Page 1

Installation Instructions

Instructionsd'lnstallation

instrucciones para la instalaci6n

\

Printed in U.S.A. P/N 137103000 (0806)

Page 2

CONTENTS

Pre-lnstallation Requirements .................................................................................................................................................. 2

Electrical Requirements .................................................................................................................................................. 3

Gas Supply Requirements ....................................................................................................................................................... 3

Exhaust System Requirements ...................................................................................................................................... 3-5

Location of Your Dryer.................................................................................................................................................... 5

Rough-in Dimensions ..................................................................................................................................................... 6

Unpacking ................................................................................................................................................................... 7

General installation ....................................................................................................................................................... 7

Replacement Parts........................................................................................................................................................ 7

Mobile Home Installation ............................................................................................................................................... 8

Reversing Door Swing................................................................................................................................................. 8

Electrical Installation .................................................................................................................................................... 9

Grounding Requirements .............................................................................................................................................. 9

Gas Connection ............................................................................................................................................................ 9

Electrical Connections--3-wire ....................................................................................................................................... 10

Electrical Connections--4-wire ........................................................................................................................................ 10

Francais................................................................................................................................................................... 11-19

Espahol.................................................................................................................................................................... 20-28

SAFETY INSTRUCTIONS

Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

install the clothes dryer according to the manufacturer's instructions and local codes.

Before beginning installation, carefully read these instructions. This will simplify the installation and ensure the dryer

is installed correctly and safely. Leave these instructions near the Dryer after installation for future reference.

NOTE: The electrical service to the Dryer must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA70, or in Canada, the Canadian electrical code C22.1 part 1.

NOTE: The gas serviceto the Dryer must conform with local codes and ordinances and the latest edition of the National Fuel Gas

Code ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000

NOTE: The Dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME USE

only. This Dryer isnot recommended for commercial applications such asrestaurants or beauty salons, etc.

Your safety and the safety of others is very important.

We have provided many important safety messages in the Use & Care Guide, Operating Instructions, Installation Instructions and

on your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to hazards that can kill or hurt you or others. All safety messages

will be preceded by the safety alert symbol and the word "DANGER" or "WARNING". These words mean:

_ You be killed or seriously injured if you don't follow instructions.

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

RiSK OFFIRE Foryour safety the information in this manual must be followed to minimize the risk of fire or

explosion or to prevent property; damage, personal injury or loss of life. SAVE THESEINSTRUCTIONS,

Do not store or usegasoline or other flammable vapors and liquid in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gassupplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

will

You can be killed or seriously injured ff you don't follow instructions.

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Fiat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.2 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Plastic knife.

Page 3

ELECTRICAL REQUIREMENTS

GAS SUPPLY REQUIREMENTS

[ ELECTR/C Dryer i

CIRCUIT- Individual 30 amp. branch circuit fused with 30 amp.

time delay fuses or circuit breakers.

Use separately fused circuits for washers and dryers, and DO

NOT operate a washer and a dryer on the same circuit.

POWER SUPPLY - 3 wire or 4-wire, 240 volt, single phase, 60

Hz,Alternating Current.

POWER SUPPLY CORD KIT - 3 wire - the dryer MUSTemploy

a 3-conductor power supply cord NEMA 10-30 type SRDTrated

at 240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS FORA 3-WIRE SYSTEM.

4 wire - The dryer MUSTemploy a 4-conductor power supply

cord NEMA 14-30 type SRDTor ST (as required) rated at 240

volt AC minimum, 30 amp., with 4 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS FORA 4-WIRE SYSTEM.

(Canada - 4-wire power supply cord isinstalled on dryer.)

WARNING - Risk of Shock, Appliance grounded to neutral

conductor through a link. Grounding through the neutral link is

prohibited for (1) New branch circuit installations (2) mobile

homes; (3) recreational vehicles; and (4) areaswhere local codes

do not permit grounding through the neutral, (1) disconnect the

link from the neutral, (2) use grounding terminal or lead to

ground appliance in accordance with local codes and (3) connect

neutral terminal or lead to branch circuit neutral in usual manner

(if the appliance is to be connected by means of a cord kit, use

4-conductor cord for this purpose). USECOPPERCONDUCTOR

ONLY.

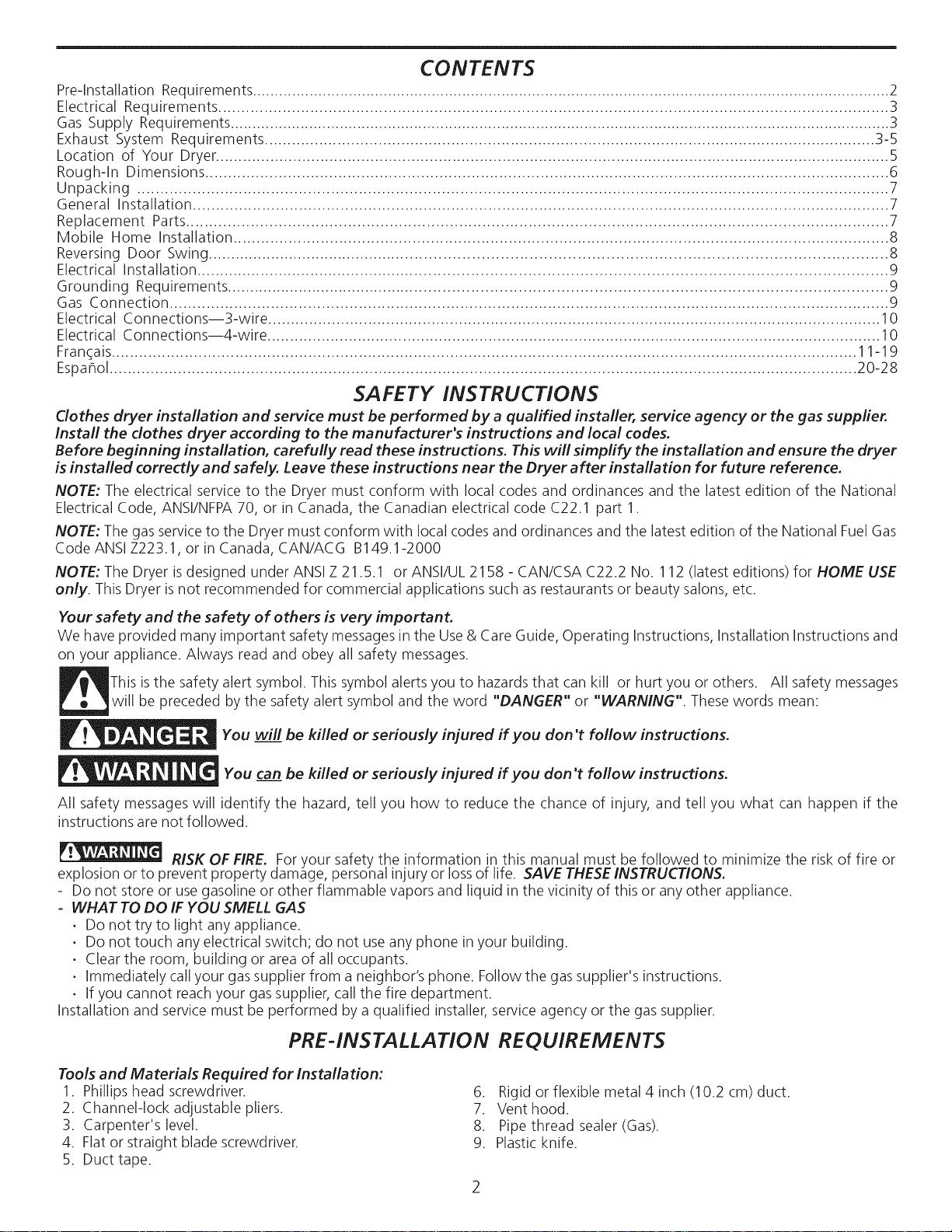

OUTLET RECEPTACLE- NEMA 10-30R receptacle to be located

so the power supply cord is accessible when the dryer is in the

installed position. (Canada - NEMA 14-30R receptacle.)

Replace copper connecting pipe that is not

plastic-coated. Stainless steel or plastic-coated brass MUST

be used.

1. Installation MUSTconform with local codes,or inthe absence

of local codes, with the National FuelGasCode, ANSIZ223.1

(latest edition).

2. The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

4. The gas supply line MUSThave an individual shutoff valve.

5. A 1/8 inch (0.32 cm) N.RT. plugged tapping, accessible for

test gauge connection, MUST be installed immediately

upstream of the gassupply connection to the dryer.

6. The dryerMUSTbe disconnected from the gas supply piping

system during any pressure testing of the gas supply piping

system at test pressures in excessof 1/2 psig (3.45 kPa).

,

The dryer MUSTbe isolated from the gas supply piping

system during any pressure testing of the gas supply piping

system at test pressures equal to or lessthan

1/2 psig (3.45 kPa).

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insects and rodents. To avoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

NEMA 10-30R NEMA 14-30R

i GAS Dryer ]

CIRCUIT- Individual 15 amp. branch circuit fused with a 15

amp. maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD - Thedryer isequipped with a 120 volt

3-wire power cord.

NOTE: Do not under any

circumstances remove

grounding prong from

plug.

_G_RR_NG PRONG

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not install a dothes dryer with flexible

plastic venting materials. If your present system is made up

of plastic duct or metal foil duct, replace itwith a rigid or semi-

rigid metal duct. In Canada and the United States if metal (foil

type) duct is installed, it must be of a specific type identified by

the appliance manufacturer assuitable for usewith clothes dryers

and in the United States must also comply with the Outline for

Clothes Dryer Transition Duct, UL standard 2158A. Flexible

venting materials are known to collapse, be easily crushed and

trap lint. These conditions will obstruct clothes dryer airflow and

increase the risk of fire, Ensure the present duct is free of

any lint prior to installing dryer duct.

Page 4

- Risk of Fire - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building A clothes dryer produces combustible lint. If the

dryer is not exhausted outdoors some fine lint will be expelled

into the laundry area. An accumulation of lint in any area of the

home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors, Regularly inspect the

outdoor exhaust opening and remove any accumulation of lint

around the outdoor exhaust opening and in the surroundinc area.

Do

............................................................................................................................................................................................

Correct Incorrect

Number

of

90 °

Turns

0

1

2

3

4

Number

of

90 °

Turns

0

1

2

3

MAXIMUM LENGTH

of 4" (10.2 cm) Dia. Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

Louvered

-44-F

(10.2 cm)

60 ft.(1&28m)

52 ft.(15.84 m)

44 ft.(13.41 m)

32 ft.(9.7Sm)

28 ft.f8.S3m)

MAXIMUM LENGTH

of 4" (10.2 cm) Dia. Flexible Metal Duct

VENT HOOD TYPE

(Preferred)

Louvered

.,4 4-F

(10.2 cm)

30 ft. (9.14 m)

22 ft. (6.71 m)

14 ft. (4.27 m)

NOT RECOMMENDED

(6.3s cm)

48ft.(14.63m)

40 ft.(12.19 m_

32ft. (9.7Sin)

24ft. (7.31m)

16ft. (4.87 m)

(6.3s cm)

18ft. (5.49m)

14 ft. (4.27 m)

lO ft. (3.osm)

DO

DON'T

Incorrect

Do not allow combustible materials (for

example: clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT be

exhausted into a chimney, a wall, a ceiling, or any concealed

space of a building which can accumulate lint, resulting in a fire

hazard.

Exceeding the length of duct pipe or number

of elbows allowed in the "MAXIMUM LENGTH" charts can

cause an accumulation of lint in the exhaust system. Plugging

the system could create a fire hazard, aswell as increase drying

times.

Do not screen the exhaust ends of the vent

system, nor use any screws, rivets or other fastening means

that extend into the duct and catch lint to assemble the

exhaust system. Lint can become caught in the screen, on the

screwsor rivets,clogging the duct work and creating afire hazard

aswell as increasing drying times. Use an approved vent hood

to terminate the duct outdoors, and sealall joints with duct tape.

All male duct pipe fittings MUST be installed downstream with

the flow of air.

Explosion hazard. Do not install the dryer

where gasoline or other flammables are kept or stored. If

the dryer is installed in a garage, it must be a minimum of 18

inches (45.7 cm) above the floor. Failure to do so can result in

death, explosion, fire or burns.

INSTALL MALE FITTINGS IN CORRECT DIRECTION

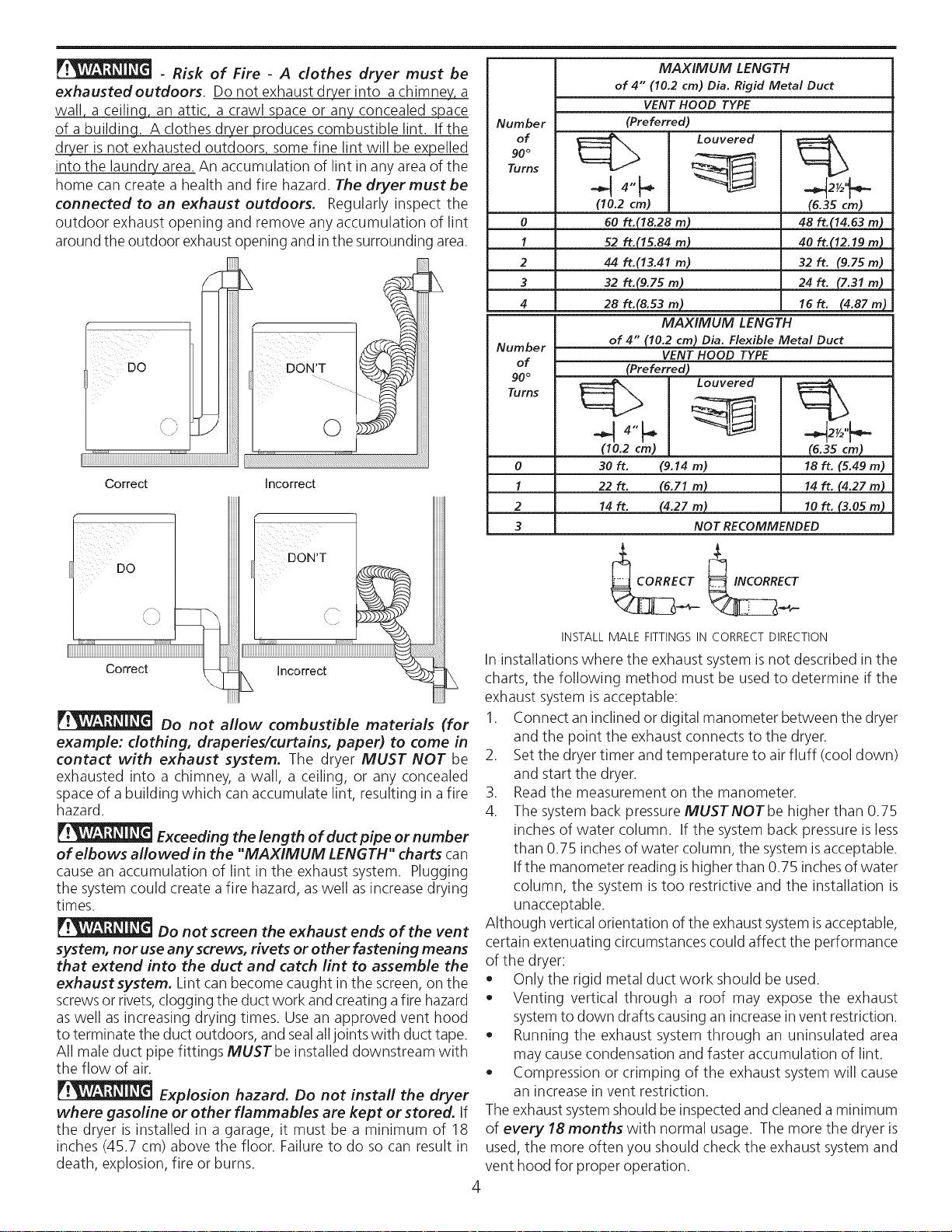

In installations where the exhaust system is not described in the

charts, the following method must be used to determine if the

exhaust system is acceptable:

1. Connect an inclined or digital manometer between the dryer

and the point the exhaust connects to the dryer.

2. Setthe dryer timer and temperature to air fluff (cool down)

and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUSTNOTbe higher than 0.75

inches of water column. If the system back pressure isless

than 0.75 inches of water column, the systemisacceptable.

If the manometer reading ishigher than 0.75 inches of water

column, the system is too restrictive and the installation is

unacceptable.

Although vertical orientation of the exhaust system is acceptable,

certain extenuating circumstances could affect the performance

of the dryer:

• Onlythe rigid metal duct work should be used.

Venting vertical through a roof may expose the exhaust

systemto down drafts causing an increasein vent restriction.

Running the exhaust system through an uninsulated area

may cause condensation and faster accumulation of lint.

Compression or crimping of the exhaust system will cause

an increase in vent restriction.

Theexhaust system should be inspected and cleaned a minimum

of every 18 months with normal usage. The more the dryer is

used, the more often you should check the exhaust system and

vent hood for proper operation.

Page 5

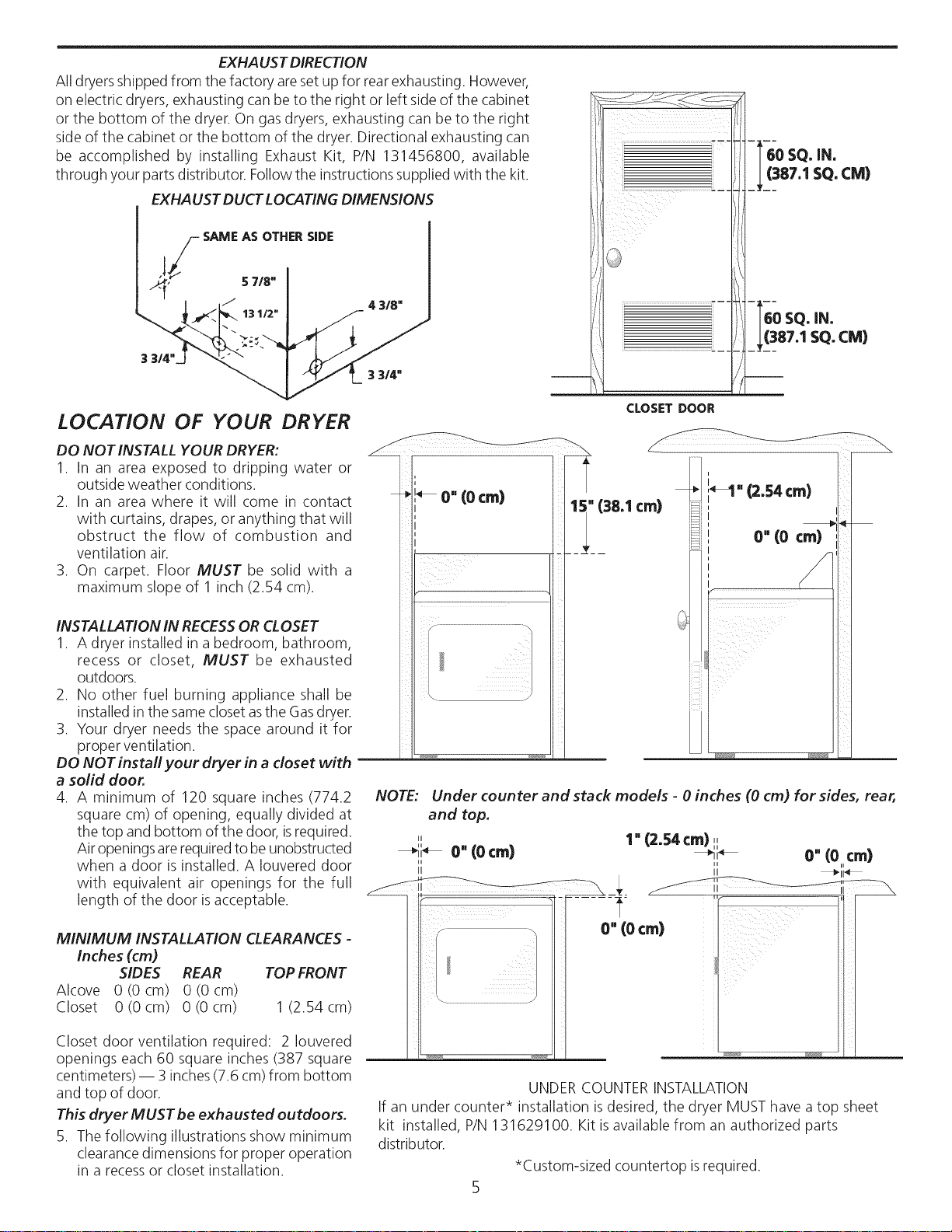

EXHAUST DIRECTION

All dryers shipped from the factory are set up for rear exhausting. However

on electric dryers, exhausting can be to the right or left sideof the cabinet

or the bottom of the dryer. On gas dryers, exhausting can be to the right

sideof the cabinet or the bottom of the dryer. Directional exhausting can

be accomplished by installing Exhaust Kit, P/N 131456800, available

through your parts distributor. Follow the instructions supplied with the kit.

EXHAUST DUCT LOCATING DIMENSIONS

SAME AS OTHER SIDE

LOCATION OF YOUR DRYER

DO NOTINSTALL YOUR DRYER:

1. In an area exposed to dripping water or

outside weather conditions.

2. In an area where it will come in contact

with curtains, drapes, or anything that will

obstruct the flow of combustion and

ventilation air.

3. On carpet. Floor MUST be solid with a

maximum slope of 1 inch (2.54 cm).

CLOSET DOOR

cm)

iNSTALLATiON iN RECESSOR CLOSET

1. A dryer installed in a bedroom, bathroom,

recess or closet, MUST be exhausted

outdoors.

2. No other fuel burning appliance shall be

installed in the same closet asthe Gasdryer.

3. Your dryer needs the space around it for

proper ventilation.

DO NOT install your dryer in a closet with

a solid door.

4. A minimum of 120 square inches (774.2

square cm) of opening, equally divided at

the top and bottom of the door, isrequired.

Air openings are requiredto be unobstructed

when a door is installed. A Iouvered door

with equivalent air openings for the full

length of the door is acceptable.

MINIMUM INSTALLATION CLEARANCES -

inches (cm)

SIDES REAR TOP FRONT

Alcove 0(0cm) 0(0cm)

Closet 0 (0 cm) 0 (0 cm) 1 (2.54 cm)

Closet door ventilation required: 2 Iouvered

openings each 60 square inches (387 square

centimeters)-- 3 inches (7.6 cm) from bottom

and top of door.

This dryer MUST be exhausted outdoors.

5. The following illustrations show minimum

clearance dimensions for proper operation

in a recessor closet installation.

NOTE: Under counter and stack models - 0 inches (0 cm) for sides, rear,

and top.

1" (2.54 cm) ::

0" (0 cm)

II

UNDER COUNTER INSTALLATION

If an under counter* installation isdesired, the dryer MUST have a top sheet

kit installed, P/N 131629100. Kit is available from an authorized parts

distributor.

*Custom-sized countertop isrequired.

5

Page 6

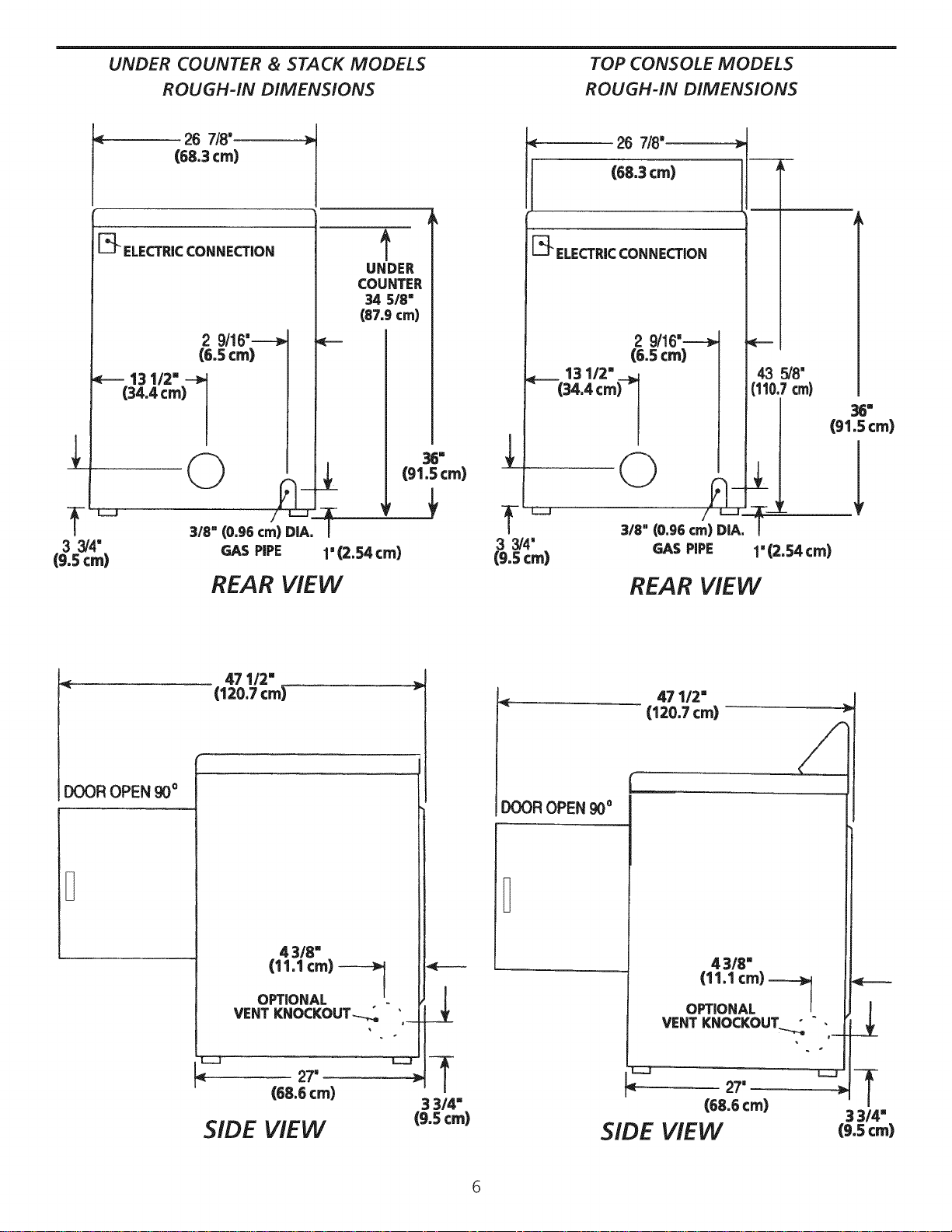

UNDER COUNTER & STACK MODELS

ROUGH-IN DIMENSIONS

TOP CONSOLE MODELS

ROUGH-IN DIMENSIONS

< 26 718' >

(68.3cm)

m

33/4"

(9.5 cm)

ELECTRICCONNECTION

©

318" (0.96 ¢m) DIA.

GASPiPE 1' (2.54cm)

REAR VIEW

/ L....J.._

UNDER

COUNTER

34 5/8"

(87.9 cm)

(91.5 cm)

6 m

33/4'

(9.5 cm)

ELECTRICCONNECTION

2 9116'-------_

(6.5 cm)

©

3/8" (0.96 ¢m) DIA.

GAS PiPE

REAR VIEW

47 1/2"

(120.7cm)

43 5/8'

(110.7cm)

36"

(91.5 cm)

1' (2.54 cm)

DOOR OPEN 90°

D

4 3/8"

(11.1 cm) --_

OPTIONAL

VENT KNOCKOUT_-,._,

'_ 27'

(68.6 cm)

SIDE VIEW

3 314"

(9.5 cm)

DOOR OPEN 90 °

D

(11.1 cm)

OPTIONAL

VENT KNOCKOUT _

'_ 27'

SIDE VIEW

4 3/8"

(68.6 cm)

L==F

.=_

3 314"

(9.5 cm)

Page 7

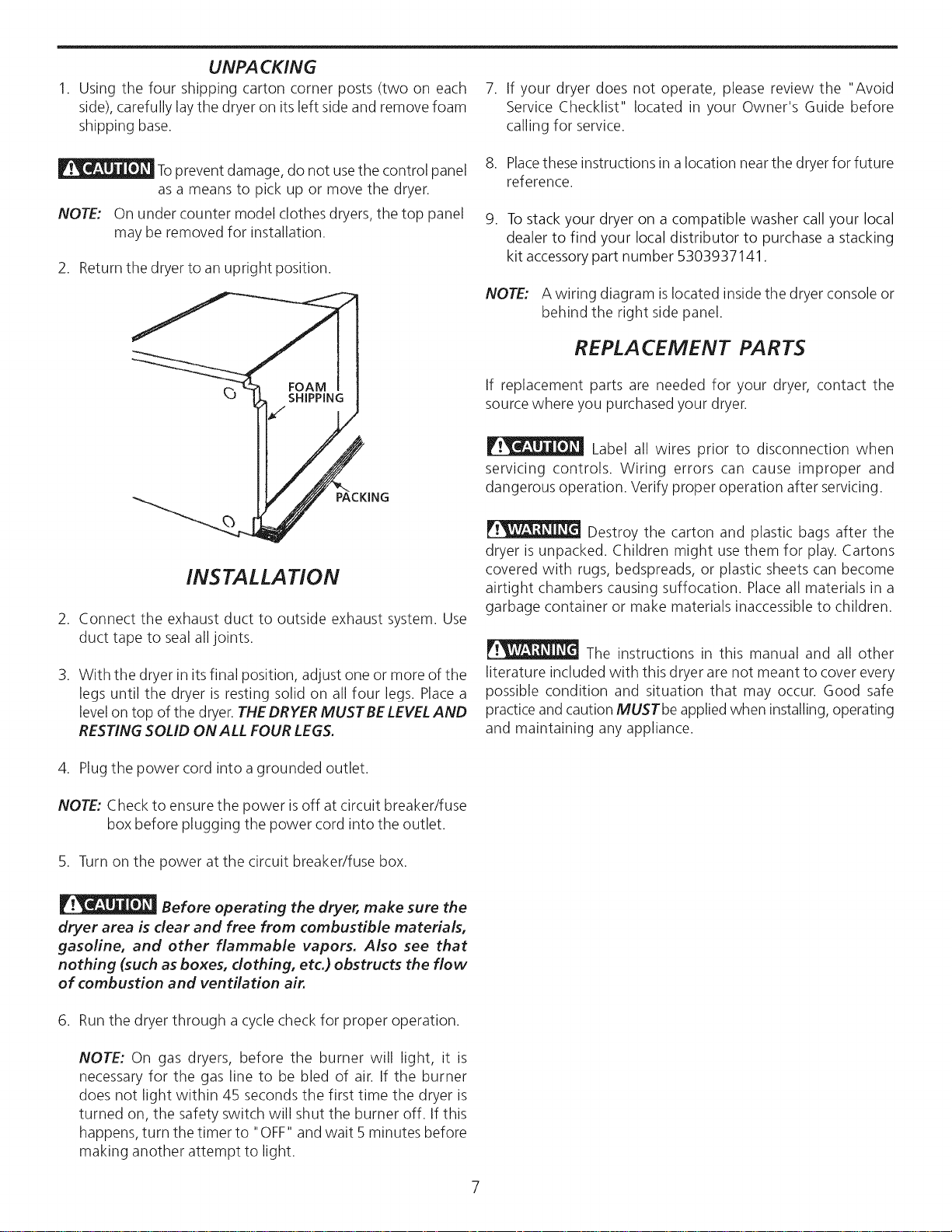

UNPACKING

Using the four shipping carton corner posts (two on each

side), carefully laythe dryer on its left side and remove foam

shipping base.

7. If your dryer does not operate, please review the "Avoid

Service Checklist" located in your Owner's Guide before

calling for service.

Toprevent damage, do not usethe control panel

as a means to pick up or move the dryer.

NOTE: On under counter model clothes dryers, the top panel

may be removed for installation.

,

Return the dryer to an upright position.

""'__-"_"_--_'_-,z--- I NG

INSTALLATION

,

Connect the exhaust duct to outside exhaust system. Use

duct tape to seal all joints.

,

With the dryer in its final position, adjust one or more of the

legs until the dryer is resting solid on all four legs. Place a

levelon top of the dryer. THEDRYER MUSTBE LEVELAND

RESTING SOLID ON ALL FOUR LEGS.

8. Placethese instructions in a location near the dryer for future

reference.

9. To stack your dryer on a compatible washer call your local

dealer to find your local distributor to purchase a stacking

kit accessory part number 5303937141,

NOTE:

A wiring diagram is located inside the dryer console or

behind the right side panel.

REPLA CEMENT PARTS

If replacement parts are needed for your dryer, contact the

source where you purchased your dryer.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

Destroy the carton and plastic bags after the

dryer is unpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plastic sheets can become

airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

The instructions in this manual and all other

literature included with this dryer are not meant to cover every

possible condition and situation that may occur. Good safe

practice and caution MUSTbe applied when installing, operating

and maintaining any appliance.

4. Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at circuit breaker/fuse

box before plugging the power cord into the outlet.

5. Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make sure the

dryer area is dear and free from combustible materials,

gasoline, and other flammable vapors. Also see that

nothing (such as boxes, clothing, etc.) obstructs the flow

of combustion and ventilation air.

6. Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If the burner

does not light within 45 seconds the first time the dryer is

turned on, the safety switch will shut the burner off. Ifthis

happens, turn the timer to "OFF" and wait 5 minutes before

making another attempt to light.

Page 8

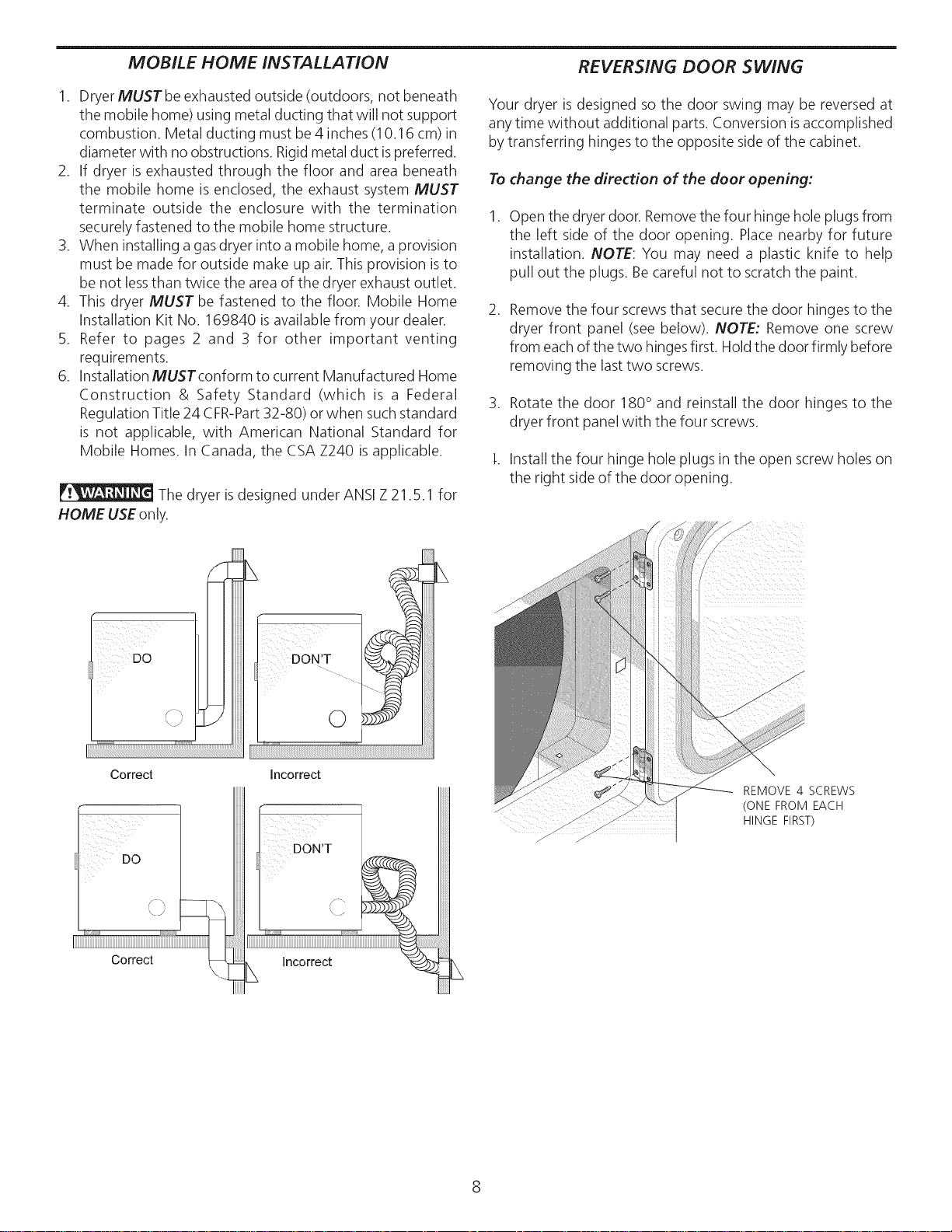

MOBILE HOME INSTALLATION

REVERSING DOOR SWING

1. Dryer MUST be exhausted outside (outdoors, not beneath

the mobile home) using metal ducting that will not support

combustion. Metal ducting must be 4 inches (10.16 cm) in

diameter with no obstructions. Rigidmetal duct ispreferred.

2. If dryer is exhausted through the floor and area beneath

the mobile home is enclosed, the exhaust system MUST

terminate outside the enclosure with the termination

securely fastened to the mobile home structure.

3. When installing a gas dryer into a mobile home, a provision

must be made for outside make up air.This provision is to

be not lessthan twice the area of the dryer exhaust outlet.

4. This dryer MUST be fastened to the floor. Mobile Home

Installation Kit No. 169840 is available from your dealer.

5. Refer to pages 2 and 3 for other important venting

requirements.

6. Installation MUST conform to current Manufactured Home

Construction & Safety Standard (which is a Federal

Regulation Title 24 CFR-Part32-80) or when such standard

is not applicable, with American National Standard for

Mobile Homes. In Canada, the CSA Z240 isapplicable.

The dryer is designed under ANSI Z 21.5.1 for

HOME USEonly.

Your dryer is designed so the door swing may be reversed at

any time without additional parts. Conversion isaccomplished

by transferring hinges to the opposite side of the cabinet.

To change the direction of the door opening:

,

Open the dryer door. Removethe four hinge hole plugs from

the left side of the door opening. Place nearby for future

installation. NOTE: You may need a plastic knife to help

pull out the plugs. Becareful not to scratch the paint.

,

Removethe four screws that secure the door hinges to the

dryer front panel (see below). NOTE: Remove one screw

from each of the two hinges first. Hold the door firmly before

removing the last two screws.

3. Rotate the door 180° and reinstall the door hinges to the

dryer front panel with the four screws.

f. Install the four hinge hole plugs in the open screw holes on

the right side of the door opening.

L

DON'T

Correct Incorrect

DO

i\ i

Correct U

Incorrect

ii_i!;;i_ii_ii!i!iiii

L

iiiiiiiii

_ _

©

REMOVE 4 SCREWS

(ONE FROM EACH

HINGE FIRST)

Page 9

ELECTRICAL INSTALLATION

i

proper and safe electrical installation of your dryer. Failure

to follow these instructions can create electrical shock and/

or a fire hazard.

This appliance MUSTbe properly grounded. Electrical shock

can result if the dryer is not properly grounded. Follow the

instructions in this manual for proper grounding.

Donot usean extension cord with this dryer. Someextension

cords are not designed to withstand the amounts of electrical

current this dryer utilizes and can melt, creating electrical shock

and/or fire hazard. Locate the dryer within reachof the receptacle

for the length power cord to be purchased, allowing some slack

in the cord. Refer to the pro-installation requirements in this

manual for the proper power cord to be purchased.

A U.L. approved strain relief must be installed onto power

cord. if the strain relief is not attached, the cord can be pulled

out of the dryer and can be cut by any movement of the cord,

resulting in electrical shock.

Do not use an aluminum wired receptacle with a copper

wired power cord and plug (or vice versa).A chemical reaction

occurs between copper and aluminum and can cause electrical

shorts The proper wiring and receptacle is a copper wired

power cord with a copper wired receptacle.

ALL ELECTRICDryers

The following are specific requirements for

I

conductor can result in a risk of electrical shock. Check with a

licensed electrician if you arein doubt asto whether the appliance

isproperly grounded.

Fora grounded, cord-connected dryer:

1. The dryer must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by a path of least resistance for electrical current.

,

Sinceyour dryer isequipped with apower supply cord having

an equipment-grounding conductor and a grounding plug,

the plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances. If in doubt, call a licensed

electrician.Do not modify plug provided with the

appliance.

1. The dryer is equipped with a three-prong (grounding) plug

for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

the plug.

Canadian ELECTRIC

Improper connection of the equipment grounding

ALL 6AS Dryers

Dryer

]

NOTE: Dryers operating on 208 volt power supply will have

longer drying times than operating on 240 volt power supply.

GRO UNDING REQ UIREMENTS

I

grounding conductor can result ina risk of electrical shock. Check

with a licensed electrician if you are in doubt asto whether the

appliance isproperly grounded.

Fora grounded, cord-connected dryer:

1. The dryer MUSTbe grounded, in the event of a malfunction

or breakdown, grounding will reducethe risk of electricalshock

by a path of least resistancefor electrical current.

2. If your dryer isequipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the

plug MUST be plugged into an appropriate, copper wired

receptacle that is properly installed and grounded in

accordance with all local codes and ordinances. If in doubt,

call a licensed electrician. Do not modify plug provided

with the appliance.

Fora permanently connected dryer:

1. ThedryerMUSTbe connected to a grounded metal, permanent

wiring system;or an equipment grounding conductor must be

run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

Non-Canadian ELECTR/CDryer

Improper connection of the equipment

GAS CONNECTION (Gas dryers on/y)

Remove the shipping cap from gas pipe at the rear of the dryer.

NOTE: DO NOTconnect the dryer to L.R gas service without

converting the gasvalve.An L.Rconversion kit must be installed

by a qualified gas technician.

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved pipe

from gas supply line to the 3/8 inch (0.96 cm) pipe located on

the back of the dryer. Use a 1/2 inch to 3/8 inch (1.27 cm to

0.96 cm) reducer for a connection. Apply an approved thread

sealer that isresistant to the corrosive action of liquefied gases

on all pipe connections.

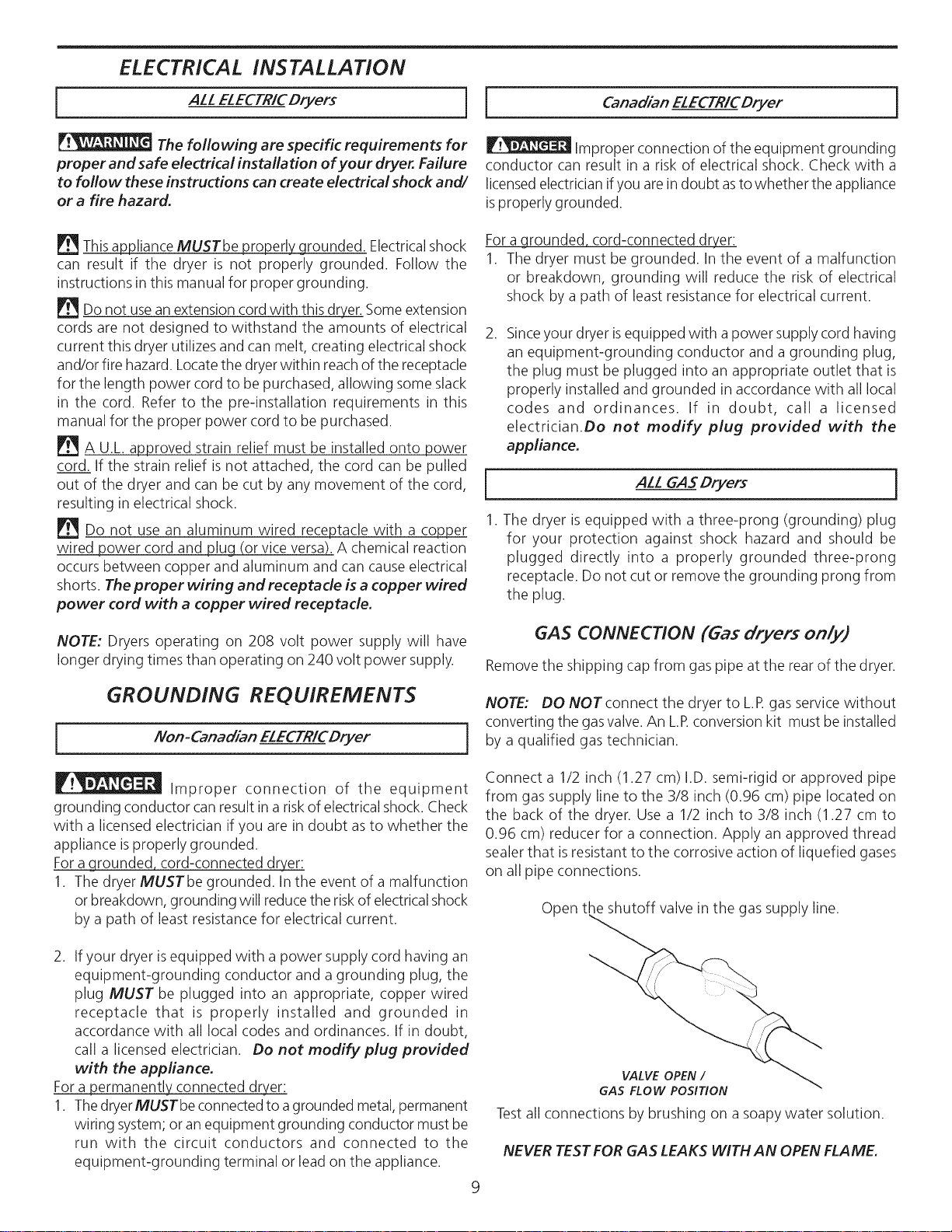

Open the shutoff valve in the gas supply line.

VALVE OPEN /

GAS FLOW POSITION

Testall connections by brushing on a soapywater solution.

NEVER TESTFOR GAS LEAKS WITH AN OPEN FLAME.

9

Page 10

ELECTRICAL CONNECTIONS

FOR 3- WIRE SYSTEM

ELECTRICAL CONNECTIONS

FOR 4- WIRE SYSTEM

Non-Canadian ELECTRICDryer

Remove the screws securing the terminal block access

cover and the strain relief mounting bracket located on

the back of the dryer upper corner.

,

Install a U.L. approved strain relief into the power cord entry

hole of the mounting bracket. Finger tighten the nut only at

this time.

GREEN GROUND SCREW

NEUTRAL

GROUND

WIRE

SILVER TERMINAL

NUT

TIGHTEN NUT TO

THESE THREADS

i Non-Canadian ELECTRICDryer 1

1. Removethe screws securing the terminal block accesscover

and the strain relief mounting bracket located on the back of

the dryer upper corner.

,

Install a U.L. approved strain relief in the entry hole of the

mounting bracket. Finger tighten the nut only at this time.

GREEN GREEN POWERCORD

GROUND'_--==GROUND WIRE SILVER TERMINAL

SCREW

I!_m-_TERMINAL

BLOCK

NEUTRAL _ , /

GROUN DI'__i "_ BIAD( TIGHTEN NUT

WIRE / //_-_ °/F'_WHITE TO THESE

RE-i_ I_/STRAIN

t I I/t RELIEF

,

Removethe ground wire from the green ground screwlocated

F// MOUNTh'V(

F/POWER

CORD

above the terminal block.

NUT HREADS

RELIEF

BRACKET

POWER CORD

3. Thread a U.L. approved 30 amp. power cord, NEMA 10-30

Type SRDT,through the strain relief.

4. Attach the power cord neutral (center wire) conductor to

the silver colored center terminal on the terminal block.

Tighten the screw securely.

5. Attach the remaining two power cord outer conductors to

the outer brass colored terminals on the terminal block.

Tighten both screws securely.

Do not make a sharp bend or crimp wiring/

conductor at connections.

6. Reattach the strain relief mounting bracket to the back of

the dryer with two screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against

the power cord.

8. Tighten the strain relief nut securely so that the strain relief

does not turn.

9. Reinstall the terminal block cover.

TYPICAL 4

CONDUCTOR BLACK

.,_WHITE

_ypICAL4 _ RED240v

CONDUCTOR "GREEN

30 AMP NEMA 14..30 TYPE SRDT OR

,

Thread a U.L. approved 30 amp power cord, NEMA 14-30

type STor SRDTthrough the strain relief.

,

Attach the green power cord ground wire to the cabinet with

the green ground screw.

,

Attach the white (neutral) power cord conductor from the

power cordand the neutral ground wire from the dryer harness

to the silver-colored center terminal on the terminal block.

Tighten the screw securely.

,

Attach the red and black power cord conductors to the outer

brass-colored terminals on the terminal block.

Do not make a sharp bend or crimp wiring/

conductor at the connections.

,

Tighten the screws securing the cord restraint firmly against

the power cord.

,

Tighten the strain relief nut securely so the strain relief does

not turn.

10. Reinstall the terminal block access cover.

10

Page 11

Table des matieres

Avant I'installation ............................................................................................................................................................ 11

Installation _lectrique .................................................................................................................................................... 12

Alimentation en gaz ......................................................................................................................................................... 12

Evacuation de I'air .................................................................................................................................................. 12-14

Emplacement de la s_cheuse ........................................................................................................................................... 14

Dimensions de I'emplacement .......................................................................................................................................... 15

D_ballage ..................................................................................................................................................... 16

Installation .......................................................................................................................................................... 16

Pi_ces de rechange ......................................................................................................................................................... 16

Installation dans une maison mobile .................................................................................................................................. 17

Porte R_versible ................................................................................................................................................... 17

Installation _lectrique ....................................................................................................................................................... 18

Mise _ la torte ................................................................................................................................................................ 18

Branchement duGaz .............................................................................................................................................................. 18

Branchement _lectrique -Installation _ 3 ills ........................................................................................................................ 19

Branchement _lectrique - Installation _ 4 ills ........................................................................................................................ 19

Mesures de Securite Importantes

L'installation et le service de la SOcheuse de v_tements doivent _tre effectu_s par un installateur qualifi_, I'agence de

service ou le fournisseur de gaz. Installez la SOcheuse de v_tement selon les instructions du fabricant et les codes Iocaux.

Avant de commencer, lire attentivement le present document. Cela simplifiera I'installation et assurera la pose

correcte et s_curitaire de la s_cheuse. AprOs I'installation, laisser ce document bproximit_ de la s_cheuse pour rOf_rence

future.

REMARQUE : L'alimentation _lectrique de las_cheuse dolt respecter lescodes et ordonnances Iocaux ainsi que I'_dition la plus r_cente

du Code ANSI/NFPA 70, ou au Canada, le Code canadien d'_lectricit_, ACNOR C22.1, pattie1.

REMARQUE : L'alimentation engaz de la s_cheusedolt respecter loscodes et ordonnances Iocaux ainsi que I'_dition la plus r_cente du

Code ANSI Z223.1, ou au Canada, le code CAN/ACG B149.1-2000.

REMARQUE : Las_cheuseest concue conform_ment au code ANSIZ 21.5.1 ou ANSI/UL 2158 - CAN/AC G C22.2 No. 112 (l'_dition la

plus r_cente) pour un USAGE DOMESTIQUEseulement. Cette s_cheusen'est pasrecommand_e pour utilisation commerciale, comme

par exemple un restaurant ou un salon de coiffure, etc.

Votre securite et cello des autres est tres importante.

Nous donnons de nombreux messagesde s_curit_ importants dans cemanuel et sur votre appareil m_nager. Assurez-vous de toujours

life tous los messages de s_curit_ et de vous y conformer.

_ Voici le symbole de mise en garde. Ce symbole met en garde contre los risques pouvant entratner le d_c_s ou des blessures

_ L'utilisateur sera tu_ gravement bless_ s'il ne suit pas cos directives.

Tous los messages relatifs b la s_curit_ indiquent le risque, comment r_duire le risque de blessure et ce qui peut

survenir si on ne suit pas les directives.

los risques d'incendie, d'explosion, de dommages materiels, de blessures et de mort. GARDEZ CESINSTRUCTIONS.

- Ne pas entreposer ni utiliser d'essence ou autres liquides ou produits inflammables _ proximit_ de cette s_cheuse ou de tout

- QUE FAIRE S'IL YA UNE ODEUR DE GAZ

L'installation et losr_parations doivent _tre effectu_es par un service de r_paration, un technicien quail% ou le fournisseur de gaz.

solou aux autres. Tous losmessages relatifs _ la s_curit_ sont precedes du symbole de mise en garde et du terme <<DANG ER

>>ou <<AVERTISSEMENT>>.Ces termes signifient •

L'utilisateur peut _tre tug ou gravement bless_s'il ne suit pasces directives.

RISQUE D'INCENDIE. Pour votre s_curit_, suivre lesdirectives _nonc_es dans lepresent guide afin de minimiser

autre appareil m_nager.

• Ne mettre en marche aucun appareil .

Netoucher aucun interrupteur _lectrique; n'utiliser aucun t_l_phone dans I'immeuble.

Fairesortir tous los occupants de la piece, de I'immeuble ou de la zone avoisinante.

Appeler la fournisseur de gaz imm_diatement en utilisant le t_l_phone d'un voisin. Suivre les directives du fournisseur de gaz.

S'il est impossible de joindre le fournisseur de gaz, appeler le service de protection des incendies.

AVANT L'INSTALLATION

Outils et mat#riel requis pour l'installation :

1. Tournevis_ pointecruciforme

2. Pinto multiprise

3. Niveau de menuisier

4. Tournevis _ pointe plate ou _ lame droite

5. Ruban adh_sif pour conduits

6. Conduite en m_tal rigide ou souple de 10,2 cm (4 po)

7. Bouched-_vacuationd'air

8. Ruban ou p_te d'_tanch_it_ pot joints filet_s (modUle _ gaz)

9. Couteau_ masticen plastique

11

Page 12

INSTALLATION L'LECTRIQUE

¢IRCUITe_LECrRIOUE-Circuit de dbrivation distinct de 30 A avec

fusibles _ retardement ou disjoncteurs d'au 30 A.

Utilisez des circuits avec un disjoncteur ou fusible s@ar_ pour los

machines _ laver et s_cheuses, et NE PASfaire fonctionner une

machine _ laver et une s_cheuse sur un m_me circuit.

ALIMENTATIONELECTRIQUE- 3 ills ou4 ills, 240 volts, unephase,

60 Hz, courant altematif. (Canada - 240 volts, une phase, 60 Hz,

courant alternatif.)

CORDOND'AL/M'ENT.4T/ONELECTR/QUE- 3 fils - las6cheuse

DO/T6tre dot@ d'un cordon d'alimentation dectrique a 3 ills

NEMA 10-30, c.a., 30 A, de type SRDTd'une capacit6 minimale

de 240 volts, avec fiche en L _ 3 broches _ extr6mit@souvertes,

relev@esou ferm@s, OUd'un cordon d'alimentation 6Iectrique

4 fib NEMA 14-30, c.a., 30 A, de type SRDTou ST (selon Ie cas)

d'une capacit6 minimale de 240 volts, avec3 connecteurs _ cosse

ouverte recourb6e vers Ie haut aux extr6mit@sou 3connecteurs

cosseferm@e, conc us pour Ie raccordement d'une s6cheuse.

4 ills - Elle DO/T6tre dot@ d'un cordon d'alimentation a 4 ills

NEMA 14-30, c.a., 30 A, de type SRDTou ST (selon le cas)d'une

capacit6 minimale de 240 volts, avec4 connecteurs _ cosseouverte

recourb6e vers Ie haut aux extr6mit6s ou 4 connecteurs acosse

ferm@e, concus pour le branchement d'une s@cheuse.Voir la

section INSTALLATIONELECTRIQUEpour plus de d_tails.

AVERTISSEMENT-Risque de choc _lectrique. Unappareil mis

la torte a I'aide d'un lien ou cable conducteur neutre. Lamise a

laterre aI'aide d'un conducteur ou cable neutre est interdite dans

loscas suivants : (1) losinstallations de nouveau circuit d_vir_ (2)

losmaisons mobiles (3) losv_hicules r_cr_atifs ou caravanes et (4)

losr_gions o0 loscodes Iocaux interdisent lamise a la torte aI'aide

d'un cable ou conducteur neutre. (1) D_branchez le conducteur

ou cable du neutre, (2) utilisez laborne de misea laterre ou lecable

de misea latorte de I'appareil conform_ment aux codes Iocaux et

(3)connectez ou branchez la borne neutre ou lecable au neutre du

circuit d@ir_de lamani_re habituelle (siI'appareil dolt _treconnect_

a I'aide d'un cordon, utilisez un cordon a 4 cables ou ills pour ce

faire). N'UTILISEZQUE DESCABLESOU FILSEN CUIVRE.

PR/S£- PriseNEMA 10-30R (3 alv@oles)ou prise NEMA 14-30R

(4 alv@oles) plac6e de facon que le cordon d'alimentation

dectrique soit accessible une fois la s@cheuseen place.

A NEUTREA 3 IlLS 120-240 VOLTS 60 CYCLES

FUSIBLES A RETARDEMENT OU

DISJONCTEUR DE30 A

u J_-k._ BO_rEAFUSIBLESPRINCIPALE

PRISEMURALE (CUIVRE)

SOUS RE'SERVEDES EXIGENCES NEMA 10-30R

LOCALES (CUIVRE)

i S_cheu_es _ GAZ ]

CIRCUIT- D@rivationdistincte de 15 A avecfusible a retardement

ou disjoncteur d'au plus1 5 A.

ALIMENTATiONELECTRIQUE- 3 ills, 120volts,

une phase, 60 Hz, courant alternatif. _ J_lI_l _J

CORDON D'ALIMENTATION ELECTRIQUE- _ _ "%_ _/

Las_cheuseest pourvue d'un cordon I _ _

d'alimentation _lectriquea3 ills de \ _ J \

120 volts. \ ( / BROCHEDE

REMARQUE : II ne faut en aucun cas rotifer _ MISE A LA

la broche de mise a la torte de la fiche. _ \ TERRE

FIL NEUTRE

ALIMENTATION EN GAZ

RemplaceHe tuyau de raccordement en

cuivre non rev_tu de plastique. Un conduit en acier

inoxydable ou en laiton rev_tu de plastique DO_T_tre utilis_.

1. L'installation DOlT respecter Ies codes Iocaux ou, s'iI n'existe

pas de codes Iocaux, Ie Code d'instaIIation des appareils et

_quipements fonctionnant au gaz natureJ, norme ACG

CANIB149.1.

2. Le conduit d'alimentation en gaz dolt mesurer 1,27 cm (1/2

po).

3. Si les codes le permettent, un tuyau en m6tal souple peut 6tre

utilis6 pour raccorder la s6cheuse au conduit d'alimentation en

gaz. Letuyau D@lT6tre en acier inoxydable ou en cuivre et rev6tu

de plastique.

4. Leconduit d'alimentation en gaz D@lTcomporter une soupape

d'arr6t distincte.

B. Une prise de manom6tre de 0,32 cm (1/8 po) a filetage NPT

DOlT6tre r6alis@tout juste en amont du raccordement du conduit

d'alimentation en gaz.

6. La s6cheuse DOlT6tre d6connect6e de Ia canalisation de gaz

pendant toute v6rification de pression de I'alimentation en gaz

des pressions d'essai exc6dant 3,4B kPa (1/2 IbipoS).

7. Las6cheuse DOlT6tre isol6e de Iacanalisation de gaz pendant

toute v6rification de pression de I'alimentation en gaz a des

pressions d'essai 6gales ou inf6rieures a 3,4B kPa(1/2 Ib/poS).

L'VACUATION DE L'AIR

Utiliser uniquement un conduit en m_tal rigide ou souple de 10,2

cm (4 po) de diam6tre (minimum) ainsi qu'une bouche

d'6vacuation approuv6e dont Ies clapets s'ouvrent Iorsque Ia

s6cheuse fonctionne. Quand Ia s6cheuse s'arr6te, Iesclapets se

ferment automatiquement pour 6viter Iescourants d'air et I'entr6e

d'insectes ou de rongeurs. Afin de ne pas obstruer Ia sortie d'air,

laisser une distance minimum de 30,5 cm (12 po) entre la bouche

d'6vacuation et lesol ou tout autre obstacle.

Lesd/re_tives su/vantes ont 4t4 @m/sesaf/n

d'as_urer /'installation appropr/e/e et s4cur/ta/re de votre

_@cheuse. Le d@faut de respecter ces directives risque

c/'entfa_ner des chocs @/ectfiques e_/ou un incendie.

N'installez pas la S_cheuse avec des materiels de

ventila tion en ma ti_res plastiques flexibles.

Silaconduite existante est en plastique ou en papier m_tallique, la

remplacer par une conduite en m_tal rigide ou flexible. Au Canada

etaux Etats-Unissile conduit estde m_tal(type feuille d'aluminium),

celui-ci dolt 6tre d'un type sp_cifique identi% par le fabricant,

recommand_ pour I'utilisation avecdes S_cheuses; et aux Etats-

Unis il dolt en outre remplir lanorme UL21 5A. Lesmat_riaux de

ventilation flexibles peuvent s'abimer facilement et recueillir du

duvet. Cosconditions obstrueront lacirculation d'air de laS_cheuse

de v_tements et augmenteront lerisque d'incendie. S'assurer

qu'i! n'y a pas de charpie dans la conduite existante avant

d'installer ia conduite de ia s_cheuse.

12

Page 13

- Risque d'incendie- une S_cheuse de v_tement doit _tre

a_r_ b I'airlibre. N'a_rez pas la S_cheuse dans une chemin_e,

une paroi, un plafond, un espace form# ou aucun espace cach#

du batiment. Unes#cheusea linge produitdela charpie

combustible. SiI'air n'#tait pasrepouss#a I'ext#rieur de la maison

de petites particules de charpie seretrouveraient dans lapiece ou

est install#e la s#cheuse.Toute accumulation de charpie dans la

maison pout pr#senter des risques pour la sant# et des risques

d'incendie. La s_cheuse doit _tre connect_e b une bouche

d'_vacuation vers I'ext_rieur du b_timent ou de I'immeuble.

Vous devez inspecter r_guli_rement I'_vent ext_rieur et enlever

toute accumulation de charpie autour de I'_vent et dans la cavit_

du conduit d'_vacuation.

Nombre de

_oudes _,90 °

0

1

2

3

4

Nombre de

_oudes _,90 °

LONGUEURS MAXIMUM

d'un conduite en m_tal rigide de

10,2 cm (4 po) de diam.

TYPE DE BOUCHE D'EVACUATION

(Recommande)

& volet

(10.2 cm)

6o ft.(18.28m)

52 ft.(IS.84 m)

44 ft.(13.41m)

32 ft.(9.FS m)

28 ft.(8.S3 m)

LONGUEURSMAXIMUM

d'une conduite en m_tal souple de

10,2 cm (4 po) de diam.

TYPE DE BOUCHE D'EVACUATION

(Recommande)

(6.35cm)

48ft.(14.6_m)

40 ft.(12.19 m)

32ft. (9.7Sin)

24ft. (7.31m)

16ft. (4.87m)

! iiiiii

...........

CORRECT

Ne laisser aucun mat_riau inflammable (comme des

v_tements, des tentures, des Hdeaux ou du papier) entrer

en contact avec le syst_me d'_vacua don.

Exc_der/a /ongueur des conduits ou /e nombre de coudes

permis au tab/eau _ LONGUEURSIVIAX/NIU/Yl _,peut entraTner

une accumulation de charpie dans Ie syst_me d'_vacuation.

L'engorgement du syst6me risque de causer un incendie et

augmenter le temps de s6chage.

_ N'obstruez les dutubedeventilation utilisezpas

extr6mit_s ni

desvis rivets ou autres moyens defixation qui peuvent obstruer le

conduit et recueillir du duvet. L'engorgement subs6quent risquerait

de ralentir letemps des6chage,voirede causerun incendie.Installer

une bouche d'6vacuation approuv6e a I'ext6rieur et sceller tous

losjoints a I'aide d'un ruban adh6sif a conduits. Tous los raccords

de conduit males DO/V£/VT6tre install6s dans le sons de la

circulation d'air.

F__ Risques d'explosion. Ne pas installer la

s_cheuse clans une piece renfermant de/'essence ou tout

autreproduitinflammaMe, Si las6cheuse est instaJI_edans un

garage, die doit 6tre a un minimum de 45,7 cm (18 po) du soI. Le

d#faut de respecter cette consigne risque d'entratner unincendie

ou une explosion pouvant causer des brOlures,voire la mort.

iNCORRECT

a volet

(10.2 cm)

0 _9.14 m)

1 (6.71 m)

2 (4.27 m)

3 NON RECOMMANDE

POSERLESRACCORDS M,a,LESDANS LA BONNE DIRECTION

30 ff'_

22 ft.

14 ft.

_.,,_... INCORRECT

18 ft. (_.49 m)

14 ft. (4.27 m)

10ft. (3.05m)

En ce qui a trait aux syst_mes d'_vacuation dont I'instalIation

n'est pas d_crite ci-dessus, Ia m_thode suivante doit 6tre utilis6e,

afin de d_terminer sile syst_me d'_vacuation est acceptable:

1. Installer un manom_tre num_rique ou a tube inclin_ entre la

s_cheuse et Ie point de raccordement du conduit a Ia s_cheuse.

2. R_gler Ia minuterie de Ia s_cheuse et Ia temperature a <<Air

Fluff >>(refroidissement) et d_marrer la s_cheuse.

3. Life Ia mesure indiqu_e au manom_tre.

4. La contre-pression NE DOITPAS 6tre sup_rieure a 0,75

pouce de colonne d'eau. Si Ia contre-pression est inf_rieure a

0,75 pouce de colonne d'eau, Ie syst_me est acceptable. Si Ia

lecture indique une pression sup_rieure a 0,75 pouce de colonne

d'eau, Iesyst_me est trop restreint et I'installation inacceptable.

Bien qu'une orientation verticale du syst_me d'_vacuation soit

acceptable, des particularit_s d'une te!le installation peuvent nuire

au rendement de Ia s_cheuse.

Seuls des conduits en m_taI rigide doivent _tre utilis_s.

L'instalIation d'un syst_me d'_vacuation a orientation

verticale, sur un toit risque de causer des refoulements et un

accroissement de Ia restriction du syst_me.

Tout isolant enveloppant Ies conduits pout causer de Ia

condensation et ainsi r_duire Iacapacit_ d'_vacuation du syst_me.

La compression ou I'aplatissement du syst_me d'_vacuation

pout restreindre I'_vacuation d'air.

Le syst6me d'_vacuation doit, au minimum, _tre inspect_ et

nettoy_ tous/es 18 mois d'utilisation normale. Plus Ias_cheuse

est utilis_e, pIus iI faut proc_der souvent a une v_rification du

syst_me et de Ia bouche d'_vacuation, afin d'en assurer le bon

fonctionnement.

13

Page 14

DIRECTION DEL'EVA CUATION D'AIR

A Ieur sortie de I'usine, Iess6cheuses sont assembI_es de facon

que I'_vacuation d'air s'effectue par I'arriere= Toutefois,dans Ie

cas des s6cheuses _Iectriques, I'_vacuation d'air peut se faire

la droite ou a Ia gauche du chassis ou encore, au bas de Ia

s_cheuse=Dans Ie cas des s_cheuses _ gaz, I'6vacuation d'air

peut sefaire _ Ia droite du chassisou au bas de Ia s_cheuse=On

peut done modifier I'orientation de I'_vacuation d'air en instalIant

un ensemble d'_vacuation d'air (n° de piece 131456800)

disponible chez votre distributeur de pi_ces=

Suivre les directives qui accompagnent cet ensemble.

EMPLACEMENTS DESSORTIES

COMME SUR L'AUTRE C6TeL

15 cm

(5 7/8 po)

34cm

-. _(131/2po)

11cm

EMPLA CEMENT DE LA SECHEUSE

NE PASINSTALLERLA SCLCHEUSE :

1. Dans un endroit expos@_ un @coulement d'eau ou aux

conditions atmosph@riques.

2. Dans un endroit ou elle serait en contact avec des rideaux,

draperies ou tout ce qui obstruera leflux d'air de combustion

et de ventilation.

3. Sur un tapis. Le plancher DOIT_tre ferme et presenter une

pente de 2,54 cm (1 po) au maximum•

INSTALLATION DANS UNEAL COVE OU UN PLACARD

1. Toute s_cheuse install_e dans une chambre _ coucher, une

salle de bain, une alc6ve ou un placard DOIT_tre reli@e_ une

conduite d'@vacuation d'air se terminant _ I'ext@rieur de la

maison.

2. Aucun autre appareil brOlant du combustible ne doit _tre

install_ dans le m_me placard que la s_cheuse au Gaz.

3. La s@cheuse a besoin d'un d%agement suffisant pour

permettre la circulation de Fair.

NEPASINSTALLERLA SE:CHEUSEDANSUN PLACARDPOURVU

D'UNEPORTE PLEINE.

4. Une ouverture minimum de 774,2 cm2 (120 po2) r@partie

%alement entre le haut et le hasde la porte est requise. Cette

ouverture ne doit pas_tre obstru@eIorsque laporte est enplace•

Une porte _voletsdont lesouvertures totalisent lanorme d@crite

ci-dessus est acceptable•

DEGAGEMENTS MINIMA UX POUR L'INSTALLATION

en po (cm)

D'AVANT COTES ARRIERE DESSUS

AIc6ve ou sous un

comptoir 0 (0) 0 (0) 0 (0) 15 (38,1)

Armoire 1 (2,54) 0 (0) 0 (0) 15 (38,1)

A@ration n@cessairedans la porte de I'armoire: 2 ouvertures

persiennesde 60 pouces carr@s(387 cm cart@s)chacun - _3 pouces

(7,6 cm) du has et du haut de la porte•

L'AE:RATION DE CETTESECHEUSESEFAIT VERSL'EXTERIEUR.

5. Les illustrations qui suivent donnent led%agement minimum

pour une installation dans une alc6ve ou un placard•

0 cm

(0 po)

NOTA: Pour les modules qui s'installent sous un comptoir et les

modules superposables -- 0 cm (0 po) sur les c6tes, I'arriere

et le dessus.

2,54 cm

,, (1 p,,o) 0 cm

-0- o cm (o po) --41.- (o po)

INSTALLATION SOUS UN COMPTOIR

Si vous desirez effectuer une installation sous un comptoir*, il

FAUT installer un ensemble P/N 131629100, une tOle superieure

de carrosserie. Cet ensemble est disponible chez un distributeur

de pieces autoris&

* Un dessus de comptoir sur mesure est necessaire.

14

Page 15

MODELES DE DESSOUS DE COMPTOIR ET

SUPERPOS£:S

DIMENSIONS DE L'EMPLA CEMENT

MODELES A UTONOMES AVEC CONSOLE

SUPERIEURE

DIMENSIONS DE L 'EMPLA CEMENT

68,3 cm

(267/8po)

[_ BRANCHEMENT

ELECTRIQUE

34,4 cm--_

(13 1/2 po)

9,5 cm

(3 3/4 po)

SOUSUN

COMPTOIR

87,9 cm

(34 5/8 po)

6,5 cm---_

(29/16po)

Q

o,96cm (3/8po) 2,54 cm (1 po)

DE DIAMETRE

VUE ARRIERE

120,7 cm

(47 1/2 po)

91,5 Cm

(36po)

_]_ BRANCHEMENT

9,5 cm

(3 3/4 po)

ELECTRIQUE

34,4 cm

(13 1/2po)

0,96 cm (3/8 po)

DE DIAMETRE

6,5 Cm

(29/16po)

©

VUE ARRIERE

120,7 cm

(47 1/2 po)

110,7 cm

(43 5/8po)

___ 91 5 cm

I t

(36 _)

_--

2,54 cm (1 po)

OUVERTURE

DE LA PORTE

90 °

H

11,1 cm

(4 3/8 po)

TROUDE

VENTILATION

A PERFORER

FACULTATIF

68,6 cm

(27po)

VUE LATeLRALE

I

OUVERTURE

DE LA PORTE

90 °

11,1 cm

!

TROUDE(4 3/8 po)----_

9,5 cm

(3 3/4 po)

VENTILATIONA _

PERFORER

FACULTATIF

68,6 cm

(27po)

VUE LATeLRALE

_w

9,5 cm

(3 3/4 po)

15

Page 16

DEBALLAGE

1. A I'aide des quatre corni_res de protection (deux de chaque

c6t_), d_poser d_licatement la s_cheuse sur son c6t_ gauche

et retirer la feuille de mousse plac_e sous la s_cheuse pour

I'exp_dition.

_Pour ne pas endommager Ia s_cheuse,

ne pas prendre prise sur le panneau de commandes pour

soulever ou d_placer la s_cheuse.

2. Remettre la s_cheuse _ Ia verticale.

DEMOUSSE

/

_,,_,,_ _ _ALLAGE

INSTALLATION GENERALE

.

Relier Ieconduit d'_vacuation d'air au syst_me d'_vacuation

ext_rieur (voir pages 12 et 14). Utiliser un ruban adh_sif

conduits pour sceller lesjoints.

.

Une fois Ia s_cheuse dans son emplacement d6finitif, r_gler

los pieds de nivelIement jusqu'_ ce que la s6cheuse repose

fermement sur sesquatre pieds. Placerun niveau sur le dessus

de Ia s_cheuse. Las_cheuse DO/T_tre de niveau et reposer

refinementsutsos quatrep/edso

.

Brancher Ie cordon d'alimentation sur une prise mise _ Ia

terre. REMARQUE : S'assurer que le courant est coup6 au

panneau de fusibles ou de disjoncteurs avant d'ins_rer le cordon

d'alimentation dans la prise.

4. Remettre Ie courant au panneau de fusibles ou de disjoncteurs.

A vantd'ut///ser/as_cheuse,

s'assurerque /'airede/essiveestexempte de toutmateriau

inf/ammab/e, d'essence et de toute autre vapeur

inf/ammab/eoS'assurer_ga/ement qu'aucun objet(boftes.

v_tements,otto)ne nuise_ /acombustion et_/a venti/ationo

6. Si Ias6cheuse ne fonctionne pas, veuilIez consulter Iasection

<<D6pannage >>du guide de I'utilisateur avant de faire appel

un technicien.

7. Placer cette notice pros de la s_cheuse pour r_f_rence future.

8. Pour empiler votre Secheuse sur une Laveuse compatible

appelez votre revendeur local pour trouver votre distributeur

local et acheter la pi@ceaccessoire num@ro 5303937141 ."

RE/I//ARQUE: Un sch@made c_blage setrouve dans le panneau

de commando ou sous le couvercle de la s@cheuse.

PIECES DE RECHANGE

Pour obtenir despi_cesde rechange pour las_cheuse, contacter le

magasin d'ou vient la s@cheuse

Avant d'effectuer tout travail d'entretien

ou de r@parationdes commandos, @tiquetertous losc_bles avant

de los d@brancher. Los erreurs de connexion de c_bles peuvent

compromettre le bon fonctionnement deI'appareil, voire las@curit@

de I'utilisateur. Une fois la r@paration ou I'entretien termin@,

s'assurerque I'appareil fonctionne correctement.

D6truire Iecarton et Iessacsen plastique apr6s

avoir d_ball_ la s_cheuse, afin d'_viter que des enfants ne s'en

servent pour s'amuser. Lescartons recouverts de tapis, de couvre-

lits ou defeuilIes de plastique peuvent former une chambre _tanche

et entratner Ia suffocation d'un enfant. Placer Ie mat_rieI

d'embalIage dans un contenant avidanges ou lemettre horsde la

pottle desenfants.

Lesdirectives qui figurent dans cette notice et

dans Ies autres documents qui accompagnent la s_cheuse ne

sautalent couvrir toutes los_ventualit_s. II/MPORTEdonc de faire

preuve de jugement et de prudence pendant I'installation,

I'utilisation et I'entretien de tout gros appareil m_nager.

5. Faire un cycle d'essai afin de v_rifier le fonctionnement de la

s_cheuse.

REMARQUE °Dans Ie cas des s_cheuses _ gaz, Ie conduit dolt

6tre vid_ de son air avant que Ie br0Ieur ne puisse s'alIumer. Si Ie

br0Ieur ne s'alIume pas dans Ies45 secondes suivant le premier

d_marrage, I'interrupteur de s0ret_ _teint Ie br01eur. Si cela se

produit, mettre Ia minuterie _ <<OFF>>et attendre 5 minutes avant

de tenter de rallumer le brOleur.

16

Page 17

INSTALLATION DANS UNE MAISON MOBILE

PORTE REVERSIBLE

L'evacuation d'air de la secheuse DOlT se faire a I'exterieur de la

maison (a I'exterieur et non pas au-dessous de la maison mobile)

I'aide de conduit en metal non inflammable, a I'epreuve du feu.

Lesconduits en metal doivent avoir 10,16 cm (4 pouces) de diametre

sans obstructions. Les conduits en metal rigide sont preferables.

2,

Si la conduite d'evacuation d'air traverse le plancher et un espace

ferme situe sous la maison mobile, I'evacuation d'air DOlT se

terminer a I'exterieur de cet espace ferme, et la sortie bien fixee

la structure de la maison mobile.

3. Lots de I'installation d'une secheuse a gaz dans une maison mobile,

il faut prevoir un apport d'air exterieur. L'espace a prevoir doit _tre

superieur de deux fois celui du conduit d'evacuation de la secheuse.

4. Cette secheuse DOlT _tre fixee au plancher. L'ensemble

d'installation no. 169840 pour maison mobile est disponible chez

votre distributeur.

5. Se referer aux pages 2 et 3 pour de plus amples informations ur les

exigences de ventilation.

6,

L'installation DOlT respecter la norme federale sur la construction

et la securite des maisons mobiles en vigueur (Manufactured Home

Construction & Safety Standard) (pattie integrante du reglement

federal 24 CFR Pattie 32-80) ou, Iorsque cette norme ne s'applique

pas, elle doit respecter la norme nationale americaine pour les

maisons mobiles (American National Standard for Mobile Homes).

Lorsque I'installation se fait au Canada, elle doit se conformer aux

normes ACNOR Z240.

La s6cheuse est concue de facon que I'ouverture de Iaporte

puisse 6tre invers6e en tout temps sans pi_cesadditionnelIes.

L'inversion de Ia porte requiert le transfert des charnieres au

cOt_ oppos_ du chassis.

Pour inverser I'ouverture d'une porte pleine :

.

Ouvrir Ia porte de la s6cheuse. Retirer lesquatre bouchons

d'orifice de visdu cOt_gauche de Ia porte et lesmettre de

c6t6. RE/I/IA!F@IJE:Un couteau _ mastic en plastique peut

s'av6rer n6cessaire pour retirer Iesbouchons. Prendre soin

de ne pas 6gratigner la peinture.

2. Retirer Ies quatre vis fixant Ies charnieres de Ia porte au

panneau avant de Ia s_cheuse (voir ci-dessous).

RE/Y/,4R@UE: Retirer d'abord une vis dans chacune des

charnieres. Tenir Ia porte fermement avant de d_visser les

deux dernieres vis.

3. Faire faire une rotation de 180° _ Ia porte et remettre en

place Iescharnieres sur le panneau avant de la s_cheuse

I'aide des quatre vis.

4. Poser lesquatre bouchons d'orifice de vis sur Ie c6t_ droit

de la porte.

La secheuse est con(;ue conformement a la

norme ANSI Z 21.5.1 pour un USAGE DOMESTIQUE seulement.

CORRECT

iNCORRECT

L

DL-VISSERLES 4 VIS

(UNE DE CHAQUE

CHARNI_'RE D'ABORD)

17

Page 18

INSTALLATION ELECTRIOUE

TOUTES/es s_cheuses ELECTRIQUES I

Los directives suivantes ont _te _mises afin

d'assurer /'installation appropr/_e et s_cur/ta/re de votre

s_cheuse. Le defaut de respecter ces directives risque

d'entrafner des chocs _/ectriques et/ou un/ncendie.

Cot apparei/DOIT_tre con venab/ement mis &

/a torte. Las_cheuse pr_senterait desrisques de choc dectrique si

elle n'@tait pas convenablement mise a Ia torte. Respecter les

directives de mise _ Iaterre contenues dans cette notice pour une

mise 3 la terre correcte.

Nepas uti/iser de ra//onge aveccette secheuse.

N'_tant pasconcuespour supporter I'intensit_ du courant qu'utilise

cette s@cheuse,certainesralIongespeuvent fondre etcauser unchoc

dectrique ou un incendie. Placer Ias_cheuse _ port@ede Ia prise

murale afin de d_terminer Ia Iongueur du cordon dectrique

acheter; pr6voir un certain jeu dans Ia Iongueur du cordon. Se

reporter _Iasection <<AvantI'instalIation>>de cette notice, afin de

d_terminer le type de cordon _ acheter.

UnserreocJb/e approuve U.L doit _tre fix_ au

cordon d'a/imentation, sansquoi Iesmouvements de I'appareiI

risquent d'arracher et de couper le cordon et de causer un choc

dectrique.

Ne pas uti/iser une prize & cJb/age en

a/uminium avecune fiche etun cordon 9 cJb/age en cuivre et

inversement Lar_action chimique provoqu_e par lecontact entre

le cuivre et I'aluminium cause des court-circuits. Le cJb/age

appropr/_ cons/ste en un cordon d'a//mentat/on & cJb/age en

cuivre et uneprise & cJb/age en cuivreo

_5echeuse connect_e en permanence & un circuit _/ectrique:

1. La s_cheuse DO/T6tre connect_e _ un circuit _Iectrique

1

m_talIique mis_ Iaterre; sinon, un fiI de mise _ Iaterre de I'appareiI

doit 6tre c_bI_ avec lesills du circuit et connect_ _ la borne ou au

fil de mise _ la terre de I'appareil.

S_cheusesELECTR/QUES Canadiennes

Leraccordement inappropri@ du fiI de terre peut

causer un choc @Iectrique.Encasde doute quant a la mise_ laterre

de I'appareil, contacter un @Iectricienqualifi@.

5echeuse raise & /atorte et branchee sur une prise _/ectrique

1. La s_cheuse DO/T_tre mise _ Ia terre. En cas de d_fectuosit_

ou de d_failIance, Ia raise _ Ia terre r_duit Ies risques de choc

_lectrique en offrant un parcours de moindre r_sistanceau courant.

2. f_tant donn_ que la s_cheuse est pourvue d'un cordon

d'alimentation dectrique comportant un filet une fiche de terre,

la fiche dolt 6tre branch@ sur une prise murale _ c_blage en

cuivre, correctement insta%e et mise _ la terre conform_ment

tous Ies codes et r_glements Iocaux. En casde doute, contacter

un _tectricien quail%.

Ne modifiez pas la prise _quip_e d'appareiL

i

Afin de prot_ger I'utilisateur contre Ies chocs _Iectriques, Ia

s_cheuse est dot@ d'une fiche a trois broches (raise 3 Ia terre) et

dolt 6tre branch6e directement sur une prise _ trois alv6oles

correctement mise 3 la terre. Ne pas couper ni enlever la broche

de mise _ la terre de cette fiche.

TOUTES/es s_cheuses a GAZ

BRANCHEMENT DU GAZ

]

REMAR@UE: Letemps de s_chage des s_cheuses connect6es

un circuit de 208 volts sera plus long que celles connect_es

un circuit de 240 volts.

MISEA LA TERRE

I

causer un choc @Iectrique.Encasde doute quanta Ia raise _la terre

de I'appareil, contacter un dectricien qualifi@.

5echeuse raise & /a torte et branch_e sur une prise

_/ectrique :

1. La s@cheuseDO/T6tre raise _ Ia terre. En cas de

d_fectuosit@ ou de d@faillance, Ia raise _ la terre r@duitIes

risques de choc dectrique en offrant un parcours de moindre

r@sistanceau courant.

2. Si Ia s_cheuse est pourvue d'un cordon d'alimentation

_tectrique comportant un filet une fiche de terre, Ia fiche DOlT

_tre branch_e sur une prise murale _ c_blage en cuivre,

correctement insta%e et mise a la terre conform_ment a tous

les codes et r_glements Iocaux. Encas de doute, contacter un

dectricien quali%.

Ne modifiez pas la prise _quip_e d'appareil.

S_cheuses ELECTRIOUES USA

Leraccordement inappropri_ du fiI de terre peut

1. Retirer Ie bouchon d'exp_dition qui recouvre Ie tuyau de gaz

I'arriere de Ia s_cheuse.

REMAR@UE:NEPASbrancher Ias_cheusesur une installation

de propane Iiquide sansavoir pos_un n_cessairede conversion.

¢e n_cessaire doit _tre insta% par un technicien quali%.

2. Raccorder un tuyau semi-rigide ou approuv_ de 1,27 cm (1/2

po) de diam_tre int_rieur au tuyau de 0,96 cm (3/8 po) situ_

I'arri_re de Ias6cheuse (volt pages6 et 7). Utiliser un r_ducteur

de 1,27 cm-0,96 cm (1/2 po-3/8 po) pour Ie raccordement.

Appliquer, sur tous Ies raccords, un ruban ou une p_te

d'_tanch_it_ pour joints filet_s approuv_ r_sistant _ corrosion

produite par lesgaz Iiqu_fi_s.

3. Ouvrir la soupape d'arr_t du conduit d'alimentation en gaz.

SOUPAPE D'ARRET EN

POSITION OUVERTE

4. V_rifier tous Iesraccordements enversant de I'eau savonneuse

sur lesjoints.

Ne JAMA/S v_rifier/a presence de fuites _ /'aide d'une

flamme nue.

18

Page 19

BRANCHEMENTL'LECTR/QUE

D'UNE INSTALLATIONA 3 FILS

BRANCHEMENT_'LECTR/QUE

D'UNE INSTALLATIONA 4 FILS

i

1. D@isser les vis qui retiennent Ie panneau du bloc de

jonction et I'_trier de d_charge de traction situ_s dans le

coin sup_rieur du dos de la s_cheuse.

2. installer un serre-c_ble approuv@U.L dans I'orifice de

I'@trier.Setter simplement I'_crou _ la main pour le

moment.

VIS DE MISE A LA

TERRE VERTE

FIL DE TERRE

NEUTRE

S#cheuses ELECTRIOUES USA

BORNE ARGENTEE

ECROU

SERRERL'ECROU

SUR CES FILETS

]

i

1. D@isserIesvisqui retiennent Iepanneau du bloc dejonction

et 1'6trier de d_charge de traction situ_s dans le coin

sup_rieur du dos de la s_cheuse.

2. InstalIer un serre-c_ble approuv_ U.L dans I'orifice de I'_trier

de d_charge de traction. Setter simplement I'_crou _ la

main pour le moment.

3. Retirer IefiI de terre de Iavis de mise a laterre verte situ_e

au-dessus du bloc de jonction.

VISDE MISE

LA TERRE

VERTE

FIL DE

TERRE

S#cheuses LeLECTRIOUES USA

FILDETERRE BORNE

BLOC DEJONCTION

NOIR

•BLANC

ECROU

SERRERL'ECROU

SUR CES FILETS

i

DECHARGE

DE

TRACTION

3. Passerun cordon d'alimentation NEMA 10=30approuv_

U.L, 30 A, de type SRDTdarts le serre=c_ble.

4. Relier Ie fiI neutre (fiI du centre) du cordon d'alimentation

Ia borne argent_e au centre du bloc de jonction. Setter

la vis a fond.

5. Relier Ies deux ills restants aux bornes cuivr_es _ droite et

gauche du bloc de jonction. Setter lesdeux vis a fond.

Ne pas aplatir, ni plier excessivement lesills

surles homes.

6. Remettre en place I'6trier de d6charge de traction

I'arriere de la s6cheuse a I'aide des deux vis. Setter les vis

fond.

7. Serrer Iesvis de la bride de retenue du cordon

d'alimentation.

8. Setter I'6crou du serre-cable de facon que ce dernier ne

puisse plus tourner.

9. Remettre en place le panneau du bloc de jonction.

D'AUMENTATION

D'ALIMENTATION

4. Passerun cordon d'alimentation NEMA 14=30approuv6

U.L., 30 A, de type STou SRDTdans le serre=cable.

PRISETYPIQUE_ 4

ALVEOLES

________F/L BLANC NEUTRE

CORDON

CORDON D'ALIMENTATION NEMA 14-30, 30 A, DE TYPE ST OU SRDT

5. Relier Ie fiI de terre vert du cordon d'alimentation au chassis

I'aide de Ia vis de mise a Ia terre verte.

6. Relier Ie fiI blanc (neutre) du cordon d'alimentation ainsi que

le fil de terre du faisceau de Ias_cheuse 3 la borne argent_e

(au centre) du bloc de jonction.

7. Relier Ies ills rouge et noir du cordon d'alimentation aux

homes cuivr_es a gauche et _ droite du bloc de jonction.

Ne pas aplatir, ni plier excessivement les fib

surles bornes.

8. Serrer les vis de la bride de retenue, afin de bien immobiliser

le cordon d'alimentation.

9. Serrer I'_crou du serre-cSble de facon que ce dernier ne

puisse plus tourner.

10. Remettre en place le panneau du bloc de jonction.

FILNOIR240 V

IL ROUGE 240 V

_'_FILDETERREVERT

19

Page 20

Tabla de Materias

Requerimientos de instalaci6n preliminares ........................................................................................................................... 20

Requerimientos el_ctricos ................................................................................................................................................... 21

Requerimientos del suministro de gas.................................................................................................................................... 21

Requerimientos del sistema de escape.............................................................................................................................. 21-23

UbicaciOn de su secadora ..................................................................................................................................................... 23

Dimensiones para la instalaci6n ........................................................................................................................................... 24

Desembalaje .................................................................................................................................................................... 25

Instalaci6n ....................................................................................................................................................................... 25

Piezas de recambio ............................................................................................................................................................ 25

Instalaci6n en casas m6viles ................................................................................................................................................. 26

Puerta reversible ................................................................................................................................................................ 26

Instalaci6n el_ctrica ........................................................................................................................................................... 27

Requerimientos para la puesta a tierra .................................................................................................................................. 27

Conexi6ne ctel Gas............................................................................................................................................................ 27

Conexi6nes el_ctricas - trifilares .......................................................................................................................................... 28

Conexi6nes el_ctricas - tetrafilares ....................................................................................................................................... 28

SEGURIDAD de SECADORA

La instalad6n y el servicio de la Secadora de ropa se deben realizar por un instalador calificado, la agencia de servido o el

surtidor de gas.

Instale la Secadora de ropa segun las instrucciones del fabricante y los c6digos locales. Antes de comenzar la instalaci6n,

lea cuidadosamente estas instrucciones. Esto simplificar4 la instalaci6n y asegurar4 que la secadora se instale correctamente

y de manera segura. Despu_s de completar la instalaci6n, coloque estas instrucciones cerca de la secadora para referencia

futura.

NO TA: Laalimen taci6n el_ctrica para lasecadora deber4 cumplir con los c6digos y reglamentos Iocales y con la ultima edici6n

del C6digo El_ctrico Nadonal, ANSI/NFPA 70 o en Canad4 CSAC22.1 C6digo ElOctrico Canadiense, Parte 1.

NO TA: La alimentad6n de gas para la secadora deber4 cumplir con los c6digos y reglamentos Iocales y con la ultima edici6n

del C6digo Nadonal para Gases Combustibles, ANSI Z223.1 o en Canad4 CAN/CGA B 149.12.

NO TA: Lasecadora est4 clasificada para USODOMESTICO solamente, de acuerdo con la norma ANSI Z 21.5.1 o ANSI/UL 2158-

CAN/CSA C22.2 No. 112 (las ultimas edici6nes). Esta secadora no se recomienda para uso commercial tal como en restaurantes,

salones de belleza, etc.

Su seguridad y la seguridad de terceros son muy importantes.

Hemos proporcionado muchos mensajes importantes para la seguridad en las Instrucciones de OperaciOn del Manual de Uso y

Mantenimiento, lasInstrucciones de Instalaci6n y en el mismo aparato. Siempre lea y obedezca todos los mensajes para seguridad.

_Este simbolo significa alerta. Estesimbolo Io alerta acerca de peligros que pueden matar o lesionar, tanto a usted como a otras

personas. Todos los mensajes de seguridad ser_inprecedidos por el simbolo de alerta para su seguridad y la palabra "PELIGRO o

ADVERTENCIA " (DANGER" o WARNING). Estaspalabras significan:

PELIGRO (DANGER) Usted morir4 o resultar4 seriamente lesionado si no sigue las instrucdones siguientes.

ADVERTENCiA (WARNING) Usted puede morir o resultar seriamente lesionado si no sigue las instrucciones

siguientes.

Todos los mensajes de seguridad identificar4n el peligro, le dir4n a usted c6mo reducir la posibilidad de lesi6n y tambi_n

qu_ puede suceder si no se siguen las instrucdones.

RiESGODEINCENDIO. Parasu seguridad, siga las instrucciones contenidas en este manual a fin de reducir a un

minimo los riesgos de incendio o explosi6n o para evitar daflos materiales, lesiones personales o la muerte. GUARDE ESTAS

INSTRUCCIONES.

- Noalmacene ni utilicegasolina u otrosvaporesyliquidosinflamablesen la proximidad de_steodecualquierotroartefactoel_ctrico.

- QUEDEBEHACERSiPERCIBEOLORA GAS

• Notrate de encender ningOn artefacto el_ctrico.

• Notoque ningOn interruptor el_ctrico; no useningOn tel_fono en suedificio.

• Haga salir atodos los ocupantes de la habitaci6n, del edificio ydel lugar.

Llame a su proveedor de gas desde el tel_fono de un vecino. Siga las instrucciones del proveedor de gas.

• Sino Iogra comunicarse con su proveedor de gas, Ilame al departamento de bomberos.

La instalaci6n yel servicio de mantenimiento debe de realizarlos un instalador calificado, la agencia de servicios o elproveedor de gas.