Frigidaire FGMV185KW, FGMV205KB, FGBM205KF, FGBM185KW, FGBM185KB Installation Manual

...

INSTALLATION INSTRUCTIONS

Over The Range Microwave Oven

BEFORE YOU BEGIN

IMPORTANT

•

inspector’s use.

IMPORTANT

•

coordinates.

•

NOTE TO INSTALLER – Be sure to leave these

instructions with the Consumer.

•

NOTE TO CONSUMER – Keep these instructions for

future reference.

• SKILL LEVEL – Installation of this appliance requires

basic mechanical and electrical skills.

Save these instructions for local

Observe all governing codes and

Read these instructions completely and carefully.

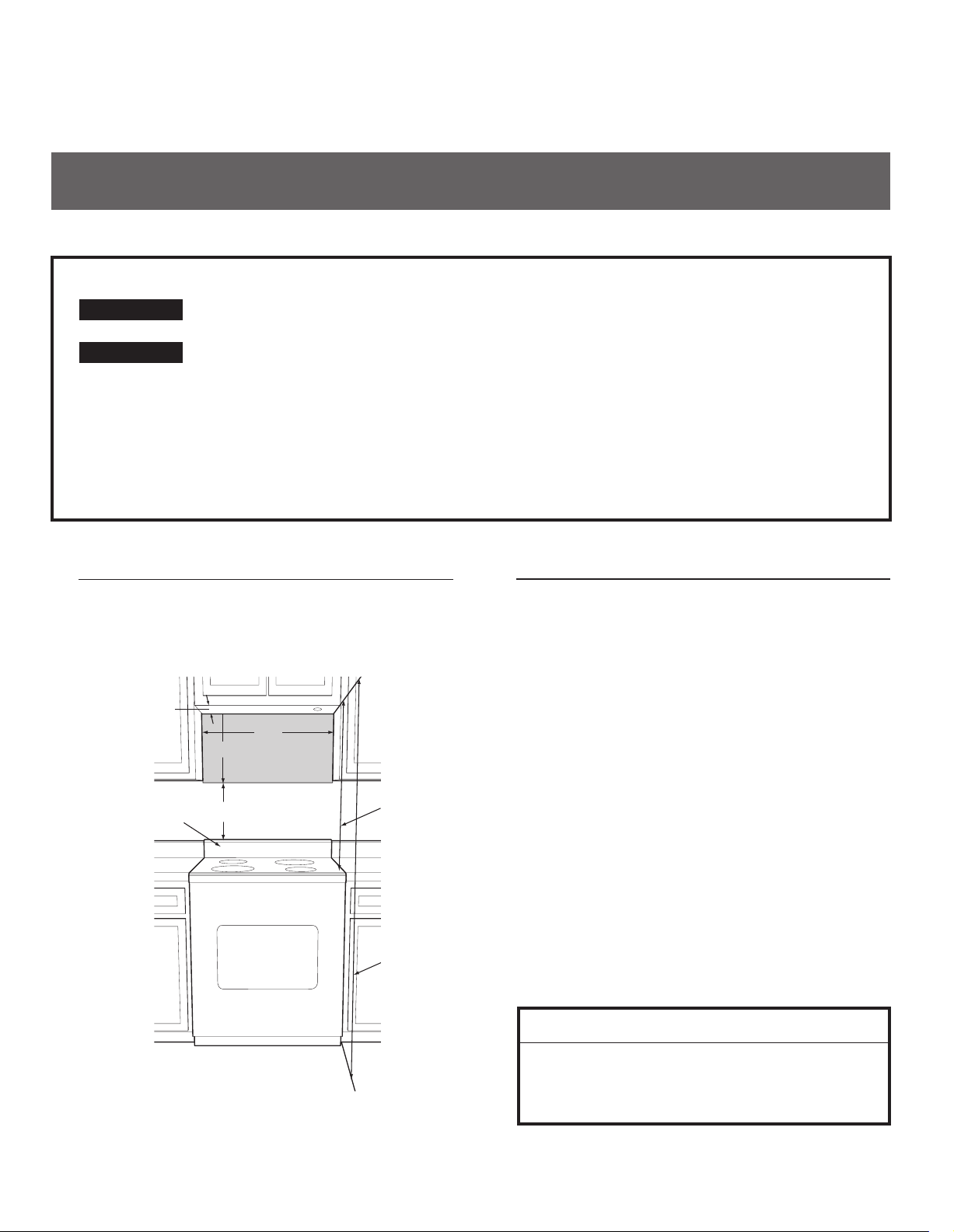

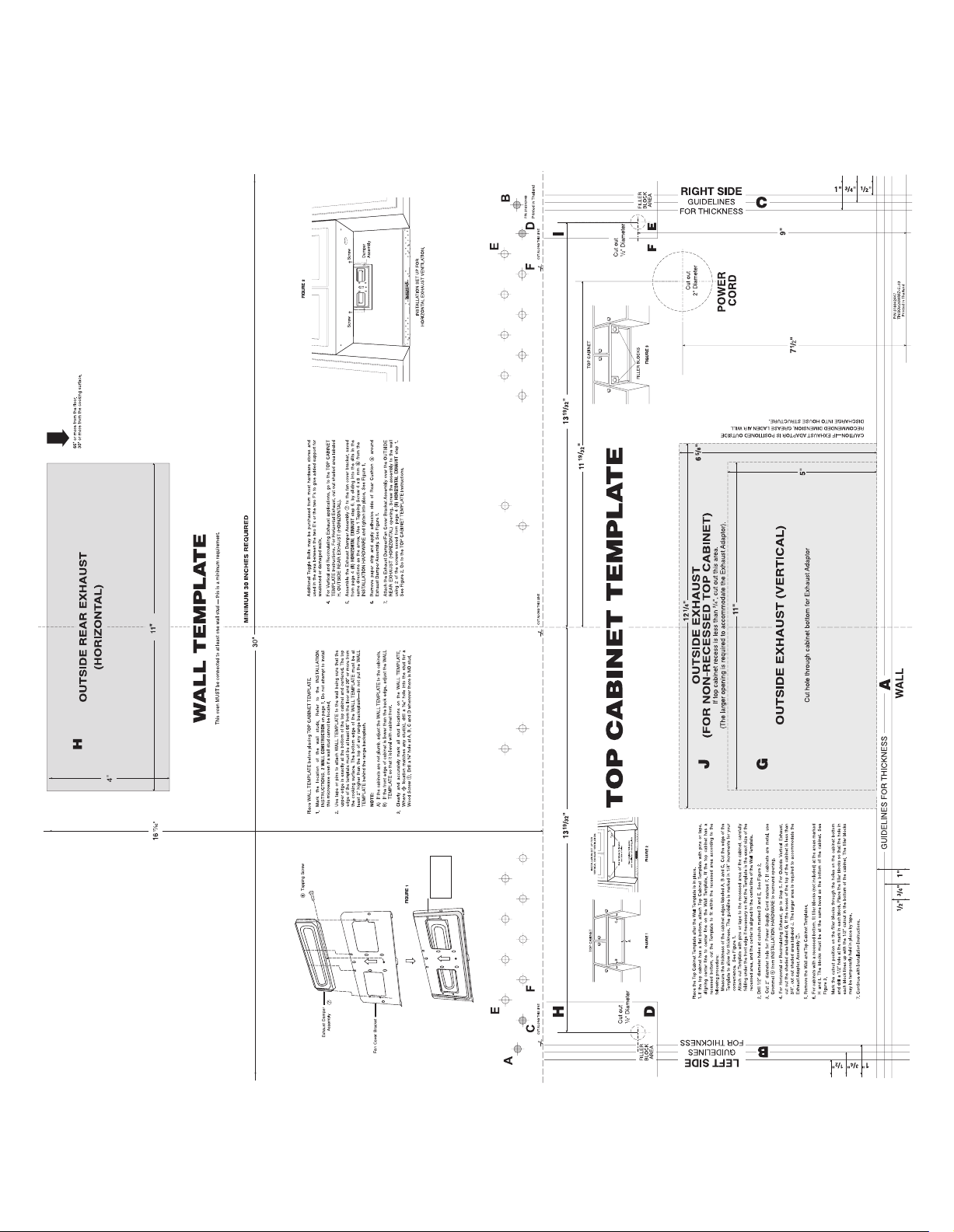

1 MOUNTING SPACE

This Over the Range Microwave Oven requires a mounting

spa ce on a wall as s hown i n Figu re 1. It i s desi gned to be use d

with standard 12" wall cabinets. The maximum depth is 13".

13” max depth.

30"

15.5"

30" or more

Backsplash

At least 2"

from cooking

surface

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not covered

under the Warranty.

• Please read all instructions thoroughly before installing

the Over the Range Microwave Oven. Two people are

recommended to install this product.

• If a new electrical outlet is required, its installation should

be completed by a qualifi ed electrician before the Over the

Range Microwave Oven is installed. See 3 ELECTRICAL

GROUNDING INSTRUCTIONS on page 2.

2 WALL CONSTRUCTION

This Over the Range Microwave Oven should be mounted

against and supported by a fl at vertical wall. The wall must

be fl at for proper installation. If the wall is not fl at, use spacers

to fi ll in the gaps. Wall construction should be a minimum of

2" x 4" wood studding and 3/8" or more thick dry wall or plaster/lath.

The mount ing sur faces mus t be c apable o f suppor ting weig ht

of 110 pounds—the oven and contents—AND the weight of

all items which would normally be stored in the top cabinet

above the unit.

The unit should be attached to a minimum of one 2" x 4"

wall stud.

To fi nd the location of the studs, one of the following methods

may be used:

A. Use a stud finder, a magnetic device which locates the

nails in the stud.

B. Use a hammer to tap lightly across the mounting surface

to find a solid sound. This will indicate stud location.

66" or more

from fl oor

Figure 1

As a guide to installation, see page 8 for Mounting

Template Information.

The center of the stud can be located by probing the wall with

a small nail to fi nd the edges of the stud and then placing a

mark halfway between the edges. The center of any adjacent

studs will normally be 16" or 24" to either side of this mark.

NEED HELP?

For customers in the United States and Canada

United States: 1-800-944-9044

Canada: 1-800-265-8352

READ CAREFULLY. KEEP THESE INSTRUCTIONS.

316902446

February 2011

TINSEB294WRRZ-EL01

Printed in Thailand

INSTALLATION INSTRUCTIONS

3 ELECTRICAL GROUNDING INSTRUCTIONS

Thi s applia nce must be gr ounded. This o ven is equ ipped wi th

a cord having a grounding wire with a grounding plug. It must

be p lugged i nto a wall recepta cle that is pr operly i nstall ed and

grounded in accordance with the National Electrical Code and

local codes and ordinances. In the event of an electrical short

circuit, grounding reduces risk of electric shock by providing

an escape wire for the electric current.

WARNING - Improper use of the grounding plug can result

in a risk of electric shock.

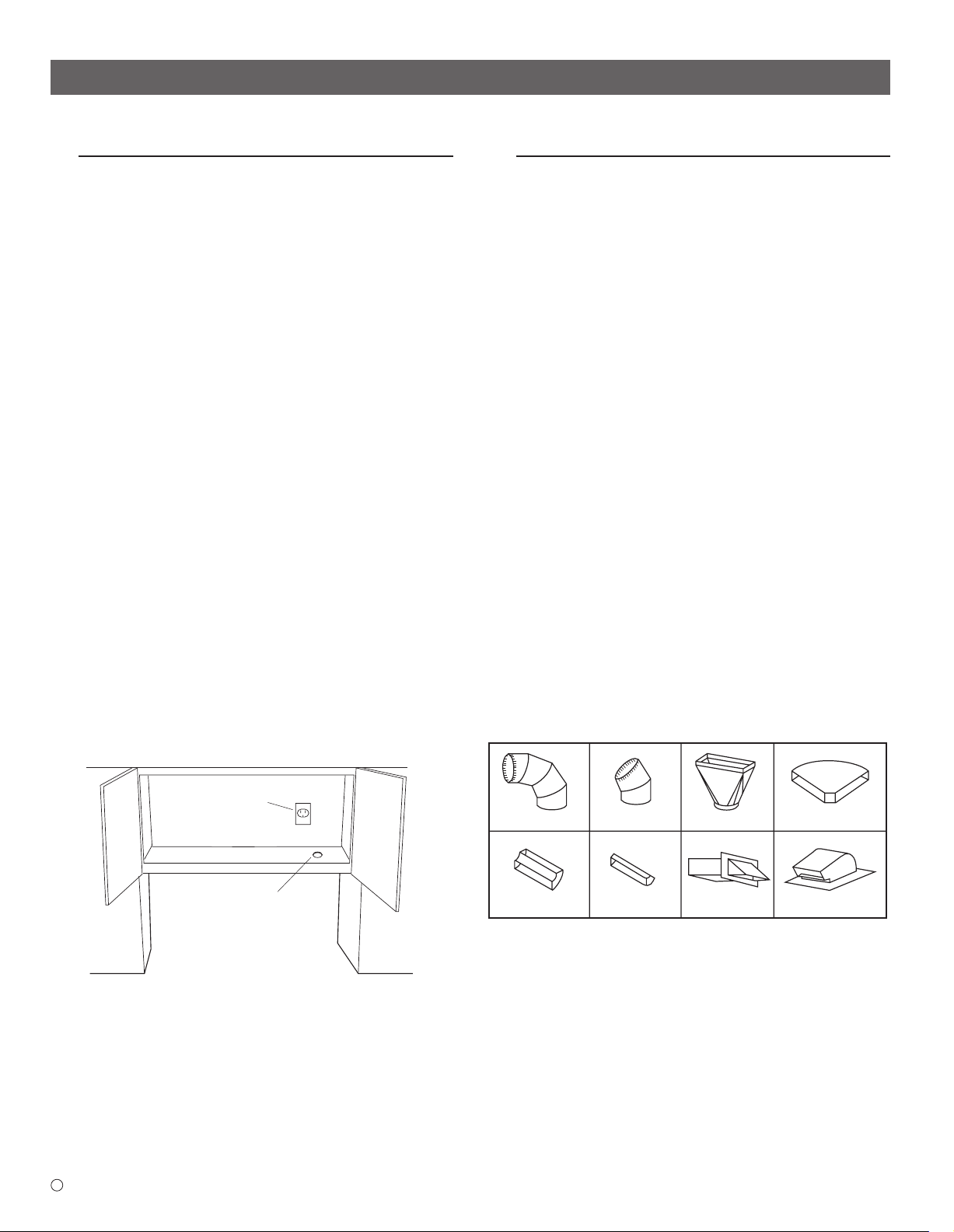

ELECTRICAL REQUIREMENTS

The oven is equipped with a 3-prong grounding plug. DO

NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE

THE GROUNDING PIN FROM THE PLUG.

DO NOT USE AN EXTENSION CORD. If the power supply

cord is too short, have a qualifi ed electrician or serviceman

install an outlet near the appliance.

The Power Supply Cord and plug must be connected to

a separate 120 Volt AC, 60 Hz, 15 Amp, or more branch

circuit, single grounded receptacle. The receptacle should

be located inside the cabinet directly above the Microwave

Oven mounting location as shown in Figure 2.

NOTE:

1. If you have any questions about the grounding or

electrical instructions, consult a qualifi ed electrician or

serviceperson.

2. Neither Electrolux nor the dealer can accept any liability for

damage to the oven or personal injury resulting from failure

to observe the correct electrical connection procedures.

4 HOOD EXHAUST DUCT

When the hood is vented to the outside, a hood exhaust duct

is r equir ed. Al l ductwork m ust b e metal ; absolute ly do n ot us e

plastic duct. Check that all connections are made securely.

Please read the following carefully:

EXHAUST CONNECTION: The hood exhaust has been designed

to connect to a standard 3

duct is required, a rectangular-to-round adapter must be

used.

REAR EXHAUST: If a rear or horizontal exhaust is to be used,

care should be taken to align the exhaust with the space

between the studs, or wall should be prepared at the time it

is constructed by leaving enough space between wall studs

to accommodate exhaust.

MAXIMUM DUCT LENGTH: For satisfactory air movement, the

total duct length of 3

duct should not exceed 140 feet.

Elbows, adapters, wall caps, roof caps, etc. present additional

resistance to air fl ow and are equivalent to a section of straight

duct which is longer than their actual physical size. When

calculating the total length, add the equivalent lengths of all

transitions and adapters plus the length of all straight duct

sections. Figure 3 shows the approximate feet of equivalent

length of some typical ductwork parts. Use the values in

parentheses for calculating air fl ow resistance equivalent,

which should total less than 140 feet.

NOTE:

Furnace duct sealing tape is recommended to seal duct

connections to the Exhaust Dampener Assembly.

1

/4" x 10" rectangular duct. If round

1

/4" x 10" rectangular or 6" diameter round

Ground

Receptacle

Opening for

Power Cord

Figure 2

E

90° Elbow (10 ft.)

90° Elbow (25 ft.)

2

45° Elbow (5 ft.)

45° Elbow (5 ft.)

Figure 3

Adaptor (5 ft.)

Wall cap (40 ft.)

10" Wide Elbow (10 ft.)

Roof cap (24 ft.)

INSTALLATION INSTRUCTIONS

5 TOOLS RECOMMENDED FOR

INSTALLATION

• Phillips Screwdriver

• Electric Drill

• 1/2", 5/8" and 3/32" Drill Bits

• 1 1/2" Wood Bit or Metal Hole Cutter

(if metal cabinet is used)

• Saw to cut exhaust opening (if needed)

• Protective Drop Cloth for product and range -

you may also use carton for protection

• Scissors

• Pencil

• Measure

• Tape

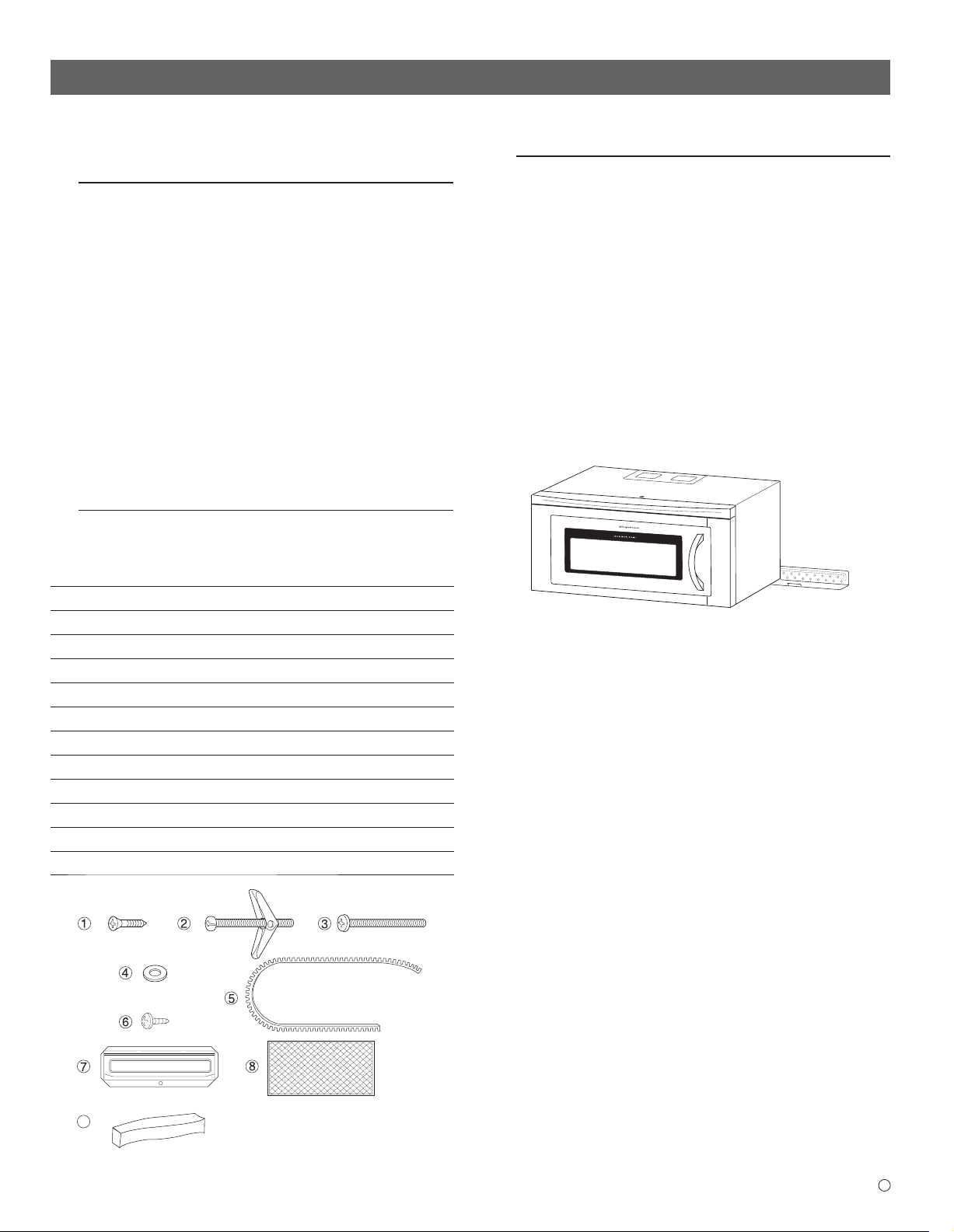

6 INSTALLATION HARDWARE

The INSTALLATION HARDWARE items ➀ - ➅ are in a small

bag. All items are in a bag packed below the oven.

Item Name Quantity

Wood Screw 5 x 35 mm

q

3

Toggle Bolt

w

Top Cabinet Screw 5 x 93 mm

e

Flat Washer 30 mm diameter

r

Grommet

t

Tapping Screw 4 x 8 mm

y

Exhaust Damper Assembly

u

Grease Filter

i

Rear Cushion

o

Installation Instructions 316902446

a

Top Template 316902447

s

Wall Template 316902448

d

/16"

6

4

2

2

1

4

1

2

1

1

1

1

7 PREPARATION OF THE OVEN

1. Open the bottom of the carton, bend the carton flaps

back and tilt the oven over to rest on plastic foam pad.

Lift carton off oven and remove all packing materials,

Installation Instructions, Wall Template, Top Template,

Turntable and Turntable Support; however, DO NOT

REMOVE THE WAVEGUIDE COVER, which is located

on the ceiling in the oven cavity. SAVE THE CARTON AS

IT MAY MAKE INSTALLATION EASIER.

2. CHECK THE OVEN.

Check the oven for any damage, such as misaligned or

bent door, damaged door seals and sealing surfaces,

broken or loose door hinges and latches and dents inside

the cavity or on the door. If there is any damage, do not

operate the oven and contact your dealer or Electrolux

AUTHORIZED SERVICER.

Mounting Plate

Figure 5

Use with metal cabinets. Surround

the power cord opening. Cut to fi t.

9

Parts shown not to common scale.

Figure 4

3

E

INSTALLATION INSTRUCTIONS

8 VENTILATION SYSTEM

(PREPARING OVEN FOR INSTALLATION)

This Over the Range Microwave Oven is designed for

adaptation to three types of hood ventilation systems. Select

the type required for your installation.

RECIRCULATING — non-vented, ductless. Follow installation

procedure (A). Recirculating requires the use of the

Charcoal Filters, which have already been installed in

the oven.

HORIZONTAL EXHAUST — outside ventilation. Follow

installation procedure (B).

VERTICAL EXHAUST — outside ventilation. Follow

installation procedure (C).

(A) RECIRCULATING: NON-VENTED, DUCTLESS OPERATION

The unit is shipped assembled for recirculating.

NOTE:

1. The Exhaust Damper Assembly is not required for

recirculating exhaust.

2. The Charcoal Filters should be replaced every 6 to 12

months, depending on use.

Oven Light Cover

Oven Light

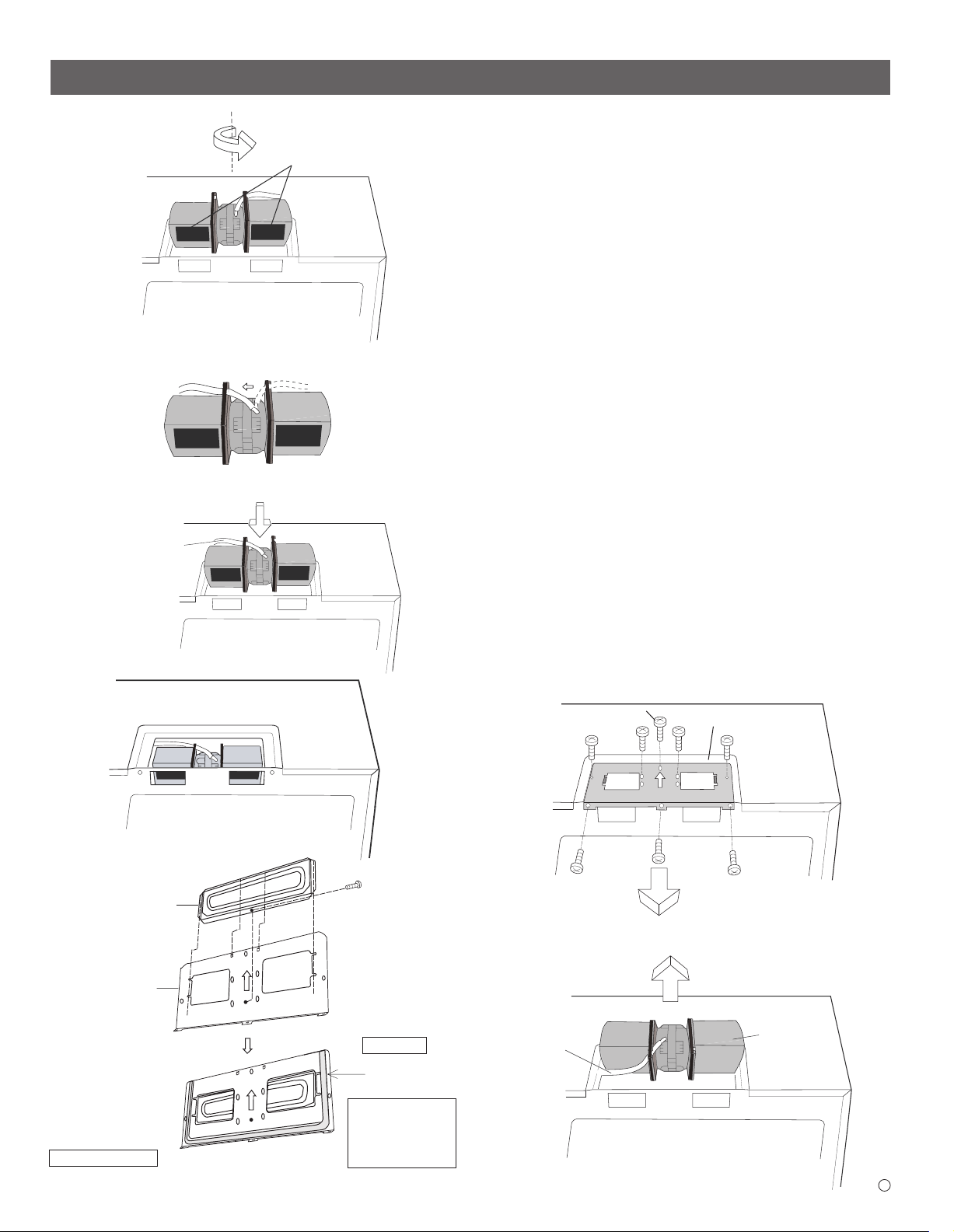

(B) HORIZONTAL EXHAUST: OUTSIDE VENTILATION

1. Remove 3 screws from back edge and 5 screws from the

top of Fan Cover Bracket. Save 3 screws to use them to

attach Exhaust Damper Assembly to the wall later and

discard remaining 5. Remove Fan Cover Bracket by

sliding it in the opposite direction of the arrow on the Fan

Cover Bracket, as shown in Figure 7.

2. Lift Hood Fan Unit carefully and slip wires out of cavity.

See Figure 8. CAUTION: Do not pull or stretch Hood Fan

Wire.

3. Rotate the Hood Fan Unit 180˚ so that the Fan Blade

Openings are facing the back of the oven. See Figure 9A on

page 5.

4. Replace Hood Fan Wire from (A) to (B). See Figure 9B

on page 5. Replace Hood Fan Unit into the oven. Be

careful not to pinch the Hood Fan Wire and the Hood

Fan Unit. See Figure 9C on page 5.

5. Put the wire back into cavity. See Figure 10A on page 5.

6. Assemble the Exhaust Damper Assembly to the Fan

Cover Bracket by sliding it into the slits in the same

direction as the arrow. Use 1 Tapping Screw 4 x 8 mm

from the INSTALLATION HARDWARE and tighten into

place. See Figure 10B on page 5.

7. This assembly will be mounted to the Outside Rear

Exhaust cutout in future instructions. See WALL

TEMPLATE for further procedures.

Hood Louver

Hood Louver (Inside)

Figure 6A

Charcoal Filters

Fan Cover Bracket

Figure 7

Upper Tab

Hood Fan Unit

Hood Fan Wire

Tabs

Figure 8

E

Figure 6B

4

INSTALLATION INSTRUCTIONS

Rotate 180°

Figure 9A

Change the position of wire to left side hole

(B) (A)

Figure 9B

Hood Fan Wire

Figure 9C

Fan Blade Openings

(C) VERTICAL EXHAUST: OUTSIDE VENTILATION

1. Remove and save 3 screws from back edge and 5 screws

from the top of the Fan Cover Bracket to use at Step 5.

Remove Fan Cover Bracket by sliding it in the opposite

direction of the arrow on the Fan Cover Bracket as shown in

Figure 11.

2. Lift Hood Fan Unit carefully and slip wires out of cavity. See

Figure 12A. CAUTION: Do not pull or stretch Hood Fan Wire.

3. Rotate the Hood Fan Unit 180° so that the Fan Blade

Openings are facing the back of the oven. See Figure 12B

on page 6. Replace Hood Fan Wire from (A) to (B). See

Figure12C on page 6. Then rotate the Hood Fan Unit 90°

so that the Fan Blade Openings are facing the top of the

oven. See Figure 13 on page 6. Replace Hood Fan Unit into

the oven. Be careful not to pinch the lead wire between the

inner bracket and the Hood Fan Unit. Put the lead wire into

Wire Box.

4. Replace the Fan Cover Bracket by sliding it into the slits in

the same direction as the arrow on the Fan Cover Bracket.

Make sure the fan blades are visible through the top

openings in the oven before proceeding. See Figure 14 on

page 6.

5. Attach the Fan Cover Bracket to unit with the 3 screws

from back edge and 4 screws except screw(A) from the top

of the Fan Cover Bracket, which were removed at Step 1

above. See Figure 14 on page 6. Screw (A) will be used at

MOUNTING OVEN THE WALL Step5 on page 7. The Hood

Fan Unit is now rotated for vertical exhaust operation.

6. Attach the Exhaust Damper Assembly to the fan cover bracket

on the top of the outercase cabinet after mounting the oven.

To attach the Exhaust Damper Assembly, refer to MOUNTING

OVEN TO THE WALL, See Figure 20 on page 7 and TOP

CABINET TEMPLATE.

Exhaust Damper

Assembly

Fan Cover Bracket

Save the assembly for

future instructions.

Oven Rear Side

Figure 10A

Figure 10B

Wall Side

Rear Cushion

Apply Rear Cushion

after Exhaust Damper

Assembly is screwed

to wall.

5

Hood Fan Wire

(A)

Fan Cover Bracket

Figure 11

Hood Fan Unit

Figure 12A

E

INSTALLATION INSTRUCTIONS

Rotate 180°

Change the position of wire to left side hole

(A) Rotate 90°

Figure 12B

(B) (A)

Figure 12C

(B)

Fan Blade Openings

Fan Blade Openings

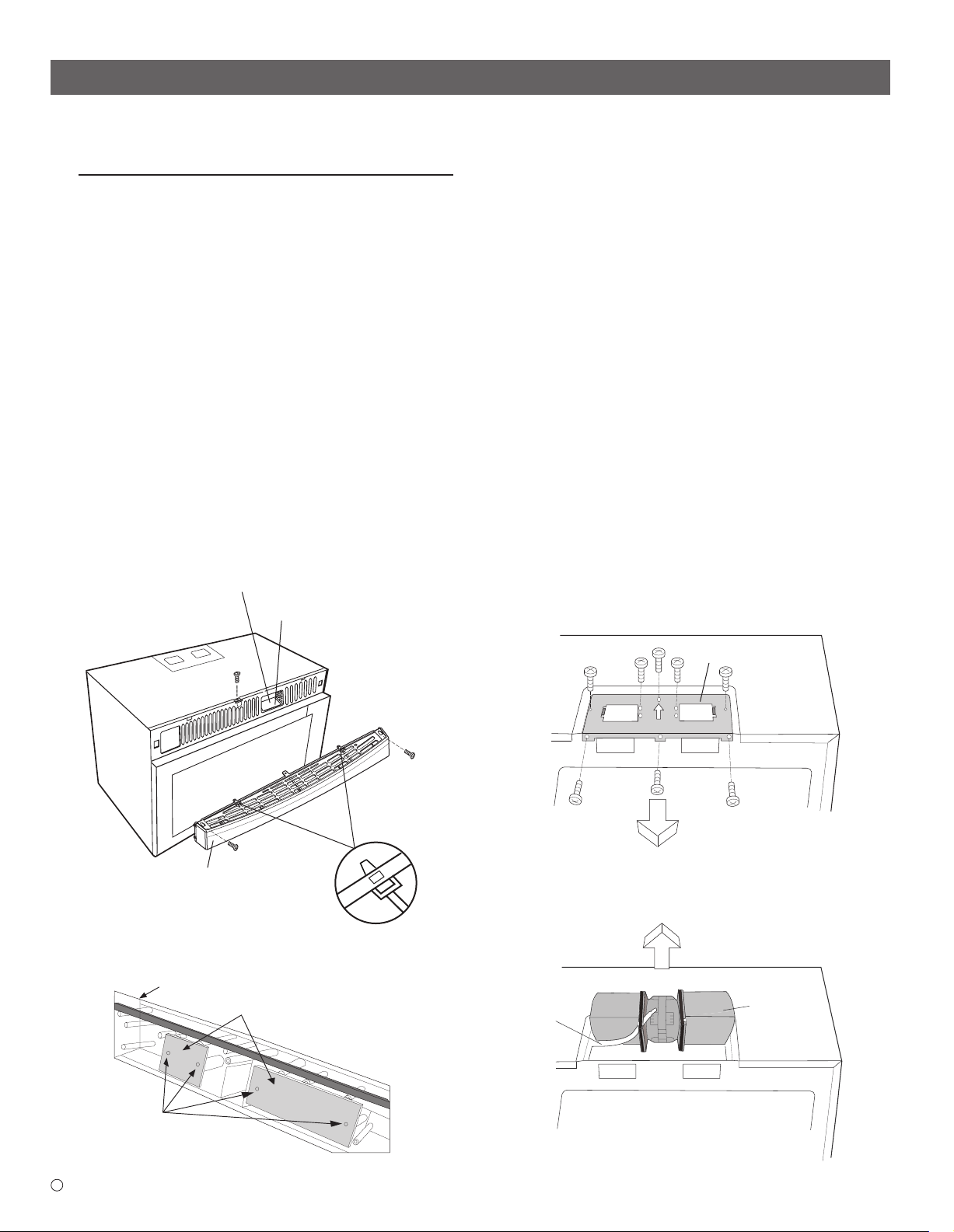

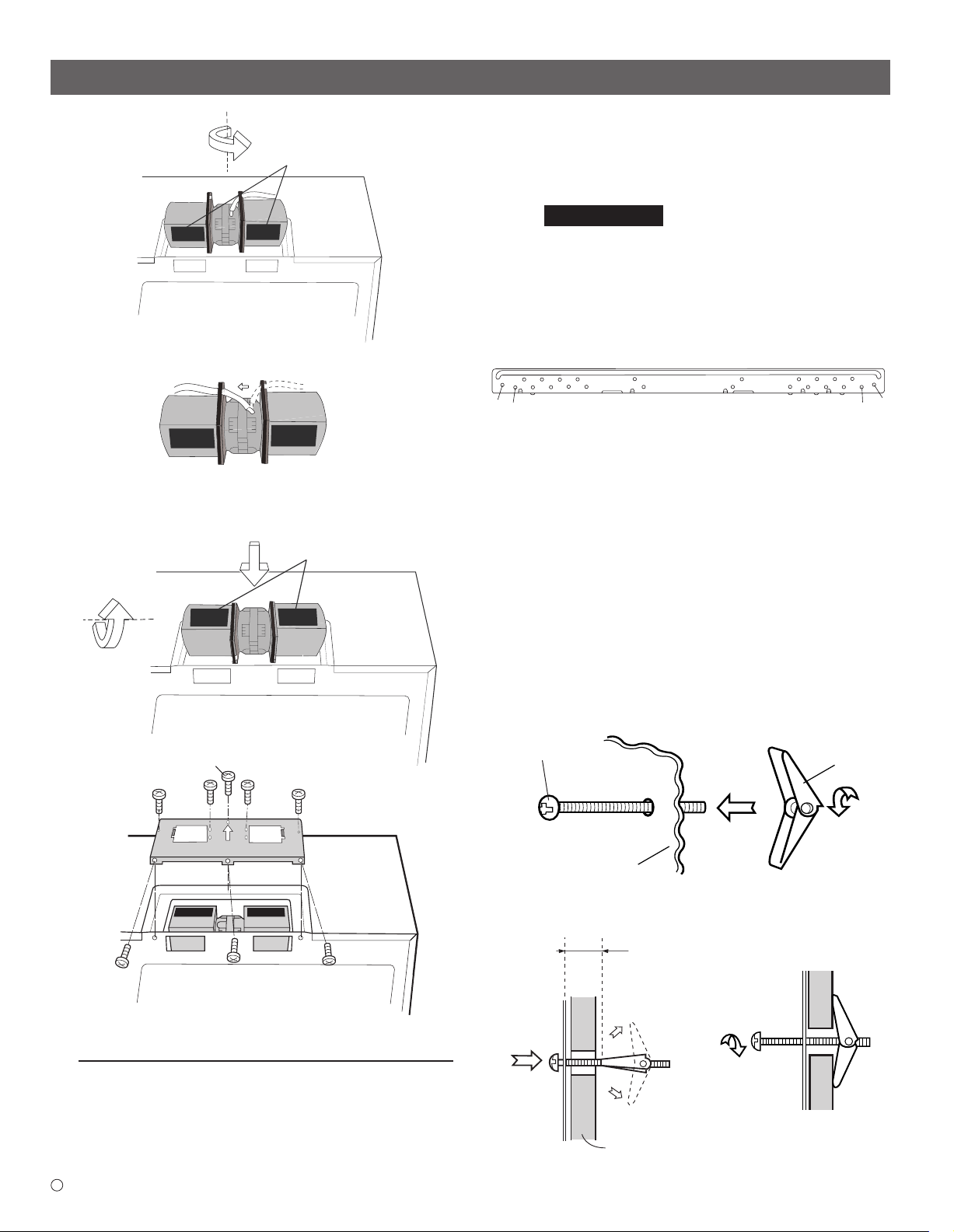

NOTE: THIS OV EN SHOULD BE ATTACHED TO AT LEAST ONE WALL ST UD.

MOUNTING PLATE

1. Separate Toggle Nuts, packed in the INSTALLATION

HARDWARE, from 4 Toggle Bolts.

IMPORTANT

2.

to Use wood screws to attach mounting plate to the

stud or studs. Use Toggle Bolts to attach mounting

plate through the holes at A, B, C and D UNLESS

THOSE HOLES ARE LOCATED ON THE STUD. Insert

one Toggle Bolt into A, B, C and D where appropriate

(these correspond to holes of the Wall Template) and

put the Toggle Nuts onto the Toggle Bolts. See Figure

15. Refer to instructions in Wall Template.

A

C

3. Position the Mounting Plate with the Toggle Bolts attached

at the wall location and insert Toggle Nuts and Bolts through

the holes in the wall with the Toggle Nuts closed. See Figure

16. Use Wood Screws to attach the Mounting Plate to

studs.

NOTE: Before insertion, be sure you leave a space more than

the thickness of the wall between the Mounting Plate and

the end of each of the Toggle Nuts (in the closed position).

If you do not leave enough space, the Toggle Nut will not

be able to open on the other side of the wall. Also, once

a Toggle Nut opens, it cannot be withdrawn from the hole;

therefore make sure all of the Toggles are in the correct

position before insertion.

4. Align the Mounting Plate carefully and hold in position

while tightening Toggle Bolts. Pull Toggle Bolt toward

you and turn clockwise to tighten. See Figure 17.

Use the mounting template provided

SUITABLE FOR USE ABOVE GAS OR ELECTRICAL

COOKING EQUIPMENT 36 INCHES OR LESS WIDE

WARNING TO REDUCE THE RISK OF FIRE AND

ELECTRICAL SHOCK,INSTALL AT LEAST 13-3/16 INCHES

ABOVE A RANGE (OR COOK TOP)

B

D

Figure 13

(A)

Figure 14

9 OVEN INSTALLATION

THIS OVEN CANNOT BE PROPERLY INSTALLED WITHOUT REFERRING

TO THE MOUNTING INST RUCTIONS FOUND ON BOTH TEMPLATES.

THE NEXT STEP IS TO READ AND FOLLOW MOUNTING INFORMATION

ON BOTH TOP CABINET A ND WALL T EMPL ATES.

E

Tog gle Bolt

Mounting Plate

Tog gle N ut

Figure 15

Space more

than wall

thickness

Figure 17

Wall

Figure 16

6

INSTALLATION INSTRUCTIONS

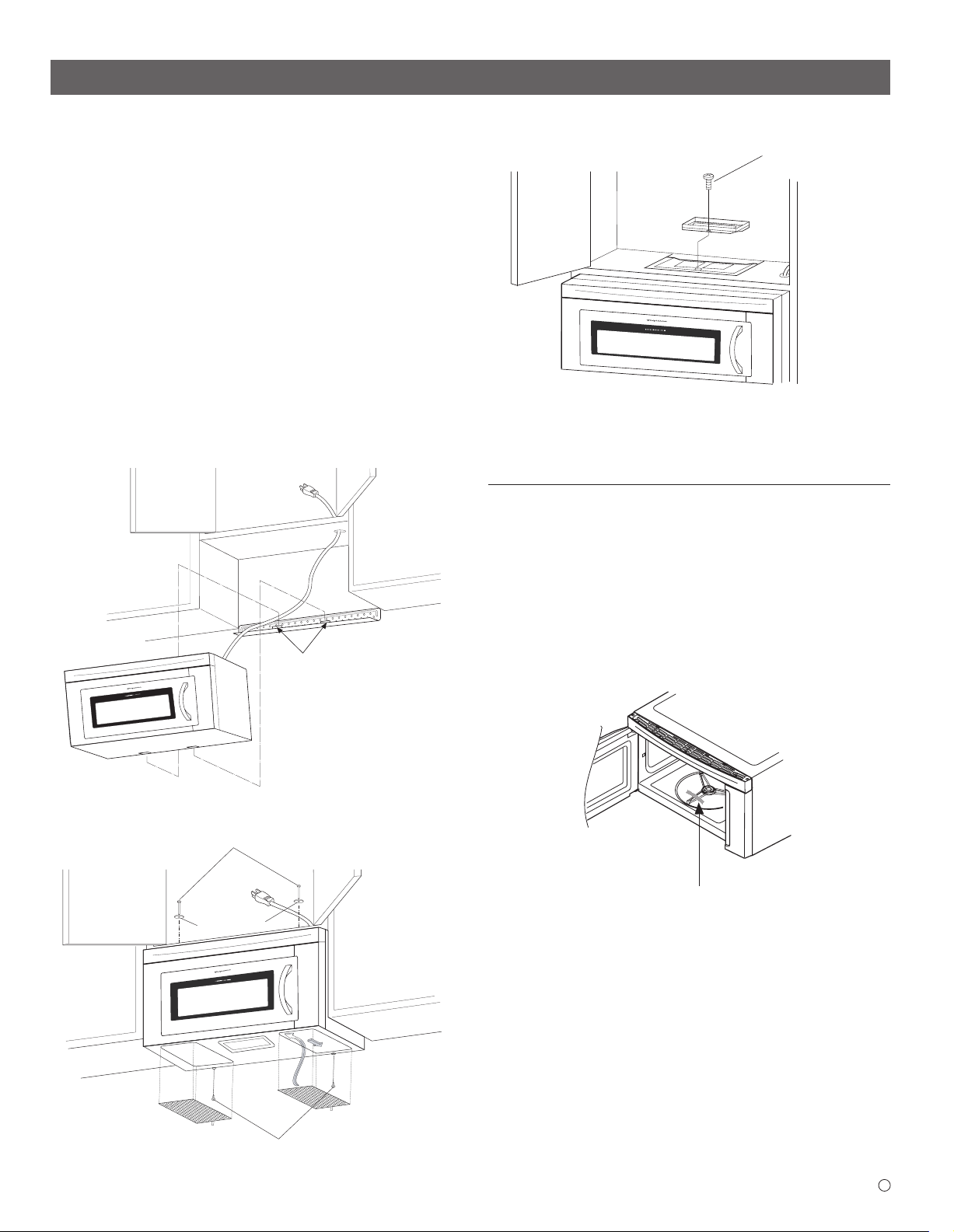

MOUNTING OVEN TO THE WALL

Two people are recommended to attach the Microwave Oven/

Hood to the Mounting Plate.

1. Thread the power supply cord through the hole made in the

bottom of the top cabinet.

2. Install the oven by tilting it forward and sliding it onto two

tabs of the Mounting Plate. Rotate the oven up so it rests

against the wall. See Figure 18 on page 7.

3. Use the two Top Cabinet Screws and two Flat Washers,

supplied in the INSTALLATION HARDWARE, to attach the

unit to the top cabinet. See Figure 19 on page 7.

4. Secure the bottom of the oven to the Mounting Plate by using

two Tapping Screws 4 x 8 mm from the INSTALLATION

HARDWARE. See Figure 19 on page 7.

5. (For Vertical Exhaust Only)

Attach the Exhaust Damper Assembly to the fan Cover

Bracket on the top of the outercase cabinet by sliding it into

the slits in the same direction as the allow using screw (A)

which removed at (C) VERTICAL EXHAUST STEP 1 on

page 5. See Figure 20 on page 7.

Tapping Screw (A)

Figure 20

CHECKLIST FOR INSTALLATION

1. Make sure the unit has been installed according to all of the

Installation Instructions and the Wall and Top Cabinet Templates.

2. Plug in the power cord.

3. Keep these Installation Instructions.

Figure 18

Top Cabinet Screws

Flat Washers

Tabs

NOTE:

Make sure to remove the tape at the turntable support before

operation. See fi gure 21.

Remove this tape before operation.

Figure 21

Tapping Screws

Figure 19

7

E

NOTES

TINSKA038WRRZ-EL01

Rear Cushion

Apply Rear Cushion

Rear Cushion

Assembly is screwed

after Exhaust Damper

to wall.

8

Loading...

Loading...