Frigidaire FGHD2433KW, FGHD2461KB, FGHD2461KW, FGHD2471KW, FGHD2433KB Service Data Sheet

...

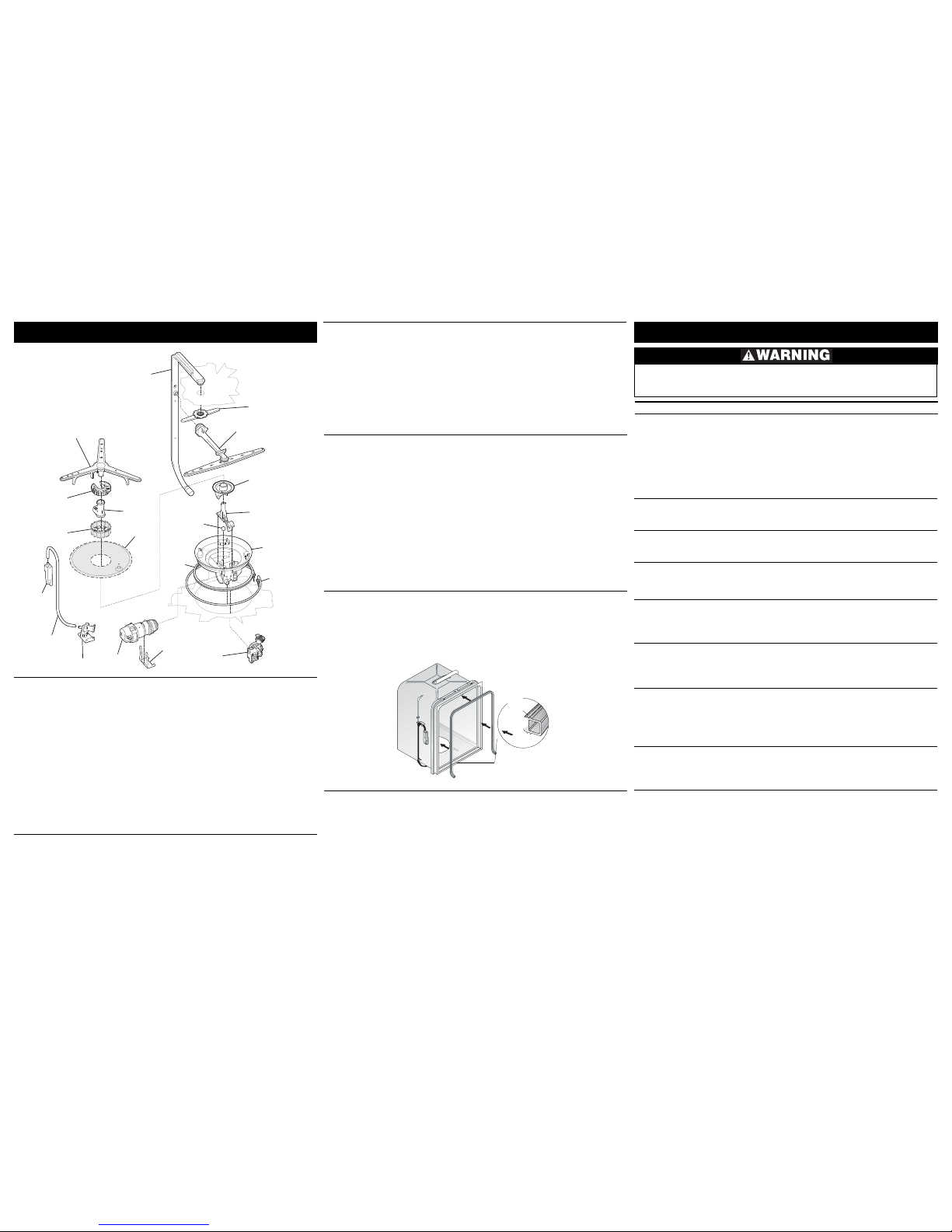

Trouble Shooting TipsExploded View of Wash System

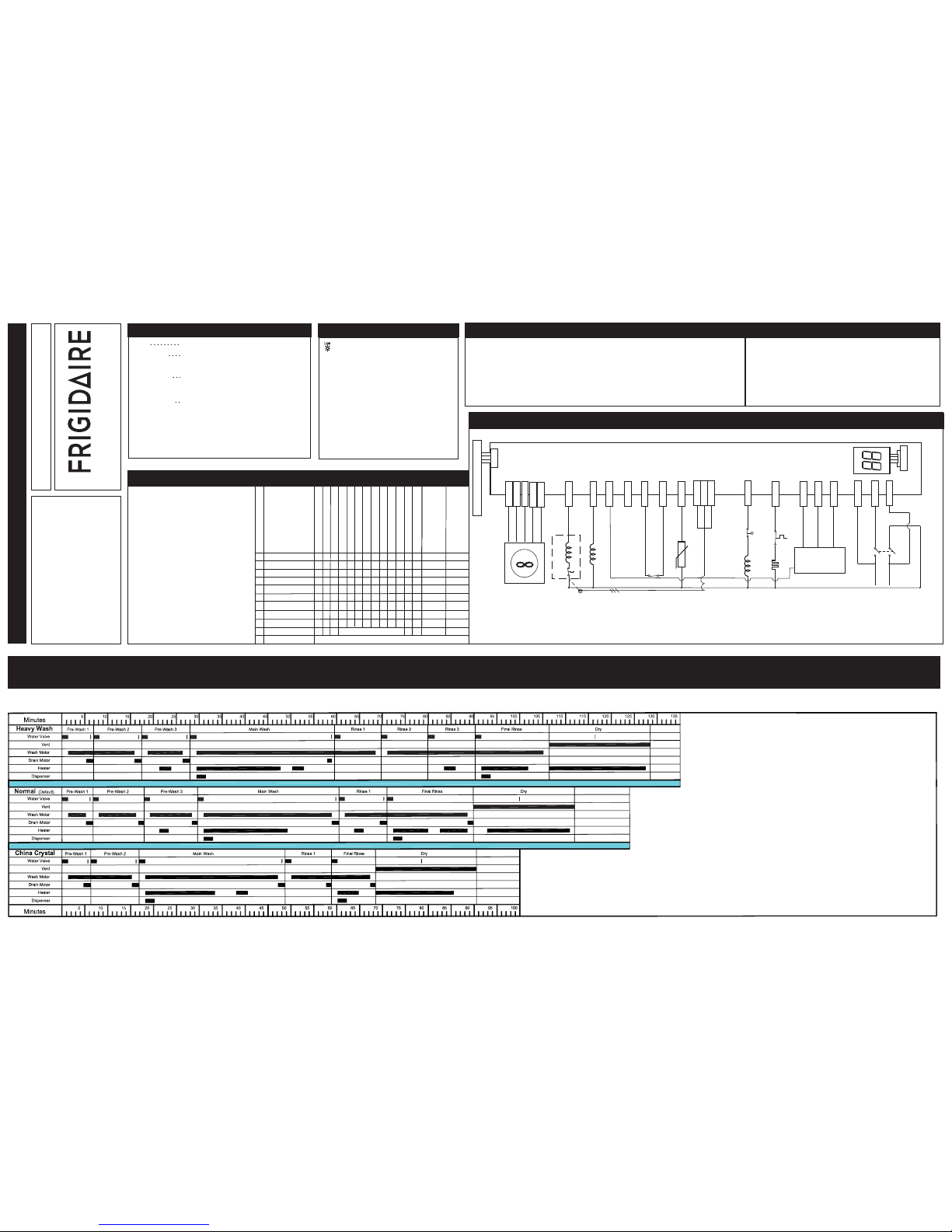

Tub and Door Seal

The door seal is pressed into the tub channel for

an interference fit. To install the seal, locate the

center mark on the seal back and press into

Product Specifications

Electrical

Rating ................................... 120 Volts, 60Hz

Separate Circuit..15 amp min.- 20 amp max.

Motor (Amps) ........................................... 1.8

Heater Wattage ....................................... 900

Total Amps (load rated) ......................... 10.0

TempAssure .............................. 140°F ±5°F

(60°C±3°C) [with outer door in place]

TempBoost............. 145°F ±5°F (63°C ±3°C)

Heated Wash/Heated Rinse

Sanitize ..................150°F ±5°F (66°C ±3°C)

Hi-Limit Thermostat ................ 200°F (93°C)

Water Supply

Suggested minimum incoming water

temperature............................. 120°F (49°C)

Pressure (PSI) min./max.................... 20/120

Connection (NPT) .....................................

3

/8"

Consumption (Normal Cycle) .......................

.............4.9 - 9.7 U.S. gal., 18.5 - 36.7 liters

Water valve flow rate (U.S. GPM)........... .83

Water recirculation rate (U.S. GPM)..............

.................................................... approx. 12

Water fill time ..................................... 87 sec.

To replace dispenser:

• shut off electricity to dishwasher,

• remove outer door panel assembly,

• disconnect wiring to the actuator,

• remove the six screws,

• remove the dispenser,

• replace and reinstall screws,

• rewire actuator.

Check the Following

1. Fuse (blown or tripped).

2. 120 VAC supply wiring connection

faulty.

3. Electronic control board defective.

4. No 12 VAC power to control.

5. Motor (inoperative).

6. Door switch (open contacts).

7. Door latch not making contact with

door switch.

8. Touch pad circuit defective.

9. No indicator lamps illuminate when

START or OPTIONS are pressed.

1. Motor (bad bearings).

2. Motor stuck due to prolonged

non-use.

1. Improper voltage.

2. Motor windings shorted.

3. Glass or foreign items in pump.

1. Heater element (open).

2. Electronic control board defective.

3. Wiring or terminal defective.

4. Hi-Limit thermostat defective.

1. Latch mechanism defective.

2. Electronic control board defective.

3. Wiring or terminal defective.

4. Broken spring(s).

5. Defective actuator.

1. Drain restricted.

2. Electronic control board defective.

3. Defective drain pump.

4. Blocked impeller.

5. Open windings.

6. Wiring or terminal defective.

1. Water supply turned off.

2. Defective water inlet fill valve.

3. Check fill valve screen for

obstructions.

4. Defective float switch.

5. Electronic control board defective.

6. Wiring or terminal defective.

7. Float stuck in “UP” position.

1. Drain hose (high) loop too low.

2. Drain line connected to a floor drain

not vented.

1. Detergent allowed to stand too long in

dispenser.

2. Dispenser wet when detergent was

added.

3. Detergent cover held closed or blocked

by large dishes.

4. Improper incoming water

temperature to properly dissolve

detergent.

5. See "Detergent cover will not open."

Always disconnect the dishwasher from the electrical power source before adjusting or

replacing components.

Personal Injury Hazard

is attached by a worm gear clamp to the discharge

end of the drain pump.

The drain hose must have a loop at a

minimum

height of 32 inches

in order to insure proper

drainage.

The main pump can easily be removed by

disconnecting the upper spray arm supply tube

hose, the drain pump connector hose, the wiring

harness connections made at the circulation

motor, the water heat thermistor located on the

bottom of the pump and rotating the four sump

retainers toward the middle of the sump.

Pump Assembly

The pump assembly is driven by a synchronous

motor. Rotation is in the counterclockwise

direction at 3600 RPM. The motor drives a pump

which supplies 100 percent filtered water at a

rate of approximately 12 GPM to one spray arm

at a time. The spray arm’s operation is alternated

by small “pauses” of the motor during the wash

cycle.

Draining is accomplished by using a small

separate synchronous drain pump mounted to

the side of the sump. The drain pump is

connected to the main pump by a small rubber

hose. The drain check valve is located at the

discharge end of the drain pump. The drain hose

Short Turn

Gasket Cross Section

Detergent and Rinse Aid Dispenser

The detergent and rinse aid dispenser is a one

piece component consisting of a molded

detergent cup and a built-in rinse aid dispenser.

The detergent cup has a spring loaded cover

and the rinse aid dispenser has a removable

cover.

Liquid rinse aid is added to the dispenser up to

the fill line indicator. The amount of rinse aid

released can be adjusted by turning the arrow

indicator from one, being the least amount, to

four, being the greatest amount.

Mounting

Rib

Tub

Interior

Remedy

1. Replace fuse or reset breaker.

2. Repair or replace wire fasteners at

dishwasher junction box.

3. Replace control board.

4. Replace control board.

5. Replace motor/impeller assembly.

6. Replace latch assembly.

7. Replace latch assembly.

8. Replace console assembly.

9. Replace console assembly.

1. Replace motor assembly.

2. Rotate motor impeller.

1. Check voltage.

2. Replace motor/impeller assembly.

3. Clean and clear blockage.

1. Replace heater element.

2. Replace control board.

3. Repair or replace.

4. Replace thermostat.

1. Replace dispenser.

2. Replace control board.

3. Repair or replace.

4. Replace dispenser.

5. Replace dispenser.

1. Clear restrictions.

2. Replace control board.

3. Replace pump.

4. Check for blockage, clear.

5. Replace pump assembly.

6. Repair or replace.

1. Turn water supply on.

2. Replace water inlet fill valve.

3. Disassemble and clean screen.

4. Repair or replace.

5. Replace control board.

6. Repair or replace.

7. Clean float.

1. Repair to proper

32-inch minimum

height

.

2. Install air gap at counter top.

1. Instruct customer/user.

2. Instruct customer/user.

3. Instruct customer/user on proper

loading of dishes.

4. Incoming water temperature of

120°F is required to properly

dissolve dishwashing detergents.

Symptom

Dishwasher will not operate when

turned on.

Motor hums but will not start or run.

Motor trips out on internal thermal

overload protector.

Dishwasher runs but will not heat.

Detergent cover will not latch or

open.

Dishwasher will not pump out.

Dishwasher will not fill with water.

Dishwasher water siphons out.

Detergent left in dispenser.

Standard Dry Air Flow

When the control advances to the “dry” portion of

the cycle, a vent actuation solenoid is closed.

This opens the vent valve and starts the vent fan

both located in the top right rear corner of the tub.

The fan draws in the air from outside the tub,

forcing the hot, humid air down and out the

020905

TUB

TUB

TUB

TUB

Lower

Spray Arm

Middle

Spray Arm

Assy.

3rd Level

Spray Arm

Assy.

Delivery

Tube

Soil

Director

Volute

Cover

Check

Ball

Glass

Trap

Spray Arm

Support

Soil

Filter

Filter

Sump

Housing

Sump

Gasket

Heating

Element

Water

Bottle

Water

Valve

Water

Inlet Tube

Circulation

Motor

Motor

Bracket

Drain

Pump

bottom of the outer door panel. This outside,

cooler, dryer air helps to speed evaporation of

water from the hot dishes. At the same time the

heating element is continually cycled on and off.

On some models the dry portion of the cycle can

be extended to improve drying performance.

place. Next, install the bottom of the seal by

creating a short turn at the bottom of the tub

channel and ensuring the seal extends to the

locator ridge at the bottom of the tub. Then align

and gently press the seal into the channel in only

a few spots. Next, close and latch the door to

allow the gasket to seat properly into the channel.

Hall sensor

Cycle Selection Options

SERVICE DAT

ASHEET

P/N: 154768201

E

lectronic Series

BK.......................... Black

BU............................Blue

PK............................Pink

R...............................Red

R-BK...............Red/Black

W............................White

Wiring Diagram

Display Codes (LED)

To s ta r t

To d el a y st ar t

Close and latch door. Press START/CANCEL pad.

Close and latch door. Press DELAY START pad to

select desired delay time.

To s el e ct a ne w

cycle or option

Press desired cycle and/or option pad. The indicator

lights will change. Press START/CANCELwithin 15

seconds to begin cycle.

To c an c el c yc l e Press START/CANCEL. Dishwasher will drain for

90 seconds, then shut off.

For controls

lock ...........

Press an d hold th e RINSE O NLY or AIR D RY

pad for 3 seconds. To unlock, press and hold the

RINSE ONLY or AIR DRY pad for 3 seconds.

SENSING

WASHING

SANITIZED

DRYING

CLEAN

OPTION LED's Flashing

STATUS LED's Flashing

----------------------Turbidity sensor is checking the condition of the wash/rinse water.

No sensing for LIGHT WASH (UPPER RACK), LIGHT WASH (LOWER RACK) and CHINA/CRYSTAL.

----------------------Wash portion of cycle.

--------------------The SANITIZED criteria has been met. Indicator light will switch off when door is opened.

------------------------ Drying portion of cycle.

------------------------ Shows completion of cycle. Indicator light will switch off when door is opened.

-- HI-TEMP WASH and NO HEAT DRY/POWER DRY OFF LED's flashing indicates power failure has

occurred. Press START/CANCEL pad and reselect desired options and cycle.

-- The STATUS LED's that are lit when the door is opened will flash. Close door.

RINSE AGENT LOW ------- The liquid rinse agent is low. Light will switch off after 5 complete wash cycles or dispenser is

filled.

This information is intended for use by

persons having electrical and

mechanical training and a level of

knowledge of these subjects generally

considered acceptable in the appliance

repair trade. Electrolux Home Products

North America cannot be responsible,

nor assume any liability, for injury or

damage of any kind arising from the

use of this Service Data Sheet.

Operation

or LO..Low liquid in the rinse aid dispenser

..........A power failure has occurred

.........Water heating delay

..........Close and latch the door

ER/ER....Switch Failure

....Hour(s) delay before start

PF

HO or Hd

CL

'01-24'

ER/CE....Configuration Error

ER/uo.....Vent will not close

ER/uF.....Fan not running

PUMP MOTOR

DRAIN MOTOR

VIO

120VAC

60HZ

USER INTERFACE SWITCH

ELECTRONIC

CONTROL

BOARD

P3-2

P6

BU

DISPENSER

R-Y

W

P3- 3

W

W

HEATER

W

HI-LIMIT

THERMOSTAT

TURBIDITY SENSOR/

THERMISTOR

R

P1

WATER VALVE

FLOAT

SWITCH

PK

P3- 1

W

Y

P3-7

P3-8

RINSE AID

LEVEL SENSE

BK

BK

P2- 8

P2- 7

P3-4

P-5

P3-6

DOOR

SWITCH

W

NEUT W

L1 BK

BK

BK

P3-5

P1

BK

P2-1

W

P2-2

R

P2-3

W

The water/service test is a

special function initiated from

the power failure mode or idle

mode.

While in power failure or idle

mode

- simultaneously press the

DRY/AIR DRY and

START/CANCEL pads for 3

seconds.

The dishwasher will then step

through the test cycle per the chart.

Pushing the START/CANCEL pad

will advance the dishwasher to the

next step.

Water/Servic e Test

27

45

0.4

75

60

90

90

447

60 1

1

0

0

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

1

1

0

0

0

1

1

1

0

X

1

1

0

0

0

1

0

0

0

1

1

1

1

1

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

1

1

1

0

0

0

0

0

1

1

2

3

4

FILL/DISPENSER

STEP

TOTAL TIME (SEC)

WATER VALVE

CIRCULATION MOTOR

DRAIN MOTOR

HEATER

DISPENSER

FAN UNIT

SENSING LED

WASHING LED

SANITIZED LED

DRYING LED

CLEAN LED

FILL

WASH/HEAT

PAUSE

WASH/HEAT

WASH/HEAT/DISP.

DRAIN

DRY

TOTAL

CLEAN LED stays on until door is opened or cycle is started.

X - denotes selectable option

5

6

7

8

0

0

0

0

0

0

1

0

(Some models)

(Some models)

0

0

0

0

0

0

P2- 4

P2- 5

P2- 6

BK

W

R

HALL SENSOR

DISPLAY

Y/BL

P2-13

P2-12

BK-W

P2-11

R

P32-6

BK

P32-9

FAN DRY UNIT

R-W

RINSE LED

SENSING LED

0

0

0

1

1

0

0

0

1

RINSE LED

Device being monitored

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

Fan damper

Display flashes when

Detection of failure

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

0

0

0

1

1

0

0

0

1

Turbidity

Fan speedFan speed

Rinse aid

Thermistor

Uo

Tu

HSUFHS

Th

RA

Color Code

Display Codes (Readout)

Y-BK.............Yellow/Black

Loading...

Loading...