Frigidaire FGQ1442ES2, FGQ1442ES3, FGQ1442FE2, FGQ1452HE0, FGQ1452HE1 Installation Guide

...Page 1

Installation Instructions

Gas & Electric Dryer

Instructionsd'lnstallation

r

Secheuse a Gaz ou Electrique

instrucciones para la instalaci6n

Secadora a Gas y Electrica

\

www.frigidaire.com P/N 137101400 (0806)

Page 2

CONTENTS

Pre-lnstallation Requirements .......................................................................................................................................... 2

Electrical Requirements .................................................................................................................................................. 3

Gas Supply Requirements ............................................................................................................................................... 3

Exhaust System Requirements ...................................................................................................................................... 3-5

Location of Your Dryer.................................................................................................................................................... S

Rough-In Dimensions ..................................................................................................................................................... 6

Unpacking ................................................................................................................................................................... 7

General Installation ....................................................................................................................................................... 7

Replacement Parts........................................................................................................................................................ 7

Mobile Home Installation ............................................................................................................................................... 8

Reversing Door Swing ................................................................................................................................................. 8-10

Electrical Installation .................................................................................................................................................... 11

Grounding Requirements .............................................................................................................................................. 11

Gas Connection ............................................................................................................................................................ 11

Electrical Connections--3-wire ....................................................................................................................................... 12

Electrical Connections--4-wire ........................................................................................................................................ 12

Francais......................................................................................................................................................................... 13-23

Espahol...................................................................................................................................................................... 24-34

SAFETY INSTRUCTIONS

Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

install the clothes dryer according to the manufacturer's instructions and local codes.

Before beginning installation, carefully read these instructions. This will simplify the installation and ensure the dryer is

installed correctly and safely. Leave these instructions near the Dryer after installation for future reference.

NOTE: The electrical serviceto the Dryer must conform with localcodesand ordinances and the latest edition of the National Electrical

Code, ANSI/NFPA70, or in Canada, the Canadian electrical code C22.1 part 1.

NOTE: The gasserviceto the Dryer must conform with local codes and ordinances and the latest edition of the National FuelGasCode

ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000

NOTE: The Dryer isdesigned under ANSIZ 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions for HOME USE only.

This Dryer is not recommended for commercial applications such as restaurants or beauty salons, etc.

RiSK OF FIRE, For your safety the information in this manual must be followed to minimize the risk of fire or

explosion or to prevent property damage, personal injury or lossof life. SAVE THESEINSTRUCTIONS.

Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Your safety and the safety of others is very important.

We have provided many important safety messages in the Use & Care Guide, Operating Instructions, Installation Instructions and on

your appliance. Always read and obey all safety messages.

This isthe safety alert symbol. This symbol alerts you to hazards that can kill or hurt you or others. All safety messages

will be preceded by the safety alert symbol and the word "DANGER" or "WARNING". These words mean:

You will be killed or seriously injured if you don't follow instructions.

You can be killed or seriously injured ff you don't follow instructions.

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for installation:

1. Phillips head screwdriver. 6.

2. Channel-lock adjustable pliers. 7.

3. Carpenter's level. 8.

4. Flat or straight blade screwdriver. 9.

5. Duct tape.

Rigid or flexible metal 4 inch (10.2 cm) duct.

Vent hood.

Pipe thread sealer (Gas).

Plastic knife.

Page 3

ELECTRICAL REQUIREMENTS

i ELECTRICDryer

CIRCUIT- individual 30 amp. branch circuit fused with 30 amp.

time delay fuses or circuit breakers.

Use separately fused circuits for washers and dryers,and DO

NOToperate a washer and a dryer on the same circuit.

POWER SUPPLY- 3 wire or 4-wire, 240 volt, single phase, 60

Hz,Alternating Current.

POWER SUPPLYCORD KIT- 3 wire - the dryer MUSTemploy a

3-conductor power supply cord NEMA 10-30 type SRDTrated at

240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONSFORA 3-WIRE SYSTEM.

4 wire - The dryer MUST employ a 4-conductor power supply 4.

cord NEMA 14-30 type SRDTor ST(asrequired) rated at 240 volt

AC minimum, 30 amp., with 4 open end spade lug connectors 5.

with upturned ends or closed loop connectors and marked for use

with clothes dryers. See ELECTRICALCONNECTIONS FOR A 4-

WIRE SYSTEM.

(Canada - 4-wire power supply cord is installed on dryer.) 6.

WARNING - Risk of Shock, Appliance grounded to neutral

conductor through a link. Grounding through the neutral link is

prohibited for (1) New branch circuit installations (2) mobile homes;

(3) recreational vehicles; and (4) areas where local codes do not

permit grounding through the neutral, (1) disconnect the link from

the neutral, (2) use grounding terminal or leadto ground appliance

in accordance with local codes and (3) connect neutral terminal

or lead to branch circuit neutral in usual manner (if the appliance

isto be connected by means of a cord kit, use4-conductor cord

for this purpose). USECOPPERCONDUCTOR ONLY.

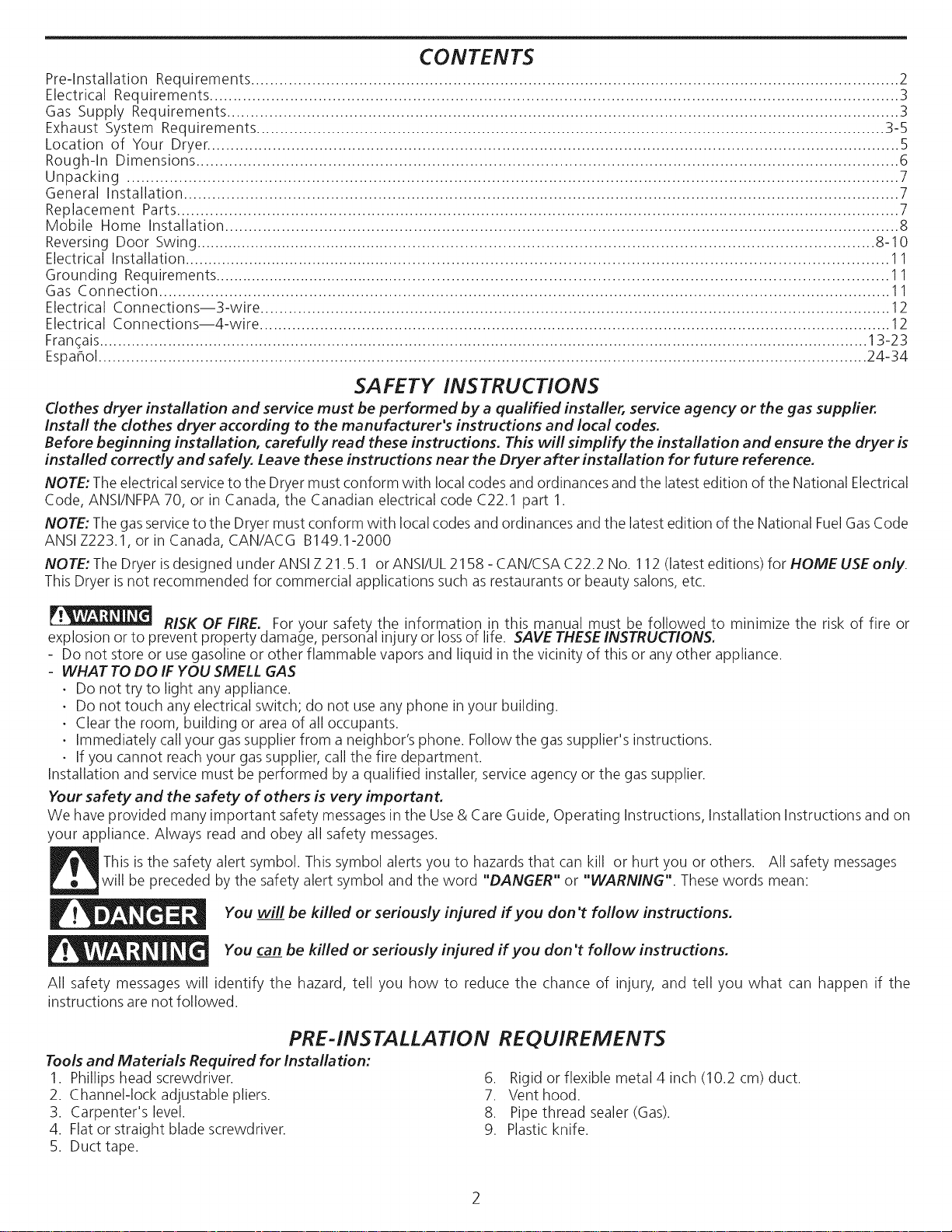

OUTLET RECEPTACLE- NEMA 10-30R receptacle to be located

so the power supply cord is accessible when the dryer is in the

installed position. (Canada - NEMA 14-30R receptacle.)

]

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe that is not

plastic-coated. Stainless steel or plastic-coated brass MUST

be used.

1. Installation MUSTconform with local codes, or in the absence

of local codes, with the National FuelGasCode, ANSIZ223.1

(latest edition).

,

The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3.

If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainlesssteel or plastic-coated brass.

The gas supply line MUSThave an individual shutoff valve.

A 1/8 inch (0.32 cm) N.RT. plugged tapping, accessible for

test gauge connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

The dryer MUSTbe disconnected from the gas supply piping

system during any pressure testing of the gas supply piping

system at test pressures in excess of 1/2 psig (3.45 kPa).

,

Thedryer MUSTbe isolated from the gassupply piping system

during any pressure testing of the gas supply piping system

at test pressures equal to or lessthan 1/2 psig (3.45 kPa).

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically dose to prevent drafts

and the entrance of insects and rodents. Toavoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or anyother obstruction.

NEMA 10-30R NEMA 14-30R

i GAS Dryer ]

CIRCUIT- Individual 15amp. branch circuit fused with a 15 amp.

maximum time delay fuse or circuit breaker.

POWER SUPPLY- 3 wire, 120 volt single phase,60 Hz,Alternating

Current.

POWER SUPPLYCORD - The dryer isequipped with a 120 volt 3-

wire power cord.

NOTE: Do not under any _f _t_ _

circumstances remove

grounding prong from

plug.

G PRONG

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not install a dothes dryer with flexible

plastic venting materials. If your present system is made up

of plastic duct or metal foil duct, replace it with a rigid or semi-

rigid metal duct. In Canada and the United States if metal (foil

type) duct isinstalled, it must be of a specific type identified by

the appliance manufacturer as suitable for usewith clothes dry-

ers and inthe United States must also comply with the Outline

for Clothes Dryer Transition Duct, UL standard 2158A. Flexible

venting materials are known to collapse, be easily crushed and

trap lint. These conditions will obstruct clothes dryer airflow and

increase the risk of fire. Ensure the present duct is free of

any lint prior to installing dryer duct.

Page 4

f

iI _ i i_i

ii _iII_

Correct

Correct

DO

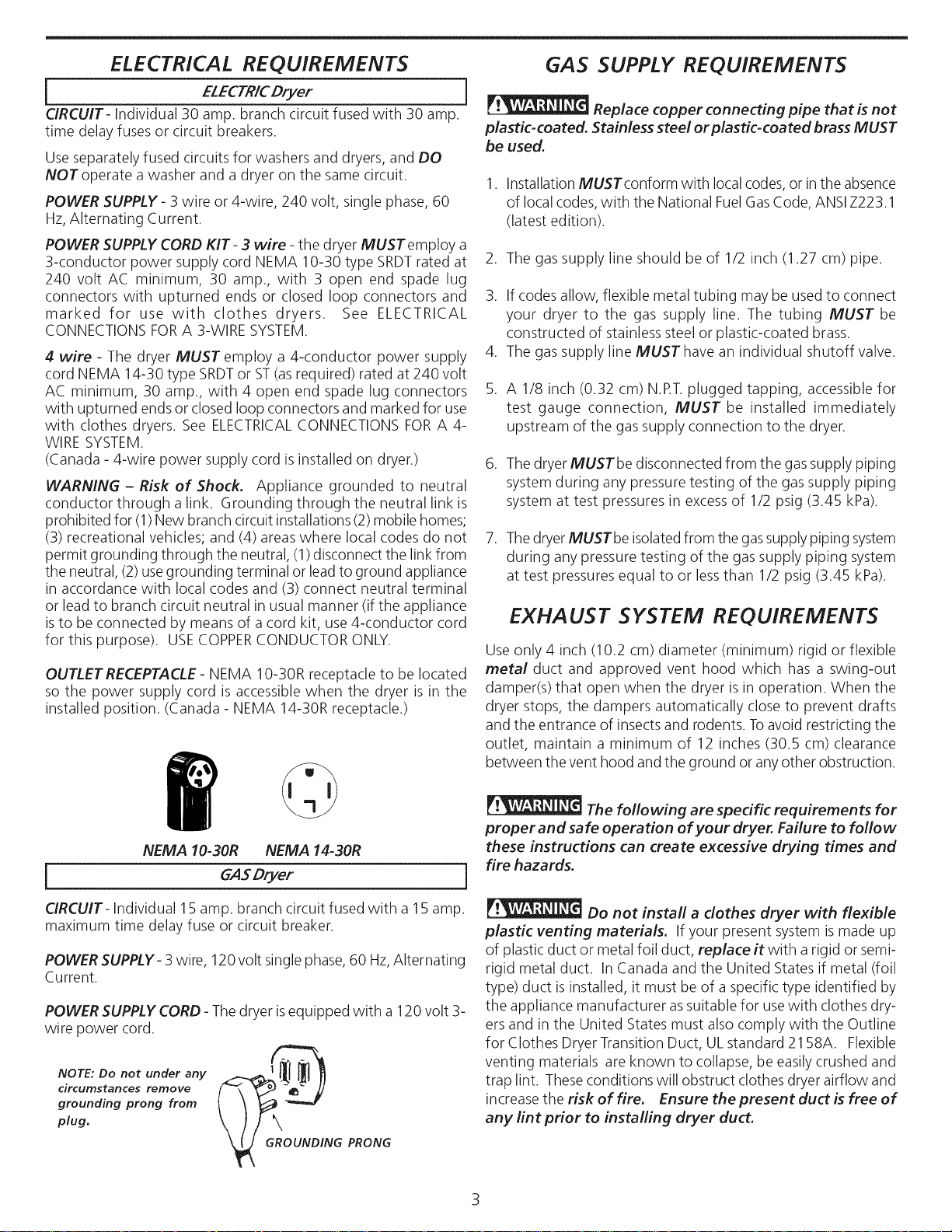

Explosion hazard. Do not install the dryer

where gasoline or other flammables are kept or stored. If

the dryer is installed in a garage, it must be a minimum of 18

inches (45.7 cm) above the floor. Failure to do so can result in

death, explosion, fire or burns.

MAXIMUM LENGTH

of 4" (10.2 cm) Dia. Rigid Metal Duct

VENT HOOD TYPE

\,y

Incorrect

E

Number

of

90 °

Turns

0

1

2

3

4

(Preferred)

Louvered

(10.2 cm)

50 ft.(18.28 m)

52 ft.(15.84 m) 40 ft.(12.19 m)

44 ft.(13.41 m) 32 ft. (9.75 m)

32 ft.(9.75 m) 24 ft. (7.31 m)

28 ft.(8.53 m) 16 ft. (4.87 m)

(6.35cm)

48 ft.(14.53 m)

MAXIMUM LENGTH

of 4" (10.2 cm) Dia. Flexible Metal Duct

VENT HOOD TYPE

_(Preferred)

Incorrect

Number

of

90 °

Turns

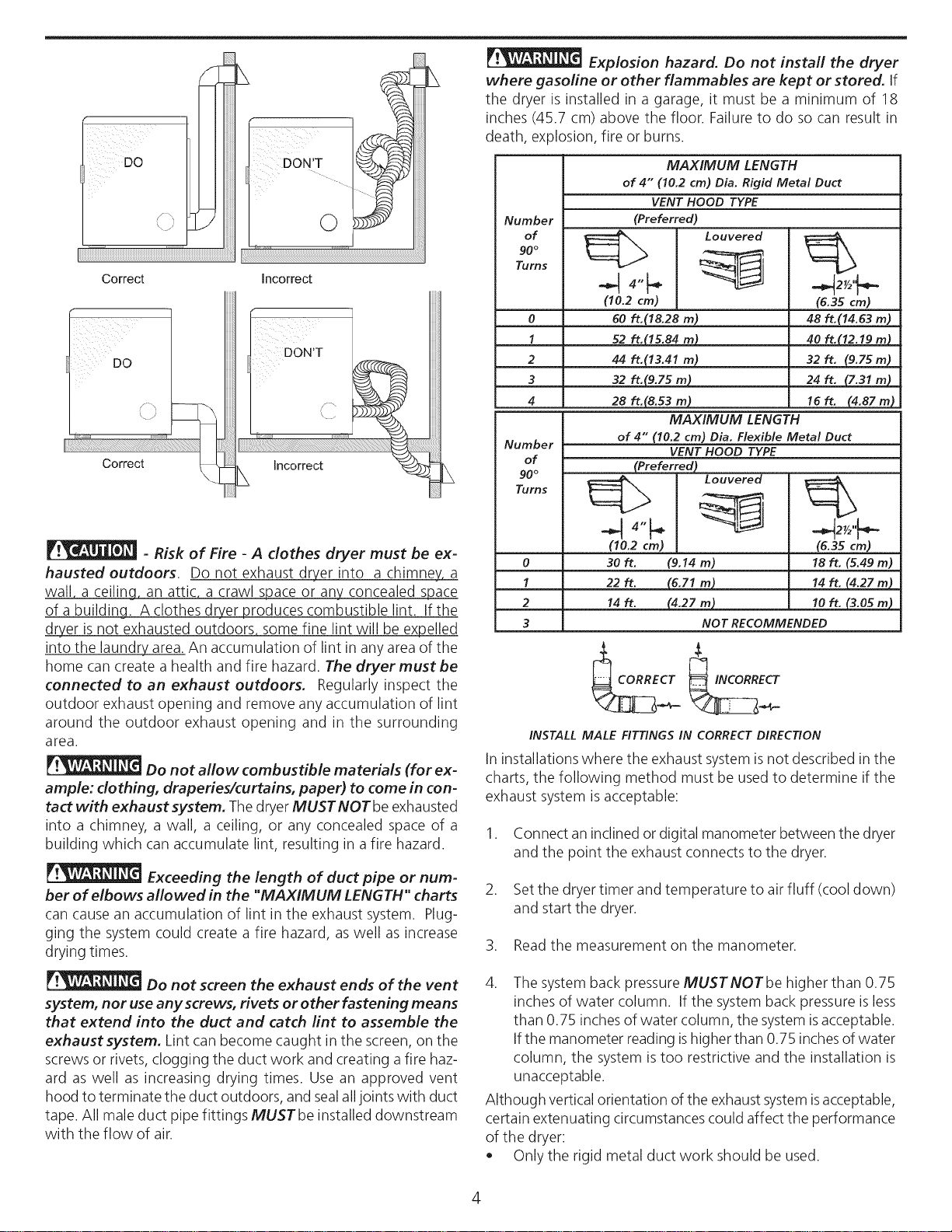

- Risk of Fire - A clothes dryer must be ex-

hausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building A clothes dryer produces combustible lint. If the

dryer is not exhausted outdoors some fine lint will be expelled

into the laundry area. An accumulation of lint in any area of the

home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors, Regularly inspect the

outdoor exhaust opening and remove any accumulation of lint

around the outdoor exhaust opening and in the surrounding

area.

Do not allow combustible materials (for ex-

ample: clothing, draperies/curtains, paper) to come in con-

tact with exhaust system. Thedryer MUSTNOT be exhausted

into a chimney, a wall, a ceiling, or any concealed space of a

building which can accumulate lint, resulting in a fire hazard.

Exceeding the length of duct pipe or num-

ber of elbows allowed in the "MAXIMUM LENGTH" charts

can cause an accumulation of lint in the exhaust system. Plug-

ging the system could create afire hazard, as well as increase

drying times.

_10.2 cm)

0

1

2

3

INSTALL MALE FITTINGS IN CORRECT DIRECTION

30 ft. (9.14 m)

22 ft. (6.71 m)

14 ft. (4.27 m)

I Louvered

(6.35cm)

18ft. (5.49m)

14 ft. (4.27 m)

lO ft. (3.05m)

NOT RECOMMENDED

CT

In installations where the exhaust system is not described inthe

charts, the following method must be used to determine if the

exhaust system is acceptable:

1. Connect an inclined or digital manometer between the dryer

and the point the exhaust connects to the dryer.

2. Setthe dryer timer and temperature to air fluff (cool down)

and start the dryer.

3. Read the measurement on the manometer.

Do not screen the exhaust ends of the vent

system, nor use any screws, rivets or other fastening means

that extend into the duct and catch lint to assemble the

exhaust system, Lint can become caught in the screen, on the

screws or rivets, clogging the duct work and creating a fire haz-

ard as well as increasing drying times. Use an approved vent

hood to terminate the duct outdoors, and sealalljoints with duct

tape. All male duct pipe fittings MUSTbe installed downstream

with the flow of air.

4. The system back pressureMUSTNOTbe higher than 0.75

inches of water column. Ifthe system back pressure is less

than 0.75 inches of water column, the system isacceptable.

If the manometer reading ishigher than 0.75 inchesof water

column, the system is too restrictive and the installation is

unacceptable.

Although vertical orientation of the exhaust system isacceptable,

certain extenuating circumstances could affect the performance

of the dryer:

• Only the rigid metal duct work should be used.

Page 5

• Ventingverticalthrougharoofmayexposetheexhaustsystem

todowndraftscausinganincreaseinventrestriction.

Runningtheexhaustsystemthroughanuninsulatedareamay

causecondensationandfasteraccumulationoflint.

Compression or crimping of the exhaust system will cause an

increase in vent restriction.

The exhaust system should be inspected and cleaned a minimum

of every 18 months with normal usage. The more the dryer is

used, the more often you should check the exhaust system and

vent hood for proper operation.

EXHAUST DIRECTION

All dryers shipped from the factory are set up for rear exhausting.

However, on electric dryers, exhausting can be to the right or left

side of the cabinet or the bottom of the dryer. On gas dryers,

exhausting can beto the right side of the cabinet orthe bottom of

the dryer. Directional exhausting can be accomplished by install-

ing ExhaustKit, P/N131456800, available through your parts dis-

tributor. Follow the instructions supplied with the kit.

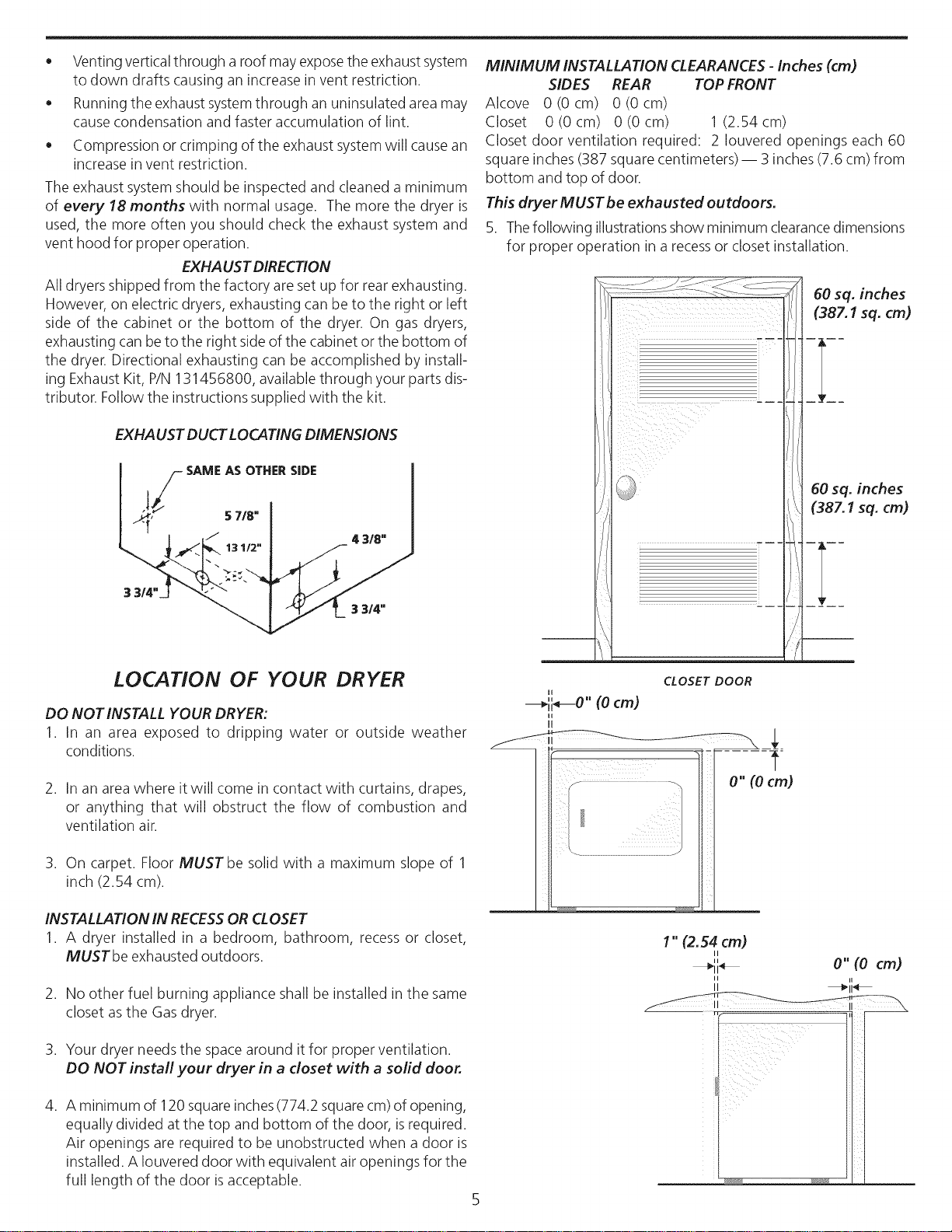

EXHAUST DUCT LOCATING DIMENSIONS

AS OTHER SIDE

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0(0cm) 0(0cm)

Closet 0 (0 cm) 0 (0 cm) 1 (2.54 cm)

Closet door ventilation required: 2 Iouvered openings each 60

square inches (387 square centimeters)-- 3 inches (7.6 cm) from

bottom and top of door.

This dryer MUST be exhausted outdoors.

5 Thefollowing illustrations show minimum clearancedimensions

for proper operation in a recessor closet installation.

3 3/4"

3 3/4"

LOCATION OF YOUR DRYER

DO NOTINSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside weather

conditions.

2. In an area where it will come in contact with curtains, drapes,

or anything that will obstruct the flow of combustion and

ventilation air.

3. On carpet. Floor MUST be solid with a maximum slope of 1

inch (2.54 cm).

INSTALLATION IN RECESSOR CLOSET

1. A dryer installed in a bedroom, bathroom, recess or closet,

MUSTbe exhausted outdoors.

2. No other fuel burning appliance shall be installed in the same

closet as the Gasdryer.

II

ii mm

---_,_--0 (Ocm)

II

II

CLOSET DOOR

o" (Ocrn)

1" (2.54 cm)

_11 "_

II

u

II

II

0"(0 cm)

ii

_11 _

3. Your dryer needs the spacearound it for proper ventilation.

DO NOT install your dryer in a closet with a solid door.

,

A minimum of 120 squareinches (774.2 square cm) of opening,

equally divided at the top and bottom of the door, isrequired.

Air openings are required to be unobstructed when a door is

installed. A Iouvered door with equivalent air openings for the

full length of the door is acceptable.

Page 6

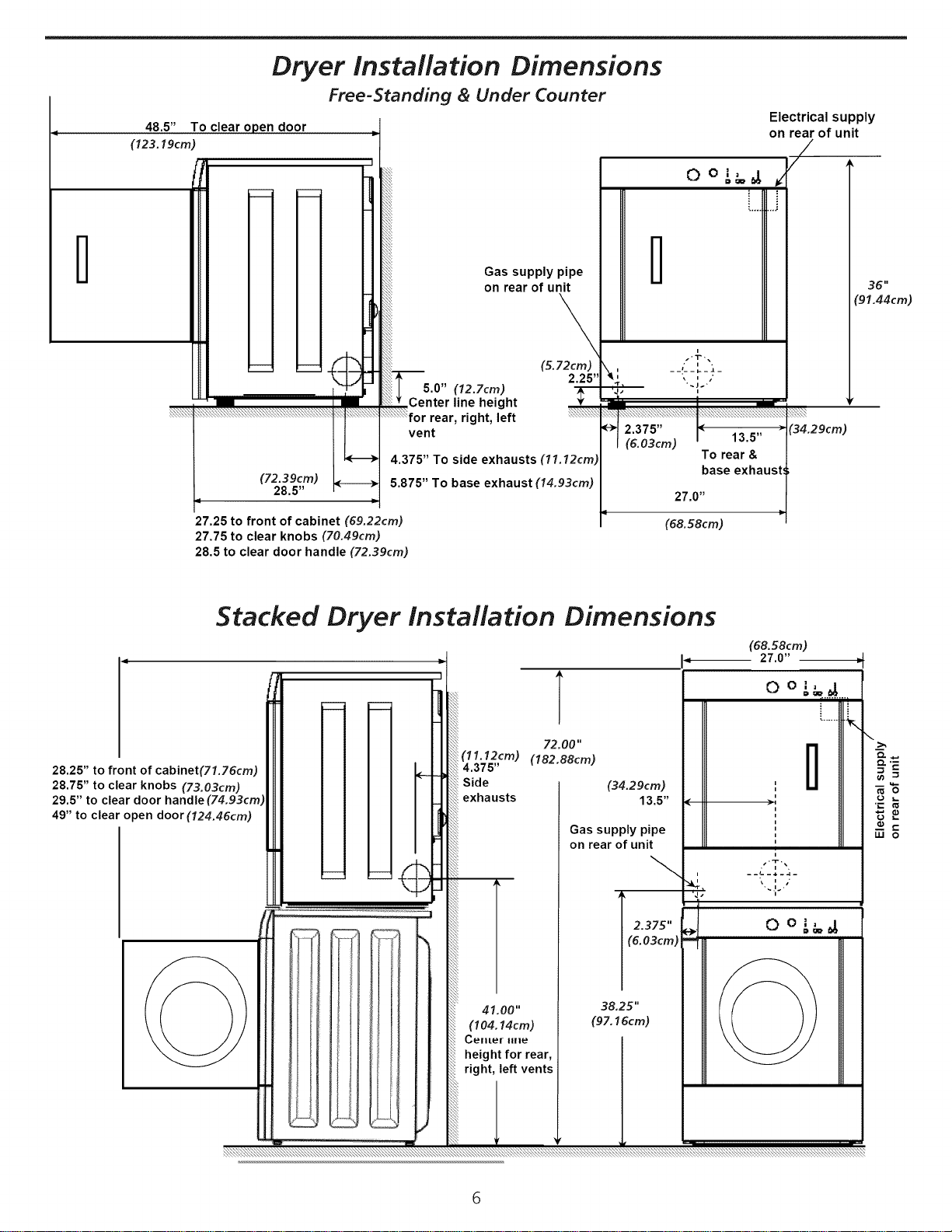

48.5" To clear open door

(123.19cm)

Dryer Installation Dimensions

Free-Standing & Under Counter

i

Electrical supply

on rear of unit

/

/

0 o,_

i.......i

D

27.25 to front of cabinet (69.22cm)

27.75 to clear knobs (70.49cm)

28.5 to clear door handle (72.39cm)

Stacked Dryer Installation Dimensions

Ja

28.25" to front of cabinet(71.76cm)

28.75" to clear knobs (73.03cm)

29.5" to clear door handle (74.93cm)

49" to clear open door(124.46cm)

(72.39cm)

28.5"

Gas supply pipe

on rear of unit

\

(5. 72cm)

5.0" (12.7cm)

Center line height

rear, right, left

vent

4.375" To side exhausts (11.12cm)

5.875" To base exhaust (14.93cm)

(11.12cm)

4.375"

Side

exhausts

2.25 _

T

72.00"

(182.88cm)

Gas supply pipe

on rear of unit

_r_

'j,

(34.29cm)

13.5" <

D

r i- J

27.0"

(68. 58cm)

i

j.'r',_

i

To rear &

base exhaust.,

4

i

l=

(68. 58cm)

27.0"

001

i

t ..-r-.

--_--+--4-

l

36"

(91.44cm)

(94.29cm)

°_,

l

0 i.

ILl 0

2.375"

(6.o3cm)_

JI_ , 'dl"

41.00"

(104.14cm)

height for rear,

right, left vents

38.25"

(97.16cm)

J

Page 7

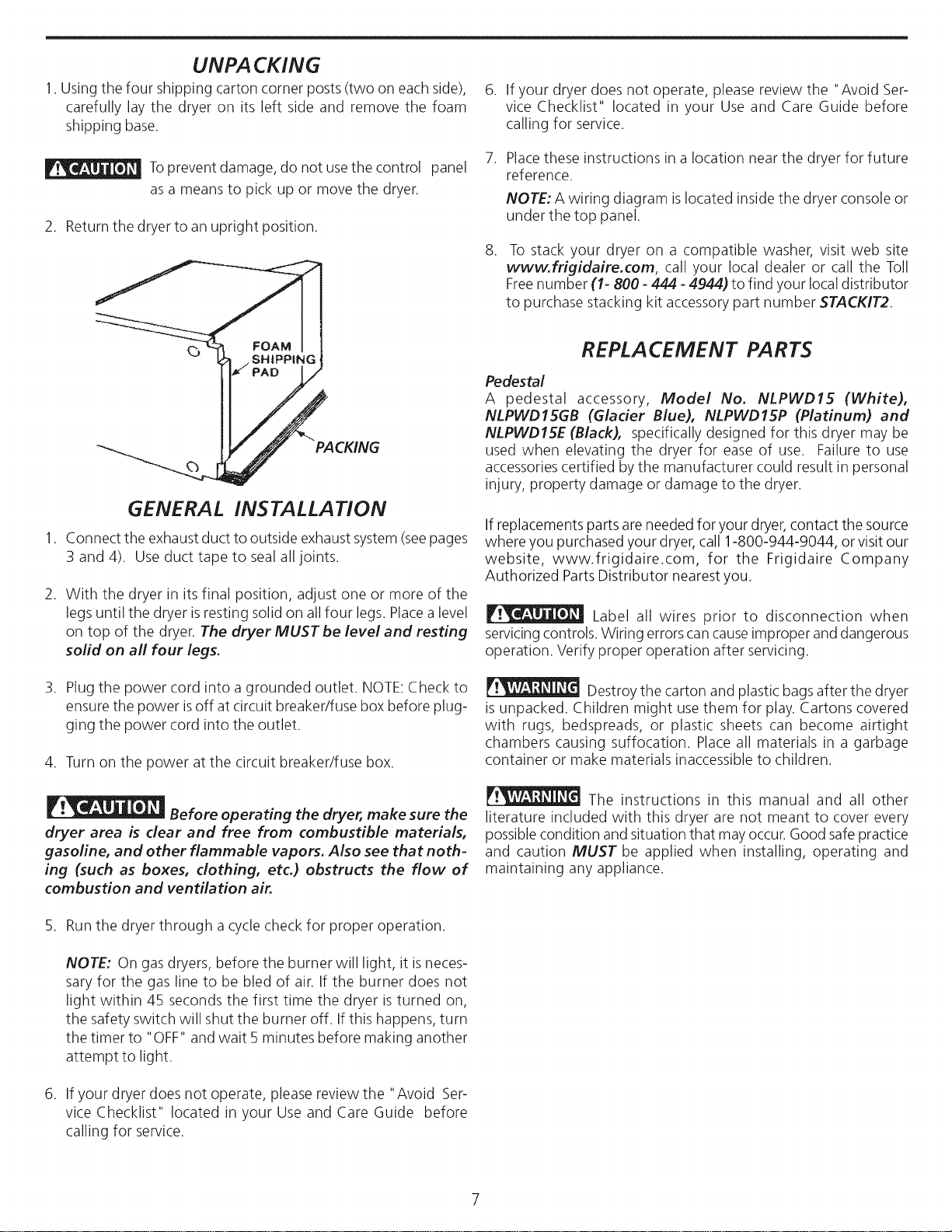

UNPACKING

1. Using the four shipping carton corner posts (two on each side),

carefully lay the dryer on its left side and remove the foam

shipping base.

Toprevent damage, do not usethe control panel

as a means to pick up or move the dryer.

2. Return the dryer to an upright position.

,

If your dryer does not operate, please review the "Avoid Ser-

vice Checklist" located in your Use and Care Guide before

calling for service.

,

Placethese instructions in a location near the dryer for future

reference.

NOTE: A wiring diagram is located inside the dryer console or

under the top panel.

,

To stack your dryer on a compatible washer, visit web site

www, frigidaire.com, call your local dealer or call the Toll

Freenumber (1- 800 -444 - 4944) tofind your local distributor

to purchase stacking kit accessory part number STACKIT2.

FOAM

PAD

PACKING

GENERAL INSTALLATION

,

Connect the exhaust duct to outside exhaust system (seepages

3 and 4). Use duct tape to seal all joints.

,

With the dryer in its final position, adjust one or more of the

legs until the dryer isresting solid on all four legs. Placea level

on top of the dryer. The dryer MUST be level and resting

sofid on all four legs.

3. Plug the power cord into a grounded outlet. NOTE: Check to

ensure the power isoff at circuit breaker/fuse box before plug-

ging the power cord into the outlet.

4. Turn on the power at the circuit breaker/fuse box.

_ -" " ' Before operating the dryer, make sure the

dryer area is clear and free from combustible materials,

gasoline, and other flammable vapors. Also see that noth-

ing (such as boxes, clothing, etc.) obstructs the flow of

combustion and ventilation air.

REPLA CEMENT PARTS

Pedestal

A pedestal accessory, Model No. NLPWD15 (White),

NLPWD15GB (Glacier Blue), NLPWD15P (Platinum) and

NLPWD15E (Black), specifically designed for this dryer may be

used when elevating the dryer for ease of use. Failure to use

accessoriescertified by the manufacturer could result in personal

injury, property damage or damage to the dryer.

If replacements parts are needed for your dryer, contact the source

where you purchased your dryer, call 1-800-944-9044, orvisit our

website, www.frigidaire.com, for the Frigidaire Company

Authorized PartsDistributor nearest you.

Label all wires prior to disconnection when

servicingcontrols. Wiring errorscan causeimproper and dangerous

operation. Verify proper operation after servicing.

Destroy the carton and plastic bags after the dryer

is unpacked. Children might use them for play. Cartons covered

with rugs, bedspreads, or plastic sheets can become airtight

chambers causing suffocation. Place all materials in a garbage

container or make materials inaccessible to children.

The instructions in this manual and all other

literature included with this dryer are not meant to cover every

possible condition andsituation that may occur. Good safe practice

and caution MUST be applied when installing, operating and

maintaining any appliance.

5. Runthe dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is neces-

sary for the gas line to be bled of air. If the burner does not

light within 45 seconds the first time the dryer is turned on,

the safety switch will shut the burner off. If this happens, turn

the timer to "OFF" and wait 5 minutes before making another

attempt to light.

6. If your dryer does not operate, please review the "Avoid Ser-

vice Checklist" located in your Use and Care Guide before

calling for service.

Page 8

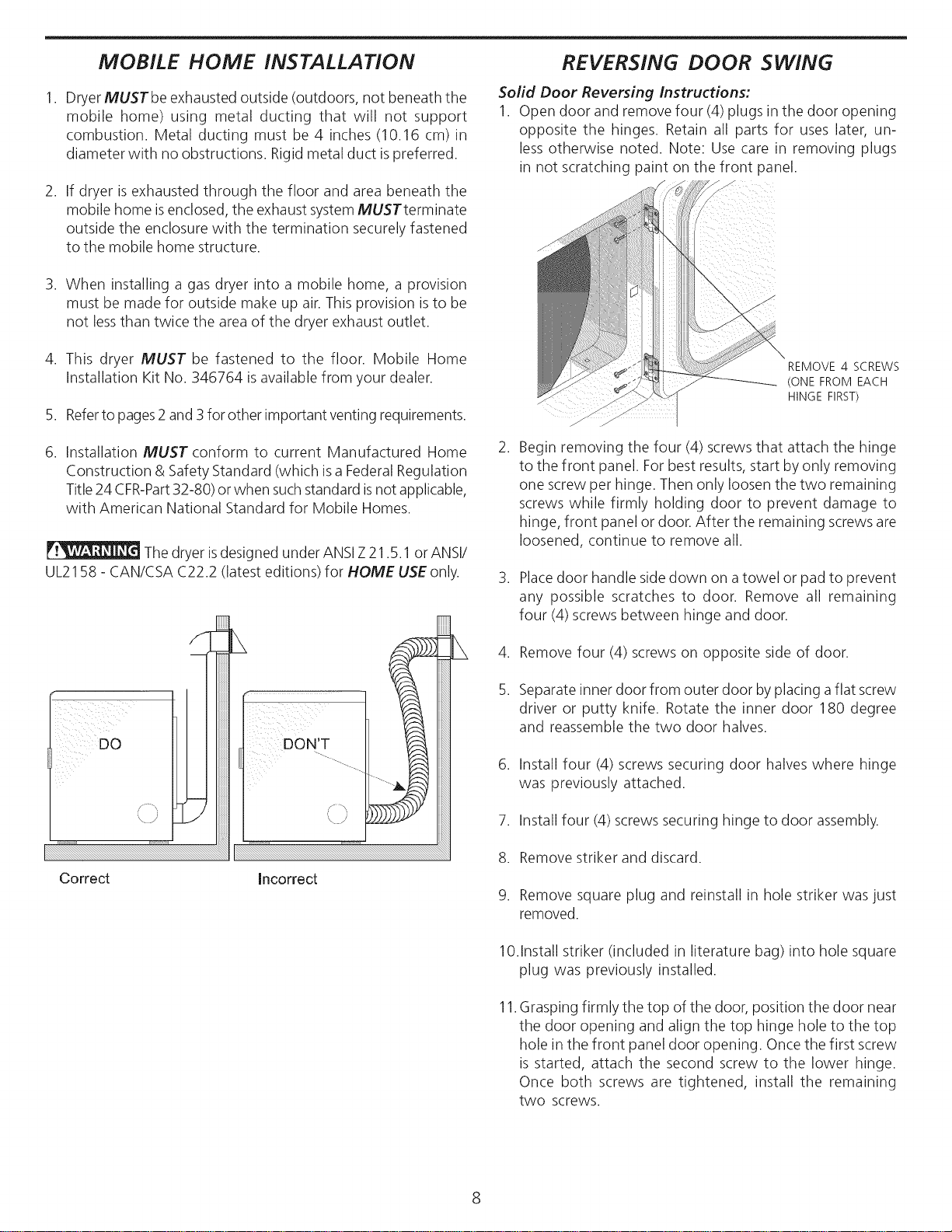

MOBILE HOME INSTALLATION

REVERSING DOOR SWING

,

Dryer MUSTbe exhausted outside (outdoors, not beneath the

mobile home) using metal ducting that will not support

combustion. Metal ducting must be 4 inches (10.16 cm)in

diameter with no obstructions. Rigid metal duct is preferred.

,

If dryer isexhausted through the floor and area beneath the

mobile home isenclosed, the exhaust systemMUST terminate

outside the enclosure with the termination securely fastened

to the mobile home structure.

,

When installing a gas dryer into a mobile home, a provision

must be made for outside make up air. This provision is to be

not lessthan twice the area of the dryer exhaust outlet.

,

This dryer MUST be fastened to the floor. Mobile Home

Installation Kit No. 346764 isavailable from your dealer.

,

Referto pages2and 3 for other important venting requirements.

6.

Installation MUST conform to current Manufactured Home

Construction & Safety Standard (which isaFederal Regulation

Title 24 CFR-Part32-80) or when such standard isnot applicable,

with American National Standard for Mobile Homes.

The dryer isdesigned under ANSI Z21.5.1 or ANSI/

UL2158 - CAN/CSA C22.2 (latest editions) for HOME USE only.

Sofid Door Reversing Instructions:

1. Open door and remove four (4) plugs in the door opening

opposite the hinges. Retain all parts for uses later, un-

less otherwise noted. Note: Use care in removing plugs

in not scratching paint on the front panel.

REMOVE 4 SCREWS

(ONE FROM EACH

HINGE FIRST)

,

Begin removing the four (4) screws that attach the hinge

to the front panel. Forbest results, start by only removing

one screw per hinge. Then only loosen the two remaining

screws while firmly holding door to prevent damage to

hinge, front panel or door. After the remaining screws are

loosened, continue to remove all.

3. Placedoor handle side down on a towel or pad to prevent

any possible scratches to door. Remove all remaining

four (4) screws between hinge and door.

Correct

\ )'

L

L

4. Remove four (4) screws on opposite side of door.

5. Separate inner door from outer door by placing a flat screw

_iill

ii _: i _

driver or putty knife. Rotate the inner door 180 degree

and reassemble the two door halves.

DON'T

6. Install four (4) screws securing door halves where hinge

was previously attached.

I

'\. S

7. Install four (4) screws securing hinge to door assembly.

8. Remove striker and discard.

incorrect

9. Remove square plug and reinstall in hole striker was just

removed.

l O.Install striker (included in literature bag)into hole square

plug was previously installed.

11.Grasping firmly the top of the door, position the door near

the door opening and align the top hinge hole to the top

hole in the front panel door opening. Once the first screw

is started, attach the second screw to the lower hinge.

Once both screws are tightened, install the remaining

two screws.

Page 9

Window Door Reversal Instructions

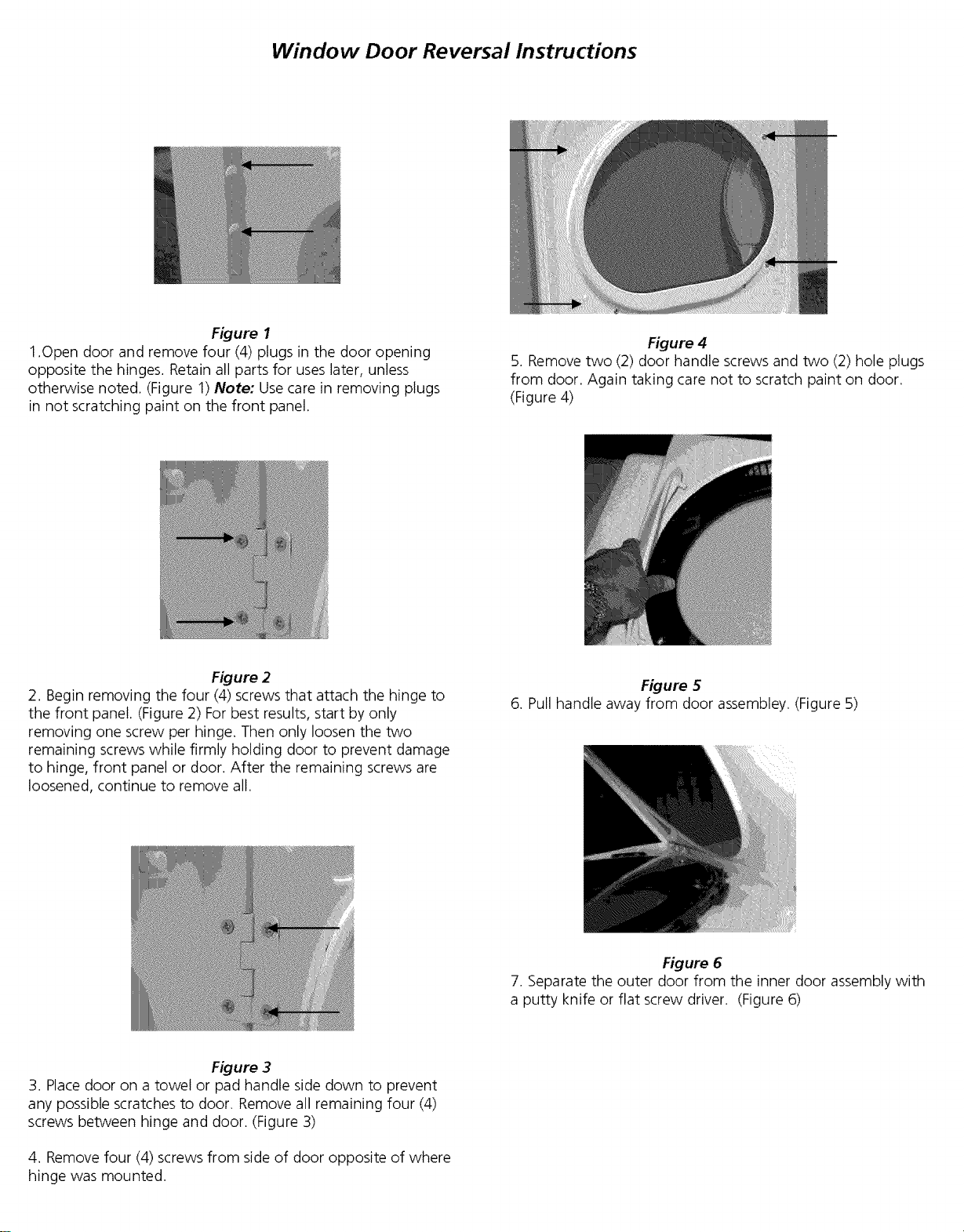

Figure 1

1.Open door and remove four (4) plugs in the door opening

opposite the hinges. Retain all parts for uses later, unless

otherwise noted. (Figure 1)Note: Use care in removing plugs

in not scratching paint on the front panel.

Figure 2

2. Begin removing the four (4) screws that attach the hinge to

the front panel. (Figure 2) For best results, start by only

removing one screw per hinge. Then only loosen the two

remaining screws while firmly holding door to prevent damage

to hinge, front panel or door. After the remaining screws are

loosened, continue to remove all.

Figure 4

5. Remove two (2) door handle screws and two (2) hole plugs

from door. Again taking care not to scratch paint on door.

(Figure 4)

Figure 5

6. Pull handle away from door assembley. (Figure 5)

Figure 3

3. Placedoor on a towel or pad handle side down to prevent

any possible scratches to door. Remove all remaining four (4)

screws between hinge and door. (Figure 3)

4. Remove four (4) screws from side of door opposite of where

hinge was mounted.

Figure 6

7. Separate the outer door from the inner door assembly with

a putty knife or flat screw driver. (Figure 6)

Page 10

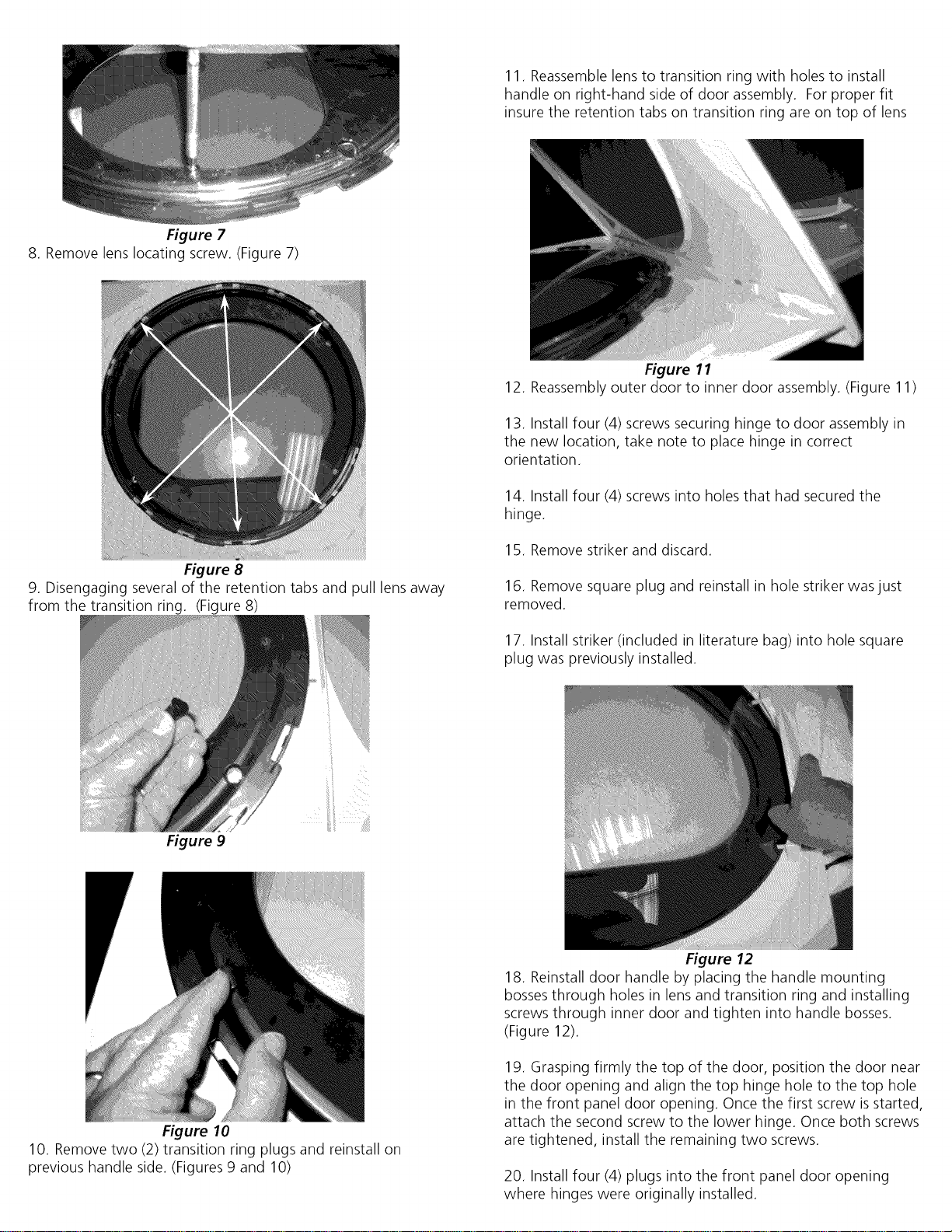

Figure 7

8. Remove lens locating screw. (Figure 7)

11. Reassemble lens to transition ring with holes to install

handle on right-hand side of door assembly. For proper fit

insure the retention tabs on transition ring are on top of lens

Figure 11

12. Reassembly outer door to inner door assembly. (Figure 11)

13. Install four (4) screws securing hinge to door assembly in

the new location, take note to place hinge in correct

orientation.

14. Install four (4) screws into holes that had secured the

hinge.

Figure 8

9. Disengaging several of the retention tabs and pull lens away

from the transition ring. (Figure 8)

Figure 9

15. Remove striker and discard.

16. Remove square plug and reinstall in hole striker was just

removed.

17. Install striker (included in literature bag) into hole square

plug was previously installed.

Figure 12

18. Reinstall door handle by placing the handle mounting

bossesthrough holes in lens and transition ring and installing

screws through inner door and tighten into handle bosses.

(Figure 12).

Figure 10

10. Remove two (2) transition ring plugs and reinstall on

previous handle side. (Figures 9 and 10)

19. Grasping firmly the top of the door, position the door near

the door opening and align the top hinge hole to the top hole

in the front panel door opening. Once the first screw isstarted,

attach the second screw to the lower hinge. Once both screws

are tightened, install the remaining two screws.

20. Install four (4) plugs into the front panel door opening

where hinges were originally installed.

Page 11

ELECTRICAL INSTALLATION

-i

Canadian ELECTR/CDryer j

I ELECTR/CDryer I

The following are specific requirements for

proper and safe electrical installation of your dryer. Failure

to follow these instructions can create electrical shock and/

or a fire hazard.

This appliance MUST be properly grounded.

Electrical shock can result if the dryer is not properly grounded.

Follow the instructions in this manual for proper grounding.

Do not use an extension cord with this dryer.

Some extension cords are not designed to withstand the amounts

of electrical current this dryer utilizes and can melt, creating

electrical shock and/or fire hazard. Locate the dryer within reach

of the receptacle for the length power cord to be purchased,

allowing some slack in the cord. Refer to the pro-installation

requirements in this manual for the proper power cord to be

purchased.

A U.L. approved strain relief must be installed

onto power cord. If the strain relief isnot attached, the cord can

be pulled out of the dryer and can be cut byany movement of the

cord, resulting in electrical shock.

Do not use an aluminum wired receptacle with

a copper wiredpower cord andplug (or vice versa). A chemical

reaction occurs between copper and aluminum and can cause

electrical shorts. The proper wiring and receptade is a copper

wired power cord with a copper wired receptacle.

NOTE: Dryers operating on 208 volt power supply will have longer

drying times than operating on 240 volt power supply.

GROUNDING REQUIREMENTS

I USA ELECTR/CDryer 1

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check with a

licensed electrician if you are in doubt asto whether the appliance

isproperly grounded.

For a grounded, cord-connected dryer:

1. The dryer MUSTbe grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electricalshock

by a path of least resistancefor electrical current.

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check with a

licensed electrician if you are in doubt asto whether the appliance

isproperly grounded.

Fora grounded, cord-connected dryer:

1. The dryer must be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock

by a path of least resistance for electrical current.

,

Since your dryer isequipped with a power supply cord having

an equipment-grounding conductor and a grounding plug, the

plug must be plugged into an appropriate outlet that isproperly

installed and grounded in accordance with all local codes and

ordinances. If in doubt, call a licensed electrician. Do not

modify plug provided with the appliance.

ALL GASDryers

1.The dryer isequipped with a three-prong (grounding) plug

for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong

from the plug.

GAS CONNECTION

,

Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOTconnect the dryer to L.R gas servicewithout

converting the gasvalve.An L.Rconversion kit must be installed

by a qualified gas technician.

2.Connect a 1/2 inch (1.27 cm)I.D, semi-rigid or approved pipe

from gas supply line to the 3/8 inch (0.96 cm) pipe located on

the back of the dryer (seepages 6 and 7). Use a 1/2 inch to 3/

8 inch (1.27 cm to 0.96 cm) reducer for a connection. Apply

an approved thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

3. Open the shutoff valve in the gas supply line to allow gas to

flow through pipe.

4. Test all connections by brushing on asoapy water solution.

NEVER test for gas leaks with an open flame.

,

If your dryer isequipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the

plug MUST be plugged into an appropriate, copper wired

receptacle that is properly installed and grounded in

accordance with all local codes and ordinances. If in doubt,

call a licensed electrician. Do not modify plug provided

with the appliance.

For a permanently connected dryer:

1. ThedryerMUSTbe connected to a grounded metal, permanent

wiring system;or an equipment grounding conductor must be

run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

VALVE OPEN /

GAS FLOW POSITION

11

Page 12

ELECTRICALCONNECTIONS

FOR 3-WIRE SYSTEM

[

1.

Remove the screws securing the terminal block access cover

USA ELECTRICDryer

and the strain relief mounting bracket located on the back of

the dryer upper corner.

,

install a U.L. approved strain relief into the power cord entry

hole of the mounting bracket. Finger tighten the nut only at

this time.

GREEN

GROUND

SCREW

NEUTRAL

GROUND

WIRE

SILVERTERMINAL

IUT

TIGHTEN NUT

TO THESE

THREADS

ELECTRICALCONNECTIONS FOR4-WIRE SYSTEM

[

USA ELECTRICDryer

J

1.

Remove the screws securing the terminal block accesscover

and the strain relief mounting bracket located on the back of

the dryer upper corner.

,

Install a U.L. approved strain relief in the entry hole of the

mounting bracket. Finger tighten the nut only at this time.

,

Remove the ground wire from the green ground screw

located above the terminal block.

GREEN GROUND WIRE

GROUND _ SILVERTERMINAL

SCREW _ [_._,_.._ . /

_ __:_TERMINALBLOCK

NEUTRAL-- YY BACK 'o H? g2UT

GREEN POWER CORD

]

RELIEF

MOUNTING

BRACKET

,

Thread a U.L. approved 30 amp. power cord, NEMA 10-30

POWER CORD

type SRDT,through the strain relief.

,

Attach the power cord neutral (center wire) conductor to the

silver colored center terminal on the terminal block. Tighten

the screw securely.

,

Attach the remaining two power cord outer conductors to the

outer brass colored terminals on the terminal block. Tighten

both screws securely.

Do not make a sharp bend or crimp wiring/

conductor at connections.

,

Reattach the strain relief mounting bracket to the back of the

dryer with two screws. Tighten screws securely.

,

Tighten the screws securing the cord restraint firmly against

the power cord.

,

Tighten the strain relief nut securely so that the strain relief

does not turn.

9. Reinstall the terminal block cover.

A NUT

/ MoRuENTING

_/// RELIEF

/ /POWERCORD

4. Thread a U.L. approved 30 amp power cord, NEMA 14-30

type STor SRDTthrough the strain relief.

TYPICAL 4

CONDUCTOR_ TYPICAL 4 BLACK

30 AMP NEMA 14-30 TYPE SRDT OR ST _GREEN

5. Attach the green power cord ground wire to the cabinet with

the green ground screw.

,

Attach the white (neutral) power cord conductor from the

power cord and the neutral ground wire from the dryer harness

to the silver-colored center terminal on the terminal block.

Tighten the screw securely.

7. Attach the red and black power cord conductors to the outer

brass-colored terminals on the terminal block.

Do not make a sharp bend or crimp wiring/

conductor at the connections.

8. Tighten the screws securing the cord restraint firmly against

the power cord.

COND UCTOR _ WHITE

9. Tighten the strain relief nut securely so the strain relief does

not turn.

l O.Reinstallthe terminal block accesscover.

12

Page 13

Table des matieres

Avant I'installation ............................................................................................................................................................ 13

Installation _lectrique .................................................................................................................................................... 14

Alimentation en gaz......................................................................................................................................................... 14

Evacuation de I'air .................................................................................................................................................. 14-16

Emplacement de la s_cheuse........................................................................................................................................... 16

Dimensions de I'emplacement ................................................................................................................................. 17

D_ballage ..................................................................................................................................................... 18

Installation .......................................................................................................................................................... 18

Pi_ces de rechange ......................................................................................................................................................... 18

Installation dans une maison mobile .................................................................................................................................. 19

Porte R_versible ............................................................................................................................................... 19-21

Installation _lectrique ....................................................................................................................................................... 22

Mise _ la torte ................................................................................................................................................................ 22

Branchement du Gaz ............................................................................................................................................................. 22

Branchement _lectrique - Installation _ 3 fils ........................................................................................................................ 23

Branchement _lectrique - Installation _4 fils ........................................................................................................................ 23

Mesures de Securite Importantes

L'installation et le service de la S_cheuse de v_tements doivent _tre effectu_s par un installateur qualifiO, I'agence de

service ou le fournisseur de gaz. Installez la SOcheuse de v_tement selon les instructions du fabricant et les codes Iocaux.

Avant de commencer, fire attentivement le prOsent document. Cela simplifiera I'installation et assurera la pose

correcte et s_curitaire de la s_cheuse. Apr_s I'installation, laisser ce document b proximit_ de la s_cheuse pour rOf_rence

future.

REMARQUE : L'alimentation _lectrique de la s_cheusedoit respecter lescodeset ordonnances Iocaux ainsi que I'_dition laplus r_cente

du Code ANSI/NFPA70, ou au Canada, leCode canadien d'_lectricit_, ACNOR C22.1, pattie1.

REMARQUE : L'alimentation en gazde la s_cheusedoit respecter loscodes et ordonnances Iocaux ainsique I'_dition la plus r_cente du

Code ANSI Z223.1, ou au Canada, le code CAN/ACG B149.1-2000.

REMARQUE : Las_cheuse est concue conform_ment au code ANSIZ21.5.1 ou ANSI/UL 2158 - CAN/AC G C22.2 No. 112 (l'_dition la

plus r_cente) pour un USAGEDOMESTIQUEseulement. Cette s_cheusen'est pasrecommand_e pour utilisation commerciale, comme

par exemple un restaurant ou un salon de coiffure, etc.

Votre securite et cello des autres est tres importante.

Nous donnons de nombreux messagesdes_curit_ importants dans cemanuel et survotre appareil m_nager. Assurez-vous detoujours

life tous losmessages de s_curit_ et de vous y conformer.

Voici lesymbole de mise en garde. Ce symbole met en garde contre los risques pouvant entratner le d_c_s ou des blessures

soiou aux autres. Tous losmessages relatifs _ la s_curit_ sont precedes du symbole de mise en garde et du terme <<DANGER

>>ou <<AVERTISSEMENT>>.Ces termes signifient :

_ L'utilisateur sera tu_ gravement bless_ s'il ne suit pas cos directives.

_ L'utilisateur peut _tre tug ou gravement bless_ s'il ne suit pas ces directives.

Tous los messages relatifs b la s_curit_ indiquent le risque, comment r_duire le risque de blessure et ce qui peut

survenir si on ne suit pas les directives.

RISQUE D'INCENDIE. Pour votre s_curit_, suivre lesdirectives _nonc_es dans le present guide afin de minimiser

los risques d'incendie, d'explosion, de dommages materiels, de blessures et de mort. GARDEZ CESINSTRUCTIONS.

- Ne pas entreposer ni utiliser d'essence ou autres liquides ou produits inflammables _ proximit_ de cette s_cheuse ou de tout

autre appareil m_nager.

- QUE FAIRE S'IL YA UNE ODEUR DE GAZ

• Ne mettre en marche aucun appareil .

Ne toucher aucun interrupteur _lectrique; n'utiliser aucun t_l_phone dans I'immeuble.

Faire sortir tous los occupants de la piece, de I'immeuble ou de lazone avoisinante.

Appeler la fournisseur de gaz imm_diatement en utilisant le t_l_phone d'un voisin. Suivre los directives du fournisseur de

gaz.

S'il est impossible de joindre le fournisseur de gaz, appeler le service de protection des incendies.

L'installation et los r_parations doivent _tre effectu_es par un service de r_paration, un technicien quali% ou lefournisseur de gaz.

AVANT L'INSTALLATION

Outils et mat_riel requis pour l'instaflation :

1. Tournevis_ pointecruciforme 6.

2. Pinto multiprise 7.

3. Niveau de menuisier 8.

4. Tournevis _ pointe plate ou _ lame droite 9.

5. Rubanadh_sif pour conduits

13

Conduite en m_tal rigide ou souple de 10,2 cm (4 po)

Bouche d-_vacuation d'air

Ruban ou p_te d'_tanch_it_ pot joints filet_s (modUle _ gaz)

Couteau _ mastic en plastique

Page 14

INSTALLATION ELECTR/OUE

[ SOcheu, e_'tLECTR/QUES ]

CiRCUiT- D_rivation distincte de 30 Aavec fusibles b retardement

ou disjoncteurs d'au 30 A.

Utilisez descircuits avec un disjoncteur ou fusible s@ar_ pour les

machines _ laver et s_cheuses, et NE PASfaire fonctionner une

machine _ laver et une s_cheuse sur un m_me circuit.

AL/MENTATIONL'LECTRIQUE- 3 ills, 240 volts, une phase,60 Hz,

courant alternatif. (Canada -240 volts, une phase, 60 Hz, courant

alternatif.)

CORDOND'ALIMENTATION_'LECTRIQUE-3FILS- Las_cheuse

DOlT _tre reli_e _ un cordon d'alimentation _lectrique

3 conducteurs NEMA 10-30 detype SRDTd'une capacit_ minimale

de 240 volts, courant alternatif, 30 A, avecfiche en L_3 broches

pleines ou repli_es concue pour le branchement d'une s_cheuse.

Se reporter _ la section BRANCHEMENT ELECTRIQUED'UNE

INSTALLATION4, 3 FILS.

3FILS- ElleDOIT_tre re%e _un cordon d'alimentation _lectrique

4 conducteurs NEMA 14-30 detype SRDTouST(au besoin)d'une

capacit_ minimale de 240 volts, courant alternatif, 30 A, avecfiche

en L_4 broches pleines ou repli_es conc ue pour le branchement

d'une s_cheuse. Se reporter _ la section BRANCHEMENT

ELECTRIQUED'UNE INSTALLATION4, 4 FILS.

(Canada - Cordon d'alimentation _4 ills branch_ _la s_cheuse.

PRISE - PriseNEMA 10-30R situ_e de facon _ ce que le cordon

d'alimentation _lectrique soit accessible une fois la s_cheuse en

place. (Canada - prise NEMA de 14-30R.)

AVERT/SSEMENT-Risque de choc #lectrique. Un appareil mis

la terre _I'aide d'un lien ou c_ble conducteur neutre. Lamise

laterre _ I'aide d'un conducteur ou c_ble neutre est interdite dans

lescas suivants : (1) les installations de nouveau circuit d_vir_ (2)

lesmaisons mobiles (3)les v_hicules r_cr_atifs ou caravanes et (4)

lesr_gions ou les codesIocaux interdisent la mise _laterre _ I'aide

d'un c_ble ou conducteur neutre. (1) D_branchez le conducteur

ou c_ble du neutre, (2) utilisez la borne de mise _ laterre ou lec_ble

de mise _laterre de I'appareil conform_ment aux codes Iocaux et

(3) connectez ou branchez laborne neutre ou le c_bleau neutre du

circuit d@ir_ dela mani_re habituelle (siI'appareil dolt _tre connect_

I'aide d'un cordon, utilisez un cordon _ 4 c_bles ou ills pour ce

faire). N'UTILISEZQUEDESCABLESOU FILSENCUIVRE.

ALIMENTATION

teLECTRIQUE

PRISE MURALE

(CUIVRE)

,_ BOJTEA FUSIBLES PRINCIPALE NEUTRE A 3

FILS 120-240 VOLTS 60 CYCLES

FUSIBLES A RETARDEMENT OU

DISJONCTEUR DE 30 A

FIL NEUTRE

SOUS RIeSERVE DES

EXIGENCES LOCALES

NEMA 10-30R

(CUIVRE)

j S#cheu_-es_ GAZ ]

CiRCUiT- D_rivation distincte de 15 A avec fusible

retardement ou disjoncteur d'au plus 15 A.

AL/MENTATION _'LECTRIQUE- REMARQUE :

3 ills, 120 volts, une phase, en aucun { '\ _

60 Hz,courant alternatif.

CORDOND'ALIMENTATION /a broche \\ ] )

Il ne faut _j_ %i t#_ [l

cas retirer _ \

_'LECTRIQUE- Las_cheuseest de raise a \ ( J BROCHE DE

pourvue d'un cordon d'alimentation/a terre de _ MISE A LA

@lectrique_3 filsde120 volts, la fiche. " ' TERRE

ALIMENTATION EN GAZ

Remplacer le tuyau de raccordement en

cuivre non recouvert de plastique. II FA UTutiliser du laiton

inoxydable ou recouvert de plastique.

1. L'instal]ation DO/Trespecter les codes Iocaux, ou s'i] n'existe

pas de codes Iocaux, le code ANSI Z223.1 (l'_dition la plus

r_cente) ou au Canada, le Code actuel CAN/CGA B149.

2. Laconduite d'alimentation engazdolt mesurer 1,27 cm(1/2 po).

3. Si lescodes le permettent, un tuyau en m_tal flexible peut 6tre

utilis_ pour connecter la s_cheuse _ I'alimentation en gaz. Le

tuyau DO/T6tre fabriqu_ en acier inoxydable ou en cuivre avec

un rev6tement de plastique.

,

Laconduite d'alimentation en gazDOITcomporter unrobinet

d'arr6t distinct.

5.

Une prise de 0,32 cm (1/8 po) NPT accessible pour le

branchement d'u n manom_tre DO/T6tre install_e toutj uste en

amont du branchement de la conduite d'alimentation en gaz

sur la s_cheuse.

6. La s@cheuseDOlT @tred@branch_ede la canalisation de gaz

pendant toute v_rification de pression de I'alimentation engaz

despressions qui d@assent 3,45 kPa(1/2 Ib/po_).

7. Las_cheuseDOIT_tre isol_ede la canalisation de gaz pendant

toute v@rification de pression de I'alimentation en gaz _ des

pressions _gales ou inf_rieures _ 3,45 kPa(1/2 Ib/po_).

EVA CUATION DE L'AIR

Utiliser uniquement une conduite en m@talrigide ou flexible de

10,2 cm(4 po) de diam_tre (minimum) ainsi qu'une grille de sortie

approuv@epourvue de clapets qui s'ouvrent Iorsque la s_cheuse

fonctionne. Quand la s_cheuse s'arr_te, les clapets se ferment

automatiquement pour @iter lescourants d'air et I'entr_e d'insectes

ou de rongeurs. Afin de ne pasobstruer I'@acuation de I'air, laisser

une distance minimum de 30,5 cm (12 po) entre la grille de sortie

et le solou tout autre obstacle.

Lesmises en garde qui suivent serapportent

directement au fonctionnement correct et s#curitaire de la

s#cheuse. Toute d#rogation b ces mises en garde pourrait

ralentir le s#chage et entrainer des risques d'incendie.

__N'instal/ez pas la S#cheuse avec des materiels de

ventila tion en ma tieres plastiques flexibles.

Silaconduite existante est en plastique ou en papier m_tallique, la

remplacer par une conduite en m_tal rigide ou flexible. Au Canada

et auxEtats-Unissileconduit estde m_tal (type feuille d'aluminium),

celui-ci dolt _tre d'un type sp@cifique identi% par le fabricant,

recommand_ pour I'utilisation avec des S_cheuses ; et aux Etats-

Unis il dolt en outre remplir la norme UL 215% Les mat_riaux de

ventilation flexibles peuvent s'abimer facilement et recueillir du

duvet. Cesconditions obstrueront lacirculation d'air de la%cheuse

de v_tements et augmenteront lerisque d'incendie. S'assurer

qu'il n'y a pas de charpie dans /a conduite existante avant

d'installer la conduite de la s#cheuse.

14

Page 15

_- Risque d'incendie- une S_cheuse de v@tement dolt @tre

a_r_ b I'air libre, N'a@rezpas la S@cheusedans une chemin@e,

une paroi, un plafond, un espaceferm@ou aucun espace cach@du

b_timent. Une s@cheuse_ linge produit de lacharpie combustible.

Si Fair n'@tait pas repouss@_ I'ext@rieurde la maison de petites

particules de charpie seretrouveraient dans lapi@ceou est install@e

la s@cheuse.Toute accumulation de charpie dans la maison peut

pr@senterdes risques pour la sant@et des risques d'incendie. La

s_cheuse dolt @trecennect_e _ une bouche d'_vacua tien vers

I'ext_rieur du b_timent ou de I'immeuble. Vous devezinspecter

r_guli_rement I'_vent ext_rieur et enlever toute accumulation de

charpie autour de I'_vent et danslacavit_ du conduit d'_vacuation.

L _@L

," r

/ 0 ,

Correct Incorrect

OUI

NON

Nombre de

coudes

90 °

0

1

2

3

4

Nombre de

coudes

90°

0

1

2

3

LONGUEUR MAXIMUM

d'une conduite en m#tal rigide de

10,16 cm (4 po) de diam.

TYPEDE GRILLE DE SORTIE

(Recommand_)

volet

cm

(4 po)

18,28 m

15,84m

13,41 m

9,75 m

8,53 m

(60 po) 14,63rr

(52po)

(44 po)

(32 po)

(28 po)

i(48 po)

12,19m (40 po)

9,75 m (32 po)

7,31 m(24 po)

4,87 m (16 po)

LONGUEUR MAXIMUM

d'une conduite en m_tal flexible

10,16 cm (4 po) de diam.

TYPEDE GRILLEDE SORTIE

(Recommand_)

a volet

crn

14po)

9,14 m (30 po)

6,71 m (22 po) 4,27 m (14 po)

4,27m (14 po) i3,05 m (10 po)

NON RECOMMANDI2

5,49 m (18 po)

de

.... s

Correct

Incorrect

_1_ Nelaisseraucun mat_riau inflammable (comme desv_tements,

des tentures, des rideaux ou du papier) entrer en contact avec les

conduits d'_vacuation.

_ Augmenter laIongueur duconduit rigide ou lenombre decoudes

permis autableau _LONGUEURMAXIMUM_ risquede r_duire la

capacit_ d'_vacuation du circuit. Obturer le circuit peut crier un

risque d'incendie et augmenter letemps de s_chage.

_ N'obstruez paslesextr_mit_s du tube deventilation ni utilisez

desvis. rivets ou autres moyens defixation qui peuvent obstruer le

conduit et recueillir du duvet. L'engorgement subsequent risquerait

de ralentir letemps de s_chage,voire decauserunincendie. Installer

une bouche d'_vacuation approuv_e _I'ext_rieur et scellertousles

joints _ I'aide d'un ruban adh_sif _conduits. Tousles raccords de

condu it m_les DO/VE/VI-_tre install_sdans lesensdela circulation

d'air.

Risques d'explesien, Ne pas installer la

s_cheuse_unendroit ou I'on qardedelagazoline outout autreproduit

inflammable. Si la s_cheuse est install_e dans un garage, elle dolt

_tre _un minimum de45,7 cm (18 po) au-dessusdu plancher. Toute

d_rogation pourrait provoquer la mort, I'explosion, I'encendie ou

lesbrOlures.

CORRECT _EC_

POSER LES RACCORDS MALES DANS LA BONNE DIRECTION

Pour lesinstallations dont le circuit d'@vacuation n'est pasd@crit

dans lestableaux, il faut utiliser lam@thode suivante si lecircuit

d'@vacuation n'est pasacceptable:

1. Brancher un manom@tre digital ou _ tube inclin@ entre la

s@cheuseet le raccord d'@vacuation de la s@cheuse.

,

R@glerla minuterie de la s@cheuseet la temp@rature _ air froid

(refroidissement) et d@marrezla s@cheuse.

3.

Life la mesure indiqu@eau manom@tre.

4.

Labassepression nedolt pas @tresup@rieure_ 0,75 pouce de

colonne d'eau. Silabassepression est inf@rieure_0,75 pouce

de colonne d'eau, lecircuit estacceptable. Sila lecture indique

une pression sup@rieure _ 0,75 pouce de colonne d'eau, la

capacit@ducircuit est insuffisante etl'installation inacceptable.

Bien qu'un circuit vertical soit acceptable, certaines circonstances

att@nuantespeuvent influencer la performance de la s@cheuse.

IIfaut utiliser uniquement des conduits rigides en m@tal.

Unesortie sur un toit d'un circuit vertical peut exposer celui-ci

un contre-tirage et ainsi r@duiresa capacit@d'@vacuation.

15

Page 16

• L'isolant que dolt traverser un tel circuit peut causer de la

condensation etainsir_duire la capacit_d'_vacuation du circuit.

Un circuit d'_vacuation comprim_ ou ondulant pout voir sa

capacit_ d'_vacuation r_duite.

IIfaut inspecter le circuit d'_vacuation et le nettoyer au moins

tousles 18mois d'utilisation normale. Plusla s_cheuseestutilis_e,

plus il faut proc_der souvent a une v_rification du bon

fonctionnement ducircuit d'_vacuation et du couvercle du registre

ou de I'_vent.

DIRECTION DEL'k'VACUATION D'AIR

Toutesless@cheusesempaquet@espar l'usine sont concuesdefacon

ce que I'@vacuation d'air se fasse _ I'arri_re. Toutefois, dans le

cas des s@cheuses@lectriques,I'@vacuation d'air pout sefaire sur

la droite ou sur la gauche du bottler ou encore, sous la s@cheuse.

Danslecasdess@cheuses_gaz, I'@vacuationd'air peut sefaire sur

la droite du bottler ou sous la s@cheuse.On pout donc modifier

I'orientation de I'@vacuation d'air en installant un ensemble

d'@vacuation d'air n° de piece 131456800 disponible chez d'un

fournisseur de pi_cesagr@@.Suivrelosdirectives qui accompagnent

cot ensemble.

EMPLA CEMENT DESBOUCHES D"k'VACUATION

,

Une ouverture minimum de 774,2 cm2 (120 po 2) r_partie

%alement entre le haut et le hasde la porte estrequise. Cette

ouverture ne dolt pas_tre obstru_e Iorsque la porte est enplace.

Uneporte _voletsdont lesouverturestotalisent lanorme d_crite

ci-dessus estacceptable.

DE-GAGEMENTSMINIMAUX POUR L'INSTALLATION en po (cm)

D'AVANT COTES ARRIERE DESSUS

AIc6ve ou sous un

comptoir 0 (0) 0 (0) 0 (0) 0 (0)

Armoire 1 (2,54) 0 (0) 0 (0) 0 (0)

A@ration n@cessairedans la porte de I'armoire: 2 ouvertures

persiennes de 60

pouces carr_s (387 cm carr_s) chacun - _ 3 pouces (7,6 cm) du

haset du haut de la porte.

L'Ak'RATION DE CETTESE'CHEUSESEFAIT VERSL'EXTEREUR.

5. Losillustrations qui suivent donnent le d%agement minimum

pour une installation dans une alc6ve ou un placard.

15crn

//-- COMME SUR L'AUTRE COTE

9,5 cn

(3 3/4 po)

11crn

po)

(3 3/4 po)

EMPLA CEMENT DE LA SECHEUSE

NEPASINSTALLER LA SECHEUSE:

1. Dans un endroit expos_ _ un _coulement d'eau ou aux

conditions atmosph_riques.

2. Dans un endroit ou elle serait en contact avec des rideaux,

draperies ou tout cequi obstruera leflux d'air de combustion et

de ventilation.

3. Surun tapis. Leplancher DOIT_tre ferme et presenter unepente

de2,54 cm (1 po) au maximum.

INSTALLATION DANS UNE AL COVEOU UN PLACARD

1. Toute s_cheuse install_e dans une chambre _ coucher, une

salle de bain, une alc6ve ou un placard DOIT_tre reli_e _ une

conduite d'_vacuation d'air se terminant _ I'ext_rieur de la

maison.

2. Aucun autre appareil br01ant du combustible ne dolt _tre

install_ dans le m_me placard que la s_cheuse au Gaz.

3. Las_cheusea besoin d'un d%agement suffisant pour permettre

la circulation de I'air.

II

_;_ 0 cm (0 po)

II

II

PORTE DU PLACARD

0 cm (0 po)

,," 2,54 cm

'_114

,, (1 po)

II

_ii_ 0 cm (0 po)

NEPASINSTALLERLASE-CHEUSEDANS UNPLACARDPOURVU

D'UNEPORTE PLEINE.

16

Page 17

Dimensions D'lnstallation De Secheuse

Independant Et Sous Le Compteur

Alimentation _lectrique sur I'arriere de I'unite

/

D

Pipe d'offre de

gaz sur I'arriere

de I'unite

D

\

/-=3-.,

27.0" _.

(68. 58cm)

5.0" (12.7cm)

Ligne taille centrale

patti, passage

4.375" (11.12cm) Aux _chappemer

(72.39cm)

28.5"

27.25 Pour affronter le coffret (69.22cm)

27.75Aux boutons clairs (70.49cm)

28.5A la poignee claire de porte (72.39cm)

5.875" (14.93cm) Aux _chappemer

(5. 72cm)

arri_re, droit,

\: --!......

2.25"

•1-I .,j .

'ji i

! i J

_237511. I< 13 5,, )(34.29cm)!_:_'i;

|(6.03cm) • Aux echappements

_s lat_raux d'arriere et de base

_.sbas

Dimensions Empilees D'lnstallation De Secheuse

I" _, ,, 27.0"

h, 1' oo,_ I

i

i

(68. 58cm)

28.25"Pour affronter le coffret(71.76cm) _ 4.375" " I I II _,/ecTqu_.sur

28.75"Aux boutons clairs (73.03cm) I" I [ Echappements i (34.29cm) I III ', U #arrl.ere ae

(11 12cm) 1 " " ration

29.,A,apoigo.eclaire.eporte(.._3cm> I H LaterauxI _3.'I"I "', I.o,te

49'a I'espace libre (124.46cm) IIII I I| I I III ', III

ouvre=porte IIII I t4 I Piped'o_redeI III i I

H"I I I I I ga_sur/'arriereI '" . '"

__ _ ' _ _ J" !__ 'l "'_" "--'4OO" 38.25"1(6"03cm)_==_! !

)) IIIH/I t / H <;_x,,o,oI (97.16cm) /11 )J II

I pour arriere

_t tH ,,o,,_o,,,/ /11 _ II

i ! passage III III

17

Page 18

DEBALLAGE

,

A I'aide desquatre coins de protection de I'emballage (deux sur

chaque cSt_), d_poser d_licatement la s_cheuse sur son cSt_

gauche et retirer lemorceau demousse plac_ sous la s_cheuse

pour I'exp_dition.

Pour nepas endommager las@cheuse,ne pas

prendre prise sur le panneau de commande pour soulever ou

d@placerla s@cheuse.

REMARQUE ; Si las@cheusedoit @treinstall@esous un comptoir,

le panneau du dessuspeut @tred@mont@pour I'installation.

2. Remettre la s@cheuse_ la verticale.

EMBALLAGE

,,I

INSTALLATION

,

Relierles conduits d'@vacuation d'air _ laconduite d'@vacuation

ext@rieure.Utiliser un ruban adh@sifpour conduites pour sceller

lesjoints.

,

Unefois las@cheusedansson emplacement ddinitif, ajuster les

pieds de nivellement jusqu'_ ce que la s@cheuserepose

fermement sur sesquatre pieds. Placerun niveau sur le dessus

de la s@cheuse.

LA SE:CHEUSEDOITETRE,ZINIVEA U ETREPOSERFERMEMENT

SURSESQUATRE PIEDS.

,

Brancherlecordon d'alimentation @lectriquedans uneprisemise

la terre. REMARQUE :S'assurer que lecourant est coup@_ la

botte defusibles ou de disjoncteurs avant de brancher lecordon

d'alimentation dans une prise.

4. Remettre le courant _ la botte de fusibles ou de disjoncteurs.

Avant d'utiliser la s@cheuse,s'assurer que les

environs delas@cheusesont exempts detout mat@riauinflammable,

d'essence et de toute autre vapeur inflammable. S'assurer

@galementqu'aucun objet (bottes, v@tements,etc.) n'obstrue la

circulation de I'air servant _ lacombustion et _ laventilation.

5. Fairefonction ner las@cheusesurun cyclecomplet pour en v@rifier

lefonctionnement.

REMARQUE: Dans lecasdess#cheuses_gaz, la conduite doit

_tre vid#e de son air avant que le braleur ne puisse s'allumer. Si

le braleur ne s'allume pas dans les 45 secondes qui suivent le

premier d#marrage, I'interrupteur de saret# #teint

automatiquement le brOleur. Si cela se produit, remettre la

minuterie _ <<OFF>>et attendre 5 minutes avant de tenter une

nouvelle fois d'allumer le braleur.

7. Si las#cheuse ne fonctionne pas, passeren revue lasection de

d#pannage inclus dans le Guide de I'utilisateur avant d'appeler

un centre de service.

8. Placercette notice pros de la s#cheuse pour r#f#rence future.

9. Pourempiler votre Secheusesurune Laveusecompatible, visitez

le site Web www, frigidaire, com, appelez votre revendeur

local ou appelez le num#ro sanscoot (1see- 444- 4944) pour

trouver votre distributeur local et acheter la piece accessoire

num#ro STACKIT2.

REMARQUE: Un sch#ma de c_blage se trouve dans le panneau

de commande ou sous le couvercle de la s#cheuse.

PIE-CES DE RECHANGE

Pi_destal

Un accessoirede pi_destal, N°de Mod_le NLPWD15(Blanc),

NLPWD15GB (Bleu Glacier), NLPWD15P (Graphite) and

NLPWD15E(Noir), asp_cifiquement concu pour cette s_cheuse

peut _tre utilis_ en _levant la s_cheuse pour la facilit_

d'utilisation. Lemanque d'utiliser des accessoires certifies par

le fabricant a pu avoir comme consequence des blessures,

des dommages materiels ou desdommages _ la s_cheuse.

Sivousd_sirez des pi_ces de remplacement pour votre machine

laver, communiquez avec le num_ro sansfrais de Serviceet pi_ces

de Frigidaire Company Authorized Parts Distributor, 1-800-944-

9044, ou visitez notre website, www, frigidaire ,com.

Lorsde tout travail d'entretien ou de r_paration

descommandes, _tiqueter tousles c_blesavant de lesd_brancher.

Les erreurs de connexion de c_ble peuvent entratner un

fonctionnement incorrect et dangereux. Une fois la r_paration ou

I'entretien terming, assurez-vous que I'appareil fonctionne

correctement.

D_truire lecarton et lessacsen plastique apr_s

avoir d_ball_ la s_cheuse. Des enfants risqueraient de s'en servir

commejouet. Lescartons recouverts d'un tapis, d'un couvre-lit ou

d'une feuille de plastique peuvent former une chambre _tanche et

faire suffoquer un enfant. Placerlemateriel d'emballage dans une

poubelle ou lesmettre hors de port_e des enfants.

Lesdirectives qui figurent danscette notice et

dans les autres documents qui accompagnent la s_cheuse ne

sauraient couvrir toutes lescirconstances et lessituations possibles.

IL FAUTdonc faire preuve de jugement et de prudence pendant

I'installation, I'utilisation et I'entretien de tout appareil

_lectrom_nager.

18

Page 19

INSTALLATION DANS UNE MAISON MOBILE

1. L'@acuation d'air de la s_cheuseDOITse faire _ I'ext_rieur de

la maison (_ I'_xterieur et non pas au-dessous de la maison

mobile) a I'aide de conduit en m_tal non inflammable,

I'@reuve du feu. Lesconduits en m_tal doivent avoir 10,16 cm

(4 pouces)de diam_tre sansobstructions. Lesconduits en m_tal

rigide sont preferables.

2. Si la conduite d'@acuation d'air traverse le plancher et un

espace ferm_ situ_ sous la maison mobile, I'@acuation d'air

DOITse terminer _ I'ext_rieur de cet espace fermi, et la sortie

bien fix@ a la structure de la maison mobile.

3. Lors de I'installation d'une s_cheuse a gaz dans une maison

mobile, ilfaut pr@oir un apport d'air ext_rieur. L'espace_pr@oir

dolt _tre sup_rieur de deux fois celui du conduit d'@acuation

de la s_cheuse.

4. Cette s#cheuse DOlT #tre fix#e au plancher. L'ensemble

d'installation no. 169840 pour maison mobile estdisponible chez

votre distributeur.

5. Ser#f#rer aux pages 2et 3 pour de plusamples informations ur

les exigences de ventilation.

6. L'installation DOITrespecter lanorme f_d_rale surlaconstruction

et la s_curit_ des maisons mobiles en vigueur (Manufactured

Home Construction & Safety Standard) (pattie int_grante du

r_glement f_d_ra124 CFRPattie32-80) ou, Iorsque cette norme

ne s'applique pas, elle dolt respecter la norme nationale

am_ricaine pour les maisons mobiles (American National

Standard for Mobile Homes). Lorsque I'installation sefait au

Canada, elle dolt seconformer aux normes ACNOR Z240.

PORTE RL'VERSIBLE

Instructions pour changer I'ouverture

de la Porte sans Fen#tre :

1. Ouvrez la Porte et enlevez les 4 bouchons d'en face ou on

trouve la charni_re. Conservez toutes les pi_ces pour les utiliser

post_rieurement, a moins qu'on ne sp_cifie le contraire. Note :

Ayez des soins en enlevant les bouchons, pour ne pas abimer la

peinture dans le Panneau Frontal.

4 VIS

(UNE DECHAQUE

)

2. D_tendez lesquatre (4)vis qui tiennent la charni_re au Panneau

Frontal. Pour de meilleurs r_sultats, enlevez seulement une des

vis. Enlevezensuite lesdeux restants, entretemps prennez la porte

fermement, pour _viter qu'il tombe et cause des degats a la

charni_re, le Panneau Frontal ou a la Porte. Apr_s avoir d_tendu

les vis restantes, enlevez les compbtement.

Las_cheuse est concueconform_ment a la

norme ANSIZ 21.5.1 pour un USAGEDOMESTIQUEseulement.

3. Placez la Porte, avec le cSt_ de la charni_re vers le has, sur

une serviette ou un matelas _troit, pour @iter qu'il soit doubl_.

Enlevez lesquatre (4) vis restantes entre la charni_re et la porte.

L

4. Enlevezquatre (4) vis dans le cSt_ oppos_ de la Porte.

5. S@arez I'anneau int_rieur de I'ext_rieur de la Porte, en placant

un tournevis plat ou un couteau sans bord. Tournez I'anneau

X i

: 70UI

i/i

:/NoN

int_rieur 180 degr_s et unis a nouveau les deux moiti_s de la

porte.

6. Installez quatre (4) vis pour assurer lesmoiti_s de la Porte, ou

,f "h

il _tait attach@ la charni_re.

7. Installez quatre (4) vis pour assurer le joint de la charni_re.

_i_!i_!8_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_;_5"

Correct

Incorrect

8. Enlevez le contre de la charni_re et jetez le aux ordures.

9. Enlevez le bouchon carr_ et installez-le dans le trou ou vous

avez enbve le contre.

10. Installez le contre (m_me qui est fourni dans la bourse de la

OUI

ii

NON_

Litt_rature) dans le trou tomb_ juste, ou vous avez enbve le

bouchon.

11. Enprenant laporte fermement de la partie sup_rieure, mettez

la pros de la cavit_ et iassurez vous d'aligner le trou sup_rieur de

la charni_re avec le trou sup_rieur du Panneau Frontal. Une fois

Incorrect

Correct

que vous avez commenc_ _ placer la premiere vis, placez la

deuxi_me dans I'inf_rieur de la charni_re. Quand tousles deux

soient serf,s, installez les autres deux vis.

12. Installezquatre (4) bouchons dans lestrous du PanneauFrontal,

ou _taient plac@s les charni_res _ I'origine.

19

Page 20

Instructions pour inverser la porte

Figure 1

1. Ouvrez la porte et retirez les quatre (4) bouchons situes dans

I'ouverture de la porte opposee aux charnieres. A moins

d'indication contraire, conservez toutes tes pbces pour les

reutiliser plus tard (figure 1). Remarque : Retirez les bouchons

avec soin afin de ne pas rayer la peinture du panneau avant.

Figure 2

2. Retirez les quatre (4) vis qui retiennent la charniere au

panneau avant (figure 2). Pour faciliter I'operation, retirez tout

d'abord une seule vis par charniere. Desserrez ensuite Ies deux

vis restantes tout en tenant fermement la porte pour eviter

d'aMmer tes charnieres, le panneau avant ou la porte. Une fois

lesvis desserrees, continuez a retirer toutes lesvis.

Figure 4

5. Retirez deux (2) vis de la poignee de porte et deux (2)

bouchons en plastique de la porte, toujours en prenant soin de

ne pas rayer la 0einture de la porte (fiqure 4).

Figure 5

6. Retirez la polgnee de la porte (figure 5).

Figure 3

3. Posez la porte sur une serviette ou un matelas, la poignee

vers le bas, pour eviter de la rayer. Retirez les quatre (4) vis

restantes qui retiennent la charniere a la porte (figure 3).

4. Retirez quatre (4) vis sur le c6te de la porte se trouvant

I'oppose de I'emplacement de la charni_re.

Figure 6

7. Dissociez la partie exterieure de la porte de la partie

interieure en utilisant un couteau a mastiquer ou un tournevis

plat (figure 6)

Figure 7

8. Retirez le ruban signalant I'emplacement de la lentiile et

jetez-te (figure 7).

Page 21

Figure 8

9. D_gagez plusieurs pattes de blocage et tirez doucement la

lentille hors de I'anneau de transition (figure 8).

10. Retirez deux (2) bouchons de I'anneau de transition. Vous

retirerez facilement les bouchons en les poussant avec un

tournevis sur I'envers de la piece. Placez-lessur I'autre c6t_ de

la poign_e (figures 9 et 10).

Figure 9

Figure 11

12. R_assemblez la porte ext_rieure et la porte int_rieure

(figure 11).

13. Vissez les quatre (4) vis qui retiennent la charni_re dans les

nouveaux trous pour fixer la charni_re _ la porte. Assurez-vous

d'orienter la charni_re dans la bonne direction.

14. Installez dans les trous les quatre (4) vis utilis_es

pr_c_demment pour fixer la charni_re.

15. A I'aide d'une pince, pressez les c6t_s de la g_che pour la

retirer de la porte int_rieure. Jetez-la.

16. Retirez le bouchon carr_ en plastique de la porte int_rieure

et placez-le dans le trou de la g_che.

17. Installez la nouvelle g_che (se trouvant dans le sac avec la

documentation) dans I'ancien trou du bouchon carr_ en

plastique.

Figure 10

11. Remettez la lentille sur I'anneau de transition comportant

des trous pour installer la poign_e du c6t_ droit de la porte.

Pour un bon ajustement, assurez-vous que les pattes de

blocage de I'anneau de transition se trouvent au-dessus de la

lentille et que les trous de la poign_e s'alignent sur lestrous de

I'anneau de transition.

Figure 12

18. Replacez la poign_e de porte en encastrant les

protuberances dans les trous de la lentille et de I'anneau de

transition. Installez lesvis dans les protuberances de la poign_e

depuis la porte int_rieure et serrez (figure 12).

19. En tenant fermement le haut de la porte, positionnez-la

pros de I'ouverture et alignez le trou de la charni_re sup_rieure

sur le trou sup_rieur du panneau avant de I'ouverture de porte.

Une fois la premiere vis engag_e, fixez la deuxi_me vis dans la

charni_re inf_rieure. Apr_s avoir serr_ les deux vis, fixez et

serrez les deux derni_res vis.

20. Placez les quatre (4) bouchons (retires _ I'_tape 1) dans

I'ancien emplacement des charni_res se trouvant sur le

panneau avant de I'ouverture de porte.

Page 22

INSTALLATION ELECTRIOUE

[

rapportent directement au branchement _lectrique correct

et s_curitaire de la s_cheuse. Toute d_rogation b ces raises

en garde pourrait entra_ner des risques choc _lectrique et

d'incendie.

laterre. Las_cheusepr_senterait desrisques choc _lectrique sielle

n'_tait pas convenablement mise _laterre. Respecter lesdirectives

de mise _laterre contenues dans cette notice pour une mise_ la

terre correcte.

s_cheuse. Certains cordons de rallonge ne sont pas _:oncuspour

supporter I'intensit_ du courant qu'utilise cette s_cheuse;ilspeuvent

fondre et presenter un risque choc _lectrique ou d'incendie. Placer

la s_cheuse a port@ de la prise murale afin de d_terminer la

Iongueur du cordon a acheter et pr@oir un certain jeu dans la

Iongueur ducordon. Sereporter blasection <<AvantI'installatiom> 2.

de cette notice pour savoir quel type de cordon acheter.

au cordon d'alimentation. Si le d_tendeur n'_taitpas present, le

cordon pourrait _tre arrach_ de las_cheuse oucoup_ par tout type

de mouvement, cequi pr_senterait un risque choc _lectrique.

aluminium avec uncordon ou une prisebconducteurs encuivre (ni I

I'inverse). Une r_action chimique se produit entre le cuivre et

I'aluminium qui pourrait causerun court-circuit.

II faut utiliser un cordon d'alimentation b conducteurs en

cuivre avec une prise b conducteurs en cuivre.

REMARQUE : Les s_cheuses qui fonctionnent avec une

alimentation de 208 volts auront un temps de s_chage plus

long que celles qui utilisent une alimentation de 240 volts.

TOUTES/es s_cheuses ELECTRIOUES

Les mises en garde qui suivent se

Cet appareil DOIT_tre convenablement mis

Nepasutiliser de cordon de rallonqeaveccette

Und_tendeur approuv_ par U L dolt _tre fix_

Ne pas utiliser une prise b conducteurs en

MISE A LA TERRE

S_cheuses ELECTR/QUESnon-Canadiennes

]

]

Pour brancher las_cheuse en permanence :

1. Las_cheuseDOIT_tre branch@ b uneinstallation m_tallique

mise alaterre en permanence; sinon, un conducteur de mise

laterre de I'appareil dolt suivrelesconducteurs du circuit et

_tre branch_ b la borne ou a la connexion de mise a la terre

de I'appareil.

I S_cheusesELECTRIQUES Canadiennes

Lebranchement inad_quat du conducteur

de miseala terre pourrait presenter un risque choc _lectrique. En

cas de doute quant b la mise a la terre adequate de I'appareil,

contacter un _lectricien agree.

Pour brancher et mettre _la terre la s_cheuse_I'aide d'un cordon

d'alimentation :

1. La s_cheuse dolt _tre mise _ la terre. En cas de mauvais

fonctionnement ou de panne, la mise _ la terre r_duit les

risques choc _lectrique en offrant un parcours de moindre

r_sistance aucourant.

Puisquela s_cheuseest pourvue d'un cordon d'alimentation

_lectrique comportant un conducteur et une fiche de terre, la

fiche dolt _tre branch@ dans une prise murale _conducteur

en cuivre convenablement raccord@ au r_seau et mise _ la

terre conform_ment _tousles codes et ordonnances Iocaux.

Encasdedoute, contacter un _lectricien agree. Nemodifiez

pas la prise _quip_e d'appareil.

TOUTES/es s_cheuses a GAZ

Pourvotre protection contre leschocs _lectriques, las_cheuseest

_quip@ d'une fiche _ trois bornes (mise _ la terre) et dolt _tre

branch@ directement dans une prise _ 3 bornes correctement

mise alaterre. Ne pascouper ni enlever lafiche de mise a la terre

de cette prise.

BRANCHEMENT DU GAZ

(Secheuses a gaz seulement)

Retirer le couvercle qui recouvre letuyau de gaz a I'arri_re de la

s_cheuse.

1

I

Lebranchement inad_quat du conducteur de

mise ala terre pourrait presenter un risque choc _lectrique. Encas

de doute quant b lamiseala terre adequate de I'appareil, contacter