Frigidaire EI30BM55HBC, EI30BM55HSC, EI30BM55HWC, EI30BM55HZC, EI30BM5CHBC Installation Guide

...Page 1

|NSTALLA'rioN INsrRucrIoNS

BEFORE YOU BEGIN

• _ Save these instructions for local

inspector's use.

• _ Observe all governing codes and

coordinates.

• NOTE TO iNSTALLER - Be sure to leave these

instructions with the Consumer.

• NOTS: TO CONSUMER - Keep these instructions for

future reference.

• SKILL LEVEL - Installation of this appliance requires

basic mechanical and electrical skills.

Readtheseinstructionscompletelyandcarefully.

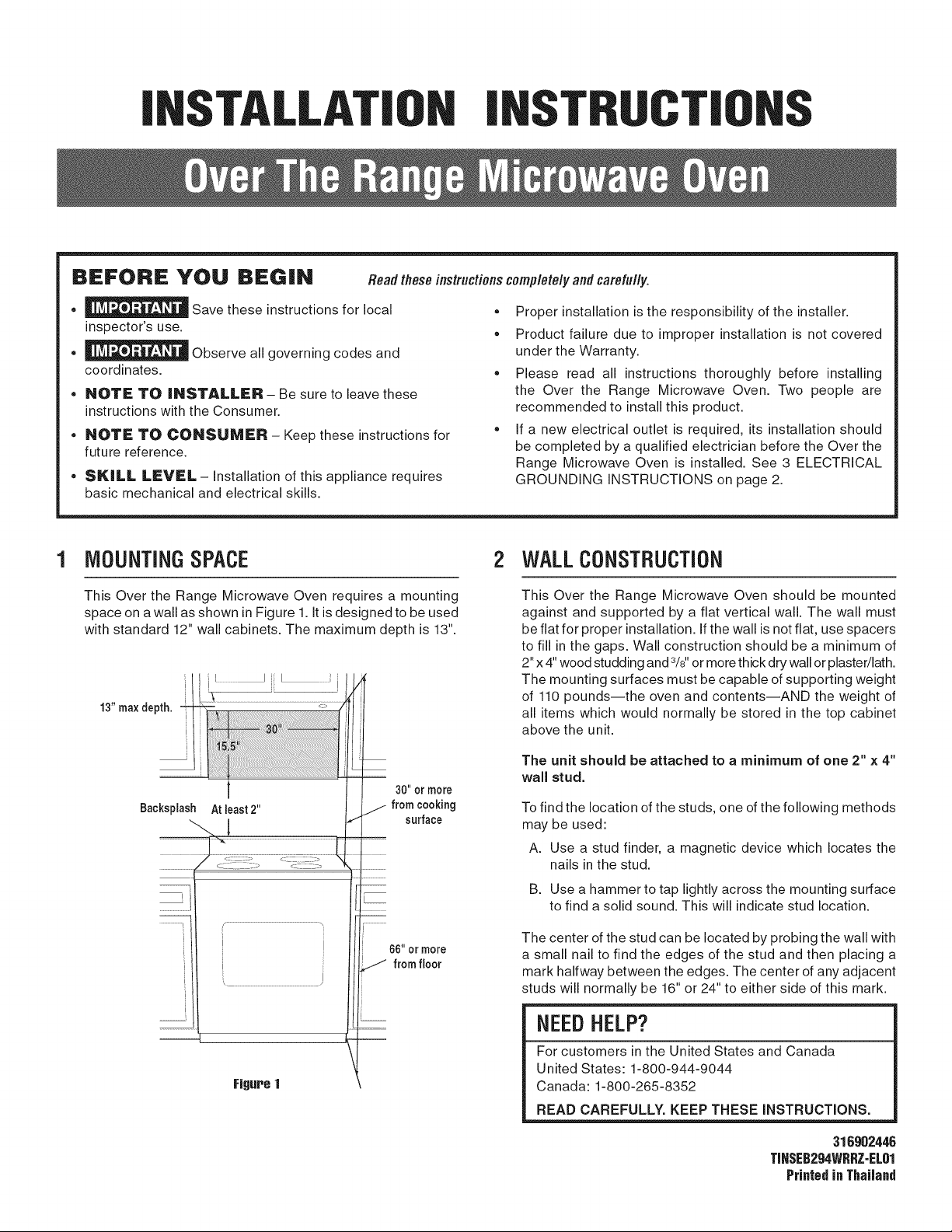

1 MOUNTINGSPACE

This Over the Range Microwave Oven requires a mounting

space on awall as shown in Figure 1.It is designed to be used

with standard 12" wall cabinets. The maximum depth is 13".

i L

13"maxdepth.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not covered

under the Warranty.

• Please read all instructions thoroughly before installing

the Over the Range Microwave Oven. Two people are

recommended to install this product.

• If a new electrical outlet is required, its installation should

be completed by a qualified electrician before the Over the

Range Microwave Oven is installed. See 3 ELECTRICAL

GROUNDING INSTRUCTIONS on page 2.

2 WALLCONSTRUCTION

This Over the Range Microwave Oven should be mounted

against and supported by a flat vertical wall. The wall must

be flat for proper installation. If the wall is not flat, use spacers

to fill in the gaps. Wall construction should be a minimum of

2"x 4"wood studding and 3/8"or morethick dry wall or plaster/lath.

The mounting surfaces must be capable of supporting weight

of 110 pounds--the oven and contents--AND the weight of

all items which would normally be stored in the top cabinet

above the unit.

30"or more

Backspiash Atleast2" from cooking

[

i

i

i

i

i

Figure1

surface

66" or more

from floor

The unit should be attached to a minimum of one 2" x 4"

wall stud.

To find the location of the studs, one ofthe following methods

may be used:

A. Use a stud finder, a magnetic device which locates the

nails inthe stud.

B. Use a hammer to tap lightly across the mounting surface

to find a solid sound. This will indicate stud location.

The center of the stud can be located by probing the wall with

a small nail to find the edges of the stud and then placing a

mark halfway between the edges. The center of any adjacent

studs will normally be 16" or 24" to either side of this mark.

NEEDHELP?

For customers in the United States and Canada

United States: 1-800-944-9044

Canada: 1-800-265-8352

READ CAREFULLY. KEEP THESE INSTRUCTIONS.

316902446

TIHSEB294WBRZ-EL81

PrintedinThailand

Page 2

3 ELECTRICALGROUNDINGiNSTRUCTiONS 4 HOODEXHAUSTDUCT

This appliance must be grounded. This oven is equipped with

a cord having a grounding wire with a grounding plug. It must

be plugged into a wall receptacle that is properly installed and

grounded in accordance with the National Electrical Code and

local codes and ordinances. In the event of an electrical short

circuit, grounding reduces risk of electric shock by providing

an escape wire for the electric current.

WARNING - Improper use of the grounding plug can result

in a risk of electric shock.

ELECTRICALREQUIREMENTS

The oven is equipped with a 3-prong grounding plug. DO

NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE

THE GROUNDING PIN FROM THE PLUG.

DO NOT USE AN EXTENSION CORD. If the power supply

cord is too short, have a qualified electrician or serviceman

install an outlet near the appliance.

The Power Supply Cord and plug must be connected to

a separate 120 Volt AC, 60 Hz, 15 Amp, or more branch

circuit, single grounded receptacle. The receptacle should

be located inside the cabinet directly above the Microwave

Oven mounting location as shown in Figure 2.

NOTE:

1. If you have any questions about the grounding or

electrical instructions, consult a qualified electrician or

serviceperson.

2. Neither Electrolux nor the dealer can accept any liability for

damage to the oven or personal injury resulting from failure

to observe the correct electrical connection procedures.

When the hood is vented to the outside, a hood exhaust duct

is required. All ductwork must be metal; absolutely do not use

plastic duct. Check that all connections are made securely.

Please read the following carefully:

EXHAUSTCONNECTION:The hood exhaust has been designed

to connect to astandard 3 V4"x 10" rectangular duct. If round

duct is required, a rectangular-to-round adapter must be

used.

REAREXHAUST: If a rear or horizontal exhaust is to be used,

care should be taken to align the exhaust with the space

between the studs, or wall should be prepared at the time it

is constructed by leaving enough space between wall studs

to accommodate exhaust.

MAXIMUM DUCT LENGTH:For satisfactory air movement, the

total duct length of 31/4" x 10" rectangular or 6" diameter round

duct should not exceed 140 feet.

Elbows, adapters, wall caps, roof caps, etc. present additional

resistance to air flow and are equivalent to a section of straight

duct which is longer than their actual physical size. When

calculating the total length, add the equivalent lengths of all

transitions and adapters plus the length of all straight duct

sections. Figure 3 shows the approximate feet of equivalent

length of some typical ductwork parts. Use the values in

parentheses for calculating air flow resistance equivalent,

which should total less than 140 feet.

NOTE:

Furnace duct sealing tape is recommended to seal duct

connections to the Exhaust Dampener Assembly.

!

Ground - [_q

Receptacle [_J

PowerCord

t Openingfor

Figure2

® 2

% o

90° Elbow(10 ft.) 45° Elbow (5 ft.) Adaptor (5 ft.)

90° Elbow (25 ft.) 45° Elbow (5 ft.) Wall cap (40 ft.) Roof cap (24 ft.)

Figure3

10"WideElbow(10ft.)

Page 3

5 7 PREPARATIONOFTHEOVENTOOLSRECOMMENDEDFOR

iNSTALLATiON

= Phillips Screwdriver

• Electric Drill

® 1/2", s/8" and 3/32"Drill Bits

1 1/2"Wood Bit or Metal Hole Cutter

(if metal cabinet is used)

Saw to cut exhaust opening (if needed)

Protective Drop Cloth for product and range -

you may also use carton for protection

• Scissors

Pencil

Measure

Tape

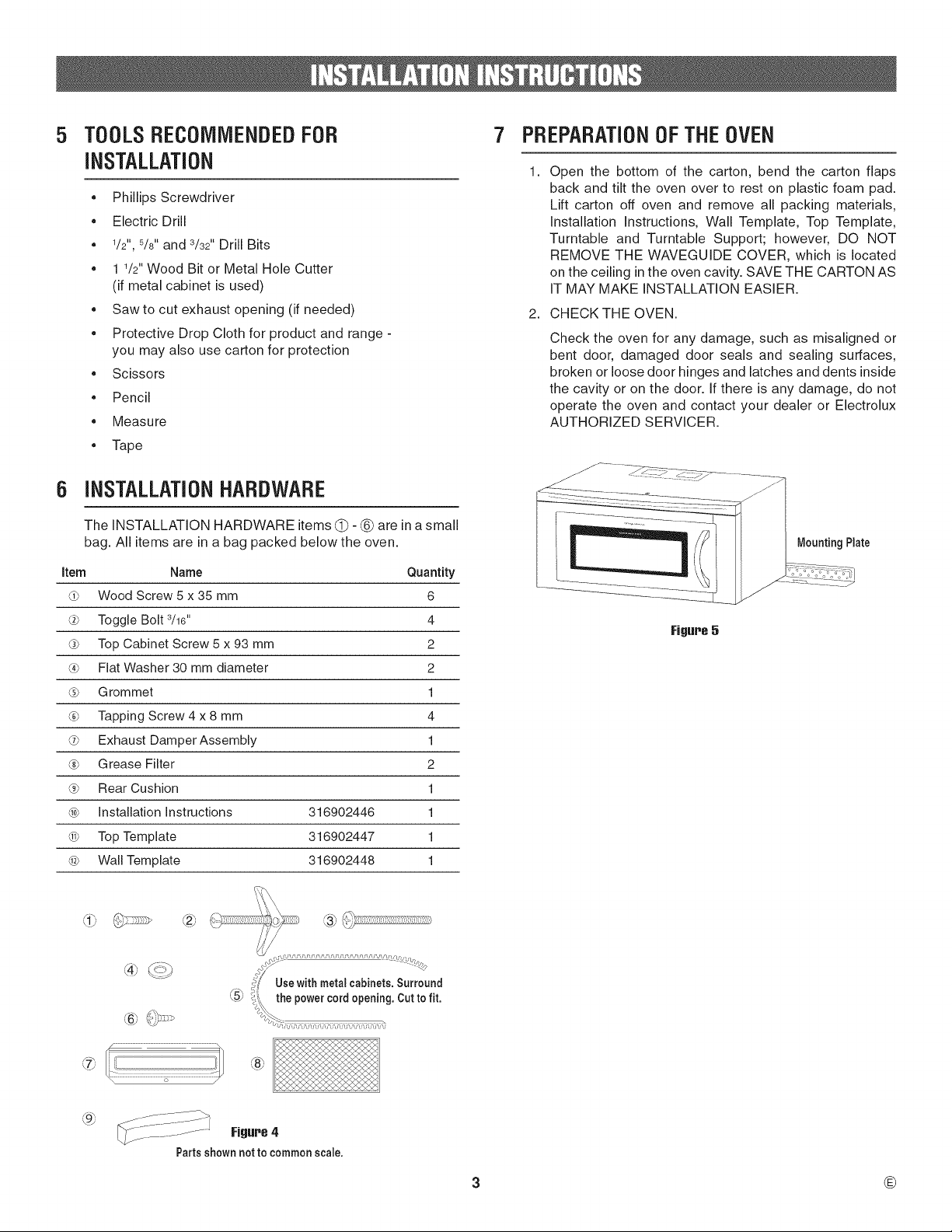

6 INSTALLATIONHARDWARE

The INSTALLATION HARDWARE items (_ - @ are in a small

bag. All items are in a bag packed below the oven.

Item Name Quantity

Wood Screw 5 x 35 mm 6

Toggle Bolt 3/16" 4

G Top Cabinet Screw 5 x 93 mm 2

Flat Washer 30 mm diameter 2

@ Grommet 1

® Tapping Screw4 x 8 mm 4

Exhaust Damper Assembly 1

® Grease Filter 2

® Rear Cushion 1

® Installation Instructions 316902446 1

® Top Template 316902447 1

@ Wall Template 316902448 1

1.

Open the bottom of the carton, bend the carton flaps

back and tilt the oven over to rest on plastic foam pad.

Lift carton off oven and remove all packing materials,

Installation Instructions, Wall Template, Top Template,

Turntable and Turntable Support; however, DO NOT

REMOVE THE WAVEGUIDE COVER, which is located

on the ceiling in the oven cavity. SAVE THE CARTON AS

IT MAY MAKE INSTALLATION EASIER.

2. CHECK THE OVEN.

Check the oven for any damage, such as misaligned or

bent door, damaged door seals and sealing surfaces,

broken or loose door hinges and latches and dents inside

the cavity or on the door. If there is any damage, do not

operate the oven and contact your dealer or Electrolux

AUTHORIZED SERVICER.

Mounting Plate

Figure5

k!J

k7_J

\J

S_

k6P_ .....

Figure 4

Partsshownnottocommonscale.

3 ®

Page 4

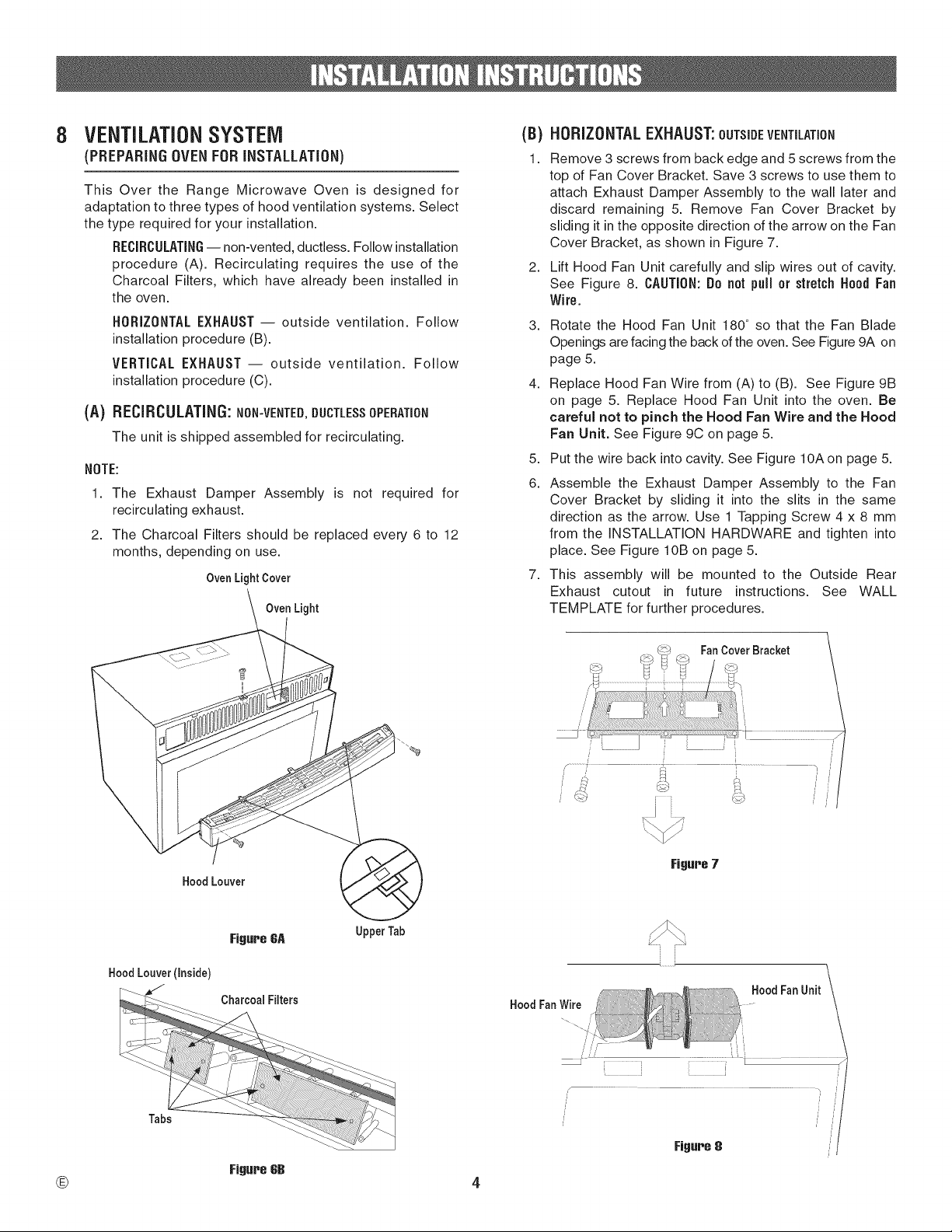

8 VENTiLATiONSYSTEM

(PREPARINGOVENFOBiNSTALLATiON)

This Over the Range Microwave Oven is designed for

adaptation to three types of hood ventilation systems. Select

the type required for your installation.

RECIRCULATING-- non-vented, ductless. Follow installation

procedure (A). Recirculating requires the use of the

Charcoal Filters, which have already been installed in

the oven.

HORIZONTAL EXHAUST -- outside ventilation. Follow

installation procedure (B).

VERTICAL EXHAUST -- outside ventilation. Follow

installation procedure (C).

(A) RECIBCULATING: NON-VENTED,DUCTLESSOPERATION

The unit is shipped assembled for recirculating.

NOTE:

1. The Exhaust Damper Assembly is not required for

recirculating exhaust.

2. The Charcoal Filters should be replaced every 6 to 12

months, depending on use.

OvenLightCover

OvenLight

HORIZONTAL EXHAUST: OUTSIDEVENTILATION

(B)

1.

Remove 3 screws from back edge and 5 screws from the

top of Fan Cover Bracket. Save 3 screws to use them to

attach Exhaust Damper Assembly to the wall later and

discard remaining 5. Remove Fan Cover Bracket by

sliding it in the opposite direction of the arrow on the Fan

Cover Bracket, as shown in Figure 7.

2,

Lift Hood Fan Unit carefully and slip wires out of cavity.

See Figure 8. CAUTION: Do net pull or stretch Hood Fan

Wire.

3. Rotate the Hood Fan Unit 180 ° so that the Fan Blade

Openings are facing the back of the oven. See Figure 9A on

page 5.

4. Replace Hood Fan Wire from (A) to (B). See Figure 9B

on page 5. Replace Hood Fan Unit into the oven. Be

careful not to pinch the Hood Fan Wire and the Hood

Fan Unit. See Figure 9C on page 5.

5. Put the wire back into cavity. See Figure 10A on page 5.

6. Assemble the Exhaust Damper Assembly to the Fan

Cover Bracket by sliding it into the slits in the same

direction as the arrow. Use 1 Tapping Screw 4 x 8 mm

from the INSTALLATION HARDWARE and tighten into

place. See Figure 10B on page 5.

7. This assembly will be mounted to the Outside Rear

Exhaust cutout in future instructions. See WALL

TEMPLATE for further procedures.

HoodLouver

HoodLouver(Inside)

FigureGA

Upper Tab

HoodFanWire

/

/

FanCover Bracket

L

FiguPe7

HoodFanUnit

/ / /

® 4

FiguPeGg

Figupe8

Page 5

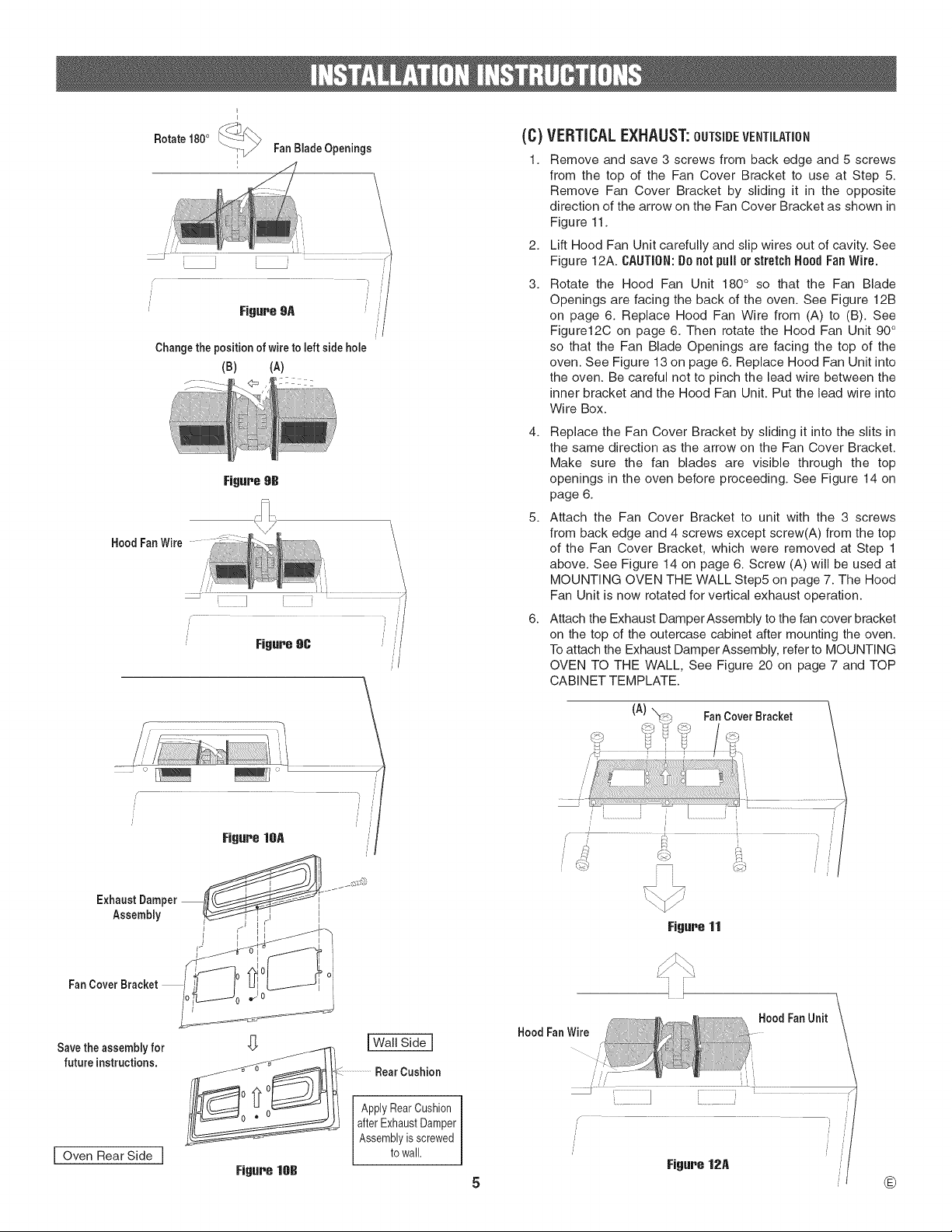

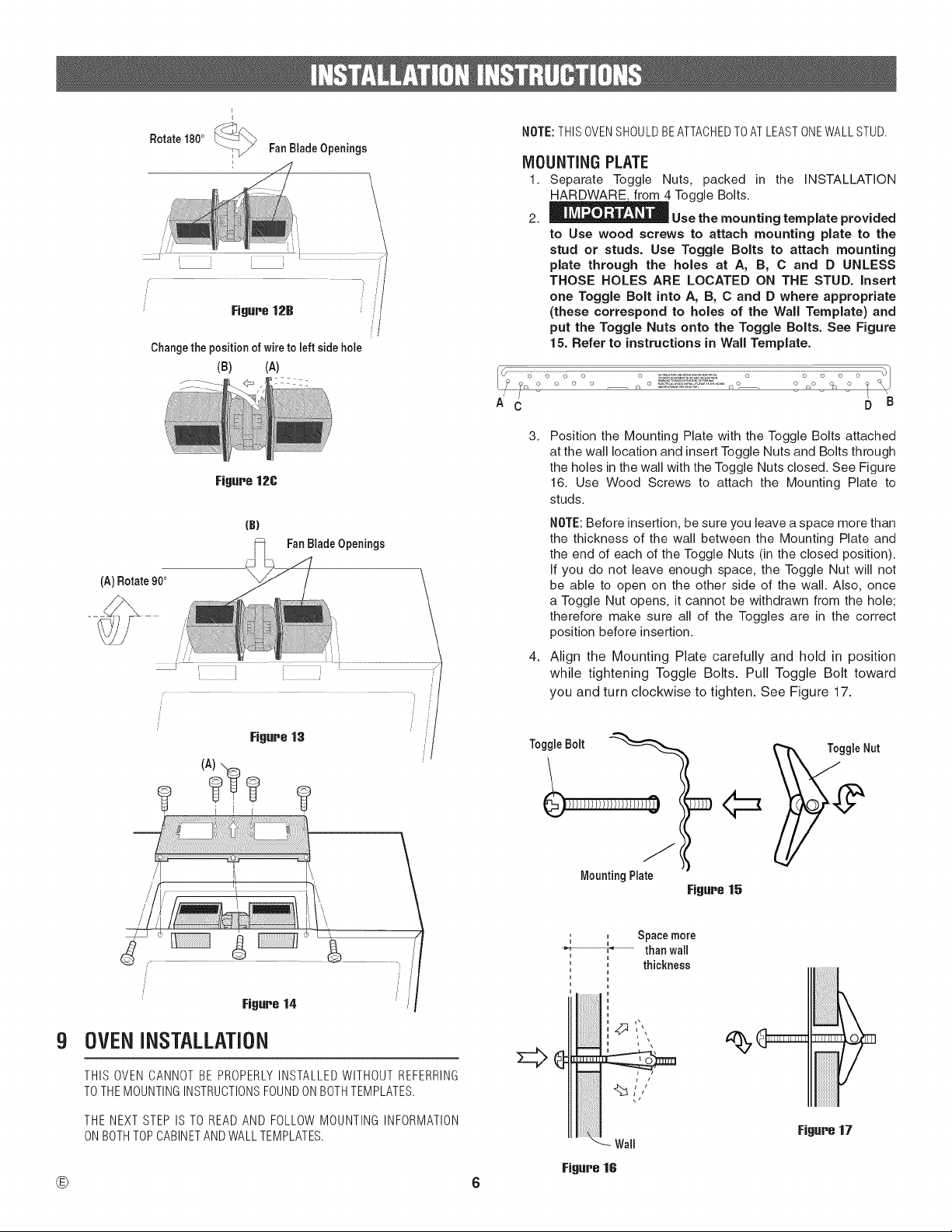

Rotate

Changethe position of wire to left side hole

FanW=re _

_-_, _

1800

_ FanBladeOpenings

(B) (A)

Figure 9B

(c)

1.

2.

3.

4. Replace the Fan Cover Bracket by sliding it into the slits in

5. Attach the Fan Cover Bracket to unit with the 3 screws

6. Attach the Exhaust DamperAssembly to the fan cover bracket

iii,i,i,i

VERTICALEXHAUST:OUTSIDEVENTiLATiON

Remove and save 3 screws from back edge and 5 screws

from the top of the Fan Cover Bracket to use at Step 5.

Remove Fan Cover Bracket by sliding it in the opposite

direction of the arrow on the Fan Cover Bracket as shown in

Figure 11.

Lift Hood Fan Unit carefully and slip wires out of cavity. See

Figure 12A. CAUTION: Do not pull or stretch Hood Fan Wire.

Rotate the Hood Fan Unit 180 ° so that the Fan Blade

Openings are facing the back of the oven. See Figure 12B

on page 6. Replace Hood Fan Wire from (A) to (B). See

Figure12C on page 6. Then rotate the Hood Fan Unit 90 °

so that the Fan Blade Openings are facing the top of the

oven. See Figure 13 on page 6. Replace Hood Fan Unit into

the oven. Be careful not to pinch the lead wire between the

inner bracket and the Hood Fan Unit. Put the lead wire into

Wire Box.

the same direction as the arrow on the Fan Cover Bracket.

Make sure the fan blades are visible through the top

openings in the oven before proceeding. See Figure 14 on

page 6.

from back edge and 4 screws except screw(A) from the top

of the Fan Cover Bracket, which were removed at Step 1

above. See Figure 14 on page 6. Screw (A) will be used at

MOUNTING OVEN THE WALL Step5 on page 7. The Hood

Fan Unit is now rotated for vertical exhaust operation.

on the top of the outercase cabinet after mounting the oven.

To attach the Exhaust Damper Assembly, refer to MOUNTING

OVEN TO THE WALL, See Figure 20 on page 7 and TOP

CABIN ET TEM PLATE.

Exhaust Dam

Assembly

FanCoverBracket

Savethe assemblyfor

future instructions.

I Oven Rear Side I

"_ _1 I Wall Side I

nlFJ_ __ .......................RearCushion

0 0 l --

, earOushio

!71I after ExhaustDamper

....... Assemblyis screwed

towall.

Figure lOB

(A)

FanCoverBracket

Figure11

®

Page 6

Rotate180° _ FanBiade Openings

Changethe positionof wiretoleftside hole

(A) Rotate900

i

i

(B) (A)

Figure12C

{B)

FanBladeOpenings

NOTE:THISOVENSHOULDBEATTACHEDTOATLEASTONEWALLSTUD.

MOUNTING PLATE

1. Separate Toggle Nuts, packed in the INSTALLATION

HARDWARE, from 4 Toggle Bolts.

2. _ Use the mounting template provided

to Use wood screws to attach mounting plate to the

stud or studs. Use Toggle Bolts to attach mounting

plate through the holes at A, B, C and D UNLESS

THOSE HOLES ARE LOCATED ON THE STUD. insert

one Toggle Bolt into A, B, C and D where appropriate

(these correspond to holes of the Wail Template) and

put the Toggle Nuts onto the Toggle Bolts. See Figure

15. Refer to instructions in Wail Template.

/ /

A C D B

3.

Position the Mounting Plate with the Toggle Bolts attached

at the wall location and insert Toggle Nuts and Bolts through

the holes in the wall with the Toggle Nuts closed. See Figure

16. Use Wood Screws to attach the Mounting Plate to

studs.

NOTE: Before insertion, be sure you leave a space more than

the thickness of the wall between the Mounting Plate and

the end of each of the Toggle Nuts (in the closed position).

If you do not leave enough space, the Toggle Nut will not

be able to open on the other side of the wall. Also, once

a Toggle Nut opens, it cannot be withdrawn from the hole;

therefore make sure all of the Toggles are in the correct

position before insertion.

4.

Align the Mounting Plate carefully and hold in position

while tightening Toggle Bolts. Pull Toggle Bolt toward

you and turn clockwise to tighten. See Figure 17.

/

9

OVEN INSTALLATION

THIS OVEN CANNOT BE PROPERLYINSTALLED WITHOUT REFERRING

TOTHEMOUNTINGINSTRUCTIONSFOUNDONBOTHTEMPLATES.

THE NEXT STEP IS TO READ AND FOLLOW MOUNTING INFORMATION

ON BOTHTOPCABINETAND WALLTEMPLATES.

Figure 14

®

ToggleBolt

Mounting Plate

, _ bpace more

i i

i

' thickness

Figure15

,_ than wail

,,%.

i /

Page 7

MOUNTINGOVENTOTHEWALL

Two people are recommended to attach the Microwave Oven/

Hood to the Mounting Plate.

1. Thread the power supply cord through the hole made in the

bottom of the top cabinet.

2. Install the oven by tilting it forward and sliding it onto two

tabs of the Mounting Plate. Rotate the oven up so it rests

against the wall. See Figure 18 on page 7.

3. Use the two Top Cabinet Screws and two Flat Washers,

supplied in the INSTALLATION HARDWARE, to attach the

unit to the top cabinet. See Figure 19 on page 7.

4. Secure the bottom of the oven to the Mounting Plate by using

two Tapping Screws 4 x 8 mm from the INSTALLATION

HARDWARE. See Figure 19 on page 7.

5. (For Vertical Exhaust Only)

Attach the Exhaust Damper Assembly to the fan Cover

Bracket on the top of the outercase cabinet by sliding it into

the slits in the same direction as the allow using screw (A)

which removed at (C) VERTICAL EXHAUST STEP 1 on

page 5. See Figure 20 on page 7.

Tapping Screw (A)

J

Figure20

CHECKLISTFORINSTALLATION

1. Make sure the unit has been installed according to all of the

Installation Instructions and the Wall and Top Cabinet Templates.

2. Plug in the power cord.

3. Keep these Installation Instructions.

Figure18

Tabs

NOTE:

Make sure to remove the tape at the turntable support before

operation. See figure 21.

l

Removethis tapebefore operation.

Figure21

Tapping Screws

Figure 19 7

Page 8

Page 9

IHSTALLA[|OH D'IHS rBUCTION

AVANT DE COMMENCER

• _ Conserver ces instructions pour l'inspecteur

local.

• _ Observer tous les r_glements et les

coordonn_es.

• NOTE A L_JI_ISTALLATI_UR- Assurez-vous de laisser

ces instructions au client.

* NOTE AU CLIENT - Conserver ces instructions pour

r_f6rence ultefieure.

. NJVI_AU i)! = COMpI_'rl_'NCI_' - Uinstallation de cette

appareil exige des comp_tences de base en m_canique et en

electricit&

Life attentivementla totafit# de cesinstructions.

1 ESPACEDEMONTAGE

Le schema 1 vous montre I'espace de montage necessaire

a. Ce four a micro-ondes a. hotte integr6e. II est con£u pour

_tre employ_ avec des armoires murales standard de 12 pc

(30,5 cm). La profondeur maximale est de 13 pouces.

Profondeur

maxJmaJe13 pc.

* Uinstallateur est responsable de sa bonne installation.

* Une panne du produit due & une mauvaise installation n'est

pas couverte par la garantie.

* Veuillez life attentivement toutes les instructions avant

d'installer le four & micro-ondes au-dessus d'une cuisiniere. II

est recommande que deux personnes installent ce produit.

* Si une nouvelle prise electfique est necessaire,il faut la faire

poser par un electricien qualifie avant d'installer le four a.

microondes au-dessus d'une cuisiniere. Voir 3 INSTRUCTIONS

POUR LA MISE _, LA TERRE €:LECTRIQUE a. la page 2.

2 CONSTRUCTIONDUIVlUR

Le four a. micro-ondes a. hotte integr6e doit _tre supporte par

un mur vertical plat. Pour une installation correcte, lemur doit

_tre plat. Si ce n'est pas le cas, employez des entretoises pour

remplir les espaces. La construction du mur dolt avoir des poteaux

muraux de 2 x 4 pc et une cloison sbche ou un pl&trage d'au moins

3/8 pc (9,5 mm) d'epaisseur. Les surfaces de montage doivent

pouvoir supporter un poids de 110 lb. (50 kg)-- le four et son

contenu -- ET le poids de tousles articles qui sont normalement

entreposes dans I'armoire au-dessus de I'appareil.

Dosseret

....................i

30pc(76 cm)

Aurnoins 2 pc (5,1 cm) la surfacede

i

[

i

aumoJnsde

cuisson.

66po (167,6cm)

i

i

i

i

$ch6ma 1

L'appareil sera fix_ a au moins un poteau mural de 2 x 4 pc

ou 2 poteaux de 2 x 3 pc.

Pour trouver I'emplacement des poteaux muraux, vous pouvez

employer une des m_thodes suivantes:

A. Employez un Iocalisateur de montants, un appareil

magn_tique qui Iocalise les clous dans le poteau.

B. Frappez doucement avec un marteau le long de la surface

de montage pour trouver un son plein. Ceci indiquera

I'emplacement du montant.

On peut Iocaliser le centre du poteau vertical en enfon£ant un petit

clou dans lemur pour trouver les bords du montant, ilsuffit alors

de marquer le centre entre les bords. Le centre des montants

suivants se trouvera normalement & 16 ou 24 pc (40,6 cm ou a.

61 cm) de chaque c6te de cette marque.

BESOIND'AIDE?

Pour les clients aux €:tats-Unis et au Canada

€:tats-Unis: 1-800-944-9044

Canada: 1-800-265-8352

.& URE ATTENTIVEIVIENT. iNSTRUCTiONS .& CONSERVER.

Page 10

3 iNSTRUCTiONSDEIVlISEA LATERRE 4 CONDUITD'i VACUATIONDELAHOTTE

Cet appareil dolt _tre mis & la terre. Ce four est equip6 d'un

cordon d'alimentation avec fil de mise b.la terre, et d'une fiche

de mise b. la terre. II faut le brancher dans une prise murale qui

a et6 installee correctement et mise b. la terre selon le Code

national de I'electricit6 et les codes et decrets Iocaux. En cas de

court-circuit electrique, la mise & la terre reduit les rJsques de

choc electrique en permettant au courant de s'echapper par le

fil de mise b.la terre.

AVERTISSEMENT- Un mauvais usage de la prise de terre peut

causer des chocs electriques.

iNSTALLATiONELECTRIQUE

Le four est equip6 d'une fiche de terre b.3 broches. IL NE FAUT

EN AUCUN CAS COUPER OU ENLEVER LA BROCHE DE

TERRE DE LA FICHE.

N'UTILISE PAS UNE RALLONGE. Si le cordon d'alimentation

fourni est trop court, demandez b. un electricien qualifie ou b.

un reparateur professionnel d'installer une prise b. proximite de

I'appareil.

II faut connecter le cordon d'alimentation et la fiche sur un

circuit s6par6 de 120 volts CA, 60 Hz, 15 A ou plus, avec prise

murale simple avec terre. La prise dolt 8tre situee dans I'armoire

directement au-dessus de I'emplacement de montage du four &

micro-ondes b. hotte integr6e. Comme illustre par le schema 2.

REMARQUE:

1. Si vous avez des questions b. propos de I'installation

electrique ou de la mise b. la terre, consultez un electricien

de m_tier ou un reparateur qualifie.

2. Ni Electrolux ni le revendeur ne peuvent accepter aucune

responsabilite des deg&ts au four, ou des blessures

personnelles resultant du non-respect des procedures

correctes de connexion electrique.

Pour une hotte avec evacuation & I'air libre, il faut installer un

conduit d'evacuation b.la hotte. Tousles conduits doivent _tre en

metal; n'employez aucun conduit en plastique. Verifiez que toutes

les connexions sont bien settees. Veuillez life attentivement ce

qui suit:

CONNEXION DEL'EVACUATION: I'evacuation de la hotte est congue

pour _tre connectee & un conduit rectangulaire standard de

31/4 x 10 po (8,3 cm x 25,4 cm). Si vous avez besoin d'un conduit

circulaire, il faut employer un adaptateur rectangulaire b. fond.

EVACUATION ARRli:RE: si vous employez une evacuation arriere

ou horizontale, Jlfaut faire attention de bien aligner I'evacuation

avec I'espace entre les poteaux muraux, ou ilfaut preparer lemur

b. I'avance et laisser assez d'espace entre les poteaux muraux

pour placer I'evacuation.

LONGUEUR MAXIMUM DU CONDUIT: pour un mouvement d'air

suffisant, la Iongueur totaie du conduit rectangulaire de 31/4 x 10 po

(8,3 cm x 25,4 cm) ou du conduit circulaire de 6 po (15,2 cm) de

diam_tre ne doit pas depasser 140 pi. (42,7 m).

Les coudes, adaptateurs, murs, mitres de toit, etc., presentent

une resistance suppiementaire au flux d'air et sont equivalents

b. une section de conduit droit qui est plus long que leur

taille reelle. Quand vous calculez la Iongueur totale, il faut

ajouter les Iongueurs equivalentes de toutes les transitions ou

adaptateurs aux sections de conduit droit. Le schema 3 montre

les Iongueurs equivalentes approximatives de quelques pi_ces

typiques. Employez les valeurs entre parentheses pour calculer

I'equivalence de resistance du flux d'air, dont le total devra _tre

de moins de 140 pi. (42,7 m).

REIVlARQUE:

IIest recommande d'utiliser le chatterton d'etanch6it6 du conduit

du four pour sceller les connexions du conduit au systeme de

mouillage de I'echappement.

Laterre _

R_ceptacle-

S'ouvrir pour le

cordonde secteur

$ch6ma2

® 2

Coude 90 ° (10 pi.)

Coude 25° (25 pi.)

Coude 45° (5 pi.)

Coude 45° (5 pi.)

$ch6ma3

i:/

Adaptateur (5 pi.)

Chapeau tour

(40 pi.)

Coude de 10 (10 pi.)

(24 pi.)

Page 11

5 7 PRi PARATIONDU FOUR0UTILS RECOIVllVlANDi SPOUR

L'INSTALLATION

,, Tournevis Phillips

,, Perceuse electrique

', Forets de 1/2", 5/8" et 3/32" (13 - 16 - 8 mm)

* Meche b. bois de 1 1/2" (38 mm) ou coupe-trou dans m_tal

(si un coffret m_tallique est utilise)

* Scie pour couper I'ouverture d'evacuation (s'il y a lieu)

* Toile de protection pour le produit et la cuisiniere

(vous pouvez aussi reutiliser le carton d'emballage)

* Ciseaux

* Crayon

* Metre

* Bande autocollante

5 IVIATI RIELD'INSTALLATION

Les articles de quincaillerie du materiel d'installation (_) fl (_1

sont emballes dans un petit sac. L'ensemble de ces pi_ces est

contenu dans un sachet plac6 sous le four.

R_f_rence

(0

(2)

(3)

(4)

(5)

(6;

(7)

(6)

@

@

@

Vis b. bois 5 x 35 mm 6

Boulon b. ailettes 3/16 po 4

Vis de coffret superieur 5 x 93 mm 2

Rondelle plate diametre 30 mm 2

Passe-ills 1

Vis autotaraudeuse 4 x 8 mm 4

Ensemble registre d'evacuation 1

Filtres b. graisse 2

Coussinet arriere 1

Instructions d'installation 316902446

Gabarit pour le plafond 316902447

Gabarit pour lemur 316902448

Description Quantit_

1. Ouvrez le fond du carton, basculez les rabats en artiste

et basculez le four pour le deposer sur la cale en mousse

plastique. Otez le carton et sortez tousles emballages de

protection, les Instructions d'installation, le gabarit mural,

le gabarit de plafond, le plateau toumant et son support.

Cependant, N'ENLEVEZ PAS LE CACHE DU GUIDE

D'ONDES qui est situe sur le haut de la cavite du four.

CONSERVEZ LE CARTON QUI PEUT VOUS FACILITER

L'INSTALLATION.

2. VC:RIFIEZ LE FOUR.

Cherchez des dommages eventuels sur le four, comme

un mauvais salignement ou une torsion de la porte,

des dommages au niveau des joints ou des surfaces

d'etanch6it6, des cassures ou desserrages de charnieres

ou de verrouillage, des entailles dans la cavit_ ou sur la

porte. Si vous trouvez un quelconque dommage, ne faites

pas fonctionner le four et contactez votre revendeur ou UN

SERVICE AGRFt¢: DE DFtPANNAGE ELECTROLUX.

ZZZZZZZ_Z................ //'_" ]

--_____ _/ Plaquede fixation

............. k_ .........

$ch6ma5

F..\,

k!u

k7)

\J

Sx,

k5_'r'_(il, PlacezautourdeI'ouverturepour cordon

_x

employeravecles armolresmetalhques.

>'xs,,_,, . - .

:_d'alimentation. Coupeza lataille voulue.

$ch6ma4

Pi_cesmontrees_desechellesdifferentes.

®

Page 12

SYSTEMEDEVENTiLATiON

8

(PBI'-='PABATIONDU FOURPOURL'INSTALLATION)

Le four b. micro-ondes A hotte integr6e est con£u pour s'adapter

b.trois types de systemes de ventilation par hotte. Choisissez le

type n_cessaire pour votre installation.

RECYCLAGE -- Hotte absorbante, b. recyclage. Suivez la

procedure d'installation (A). Ce type de hotte requiert

I'utilisation de filtres b. charbon actif, dejb. installes dans le

four.

r:CHAPPEMENTHORIZONTAL-- Ventilation exterieure. Suivez

la procedure d'installation (B).

ECHAPPEMENTVERTICAL -- Ventilation exterieure. Suivez la

proc6dure d'installation (C).

(A) A RECIBCULATIOND'AIB:FONCTIONNEIVlENTSANS

ECHAPPEMENTOUTUYAUTEBIE

L'unite est livree pour un fonctionnement b. recirculation

d'air.

REMARQUE:

1. L'ensemble de d'evacuation 9 West pas n_cessaire en cas

d'evacuation avec recyclage.

2. Les filtres b. charbon actif devraient _tre remplac_s tousles

6 b. 12 mois, selon la frequence d'utilisation.

Protection dela Lampedu Four

Lampedu Four

[:CHAPPEIVIENTHORIZONTAL:VENTILATIONEXTI_RIEURE

(B)

1.

Enievez les 3 vis du bord arriere et les 5 vis au-dessus de

la fixation du couvercie de ventilateur. Mettez de c6te les

3 vis qui seront r6utilis_es pour fixer I'ensemble registre

d'evacuation au mur, et jetez les 5 autres. Enlevez cette

piece en la glissant dans la direction oppos6e b. la fieche

marquee dessus, comme illustre sur le Schema 7.

2.

Levez I'unite de ventilation de hotte avec precaution et glissez

les ills hors de la cavite (voir le Schema 8). ATTENTION: NE

TIBEZ PAS SUB LES FILS DE CABLAGEET NELES I_TIBEZPAS.

3. FaRes pivoter I'unite de ventilation de la hotte de 180 ° de fagon

b.ce que les ouvertures de pales de ventilateur soient orientees

vers I'arriere du four. Voir le schema 9A, page 5.

4. Remplacez le c&ble de I'unite de ventilation de (A) b.(B). Voir

le schema 9B, page 5. Rempiacez I'unite de ventilation de

la hotte dans le four. Faites attention de ne pas pincer le

c_bie et I'unit_ de ventilation de la hotte. Voir le schema

9C, page 5.

5. Piacez le fil de connexion dans le coffret de fils. Voir le

schema 10A, page 5.

6. Fixer le registre d'evacuation au Support du Couvercie du

Ventilateur en le glissant dans les fentes dans la m_me

direction que la fleche. Utiliser 1 vis autotaraudeuse de 4 x

8 mm de la QUINCAILLERIE D'INSTALLATION et setter en

place. Voir le Schema lOB, page 5.

7. Cet ensemble sera monte dans le decoupage arri_re

exterieur du registre dans des instructions ulterieures. Voir

GABARIT MURAL pour le reste de la procedures.

Persiennesdela Hotte

$ch6ma GA

Persiennesdela

Hotte (Interieur)

_ _-- Filtres _ Charbon

J ) -2_

_*":-L'--- ;>h-LL ....

Fixation ....-'-':'._-

Languettede Fixation

Superieure

$ch6maGB

® 4

$ch6ma7

C_ble de

I'unit_ de

Ventilation

Schema8

Page 13

i

Tournez180o __-_ OuvertureSduVentiJateurP°UrPales

Modifiez la position du filet placez-le dans Forifice gauche

(B) (A)

Schema9B

C_bJede

Funit_ de

Ventilation

(C) I_CHAPPEMENTVERTICAL: VENTILATIONEXTERIEURE

1. Enlevez les 3 vis du bord arri_re et les 5 vis au-dessus de

la fixation du couvercie de ventiiateur pour les utiiiser b. F6tape

5. Enievez la fixation du couvercie de ventiiateur en la faisant

glisser dans le sens oppos6 & la fleche sur la fixation du

couvercle de ventilateur, comme illustr6 sur le Schema 11.

2. Levez I'unit6 de ventilation de hotte avec pr6cautions et glissez

les ills hors de la cavite. Voir le Sch6ma 12A. ATTENTION: NE

TIREZ PASSUR LESFILS DE CABLAGEET NE LESrtTIREZPAS.

3. Faites pivoter I'unite du ventilateur de hotte de 180 ° de

fa£on b. ce que les ouvertures des pales du ventilateur

soient orientees vers I'arriere du four. Voir schema 12B A la

page 6. Deplacez le c&ble du ventilateur de hotte de (A) b.

(B). Voir Schema 12C b. la page 6. Faites ensuite pivoter le

ventilateur de hotte de 90 ° de fa£on Ace que les ouvertures

des pales du ventilateur soient orient6es vers le haut du

four. Voir le schema 13, page 6. Remplacez le ventilateur

dans le four. Faites attention A ne pas pincer le fil de fil entre

la fixation int6rieure et I'unite de ventilation. Placez le fil de

connexion dans la botte de raccordement.

4. Remettez en place la fixation du couvercle de ventilateur

en la glissant dans les fentes dans la m6me direction que

la fleche marquee dessus. Assurez-vous que les pales de

ventilateur sont visibles au travers des ouvertures b. I'arri_re

avant de poursuivre. Voir le schema 14, page 6.

5. Fixez le support du capot du ventilateur b. I'unite gr&ce aux

3 vis du bord artiste et 4 vis A partir du haut du support du

couvercle du ventilateur b. I'exception de la vis (A) enlev6e

b. I'etape 1 ci-dessus. Voir Schema 14 A la page 6. La Vis

(A) sera utilisee pour la FIXATION DU FOUR SUR LE

MUR E_tape 5 A la page 7. L'unit6 de ventilateur de hotte

est maintenant positionn6e pour un fonctionnement en

evacuation A la verticale.

6. Fixez I'ensemble registre d'6vacuation au couvercle de

ventilateur sur le dessus du coffret de carter avant de monter

le four. Pour fixer I'ensemble registre d'6vacuation, reportez-

vous A la section MONTAGE MURAL DU FOUR, voir le

Sch6ma 20, page 7 et GABARIT DE PLAFOND.

c

Registre d'evacuation

Support du Couvercle

duVentilateur

Conserver cet ensemble

pour des instructions

uit6rieures.

C6te arriere du four

$ch6ma10A

_ JC6t6 mur I

_J tli

o 1i......................JointCoussine

/III o

/Jt/J/_ 0_=_=,_=='_--tli P0serleJ0intC0ussine

iIh_===_==___ arriereuneFoisle

...... Registred'evacuati0n

visseau mur.

$ch6ma 10B

(A)

Support du Couvercle du Ventilateur

©

$ch6ma 11

C_ble de

Funitede

Ventilation

,,

,i/- ii' i,i/

,iiii`' $ch6ma12A i i'

Unite de \

Ventilation de/

la Hotte \

/

®

Page 14

Tournez180°

IVIodifiezla position dufil et placez-ledans I'orificegauche

(B) (A)

$ch6ma 12C

Ouvertures pour Pales

duVentilateur

(B)

Ouvertures pour Pales du Ventilateur

(A)Tournez 90°

REMARQUE:CEFOUR DOITf:TREFIXEAAU MOINSUN POTEAUMURAL.

PLAQUE DE FiXATiON

1. S6parez les 4 boulons & ailettes, emballes avec le MATC:RIEL

d'INSTALLATION, des ecrous a.ailettes.

2. _ Utilisez Je gabarit de montage fourni

ainsi que les visa bois pour monter la plaque de fixation

sur Je ou les montants. UtiJisez ensuite Jes boulons

ailettes pour monter la plaque de fixation en utilisant les

orifices A, B, C et D, SAUF SI CES ORiFiCES TOMBENT

SUR LES MONTANTS. Ins_rez un boulon ou il y a lieu

en A, B, C ou D (correspondant aux orifices du gabarit

mural), puis vissez les aiJettes articui_es (voir Je Schema

15). Reportez-vous aux instructions du gabarit mural.

A C

3.

Placez la plaque de fixation avec les boulons a.ailettes sur

lemur et ins6rez les boulons & ailettes avec leurs ecrous

dans les trous dans le mur, les ailettes refermees. Voir le

schema 16. Employez les vis a.bois pour fixer la plaque de

fixation aux poteaux muraux.

REMARQUE: Avant d'inserer les boulons, veillez a. laisser

un espace sup6rieur a. I'epaisseur du mur entre la plaque

de fixation et I'extremit6 des ecrous & ailettes (en position

ferm_e). Si vous ne laissez pas assez d'espace, I'ecrou a.

ailettes ne pourra pas s'ouvrir de I'autre c6te du mur. En

outre, une fois que les ailettes sont ouvertes, on ne peut plus

enlever le boulon du mur, il faut donc veiller & ce que boulons

a.ailettes soient dans la bonne position avant de les inserer.

4.

Alignez soigneusement la plaque de fixation et tenez-la en

place pendant que vous serrez les boulons a. ailettes. Tirez

les boulons a.ailettes vers vous et vissez dans le sens des

aiguilles d'une montre. Voir le schema 17.

$ch6ma14

g INSTALLATIONDEFOUR

CE FOUR NE PEUT f:TREINSTALLr:CONVENABLEMENT QUE SiL'ON

SEREFi:REAUX iNSTRUCTiONSDEMONTAGE QUISETROUVENT SUR

LES DEUX GABARITS.

L'r:TAPESUIVANTEESTDELIREETDE SUIVRELESRENSEIGNEIVIENTS

DE MONTAGE QUi SE TROUVENT SUR LES GABARITS D'ARMOIRE

SUPr:RIEUREETDE MUR.

®

Ailettes

$ch6ma 15

$ch6ma 17

--- Mur

$ch6ma18

Page 15

MONTAGE MURAL DU FOUR

II recommande d'utiliser deux personnes pour placer le four b.

micro -ondes et sa hotte sur la plaque de fixation.

1. Passez le cordon secteur par le trou fait dans le fond du

cofret sup@ieur.

2. Installez le four en le faisant pencher vers I'avant, puis en

le faisant glisser sur les deux languettes de la plaque de

fixation. Poussez le four vers le haut et vers I' arri_re de

sorte qu'il cale contre lemur. Voir le schema 18, page 7.

3. Utilisez les deux vis de coffret sup@ieur et deux rondelles

plates foumies dans la PIF:CES D'INSTALLATION pour fixer

I'unite sur le coffret sup@ieur. Voir le schema 19, page 7.

4. Fixez le fond du four sur la plaque de fixation en vous

servant de deux vis autotaradeuses 4 x 8 mm dans les

PIF:CES D'INSTALLATION. Voir le schema 19, page 7.

5. (Uniquement pour I'echappement vertical)

Fixer le systeme de mouillage de I'echappement sur le

support du couvercle du ventilateur qui se trouve au dessus

du coffret le plus & I'exterieur en le glissant dans les fentes

en suivant la direction de la fleche et en se servant de la vis

(A) enlevee en (C) ECHAPPEMENT VERTICAL, €:TAPE 1

b.la page 5. Voir Schema 20 b.la page 7.

Vis Autotaraudeuse(A)

/

/

_J

$ch6ma20

PEHSE-BETEPOURL'INSTALLATION

1. Assurez-vous que I'appareil a et6 installe en suivant toutes les

instructions et en utilisant le gabarit mural et de plafond.

2. Branchez le cordon d'alimentation secteur.

3. Conservez ces Instructions d'installation.

Languettesde Fixation

Schema18

Vis pourCompartiment Sup@ieur

/

/

Rondelles

J..... Plates

REIVlAROUE:

Assurez-vous de retirer I'adhesif sur le support de plateau tournant

avant mise en fonctionnement. Voir le schema 21.

t

Retirer cet adhesifavant laraise en fonctionnement.

$ch6ma21

/

Vis Autotaraudeuse

$ch6ma19 7 (D

Page 16

Page 17

f

|HSrRU

ANTES DE COMENZAR

,, _ Guarde estas instrucciones para uso del

inspector local.

• _ Cumpla con los c6digos y normas vigentes.

NOTA PARA I_L |NS't'AllADOR - AsegOrese de

entregar estas instrucciones al consumidor.

NO3['A A II OONSUM|DOR - Conserve estas

instrucciones para referencias futuras.

• N|VEL DE CONOCJMJENTO- La instalaci6n de este

aparato requiere de conocimientos b_.sicos sobre mec_.nica

y electricidad.

NES DE INSTALACION

Leaestasinstruccionescomp/etaydetal/adamente.

1 ESPACIODEiVlONTAJE

• La correcta instalaci6n es responsabilidad del instalador

• La garantia no cubre la falla del producto por instalaci6n

inapropiada.

• Lea detenidamente las instrucciones antes de instalar el Homo

microondas sobre estufa. Se recomienda que la instalaci6n de

este producto sea realizada entre dos personas.

• Si se requiere un tomacorriente el_ctrico nuevo, su instalaci6n

debe ser realizada por un electricista calificado antes de

instalar el Homo microondas sobre estufa. Vea el capitulo 3

INSTRUCCIONES DE CONEXlON ELg:CTRICA A TIERRA

en la pagina 2.

2 COHSTRUCCII NDEPARED

Este Horno microondas sobre estufa requiere de un espacio

de montaje en la pared como se muestra en la Figura 1. Esta

diseSado para ser utilizado en gabinetes de pared est_,ndar

de 12". La profundidad maxima es 13 pulgadas.

30" 0 mas con

Salpicadero

I

respectoa la

superficiede

lacocina

66" o m_s

con respecto

al piso

Este Homo microondas sobre estufa debe montarse y

apoyarse en una pared vertical plana. La pared debe ser

plana para una instalaci6n apropiada. Si la pared no es plana,

utilice espaciadores para Ilenar los vacios. La construcci6n de

pared debe consistir de montantes de madera de 2"x 4" como

minimo y tablaroca o yeso/list6n de 3/8"o m_.s de espesor. Las

superficies de montaje deben set capaces de soportar un peso

de 50 kg (110 libras) --el horno y su contenido--ADEMAS

de todos los elementos que generalmente se guardan en el

gabinete superior por encima de la unidad.

La unidad debe set fijada como minimo a un montante

de 2" × 4".

Para encontrar la ubicaci6n de los montantes, puede seguir

uno de los siguientes m6todos:

A.

Utilice un Iocalizador de montantes, un dispositivo

magn6tico que Iocaliza los clavos en el montante.

a.

Utilice un martillo para golpear levemente la superficie

de montaje tratando de encontrar un sonido macizo. Esto

le indicar_, la ubicaci6n del montante.

El centro del montante puede ser ubicado sondeando la pared

con un pequeSo clavo para encontrar los bordes del montante

y luego colocando una marca en el punto medic entre los

bordes. El centro de cualquier montante adyacente por Io

general estara a 16" o 24" de cualquier lado de esta marca.

,NECESITAAYUDA?

Para clientes en Estados Unidos y Canada. Ilame al

Estados Unidos :1-800-944-9044

Canada: 1-800-265-8352

LEACUIDADOSAMENTE.GUARDE ESTASINSTRUCCIONES.

Page 18

INSTBUCCIONESDECONEXI6NATiEBBA

ELECTRiCA

4 DUCTODEESCAPEDECAIVlPANA

EXTBACTOBA

Este aparato debe conectarse a tierra. Este horno est,.

equipado con un cable que tiene un alambre de tierra y

enchufe con pata de tierra. ¢:ste debe enchufarse en un

tomacorriente de pared instalado apropiadamente y conectado

a tierra de acuerdo con el C6digo El_ctrico Nacional, y los

c6digos y ordenanzas locales. En caso que se produzca un

cortocircuito el6ctrico, la conexi6n a tierra reduce el riesgo

de descarga el_ctrica proporcionando un alambre de escape

para la corriente el6ctrica.

ADVERTENCiA- El uso inapropiado del enchufe con pata de

tierra puede resultar en peligro de descarga e 16ctrica.

BEQUEBllVilENTOSEL[:CTBICOS

El homo esta equipado con un enchufe de conexi6n a tierra,

de tres patas. BAJO NINGUNA CIRCUNSTANCIA CORTE O

RETIRE LA PATA DE TIERRA DEL ENCHUFE.

NO UTILICE EXTENSIONES DE CABLE. Si el cable de

alimentaci6n es demasiado corto, deje que un electricista

o t6cnico calificado instale un tomacorriente cerca del

aparato.

El Cable de Suministro de Energia y el enchufe deben

conectarse en un tomacorriente conectado a tierra de

circuito separado de 120 Voltios AC, 60 Hz, 15 Amp, 6 mas.

El tomacorriente debe ubicarse dentro del gabinete ubicado

directamente sobre el sitio de montaje del homo microondas

mostrado en la Figura 2.

NOTA:

1. Si tiene preguntas acerca de las instrucciones el6ctricas o

de conexi6n a tierra, consulte un electricista calificado.

2. Ni Electrolux ni el distribuidor pueden aceptar ninguna

responsabilidad por da_o al homo opor lesiones personales

resultantes de no seguir los procedimientos correctos de

conexi6n el6ctrica.

Cuando la campana extractora tiene escape hacia el

exterior, se requiere un ducto de escape de campana. Todo

el ducto debe ser metalico, categ6ricamente no utilice ducto

plastico. Verifique que todas las conexiones est_.n sujetadas

firmemente. Por favor lea cuidadosamente Io siguiente:

CONEXION DE ESCAPE: El escape de la campana ha sido

diseSado para conectarse con un ducto rectangular est_.ndar

de 3 W'x 10". Si se requiere ducto redondo, debe utilizarse

un adaptador de rectangular a redondo.

ESCAPETRASERO: Si debe utilizarse un escape trasero o

escape horizontal, debe tenerse cuidado de alinear el escape

con el espacio entre las columnas, o la pared debe prepararse

en el momento de construirse dejando suficiente espacio

entre las columnas de pared para acomodar el escape.

LONGITUD MAXIMA DEL DUCTO: Para movimiento satisfactorio

del aire, la Iongitud total del ducto rectangular de 3 W'x 10" 6

del ducto redondo con di_.metro de 6" no debe exceder 140

pies (42.7 m).

Los codos, adaptadores, tapas de pared, tapas de techo,

etc., presentan resistencia adicional al flujo de aire y son

equivalentes a una secci6n recta de ducto con Iongitud

superior a su Iongitud fisica real. Cuando se calc ula la

Iongitud total, agregue las longitudes equivalentes de todas

las transiciones y adaptadores m_.s la Iongitud de todas las

secciones rectas de ducto. La Figura 3 muestra la Iongitud

equivalente aproximada en pies de algunas partes de ducto

tipicas. Utilice los valores dentro de par6ntesis para calcular

la resistencia al fiujo de aire equivalente que debe ser un valor

total inferior a 140 pies (42.7 m).

NOTA:

Se recomienda utilizar cinta selladora en los conductos del

homo para sellar las conexiones de los conductos al regulador

de succi6n de extracci6n.

Tomacorriente

Conectado a IOI

Tierra

Orificio para el Cable

deEnergia

Figura2

® 2

90° Codo (10 pies.)

90° Codo (25 pies.)

45 °Codo (5 pies.)

45 °Code (5 pies.)

Adaptador (5 pies.)

Tapa de Pared

(40 pies.)

Figura3

Code Ancho de 10

pulgadas (10 pies.)

Tapa de Techo

(24 pies.)

Page 19

5 HERRAIVilENTASRECOiVlENDADASPARA

LAINSTALACION

• Atornillador Phillips

• Taladro el6ctrico

• Brocas de 1/2", 5/8"y 3/32"

" Broca para madera de 11/2"6 Cortador de orificios en

metal (si se utiliza gabinete met&lico)

• Scie pour couper I'ouverture d'6vacuation (s'il y a lieu)

• Sierra para cortar el orificio de escape (sise requiere)

• Patio para proteger el homo - tambi6n se puede utilizar

cart6n para protecci6n

• Tijeras

• L@iz

• Cintapara medir

6 HERRAJESDEINSTALACiON

Los elementos de latornilleria de instalaci6n del d; - @estan

en una bolsa pequefia. Todos los elementos se encuentran

en una caja de cart6n debajo del homo.

Elemento Nombre Cantidad

_1) Torniiio para Madera de 5 x 35 mm 6

_2) Perno de Anclaje de 3/16" 4

_3_ Tornillo Gabinete Superior de 5 x 93 mm 2

Arandela Plana con diD.metro de

@ 2

30 mm

_5) Anillo de Refuerzo 1

_6) Tornillo Auto-Perforante de 4 x 8 mm 4

_7) Regulador de Succi6n de Extracci6n 1

_) Filtros de grasa 2

_) Amortiguador posterior 1

@ Instrucciones de instalaci6n 316902446

® Plantilla superior 316902447

@ Plantilla de pared 316902448

7 PREPARACIONDELHORNO

1.

Abra la parte inferior de la caja de cart6n, doble hacia

atras las alas de la caja de cart6n y voltee la caja para

colocar el homo sobre el cojin de espuma plastica.

Levante y extraiga la caja de cart6n del homo y saque

todos los materiales de empaque, las Instrucciones de

instalaci6n, la plantilla de pared, la bandeja giratoria y su

soporte; sin embargo, NO EXTRAIGA LA CUBIERTA DE

GUIA DE ONDAS que est,. ubicada en el techo dentro de

la cavidad del homo. GUARDE LA CAJA DE CARTON

YA QUE t_STA PODRIA FACILITAR LA INSTALACION.

REVISE EL HORNO. Revise el horno en cuanto a

2.

dafio, tal como puerta desalineada o doblada, sellos y

superficies de sellado de puerta dafiadas, bisagras y

cerrojos de puerta rotos o flojos, y abolladuras dentro

de la cavidad o en la puerta. Si existe algOn dafio, no

opere el homo y comuniquese con su distribuidor o

con el PROVEEDOR DE SERVICIOAUTORIZADO DE

ELECTROLUX.

Figura5

_1_ _. k2_,

\ /

Laspartes mostradas no estan aesca[a.

<_i/ Utilice con gabJnetes metalicoe.

_5_ _,i<, Bordee el orJficio para el cable de

i_ energia. Corte para ajustar.

_,'_,.

s -h

,@

Fitura 4

®

Page 20

SISTElVlADEVENTILACICN

8 1.

(PREPARACIONDELHOBNOPABASU INSTALACION)

Este Horno microondas sobre la estufa esta dise_ado

para adaptarse a tres tipos de sistemas de ventilaci6n de

campana extractora. Seleccione el tipo correspondiente a

su instalaci6n.

RECIRCULANTE- sin extracci6n al exterior, sin ducto.

Siga el procedimiento de instalaci6n (A). La recirculaci6n

requiere el uso de los filtros de carb6n vegetal, que est_.n

instalados en el horno.

ESCAPEHORIZONTAL-- extracci6n hacia el exterior. Siga

el procedimiento de instalaci6n (B).

ESCAPEVERTICAL-- extracci6n hacia el exterior. Siga el

procedimiento de instalaci6n (C).

RECIBCULACION: OPEBACIONSINEXTBACCIONAL XTEBIOB,

(A)

SINDUCTO

La unidad viene ensamblada para recirculaci6n.

1. No se requiere el conjunto del amortiguador de escape

para recircular el escape.

2. Los filtros de carb6n vegetal deben sustituirse cada 6 o

12 meses, segOn el uso.

(B)ESCAPE HORIZONTAL:EXTBACCI{)NHACIAELEXTERIOR

CubiertadelaLuzdelHorno

Luz del Horno

Retire 3 tornillos del borde posterior y 5 tornillos de la

parte superior del soporte de la cubierta del ventilador.

Guarde los 3 tornillos para utilizarlos mas tarde para

fijar el conjunto del amortiguador de escape a la pared

y deseche los 5 tomillos restantes. Retire el soporte de

la cubierta del ventilador deslizandolo en la direcci6n

contraria de la flecha que aparece en el soporte, como

se muestra en la Figura 7.

2.

Levante la unidad de ventilador de la campana extractora

y deslice los alambres afuera de la cavidad. Vea la

Figura 8. Precauci6n: No jale o estire los Alambres

del Ventilador de la Campana.

3.

Gire la unidad de ventilador de la campana 180 ° para

que los Orificios de las Paletas del Ventilador est_n

frente a la parte posterior del horno. Vea la Figura 9A de

la p_.gina 5.

4.

Vuelva a colocar el cable del ventilador de (A) a (B).

Vea la Figura 9B de la p_.gina 5. Coloque nuevamente

la unidad del ventilador de la campana en el homo.

Tenga cuidado de no atrapar el cable y la unidad

del ventilador de la campana. Vea la Figura 9C de la

pagina 5.

5.

Coloque el alambre nuevamente en la cavidad. Vea la

Figura 10A de la p_.gina 5.

6.

Ensamble el conjunto del amortiguador de escape al

Soporte de la Cubierta del Ventilador desliz_ndolo por

las ranuras en la misma direcci6n de la flecha. Utilice 1

tornillo autorroscante de 4 x 8 mm de la TORNILLERiA

DE INSTALACION y apriete hasta colocarlo en posici6n.

Vea la Figura 10B de la p_.gina 5.

7.

Este conju nto se montarA en el recorte del escape posterior

exterior para instrucciones futuras. Vea la PLANTILLA

DE PARED para seguir con el procedimiento.

RejilladeVentilacionde

CampanaExtractora

RejilladeVentilaciondeCampana

Extractora(Interior)

Lengiietas

®

FiltrosdeCarbCnVegetal

Figura eg

Lengiieta Superior

Alambresdel

Ventiladorde

laCampana

Figura7

Unidadde

Ventiladord(

la Campana

//

Page 21

Gire 1800 Orificios de lasPaletas

del Ventilador

Cambielap0sici6ndelcablealoriliciedelladeizquierdo.

(B) (A)

Figura9B

Alambresdel

Ventiladorde

laCampana

ESCAPEVERTICAL:EXTRACCIONHACIAELEXTERIOR

(c)

1.

Retire y guarde 3 tornillos del horde posterior y 5 tornillos de

la parte superior del soporte de la cubierta del ventilador para

utilizarlos en el Paso 5. Retire el soporte de la cubierta del

ventilador deslizb,ndolo en la direcci6n opuesta a la flecha en

el soporte de la cubierta del ventilador, segOn se muestra en la

Figura 11.

2. Levante la unidad de ventilador de la campana extractora y

deslice los alambres afuera de la cavidad. Vea la Figura 12A.

Precaucibn: No jale o estire los Alambres del Ventilador de

la Campana.

3. Gire el ventilador de la campana 180 ° para que los orificios

de las paletas del ventilador queden mirando hacia el homo.

Consulte la Figura 12B en la pb,gina 6. Cambie el cable del

ventilador del homo de (A) a (B). Consulte la Figura 12C en la

pagina 6. Despues gire el ventilador del homo 90 ° de manera

que los orificios de las paletas del ventilador queden mirando

hacia la parte superior del homo. Vea la Figura 13 de la pb,gina

6. Coloque nuevamente la unidad de ventilador de la campana

en el homo. Tenga cuidado de no atrapar el conductor entre

el soporte interior y la unidad de ventilador de la campana.

Coloque el conductor en la caja de alambres.

4. Coloque nuevamente el soporte de la cubierta del ventilador

deslizandolo porlas ranurasen lamismadirecci6n delaflechadela

cubiertadelventilador.Aseg_ resedequelas paletasdelventilador

sean visibles a traves de los orificios superiores en el homo antes

de preceder. Vea la Figura 14 de la pb,gina 6.

5. Fije el soporte de la cubierta del ventilador a la unidad con los

3 tornillos del horde trasero y 4 tornillos, excepto el tornillo (A),

de la parte superior del soporte de la cubierta del ventilador,

que se retiraron en el Paso 1 anterior. Consulte la Figura 14 en

la pagina 6. El tornillo (A) se utilizarb, para MONTAR SOBRE

LA PARED en el Paso 5 en la p6,gina 7. Ahora, la unidad de

ventilador de la campana ha girado para una operaci6n de

escape vertical.

6. Despues de montar el homo, sujete el Regulador de Succi6n de

Extracci6n a la cubierta del ventilador ubicada en la parte superior

del homo. Para sujetar el Regulador de Succi6n de Extracci6n,

remitase al capftulo "MONTAJE DEL HORNO EN LA PARED",

Vea la Figura 20 de la pagina 7 y la PLANTILLA DEL GABINETE

SUPERIOR.

Conjunto del

Amortiguadorde

Escape

Soporte de la

Cubierta del

Ventilador

ILado de .a]

GuardeesteConjunto para _ pared. I

FuturasInstrucciones. _-JJJ_i

__ _ _ Amortiguador

li!_ ° _0_ II Ap_ue elAmortiguador

__1 PosteriorLuegode Fijar

__ ........ I ala ParedelConjunto

I de Amort guador

IParte posterior del homo. I FiguPa 11)B l deEscape.

Alambresdel

Ventiladorde

la Campana

®

Page 22

Gire 180° Orificios de LasPaletas

i

i

delVentilador

Cambielaposici6ndelcableal0rifici0dellad0izquierdo.

(B) (A)

N0]A: ESTE HORNO DEBE SUJETARSE A AL MENOS UNA

COLUMNA DE PARED.

PLACADEMONTAJE

1. Extraiga las tuercas de anclaje, empaquetadas en los

HERRAJES DE INSTALACION, de los 4 pernos

2. _ UtiJice Ja pJantiJJa de montaje que se

incJuye para el uso de torniJJos para madera para sujetar

la placa de montaje a la columna o columnas. UtiJice

los pernos de anclaje para sujetar la placa de montaje

a trav_s de Jos orificios en A, B, C y D A MENOS QUE

ESTOS ORIFICIOS SE ENCUENTREN UBICADOS SOBRE

LA COLUMNA. Inserte un perno de anclaje en A, B, C y D

donde sea apropiado (_stos corresponden a Jos orificios

de JapJantiJJa de pared) y coloque Jas tuercas de anclaje

sobre los pernos de anclaje. Vea la Figura 15. Consulte

Jas instrucciones de Ja pJantiJJa de pared.

(A)Gire 90°

Figura12C

(B) 0rifici0sdelasPaietas

delVentilad0r

A C

3.

Coloque la Placa de Montaje con los Pernos de Anclaje

sujetados, en el sitio de pared e inserte los Pernos y Tuercas

de Anclaje a trav6s de los orificios en la pared con las Tuercas

de Anclaje cerradas. Vea la Figura 16. Utilice Tornillos para

Madera.

N0]A: Antes de la inserci6n, aseg0rese de dejar un espacio

superior al espesor de la pared entre la Placa de Montaje

y el extremo de cada una de las Tuercas de Anclaje (en la

posici6n cerrada). Si usted no deja suficiente espacio, la

Tuerca de Anclaje no podrb, abdrse en el otto lado de la

pared. Adem_.s, una vez que la Tuerca de Anclaje se abre,

esta no puede retirarse del orificio; por Io tanto asegurese

que todos los Anclajes est_.n en la posici6n correcta antes

de la inserci6n.

4.

Alinee cuidadosamente la Placa de Montaje y sostenga en

posici6n mientras aprieta los Pernos de Anclaje. Hale el

Perno de Anclaje hacia usted y gire en sentido horatio para

apretar. Yea la Figura 17.

Pernode Anclaje

Placade Montaje j

D B

Figura15

9 INSTALACIONDELHORNO

ESTE HORNO NO PUEDE INSTALARSE APROPIADAMENTE

Sl NO SE CONSULTAN LAS INSTRUCCIONES DE MONTAJE

QUE SE ENCUENTRAN EN AMBAS PLANTILLAS.

EL SlGUIENTE PASO ES LEER Y SEGUIR LA INFORMACION

DE MONTAJE QUE SE ENCUENTRA TANTO EN EL

GABINETE SUPERIOR Y EN LAS PLANTILLAS DE

PARED.

®

i

i

i

i

i

i

Oejeespaciosuperior

aJespesordepared

Figura17

Page 23

MONTAJE DEL HORNO EN LA PARED

II recommande d'utiliser deux personnes pour placer le four b.

micro-ondes et sa hotte sur la plaque de fixation.

1. Passez le cordon secteur par le trou fait dans le fond du

cofret sup_rieur.

2. Instale el homo inclinandolo hacia delante y desliz&ndolo sobre

las lengQetas de la placa de montaje. Gire el homo arriba tan

descansa contra la pared. Vea la Figura 18 de la p_.gina 7.

3. Utilisez les deux vis de coffret superieur et deux rondelles plates

fournies dans la HERRAJES DE INSTALACION pour fixer

I'unit_ sur le coffret superieur. Vea la Figura 19 de la pb.gina 7.

4. Asegurar el fondo del homo a la Placa de Montaje utilice dos

Tornillo Auto-perforante de 4 x 8 mm de los HERRAJES DE

INSTALACION. Vea la Figura 19 de la p_.gina 7.

5. (Solo para escape vertical)

Conecte el regulador de succi6n de extracci6n al soporte

de la cubierta del ventilador en la parte superior del homo al

deslizarlo en las ranuras en la misma direcci6n que marca la

Leng_ietas

TorniJloAuto-perforante (A)

Figura20

flecha hasta que el tornillo (A), que se retir6 en (C) ESCAPE

VERTICAL, PASO 1 en la p_.gina 5. Consulte la Figura 20

en la p_.gina 7.

LISTADEVERIFICACIONPARAINSTALACION

1. AsegOrese que la unidad ha sido instalada de acuerdo con

todas las Instrucciones de Instalaci6n y las Plantillas de Pared

y las Plantillas del Gabinete Superior.

2. Enchufe el cable de energia.

3. Conserve estas Instrucciones de instalaci6n.

NOTA:

AsegQrese de retirar la cinta del soporte del plato giratorio antes de

poner el homo en marcha. Vea la Figura 21.

Figura 18

Tornillos Gabinete Superior

_-' Arandelas Planas j

TorniJloAuto-perforante

Figura19

I

Quiteestacintaantesdeponerelhomoenmarcha.

Figura21

®

Page 24

Loading...

Loading...