammable liquids in the vicinity

of this or any other appliance. Read

product labels for warnings regarding

flammability and other hazards.

• DO NOT place items exposed to

cooking oils in your dryer. Items

contaminated with cooking oils may

contribute to a chemical reaction

that could cause a load to catch

fire. To reduce the risk of fire due to

contaminated loads, the final part of

a tumble dryer cycle occurs without

heat (cool down period). Avoid

stopping a tumble dryer before the

end of the drying cycle unless all items

are quickly removed and spread out so

that the heat is dissipated.

5

• DO NOT dry articles containing rubber,

plastic or similar materials such as

bras, galoshes, bath mats, rugs, bibs,

baby pants, plastic bags, and pillows

that may melt or burn. Some rubber

materials, when heated, can under

certain circumstances produce fire by

spontaneous combustion.

• Clean the lint filter before or after

each load. The interior of the dryer,

lint filter housing, and exhaust duct

should be cleaned approximately

every 18 months by a qualified

service professional. An excessive

amount of lint build-up in these areas

could result in inecient drying and

possible fire.

• DO NOT operate the dryer if the lint

filter is blocked, damaged or missing.

Fire hazard, overheating, and damage

to fabrics can occur.

WARNING

A clothes dryer produces combustible

lint. The dryer must be connected to an

outdoors exhaust. Regularly inspect the

outdoor exhaust opening and remove

any accumulation of lint around the

opening and in the surrounding area.

• DO NOT operate the appliance in the

presence of explosive fumes.

• DO NOT obstruct the flow of

ventilating air. DO NOT stack or place

laundry or throw rugs against the front

or back of the dryer.

• DO NOT spray any type of aerosol

into, on or near dryer at any time.

• DO NOT use fabric softeners or

products to eliminate static unless

recommended by the manufacturer of

the fabric softener or product.

• DO NOT continue to use the laundry

center if you hear squeaking,

grinding, rubbing or other unusual

noises. This could be a sign of

mechanical breakdown and lead

to fire or serious injury. Contact a

qualified technician immediately.

• Failure to comply with these

warnings could result in fire,

explosion, serious bodily injury, and/

or damage to the rubber or plastic

parts of the laundry center.

See Care and Cleaning

FIRE HAZARD

.

Page 6

6

IMPORTANT SAFETY INFORMATION

Protect children

• DO NOT allow children to play

on or in the laundry center. Close

supervision of children is necessary

when the laundry center is used near

children. As children grow, teach them

the proper, safe use of all appliances.

• Destroy the carton, plastic bag, and

other packing materials after the laundry

center is unpacked. Children might use

them for play. Cartons covered with

rugs, bedspreads or plastic sheets can

become airtight chambers.

• Keep laundry products out of

children’s reach. To prevent personal

injury, observe all warnings on

product labels.

• Before the laundry center is removed

from service or discarded, remove

the washer and dryer doors to

prevent accidental entrapment.

• Failure to comply with these

warnings could result in serious

personal injuries.

Risk of child entrapment

Child entrapment and suocation are not

problems of the past. Junked or abandoned

washer and dryers are still dangerous – even

if they will sit for “just a few days”. If you

are getting rid of your old washer or dryer,

please follow the instructions below to help

prevent accidents.

We strongly encourage responsible

appliance recycling/disposal methods.

Contact your State/Provence Energy

Oce, Local Electric and Water Utilities or

Conservation Program Oce or visit www.

energystar.gov/recycle for more information

on recycling your old washer or dryer.

Before you throw away your old washer

or dryer:

• Remove doors.

• Remove the electric power cord.

• Secure all hoses and drain pipes to

prevent water from leaking out and

creating a slip hazard.

Prevent injury

• To prevent shock hazard and assure

stability during operation, the

laundry center must be installed and

electrically grounded by a qualified

service person in accordance with

local codes. Installation instructions

are packed in the washer for

installer’s reference. Refer to

Installation Instructions

grounding procedures. If the laundry

center is moved to a new location,

have it checked and reinstalled by a

qualified service person.

for detailed

• To prevent personal injury or damage

to the laundry center, the electrical

power cord of a gas dryer must be

plugged into a properly grounded

and polarized 3-prong outlet. The

third grounding prong must never be

removed. Never ground the dryer to

a gas pipe. DO NOT use an extension

cord or an adaptor plug.

• ALWAYS disconnect the laundry

center from the electrical supply

before attempting any service or

cleaning. Failure to do so can result

in electrical shock or injury.

• DO NOT use any type spray cleanser

when cleaning dryer interior.

Hazardous fumes or electrical shock

could occur.

• To prevent injury, DO NOT reach into

the laundry center while parts are

moving. Before loading, unloading

or adding items, push in the cycle

selector knob to stop the cycle.

Allow the wash tub or dryer drum

to coast to a complete stop before

reaching inside.

• The lid will remain locked for up to 6

minutes after the cycle ends, to allow the

wash tub to stop spinning.

• Follow package directions when

using laundry products. Incorrect

usage can produce poisonous gas resulting in serious injury or death.

• DO NOT combine laundry products

for use in 1 load unless specified on

the label.

• DO NOT mix chlorine bleach with

ammonia or acids such as vinegar.

WARNING

HARMFUL VAPOR HAZARD

DO NOT use or mix liquid chlorine

bleach with other household chemicals

such as toilet cleaners, rust removers,

acids such as vinegar, or products

containing ammonia. These mixtures

can produce dangerous fumes which

can cause serious injury or death.

Page 7

IMPORTANT SAFETY INFORMATION

7

Prevent injury and damage to the

appliance

To prevent serious personal injury and

damage to the laundry center:

• All repairs and servicing must

be performed by an authorized

service agent unless specifically

recommended in this

Guide

. Use only authorized factory

parts.

• DO NOT tamper with controls.

• DO NOT install or store the laundry

center where it will be exposed to

the weather. DO NOT operate the

laundry center in below freezing

temperatures.

• DO NOT install on carpet. Install

laundry center on a solid floor. It may

be necessary to reinforce the floor to

prevent vibration or movement.

• DO NOT sit on, step on or stand on

the laundry center. DO NOT rest

Use & Care

heavy loads on top. The laundry

center is not meant to support

weight.

• To reduce the risk of electric shock,

disconnect this appliance from the

power supply before attempting

any user maintenance. Canceling a

cycle or turning the power o at the

console does not disconnect this

appliance from the power supply.

• This laundry center is equipped with

an electrical overload protector. The

washer motor will stop if it becomes

overheated.

• A thermal limiter switch automatically

turns o the dryer motor in the

unlikely event of an overheated

situation. A service technician must

replace the thermal limiter switch

after correcting the fault.

• Failure to comply with these

warnings could result in property

damage or serious personal injuries.

WARNING

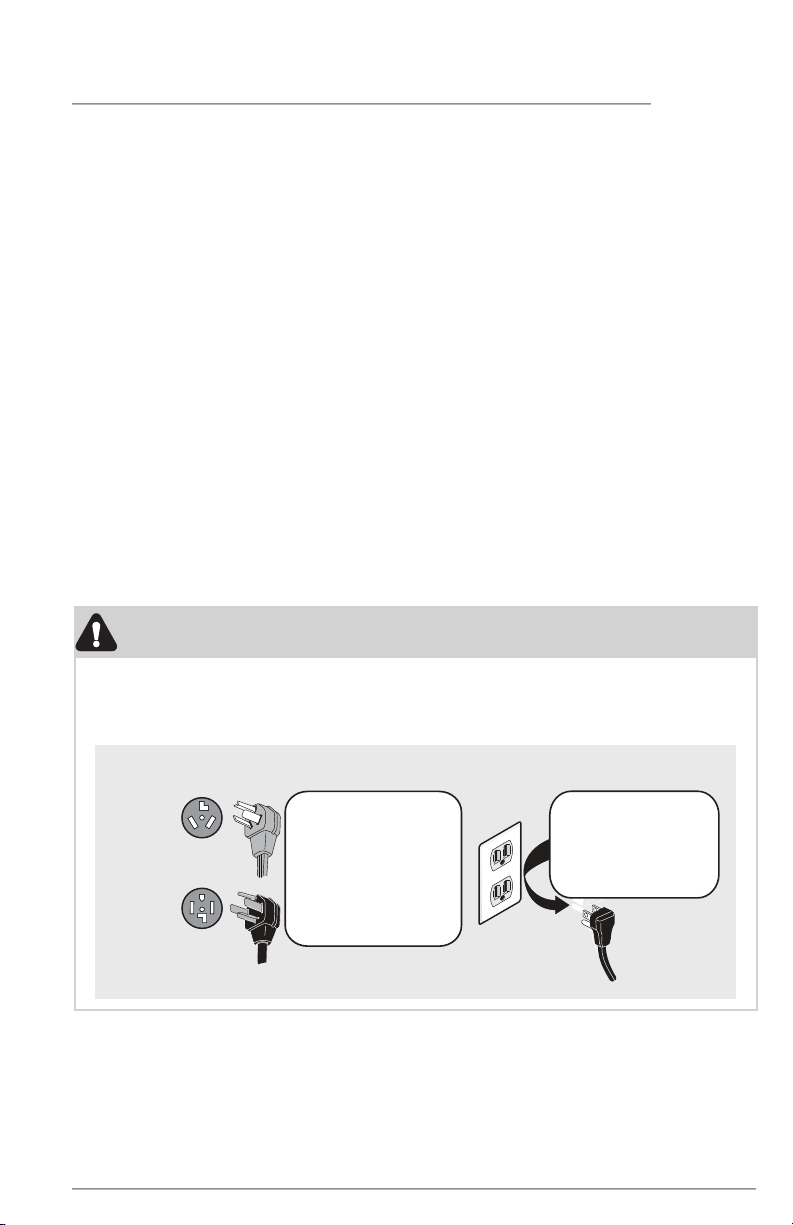

Avoid fire hazard or electrical shock. DO NOT use an adaptor plug or extension

cord or remove grounding prong from electrical power cord. Failure to follow this

warning can cause serious injury, fire, or death.

FIRE/ELECTRICAL SHOCK HAZARD

10-30R

3-wire

(fused 30 amp)

14-30R

4-wire

(fused 30 amp)

240 v Electric Dryer

UL-approved service

cord must be installed

on electric dryers (not

provided with unit

except those

manufactured for sale

in Canada).

Grounding

type wall

receptacle

Power cord

with 3-prong

grounded plug

120 v Gas Dryer

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Page 8

8

FEATURES

Dryer

Unit

Washer Controls

Dryer Controls

Washer

Unit

Washer Lid Lock

Leveling Leg

Leveling Leg

Page 9

PRE-INSTALLATION REQUIREMENTS

Installation Checklist

9

Shipping hardware

Foam shipping restraint (inside

wash tub) removed and stored

Foam shipping support (underneath

appliance) removed and stored

Leveling

Laundry center is level, side-to-side

and front-to-back

Cabinet is setting solid on all corners

Water supply

Use only new hoses and verify

rubber sealing washers are installed

HOT supply is connected to HOT

inlet and COLD supply is connected

to COLD inlet

HOT and COLD water supply turned on

No leaks present at water supply

connections or appliance inlet

connections -recheck in 24 hours

Drain

Stand pipe or wall drain height min. 33”

Drain hose secured in place with

cable tie (shipped in drum)

Exhaust venting

Free-flowing, clear of lint buildup

4 inch (102 mm) rigid or semi-rigid

ducting of minimal length and turns

NO foil or plastic venting material

Approved vent hood exhausted to

outdoors

Gas supply (Gas Dryer)

Manual shuto valve present in supply

All connections sealed with

approved sealer and wrench tight

Conversion kit for LP system

Gas supply turned on

No leaks present at all connections -

check with soapy water, NEVER

check with flame

240V electric supply

(electric dryer)

Approved NEMA 10-30R or 14-30R

service cord with all screws tight on

terminal block

Approved strain relief installed

Terminal access cover installed

before initial operation

Electrical power

House power turned on

Laundry Center plugged in

Final checks

Installation Instructions and Use &

Care Guide read thoroughly

Water enters drum when cycle

starts with lid lowered and dryer

door latches and drum tumbles

when cycle starts

Registration card sent in

Tool requirements

Tools and materials needed for installation:

• Adjustable pliers

• Phillips, straight, & square bit

screwdrivers

• Adjustable wrench

• Pipe wrench for gas supply (gas dryer)

• LP-resistant thread tape (for natural

gas or LP supply, gas dryer)

• Carpenter’s level

• External vent hood

• 4-inch (102 mm), rigid metal or semirigid metal exhaust duct work

• 3-wire or 4-wire 240 volt cord kit

(electric dryer)

• 4 in. (102 mm) clamp

• Gas line shuto valve (gas dryer)

• 1/2 NPT union flare adapters (x2) and

flexible gas supply line (gas dryer)

• Metal foil tape (not duct tape)

• Inlet hoses (x2)

NOTE

Hoses are not included with washer

purchase.

Page 10

10

PRE-INSTALLATION REQUIREMENTS

Electrical system

requirements

NOTE

Because of potentially inconsistent

voltage capabilities, the use of this dryer

with power created by gas powered

generators, solar powered generators,

wind powered generators or any other

generator other than the local utility

company is not recommended.

Electrical requirements for

laundry center with electric dryer

CIRCUIT - Individual 30 amp. branch

circuit fused with 30 amp. time delay

fuses or circuit breakers.

POWER SUPPLY - 3-wire or 4-wire, 240 volt,

single phase, 60 Hz, Alternating Current.

IMPORTANT

This laundry center is internally

grounded to neutral unless it was

manufactured for sale in Canada.

Only a 4-conductor cord shall be used

when the appliance is installed in a

location where grounding through

the neutral conductor is prohibited.

Grounding through the neutral link is

prohibited for: (1) new branch circuit

installations, (2) mobile homes, (3)

recreational vehicles, and (4) areas

where local codes DO NOT permit

grounding through the neutral.

OUTLET RECEPTACLE - NEMA 10-30R or

NEMA 14-30R receptacle to be located so

the power supply cord is accessible when

the dryer is in the installed position.

GROUNDING CONNECTION - See

“Grounding requirements” in Electrical

Installation section.

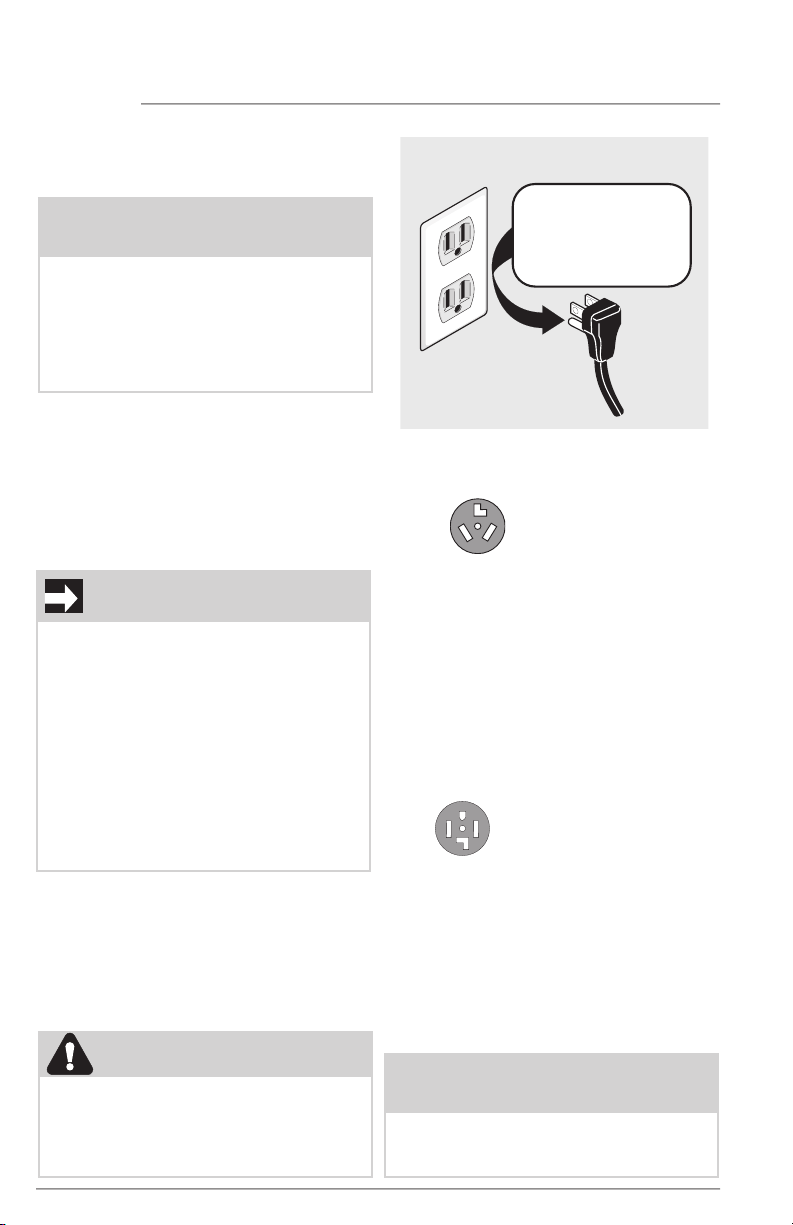

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician

if you are in doubt as to whether the

appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

3-Wire power supply cord kit

(not supplied)

3-wire receptacle

(NEMA type 10-

30R)

The dryer MUST employ a 3-conductor

power supply cord NEMA 10-30 type

SRDT rated at 240 volt AC minimum,

30 amp, with 3 open end spade lug

connectors with upturned ends or closed

loop connectors and marked for use

with clothes dryers. For 3-wire cord

connection instructions see ELECTRICAL

CONNECTIONS FOR A 3-WIRE SYSTEM.

4-Wire power supply cord kit

(not supplied)

4-wire receptacle

(NEMA type 14-

30R)

The dryer MUST employ a 4-conductor

power supply cord NEMA 14-30 type SRDT

or DRT (as required) rated at 240 volt

AC minimum, 30 amp, with 4 open end

spade lug connectors with upturned ends

or closed loop connectors and marked for

use with clothes dryers. For 4-wire cord

connection instructions see ELECTRICAL

CONNECTIONS FOR A 4-WIRE SYSTEM.

NOTE

Laundry centers manufactured for sale

in Canada have factory-installed, 4-wire

power supply cord (NEMA 14-30R).

Page 11

PRE-INSTALLATION REQUIREMENTS

11

Electrical requirements for

laundry center with gas dryer

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician

if you are in doubt as to whether the

appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

CIRCUIT - Individual, properly polarized

and grounded 15 amp. branch circuit

fused with 15 amp. time delay fuse or

circuit breaker.

POWER SUPPLY - 2-wire, with ground,

120 volt, single phase, 60 Hz, Alternating

Current.

POWER SUPPLY CORD - The dryer is

equipped with a 120 volt 3-wire power

cord.

GROUNDING CONNECTION - See

“Grounding requirements” in Electrical

Installation section.

Gas supply requirements

WARNING

EXPLOSION HAZARD

Uncoated copper tubing will corrode

when subjected to natural gas, causing

gas leaks. Use ONLY black iron,

stainless steel, or plastic-coated brass

piping for gas supply.

1. Installation MUST conform with local

codes, or in the absence of local codes,

with the National Fuel Gas Code, ANSI

Z223.1 (latest edition).

2. The gas supply line should be 1/2 inch

(1.27 cm) pipe.

3. If codes allow, flexible metal tubing

may be used to connect your dryer to

the gas supply line. The tubing MUST

be constructed of stainless steel or

plastic-coated brass.

4. The gas supply line MUST have an

individual shuto valve installed in

accordance with the B149.1, Natural

Gas and Propane Installation Code.

5. A 1/8 inch (0.32 cm) N.P.T. plugged

tapping, accessible for test gauge

connection, MUST be installed

immediately upstream of the gas

supply connection to the dryer.

6. The dryer MUST be disconnected from

the gas supply piping system during

any pressure testing of the gas supply

piping system at test pressures in

excess of 1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the

gas supply piping system during any

pressure testing of the gas supply

piping system at test pressures equal

to or less than 1/2 psig (3.45 kPa).

8. Connections for the gas supply

must comply with the Standard for

Connectors for Gas Appliances, ANSI

Z21.24 - CSA 6.10.

Water supply requirements

Hot and cold water faucets MUST be

installed within 42 inches (107 cm) of your

washer’s water inlet. The faucets MUST

be 3/4 inch (1.9 cm) with threading for

laundry hose connection. Water pressure

MUST be between 10 psi (0.69 bars) and

120 psi (8.27 bars). Pressure dierence

between hot and cold cannot be more

than 10 psi. Your water department can

advise you of your water pressure.

NOTE

Washers connected to water supplies

with lower inlet pressure will experience

longer filling times and may not

complete cycles as quickly.

Page 12

12

Correct

Correct

PRE-INSTALLATION REQUIREMENTS

Drain system requirements

1. Drain capable of eliminating 17 gals

(64.3 L) per minute.

2. A standpipe diameter of 1-1/4 in. (3.18

cm) minimum.

3. Standpipe height above the floor

should be:

Minimum height: 33 in. (84 cm)

Maximum height: 96 in. (244 cm)

NOTE

For installations requiring a longer

drain hose, have a qualified technician

install a longer drain hose (according to

your model number) available from an

authorized parts distributor. For drain

systems in the floor, install a syphon

break kit available from your local

hardware store.

96"

(244cm)

max.

WARNING

FIRE HAZARD

Failure to follow these instructions can create

excessive drying times and fire hazards.

The following are specific requirements for

proper and safe operation of your dryer.

WARNING

FIRE HAZARD

DO NOT install a clothes dryer with

flexible plastic or metal foil venting

materials. Flexible venting materials are

known to collapse, be easily crushed

and trap lint. These conditions will

obstruct clothes dryer airflow and

increase the risk of fire.

If your present system is made up of

plastic duct or metal foil duct, replace it

with a rigid or semi-rigid metal duct. Also,

ensure the present duct is free of any lint

prior to installing dryer duct.

33"

(84cm)

min.

Exhaust system requirements

Duct work requirements

Use only 4 inch (102 mm) diameter rigid

or flexible metal duct and approved vent

hood which has a swing-out damper(s)

that open when the dryer is in operation.

When the dryer stops, the dampers

automatically close to prevent drafts and

the entrance of insects and rodents. To

avoid restricting the outlet, maintain a

minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground

or any other obstruction.

Incorrect

Page 13

PRE-INSTALLATION REQUIREMENTS

13

WARNING

FIRE HAZARD

A clothes dryer must be exhausted

outdoors. DO NOT exhaust dryer into

a chimney, a wall, a ceiling, an attic, a

crawl space or any concealed space of

a building. A clothes dryer produces

combustible lint. If the dryer is not

exhausted outdoors, some fine lint will

be expelled into the laundry area. An

accumulation of lint in any area of the

home can create a health and fire hazard.

The dryer must be connected to an

exhaust outdoors. Prior to installing your

new dryer, inspect the outdoor exhaust

opening and remove any accumulation of

lint around the outdoor exhaust opening

and in the surrounding area.

WARNING

FIRE HAZARD

• DO NOT allow combustible materials

(for example: clothing, draperies/

curtains, paper) to come in contact

with exhaust system. The dryer MUST

NOT be exhausted into a chimney,

a wall, a ceiling, or any concealed

space of a building which can

accumulate lint, resulting in a fire

hazard.

• DO NOT screen the exhaust ends of

the vent system, or use any screws,

rivets or other fasteners that extend

into the duct to assemble the exhaust

system. No screen, grate, or guard

of any mesh

size is allowed to cover

the exhaust opening.

Lint can become caught

in the screen, grate,

guard, or on the screws or

rivets, clogging the duct work

and creating a fire hazard as well

as increasing drying times. Use an

approved vent hood to terminate

the duct outdoors, and seal all

joints with metal foil tape. All male

duct pipe fittings MUST be installed

downstream with the flow of air.

WARNING

FIRE HAZARD

Failure to follow safety warnings

exactly could result in serious injury,

death, or property damage.

DO NOT install a booster fan in the

exhaust duct.

Install ALL clothes dryers in accordance

with the installation instructions in this

manual.

WARNING

Never exceed more than 3-90˚

elbows in the exhaust duct system.

Exceeding the length of duct pipe

or number of elbows allowed in the

“MAXIMUM LENGTH” charts can cause

an accumulation of lint in the exhaust

system. Plugging the system could

create a fire hazard, as well as increase

drying times.

Number of 90° turns

4” (10.2 cm) louvered 2.5” (6.35 cm)

0 56 ft. (17 m) 42 ft. (13 m)

1 48 ft. (14.5 m) 34 ft. (10.5 m)

2 40 ft. (12 m) 26 ft. (8 m)

3 32 ft. (9.5 m) 18 ft. (5.5 m)

FIRE HAZARD

MAXIMUM LENGTH

of 4” (102 mm) Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

WARNING

FIRE HAZARD

• DO NOT install flexible plastic or

flexible foil venting material.

• If installing semi-rigid venting, DO

NOT exceed 8 ft. (2.4 m) duct length

Page 14

14

PRE-INSTALLATION REQUIREMENTS

WARNING

FIRE HAZARD

• Failure to follow safety warnings

exactly could result in serious injury,

death, or property damage.

• DO NOT install a booster fan in dryer

exhaust duct.

• Install all clothes dryers in

accordance with the installation

instructions in this manual.

Install male fittings in correct direction:

• Venting vertically through a roof may

expose the exhaust system to down

drafts causing an increase in vent

restriction.

• Running the exhaust system

through an uninsulated area may

cause condensation and faster

accumulation of lint.

• Compression or crimping of the

exhaust system will cause an increase

in vent restriction.

• The exhaust system should be

inspected and cleaned a minimum of

every 18 months with normal usage.

The more the dryer is used, the more

often you should check the exhaust

system and vent hood for proper

operation.

Correct Incorrect

In installations where the exhaust

system is not described in the charts,

the following method must be used

to determine if the exhaust system is

acceptable:

1. Connect an inclined or digital

manometer between the dryer and the

point the

exhaust connects to the dryer.

2. Set the dryer timer and temperature to

air flu (cool down) and start the dryer.

3. Read the measurement on the

manometer.

4. The system backpressure MUST NOT

be higher than 0.6 inches of water

column. If the system back pressure

is less than 0.6 inches of water

column, the system is acceptable.

If the manometer reading is higher

than 0.6 inches of water column,

the system is too restrictive and the

installation is unacceptable.

Although vertical orientation of the

exhaust system is acceptable, certain

extenuating circumstances could aect

the performance of the dryer:

• Only rigid metal duct work should be

used.

Rear flush exhaust requirements

The laundry center may be exhausted four

(4) ways with rear flush installation:

1. Straight back

2. Down (8 inch [20.3 cm] length of 4

inch diameter [102 mm] rigid duct and

1 elbow down)

3. Left (8 inch [20.3 cm] length of 4 inch

diameter [102 mm] rigid duct, 1 elbow

down and 1 elbow left)

4. Right (8 inch [20.3 cm] length of 4 inch

diameter [102 mm] rigid duct, 1 elbow

down and 1 elbow right)

Page 15

PRE-INSTALLATION REQUIREMENTS

15

An exhaust hood positioned to line up

with the dryer exhaust can be installed

directly through the outside wall. To

exhaust to the side or down, add an 8

inch (20.3 cm) length of standard 4 inch

(102 mm) diameter duct and a 90° elbow.

To exhaust up, add an 11 inch (28 cm)

length of standard 4 inch (102 mm)

diameter duct and a 90° elbow. The unit

will be positioned about 4.5 inches (11.5

cm) away from the wall (flush to wall

exhausting may be done by going below

the dryer then sideways).

See also

instruction.

Clearance Requirements

in this

Manufactured or mobile

home installation

1. Installation MUST conform to current

Manufactured Home Construction &

Safety Standard, Title 24 CFR Part

3280 (formerly the Federal Standard

for Mobile Home Construction and

Safety, Title 24, HUD Part 280) or

Standard CAN/CSA-Z240 MH.

2. Dryer MUST be exhausted outside

(outdoors, not beneath the mobile

home) using metal ducting that will

not support combustion. Metal ducting

must be 4 inches (10.16 cm) in diameter

with no obstructions. Rigid metal duct

is preferred. Exhaust ducts must be

securely fastened to a noncombustible

portion of the mobile home structure.

3. If dryer is exhausted through the floor

and area beneath the mobile home is

enclosed, the exhaust system MUST

terminate outside the enclosure with

the termination securely fastened to

the mobile home structure.

4. Refer to previous sections in this guide

for other important exhaust venting

system requirements.

5. When installing a gas dryer into a

mobile home, a provision must be

made for outside make up air. This

provision is to be not less than twice

the area of the dryer exhaust outlet.

6. Installer MUST anchor this laundry

center to the floor with approved

Mobile Home Installation Kit - P/N

137067200

Installation in a recess or

closet

1. A dryer installed in a bedroom,

bathroom, recess or closet, MUST be

exhausted outdoors.

2. No other fuel burning appliance shall

be installed in the same closet as the

gas dryer.

3. Your dryer needs the space around it

for proper ventilation.

4. DO NOT install your dryer in a closet

with a solid door.

5. Closet door ventilation required: A

minimum of 120 square inches (774.2

cm2) of opening, equally divided at

the top and bottom of the door, is

required. Openings should be located

3 inches (7.6 cm) from bottom and top

of door. Openings are required to be

unobstructed when a door is installed.

A louvered door with equivalent air

openings for the full length of the

door is acceptable.

3"

(7.6cm)

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

3"

(7.6cm)

closet door

Clearance requirements

MINIMUM INSTALLATION CLEARANCES

Alcove

Closet

- Inches (cm)

SIDES REAR TOP FRONT

0"

(0 cm)0"(0 cm)1”(2.5 cm)

0”

(0 cm)0”(0 cm)1”(2.5 cm)1”(2.5 cm)

n/a

Page 16

16

31.5" (80 cm)

cm)

PRE-INSTALLATION REQUIREMENTS

WARNING

EXPLOSION HAZARD

DO NOT install the laundry center where

gasoline or other flammables are kept or

stored. If the laundry center is installed

in a garage, the dryer portion must be a

minimum of 18 inches (45.7 cm) above

the floor. Failure to do so can result in

death, explosion, fire or burns.

IMPORTANT

DO NOT INSTALL YOUR LAUNDRY

CENTER:

• In an area exposed to dripping water

or outside weather conditions. The

ambient temperature should never

be below 60° F (15.6° C) to maximize

detergent eectiveness.

• In an area where it will come in

contact with curtains, drapes, or

anything that will obstruct the flow

of combustion and ventilation air.

• On carpet. Floor MUST be solid with

a maximum slope of 1 inch (2.5 cm).

To minimize vibration or movement,

reinforcement of the floor may be

necessary.

Laundry center dimensions

Front view

gas supply

(24 cm)

(14 cm)

1

pipe on rear

of gas unit

9.4"

5.5"

4 in. (102 mm)

exhaust vent

on rear of unit

water supply

connection on

rear of washer

31.5" (80 cm)

center line height

for 4 in. (102 mm)

exhaust outlet

43.5"

(110.5

17.6"

(45 cm)

77"

(196.5 cm)

drain

hose-

retention

clips on

rear of

washer

Side view

55.75"

(141.5 cm)

power cord

attachment

location on

rear of unit

23"

(58.5 cm)

2

13"

(33 mm)

27" (68.5 cm)

47.5" (120.5 cm)

1” 0”

(2.5 cm)

(0 cm)

27”

(68.5 cm

0”

(0 cm)

)

(1”)

(2.5 cm)

41.5"

38"

(96.5 cm)

1

Power supply cord length on gas unit

(105.5 cm)

approximately 60 inches (152.5 cm).

2

Loose drain hose length beyond clamp

approximately 51.5 inches (131 cm).

Page 17

Plastic

INSTALLATION

17

Unpacking instructions

IMPORTANT

To prevent vibration, possible machine

damage and maximize performance,

the following steps must be completed.

1. If foam tub block has been removed,

reinsert it now and tape the lid securely.

2. Carefully cut the front and back

corners of the left side of the remaining

cardboard.

Front

3. With help from a second person,

carefully tip the laundry center slightly

to the left as shown in the picture below.

Remove the foam shipping support from

the base of the unit. Save packaging

foam for future use.

4. Carefully lower the laundry center to an

upright position and remove the tape

holding the lid shut. Remove the foam

tub block, all foam inserts, and other

tub contents.

NOTE

If the laundry center is to be

transported at a later date, the tub

blocking pad, foam base and tub

support should be retained.

5. From the back of the washer, remove the

wire shipping clips securing the drain hose.

6. DO NOT remove the PLASTIC CLIPS

which secure the drain hose to the right

side of the washer back sheet. It helps

form a standpipe to prevent water

siphoning.

1

2

Wire

Clip

7. Carefully move the laundry center to

within four (4) feet of the final location

for the start of the installation.

Clips

CAUTION

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have more

than one person move or lift the appliance.

Page 18

18

INSTALLATION

Connecting the gas

1. Remove the shipping cap from gas

pipe at the rear of the dryer.

IMPORTANT

DO NOT connect the dryer to L.P. gas

service without converting the gas

valve. An L.P. conversion kit must be

installed by a qualified gas technician.

2. Connect a 1/2 inch (1.27 cm) I.D.

semi-rigid or approved pipe from gas

supply line to the 3/8 inch (0.96 cm)

pipe located on the back of the dryer.

Use a 1/2 inch to 3/8 inch (1.27 cm to

0.96 cm) reducer for the connection.

Apply an approved thread sealer that

is resistant to the corrosive action of

liquefied gases on all pipe connections.

Manual

Shutoff

Valve

Open

All connections must be wrench-tightened

Closed

Flare

Union

Nipple

GAS FLOW

Flexible

Connector

Flare

Union

Inlet Pipe on

Back of Dryer

3. Open the shuto valve in the gas

supply line to allow gas to flow through

the pipe. Wait a few minutes for gas to

move through the gas line.

to dryer

from gas supply

Shutoff Valve - Open position

4. Check for gas system leaks with a

manometer. If a manometer is not

available, test all connections by

brushing on a soapy water solution.

WARNING

EXPLOSION HAZARD

NEVER test for gas leaks with an open

flame.

IMPORTANT

The supply line must be equipped with

an approved manual shuto valve. This

valve should be located in the same

room as the dryer and should be in a

location that allows ease of opening

and closing. DO NOT block access to

the gas shuto valve.

Page 19

Connecting the electrical

system

The following are specific requirements

for proper and safe electrical installation

of your dryer. Failure to follow these

instructions can create electrical shock

and/or a fire hazard

INSTALLATION

NOTE

Dryers operating on 208 volt power

supply will have longer drying times

than dryers operating on 240 volt

power supply.

19

WARNING

ELECTRICAL SHOCK HAZARD

• This appliance MUST be properly

grounded. Electrical shock can result

if the dryer is not properly grounded.

Follow the instructions in this manual

for proper grounding.

• DO NOT use an extension cord with

this dryer. Some extension cords

are not designed to withstand the

amounts of electrical current this

dryer utilizes and can melt, creating

electrical shock and/or fire hazard.

Locate the dryer within reach of the

receptacle for the length power cord

to be purchased, allowing some slack

in the cord. Refer to the pre-installation

requirements in this manual for the

proper power cord to be purchased.

WARNING

ELECTRICAL SHOCK HAZARD

• A U.L.-approved strain relief must

be installed onto power cord. If the

strain relief is not attached, the cord

can be pulled out of the dryer and

can be cut by any movement of the

cord, resulting in electrical shock.

• DO NOT use an aluminum wired

receptacle with a copper wired

power cord and plug (or vice versa).

A chemical reaction occurs between

copper and aluminum and can cause

electrical shorts. The proper wiring and

receptacle is a copper wired power

cord with a copper wired receptacle.

NOTE

A 120/208 volt, single phase 60Hz,

Alternatintg Current supply may be

used on dryers marked for use on

rating plate.

NOTE

The electric dryer has been designed

and certified to operate at both

240V and 208V. Drying times on a

208V power supply will, however, be

approximately 20% longer than drying

times on a 240V power supply. This

is normal and expected behavior and

applies to all drying cycles.

Grounding the electric dryer (USA)

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician

if you are in doubt as to whether the

appliance is properly grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the

event of a malfunction or breakdown,

grounding will reduce the risk of

electrical shock by a path of least

resistance for electrical current.

2. After you purchase and install a 3-wire

or 4-wire power supply cord having

an equipment-grounding conductor

and a grounding plug that matches

you wiring system, the plug MUST be

plugged into an appropriate, copper

wired receptacle that is properly

installed and grounded in accordance

with all local codes and ordinances. If

in doubt, call a licensed electrician.

3. DO NOT modify the plug you’ve

installed on this appliance. If it will

not fit the outlet, have a proper outlet

installed by a qualified electrician.

For a permanently connected dryer:

The dryer MUST be connected to a

grounded metal, permanent wiring

system; or an equipment grounding

conductor must be run with the circuit

conductors and connected to the

equipment-grounding terminal or lead on

the appliance.

Page 20

20

INSTALLATION

Grounding the electric dryer

(Canada)

WARNING

Improper grounding of the laundry

center may cause serious injury or death.

Check with a licensed electrician if you

are in doubt as to whether the appliance

is properly grounded.

For a grounded, cord-connected dryer:

1. The laundry center MUST be grounded.

In the event of a malfunction or

breakdown, grounding will reduce the

risk of electrical shock by a path of

least resistance for electrical current.

2. Since your laundry center is equipped

with a power supply cord having an

equipment-grounding conductor and

a grounding plug, the plug must be

plugged into an appropriate outlet that

is properly installed and grounded in

accordance with all local codes and

ordinances. If in doubt, call a licensed

electrician.

3. DO NOT modify the plug provided

with this appliance. If it will not fit the

outlet, have a proper outlet installed

by a qualified electrician.

Grounding the gas dryer (USA

and Canada)

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician

if you are in doubt as to whether the

appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

1. The laundry center is equipped with a

three-prong (grounding) plug for

your protection against shock hazard

and should be plugged directly into

a properly grounded three-prong

receptacle.

2. The plug must be plugged into an

appropriate outlet that is properly

installed and grounded in accordance

with all local codes and ordinances. If in

doubt, call a licensed electrician.

3. DO NOT modify the plug provided with

this appliance. If it will not fit the outlet,

have a proper outlet installed by a

qualified electrician.

Electrical connection

(non-Canada) - 3-wire cord

3-wire receptacle

(NEMA type 10-

30R)

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source

before servicing could result in personal

injury or even death.

1. Turn o power supply to outlet.

2. Remove the screw securing the

terminal block access cover on the

back of the dryer.

3. Install a UL-approved strain relief

according to the power cord/strain

relief manufacturer’s instructions in

the power cord entry hole below the

access panel. At this time, the strain

relief should be loosely in place.

4. Thread an UNPLUGGED, UL-approved,

30 amp. power cord, NEMA 10-30 type

SRDT, through the strain relief.

5. Attach the power cord neutral (center

wire) conductor to the SILVER colored

center terminal on the terminal block.

Tighten the screw securely.

Power cord with

3-prong grounded plug

30 AMP

NEMA 10-30

Neutral

(center wire)

Page 21

INSTALLATION

21

6. Attach the remaining two power cord

outer conductors to the outer, BRASS

colored terminals on the terminal block.

Tighten both screws securely.

DO NOT remove

internal ground in

a 3-wire system!!

Neutral

terminal

WARNING

ELECTRICAL SHOCK HAZARD

DO NOT make a sharp bend or crimp

wiring/conductor at connections.

7. Follow manufacturer’s guidelines for

firmly securing the strain relief and

power cord.

8. Reinstall the terminal block cover.

IMPORTANT

If moving dryer from a 4-wire system

and installing it in a 3-wire system,

move the internal ground from the

center terminal back to the GREEN

screw next to the terminal block.

1. Turn o power supply to outlet.

2. Remove the screw securing the

terminal block access cover on the

back of the dryer.

3. Install a UL-approved strain relief

according to the power cord/strain

relief manufacturer’s instructions in

the power cord entry hole below the

access panel. At this time, the strain

relief should be loosely in place.

4. Thread an UNPLUGGED, UL-approved,

30 amp. power cord, NEMA 14-30 type

DRT or SRDT, through the strain relief.

30 AMP

NEMA 14-30

5. Disconnect the internal (WHITE) dryer

harness ground wire from the (GREEN)

ground screw next to the terminal block.

6. Attach the ground (GREEN) power

cord wire to the cabinet with the

ground (GREEN) screw. Tighten the

screw securely.

7. Move the internal dryer harness ground

(WHITE) wire to the terminal block and

attach it along with the neutral (WHITE)

power cord wire conductor to the center,

SILVER colored terminal on the terminal

block. Tighten the screw securely.

8. Attach the RED and BLACK power

cord conductors to the outer, BRASS

colored terminals on the terminal block.

Tighten both screws securely.

Ground

(GREEN

wire)

Neutral

(WHITE

wire)

Electrical connection

(non-Canada) - 4-wire cord

4-wire receptacle

(NEMA type 14-

30R)

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source

before servicing could result in personal

injury or even death.

Move internal ground (WHITE)

wire to neutral (SILVER)

terminal for 4-wire system.

GREEN

ground screw

GREEN

ground wire

BLACK or

RED power wire

Neutral

terminal

WHITE

neutral wire

BLACK

or RED

power wire

Page 22

22

INSTALLATION

WARNING

ELECTRICAL SHOCK HAZARD

DO NOT make a sharp bend or crimp

wiring/conductor at connections.

9. Follow manufacturer’s guidelines for

firmly securing the strain relief and

power cord.

10. Reinstall the terminal block

Leveling the laundry center

Excessive noise and vibration can be

prevented by properly leveling the

laundry center.

1. With the

laundry center

within 4 feet (1

m) of its final

location, place

a level on top of

the washer lid.

2. Use adjustable

pliers to adjust

the leveling

legs so the

laundry center

is level frontto-rear and

side-to-side,

and stable

corner-tocorner.

3. Press down

on alternate

corners and

sides and

feel for the

slightest

movement.

Adjust the

appropriate leg(s) so the laundry

center sits solidly on the floor on

ALL four legs. Keep the leveling leg

extension at a minimum for best

performance of the washer.

raise

lower

Connecting the water

1. Run some water

from the hot and

cold faucets to flush

the water lines and

remove particles that

might clog the water

valve screens and

to determine which

faucet is hot and

which is cold supply

2. Check to ensure that

the inlet hoses have

the rubber washer

firmly in place. Use

only new hoses.

NOTE

Hoses are not included with laundry

center purchase and must be

purchased separately.

3. Connect the

HOT inlet

hose to the

HOT inlet

connection

on the washer

and the COLD

inlet hose to

the COLD inlet

connection

on the washer (cold on top). Tighten

by hand until snug. Then tighten each

supply connection another 2/3 turn

with pliers. DO NOT cross thread or

over-tighten these connections.

4. Connect the

HOT inlet hose

to the HOT

water supply

and the COLD

inlet hose to

the COLD

water supply.

Tighten by

hand until

snug.

5. Tighten

each supply

connection

another 2/3

turn with pliers.

DO NOT bend,

kink, or pinch

water inlet

hoses.

6. Turn on the water and check for leaks.

Page 23

INSTALLATION

23

Connecting the exhaust

1. Remove the two screws securing the

dryer front access panel to the dryer

cabinet. Lift the panel until the tabs

can be disengaged from the cabinet,

remove the panel and set aside.

Screws

2. Connect the exhaust duct to the

outside exhaust system. Use of a 4”

(10.2 cm) clamp is recommended to

connect the dryer to the exhaust vent

system. Use metal foil tape to seal all

other joints.

4. Carefully slide the laundry center to

its final position. Recheck for level and

rock corners for stability.

Connecting the drain

1. Form a “U” shape on the end of the

drain hose with the hose pointed

toward the drain.

2. Place the formed end in a laundry

tub or a standpipe and secure the drain

hose with the cable tie (provided in the

enclosure package) to the standpipe, inlet

hose, laundry tub, etc. so the hose does

not pull out from the force of the water.

Insert Less

Than 8.5"

(21.5 cm)

Clamp

3. Reinstall the dryer front access panel.

WARNING

ELECTRIC SHOCK HAZARD

Certain internal parts are intentionally

not grounded and may present a risk

of electrical shock if contacted during

installation. Do not contact the following

parts while the appliance is energized:

• Pump

• Drive Motor

• Electronic control boards

• Water valve

Cable Tie

NOTE

The standpipe inside diameter must be

1-1/4” (3.2 cm) minimum. There must be

an air gap around the drain hose in the

standpipe. A snug hose fit can cause a

siphoning action.

Page 24

24

INSTALLATION

Completing the installation

IMPORTANT

Check to ensure the power is o at

a circuit breaker/fuse box before

plugging the power cord into an outlet.

1. Plug the power cord into a grounded

outlet

WARNING

Improper grounding of the dryer may

cause serious injury or death. Check

with a licensed electrician if you are in

doubt as to whether the appliance is

properly grounded.

Grounding type wall receptacle

NOTE

A wiring diagram and technical data

sheet are located behind the dryer

access panel.

WARNING

When discarding or storing your old

laundry center, ALWAYS remove the

washer and dryer doors.

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

2. Turn on the power at the circuit

breaker/fuse box.

3. Run the washer through a complete

cycle, checking for water leaks and

proper

operation.

4. If you have any questions during initial

operation, please review

before calling for service.

5. Place these instructions in a location

near the appliance for future reference.

Self Help

Page 25

CONTROLS AND SETTINGS

25

Washer controls and settings

This manual covers many models and not all cycles, options, or features listed are available on

every model. Consoles shown above for reference only. Your model may dier.

Wash cycle selection

For best results

Follow the fabric care

label instructions on

items to be washed.

Turn the washer cycle selector in either

direction to select a washing cycle.

Normal

Select this cycle for normally soiled cottons,

linens, towels, shirts, denims, and mixed loads.

Activewear

Select this cycle for small loads of lightweight, synthetic apparel worn for

working out, running, swimming, cycling,

tennis, and similar activities when

removal of light soil

and perspiration are important.

Delicates

Select this cycle for lightly soiled knits

and delicates which require gentle

washing.

Quick Wash

Select this cycle to quickly wash a small,

lightly soiled load in 35 minutes.

Rinse & Spin

Select this cycle for loads that require a

cold water rinse or to add fabric softener

that may have been omitted in a regular

cycle.

Soak

Select this cycle to soak heavily soiled

and stained items before washing. Cold

water is recommended with this cycle as

warmer water may set some stains. Use

the amount of detergent recommended

for a normal wash cycle. If desired, use

a bleach or a soaking agent safe for the

fabric. The washer will continue on with

a soil-loosening wash cycle immediately

after the soak phase.

Light Soil

Select this cycle for lightly soiled cottons,

linens, towels, shirts, denims, and mixed

loads.

Colors

Select this cycle for lightly soiled, dark,

or highly dyed fabrics which may be

susceptible to dye loss.

Heavy Soil

Select this cycle for heavily soiled cottons,

linens, towels, shirts, denims, and mixed loads.

Bulky

Select this cycle for bulky items such

as comforters, blankets, mattress pads,

sleeping bags, and other similar items.

NOTE

Washers connected to water supplies

with lower inlet pressure will experience

longer filling times and may not

complete cycle as quickly.

Page 26

26

CONTROLS AND SETTINGS

Wash cycle settings

Wash temp (water temperature)

Press the Wash Temp button to cycle

through wash water temperatures until

the desired temperature is selected.

The LED will light to indicate the

current selection. Select a wash water

temperature according to fiber content,

colorfastness, and soil level. To protect

your fabrics, the temperature range of

cold to hot settings may be dierent

depending on cycle selected.

The water heater setting, its distance from

the washer, water usage in other parts

of the home, and seasonally low ground

water temperature in some geographic

areas can aect water temperature.

Hot

Select this setting for heavily soiled white

or colorfast cottons and blends.

Warm

Select this setting for normally soiled

white or colorfast cottons or blends.

Cold

Select this setting for lightly soiled

non-colorfast items, knits, delicates, and

hand washables. Some warm water will

automatically blend with cold tap supply to

achieve cold.

Water level

Press the Water Level button to cycle

through wash water level until the desired

water level is selected. The recommended

water level can be determined by the size

of the wash load.

MaxFill

Select the MaxFill water level setting if

the tub is over one half (1/2) full.

Med (Medium)

Select the Medium water level setting if

the

tub is between one third (1/3) and one

half (1/2) full.

Low

Select the Low setting if the tub is one

third (1/3) or less full.

The Medium and MaxFill settings are also

recommended for heavily soiled loads to

remove excess dirt and detergent or if

household members have sensitive skin.

For best results

Follow the fabric care

label instructions on

items to be washed.

Washer setting chart

These temperatures and water levels are available with the following cycles

Quick

Wash

Delicates

Activewear

Normal

Bulky

Heavy Soil

Colors

Light Soil

Water Temperature

Hot

Warm

Cold

Water Level

MaxFill

Med

Low

= Available selections. = Factory presets. = Non-modiable presets.

Soak

Rinse &

Spin

Page 27

CONTROLS AND SETTINGS

27

Wash cycle controls

(Start, Pause, and Cancel)

Start

Press the washer

START|PAUSE button once to

begin the wash cycle. The unit

will emit two short beeps, the

LED will turn solid green, and the

door lid lock will engage with an

audible double click.

Pause

Press the washer START|PAUSE button

once while the washer is running to pause the

wash cycle. The unit will emit one short beep,

the LED will blink, the wash tub will come to

a complete stop, and the door lid safety lock

will disengage with an audible double click.

The wash tub can take up to 6 minutes

to stop after the START|PAUSE button is

pressed. DO NOT force open the locked

lid. Press the START|PAUSE button again to

restart the wash cycle.

Cancel

Press the washer CANCEL button to cancel

the wash cycle. The unit will emit one long

beep, the wash tub will come to a complete

stop, and the door lid safety lock will

disengage with an audible double click. The

wash tub can take up to 6 minutes to

stop after the CANCEL button is pressed.

DO NOT force open the locked lid.

Wash cycle indicator lights

The washing cycle

indicator lights

provide information

during the wash

cycle.

The Close Washer

Lid advisory LED

will illuminate if the

washer lid is open.

Fully close the

washer lid before

starting the washer. The washer will not

operate with the lid open.

The Balance Load advisory LED indicator

will illuminate if the wash load is

unbalanced in the drum during the wash

cycle. Pause the washer and redistribute

the wash load.

The Cycle Status Lights will illuminate as

each stage of the wash cycle is reached.

Cycle Status Light stages include:

Washing, Rinsing, Spinning and Done.

WARNING

To reduce the risk of fire or serious

injury to persons or property, comply

with the basic warnings listed below:

• Read and comply with all instructions

on stain removal products.

• Keep stain removal products in their

original labeled containers and out of

children’s reach.

• DO NOT combine stain removal

products, especially ammonia and

chlorine bleach. Dangerous fumes

can result.

• Never wash items which have been

previously cleaned in, washed in,

soaked in or spotted with gasoline,

dry cleaning solvents or other

flammable or explosive substances

because they give o vapors that

could ignite or explode.

• Never use highly flammable solvents,

such as gasoline, inside the home.

Vapors can explode on contact with

flames or sparks.

WARNING

HARMFUL VAPOR HAZARD

DO NOT use or mix liquid chlorine

bleach with other household chemicals

such as toilet cleaners, rust removers,

acid or products containing ammonia.

These mixtures can produce dangerous

fumes which can cause serious injury

or death.

Page 28

28

CONTROLS AND SETTINGSCONTROLS AND SETTINGS

Dryer controls and settings

This manual covers many models and not all cycles, options, or features listed are available on

every model. Consoles shown above for reference only. Your model may dier.

Dry cycle selection

For best results

Follow the fabric care label

instructions on items to be washed.

Turn the DRYER cycle selector in either

direction to select a drying cycle.

NOTE

To change settings after the cycle starts,

press the START|PAUSE button and adjust

the setting. Press the START|PAUSE

button again to resume the cycle.

Auto dry cycles

Auto Dry cycles take the guesswork out

of selecting the correct drying time for

each load. With auto dry cycles, the load

will automatically be dried at the selected

temperature. When the load has neared the

end of the drying cycle, it will continue to

tumble for a brief cool down period. This helps

reduce wrinkling and makes items easier to

handle during unloading.

Drying time varies depending on size of

load, dampness of load, and fabric type.

Available auto dry settings are as follows:

Normal

Select this cycle to dry everyday fabrics

including cottons, linens, and sheets.

Bulky

Select this cycle for bulky items such as

comforters, blankets, mattress pads, sleeping

bags, and other similar items.

Delicates

Select this cycle to dry cottons, blends, and

permanent press items with a no-iron nish.

Activewear

Select this specialty cycle to dry lightweight

synthetic athletic apparel including stretch fabrics.

Timed dry cycles

WARNING

FIRE HAZARD

To avoid fire hazard, DO NOT use heat

to dry items containing feathers or

down, foam rubber, plastics similarly

textured, rubber-like materials. Use the

Air Flu setting.

Quick Dry

Select this timed cycle to quickly dry a

small load made up of just a few items.

It provides approximately 25 minutes of

tumbling including a cool down period.

Timed dry

Select a timed drying cycle for any load

using one of the preset cycles of 15, 30, 60,

or 90 minutes. The dryer will continue to

heat throughout the cycle until the final cool

down period.

Air Flu

Select this cycle for loads that require air drying

only. No heat will be used with this setting.

This setting should be used for dry items

such as items containing feathers, down,

foam rubber, plastics, or rubber-like

materials; to refresh clothing, stued animal,

pillows, or blankets; and to dust draperies.

Page 29

CONTROLS AND SETTINGSCONTROLS AND SETTINGS

29

Drying cycle settings

Drying Temperature (Dry Temp)

Select the temperature setting most

suitable for each load. To protect your

fabrics, not all temperatures are available

with every cycle. If an unavailable

temperature setting is selected by the

user, the nearest available temperature

will be substituted.

High

Recommended for durable fabrics and towels.

Normal

Recommended for most cotton fabrics.

Low

Recommended for delicate fabrics.

NOTE

Air Flu setting does not use heat and

WILL NOT illuminate any of the Dry Temp

LED lights.

Drying cycle controls

(Start, Pause, and Cancel)

START

Press DRYER START|PAUSE

button once to begin the

drying cycle. The unit will

emit one beep before the

drum begins to rotate.

PAUSE

Press DRYER START|PAUSE button while

the dryer is running to pause the drying

cycle. Opening the door with a cycle

running will

also pause the cycle. You will hear two

beeps. Allow the drum to come to a

complete stop before reaching inside.

Press the DRYER START|PAUSE button

while paused to restart the drying cycle.

CANCEL

Press the DRYER CANCEL button to

cancel the drying cycle. Wait for the

drum to come to a complete stop before

reaching inside.

Drying cycle indicator lights

The drying cycle indicator lights provide

information during the dry cycle.

The Close Dryer

Door advisory LED

will illuminate if the

dryer door is open.

Fully close the dryer

door before starting

the dryer. The dryer

will not operate with

the door open.

The Clean Lint LED

will illuminate after each drying cycle

as a reminder to clean the lint filter. The

lint filter must be cleaned after every

load. This is NOT a warning of a clogged

exhaust duct or filter. Open door or press

CANCEL to turn o the LED.

The cycle status lights will illuminate as

each stage of the drying cycle is reached.

Stages include: Drying, Cooling, and Done.

Dryer Setting Chart

These temperatures and water levels are available with the following cycles

Quick Dry

(25 min)

Delicates

(Auto dry)

Activewear

(Auto dry)

Normal

(Auto dry)

Bulky

(Auto dry)

Air Flu - no

heat(30 min)

90 min

60 min

Dry Temp (Temperature)

High

Normal

Low

= Available selections. = Factory presets. = Non-modifiable presets.

30 min

15 min

Page 30

30

OPERATING INSTRUCTIONS

Operating the washer

WARNING

To reduce the risk of fire, electric shock

or injury to persons, read the Important

Safety Information in this

Guide

before operating your washer.

WARNING

DO NOT wash water-resistant and waterrepellent type clothing or other materials.

Failure to closely follow these instructions

may result in abnormal vibrating and outof-balance conditions that could result in

physical injury, property damage, and/or

appliance damage

STEPS TIPS IMPORTANT

1. Sort laundry

into loads

that can

be washed

together.

2. Prepare

items for

washing.

3. Pretreat

stains and

heavy soil.

4. Add liquid

detergent

or powder

detergent

to wash tub

BEFORE

adding load.

• Sort by recommended cycle

• Separate white, light, and

• Separate items that shed lint

• Separate heavily soiled items

• Separate lacy, sheer, loosely

• Empty pockets.

• Brush o lint and dirt. Shake

• Close zippers, fasten hooks,

• Place delicate and small items

• See

• Detergent packs can also be

• The amount of detergent

Use & Care

and water temperature.

colorfast items from dark and

non-colorfast items.

from items that attract lint.

Casual, synthetic, knit, and

corduroy items will pick up

lint from towels, rugs, and

bedspreads.

from lightly soiled items.

knit, or delicate items from

durable items.

out rugs and beach towels.

button buttons, and tie strings/

sashes. Remove non-washable

trims and ornaments.

such as bras and hosiery in a

mesh bag (not included).

Stain Removal Guide

instructions.

used but may not fully dissolve

in some cycles.

required depends on the type

of detergent, load size, and

water hardness.

CAUTION

To avoid serious personal injury, DO NOT

operate washer if safety lid lock is missing,

damaged or operating improperly.

NOTE

To prevent injury,

the lid will remain

locked for up to

6 minutes after

the cycle ends, to

allow the wash tub

to stop spinning.

• DO NOT machine wash items

containing fiberglass. Small

particles of fiberglass left in

drum may transfer to fabrics

in other loads and cause skin

irritation and/or damage to

fabrics.

• DO NOT wash water-resistant

and water-repellent type

clothing or other materials

• Mend rips and tears to prevent

further damage during

washing.

• Turn knit items inside out to

prevent pilling.

for safe, successful stain removal

• Follow manufacturer’s

instructions for recommended

amount of detergent.

• Use a low-sudsing, higheciency detergent to prevent

oversudsing.

• Look for the higheciency symbol on the

detergent label.

Safety Lid Lock

Page 31

OPERATING INSTRUCTIONS

STEPS TIPS IMPORTANT

31

5. Add other

wash products

to wash tub (if

desired).

6. Add bleach

(if desired)

before adding

load.

7. Add laundry

load to wash

tub.

8. Add liquid

fabric

softener to

the final rinse

(if desired).

• Water conditioners, detergent

boosters, and enzyme products

may be added with detergent.

• If using liquid bleach, add to

bleach dispenser located in left

front corner under lid. Then

add 1 cup (240 ml) water to

flush dispenser.

• If using powdered bleach, add

directly to the empty tub.

• Add items one at a time, each

tightly bunched into its own

“ball” to allow beneficial item

interaction. Avoid loading

items in a flat, laid-out fashion.

• For best washing performance,

dry load level should not be

higher than the upper row of

holes in the wash tub.

• Combine large and small items

in a load. Load small items first.

Large items should not be more

than half the total wash load.

• When washing a single heavy

item, add 1 or 2 towels to

balance the load.

• Add diluted fabric softener

to the final rinse following

fabric softener manufacturer’s

instructions.

• A fabric softener dispensing

ball can also be used.

• See product manufacturer’s

instructions.

• Follow manufacturer’s

instructions for recommended

amount of bleach.

• DO NOT use powdered bleach

in bleach dispenser.

• DO NOT overload the washer.

• To prevent staining, do not

pour liquid fabric softener

directly on to wash load.

• Use of multi-product

(detergent plus softener)

sheets or color-absorbing

sheets NOT recommended.

They could damage or disable

your machine.

9. Select

washing

cycle and

settings for

each load.

10. Close the

washer lid

and start the

washer.

11. Remove

items when

the cycle is

completed.

Safety Lid Lock

• See

Washer Cycle Selection

and