Page 1

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

-- Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

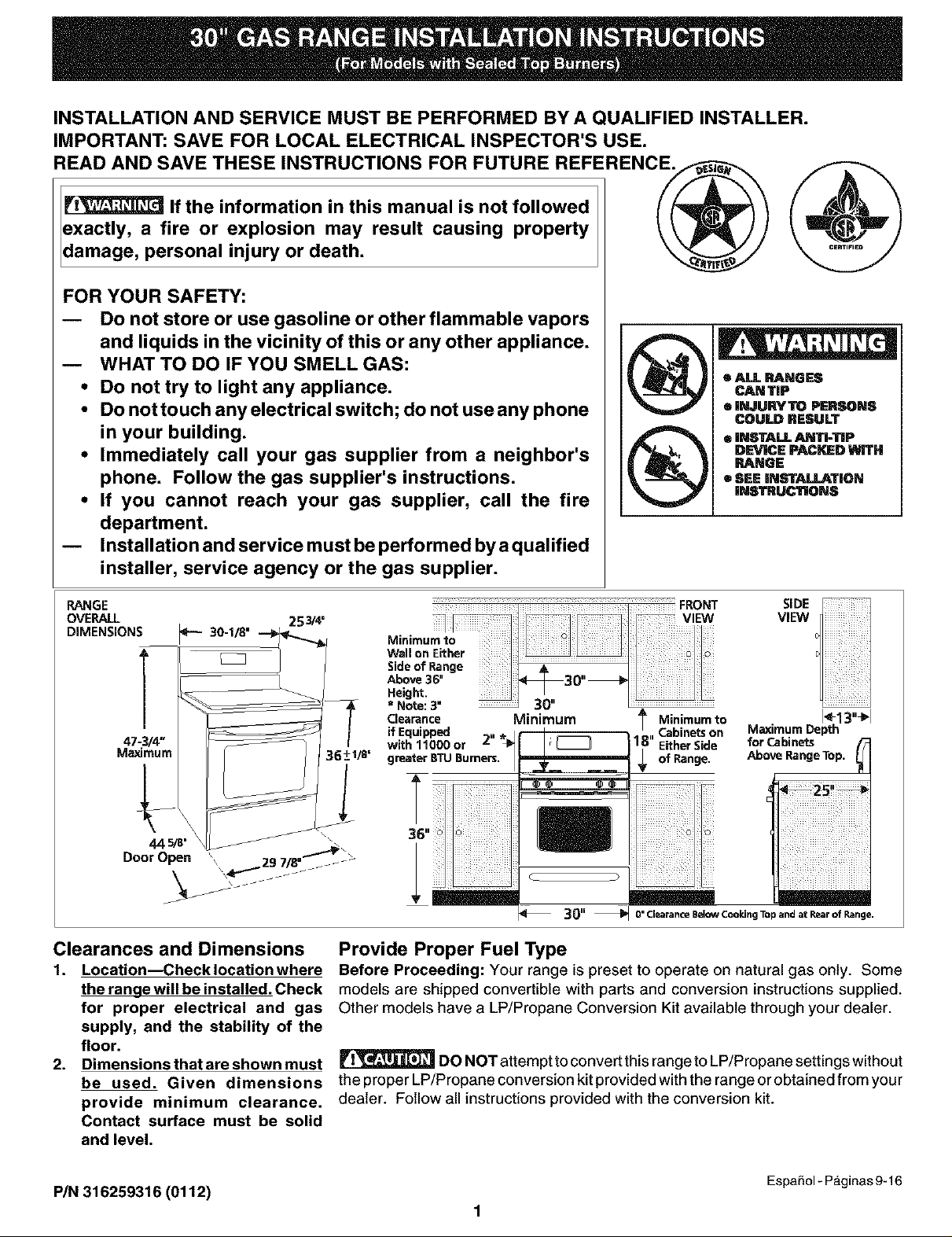

RANGE

OVERALL

DIMENSIONS _--

253/4 •

I_i3"_1

Maximum Depth

Above RangeTop,

forCabinets

Door Open __.29 7/8jj j_

Clearances and Dimensions

1. Location_heck location where

3o"_

Provide Proper Fuel Type

Before Proceeding: Your range is preset to operate on natural gas only. Some

0" ClearanceBelowCooking Topand at Rearof Range.

the range will be installed. Check models are shipped convertible with parts and conversion instructions supplied.

for proper electrical and gas Other models have a LP/Propane Conversion Kit available through your dealer.

supply, and the stability of the

floor.

2.

Dimensions that are shown must

be used. Given dimensions

provide minimum clearance.

the proper LP/Propane conversion kit provided with the range or obtained from you r

dealer. Follow all instructions provided with the conversion kit.

DO NOT attempt to convert this range to LP/Propane settings without

Contact surface must be solid

and level.

ii_i_i!i_i_i_!iiiiiiiiiiii_i_ilI ........

m

m

P/N 316259316 (0112)

Espahol - Paginas 9-16

1

Page 2

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven compartments

before connecting the gas and electrical supply to the

range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

1. Keep these instructions with your owner's guide for

future reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes or, in

the absence of local codes, with the National Fuel Gas Code

ANSI Z223.1--1atest edition when installed in the United

States.

This range has been design certified by CSA International.

As with any appliance using gas and generating heat, there

are certain safety precautions you should follow. You will find

them in the Use & Care Manual, read it carefully.

• Be sure your range is installed and grounded properly

by a qualified installer or service technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No .70_

latest edition when installed in the United States.

See Grounding Instructions on page 5.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering, make

sure the floor covering can withstand heat at least

90°F above room temperature without shrinking,

warping or discoloring. Do not install the range over

carpeting unless you place an insulating pad or sheet of

1/4-inch thick plywood between the range and carpeting.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the lower

front panel of the range. Avoid touching the vent

openings or nearby surfaces as they may become hot

while the oven is in operation. This range requires fresh

air for proper burner combustion.

Never leave children alone or unattended

in the area where an appliance is in use. As children grow,

teach them the proper, safe use of all appliances. Never

leave the oven door open when the range isunattended.

Stepping, leaning or sitting on the doors

or drawers of this range can result inserious injuries and

can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as astorage space. This creates

a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

• Reset all controls to the "off" position after using a

programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils before

self-cleaning the oven. Wipe up excess spillage. Follow

the precteaning instructions in the Owner's Guide.

• Unlike the standard gas range, THIS COOKTOP IS

NOT REMOVABLE. Do not attempt to remove the

cooktop.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING AN

ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes if the oven thermostat control

was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit with

a match. Hold a lighted match to the burner, then slowly turn

the knob to the LITE position. Use extreme caution when

lighting burners this way.

2

Page 3

Before Starting

Tools You Will Need

For leveling legs and Anti=Tip Bracket:

• Adjustable wrench or channel lock pliers

• 5/16" Nutdriver or Flat Head Screw Driver

• Electric Drill & 1/8" Diameter Drill Bit (5/32" Masonry Drill

Bit if installing in concrete)

For gas supply connection:

• Pipe wrench

For burner flame adjustment:

• Phillips head _ and

blade-type screwdrivers

For gas conversion (LP/Propane or Natural):

• Open end wrench - 1/2"

Additional Materials You Will Need

• Gas line shut-off valve

• Pipe joint sealant that resists action of LP/Propane gas

A new flexible metal appliance conduit (1/2" NPT x 3/4"

or 1/2" I.D.) must be design certified by CSA International.

Because solid pipe restricts moving the range we

recommend using a new flexible conduit (4 to 5 foot

length) for each new installation and additional

reinstallations.

A.

Locate the Bracket Using the Template- (Bracket may

be located on eitherthe left or right side ofthe range. Use

the information below to locate the bracket iftemplate is

not available). Mark the floor or wall where left or right

side of the rangewill be located. If rear ofrange isagainst

thewall orno further than 1-1/4" from wall when installed,

you may use the wall or floor mount method. If molding

is installed and does not allow the bracket to fit flush

against the wall, remove molding or mount bracket tothe

floor. For wall mount, locate the bracket by placing the

back edge of the template against the rear walt and the

side edge of template on the mark made referencing the

side of the range. Place bracket on top of template and

mark location of the screw holes in walt. If rear of range

is further than 1-1/4" from the wall when installed, attach

bracket to the floor. For floor mount, locate the bracket

by placing back edge of the template where the rear of

the range will be located. Mark the location of the screw

holes, shown in template.

S.

Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot

hole where screws are to be located. If bracket is to be

mounted to the wall, drill pilot hole at an approximate 20°

downward angle. Ifbracket isto be mounted to masonry

or ceramic floors, drill a5/32" pilot hole 1-3/4" deep. The

screws provided may be used in wood or concrete

material. Use a 5/16" nut-driver or flat head screwdriver

to secure the bracket in place.

• Always use the (2) new flare union adapters (1/2" NPT x

3/4" or 1/2" I.D.) supplied with the new flexible appliance

conduit for connection of the range.

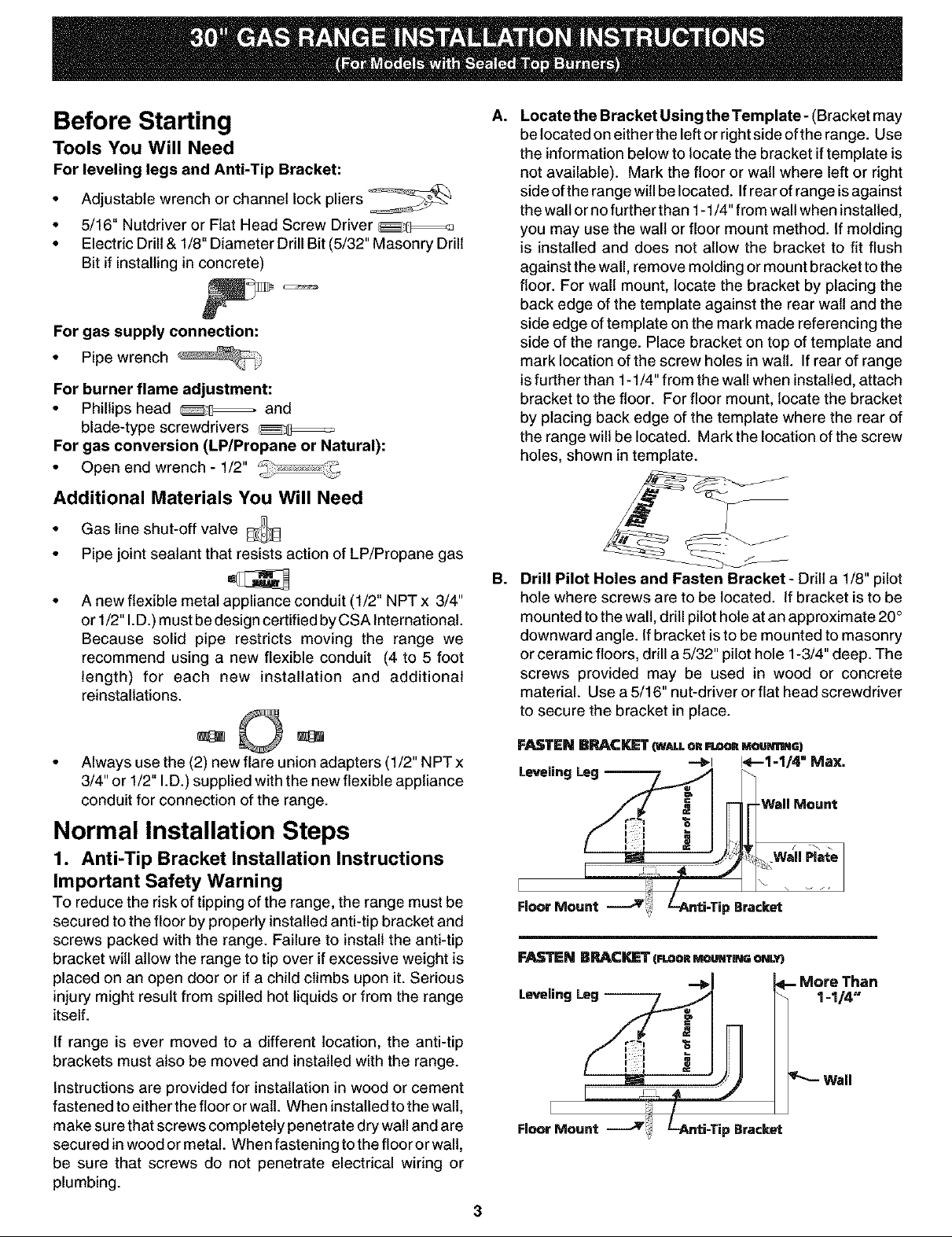

Normal Installation Steps

1. Anti-Tip Bracket Installation Instructions

Important Safety Warning

To reduce the risk of tipping of the range, the range must be

secured to the floor by properly installed anti-tip bracket and

screws packed with the range. Failure to install the anti-tip

bracket witl allow the range to tip over if excessive weight is

placed on an open door or if a child climbs upon it. Serious

injury might result from spilled hot liquids or from the range

itself.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the floor or wall. When installed to the wall,

make sure that screws completely penetrate dry wall and are

secured inwood or metal. When fastening to the floor or wall,

be sure that screws do not penetrate electrical wiring or

plumbing.

FAST£N BRACI_T (WALLORROORMourmNG)

---_l I.=--%1/4" Max.

LevelingLeg _ _

FloorMount ----------'_:i_i /--Anti-Tip Bracket

Floor Mount

3

p Bracket

Page 4

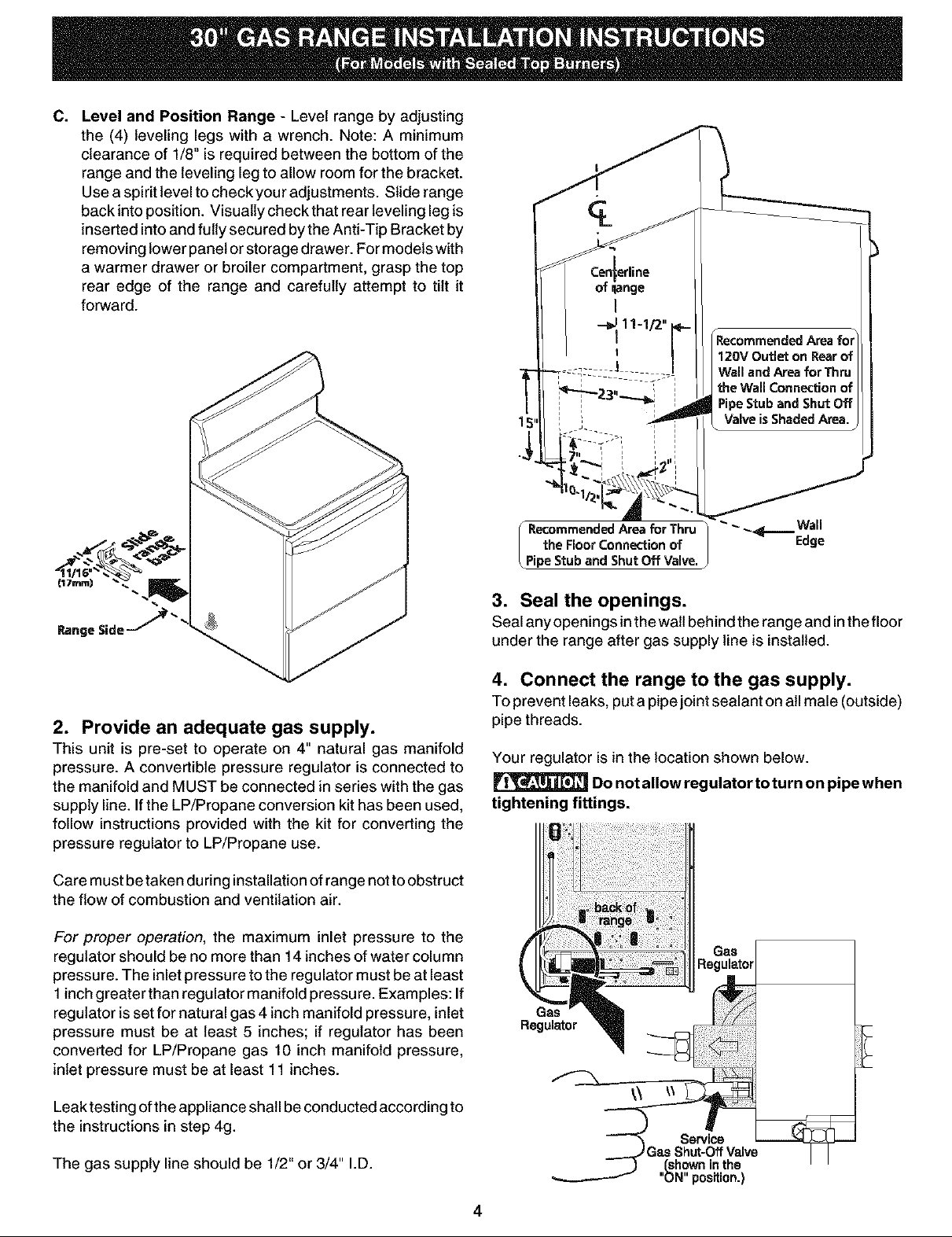

C.

Level and Position Range - Level range by adjusting

the (4) leveling legs with a wrench. Note: A minimum

clearance of 1/8" is required between the bottom of the

range and the leveling leg to allow room for the bracket.

Use a spirit level to check you radjustments. Slide range

back into position. Visually check that rear leveling leg is

inserted into and fully secured by the Anti-Tip Bracket by

removing lower panel or storage drawer. For models with

a warmer drawer or broiler compartment, grasp the top

rear edge of the range and carefully attempt to tilt it

forward.

I

(17ram)

%

%

Range Side

%

2. Provide an adequate gas supply.

This unit is pre-set to operate on 4" natural gas manifold

pressure. A convertible pressure regulator is connected to

the manifold and MUST be connected in series with the gas

supply line. Ifthe LP/Propane conversion kit has been used,

follow instructions provided with the kit for converting the

pressure regulator to LP/Propane use.

• -_ 11-1/2"

II

the FloorConnectionof

PipeStuband ShutOff Valve.

120V Outlet on Rearof

Wall and Area for Thru

the Wall Connectionof

PipeStuband Shut Off

ValveisShadedArea.

Area for

Wall

Edge

3. Seal the openings.

Seal any openings inthe walt behind the range and inthe floor

under the range after gas supply line is installed.

4. Connect the range to the gas supply.

To prevent leaks, put a pipe jointsealant on all male (outside)

pipe threads.

Your regulator is in the location shown below.

Do not allow regulator to turn on pipe when

tightening fittings.

Care must be taken du ring installation of range not to obstruct

the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water column

pressure. The inlet pressure to the regulator must be at least

1 inch greater than regulator manifold pressu re. Examples: If

regulator is set for natural gas 4 inch manifold pressure, inlet

pressure must be at least 5 inches; if regulator has been

converted for LP/Propane gas 10 inch manifold pressure,

inlet pressure must be at least 11 inches.

Leak testing ofthe appliance shall be conducted according to

the instructions in step 4g.

The gas supply line should be 1/2" or 3/4" I.D.

4

Page 5

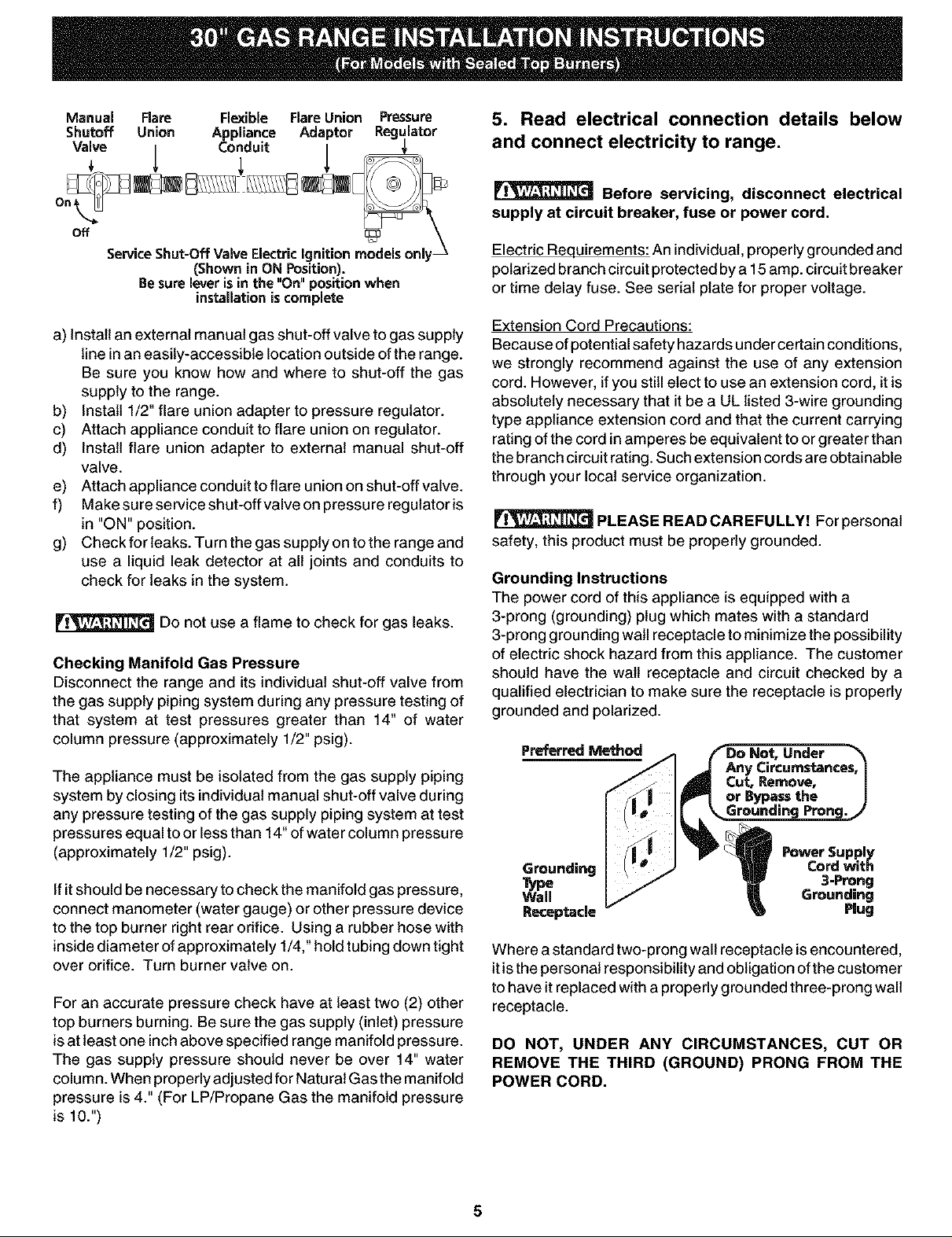

Manual Flare Flexible FlareUnion Pressure

Shutoff Union Appliance Adaptor Regulator

off

ServiceShut-OffValveElectricIgnitionmodelsonly_

(Shownin ON Position).

Besureleverisin the "On"positionwhen

installationiscomplete

a) install an external manual gas shut-off valve to gas supply

line in an easily-accessible location outside of the range.

Be sure you know how and where to shut-off the gas

supply to the range.

b) Instait 1/2" flare union adapter to pressure regulator.

c) Attach appliance conduit to flare union on regulator.

d) install flare union adapter to external manual shut-off

valve.

e) Attach appliance conduit to flare union on shut-off valve.

f) Make sure service shut-offvalve on pressure regulator is

in "ON" position.

g) Check for leaks. Turn the gas supply on to the range and

use a liquid leak detector at all joints and conduits to

check for leaks in the system.

Do not use a flame to check for gas leaks.

Checking Manifold Gas Pressure

Disconnect the range and its individual shut-off valve from

the gas supply piping system during any pressure testing of

that system at test pressures greater than 14" of water

column pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 14" of water column pressu re

(approximately 1/2" psig).

If it should be necessary to check the manifold gas pressure,

connect manometer (water gauge) or other pressure device

to the top burner right rear orifice. Using a rubber hose with

inside diameter of approximately 1/4," hold tubing down tight

over orifice. Turn burner valve on.

For an accurate pressure check have at least two (2) other

top burners burning. Be sure the gas supply (inlet) pressure

is at least one inch above specified range manifold pressure.

The gas supply pressure should never be over 14" water

column. When properly adjusted for Natural Gas the manifold

pressure is 4." (For LP/Propane Gas the manifold pressure

is 10.")

\

5. Read electrical connection details below

and connect electricity to range.

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric Requirements: An individual, properly grounded and

polarized branch circuit protected by a 15amp. circuit breaker

or time delay fuse. See serial plate for proper voltage.

Extension Cord Precautions:

Because ofpotential safety hazards under certain conditions,

we strongly recommend against the use of any extension

cord. However, if you still elect to use an extension cord, it is

absolutely necessary that it be a UL listed 3-wire grounding

type appliance extension cord and that the current carrying

rating of the cord in amperes be equivalent to or greater than

the branch circuit rating. Such extension cords are obtainable

through your local service organization.

PLEASE READ CAREFULLY! For personal

safety, this product must be properly grounded.

Grounding Instructions

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle to minimize the possibility

of electric shock hazard from this appliance. The customer

should have the walt receptacle and circuit checked by a

qualified electrician to make sure the receptacle is properly

grounded and polarized.

Preferred Method /,

fll II

TypeGrounding

Wall

Receptacle

Where a standard two-prong wall receptacle isencountered,

itisthe personal responsibility and obligation ofthe customer

to have itreplaced with a properly grounded three-prong wall

receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM THE

POWER CORD.

Do Not, Under

Any Circumstances, I

Cut, Remove, |

or Bypassthe J

_ Power Supply

Cord with

_' 3-Prong

Grounding

_lb Plug

5

Page 6

Operation of Surface Burners

6. Installation of Burner Cap Assembly

Your range is equipped with any combination of the sealed

burners. Refer to the chart to find your surface burner and

surface burner cap configu ration. Be sure to place the correct

PossibleSurfaceBurner andCap configurations:

t2k

_,. # &

7. Electric Ignition Surface Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

a. To check for proper lighting, push in and turn a surface

burner knob counterclockwise to the LITE position.

You will hear the igniter sparking.

b.

The surface burner should light when gas is available to

the top burner. Purge air from supply lines by leaving

knob in the LITE position until burner ignites. Each

burner should light within four (4) seconds in normal

operation after air has been purged from supply lines.

c. Visually check that burner has lit. Once the burner lights,

the control knob should be turned out of the LITE position.

d. There are separate electrodes (igniters) for each burner.

Try each knob separately until all burner valves have

been checked.

Note: Knob styles may vary from those pictured below.

burner cap at on alt four surface burners.

Install the parts shown below at all four surface burner

locations:

1st - Install the surface burner pans (if equipped); 2rid -install

the surface burner heads; 3rd - install the surface burner caps

and 4th; install the burner grates.

Suriece

Burner

Gr_

c. If burner goes out, reset control to OFF.

OFF ..LITE..hi 6 5 4 3 2 Io

Removable

Burner

Drip Pan

Orifice _n some models)

6

Page 7

8. Adjust the "LOW" Setting of Surface Burner After removing all packing materials and literature from the

Valve (Linear Flow Valves Only):

%

TO

Surface

Burner

Test to verify if "LOW" setting should be adjusted

a. Push in and turn control to LITE until burner ignites.

b. Push in and quickly turn knob to LOWEST POSITION.

d. Remove the surface burner control knob.

e. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased with the turn ofthe screw.

Turn counterclockwise to increase flame size. Turn

clockwise to decrease flame size.

BurnerFlameSize _1 5/8"i_

oven:

a) Set oven to BAKE at 300-°F.See Use & Care Manual for

operating instructions.

b) Within 60 seconds the oven burner should ignite. Check

for proper flame, and allow the burner to cycle once.

Reset controls to off.

c) If your model is equipped with a waist-high broiler, set

oven to BROIL. See Use & Care Manual for operating

instructions.

d) Within 60 seconds the broil burner should ignite. Check

for proper flame. Reset controls to off.

10. Air Shutter-Oven Burner

Waist-High Burner

(SelfClean Models)

Shutter :

i

j Main

Top

Adjust flame until you can quickly turn knob from LITE to

LOWEST POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

Operation of Oven Burners and

Oven Adjustments

9. Electric Ignition Burners

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

The oven burner is equipped with an electric control system

as welt as an electric oven burner igniter. If your model is

equipped with a waist-high broil burner, it will also have an

electric burner igniter. These control systems require no

adjustment. When the oven isset to operate, current wilt flow

to the igniter. It will "glow" similar to a light bulb. When the

igniter has reached a temperature sufficient to ignite gas, the

electrically controlled oven valve will open and flame will

appear at the oven burner. There is a time lapse from 30 to

60 seconds after the thermostat is turned ON before the

flame appears at the oven burner. When the oven reaches

the dial setting, the glowing igniter will go off. The burner

flame will go "out" in 20 to 30 seconds after the igniter goes

"OFF." To maintain any given oven temperature, this cycle

will continue as long as the dial (or display) is set to operate.

LowerOven Bottorr

(Removable)

J

The approximate flame length of the oven burner is 1 inch

(distinct inner, blue flame).

To determine if the oven burner flame is proper, remove the

oven bottom and burner baffle and set the oven to bake at

300°F.

To remove the oven bottom, remove oven hold down screws

at rear ofoven bottom. Pull upat rear, disengage front ofoven

bottom from oven front frame, and pull the oven bottom out

of the oven. Remove burner baffle so that the burner flame

can be observed.

If the flame is yellow in color, increase air shutter opening

size. (See "2" in illustration below.) If the flame is a distinct

blue, reduce the air shutter opening size.

To adjust loosen lock screw (see "3" illustration below),

reposition air shutter, and tighten lock screw. Replace oven

bottom.

7

Page 8

11.Air Shutter-Broil Burner

The approximate flame length of the broil burner is 1 inch

(distinct inner, blue flame).

To determine if the broil burner flame is proper, set the oven

to broil.

Before You Call for Service

Read the "Before You Call" and operating instruction sections

in your Use & Care Manual. It may save you time and

expense. The list includes common occurrences that are not

the result of defective workmanship or materials in this

appliance.

If the flame is yellow in color, increase air shutter opening

size. (See "2" in illustration above.) If the flame is a distinct

blue, reduce the air shutter opening size.

To adjust, loosen lock screw (see "3" in illustration above),

reposition air shutter, and tighten lock screw.

12.Make Sure Range is Level.

Level the range by placing a level horizontally on an oven

rack. Check diagonally from front to back, then level the

range by either adjusting the leveling legs or by placing shims

under the corners of the range as needed.

13.After installation is complete, make sure all

controls are left in the OFF position.

Model and Serial Number Location

For sealed burner ovens, the serial plate is located on the

right-hand surface of the oven front frame at the storage or

warmer drawer; or the lower panel area.

When ordering parts for ormaking inquires about you r range,

always be sure to include the model and serial numbers and

a lot number or letter from the serial plate on your range.

Refer to the warranty in your Use & Care Manual for our toll-

free service number and address. Please call or write if you

have inquiries about your range product and/or need to order

parts.

Your serial plate also tells you the rating of the burners, the

type offuel and the pressu rethe range was adjusted for when

it left the factory.

Care, Cleaning and Maintenance

Refer to the Use & Care Manual for cleaning instructions.

If removing the range is necessary for cleaning or

maintenance, shut off gas supply. Disconnect the gas and

electrical supply. Ifthe gas or electrical supply is inaccessible,

lift the unit slightly at the front and pull out away from the wall.

Pull only as far as necessary to disconnect the gas and

electrical supply. Finish removing the unit for servicing and

cleaning. Reinstall in reverse order making sureto level the

range and check gas connections for leaks. See page 3,

step 1for proper anchoring instructions.

Serial plate IocaUon

Open storage

or remove lower panel

(on some models)

8

Page 9

LA INSTALACION Y CUALQUIER TIPO DE SERVICIO DEBERAN REALIZARLO UN

INSTLADOR CUALIFICADO.

IMPORTANTE: GUARDE ESTAS INSTRUCClONES PARA USO DEL INSPECTOR LOCAL Y

PARA REFERENCIAS FUTURAS.

Si no se sigue con exactitud la informaci6n que se

proporciona en el presente manual, podrfa producirse fuego o

una explosi6n y causar graves dahos a la propiedad, personales

incluso la muerte.

PARA SU SEGURIDAD:

-- No almacene, ni utilice gasolina o cualquier otro tipo de Ifquidos

o gases inflamables cerca de esta o de cualq uier otra aplicacibn

de este tipo.

--QUE DEBE HACER SI HUELE A GAS:

• No intente encender ninguna de las aplicaciones.

• No toque ning_n interruptor el_ctrico, ni utilice los tel_fonos

que pueda haber en el edificio.

• Avise inmediatamentea laempresa desuministrode gasdesde untel_ono

en el exterior del edificio. Siga las instrucciones que le proporcione la

empresadesuministro degas.

• Si no pudiera ponerse encontacto con laempresa desuministro de gas,

avise de inmediato alcuerpo de bomberos desu Iocalidad.

-- La instalacibn y cualquier tipo de servicio deberd realizarlo un

instalador cualificado, una agencia de reparaciones certificada

o la empresa de suministro de gas.

=Todaslascocinas

pueden volcar

=Puedenproducirse

dafiospersonales

einstale el dispositivo

antivuelcoque se

suministraconla cocina

• Consultelasinstrucciones

de instalaci6n

DiMENSIONES

rOTALESDE

LACOCINA _ 30-1/8"

47-3/4"

M_ximo

Puerta abierta \\\ ,_._ 29 7/a __

Dimensiones y distancias

1. Ubicaci6n -- Compruebe el lugar

de instalaci6n de la cocina.

Compruebe que los suministros de

gasyelectricidad sonIosadecuados

y laestabilidad del suelo.

2. Lasdimensiones que semuestran

son las que deben utilizarse. Las

dimensiones quese proporcionan

dejardn el espacio minimo. La

superficie de contacto debe ser

s61ida y estar nivelada.

253/4"

de3" (7,61cms) M|nimo

sise equipa con

/8' quemadores de 2"

11000 BTUo

superi_e_sm

\\

Profundidad m_ixima ara

armarios por endma o_ la (_

parte superior de la cocina. L_

II

I_13"_'1

; lDi

NOdejar ningLin_peclo pot debajo do la parte superior

d_ la o_dna y1,1parte tr_m.

Tipo de combustible adecuado

Antes de conectarlo:

La cocina que acaba de adquirir funciona solamente con gas natural. Este

modelo es convertible y se suministra con las piezas necesarias y las

instrucciones para realizar la conversi6n.

NUNCA intente convertir esta cocina para hacerla funciona con

propano/PL sin poseer el juego de conversi6n adecuado para Ilevarlo a cabo

que se suministra o que podrd adquirir en las instalaciones de su proveedor

habitual. Siga las instrucciones que se proporcionan con este juego de

conversi6n.

9

Page 10

Instrucciones importantes para el instalador

1. Lea todas las instrucciones que se proporcionan en este

manual de instalaciSn antes de comenzara instalar la cocina.

2. Retire todo el material de embalaje de los compartimentos

del homo antes de conectar el suministro de energ[a el_ctdca

y de gas a la cocina.

3. Siga siempre todos los cSdigos y normafivas locales

referentes a instalaci6n de cocinas.

4. AsegQrese de que el comprador guarde estas instrucciones.

lnsfrucciones importantes para el comprador

1. Guarde estas instrucciones junto con la Guia de uso y

mantenimiento para referencias futuras.

INSTRUCCIONES DE SEGUIRDAD IMPORTANTES

La instalaci6n de esta cocina deber_ realizarse de acuerdo a la

normativa local o, en caso de que no existiera, de acuerdo a la

norma National Fuel Gas Code ANSi Z223.1_ltima edici6n, si

la instalaciSn se realiza en Estados Unidos.

Si la cocina se instala en una casa mSvi] (caravana), la instalaciSn

deberA realizarse de acuerdo a los estAndar de seguridad

Manufactured Home Construction and Safety Standard

(Est_,ndar de seguridad y construcciSn de casa prefabdcadas),

Tffulo 24 CFR, SecciSn 3280 [anteriormente denominada Federal

Standard for Mobile Home Construction and Safety (Est_,ndar

federal para seguridad y construcciSn de casas prefabdcadas),

Tffulo 24, HUD (Secci6n 280)] o, en caso de que dicho estAndar

no sea aplicable, deberA seguirse la norma marcada por el

Standard for Manufactured Home installations, ANSi/NCSBCS

A225.1, o bien, toda la normativa legal existente referente a

casas m6viles.

El diseSo de esta cocina posee la certificaciSn de CSA

International. Del mismo modo que sucede con otras aplicaciones

que utilizan gas y generan calor, existen ciertas recomendaciones

de seguridad que deber_,n seguirse siempre. Lea con detenimienfo

la Guia de uso y mantenimiento.

Asegdrese de que un instalador cualificado o un tdcnico

del servicio de reparaciones certifica que su cocina se ha

instalado y posee una toma de tierra adecuada.

Esta cocina deberd poseer una toma de tierra adecuada de

acuerdo a la normativa local o bien, si no existiera, de

acuerdo a Io establecido en el c6digo National Electrical

Code ANSI/NFPA N-°70-- dltima edici6n si se instala en los

Estados Unidos. Consulte las instrucciones de instalaci6n

de la toma de tierra que se proporcionan en la pdgina 5.

Antes de instalar la cocina en una zona con recubrimiento

de lin61eo o con cualquier otro tipo de suelo sint_tico,

deberd asegurarse de que el recubrimiento del suelo

podrd soportar temperaturas que superen 32-°C la

temperatura ambiente sin que se deterioren, se

resquebrajen o pierdan color. No instale la cocina sobre

suelos enmoquetados a no ser que se coloque un

recubrimiento de protecci6n o una Idmina de aislamiento

de 1/4" contrachapada para aislar la cocina de la moqueta.

Asegdrese de que las cubiertas que se coloquen alrededor

de la cocina puedan soportar el calor que genere la cocina.

No obstruya el flujo de aire de combusti6n del orificio de

ventilaci6n, ni alrededor de la base o entre el panel frontal

inferior dela cocina. No toque las aperturas de ventilaci6n,

ni las superficies adyacentes ya que es posible que se

calienten en exceso cuando el horno est_ en

funcionamiento. Esta cocina requiere airefresco para que

la combusti6n del quemador sea la adecuada.

No deje nunca niSos solos o desatendidos en

la zona en la que se utilice la aplicaci6n. Conforme vayan

creciendo los niSos, deberd explicarles el modo correcto de

utilizar este tipo de aplicaciones. No deje nunca abierta la

puerta del homo si la cocina se va a quedar desatendida.

No se suba, se apoye o se siente en las puertas

o en los cajones de esta cocina ya que podr(an producirse

graves daSos personales yen la propia cocina.

No atmacene articulos que puedan Ilamar la atenci6n de

niSosen Iosarmarios que hayaencima dela cocina.Cuatquier

niSo podr(a sufrir quemaduras de gravedad al subirse en la

cocina para alcanzar dichos objetos.

Para evitar tener que alcanzar cualquier objeto que se

encuentre por encima de los quemadores de la cocina, evite

la instalaci6n de armarios encima de la misma.

• Ajuste el tamaSo de la llama del quemador de tal modo que

no rebase los limites delos cazos o utensilios que se utilicen

para cocinar. Una llama excesiva puede ser peligrosa.

No utiliceel horno comolugar dealmacenamiento. Si Iohace

pueden producirse situaciones de peligro reales.

No utilice nunca la cocina para calentar la habitaci6n. Un uso

prolongado de la cocina en espacios sin la ventilaci6n

adecuada es peligroso.

No atmacene gasolina ni cualquier otro tipo de combustible

o gas inflamable cerca de lacocina o de cualquier otrotipo de

aplicaci6n. Puede producirse fuego o una explosi6n.

- Coloque todos los controles de la cocina en la posici6n de

"apagado" despu_s de haber utilizado la funci6n de

temporizaci6n programable.

PARA MODELOS AUTOLIMPIABLES:

Retire la parrilla, alimentos o cualquier otro utensilio antes

de activar esta funci6n. Retire con un paso si hay un

exceso de derrames. Siga las instrucciones de Umpieza

que se proporcionan en la Guia de uso y mantenimiento.

A diferencia que las cocinas de gas estdndar, ESTA PLACA

NO SE PUEDE RETIRAR. No intente levantar la placa.

NO INTENTE ENCENDER EL HORNO DE

IGNICI6N ELECTRICA DURANTE UN APAG6N DE LUZ.

COLOQUE TODOS LOS CONTROLES EN LA POSICI_N DE

"APAGADO" CUANDO SE PRODUZCAN SITUAClONES DE

ESTETIPO.

El encendedor el_ctrico, volvera a encenderse

automAticamente al volver a conectarse el suministro de

energia el_ctrica fras un apag6n si se han dejado los controles

en ]a posiciSn de "ENCENDIDO".

Si se produce un apagSn el6ctrico cuando est_ utilizando la

aplicaci6n, los quemadores de superficie continuar#,n en

funcionamiento y podr#, encendeflos con una cerilla.

Coloque una cerilla encendida al ]ado del quemador y, a

continuaci6n, gire lentamente el mando hasta colocarlo en

a posici6n LITE de encendido. Extreme ]as precauciones la

encender el quemador de este modo.

10

Page 11

Antes de comenzar

Herramientas que va a necesitar

Para patas de nivelaci6n y montura anti-vuelco:

Llave ajustable o alicates_ "4

Llave para apretar tuercas de 5/16" o un destomillador de

cabeza plana

Taladro el_ctrico y una broca de 1/8" (broca de taladro de

hormig6n de 5/32" si se instala sobre hormigSn)

Para la conexi6n al suministro de gas:

Llave grifa _

Para el ajuste de la llama de los quemadores:

Destornilladores de estrella _ y

de cabeza plana

Para la conversi6n a gas (PI,JPropano o gas natural):

Llave de boca de 1/2"

Material adicional que va a necesitar

VAlvula de desconexi6n de la linea de gas

Sellador para uniones de tuberias que resista la acci6n del

gas propano/PL

Un conducto de metal flexible (1/2" NPT x 3/4" o de 1/2" de

D.L) con diseSo certificado por CSA International. Ya que

]as tuberias rigidas restringen el movimiento de la cocina, se

recomienda el uso de tuberfas flexibles nuevas (de entre

1,20 a 1,50 mts) durante la instalaci6n y cada vez que se vaya

a instalar de nuevo o se cambie de lugar postedormente.

A=

Ubicaci6n de la montura con la ayuda de la plantilla- (la

montura puede ubicarse a la izquierda o a la derecha de la

cocina. A continuaci6n se proporciona la informaci6n

necesaria para ubicar la montura si no dispone de la plantilla).

Haga una marca en el suelo o en la pared a la izquierda o la

derecha. Si la parte posterior de la cocina va a quedar

apoyada contar la pared ova a quedar a menos de 1-1/4" de

]a misma. Siga los pasos que se describen en el m6todo de

montaje en pared o suelo. Si se coloca una moldura que

impide que la montura se adapte completamente a la pared,

deber_, retira la moldura o bien, instalar ]a montura en el

suelo. En caso de que se monte en la pared, ubique la

montura colocando el borde trasero de ]a plantina contra la

pared posterior y el borde lateral sobre la marca de referencia

realizada en el lateral de la cocina. Coloque la montura sobre

]a plantilla y marque la ubicaci6n de los agujeros de los

tomillos en la pared. Si la parte posterior de la cocina se

encuentra a m#,s de 1-1/4" de la pared cuando la instale,

deber#, fijar la montura al suelo. Para montaje sobre suelo,

coloque el borde trasero de la plantina en el lugar en el que se

vaya a instalar la cocina. Marque la ubicaci6n de los agujeros

de los tominos que se muestra en la plantilla.

B.

Perforaci6n de agujeros piloto y montura de sujeci6n -

Perfore un agujero piloto de 1/8" en el lugar en el que se vayan

a instalar los tominos. Si la montura se va a instalar a en la

pared, practique un agujero piloto con una inclinaci6n

aproximada de 20° hacia abajo. Si la montura se va a instalar

sobre hormig6n para suelos cerAmicos, practique un agujero

de 5/32" con una profundidad de 1-3/4". Los tomillos que se

suministran pueden utilizarse en homlig6n o madera. Para

fijar la montura en su sitio, utilice un destomillador de cabeza

plana o una nave para apretar tuercas de 5/16".

Utilice siempre los dos (2) adaptadores de campana (1/

2" NPT x 3/4" o de 1/2" D.I.) que se suministran con el

conducto flexible nuevo para la conexi6n de la cocina.

Pasos para la instalacibn

1. Advertencia de seguridad importante sobre las

instrucciones de instalacibn de la montura anti-vuelco

Para reducir el riesgo de que se vuelque la cocina, 6sta deber_

asegurarse al suelo mediante la montura especial anti-vuelco

que deberA sujetarse al mismo del modo adecuado con los

tomillos que se suministran. Si no se instala del modo adecuado

esta montura, la cocina estA expuesta a volcarse si se coloca

un peso excesivo sobre una puerta abierta o en el caso de que

un niSo se agarre a la misma e intente subirse a ella. Estas

situaciones pueden provocar graves daSos personales por el

derramamiento de liquidos muy calientes o bien, por el peso de

]a cocina en si.

Si en algQn momento se cambia de lugar la cocina, deberAn

cambiarse de lugar tambi_n e instalarse de nuevo las monturas

anti-vuelco.

Estas instrucciones explican el modo de instalar la cocina

sobre madera o cemento y el modo de sujetarla a la pared o

al suelo. Si se instala sujeta a la pared, deber_, asegurarse de

que los tornillos se introducen completamente en ]a pared

seca y se aseguran en madera o metal. Cuando sujete la

cocina al suelo o a la pared, debera asegurarse de que los

tomillos no perforan ningQn cable el6ctrico o tuberfas.

Plata

de pared

MONTURA DE SUJECI6N (sOLoMONTHSENSUmLO)

Montaje _ - Montura

en suelo =ntivuelco

11

Page 12

C.

Nivelaci6n y colocaci6n de la cocina -Para nivelar la

cocina, deber_ ajustar ]as cuatro (4) pates de nivelaciSn

con una Ilave. Nora: Es necesario mantener un espacio

minimo de 1/8" entre el fondo de la cocina y la pata de

nivelaciSn pare dejar espacio suficiente para instalar la

montura de sujeciSn. Compruebe los ajustes realizados

con un nivel de burbuja de aire. Deslice la cocina hacia

atr&s hasta colocada en su posiciSn. Retire el panel

posterior o el caj6n de almacenamiento para comprobar

que la pata de nivelaciSn posterior se introduce y queda

completamente fijada en la montura anti-vuelco. En

modelos que posean un cajSn pare calentar o un grill,

deberA sujetar el borde trasero superior de la cocina e

intentar, con cuidado, inclinado hacia adelante.

La zone recomendada

pare la salidade 120V

an ie parts posterior

de la Raredy ia zone

pare la €onexi6n a

frav_s de Dared del

tope de t'uberiay

v_ivu=ade desconexibn

as ia zone sernbreada

• J

2. Conexibn a un suministro de gas adecuado.

Esta unidad se ha dise_ado para funcionar con un colector de

gas natural de 4". El colector esta conectado a un regulador

de presiSn convertible y DEBE conectarse en serie con la linea

de suministro de gas. Si se ha utilizado el juego de conversiSn

para PL/Propano, siga las instrucciones que se proporcionan

con el juego de conversiSn. Este juego podrA encontrarlo en

]a parte posterior de la cocina. Extreme ]as precauciones

durante la instalaciSn de la cocina par no obstruir el flujo del

aire de combustiSn y ventilaci6n.

Para que el funcionamiento sea adecuado, la presiSn de

entrada maxima al regulador no debe ser superior a 14" de

presiSn de columna de agua. La presi6n de entrada al regulador

deber_ ser al menos 1" m#,s que la presi6n del colector del

regulador. Ejemplo: Si el regulador se configura para una

presiSn de colector de 4" de gas natural, la presiSn de entrada

deber_ ser al menos de 5". Si el regulador se ha convertido para

uso con una presiSn de colector de 10" de gas Propano/PL,

]a presiSn de entrada deberA ser al menos de 11".

Zone ret_mendeda pareconexi6n _"

a tray,s del suelodel tope de /

tuberia y v_lvula de desconexibnj

_,_ Bordede

"_ ia pared

3. Sellado de las aperturas.

Selle las aperturas de la pared por detr_s de la cocina yen el

suelo bajo la cocina despu6s de haber instalado ]a linea de

suministro de gas.

4. Conecte la cocina al suministro de gas.

Pare evitar fugas, aplique sellador de tuberias en todas las

partes roscadas machos (exterior) de la tuberia. El regulador

se encuentra en el lugar que se muestra en la ilustraci6n.

NO permita que el regulador gire sobre la

tuberia al apretar las uniones.

Reguladot

Regulador

Realice una comprobaci6n del sistema para buscar fugas tal

y come se describe en el paso 4g de las instrucciones.

La linea de suministro de gas debe ser de 1/2" o 3/4" de D.I.

12

de

desconexi6ndegasde J J

servicio(semuestraen

laposicibndeconexi6n"ON')

Page 13

V_lvula de Uni6n de Conducto Adaptador Regulador

desconexi6n €_mpana flexible de uni6n de presi6n

maiua' / / de campana

S61omodelos de ignici6n el_trica con v_tlvulade desconexi6n de _

servido (se muestra en la posici6n de €onexi6n "ON'). Aseg,',rese

de que la palanca est_ en la 13osici6nde coflexi6n "ON" al f[nalizar

la instalaci6n.

a) Instale una v&lvula manual externa para cierre de gas

hacia la linea de suministro de gas que tenga una

ubicaci6n de f&cil acceso fuera de la cocina. Asegt3rese

de conocer d6nde y c6mo se cierra el suministro de gas

hacia la cocina.

b) Instaleunadaptadorparauni6ndecampanadel/2"hacia

el regulador de presi6n.

c) Conecte et conducto de la aplicaci6n a la uni6n de

campana en el regulador.

d) Instale el adaptador de la uni6n de campana hacia la

vAIvula manual externa de cierre.

e) Conecte et conducto de la aplicaci6n a la uni6n de

campana en la vAIvula de cierre.

f) Asegdrese que la vdlvula de cierre de servicio sobre el

regulador de presi6n se encuentra en la posici6n de

encendido"ON".

g) Verifique si existen fugas. Encienda el suministro de gas

hacia la cocina y use el detector de derrames de liquidos

en todas las uniones y conductos para comprobar la

existencia de fugas en el sistema.

No use fuego para comprobar laexisteneia

de fugas de gas.

Revisi6n de la presidn de gas en el colector

Desconecte la cocina y su vAIvula de cierre individual del

sistema de tuberia det suministro de gas durante cualquier

prueba de presi6n de ese sistema para presiones de prueba

superiores a 14" de presi6n de columna de agua

(aproximadamente 1/2" psig).

La aplicaci6n debe aistarse del sistema de la tuberia de

suministro de gas cerrando su v&lvula de cierre manual

individual durante cualquier prueba de presi6n del sistema de

tuberia de suministro de gas para presiones de prueba

iguales o mayores a 14" de presi6n de columna de agua

(aproximadamente 1/2" psig).

Si fuera necesario revisar la presi6n de gas en el colector,

conecte el man6metro (medidor de agua) u otro dispositivo

de presi6n al orificio posterior derecho del quemador superior.

Usando una manguera de caucho con un diAmetro interior de

aproximadamente 1/4", sostenga fuerte la tuberia hacia abajo

sobre el orificio. Encienda la vAlvula del quemador.

Para una revisi6n exacta de la presi6n, tenga por Io menos

otros dos (2) quemadores superiores. Asegt_rese que la

presi6n del suministro de gas (entrada) se encuentra per lo

menos una pulgada per encima de la presi6n especificada en

el colector de la cocina. La presi6n del suministro de gas

nunca debe encontrarse per encima de 14" de la columna de

agua. Cuando se encuentra debidamente ajustado para Gas

Natural, la presi6n en el colector es 4" (para PL/Gas Propane,

la presi6n en el colector es 10").

5. Lea los detalles sobre conexibn el_ctrica en

la parte inferior y conecte la electricidad segdn

la cocina.

Antes de realizar cualquier tarea de

mantenimiento, desconecte el suministro el_ctrico en el

interruptor,fusible ocable delsuministto deenergia el_'trica.

Reauisitos del sistema el_ctrico: Un circuito de derivaci6n

individual polarizado, con toma de tierra, protegido per un

interrupter de 15 A o un fusible de retardo de tiempo.

Consulte la placa de dates t_cnicos en la que se indica la

tensi6n adecuada.

Precauciones a tener en cuenta sobre alarqadores de cables:

Debido a los peligros potenciales de seguridad bajo algunas

condiciones, le recomendamos no hacer use de ningt3ncable

de extensi6n. Sin embargo, si a pesar de esto elige usar un

cable de extensi6n, es absolutamente necesario que sea un

cable de extensi6n tipo cableado a tierra de tres cables con

aprobaci6n UL y que el promedio de carga de corriente del

cable en amperios sea equivalente o mayor al promedio del

circuito de derivaci6n. Estos cables de extensi6n pueden

obtenerse a trav_s de su organizaci6n de servicio local.

LEA CON DETENIMIENTO. Parasu seguridad

personal, este producto debe ser debidamente conectado

a una toma de tierra.

Instrucciones para la toma de tierra

El cable del suministro el_ctrico de esta aplicaci6n est;&

equipado con un enchufe de 3 patillas (para toma de tierra)

que coincida con un enchufe de pared estAndar con toma

de tierra de 3 patitlas para minimizar la posibilidad de que

se produzcan descargas el_ctricas. El cliente deberA

encargar a un t_cnico etectricista la revisi6n del enchufe de

la pared y del circuito para asegurarse de que el enchufe

se encuentra debidamente conectado a tierra y polarizado.

En lugares en los que haya un enchufe de pared estAndar

de dos patillas, el cliente tendr& responsabilidad directa y

la obligaci6n de reemplazarlo per un enchufe de pared de

tres patillas debidamente cableado a tierra.

M_todo preferido

Enchufe de surninistro

pared con el6ctrico con

toma de enchufe con

tierta t_ma de tierra

BAJO NINGUNA ClRCUNSTANCIA, CORTE, RETIRE O

DERIVE LA TERCERA PATILLA (DE TOMA DE TIERRA)

DEL CABLE DEL SUMINISTRO DE ENERGIA ELECTRICA.

Cable de

13

Page 14

Accionamiento -quemadores de superficie

6. Instal. de las tapas del quemador de superficie

Su cocina esta equipada con cualquier combinaci6n de los

quemadores sellados. Refi6rase al gr_,ficoen la parte de abajo

para encontrar su quemador de superficie y ]a configuraci6n de

]a tapa del quemador de supefficie.

/a..........

.... • 5 _ _ i!i i!ii _,_ii

9.512k;;; ::;;

Posiblesconfiguracionesdetapa y quemadordesuperfice

AsegQrese de colocar la tapa correcta del quemador en los

cuatro quemadores de superficie. Instale las piezas que se

indican a continuacidn en las cuatro ubicaciones para quemador

de superficie.:

1°. Instale las bandejas del quemador de superficie (si se

dispone de la smismas);

2-o-instale los cabezales det quemador de superficie;

3-°- instale las tapas del quemador de superficie e

4-°- instal_ las parritlas del quemador.

7. Quemadoresdesuperficiedeignicibnel_ctrica

La operaci6n de los encendedores et6ctricos debe ser

revisada despues de que la cocina y los conectores de la

lfnea de suministro hayan sido cuidadosamente conectados

a la corrienteel6ctrica. Las v&lvulasde gas det quemador de

superficie cuenta con posiciones de ret_n en las posiciones

de Off (Apagado) y LITE (ENCENDIDO). La peritla debe ser

empujada hacia dentro para girarla pasando estas posiciones

de ret_n.

a. Para revisar si existe un adecuado encendido, empuje

hacia adentro y gire una peritla del quemador de superficie

hacia la izquierda a la posici6n de LITE. EscucharA que el

encendedor emite unas chispas (vea el grafico de abajo).

b. Et quemador de superficie debe encender cuando el gas

est& disponibte para el quemador superior. Purgue el aire

de las lineas de suministro dejando la peritla en la

posici6n de LITE hasta que se encienda el quemador.

Cada quemador debe encenderse en cuatro (4)segundos

en operaci6n normal luego que el aire ha side purgado de

las lineas de suministro.

c. Compruebe visualmente que el quemador ha encendido.

Una vez que el quemador se enciende, la peritla de

control debe ser empujada hacia adentro y girada fuera

de la posici6n de LITE (ENCENDIDO).

d. Existen electrodes separados (encendedores) para

carla quemador. Pruebe cada perilta per separado hasta

que todas lasvAlvulas de quemador hayan side revisadas.

Nota: Las formas y colores de las periltas pueden ser

diferentes a las que se muestran en la figura.

_del

P_rdlladel

quemador

,or

14

Page 15

8. Ajuste la configuracibn "LOW" ("BAJA") de la

vdlvula del quemador de superficie (sblo en vdlvulas

de flujo lineal):

Pruebe para comprobar si ]a configuraciSn "LOW" ("BAJA")

debe ser ajustada

a. Presione hacia adentro y gire el control hacia LITE hasta que el

quemador se encienda.

b. Presione hacia adentro y gire r_pidamente la penlla hacia la

POStCION M,_S BAJA.

c. Si el quemador se apag& Ileve el control hacia la posiciSn de OFF

(APAGADO).

d. Retire la penUade control del quemador de superficie.

e. Inserte un destomUlador de hoja delgada en la v_,lvula hueca y

enganche el tomillo ranurado dentro. El tamaSo de la llama

puede ser aumentado o disminuido girando el tomillo. Gire a la

izquierda para aumentar eltamaSo de la llama. Gire a la derecha

para disminuir el tamaSo de la llama.

alcanza la configuraci6n del dial, el encendedor

resplandeciente se apagarA. La llama del quemador

desaparecer& por 20 a 30 segundos despu6s que el

encendedor se APAGUE. Para mantener cualquier

temperatura de homo dada, este cielo continuarA tanto como

el dial (o visualizador) est6 configurado para operar.

Despu6s de retirar todos los materiales del empaque y la

literatura del homo:

a) Fije el homo en HORNEAR (BAKE) a 300-°F.Vea la Guia

para Uso y Cuidado para conocer las instrucdones de

funcionamiento.

b) En 60 segundos, el quemador del homo se encender&

Revise que exista un fuego adecuado, y permita que el

quemador cumpla su dclo unavez. Ueve los controladores

hacia off (APAGADO).

c) Si su modelo est& equipado con un asador central

superior, fije el homo en ASAR. Vea la Guia de Uso y

Cuidado para conocer las instrucciones de

funcionamiento.

d) En 60 segundos el quemador de asar debe encenderse.

Revise si existe una llama adecuada. Ueve los controles

hacia off (APAGADO).

10. Obturador de Aire - Quemador del horno

Tama_odelquemadordelarco de encendido i 5/8" 14

Cubierta

/principal

Ajuste el fuego hasta que pueda girar la perilla de manera rApida

desde UTE hacia la POStCI_N M,_,S BAJA sin extinguir el fuego.

El fuego debe ser tan pequeSo como sea posible sin apagado.

Nora: El ajuste de la mezola de aire no es necesario en quemadores

de superficie.

Operacibn en Quemadores del

Horno y Ajustes de Horno

9. Quemadores de ignicibn el6ctrica

La operaci6n de los encendores el6ctricos debe ser revisada

luego que la coelna y los conectores de la linea de suministro

han side cuidadosamente revisados para descartar fugas y

que la coelna ha side conectada a la corriente el6ctrica. El

quemador del homo est&equipado con un sistema de control

el6ctrico asi como un encendedor de quemador de homo

el6ctrico. Si su modelo estA equipado con un quemador de

asado central superior, tambi6n contarA con un encendedor

de quemador el6ctrico. Estos sistemas de control no requieren

ajustes. Cuando el homo es configurado para operar, la

corriente fluirA hacia el encendedor y tendr& un resplandor de

manera similar a una bombitla de luz. Cuando el encendedor

ha alcanzado una

temperatura sufielente para encender el gas, la v&lvula del

homo controlada el6ctricamente se abrir& y elfuego aparecer&

en el quemador del horno. Hay un lapso de tiempo de 30 a60

segundos luego que el termostato se enciende antes que la

llama aparezca en el quemador del horno. Cuando el homo

auto limpiables)

(modelos

Obturador

Drdel

homo (extrai'ole)

_== Obturador de aire

la Iongitud aproximada de la llama dot quemador de homo es 1

pulgada (interiordaro, flama azul). Para determinar si la llama det

quemader de homo es la adecuada, retire et fonde del homo y

el deflector det quemador y fije et homo en la opci6n homear a

300°F.

Para retirar el rondo del homo, retire los tomillos de ajuste det

homo en la parte posterior del rondo det homo. Jale hada arriba,

desenganche etfrente del fondo det marco anterior del homo, y

jale la base del homo hada afuera de 6ste. Retireel deflector det

quemader de manera quelallama dethomo puedaser observada.

Si la llama es de color amarillo, aumente ettamaSo de la abertura

del obturader de aJre(Vea el tama5o "2" en et grafico de abajo).

Si la llama es de azul daro, reduzca ettamaSo de la abertura det

obturador de aire. Para ajustar un tomitlo de derre flojo (vea et

grAfico "3" de abajo), vuelva a colocar el obturador de aire, y

ajuste et tornillo de derre. Reemplace et fondo del homo.

15

Page 16

Antes de Ilamar al servicio t cnico

Lea las secciones "Antes de ltamar" e instrucci6n sobre

funcionamiento en su Gufa de Uso y Cuidado. Puede

ayudarle a ahorrar tiempo y dinero.

La lista incluye problemas comunes que no son resultado

de una manipulaci6n o materiales defectuosos en este

artefacto. Refi_rase a la garanfia en su Gufa de Uso y

Cuidado para obtener nuestro nt3mero telef6nico gratuito

de servicio t6cnico y nuestra direcci6n. Sffvase Ilamarnos

o escribirnos en case de dudas acerca del producto para

su cocina y/o cualquier requerimiento de partes.

11. Obturador de aire - Quemador de asado

La Iongitud aproximada de la llama del quemador de asado

es 1 pulgada (interior clare, flama azul). Para determinar si la

llama del quemador de asado es la adecuada, el horno en la

opci6n asar.

Si la llama es de color amarillo, aumente el tamafio de la

abertura del obturador de aire (Vea el tamafio "2" en el gn&fico

de abajo). Si la llama es de azul clare, reduzca el tamafio de

la abertura del obturador de aire. Para ajustar un tornillo de

cierre flojo (vea el grAfico "3" de abajo), vuelva a colocar el

obturador de aire, y ajuste el tornitlo de cierre.

12. Asegdrese que la cocina estd nivelada.

Nivele la cocina colocando un nivelador de manera horizontal

sobre un soporte para hornos. Revise diagonalmente desde

la parte anterior hacia atrAs, luego nivele la cocina ya sea

ajustando las patas de nivelaci6n o colocando cutlas debajo

de las esquinas de la cocina segt3n sea necesario.

13. Luego que la instalacibn ha sido terminada,

asegdrese que todos los controles son dejados

en la posicibn de OFF (APAGADO).

Ubicacibn del Ndmero de Modelo

Cuidado, Limpieza y Mantenimiento

Refi_rase a la Gufa de Uso y Cuidado para conocer las

instrucciones de limpieza.

Si es necesario retirar la cocina para la limpieza o

mantenimiento, cierre el suministro de gas. Desconecte et

suministro de gas y el suministro el_ctrico. Si no tiene

acceso al suministro de gas o et_ctrico, levante la unidad

levemente en el frente y sepArelo de la pared. Jale s61o1o

necesario para desconectar el suministro de gas y de

electricidad. Termine de retirar la unidad para realizar et

servicio t_cnico y la limpieza. Vuelva a instalar en el orden

inverse asegurAndose de nivetar la cocina y revise las

conexiones de gas para descartar la existencia de fugas.

Vea la pAgina 3, paso 1 para conocer las instrucciones

sobre un adecuado aseguramiento en et piso.

y de Serie

En los hornos de quemador sellado, la placa de identificaci6n

estA ubicada sobre la superficie derecha del marco anterior

det horno en et caj6n para almacenar o calentar; o el Area

det panel inferior.

AI solicitar las partes o realizar pedidos sobre su cocina,

siempre asegt_rese de incluir el nt_mero de modelo y de

serie y un nt_mero o letra de tote de la placa de datos

t_cnicos que se encuentra en su cocina. Su placa de datos

t_cnicos tambi_n le indica el promedio de sus quemadores,

el tipo de combustible y la presi6n en la cual la cocina fue

ajustada al salir de la fAbrica.

Ubicaci6n de la plata de datos

t_cnicos: Abra el caj6n para

a[macenar o calerttar que se eRcuerttra en

la parte derecha del bastidor de la cocina.

16

Loading...

Loading...