Page 1

INSTALLATIONAND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

pr_ If the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

-- Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

ALL RANGES

CAN TIP.

INJURY TO

PERSONS

COULD

RESULT.

INSTALL

ANTI-TIP

DEVICE

PACKED WITH

RANGE.

SEE

INSTALLATION

INSTRUCTIONS.

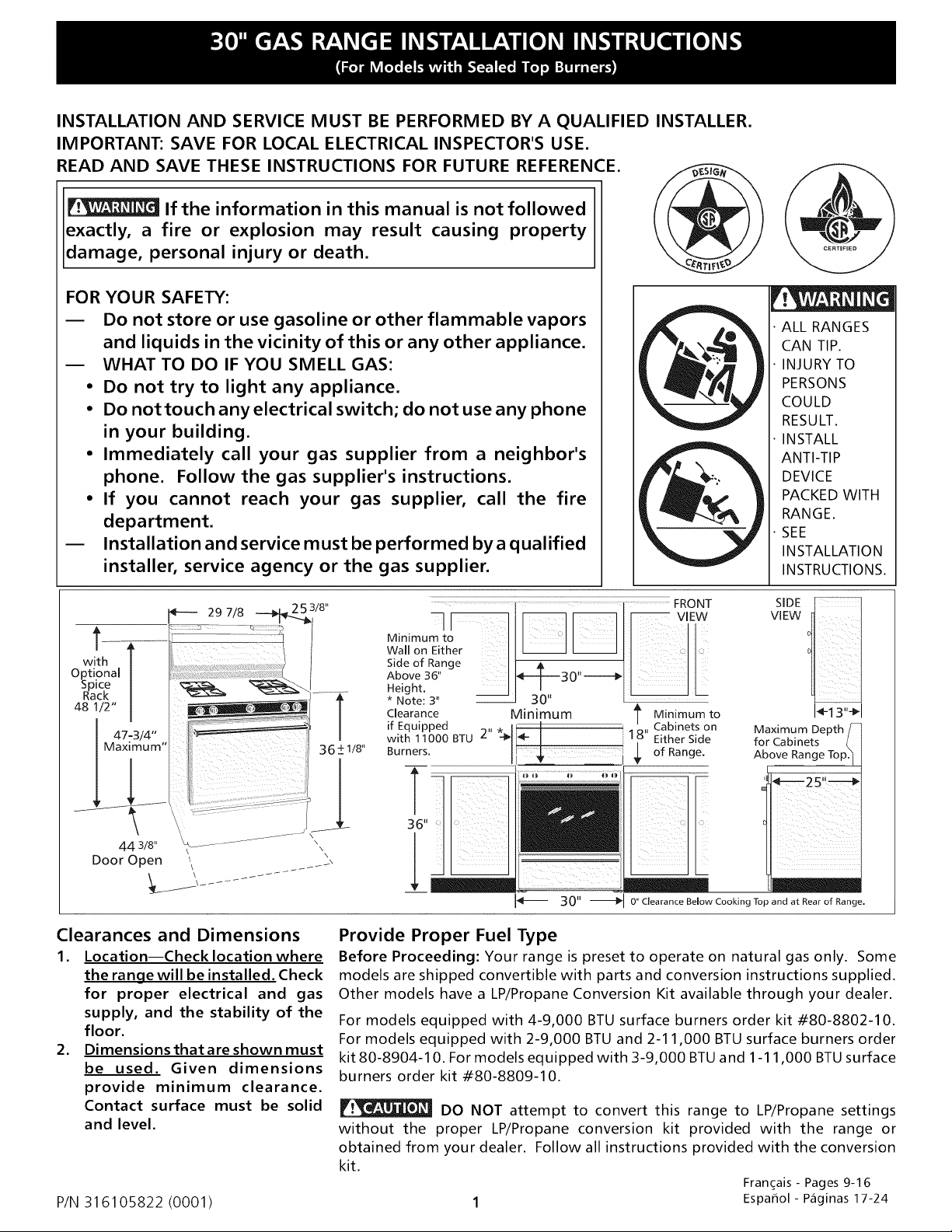

297/8

2 53/8"

t

Optional

Spice

Rack

with 1

48 1/2"

47-3/4"

Maximum"

44 3/8" \

Door Open \\

Clearances and Dimensions

1. Location--Check location where

the range will be installed. Check

for proper electrical and gas

supply, and the stability of the

floor.

2. Dimensions that are shown must

be used. Given dimensions

provide minimum clearance.

Contact surface must be solid

and level.

P/N 316105822 (0001)

VIEW

Side of Range I I

Above 36" I_--- B O" -------_

SIDE

*"e4go_t;s,,I 3;"

Clearance Minimum

if Equipped 2"

with 11000 BTU

Burners.

30" Clearance Below Cooking Top and at Rear of Range.

t Minimum to

18" Cabinetson

Either Side

of Range.

Maximum Depth

for Cabinets

Above Range

Provide Proper Fuel Type

Before Proceeding: Your range is preset to operate on natural gas only. Some

models are shipped convertible with parts and conversion instructions supplied.

Other models have a LP/Propane Conversion Kit available through your dealer.

For models equipped with 4-9,000 BTU surface burners order kit #80-8802-10.

For models equipped with 2-9,000 BTU and 2-11,000 BTU surface burners order

kit 80-8904-10. For models equipped with 3-9,000 BTU and 1-11,000 BTU surface

burners order kit #80-8809-10.

DO NOT attempt to convert this range to LP/Propane settings

without the proper LP/Propane conversion kit provided with the range or

obtained from your dealer. Follow all instructions provided with the conversion

kit.

Fran(_ais- Pages 9-16

1 Espafiol- P_ginas 17-24

1÷13"÷1

Page 2

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

1. Keep these instructions with your owner's guide for

future reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1--1atest edition when installed in the

United States. When installed in Canada, installation must

conform with CAN/CGA-B149.1 and CAN/CGA-B149.2.

This range has been design certified by CSA International.

As with any appliance using gas and generating heat, there

are certain safety precautions you should follow. You will

find them in the Owner's Guide., read it carefully.

• Be sure your range is installed and grounded properly

by a qualified installer or service technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSl/NFPA

No .70--latest edition when installed in the United

States. When installed in Canada, this range must be

electrically grounded in accordance with CSA Standard

C22.1, Canadian Electrical Code, Part 1. See Grounding

Instructions on page 5.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering,

make sure the floor covering can withstand heat at

least 90°F above room temperature without

shrinking, warping or discoloring. Do not install the

range over carpeting unless you place an insulating

pad or sheet of 1/4-inch thick plywood between the

range and carpeting.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the lower

front panel of the range. Avoid touching the vent

openings or nearby surfaces as they may become hot

while the oven is in operation. This range requires fresh

air for proper burner combustion.

Never leave children alone or unattended

in the area where an appliance is in use. As children

grow, teach them the proper, safe use of all appliances.

Never leave the oven door open when the range is

unattended.

Stepping, leaning or sitting on the doors

or drawers of this range can result in serious injuries

and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This creates

a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

• Reset all controls to the "off" position after using a

programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils before

self-cleaning the oven. Wipe up excess spillage. Follow

the precleaning instructions in the Owner's Guide.

• Unlike the standard gas range, THIS COOKTOP IS

NOT REMOVABLE. Do not attempt to remove the

cooktop.

DO NOT MAKE ANYATTEMPTTO OPERATE

THE ELECTRIC IGNITION OVEN DURING AN ELECTRICAL

POWER FAILURE. RESET ALL OVEN CONTROLS TO "OFF"

IN THE EVENT OF A POWER FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes if the oven thermostat

control was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit with

a match. Hold a lighted match to the burner, then slowly

turn the knob to the LITE position. Use extreme caution

when lighting burners this way.

Page 3

Before Starting

Tools You Will Need

For leveling legs and Anti-Tip Bracket:

• Adjustable wrench or channel lock pliers

• 5/16" Nutdriver or Flat Head Screw Driver (__

• Electric Drill & 1/8" Diameter Drill Bit (5/32" Masonry

Drill Bit if installing in concrete)

For gas supply connection:

• Pipe wrench

For burner flame adjustment:

• Phillips head and

blade-type screwdrivers

For gas conversion (LP/Propane or Natural):

• Open end wrench - 1/2"

Additional Materials You Will Need

• Gas line shut-off valve i._,_:

• Pipe joint sealant that resists action of LP/Propane gas

A new flexible metal appliance conduit (1/2" NPT x 3/

4" or 1/2" I.D.) must be design certified by CSA

International. Because solid pipe restricts moving the

range we recommend using a new flexible conduit (4

to 5foot length) for each new installation and additional

reinstallations.

_1

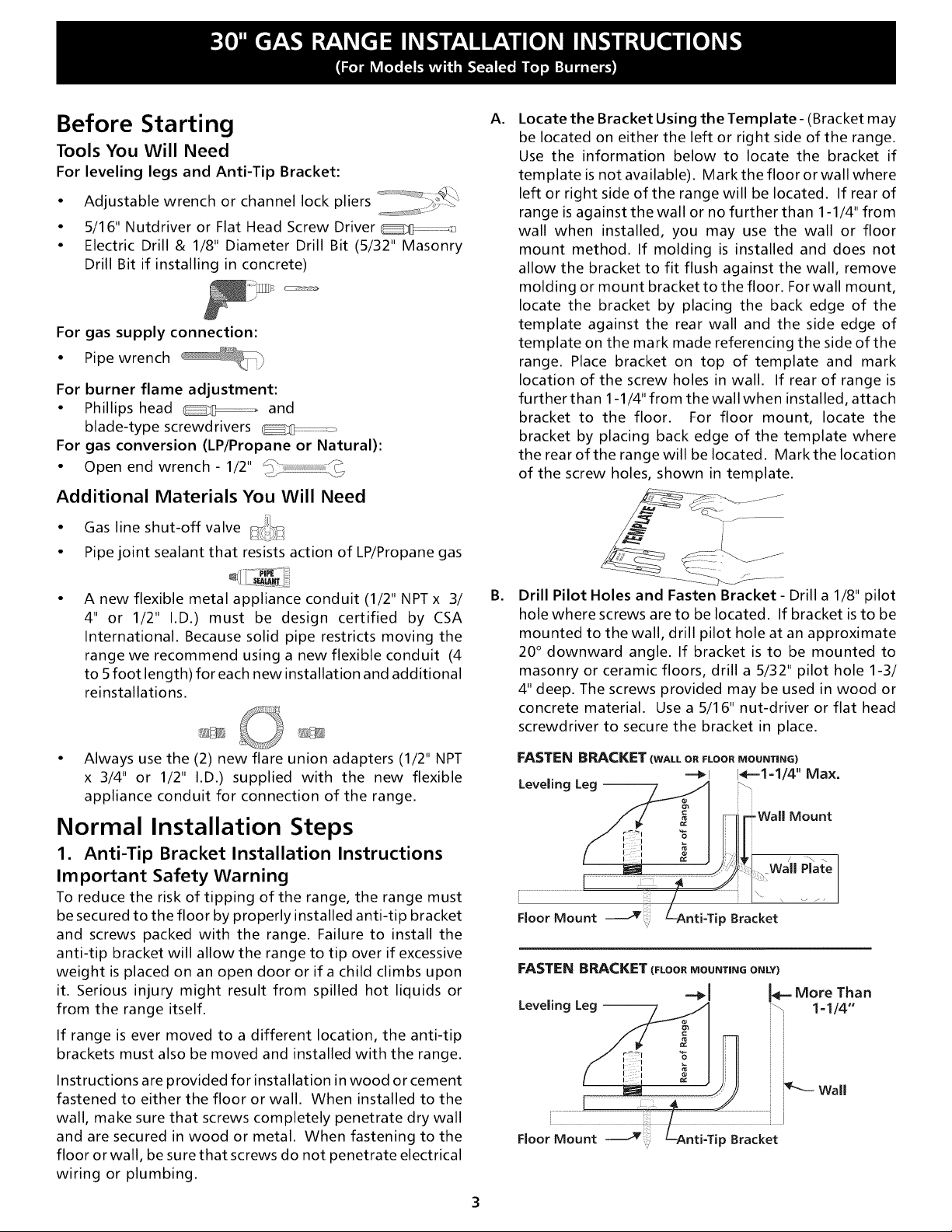

A. Locate the Bracket Using the Template- (Bracket may

be located on either the left or right side of the range.

Use the information below to locate the bracket if

template is not available). Mark the floor or wall where

left or right side of the range will be located. If rear of

range is against the wall or no further than 1-1/4" from

wall when installed, you may use the wall or floor

mount method. If molding is installed and does not

allow the bracket to fit flush against the wall, remove

molding or mount bracket to the floor. For wall mount,

locate the bracket by placing the back edge of the

template against the rear wall and the side edge of

template on the mark made referencing the side of the

range. Place bracket on top of template and mark

location of the screw holes in wall. If rear of range is

further than 1-1/4" from the wall when installed, attach

bracket to the floor. For floor mount, locate the

bracket by placing back edge of the template where

the rear of the range will be located. Markthe location

of the screw holes, shown in template.

- .......

/

..........

B. Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot

hole where screws are to be located. If bracket is to be

mounted to the wall, drill pilot hole at an approximate

20 ° downward angle. If bracket is to be mounted to

masonry or ceramic floors, drill a 5/32" pilot hole 1-3/

4" deep. The screws provided may be used in wood or

concrete material. Use a 5/16" nut-driver or flat head

screwdriver to secure the bracket in place.

• Always use the (2) new flare union adapters (1/2" NPT

x 3/4" or 1/2" I.D.) supplied with the new flexible

appliance conduit for connection of the range.

Normal Installation Steps

1. Anti-Tip Bracket Installation Instructions

Important Safety Warning

To reduce the risk of tipping of the range, the range must

be secured to the floor by properly installed anti-tip bracket

and screws packed with the range. Failure to install the

anti-tip bracket will allow the range to tip over if excessive

weight is placed on an open door or if a child climbs upon

it. Serious injury might result from spilled hot liquids or

from the range itself.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the floor or wall. When installed to the

wall, make sure that screws completely penetrate dry wall

and are secured in wood or metal. When fastening to the

floor or wall, be sure that screws do not penetrate electrical

wiring or plumbing.

\

p Bracket

FASTEN BRACKET (FLOOR MOUNTING ONLY)

Leveling Leg --

iiiiil

Floor Mount p Bracket

Mount

Wall Plate

I_e- More Than

1=1/4"

_k Wall

Page 4

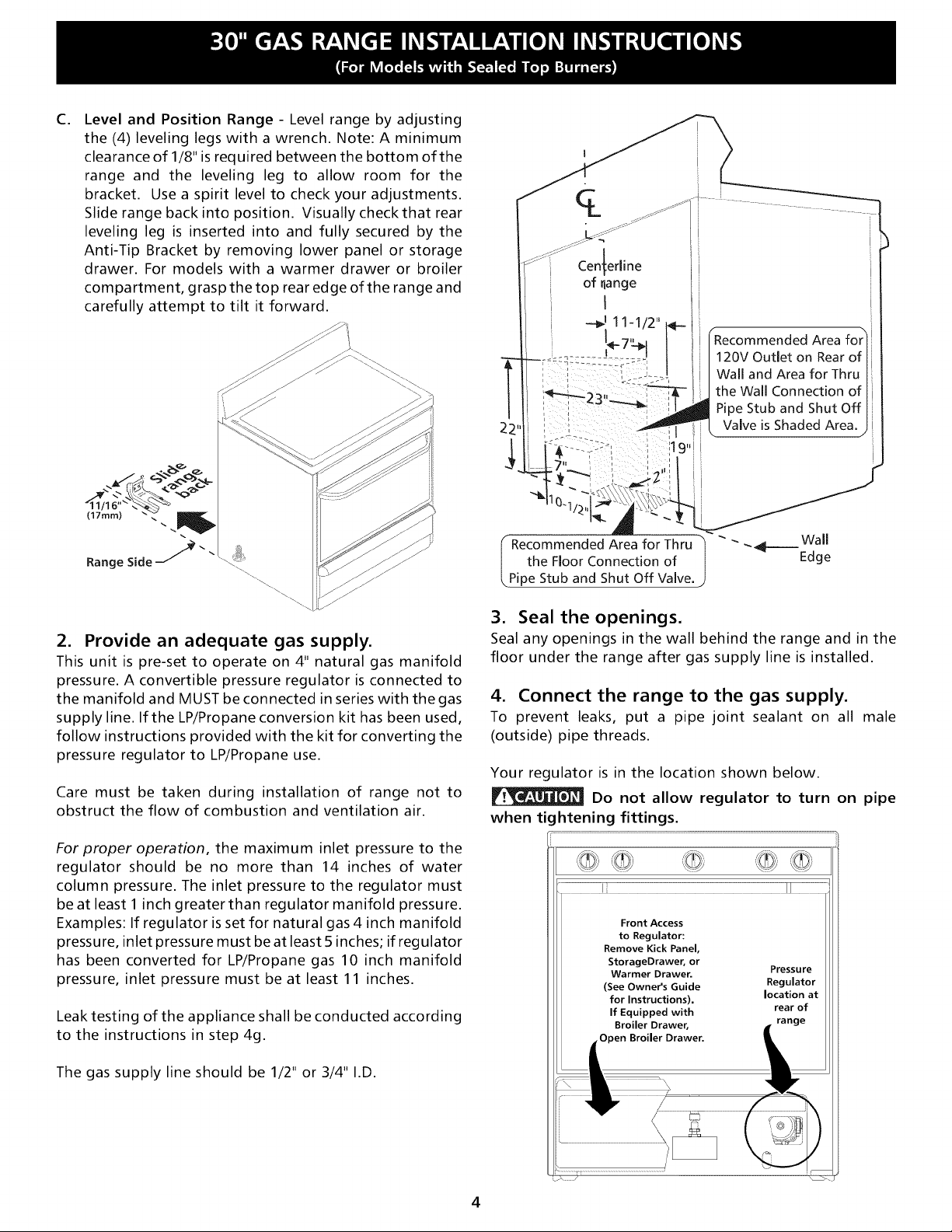

C.

Level and Position Range - Level range by adjusting

the (4) leveling legs with a wrench. Note: A minimum

clearance of 1/8" is required between the bottom of the

range and the leveling leg to allow room for the

bracket. Use a spirit level to check your adjustments.

Slide range back into position. Visually checkthat rear

leveling leg is inserted into and fully secured by the

Anti-Tip Bracket by removing lower panel or storage

drawer. For models with a warmer drawer or broiler

compartment, grasp the top rear edge of the range and

carefully attempt to tilt it forward.

(17turn)

[

for

120V Outlet on Rear of

Wall and Area for Thru

the Wall Connection of

Pipe Stub and Shut Off

Valve is Shaded Area.

9.11

Range Side

2. Provide an adequate gas supply.

This unit is pre-set to operate on 4" natural gas manifold

pressure. A convertible pressure regulator is connected to

the manifold and MUST be connected in series with the gas

supply line. If the LP/Propane conversion kit has been used,

follow instructions provided with the kit for converting the

pressure regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water

column pressure. The inlet pressure to the regulator must

be at least 1 inch greater than regulator manifold pressure.

Examples: If regulator is set for natural gas 4 inch manifold

pressure, inlet pressure must be at least 5 inches; if regulator

has been converted for LP/Propane gas 10 inch manifold

pressure, inlet pressure must be at least 11 inches.

Leak testing of the appliance shall be conducted according

to the instructions in step 4g.

Recommended Area for Thru

the Floor Connection of

Pipe Stub and Shut Off Valve.

I " - - 41_-- Wall

Edge

3. Seal the openings.

Seal any openings in the wall behind the range and in the

floor under the range after gas supply line is installed.

4. Connect the range to the gas supply.

To prevent leaks, put a pipe joint sealant on all male

(outside) pipe threads.

Your regulator is in the location shown below.

Do not allow regulator to turn on pipe

when tightening fittings.

Front Access

to Regulator:

Remove Kick Panel,

StorageDrawer, or

Warmer Drawer.

(See Owner's Guide

for Instructions).

If Equipped with

Broiler Drawer,

Broiler Drawer.

Pressure

Regulator

location at

rear of

The gas supply line should be 1/2" or 3/4" I.D.

4

Page 5

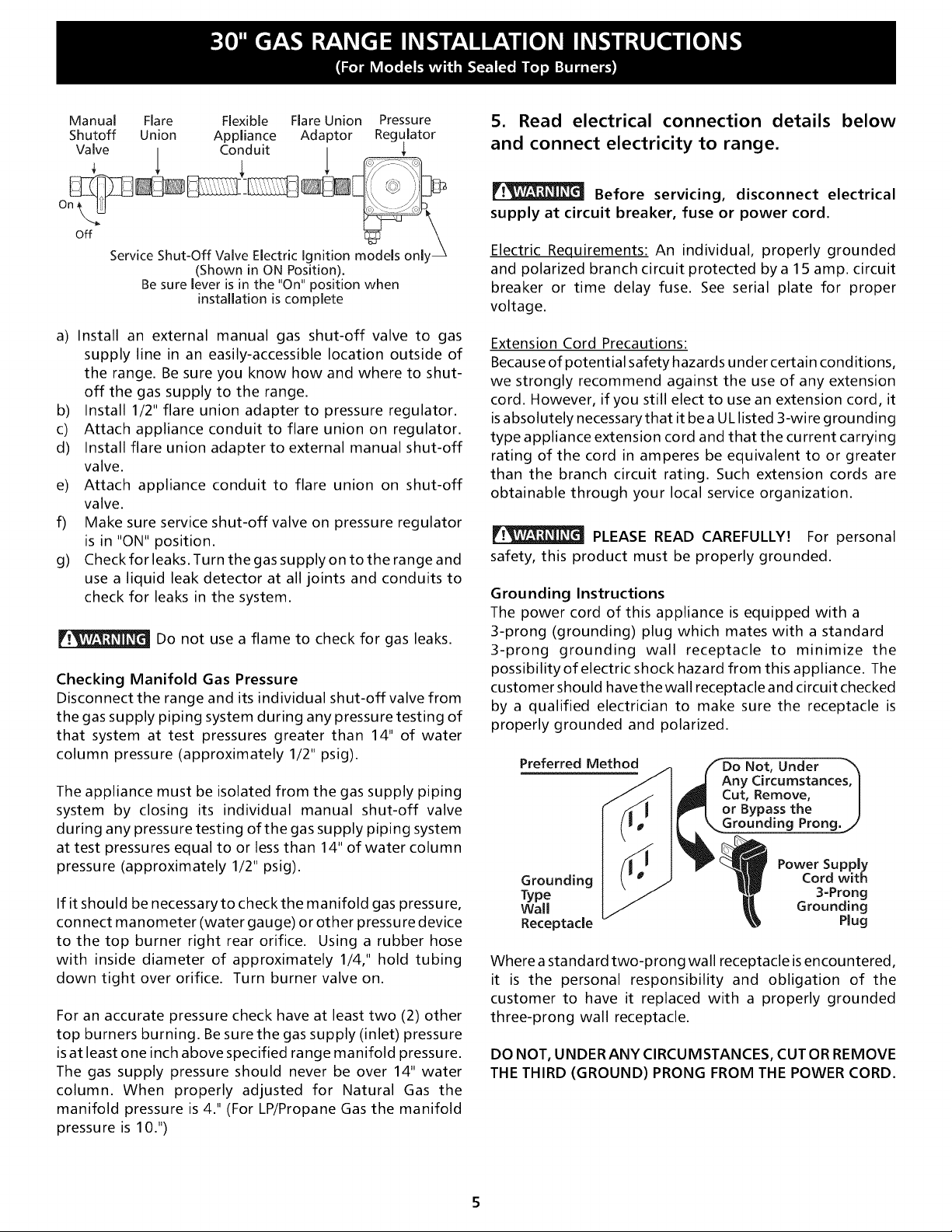

Manual Flare Flexible Flare Union Pressure

Shutoff Union Appliance Adaptor Regulator

Valve / Conduit /

off

Service Shut-Off Valve Electric Ignition models only _

(Shown in ON Position).

Be sure lever is in the "On" position when

installation is complete

5. Read electrical connection details below

and connect electricity to range.

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric Requirements: An individual, properly grounded

and polarized branch circuit protected by a 15 amp. circuit

breaker or time delay fuse. See serial plate for proper

voltage.

a) Install an external manual gas shut-off valve to gas

supply line in an easily-accessible location outside of

the range. Be sure you know how and where to shut-

off the gas supply to the range.

b) Install 1/2" flare union adapter to pressure regulator.

c) Attach appliance conduit to flare union on regulator.

d) Install flare union adapter to external manual shut-off

valve.

e) Attach appliance conduit to flare union on shut-off

valve.

f) Make sure service shut-off valve on pressure regulator

is in "ON" position.

g) Check for leaks. Turn the gas supply on to the range and

use a liquid leak detector at all joints and conduits to

check for leaks in the system.

Do not use a flame to check for gas leaks.

Checking Manifold Gas Pressure

Disconnect the range and its individual shut-off valve from

the gas supply piping system during any pressure testing of

that system at test pressures greater than 14" of water

column pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping system

at test pressures equal to or less than 14" of water column

pressure (approximately 1/2" psig).

If it should be necessaryto checkthe manifold gas pressure,

connect manometer (water gauge) or other pressure device

to the top burner right rear orifice. Using a rubber hose

with inside diameter of approximately 1/4," hold tubing

down tight over orifice. Turn burner valve on.

For an accurate pressure check have at least two (2) other

top burners burning. Be sure the gas supply (inlet) pressure

is at least one inch above specified range manifold pressure.

The gas supply pressure should never be over 14" water

column. When properly adjusted for Natural Gas the

manifold pressure is 4." (For LP/Propane Gas the manifold

pressure is 10.")

Extension Cord Precautions:

Because of potential safety hazards under certain conditions,

we strongly recommend against the use of any extension

cord. However, if you still elect to use an extension cord, it

isabsolutely necessarythat it be a UL listed 3-wire grounding

type appliance extension cord and that the current carrying

rating of the cord in amperes be equivalent to or greater

than the branch circuit rating. Such extension cords are

obtainable through your local service organization.

PLEASE READ CAREFULLY! For personal

safety, this product must be properly grounded.

Grounding Instructions

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle to minimize the

possibilityof electric shock hazard from this appliance. The

customer should have the wall receptacle and circuit checked

by a qualified electrician to make sure the receptacle is

properly grounded and polarized.

Preferred

Grounding

Type

Wall

Receptacle

Where a standard two-prong wall receptacle is encountered,

it is the personal responsibility and obligation of the

customer to have it replaced with a properly grounded

three-prong wall receptacle.

Not, Under

Any Circumstances, I

Cut, Remove, |

or Bypass the J

Grounding Prong.,/'

Power Supply

Cord with

3-Prong

Grounding

Plug

DO NOT, UNDER ANY CIRCUMSTANCES, CUT ORREMOVE

THE THIRD (GROUND) PRONG FROM THE POWER CORD.

Page 6

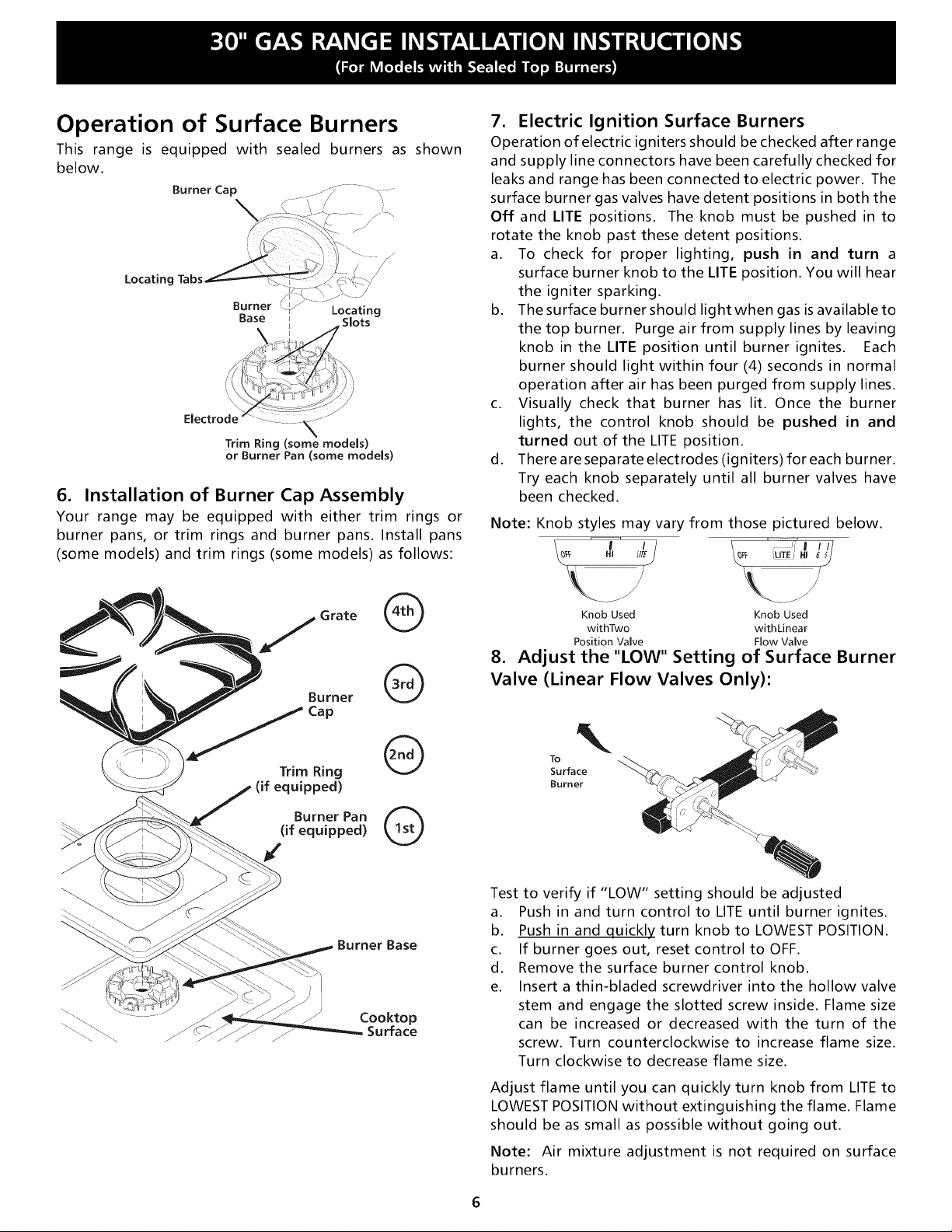

Operation of Surface Burners

This range is equipped with sealed burners as shown

below.

Burner Cap

Locating Tabs

Trim Ring (some models)

or Burner Pan (some models)

6. Installation of Burner Cap Assembly

Your range may be equipped with either trim rings or

burner pans, or trim rings and burner pans. Install pans

(some models) and trim rings (some models) as follows:

7. Electric Ignition Surface Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power. The

surface burner gas valves have detent positions in both the

Off and LITE positions. The knob must be pushed in to

rotate the knob past these detent positions.

a. To check for proper lighting, push in and turn a

surface burner knob to the LITE position. You will hear

the igniter sparking.

b. The surface burner should light when gas is available to

the top burner. Purge air from supply lines by leaving

knob in the LITE position until burner ignites. Each

burner should light within four (4) seconds in normal

operation after air has been purged from supply lines.

c. Visually check that burner has lit. Once the burner

lights, the control knob should be pushed in and

turned out of the LITE position.

d. There are separate electrodes (igniters) for each burner.

Try each knob separately until all burner valves have

been checked.

Note: Knob styles may vary from those pictured below.

Burner

J Cap

Trim Ring

Burner Pan

(if equipped)

€,

Grate @

_ed)

Burner Base

Cooktop

Surface

@

@

®

Knob Used KnobUsed

withTwo withkinear

PositionValve FlowValve

8. Adjust the "LOW" Setting of Surface Burner

Valve (Linear Flow Valves Only)"

TO

Surface

Burner k_

Test

to verify if "LOW" setting should be adjusted

a.

Push in and turn control to kITE until burner ignites.

b.

Push in and quickly turn knob to LOWEST POSMON.

C.

If burner goes out, reset control to OFF.

d.

Remove the surface burner control knob.

e.

Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased with the turn of the

screw. Turn counterclockwise to increase flame size.

Turn clockwise to decrease flame size.

Adjust flame until you can quickly turn knob from LITE to

LOWEST POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

Page 7

Operation of Oven Burners and

Oven Adjustments

9. Electric Ignition Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

The oven burner is equipped with an electric control system

as well as an electric oven burner igniter. If your model is

equipped with a waist-high broil burner, it will also have an

electric burner igniter. These control systems require no

adjustment. When the oven is set to operate, current will

flow to the igniter. It will "glow" similar to a light bulb.

When the igniter has reached a temperature sufficient to

ignite gas, the electrically controlled oven valve will open

and flame will appear at the oven burner. There is a time

lapse from 30 to 60 seconds after the thermostat is turned

ON before the flame appears at the oven burner. When the

oven reaches the dial setting, the glowing igniter will go

off. The burner flame will go "out" in 20 to 30 seconds after

the igniter goes "OFF." To maintain any given oven

temperature, this cycle will continue as long as the dial (or

display) is set to operate.

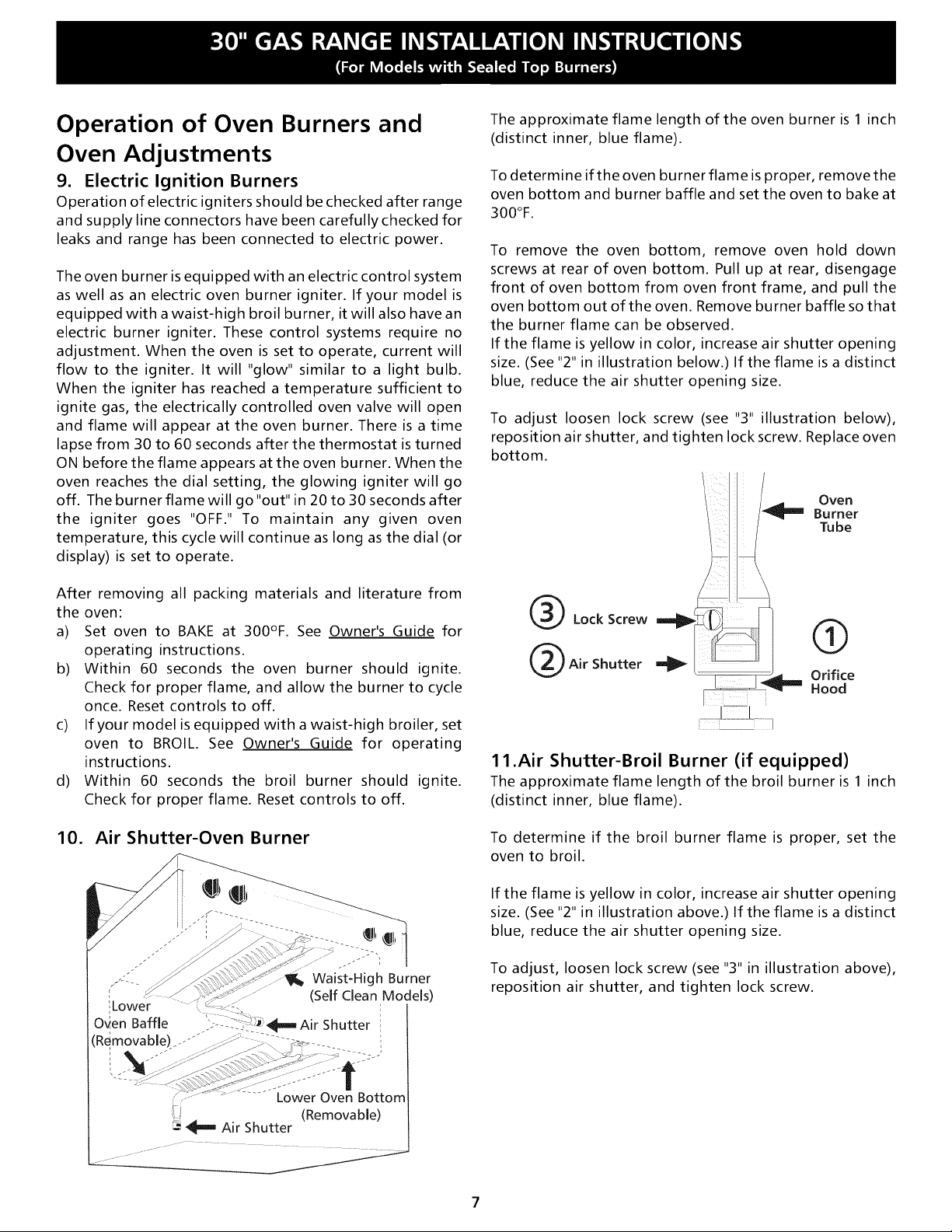

The approximate flame length of the oven burner is 1 inch

(distinct inner, blue flame).

To determine ifthe oven burner flame is proper, remove the

oven bottom and burner baffle and set the oven to bake at

300°F.

To remove the oven bottom, remove oven hold down

screws at rear of oven bottom. Pull up at rear, disengage

front of oven bottom from oven front frame, and pull the

oven bottom out of the oven. Remove burner baffle so that

the burner flame can be observed.

If the flame is yellow in color, increase air shutter opening

size. (See "2" in illustration below.) If the flame is a distinct

blue, reduce the air shutter opening size.

To adjust loosen lock screw (see "3" illustration below),

reposition air shutter, and tighten lock screw. Replace oven

bottom.

Oven

'_ Burner

Tube

After removing all packing materials and literature from

the oven:

a) Set oven to BAKE at 300°F. See Owner's Guide for

operating instructions.

b) Within 60 seconds the oven burner should ignite.

Check for proper flame, and allow the burner to cycle

once. Reset controls to off.

c) If your model is equipped with a waist-high broiler, set

oven to BROIL. See Owner's Guide for operating

instructions.

d) Within 60 seconds the broil burner should ignite.

Check for proper flame. Reset controls to off.

10. Air Shutter-Oven Burner

Waist-High Burner

Lower

Oven Baffle

Rqmovable)z..-"

(Self Clean Models)

"- i:_Air Shutter i

i

_I I_

@ LockScrew @

Air Shutter Orifice

Hood

1 1.Air Shutter-Broil Burner (if equipped)

The approximate flame length of the broil burner is 1 inch

(distinct inner, blue flame).

To determine if the broil burner flame is proper, set the

oven to broil.

If the flame is yellow in color, increase air shutter opening

size. (See "2" in illustration above.) If the flame is a distinct

blue, reduce the air shutter opening size.

To adjust, loosen lock screw (see "3" in illustration above),

reposition air shutter, and tighten lock screw.

'Lower Oven Bottom

_ Air Shutter

(Removable)

Page 8

12.Make Sure Range is Level.

Level the range by placing a level horizontally on an oven

rack. Check diagonally from front to back, then level the

range by either adjusting the leveling legs or by placing

shims under the corners of the range as needed.

13.After installation is complete, make sure all

controls are left in the OFF position.

Model and Serial Number

Location

For porcelain enamel ovens, the serial plate is located on

the right-hand surface of the oven front frame in the broiler

or storage drawer area.

For continuous clean ovens, the serial plate is located on

the right front edge of the floor shield located in the broiler

compartment.

When ordering parts for or making inquires about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate on

your range.

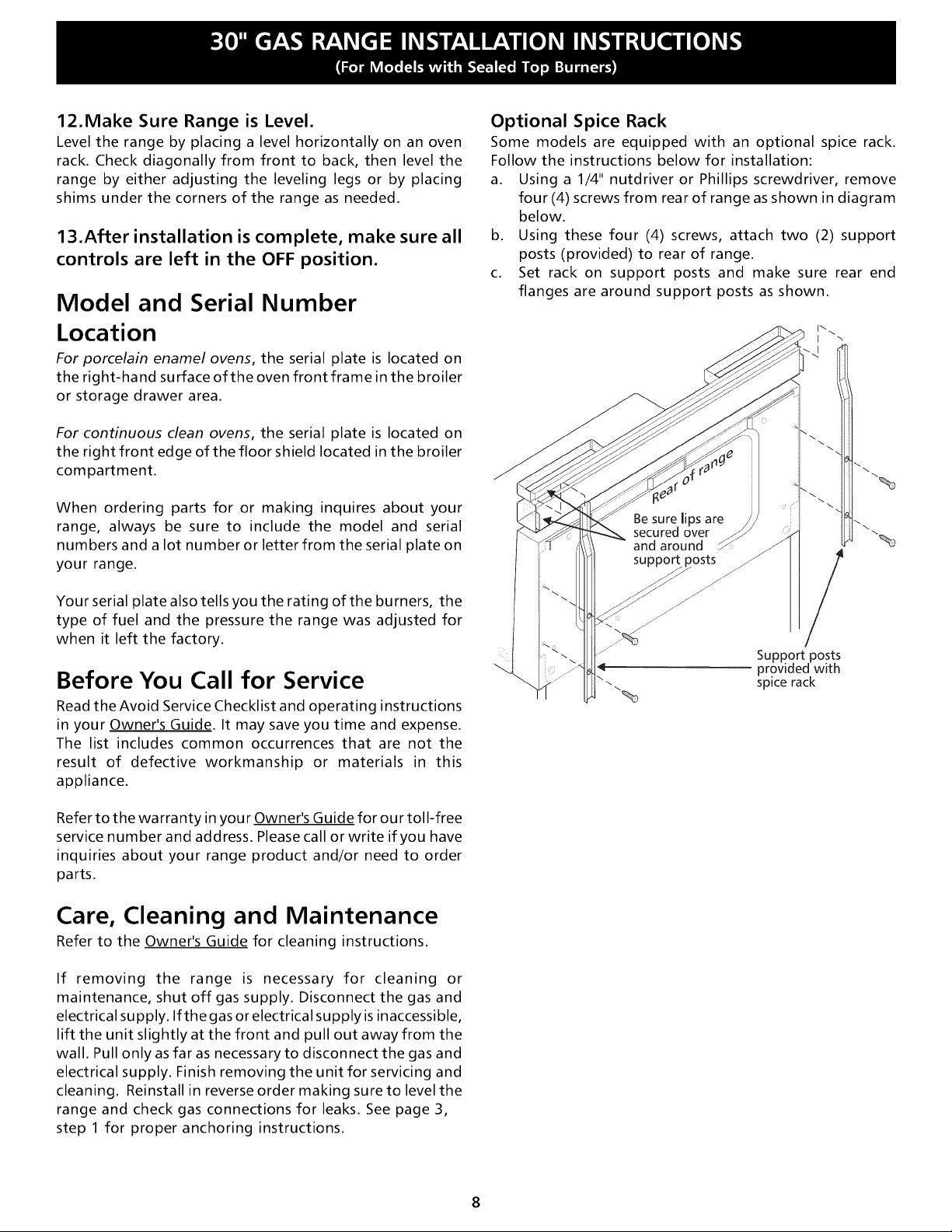

Optional Spice Rack

Some models are equipped with an optional spice rack.

Follow the instructions below for installation:

a. Using a 1/4" nutdriver or Phillips screwdriver, remove

four (4) screws from rear of range as shown in diagram

below.

b. Using these four (4) screws, attach two (2) support

posts (provided) to rear of range.

c. Set rack on support posts and make sure rear end

flanges are around support posts as shown.

Your serial plate also tells you the rating of the burners, the

type of fuel and the pressure the range was adjusted for

when it left the factory.

Before You Call for Service

Read the Avoid Service Checklist and operating instructions

in your Owner's Guide. It may save you time and expense.

The list includes common occurrences that are not the

result of defective workmanship or materials in this

appliance.

Refer to the warranty in you r Owner's Guide for our toll-free

service number and address. Please call or write if you have

inquiries about your range product and/or need to order

parts.

Care, Cleaning and Maintenance

Refer to the Owner's Guide for cleaning instructions.

If removing the range is necessary for cleaning or

maintenance, shut off gas supply. Disconnect the gas and

electrical supply. If the gas or electrical supply is inaccessible,

lift the unit slightly at the front and pull out away from the

wall. Pull only as far as necessary to disconnect the gas and

electrical supply. Finish removing the unit for servicing and

cleaning. Reinstall in reverse order making sure to level the

range and check gas connections for leaks. See page 3,

step 1 for proper anchoring instructions.

/

Support posts

provided with

spice rack

Page 9

L'INSTALLATION ET LES RI_PARATIONS DOIVENT I_TRE EFFECTUI_ES PAR UN TECHNICIEN QUALIFII_.

IMPORTANT • CONSERVER CETTE NOTICE POUR L'INSPECTEUR D'INSTALLATIONS I_LECTRIQUES DE LA

LOCALITE.

LIRE ET CONSERVER CETTE NOTICE POUR RI_FI_RENCE FUTURE.

Toute derogation aux directives donnees dans cette

notice peut entrainer des risques d'incendie, d'explosion, de

dommages materiels, de blessures ou de mort.

POUR VOTRE SI_CURITI_ :

-- Ne pas entreposer ni utiliser d'essence ou d'autre vapeurs ou

liquides inflammables a proximite de cette cuisiniere ou de tout

autre appareil electromenager.

-- QUE FAIRE S'ILYA UNE ODEUR DE GAZ

• N'allumeraucun appareil electrique.

• Ne toucher aucun commutateur electrique; ne pas utiliser le

telephone dans I'immeuble.

• Appeler la compagnie de gaz immediatement en utilisant le

telephone d'un voisin. Suivre les instructions de la compagnie

de gaz.

• S'il est impossible de joindre la compagnie de gaz, appeler les

pompiers.

-- L'installation et les reparations doivent _tre effectuees par un

TOUTES LES

CUISINIERES

PEUVENT

BASCULER.

DES BLESSURES

POURRAIENT

SURVENIR.

INSTALLER LES

AMARRES QUI

ACCOM-

PAGNENT LA

CUISINII_RE.

SE REPORTER

AUX DIRECTIVES

D'INSTALLATION

DES AMARRES.

technicien qualifie, un agent de service ou la compagnie de gaz.

29 7/8" 2 53/8"

48 1/2"

Maximum

avec

tablettes

6pices

47-3/4"

J Maximum"

44 3/8" \\

Porte ouverte \ \

Degagement et dimensions

1, Emplacement--Verifier I'esaace ou la

cuisiniere dolt _tre installee. S'assurer

que I'alimentation en gazet en

electricite est adequate et que le

plancher est stable.

2. Les dimensions indiquees doivent _tre

resDectees. Les dimensions indiquees

stipulent le degagement minimum

requis. Le plancher dolt _tre ferme et

au niveau.

Distance min. du

mur de chaque

c6t6 de la .........

cuisJni_r, au-dessus

de 36" de hauteur.

* Remarque: Un

d6gagement de

3 po est n6cessaire

si la cuisini_re est

dot6e de brOleurs

de 11 000 BTU.

\

30 _ _ Espace de 0" sous la surface de suisson et derriere la cuisini6re,

__Vue De

L'Avant

t Distance min.

I'armoire du

18" haut du c6t6

gauche ou

c

Vue De

C6t6

Profondeur I÷I 3"-_I

armolres slses

au-dessus de

maximum des _-

la cuisini_re.

Prevoir le type de combustible convenable

avant d'aller plus loin:

Votre cuisini_re a 6t6 r6gl6e afin de fonctionner avec du gaz naturel seulement. Certains

modules sont exp6di6s avec des pi_ces de conversion ainsi que des instructions. Deux ou trois

modules comportent un ensemble de conversion au gaz propane/GLP qui peut _tre obtenu

aupr_s du marchand.

Pour les modules dot_s de quatre br01eurs de surface de 9 000 BTU, commandez I'ensemble n°

80-8802-10. Pourlesmod_lesdot6sde2 br01eurs de surface de 9 000BTUetde2de

11 000 BTU, commandez I'ensemble n° 80-8904-10. Pour les modules dot6s de 3 br01eurs de

surface de9 000BTUetdel dell 000BTU, commandezl'ensemblen ° 80-8809-10.

I[-_ _ ' _°_ Ne pas tenter de modifier les r6glages de cette cuisini_re _ des

r6glages pour gaz propane/GLP sans I'ensemble de conversion au gaz propane/GLP appropri6

fourni avec la cuisini_re ou obtenu chez un marchand. Suivez toutes les instructions fournies

avec I'ensemble de conversion.

Page 10

Remarques importantes a I'intention de

I'installateur

1. Lire les directives contenues dans cette notice d'installation

avant d'installer la cuisini_re.

2. Retirer tout le materiel d'emballage de I'int_rieur de la cuisini_re

avant de brancher la cuisini_re _ I'alimentation en gaz et en

_lectricit&

3. Respecter tousles codes et ordonnances qui s'appliquent.

4. Laisser cette notice d'installation au client.

Remarque importante a I'intention du client

1. Conserver cette notice d'installation avec le Guide de I'utilisateur

pour r_f_rence future.

f f

CONSlGNES DE SECURITE

IMPORTANTES

Cette cuisini_re doit 6tre install6e conform_ment aux codes Iocaux

ou, s'il n'existe pas de codes Iocaux, _ 1'6dition la plus r_cente de la

norme ANSI Z223.1 si elle est install6e aux I_tats-Unis. Au Canada,

I'installation doit respecter les normes CAN/CGA-B149.1 et

CAN/CGA-B149.2

_J___ Ne pas monter, s'appuyer ou s'asseoir sur

les portes ou les tiroirs de cette cuisiniere; cela pourrait entrainer

des blessures graves et endommager la cuisiniere,

• Ne pas ranger des articles pouvant attirer des enfants dans

les armoires situees au-dessus de la cuisiniere. Les enfants

pourraient se br01er gravement en grimpant sur la cuisini_re

pour atteindre ces objets.

• II est preferable de ne pas utiliser I'espace de rangement

situe au-dessus des br01eurs de surface pour ne pas avoir

tendre les bras au-dessus de ceux-ce.

• Ajuster I'intensite de la flamme des br6leurs de surface de

fa_on ace qu'elle ne depasse pas le bord de la casserole, Les

flammes trop vives pr_sentent des dangers.

• Ne pas utiliser la cuisiniere comme espace de rangement.

Cela pourrait presenter des dangers.

• Ne jamais utiliser la cuisiniere pour rechauffer ou chauffer la

piece. II est dangereux d'utiliser la cuisini_re de fa_on prolong_e

sans une a_ration suffisante.

• Ne pas entreposer d'essence ou d'autres vapeurs ou liquides

inflammables a proximite de cet appareil ou de tout autre

appareil electromenager, Cela pourrait entrafner une explosion

ou un incendie.

• Remettre tousles boutons de commande a la position _off))

apres avoir utilise une fonction de la minuterie,

La conception de cette cuisini_re a _t_ ag r_e par I'CSA International.

Comme c'est le cas pour tout appareil qui utilise du gaz naturei et qui

_met de la chaleur, certaines consignes de s_curit_ doivent 6tre

respect_es. Ces consignes sont _nonc_es dans le Guide de I'utilisateur;

lire ce guide attentivement.

• S'assurer que la cuisiniere est correctement installee et mise

la terre par un installateur ou un technicien qualifi&

• Cette cuisiniere doit _tre mise a la terre conformement aux

codes Iocaux ou, s'il n'existe pas de codes Iocaux, a I'edition

la plus recente de la norme ANSl/NFPA n° .70 si elle est

installee aux letats-Unis. Au Canada, la mise _ la terre doit

respecter la norme CSA C22.1 du Code de I'_lectricit_ du Canada,

partie 1. Se reporter aux directives de mise _ la terre _ la page 13.

• Avant d'installer la cuisiniere dans un endroit recouvert de

linoleum ou de tout autre couvre-plancher synthetique,

s'assurer que le couvre-plancher peut supporter une chaleur

superieure d'au moins 32,2°C (90°F) a la temperature de la

piece sans retrecir, se tordre ou changer de couleur, Ne pas

installer la cuisini_re sur un tapis _ moins de placer un rev_tement

isolant en contre-plaqu_ de 0,64 cm (1/4 po) entre la cuisini_re

et le tapis.

• S'assurer que le rev_tement des murs qui entourent la

cuisiniere peut supporter la chaleur qu'emet cet appareil.

• Ne pas obstruer la circulation de I'air servant a la combustion

pres de la grille d'aeration ni autour de la base ou sous le

panneau avant de la cuisiniere. I_viter detoucher aux ouvertures

d'a_ration ou aux surfaces avoisinantes car elles peuvent devenir

tr_s chaudes pendant le fonctionnement de la cuisini_re. Cette

cuisini_re a besoin d'air frais pour que la combustion soit

adequate.

POUR LES MODI_LES AUTONETTOYANTS:

• Retirer la lechefrite, la nourriture et tout autre ustensile de

cuisson avant de nettoyer la cuisiniere. Essuyer le surplus de

salet& Suivre les directives de preparation au nettoyage contenues

dans le Guide de I'utilisateur.

• Contrairement a la cuisiniere au gaz standard, LA SURFACE

DE CUISSON DE CETTE CUISlNII_RE N'EST PAS AMOVlBLE, Ne

pas tenter de retirer la surface de cuisson.

NE PAS TENTER DE QUELQUE FA(_ON

QUE CE SOIT D'UTILISER LE FOUR /_ ALLUMAGE I_LECTRIQUE

PENDANT UNE PANNE D'I_LECTRICITI_. EN CAS DE PANNE

D'I_LECTRICITI_, REMETTRE TOUTES LES COMMANDES DU FOUR/_

LA POSITION _<OFF>>.

Si le thermostat du four restait allum6 (position <{ON>>)pendant

une panne d'61ectricit6, I'allumeur _lectrique red_marrerait

automatiquement le brOleur du four une fois la panne r_tablie.

Ne jamais laisser des enfants seuls ou

sans surveillance pres d'un appareil electromenager en marche.

D_s que les enfants sont assez grands, leur enseigner I'utilisation

correcte et s_curitaire de tousles appareils _lectrom_nagers. Ne

jamais laisser la porte du four ouverte Iorsque aucun adulte ne se

trouve _ proximit&

Si la panne d'61ectricit6 survient apr_s I'allumage de I'un des

brOleurs de surface, ce brOleur continuera de fonctionner.

Pendant une panne d'_lectricit_, les brOleurs de surface peuvent

_tre allum_s _ I'aide d'une allumette. Tenir une allumette allum_e

au-dessus du br01eur, puis tourner lentement le bouton vers la

position d'allumage (_LITD>. Faire preuve d'une grande prudence

en allumant les brOleurs de cette fa_on.

10

Page 11

Avant I'installation

Outils requis

Pour mettre les pieds au niveau :

• Cl_ _ douille (1 3/8 po hexagonale) ou pinces multiprise

• Tourne-_crou de 5/16 po ou tournevis _ lame plate

• Perceuse 61ectrique et foret de 1/8 po de diam_tre (foret

ma_onnerie pour une installation dans le b_ton)

Pour le branchement du gaz :

• CI_ _ tuyau

Reglage de la flamme du br[31eur:

• Tournevis Phillips __ et tournevis _ t6te plate

Pour la conversion du type de gaz (gaz propane ou gaz naturel) :

• CI_ ouverte de 1/2 po

Materiel additionnel requis

• Robinet d'arr6t de la conduite de gaz. :_,:_:j

• P_te _ joint qui r_siste _ Faction du gaz propane/gaz de p_trole

liqu_fi_ GPL

Les directives fournies sont pr6vues pour la fixation dans le bois ou

dans le b_ton, dans le plancher ou dans un mur. Lors de I'installation

sur un mur, assurez-vous que les vis traversent compl_tement lemur

sec et qu'elles se fixent dans du bois ou du m_tal. Lors de la fixation

un plancher ou _ un mur, assurez-vous que les vis ne p6n_trent pas

dans du c_blage _lectrique ou des accessoires de plomberie.

A.

Positionnez le support a I'aide du qabarit - (Le support peut

6tre plac_ sur la gauche comme sur la droite de la cuisini_re.

Positionnez le support _ I'aide du schema ci-dessous sile gabarit

n'estpasdisponible.) Faitesunrep_resurleplancherousurle

mur, I_ ou le c6t_ gauche ou le c6t_ droit de la cuisini_re se

trouvera situS. Si I'arri_re de la cuisini_re est contre lemur ou

une distance maximale de 1-1/4 po (3,18 cm) une fois install_e,

vous pouvez recourir _ la m_thode de I'installation au mur ou au

plancher. Siunemoulurevousemp_chedemonterlesupport

contrelemur, enlevez-laoufixezlesupportauplancher. Pour

un montage au mur, situez le support en pla(_ant le bord arri_re

du gabarit contre lemur arri6re, et le bord lat6rai du gabarit sur

le rep6re fait par rapport au c6t_ de la cuisini6re. Placez le

support au-dessus du gabarit et marquez I'emplacement des

trous de vis dans lemur. Si I'arri_rede la cuisini6re est _ plus de

1-1/4 po (3,18 cm) du mur une fois install6e, fixez le support au

plancher. Pour un montageau plancher, situezlesupporten

pla_ant le bord arri_re du gabarit I_ ou sera situ6 I'arri_re de la

cuisini6re. Faites un rep_re des trous de vis indiqu_s sur le

gabarit.

Un nouveau conduit en metal flexible pour appareil menager (1/2

po NPT x 3/4 po ou 1/2 po diam. interieur) dolt &tre certifie selon

une conception CSA International. Etant donne que les tuyaux

rigides ne permettent pas le deplacement facile de la cuisiniere,

nous recommandons I'emploi d'un nouveau tuyau flexible (de 4

5 pieds de Iongueur) pour les nouvelles installations et les

reinstallations supplementaires.

Utilisez toujours les deux (2) nouveaux raccords _ collet (1/2 po

NPT x 3/4 po ou 1/2 po diam. int6rieur) fournis avec le nouveau

tuyau flexible de I'appareil m_nager pr_vu pour raccorder la

cuisini_re.

Etapes d'installation normales

1. Directives de montage du support anti-

renversement

Avertissement important sur la securite

La cuisinini_re dolt 6tre fix6e au plancher pour _viter qu'elle nese

renverse. Ceci se r6alise en installant un support anti-renversement

I'aide des vis fournies avec la cuisini6re. Si le support anti-

renversement n'est pas install6, la cuisini_re peut basculer Iorsqu'un

poids excessif est exerc_ sur une porte ouverte ou qu'un enfant

montedessus. Des blessures graves peuvent s'ensuivre provenant de

la cuisini6re elle-m6me ou du renversement de liquides chauds.

Percez des avant-trous et fixez le support - Percez un avant-

trou de 1/8 po (3,2 mm) I_ ou seront situ_es les vis. Sile support

doit _tre mont_ au mur, percez un avant-trou _ une inclinaison

d'environ 20 ° vers le bas. Si vous installez le support sur un

plancher en c_ramique ou ma(_onnerie, percez un avant-trou de

5/32 po (3,9 mm) _ une profondeur de 1-3/4 po (4,44 cm). Les

vis fournies pourront _tre utilis_es dans le bois comme dans le

b_ton. Utilisezuntourne-_croude5/16poouuntourne-vis

lame plate pour fixer le support en place.

FIXEZLESUPPORT(Montage au rnur ou au plancher)

-_1 1_--1-1/4 po max.

-Montage sur lernur

Lisse

Montage au plancher--_'L!, ipport anti-renversement

F|XEZLESUPPORT(Montage au plan€her seulement)

-_1 Plus de

Piedde 1=1/4 po

i_r_-- Mur

S'il fallait d_placer la cuisini_re _ un autre endroit, les supports anti-

renversement devraient _galement 6tre enlev_s et remont_s _ nouveau

avec la cuisini_re.

Montage au plancher------_ Support anti-renversernent

11

Page 12

C, Placement et mise a niveau de la cuisiniere - Mettez la

cuisini_re _ niveau en r6glant les quatre (4) pieds de nivellement

I'aided'unecl_. Remarque: Und_gagementminimaldel/8

po (3,2 mm) est n_cessaire entre le bas de la cuisini_re et le pied

de nivellement pour Ioger le support. Utilisez un niveau _ bulle

d'air pour v6rifier vos r_glages. Remettez la cuisini_re en place.

V_rifiez visuellement si le pied de nivellement arri_re se trouve

Iog_ et bien fix_ dans le support anti-renversement en enlevant

le panneau inf_rieur ou le tiroir de rangement. Pour les modules

avec tiroir chauffant ou compartiment _ I_chefrite, prenez le

bord arri6re sup_rieur de la cuisini6re et essayez doucement

d'incliner la cuisini6re vers I'avant.

I

Centre de

la cuisini_re

129,21 cm

--_(11-1/2

55,8

(22 p,

Espace recommand_ pour le

branchement du tuyau et du

0binet d'arr_t dans le planchel

La zone ombrag_e

indique I'espace

recommand_ pour la

rise de ! 20 V sur le m_

et I'espace pour le

et du robinet d'arr_t

dans lemur.

2. Assurer une alimentation en gaz adequate.

Cet appareil est con(_u pour fonctionner sur une pression de 10,16 cm

(4 po) produite par un distributeur de gaz naturel. Un r_gulateur de

pression ajustable est branch_ au distributeur; ce r6gulateur DOlT

_tre reli_ en s6rie avec la conduite d'alimentation en gaz. Si un

ensemble de conversion au gaz propane a 6t6 install6, suivre les

directives qui accompagnent I'ensemble en question pour convertir

le r6gulateur de pression _ I'alimentation de gaz propane.

II faut prendre grand soin pendant I'installation de la cuisini_re de ne

pas obstruer la circulation de Fair servant _ la combustion et _ la

ventilation.

Pour que la cuisiniere fonctionne correctement, la pression

d'admission maximum au r6gulateur ne dolt pas d@asser 35,56 cm

(14 po) d'eau. La pression d'admission au r6gulateur dolt _tre d'au

moins 2,54 cm (1 po) plus 61ev6e que la pression au distributeur. Par

exemple, si le r_g ulateur est r_gl_ de fa(_on _ ce que la pression de gaz

naturel soit de 10,16 cm (4 po) au distributeur, la pression

d'admissiondoit6tred'aumoins12,7 cm(5 po).Siler_gulateura

_t6 converti _ une alimentation en gaz propane et que la pression au

distributeur est de 25,4 cm (10 po), la pression d'admission doit

_tred'aumoins27,94 cm (11 po).

Un essai dI_tanch_it_ de I'appareil dolt _tre r_alis_ selon les instructions

fournies _ I'_tape 4g.

Laconduited'alimentationengazdoit_trede1,27 cm(1/2 po) ou

1,9 cm (3/4 po) d.i.

3. Sceller les ouvertures.

Sceller toute ouverture dans lemur, derri6re la cuisini6re, et dans le

plancher, sous la cuisini6re, une fob la conduite d'alimentation en

gaz install_e.

4. Brancher la cuisiniere a I'alimentation en gaz.

Pour pr6venir les fuites, appliquer un mastic de joint pour tuyaux sur

les filets de tousles raccords m_les (filets sur I'ext6rieur).

Le r_gulateur est situ_ dans I'un des deux emplacements illustr_s ci-

dessous.

_!_J___ Ne pas permettre au regulateur detourner

sur le tulau pendant le serrement des pieces,

Front Access

to Regulator:

Remove Kick Panel,

StorageDrawer, or

Warmer Drawer. Pressure

(See Owner's Guide Regulator

for Instructions). location at

If Equipped with rear of

Broiler Drawer,

Broiler Drawer.

12

Page 13

Robinet Adaptateur Connecteur Adaptateur R_gulateur

d'arr_t _ soupie de _ de pression

manuel _vasement I'appareil _vasement

(illustr__ la position {{ONe>(OUVERT).

S'assurerque le levier setrouve & laposition {{ON>>unef0is I'installation termin_e.

5. Lire les directives relatives au branchement

electrique ci-dessous et brancher la cuisiniere

I'alimentation electrique.

E_ _'_ " ' _ Avantlebranchement, couperl'alimentation

_lectrique _ la bofte de fusibles ou de disjoncteurs ou au cordon

d'alimentation.

Installation 61ectrique : D6rivation distincte ad6quatement mise & la

terre et polaris_e avec disjoncteur ou fusible _ retardement de 15 A.

Se reporter _ la plaque signal_tique pour la tension recommand6e.

a) Poser un robinet d'arr6t manuel externe sur la conduite

d'alimentation en gaz dans un endroit facile d'acc_s _ I'ext_rieur

de la cuisini_re. S'assurer de savoir comment et ou couper

I'alimentation en gaz de la cuisini6re.

b) Poser un adaptateur _ _vasement de 1,27 cm (1/2 po) sur le

r6gulateur de pression.

c) Fixer le connecteur de I'appareil _ I'adaptateur _ _vasement reli_

au r6gulateur.

d) Fixer un autre adaptateur _ _vasement au robinet d'arr6t manuel

externe.

e) Fixer le connecteur de I'appareil _ I'adaptateur _ _vasement reli_

au robinet d'arr6t.

f) S'assurer que le robinet d'arr_t du r6gulateur de pression est

ouvert (position _ON_>).

g) V_rifier s'il y a des fuites. Ouvrir I'alimentation en gaz de la

cuisini_re et appliquer un d6tecteur de fuite liquide sur tousles

joints et les raccords de fa_on _ d_celer toute fuite dans la

conduite.

Ne pas utiliser une flamme vive pour d_tecter

les fuites de gaz.

Verifier la pression de gaz du distributeur

D_brancher la cu isin i_re et son robinet d'arr_t distinct de la canalisation

de gaz pendant toute v_rification de pression de I'alimentation en

gaz&despressionsquid6passent35,56 cm(14 po) d'eau(environ

3,45 kPa (1/2 Ib/po2)).

Consignes de s6curit_ relatives aux cordons de rallonge :

En raison des risques que peuvent presenter les cordons de rallonge

dans certaines circonstances, nous recommandons fortement de ne

pas utiliser de cordon de rallonge avec la cuisini_re. Toutefois, si I'on

d_cide tout de m_me d'utiliser un cordon de rallonge, celui-ci dolt

_tre _ 3 conducteurs, agr_ UL, mis _ la terre et con_u pour le

branchement d'appareils _lectrom_nagers; il doit _tre en mesure de

soutenir une tension _quivalente ou sup_rieure _ I'amp_rage de la

d_rivation. On peut se procurer ce type de cordon de rallonge aupr_s

de I'agent de service apr_s-vente agr_ le plus proche.

LIREATTENTIVEMENT ! Pourvotres6curit_,

cet appareil dolt _tre convenablement mis _ la terre.

Mise a la terre

Le cordon d'alimentation _lectrique de cet appareil est pourvu d'une

fiche_ 3 broches (mise_ laterre) quiconvient auxprises murales

standard _ 3 ouvertures mises _ la terre, et ce de fa(_on _ minimiser

les risques d'_lectrocution que pourrait presenter cet appareil. Le

consommateur dolt faire v_rifier la prise murale et le circuit par un

_lectricien agr_ afin de s'assurer que la prise est correctement mise

la terre et polaris_e.

Methode

privil_gi_e

ne faut en aucun cas_

couper, retirer ou |

contourner la broche [

de terre de cette fiche. _

J

L'appareil dolt _tre isol_ de la canalisation de gaz par la fermeture de

son robinet d'arr6t manuel pendant toute v_rification de pression de

la canalisation de gaz _des pressions 6gales ou inf_rieures _ 35,56 cm

(14 po) d'eau (environ 3,45 kPa (1/2 Ib/po2)).

S'il s'av_re n_cessaire de v_rifier la pression de la canalisation de gaz,

brancher un manom_tre (hydrom_tre) ou un autre appareil de

v_rification de pression _ I'orifice du brOleur de surface arri_re droit.

Tenir un boyau en caoutchouc d'environ 0,6 cm (1/4 po) dediam_tre

int_rieur reli_ _ I'appareil de v_rification bien serr_ sur I'orifice. Ouvrir

le robinet du brOleur.

Pour une v_rification de pression fiable, faire fonctionner au moins

deux (2) autres br01eurs de surface pendant la v_rification. S'assurer

que la pression d'alimentation en gaz (pression d'admission) est

sup_rieured'aumoins2,54 cm(1 po)_lapressiondudistributeur.

La pression de I'alimentation en gaz ne dolt jamais _tre sup_rieure

35,56 cm (14 po) d'eau. Lorsque la pression du distributeur est bien

ajust_eaugaznaturel, elleestde10,16 cm (4 po).Danslecasdu

gazpropane, lapressiondudistributeurestde25,4 cm(10 po).

Prise rnurale

mise & la terre

Lorsque la prise murale n'a que deux ouvertures, il incombe au

propri_taire de I'appareil de faire remplacer cette prise par une prise

trois ouvertures convenablement mise _ la terre.

IL NE FAUT EN AUCUN CAS COUPER OU RETIRER LA BROCHE DE

TERRE DU CORDON D'ALIMENTATION ELECTRIQUE.

Cordon

d'alimentation

avec fiche & 3

broches raise

la terre

13

Page 14

Fonctionnement des brOleurs de

surface

Cette cuisini6re est pourvue de br01eurs scell_s, comme le montre

I'illustration qui suit.

Couverde du

br_leur

Languettes

de fixation

Base du Ouvertures de

brOleur fixation

I_lectrode _- .......

Anneau de garniture (certains modules)

ou cuvette du br61eur (certains mod¢les)

7. Br61eurs de surface a allumage electrique

Le fonctionnement de I'allumage _lectrique doit 6tre v_rifi_ une fois

que la d_tection de fuite dans les raccords de la cuisini_re et de la

conduite d'alimentation a _t_ effectu_e et que la cuisini_re a _t_

branch_e _ I'alimentation _lectrique. Les soupapes des br01eurs de

surface sont dot_es d'un encliquetage aux positions <_OFF_>(arr_t) et

<_LITE_>(allumage). II faut enfoncer le bouton et le tourner au-del_ de

ces positions d'encliquetage.

a. Pour v_rifier I'allumage, enfoncer et tourner le bouton d'un

br01eur de surface _ la position _LITE_>.On entend une _tincelle

dans le dispositif d'allumage.

b. Le br01eur de surface devrait s'allumer si I'alimentation en gaz

est reli_e au br01eur. Purger I'air des canalisations d'alimentation

en laissant le bouton _ la position _LITD> jusqu'au moment ou le

br01eur s'allume. Dans des conditions normales, chaque br01eur

devrait s'allumer dans les quatre (4) secondes une lois que Fair

a _t_ purg_ des conduites d'alimentation.

c. V_rifier visuellement si le br01eur est allum_. Une lois le br01eur

allum_, le boutondecommandedoit _treenfonc_ettourn_

hors de la position _LITE_>.

d. Chaque br01eur est pourvu d'un allumeur distinct. V_rifier chacun

des boutons pour tester tousles br01eurs.

Remarque : Le style des boutons peut diff_rer des styles illustr_s.

' l' /

_ HI z!r_/ '_ ii I I I...........

_'_ LiTEi HI _//

6. Installation des pieces qui recouvrent le br61eur

La cuisini6re est pourvue d'anneaux de garniture ou de cuvettes, ou

encore de ces deux dispositifs. Installer les cuvettes (certains modules)

et les anneaux de garniture (certains modules) comme suit '

Grille Q

Couverde Q

J du Br_leur

Anneau de Q

,Garniture

y a lieu)

Cuvette du Q

Br_leur

y a lieu)

Base du BrOleur

Surface de

=Cuisson

Commande Commande

_ deux _ d6bit

positions lin_aire

8. Ajustement du reglage faible ((LOW)) du robinet

des br61eurs (commandes a debit lineaire ou a trois

positions seulement) •

d'almentation

en gaz

a)

Tourner le bouton de commande _ la position _LITE_>jusqu'_ ce

que le brQleur s'allume.

b)

Tourner rapidement la commande _ la POSITION LA PLUS FAIBLE.

c)

Si le brOleur s'_teint, ajuster le robinet de la fa(;on suivante :

Remettre le bouton de commande _ la position (_OFF>>.Retirer le

bouton de commande du brOleur, insurer un tournevis _ lame mince

dans la tige creuse du robinet et saisir la vis _ filets interrompus. La

taille de la flamme peut 6tre augment6e ou r_duite par le r6glage de

cette vis. Ajuster la flamme jusqu'_ ce que le bouton de commande

puisse _tre tourn_ rapidement de la position _LITE_>_ la POSITION LA

PLUS FAIBLE sans que la flamme ne s'_teigne. La flamme doit _tre

aussi petite que possible sans s'6teindre.

Remarque : L'ajustement du m_lange d'air n'est pas requis pour les

brOleurs de surface.

14

Page 15

Fonctionnement des brOleurs du

four et ajustement du four

9. Br_leurs a allumage electrique

Le fonctionnement de I'allumage _lectrique doit 6tre v_rifi_ une fois

que la d6tection de fuite dans les raccords de la cuisini_re et de la

conduite d'alimentation a 6t_ effectu_e et que la cuisini_re a _t_

branch_e _ I'alimentation _lectrique.

Le brOleur du four est pourvu d'un dispositif de contr61e 61ectrique

ainsi que d'un dispositif d'allumage _lectrique. Si la cuisini_re est

pourvue d'un brOleur de grillage _ hauteur de la taille, ce brOleur

dispose 6galement d'un dispositif d'allumage 61ectrique. Cesdispositifs

de contr61e n'ont pas _6tre ajust_s. Une fois le four pr6t _ fonction ner,

I'alimentation 61ectrique se rend au dispositif d'allumage. Ce dispositif

{{s'illumine>> comme une ampoule 61ectrique. Lorsque le dispositif

d'allumage atteint la temp6rature requise pour enflammer le gaz, le

robinet _ commande 61ectriq ue du four s'ouvre et la flamme se forme

sur le brOleur. II fautde30 _ 60 secondes entrele moment ou le

thermostat est allum_ et I'apparition de la flamme sur le brOleur.

Lorsque le four atteint la tem p6rature pr6vue, le dispositif d'allumage

s'_teint. La flamme du brOleur s'_teint dans les 20 _ 30 secondes qui

suivent la fermeture du dispositif d'allumage. Pour maintenir une

temperature donn_e dans le four, le cycle se poursuit tant que la

commande (ou le voyant) fonctionne.

Une fois tout le materiel d'emballage et la documentation sortis du

four:

a) R_gler le four sur CUISSON {_BAKE>>_ 154°C (300°F). Se reporter

au Guide de I'utilisateur pour les directives de fonctionnement.

b) LebrOleurdu fourdevraits'allumerdansles 60 secondesqui

suivent. S'assurer que la flamme est adequate et permettre au

brOleur d'accomplir un cycle complet. Refermer les boutons de

commande (position <{offl>).

c) Si la cuisini_re est pourvue d'un brOleur de grillage _ hauteur de

la taille, r6gler le four sur GRILLAGE <{BROID>. Se reporter au

Guide de I'utilisateur pour les directives de fonctionnement.

d) LebrOleurdegrillagedevraits'allumerdansles60 secondesqui

suivent. S'assurer que la flamme est adequate. Refermer les

boutons de commande.

LaflammedubrOleurdufourmesureenviron2,5 cm(1 po)(flamme

int_rieure de couleur bleue).

Pour d6terminer si la flamme du brOleur du four est ad6quate, retirer

le fond du four et le d_flecteur, puis r_gler le four sur CUISSON

_BAKD> _ 1 54°C (300°F).

Pour retirer le fond du four, enlever les vis de support situ_es sur sa

partie arri_re. Le soulever par I'arri_re, d_sengager son devant du

cadre avant du four, puis le tirer pour le sortir du four. Retirer le

d_flecteur de fa_on _ pouvoir observer la flamme.

Si la flam me est de couleur jaune, accroftre I'ouverture de I'obturateur

d'air. (Se reporter au num6ro 2 de I'illustration qui suit.) Si la flamme

est d'un bleu marque, r6duire I'ouverture de I'obturateur d'air.

Pour ajuster la flamme, desserrer la vis de blocage (se reporter au

num6ro 3 de I'illustration qui suit), ajuster I'obturateur d'air, puis

resserrer la vis de blocage. Remettre le fond du four en place.

_ Tuyau du

br_leur

du four

®v,sdob,oca0o®

(_ Obturateur d'air _ Capuchon

...........i_1

11.0bturateur d'air/ br61eur de grillage (s'il y a

lieu)

LaflammedubrOleurdufourmesureenviron2,5 cm(1 po)(flamme

int_rieure de couleur bleue).

de I'orifice

I

10. Obturateur d'air/br_leur du four

BrOleur _ hauteur

L

D_flecteur

inf_rieur ,-'_'-

du four amovible ,,-'"

_m=Obturateur d'air (amovible)

del le taille (modUles

autonettoyants)

Pour d6terminer si la flamme du brOleur de grillage est adequate,

r_gler le four sur GRILLAGE {_BROID>.

Si la flam me est de couleur jaune, accroftre I'ouverture de I'obturateur

d'air. (Se reporter au num6ro 2 de I'illustration qui pr6c_de.) Si la

flamme est d'un bleu marque, r_duire I'ouverture de I'obturateur

d'air.

Pour ajuster la flamme, desserrer la vis de blocage (se reporter au

num_ro 3 de I'illustration qui precede), ajuster I'obtu rateu r d'air, puis

resserrer la vis de blocage.

d'air

Fond du four

15

Page 16

12. S'assurer que la cuisiniere est au niveau

Mettre la cuisini_re au niveau en pla_ant un niveau _ I'horizontale sur

une gille du four. V_rifier en diagonale d'avant en arri_re, puis mettre

la cuisini_re au niveau, soit en ajustant les pieds de nivellement, soit

en pla_ant des cales sous les coins au besoin.

13. Une fois I'installation terminee, s'assurer que

tous les boutons de commande sont fermes

(position (_off))).

Emplacement des num ros de

module et de s rie

Dans le cas des fours 6maill6s, la plaque signal6tique est situ_e sur le

bord avant droit du cadre du four, dans le compartiment du grilloir

ou le tiroir de rangement.

Dans le cas des fours b nettoyage continu, la plaque signal_tique est

situ6e sur le bord avant droit du protecteur de plancher situ_ dans le

compartiment du grilloir.

Lorsqu'il faut commander des pi6ces ou poser des questions sur la

cuisini_re, s'assurer de mentionner le num6ro de module et le num_ro

de s_rie ainsi que le num_ro de lot ou la lettre qui figurent sur la

plaque signal_tique de la cuisini6re.

Installer le support a epices.

Ce four est _quip_ d'un support _ _pices _ ajouter ou non, au choix.

Pour affixer-le sur la cuisini_re:

a. Avec un tournevis Phillips, enlever quatres (4) vis de la derriere

de la cusini_re comme idinqu_ ci-dessous.

b. Employant ces quatres (4) vis, rattacher les deux colonnes de

soutient (fournis) _ I'arri_re de la cuisini_re.

c. Placer le support _ _pices sur les poteaux de soutient en tant que

les rebords entourent les poteaux de soutient comme indiqu_ ci-

dessous.

La plaque signal_tique indique _galement le calibre des brOleurs, le

type de carburant _ utiliser et la pression pr_ajust_e au moment ou

la cuisini_re a quitt_ I'usine.

Avant de faire appel b un centre de

service

Lire le Guide de d_pannage et les directives d'utilisation qui figurent

dans le Guide de I'utilisateur. Cela peut _pargner du temps et des

d_penses inutiles. Le Guide de d_pannage d_crit les probl_mes

courants qui ne sont pas causes par un vice de fabrication ou de

mat_riaux.

Se reporter _ la garantie qui figure dans le Guide de I'utilisateur pour

connaftre le num_ro sans frais et I'adresse de notre service _ la

clientele. N'h_sitez pas _ nous appeler ou _ nous _crire si vous avez

des questions au sujet de votre cuisini_re ou pour commander des

pi_ces.

Entretien et nettoyage

Se reporter au Guide de I'utilisateur pour les directives de nettoyage.

S'il faut d6placer la cuisini_re pour la nettoyer ou la r_parer, fermer

I'alimentation en gaz. D_brancher I'alimentation en gaz et

I'alimentation 61ectrique. Si les sources de gaz et d'_lectricit6 ne sont

pas accessibles, soulever I_g_rement le devant de la cuisini_re et tirer.

Tirer juste assez pour _tre en mesure de couper I'alimentation en gaz

et en _lectricit_. Poursuivre le d6placement de la cuisini6re pour

I'entretien ou le nettoyage. R6installer la cuisini6re dans I'ordre

inverse en s'assurant qu'elle est au niveau et qu'il n'y a pas de fuite

dans les raccords dela conduite degaz. Sereporter au dela page 11

pour savoir comment amarrer correctement la cuisini6re.

/

Pied supports

fournis avec les

tablettes & _pices

16

Page 17

LA INSTALAClON Y EL SERVIClO DEBEN SER EFECTUADOS POR UN INSTALADOR CALIFICADO.

IMPORTANTE: CONSERVE ESTAS INSTRUCClONES PARA USO DEL INSPECTOR LOCAL DE ELECTRIClDAD.

LEA Y CONSERVE ESTAS INSTRUCClONES PARA REFERENClA FUTURA.

Si la informacion contenida en este manual no es

seguida exactamente, puede ocurrir un incendio o explosion

causando daEos materiales, lesion personal o la muerte.

PARA SU SEGURIDAD:

-- No almacene ni utilice gasolina u otros vapores y liquidos

inflamables en la proximidad de este o de cualquier otro

artefacto.

-- QUE DEBE HACER Sl PERClBE OLOR A GAS:

• No trate de encender ningun artefacto.

• No toque ningun interruptor electrico; no use ningun telefono

en su edificio.

• Llame a su proveedor de gas desde el telefono de un vecino.

Siga las instrucciones del proveedor de gas.

• Si no Iogra comunicarse con su proveedor de gas, Ilame al

departamento de bomberos.

-- La instalacion y el servicio de mantenimiento debe realizarlo

un instalador calificado, la agencia de servicios o el proveedor

de gas.

• TODAS LAS

ESTUFAS

PUEDEN

VOLCARSE.

• PUEDEN

RESULTAR

LESIONES

PERSONALES.

• INSTALE EL

DISPOSITIVO

ANTIVUELCO

EMPACADO

CON LA ESTUFA.

• VEA LAS

INSTRUCCIONES

DE

INSTALACION.

Espacios libres y dimensiones

1. Ubicacion - Examine la ubicacion donde

va a instalar la estufa. Compruebe que la

alimentacion el_ctrica y de gas sea

adecuada ycompruebe la estabilidad del

piso.

2.

Las dimensiones que se muestran deben

ser usadas. Las dimensiones dadas

proporcionan el espacio minimo

necesario. Lasu perficie de contacto debe

ser solida y nivelada.

VISTA DE

pared en cada

Minimo a ,a __ FRENTE

lado de la estufa

sobre una altura o

* Nota: Sedebe

dejar un espacio

libre de 3' si est_

equipada con Minimo a los

quemadores en la _,, , 18" armarios en

tapa de la estufa L

dede36,, _ /._ la estufa

11,000 BTU

cada lado de

VISTA

LATERAL

Profundidad I÷13"_1

m_xima de los

armarios sobre

la cubierta de

la estufa.

_25,_

I_----

30" _ Espacio fibre de 0" debajo de la cubierta yen la parte

Utilice el tipo de combustible apropiado

Antes de proceder:

Suestufa ha sido dise_ada para funcionar con gas natural solamente. Algunos modelos pueden

ser transformados y se envian con las piezas y las instrucciones de conversion. Otros modelos

tienen un juego de conversion a propano liq uido que puede obtener a trav_s de su distribuidor.

Para los modelos equipados con quemadores de superficie de 4-9.000 BTU, solicite el juego

#80-8802-10. Para los modelos equipados con quemadores de superficie de 2-9.000 BTU y 2-

11.000 BTU, solicite el juego #80-8904-10. Para los modelos equipados con quemadores de

superficie de 3-9.000 BTU y 1-11.000 BTU, solicite el juego #80-8809-10.

NO intente convertir esta estufa a propano liquido sin tener el juego de

conversion a propano liquido suministrado con la estufa u obtenido de su distribuidor. Siga las

instrucciones incluidas con el juego de conversion.

trasera de la estufa.

17

Page 18

D A D A

Importantes notas para el instalador

1. Lea todas las instrucciones contenidas en estas instrucciones

para la instalacion antes de instalar la estufa.

2. Saque todos los materiales de embalaje de los compartimientos

del horno antes de conectar la alimentacion de gas y electricidad

a la estufa.

3. Observe todos los codigos y ordenanzas en vigor.

4. Aseg0rese de dejar estas instrucciones al cliente.

Nota importante para el cliente

1. Guarde estas instrucciones con la guia del propietario para

referencia futura.

IMPORTANTES

INSTRUCCIONES DE

SEGURIDAD

La instalacion de esta estufa debe estar conforme con los codigos

locales, o si no existen c6digos locales, con el National Fuel Gas Code

(Codigo Nacional para Gases Combustibles), ANSI Z223.1--1a edicion

m_s reciente cuando se instala en los Estados Unidos. Si se instala en

Canada, la instalacion debe estar conforme con CAN/CGA-B149.1 y

CAN/CGA- B149.2.

El dise_o de esta estufa ha sido certificado por la CSA International.

Igual que con cualquier electrodom_stico que utiliza gas y genera

calor, existen ciertas precauciones de seguridad que debera seguir.

Las encontrar_ en la Guia del Propietario. L_alas con atencion.

• Asegurese de que su estufa sea instalada y puesta a tierra

debidamente por un instalador capacitado o un tecnico de

servicio,

• Esta estufa debe ser puesta a tierra de acuerdo con los

codigos locales, o si no existen codigos locales, con el

National Electrical Code (Codigo Electrico Nacional), ANSI/

NFPA N° 70 -- la edicion mas reciente cuando se instala en

los Estados Unidos. Si se instala en Canada, esta estufa debe ser

puesta a tierra de acuerdo con la Norma CSA Standard C22.1,

Canadian Electrical Code (Codigo El_ctrico Canadiense), Parte 1.

Vea las instrucciones para la puesta a tierra en la p_gina 21.

• Antes de instalar la estufa en un area cubierta con linoleo o

cualquier otro material de recubrimiento sintetico para

pisos, asegurese de que el recubrimiento para pisos pueda

soportar una temperatura de por Io menos 90°F (32,2°C) por

encima de la temperatura ambiente sin encogerse, doblarse

ni cambiar de color. No instale la estufa encima de un alfombrado

a menos que coloque una alfombrilla o I_mina aislante de

madera chapada de 1/4 de pulgada (6,3 mm) de espesor entre la

estufa y el alfombrado.

• Asegurese de que el papel tapiz de paredes alrededor de la

estufa pueda soportar el calor generado por la estufa.

• No obstruya el paso de aire de combustion en la rejilla de

ventilacion del horno ni alrededor de la base ni debajo del

panel delantero inferior de la estufa. Evite tocar las aberturas

de ventilacion o las superficies cercanas ya que pueden calentarse

cuando el horno est_ en funcionamiento. Esta estufa requiere

aire fresco para la combustion adecuada del quemador.

_: -w, - _ = No deje nunca a los ni_os solos o

desatendidos en el area donde un electrodomestico este en

funcionamiento. Cuando los ni_os crezcan, ens_eles el uso correcto

yseguro de todos los electrodom_sticos. No deje nunca la puerta del

horno abierta cuando la estufa est_ desatendida.

Subirse, apoyarse o sentarse sobre las

puertas o cajones de esta estufa puede provocar lesiones de

consideracion y tambien puede da_ar la estufa,

• No almacene articulos de interes para los ni_os dentro de los

armarios situados por encima de la estufa. Los ni_os que se

suban a la estufa para alcanzar articulos podrian resultar

gravemente quemados..

• Para eliminar la necesidad de colocarse sobre los quemadores

de la superficie, deben evitarse los armarios por encima de

los quemadores.

• Ajuste el tama_o de la llama del quemador de superficie

para que no sobrepase el borde del utensilio de cocina, Las

llamas excesivas son peligrosas.

• No use el horno para almacenar cosas, Esto crea una situacion

peligrosa potencial.

• No use nunca su estufa para mantener un cuarto caliente ni

para calentarlo. El uso prolongado de la estufa sin ventilacion

adecuada puede ser peligroso.

• No guarde ni utilice gasolina ni otros vapores y liquidos

inflamables en las cercanias de este o cualquier otro

electrodomestico, Pueden ocurrir incendios o explosiones.

• Vuelva a colocar todos los controles en la posicion de "off"

(apagado) despues de haber utilizado una operacion con el

programador,

PARA MODELOS CON LA CARACTERISTICA DE

AUTOLIMPIEZA:

• Saque la bandeja del asador, los alimentos y cualquier otro

utensilio antes de poner en marcha la autolimpieza. Limpie

el exceso de derrames de comida. Siga las instrucciones para la

limpieza previa en la Guia del Propietario.

• A diferencia de las estufas a gas communes, LA TAPA DE LA

ESTUFA NO ES REMOVlBLE, No trate de sacar la tapa.

['' " _' _ = NO TRATE DE UTILIZAR EL ENCENDIDO

ELECTRICO DURANTE UNA FALLA DEL SUMINISTRO ELECTRICO.

COLOQUE TODOS LOS CONTROLES DEL HORNO EN "OFF"

(APAGADO) EN CASO DE UNA FALLA ELECTRICA.

El encendedor el_ctrico volvera a encender

autom_ticamente el quemador del horno cuando regrese el

suministro el_ctrico si el control del termostato del horno se dejo

en la posicion de "ON" (encendido).

Cuando ocurra una falla el_ctrica durante el uso, los quemadores

de superficie continuar_n funcionando.

Durante una falla el_ctrica, los quemadores de superficie pueden

ser encendidos con una cerilla. Sujete una cerilla encendida justo

al lado del quemador y gire despacio la perilla a la posicion de LITE

(encendido). Tenga muchisimo cuidado cuando encienda los

quemadores de esta manera.

18

Page 19

Antes de comenzar

Herramientas necesarias

Para las patas niveladoras:

• Herramienta para insertar casquillos (1-3/8" hex) o alicates

channel lock

• Llave para tuercas de 5/16"o Destornillador para tornillos de

cabeza plana (E_Z_]_

• Taladro el_ctrico y broca de 1/8" de di_metro (broca de alba_ileria

si est_ instalando en hormigon)

Para la conexion de la alimentacion de gas:

• Llave para tuberias

Para ajustar la llama del quemador:

• Destornillador phillips y destornillador para tornillos de cabeza

plana .....

Para conversion del gas (LP/propano o natural):

• Llave de boca abierta de 1/2

Materiales adicionales necesarios

• V_lvula de cierre de la linea de gas _

• Sellador de juntas de tuberias que resista la accion del gas

Propano liquido

• Un conducto flexible met_lico nuevo para electrodom_sticos

(1/2" NPT x 3/4" o 1/2" de di_metro interior) certificado por CSA

International. Debido a que la tuberia solida restringe el

movimiento de la estufa, recomendamos quese use un conducto

flexible nuevo (4 a 5 pies de largo) para cada nueva instalacion

y reinstalaciones adicionales.

A.

Ubique el soporte usando la plantilla - (el soporte puede

encontrarse en el lado derecho o izquierdo de la estufa. Utilice

el diagrama siguiente para ubicar el soporte si la plantilla no est_

disponible.) Marque en el piso o en la pared donde quedar_

ubicado el borde derecho o izquierdo de la estufa. Si la parte

trasera de la estufa est_ contra la pared o no est_ a m_s de 1-1/

4" de la pared, usted puede usar el m_todo de montaje en el piso

o en la pared. Si tiene moldura instalada que no permite que el

soporte quede a ras contra la pared, retire la moldura o instale

el soporte en el piso. Para instalacion en la pared, ubique el

soporte colocando el borde trasero de la plantilla contra la pared

trasera y el borde lateral de la plantilla en la marca hecha que

muestra el lado de la estufa. Coloque el soporte arriba de la

plantilla y marque la ubicacion de los agujeros de los tornillos en

la pared. Si la parte trasera de la estufa ya instalada est_ a m_s

de 1 -1/4" de la pared, instale el soporte en el piso. Para montaje

en el piso, ubique el soporte colocando el borde trasero de la

plantilla donde quedar_ ubicada la parte trasera de la estufa.

Marque la ubicacion de los agujeros de los tornillos, mostrados

en la plantilla.

B,

Taladre agujeros pilotos e instale el soporte - Taladre un

agujero piloto de 1/8" donde se van a instalar los tornillos. Si el

soporte va a ser instalado en la pared, taladre el agujero piloto

a un _ngulo descendente de aproximadamente 20 °. Si el soporte

va a ser instalado en pisos de alba_ileria o cer_mica, taladre un

agujero piloto de 5/32" de 1-3/4" de profundidad. Los tornillos

provistos pueden ser usados en pisos de madera o concreto. Use

una Ilave para tuercas de 5/16"0 un destornillador de hoja plana

para asegurar el soporte en su lugar.

ASEGURE EL SOPORTE (MONTAJEENLAPARED0ENELP|SO)

_1 I_- 1-1/4" M_x

Siempre use los (2) adaptadores de union abocinados nuevos

(1/2" NPT x 3/4"o 1/2" de di_metro interior) suministrados con el

conducto flexible nuevo para electrodom_sticos, para la conexion

de la estufa.

Pasos de la Instalacion Normal

1. Instrucciones para la instalacion del soporte

antivuelco

Advertencia de Seguridad Importante

A fin de reducir el riesgo de que la estufa se vuelque, _sta debe ser

asegurada al piso mediante la instalacion adecuada de un soporte

antivuelco usando los tornillos incluidos con la estufa. Si no se instala

el soporte antivuelco la estufa puede volcarse si se coloca peso

excesivo en una puerta abierta o si un ni_o se sube a ella. Se puede

producir una lesion grave a causa del derrame de liquidos calientes

o de la estufa misma si se vuelca.

Si la estufa es cambiada a otro lugar, los soportes antivuelco pueden

tambi_n ser cambiados e instalados con la estufa.

Las instrucciones son para instalacion en madera o cemento y anclaje

al piso o a la pared. Cuando se instala en la pared, asegOrese de que

los tornillos penetren completamente ei muro seco y que est_n

asegurados en madera o metal. Cuandoseasegura al piso o a la

pared, asegOrese de que los tornillos no toquen ningOn alambrado

el_ctrico o tuberias.

19

- Montaje en la pared

_laca mura

Montaje en el piso

ASEGURE EL SOPORTE (MO_TAJEE_ ELPJSOSOLAMENTE)

Para Niveladora -- _'- 1=1/4"

i i

Montaje en el piso _oporte Antivuelco

Soporte Antivuelco

i _k-_--Pared

Page 20

C.

Nivele y posicione la estufa - Nivele la estufa ajustando las

cuatro (4) patas niveladoras con una Ilave. Nota: Sedebe dejar

un espacio libre de por Io menos 1/8" entre la parte inferior de la

estufa y la pata niveladora a fin de que quede espacio para el

soporte. Use un nivel de burbuja para verificar los ajustes.