Page 1

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

INSTALLATION AND SERVICE MUST BE PERFORMED BY

A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

— Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

· ALL RANGES

CAN TIP.

· INJURY TO

PERSONS

COULD

RESULT.

· INSTALL

ANTI-TIP

DEVICE

PACKED WITH

RANGE.

· SEE

INSTALLATION

INSTRUCTIONS.

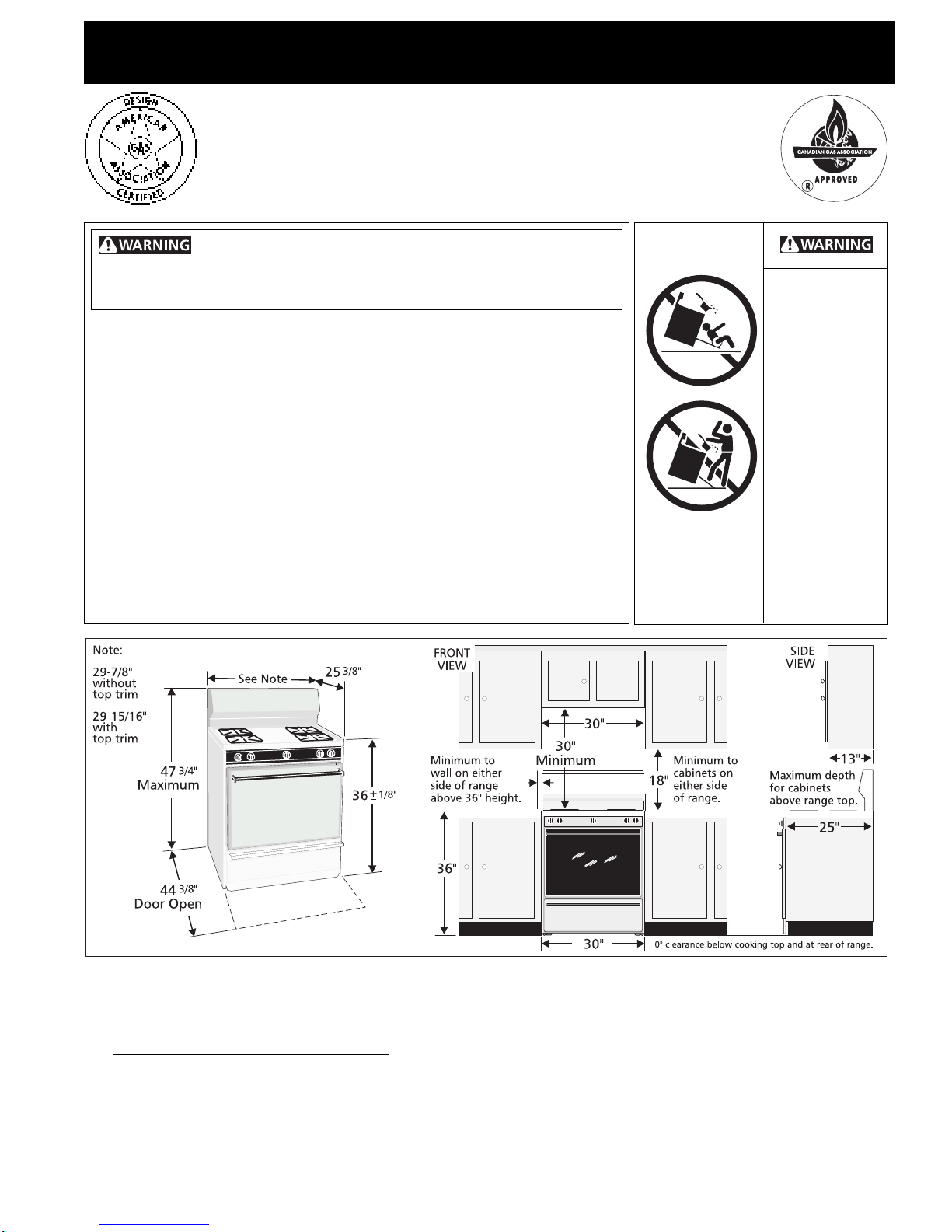

Clearances and Dimensions

1. Location—Check location where the range will be installed. Check for proper electrical and gas supply, and the stability

of the floor.

2. Dimensions that are shown must be used. Given dimensions provide minimum clearance. Contact surface must be solid

and level.

P/N 316002989 (9510)

3"

2"

English—Pages 1-8

Français—Pages 9-16

1

Español—Pages 17-24

Page 2

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

1. Keep these instructions with your owner's guide for

future reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1—latest edition when installed in

the United States. When installed in Canada, installation

must conform with CAN/CGA-B149.1 and CAN/CGAB149.2.

This range has been design certified by the American

Gas Association and the Canadian Gas Association. As

with any appliance using gas and generating heat, there

are certain safety precautions you should follow. You

will find them in the Owner's Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA

No .70—latest edition when installed in the

United States. When installed in Canada, this range

must be electrically grounded in accordance with CSA

Standard C22.1, Canadian Electrical Code, Part 1. See

Grounding Instructions on page 5.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/4-inch

thick plywood between the range and carpeting.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at

the oven vent nor around the base or beneath

the lower front panel of the range. Avoid touching

the vent openings or nearby surfaces as they may

become hot while the oven is in operation. This range

requires fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is in

use. As children grow, teach them the proper, safe use

of all appliances. Never leave the oven door open when

the range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be

seriously burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• Reset all controls to the "off" position after using

a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the

Owner's Guide.

• Unlike the standard gas range, THIS COOKTOP IS

NOT REMOVABLE. Do not attempt to remove the

cooktop.

2

Page 3

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING AN

ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the

oven burner when power resumes if the oven

thermostat control was left in the "ON" position.

When an electrical power failure occurs during use,

the surface burners will continue to operate.

During a power outage, the surface burners can be

lit with a match. Hold a lighted match to the burner,

then slowly turn the knob to the LITE position. Use

extreme caution when lighting burners this way.

Before Starting

Tools You Will Need

For leveling legs:

• Socket wrench (1-3/8" hex) or channel lock pliers

For gas supply connection:

• Pipe wrench

For burner flame adjustment:

• Phillips® head and blade-type screwdrivers

Additional Materials You Will Need

• Gas line shut-off valve

• Pipe joint sealant that resists action of LP/Propane

gas

• Flexible metal appliance conduit (1/2" NPT x 3/4" or

1/2" I.D.) must be AGA/CGA design certified.

Because solid pipe restricts moving the range we

recommend using this flexible conduit (4 to 5 foot

length).

• (2)Flare union adapters (1/2" NPT x 3/4" or 1/2"

I.D.) for connecting flexible appliance conduit.

To convert your range for LP/Propane use, please follow

conversion instructions supplied with the range or

LP/Propane conversion kit now.

DO NOT attempt to convert this range to

LP/Propane settings without the proper LP/Propane

conversion kit provided with the range or obtained from

your dealer.

1. Install Anti-Tip Bracket(s). (See page 8.)

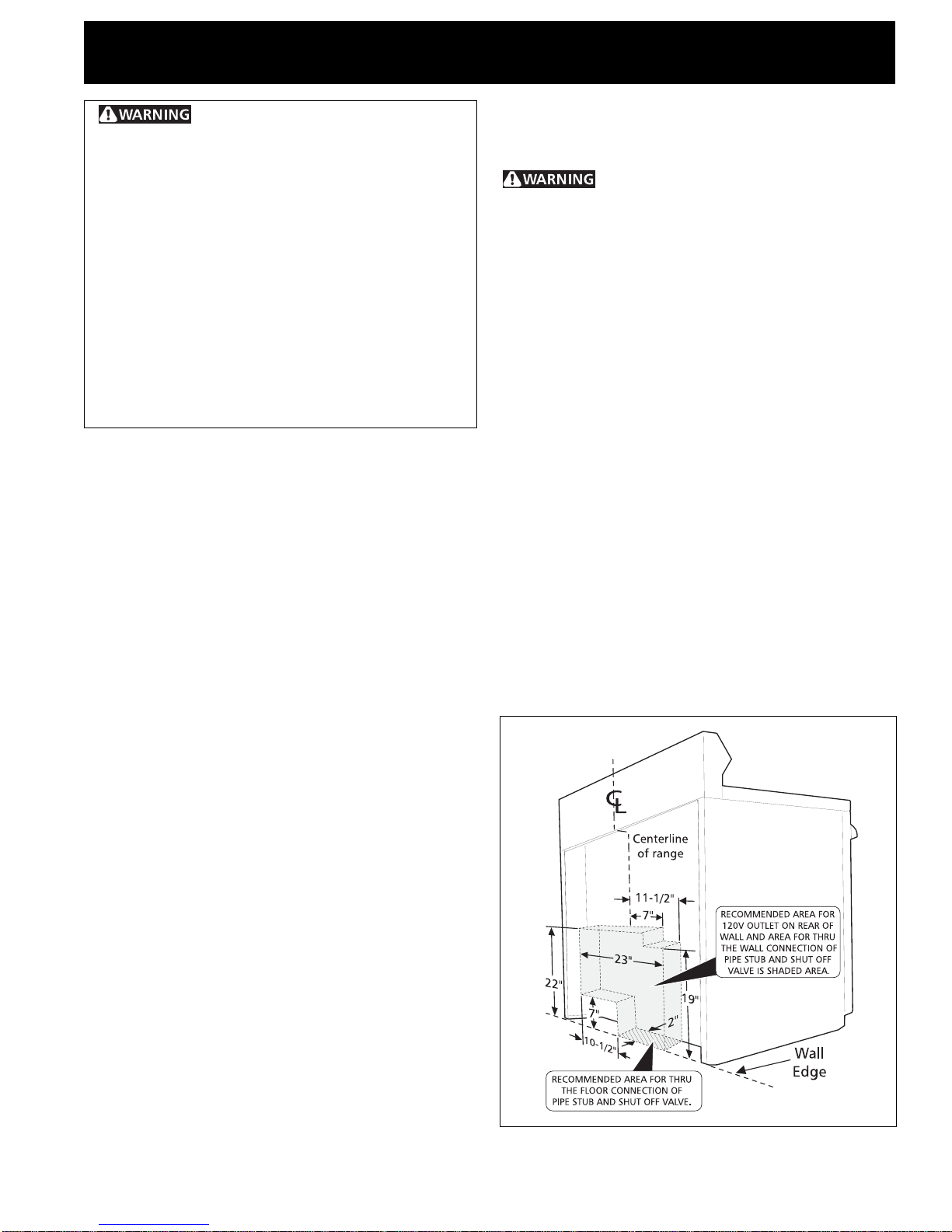

2. Provide an adequate gas supply. This unit is

pre-set to operate on 4" natural gas manifold pressure.

A convertible pressure regulator is connected to the

manifold and MUST be connected in series with the gas

supply line. If the LP/Propane conversion kit has been

used, follow instructions provided with the kit for

converting the pressure regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water

column pressure. The inlet pressure to the regulator must

be at least 1 inch greater than regulator manifold

pressure. Examples: If regulator is set for natural gas

4 inch manifold pressure, inlet pressure must be at least

5 inches; if regulator has been converted for LP/Propane

gas 10 inch manifold pressure, inlet pressure must be at

least 11 inches.

The gas supply line should be 1/2" or 3/4" I.D.

Normal Installation Steps

Before Proceeding

Your range has been preset at the factory to operate

on natural gas only. Some models are shipped

convertible with parts and conversion instructions

supplied. Other models have an LP/Propane

Conversion Kit, number 80-8802-10, available

through your dealer.

3

Page 4

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

3. Seal the openings. Seal any openings in the wall

behind the range and in the floor under the range

after gas supply line is installed.

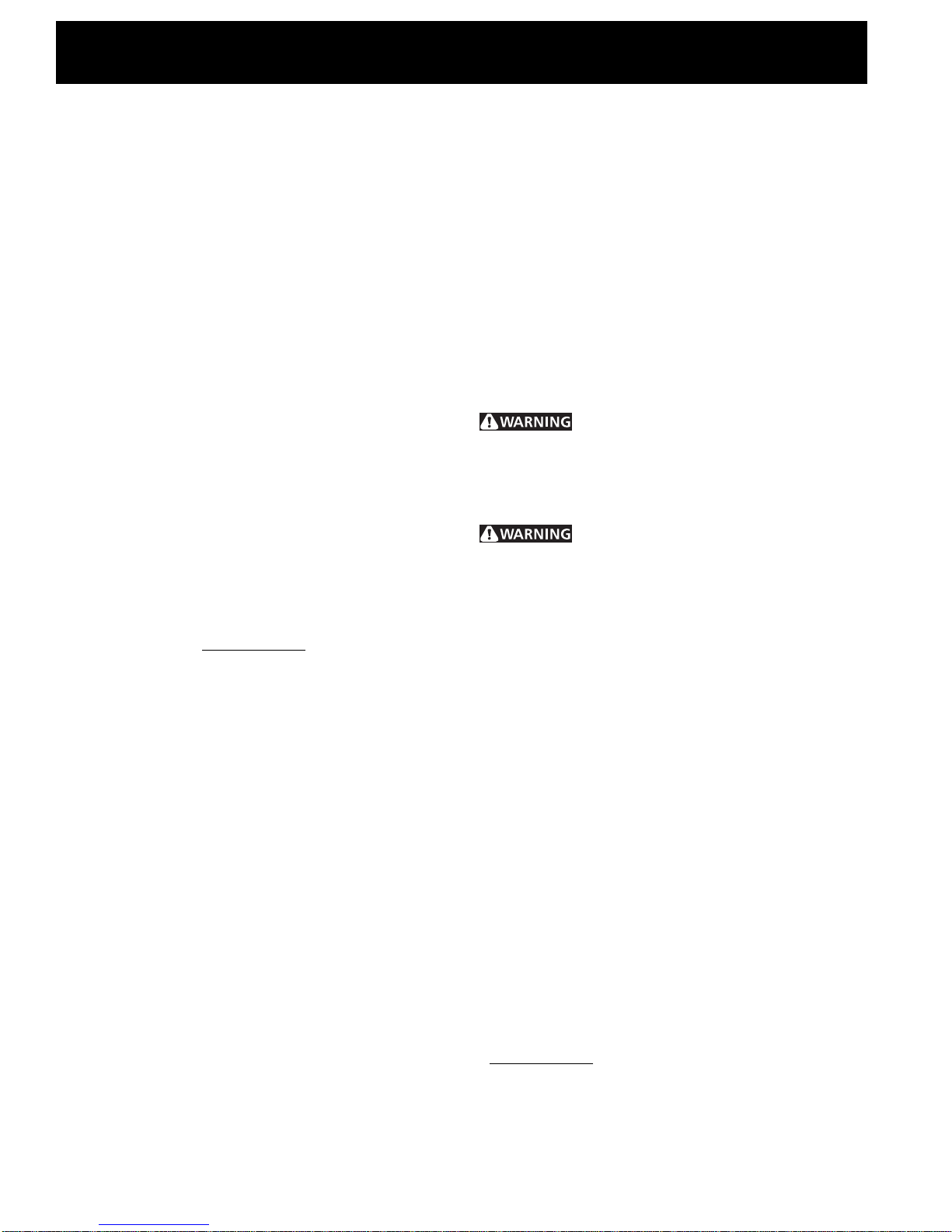

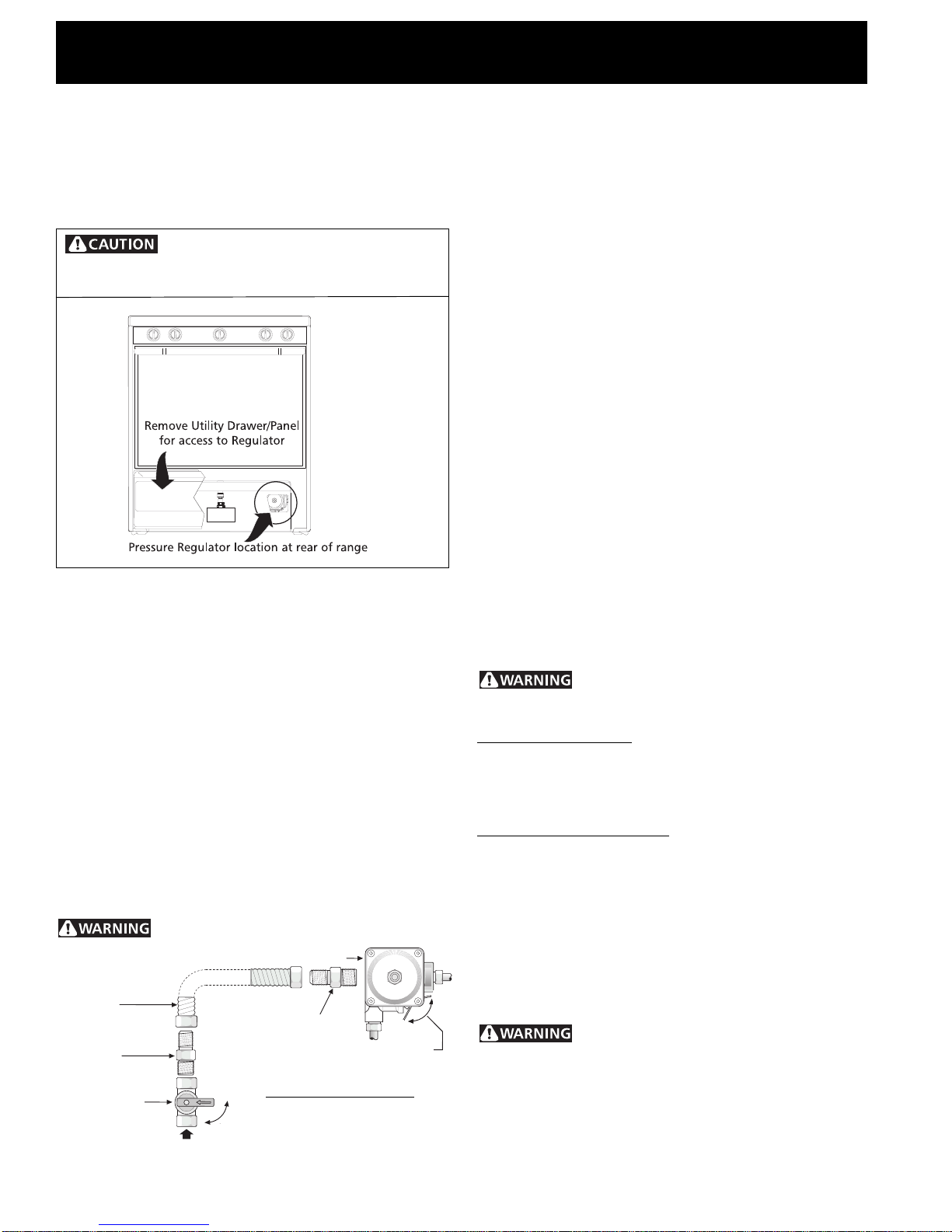

4. Connect the range to the gas supply. To

prevent leaks, put a pipe joint sealant on all male

(outside) pipe threads.

Do not allow regulator to turn on

pipe when tightening fittings. Your regulator is in

one of the two locations shown below.

a) Install an external manual gas shut-off valve to gas

supply line in an easily-accessible location outside of

the range. Be sure you know how and where to

shut-off the gas supply to the range.

b) Install 1/2" flare union adapter to pressure

regulator.

c) Attach appliance conduit to flare union on

regulator.

d) Install flare union adapter to external manual

shut-off valve.

e) Attach appliance conduit to flare union on shut-off

valve.

f) Make sure service shut-off valve on pressure

regulator is in "ON" position.

g) Check for leaks. Turn the gas supply on to the

range and use a liquid leak detector at all joints and

conduits to check for leaks in the system.

Do not use a flame to check for gas leaks.

Pressure Regulator

Flexible

Appliance

Conduit

Flare

Union

Adaptor

External Manual

Shutoff Valve

Gas Supply

On

Off

Flare Union

Adaptor

Service Shut-Off Valve

Electric Ignition models

only.

Be sure lever is in the

"On" position when

installation is complete.

Off

On

Checking Manifold Gas Pressure

Disconnect the range and its individual shut-off valve

from the gas supply piping system during any pressure

testing of that system at test pressures greater than 14"

of water column pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 14"

of water column pressure (approximately 1/2" psig).

If it should be necessary to check the manifold gas

pressure, connect manometer (water gauge) or other

pressure device to the top burner right rear orifice.

Using a rubber hose with inside diameter of

approximately 1/4," hold tubing down tight over orifice.

Turn burner valve on.

For an accurate pressure check have at least two (2)

other top burners burning. Be sure the gas supply (inlet)

pressure is at least one inch above specified range

manifold pressure. The gas supply pressure should never

be over 14" water column. When properly adjusted for

Natural Gas the manifold pressure is 4." (For LP/Propane

Gas the manifold pressure is 10.")

5. Read electrical connection details below

and connect electricity to range.

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric Requirements: An individual, properly grounded

and polarized branch circuit protected by a 15 amp.

circuit breaker or time delay fuse. See serial plate for

proper voltage.

Extension Cord Precautions: Because of potential safety

hazards under certain conditions, we strongly

recommend against the use of any extension cord.

However, if you still elect to use an extension cord, it is

absolutely necessary that it be a UL listed 3-wire

grounding type appliance extension cord and that the

current carrying rating of the cord in amperes be

equivalent to or greater than the branch circuit rating.

Such extension cords are obtainable through your local

service organization.

PLEASE READ CAREFULLY! For personal

safety, this product must be properly grounded.

4

Page 5

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

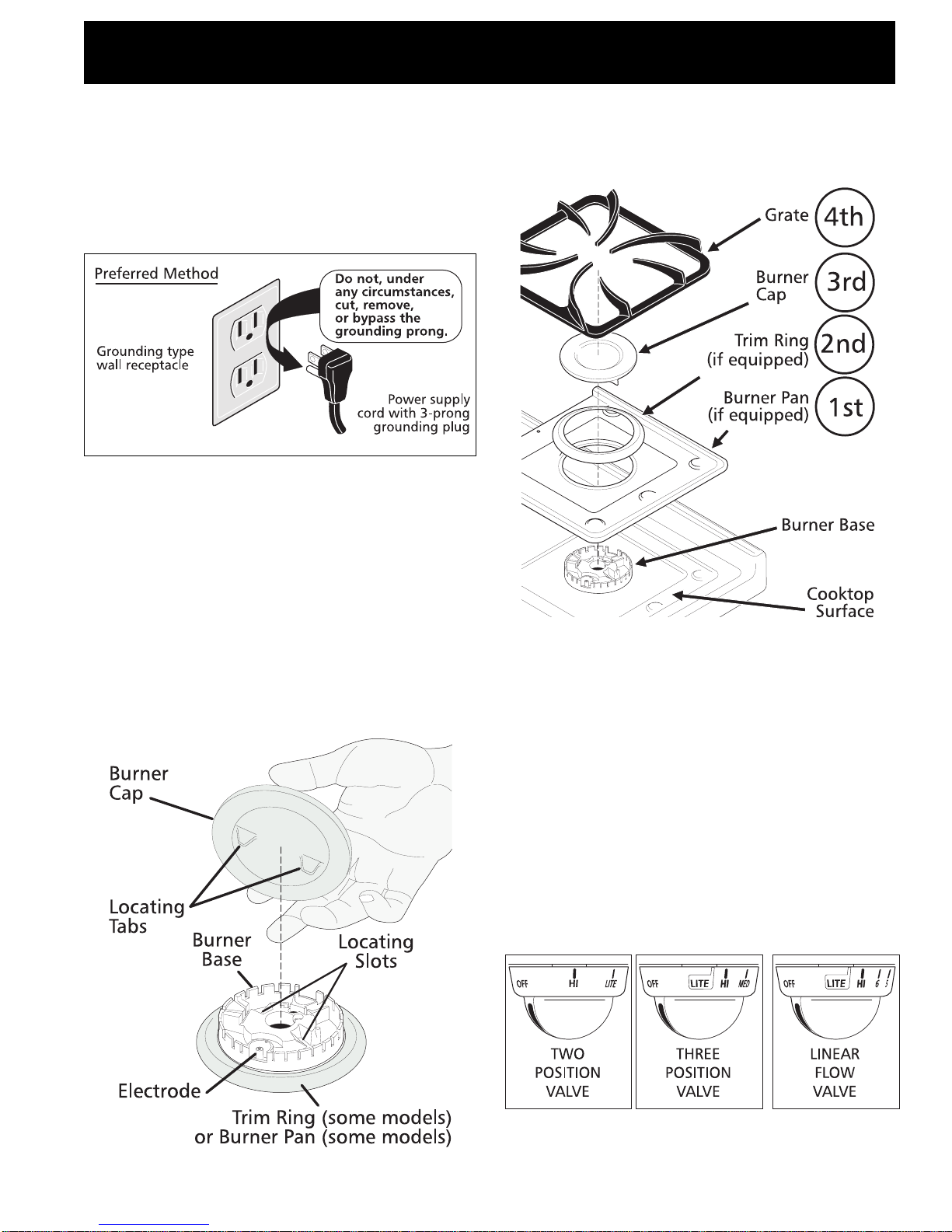

Grounding Instructions

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

The customer should have the wall receptacle and circuit

checked by a qualified electrician to make sure the

receptacle is properly grounded and polarized.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with a

properly grounded three-prong wall receptacle.

6. Installation of Burner Cap Assembly

Your range may be equipped with either trim rings or

burner pans, or trim rings and burner pans. Install pans

(some models) and trim rings (some models) as follows:

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM THE

POWER CORD.

Operation of Surface Burners

This range is equipped with one of the burner types

shown below.

Connecteur

souple de

l’appareil

7. Electric Ignition Surface Burners

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting, push in and

turn a surface burner knob to the LITE position. You will

hear the igniter sparking. The surface burner should light

when gas is available to the top burner. Each burner

should light within four (4) seconds in normal operation

after air has been purged from supply lines. Visually

check that burner has lit. Once the burner lights, the

control knob should be rotated out of the LITE position.

There are separate ignition devices for each burner. Try

each knob separately until all burner valves have been

checked.

Note: Knob styles may vary from those pictured above.

5

Page 6

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

8. Adjust the "LOW" Setting of Surface

Burner Valve (Three Position and Linear

Flow Valves only):

a) Turn control to LITE until burner ignites.

b) Quickly turn knob to LOWEST POSITION.

c) If burner goes out, readjust valve as follows:

Reset control to OFF. Remove the surface burner control

knob, insert a thin-bladed screw driver into the hollow

valve stem and engage the slotted screw inside. Flame

size can be increased or decreased with the turn of the

screw. Adjust flame until you can quickly turn knob from

LITE to LOWEST POSITION without extinguishing the

flame. Flame should be as small as possible without

going out.

After removing all packing materials and literature from

the oven:

a) Set oven to BAKE at 300ºF. See Owner's Guide for

operating instructions.

b) Within 60 seconds the oven burner should ignite.

Check for proper flame, and allow the burner to

cycle once. Reset controls to off.

c) If your model is equipped with a waist-high broiler,

set oven to BROIL. See Owner's Guide for operating

instructions.

d) Within 60 seconds the broil burner should ignite.

Check for proper flame. Reset controls to off.

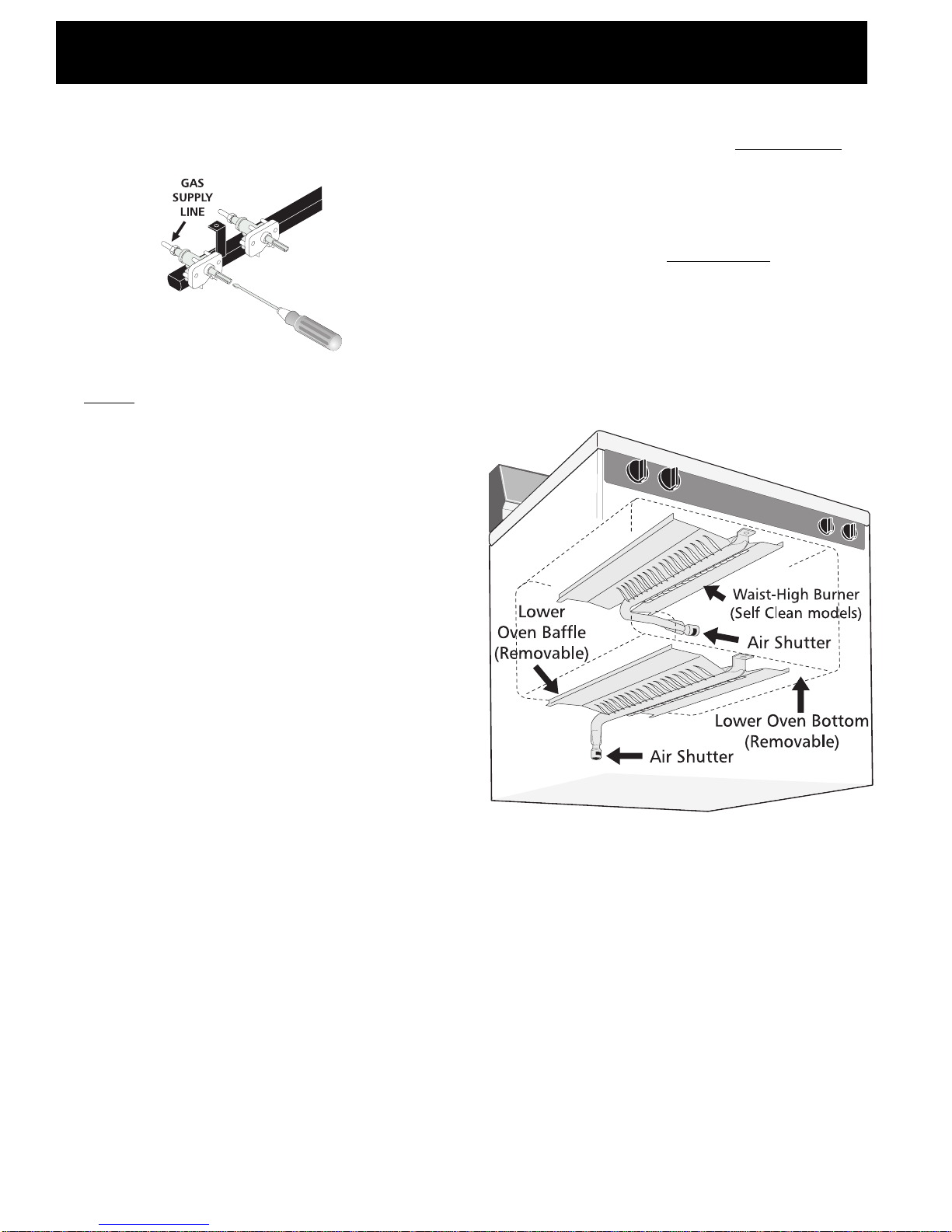

10. Air Shutter-Oven Burner

The approximate flame length of the oven burner is

1 inch (distinct inner, blue flame).

Note: Air mixture adjustment is not required on surface

burners.

Operation of Oven Burners and

Oven Adjustments

9. Electric Ignition Burners

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power.

The oven burner is equipped with an electric control

system as well as an electric oven burner igniter. If your

model is equipped with a waist-high broil burner, it will

also have an electric burner igniter. These control

systems require no adjustment. When the oven is set to

operate, current will flow to the igniter. It will "glow"

similar to a light bulb. When the igniter has reached a

temperature sufficient to ignite gas, the electrically

controlled oven valve will open and flame will appear at

the oven burner. There is a time lapse from 30 to 60

seconds after the thermostat is turned ON before the

flame appears at the oven burner. When the oven

reaches the dial setting, the glowing igniter will go off.

The burner flame will go "out" in 20 to 30 seconds after

the igniter goes "OFF." To maintain any given oven

temperature, this cycle will continue as long as the dial

(or display) is set to operate.

To determine if the oven burner flame is proper, remove

the oven bottom and burner baffle and set the oven to

bake at 300°F.

To remove the oven bottom, remove oven hold down

screws at rear of oven bottom. Pull up at rear, disengage

front of oven bottom from oven front frame, and pull the

oven bottom out of the oven. Remove burner baffle so

that the burner flame can be observe.

6

Page 7

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

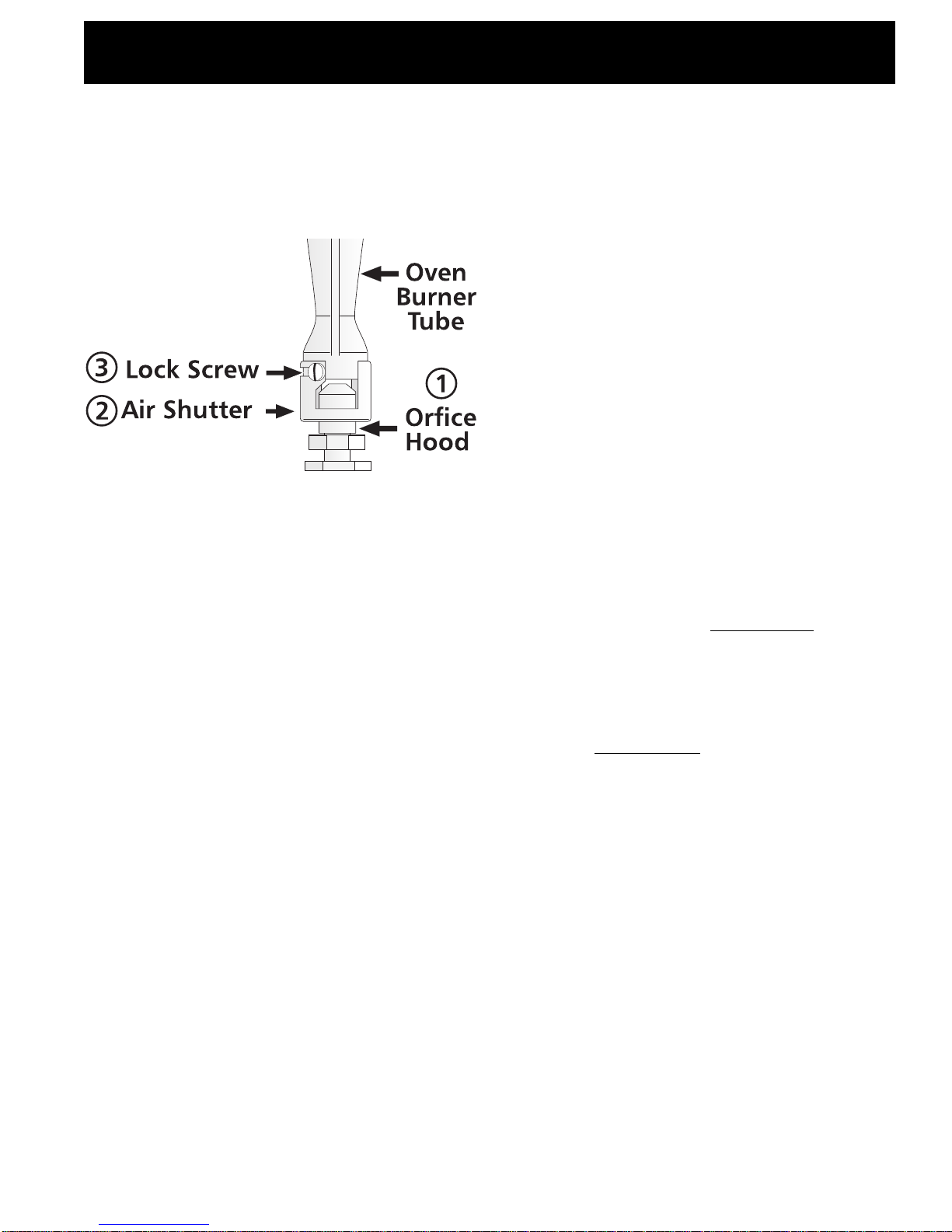

If the flame is yellow in color, increase air shutter

opening size. (See "2" in illustration below.) If the flame

is a distinct blue, reduce the air shutter opening size.

To adjust loosen lock screw (see "3" illustration below),

reposition air shutter, and tighten lock screw. Replace

oven bottom.

11. Air Shutter-Broil Burner (if equipped)

The approximate flame length of the broil burner is

1 inch (distinct inner, blue flame).

To determine if the broil burner flame is proper, set the

oven to broil.

If the flame is yellow in color, increase air shutter

opening size. (See "2" in illustration above.) If the flame

is a distinct blue, reduce the air shutter opening size.

Model and Serial Number

Location

For porcelain enamel ovens, the serial plate is located

on the right-hand surface of the oven front frame in the

broiler or storage drawer area.

For continuous clean ovens, the serial plate is located on

the right front edge of the floor shield located in the

broiler compartment.

When ordering parts for or making inquires about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the range was adjusted

for when it left the factory.

Before You Call for Service

Read the Avoid Service Checklist and operating

instructions in your Owner's Guide. It may save you

time and expense. The list includes common

occurrences that are not the result of defective

workmanship or materials in this appliance.

Refer to the warranty in your Owner's Guide for our

toll-free service number and address. Please call or write

if you have inquiries about your range product and/or

need to order parts.

To adjust, loosen lock screw (see "3" in illustration

above), reposition air shutter, and tighten lock screw.

12. Make Sure Range is Level.

Level the range by placing a level horizontally on an

oven rack. Check diagonally from front to back, then

level the range by either adjusting the leveling legs or by

placing shims under the corners of the range as needed.

13. After installation is complete, make

sure all controls are left in the OFF

position.

Care, Cleaning and Maintenance

Refer to the Owner's Guide for operating and cleaning

instructions.

If moving the range is necessary for cleaning or

maintenance, shut off gas supply. Disconnect the gas

and electrical supply. If the gas or electrical supply is

inaccessible, lift the unit slightly at the front and pull out

away from the wall. Pull only as far as necessary to

disconnect the gas and electrical supply. Finish removing

the unit for servicing and cleaning. Reinstall in reverse

order making sure to level the range and check gas

connections for leaks. See page 8, paragraph 5 for

proper anchoring instructions.

7

Page 8

30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with 4 Standard Sealed Top Burners)

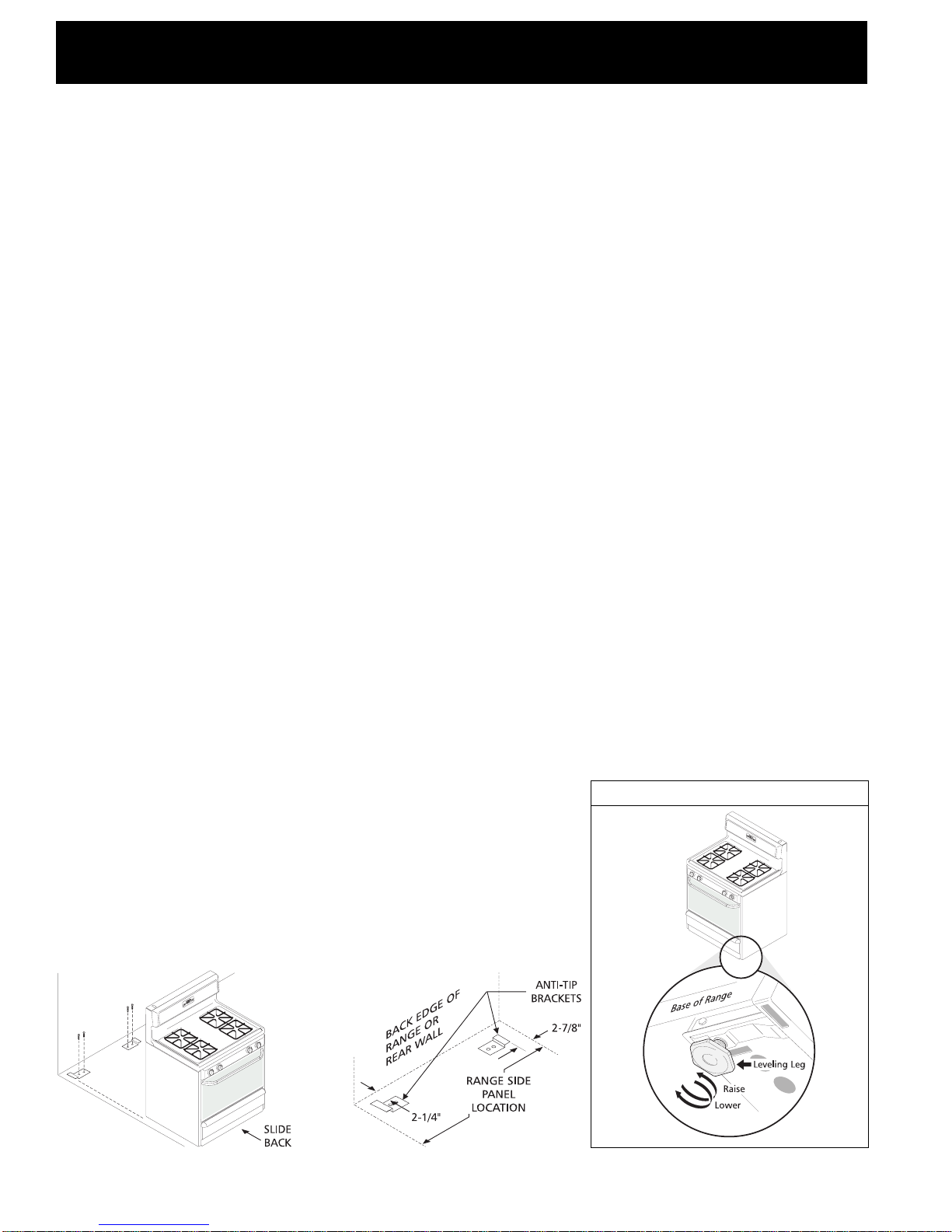

Anti-Tip Brackets Installation

Instructions

Important Safety Warning

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed anti-tip

brackets and screws packed with the range. Failure to

install the anti-tip brackets will allow the range to tip

over if excessive weight is placed on an open door or if a

child climbs upon it. Serious injury might result from

spilled hot liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16" Diameter Drill Bit

3/16" Diameter Masonry Drill Bit (if installing in concrete)

Anti-Tip Brackets Installation Instructions

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete. The anti-tip brackets are attached to the

back of the range.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram below to locate

brackets if template is not available.)

2. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16" diameter pilot holes 1/2" deep can be drilled

into the floor.

3. Remove template and place brackets on floor with

turned up flange to the front. Line up holes in

brackets with marks on floor and attach with 4

screws provided. Brackets must be secured to solid

floor. If attaching to concrete floor, first drill 3/16"

dia. pilot holes using a masonry drill bit.

4. Level range if necessary, by adjusting 4 leg levelers

with wrench. (See Figure 1 below.) A minimum

clearance of 1/8" is required between the bottom of

the range and the rear leg levelers to allow room for

the anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to be

shifted slightly to one side as it is being pushed back

to allow rear legs to align with brackets. Remove

lower panel, storage drawer or open broiler

compartment to inspect brackets. You may also

grasp the top rear edge of the range and carefully

attempt to tilt it forward to make sure range is

properly anchored.

Two Piece Anti-Tip Bracket

12:00

Figure 1

12:00

8

Page 9

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

L’INSTALLATION ET LES RÉPARATIONS DOIVENT ÊTRE EFFECTUÉES

PAR UN TECHNICIEN QUALIFIÉ.

IMPORTANT : CONSERVER CETTE NOTICE POUR L’INSPECTEUR

D’INSTALLATIONS ÉLECTRIQUES DE LA LOCALITÉ.

LIRE ET CONSERVER CETTE NOTICE POUR RÉFÉRENCE FUTURE.

Toute dérogation aux directives données

dans cette notice peut entraîner des risques d’incendie,

d’explosion, de dommages matériels, de blessures ou de mort.

POUR VOTRE SÉCURITÉ :

— Ne pas entreposer ni utiliser d’essence ou d’autre vapeurs

ou liquides inflammables à proximité de cette cuisinière

ou de tout autre appareil électroménager.

— QUE FAIRE S’IL Y A UNE ODEUR DE GAZ

• N’allumer aucun appareil électrique.

• Ne toucher aucun commutateur électrique; ne pas utiliser

le téléphone dans l’immeuble.

• Appeler la compagnie de gaz immédiatement en utilisant

le téléphone d’un voisin. Suivre les instructions de la

compagnie de gaz.

• S’il est impossible de joindre la compagnie de gaz, appeler

les pompiers.

— L’installation et les réparations doivent être effectuées par

un technicien qualifié, un agent de service ou la compagnie

de gaz.

· TOUTES LES

CUISINIÈRES

PEUVENT

BASCULER.

· DES

BLESSURES

POURRAIENT

SURVENIR.

· INSTALLER LES

AMARRES QUI

ACCOMPAGNENT LA

CUISINIÈRE.

· SE REPORTER

AUX

DIRECTIVES

D’INSTALLATION

DES

AMARRES.

Remarque :

75,88 cm

(29 7/8 po)

sans la

garniture

du dessus

76,04 cm

(29 15/16 po)

avec la

garniture

du dessus

121,28 cm

(47 3/4 po)

maximum

112,7 cm

(44 3/8 po)

porte ouverte

Voir la remarque

64,45 cm

(25 3/8 po)

91,44 cm ± 0,32 cm

(36 po ± 1/8 po)

Dégagement

minimum entre les

murs latéraux et la

cuisinière au-del

de 91,44 cm (36 po)

de hauteur

VUE

FRONTALE

91,44 cm

(36 po)

VUE

LATÉRALE

76,2 cm

(30 po)

76,2 cm

(30 po)

minimum

à

5,08 cm

(2 po)

76,2 cm (30 po)

45,72 cm

(18 po)

Espace de 0 cm sous la surface de cuisson et derrière la cuisinière.

Dégagement

minimum sous

les armoires

sur les côtés

de la cuisinière

Profondeur

maximum

des armoires

au-dessus de

la cuisinière.

33 cm

(13 po)

63,5 cm

(25 po)

Dégagement et dimensions

1. Emplacement—Vérifier l’espace où la cuisinière doit être installée. S’assurer que l’alimentation en gaz et en électricité

est adéquate et que le plancher est stable.

2. Les dimensions indiquées doivent être respectées. Les dimensions indiquées stipulent le dégagement minimum requis.

Le plancher doit être ferme et au niveau.

No de pièce 316002989 (9510)

English—Pages 1-8

Français—Pages 9-16

9

Español—Pages 17-24

Page 10

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

Remarques importantes à l’intention de

l’installateur

1. Lire les directives contenues dans cette notice

d’installation avant d’installer la cuisinière.

2. Retirer tout le matériel d’emballage de l’intérieur de la

cuisinière avant de brancher la cuisinière à l’alimentation

en gaz et en électricité.

3. Respecter tous les codes et ordonnances qui s’appliquent.

4. Laisser cette notice d’installation au client.

Remarque importante à l’intention du client

1. Conserver cette notice d’installation avec le Guide de

l’utilisateur pour référence future.

CONSIGNES DE SÉCURITÉ

IMPORTANTES

Cette cuisinière doit être installée conformément aux codes

locaux ou, s’il n’existe pas de codes locaux, à l’édition la plus

récente de la norme ANSI Z223.1 si elle est installée aux ÉtatsUnis. Au Canada, l’installation doit respecter les normes CAN/

CGA-B149.1 et CAN/CGA-B149.2

La conception de cette cuisinière a été agréée par l’American

Gas Association et par l’Association canadienne du gaz.

Comme c’est le cas pour tout appareil qui utilise du gaz naturel

et qui émet de la chaleur, certaines consignes de sécurité

doivent être respectées. Ces consignes sont énoncées dans le

Guide de l’utilisateur; lire ce guide attentivement.

• S’assurer que la cuisinière est correctement installée

et mise à la terre par un installateur ou un technicien

qualifié.

• Cette cuisinière doit être mise à la terre conformément

aux codes locaux ou, s’il n’existe pas de codes locaux,

à l’édition la plus récente de la norme ANSI/NFPA

no .70 si elle est installée aux États-Unis. Au Canada, la

mise à la terre doit respecter la norme CSA C22.1 du Code

de l’électricité du Canada, partie 1. Se reporter aux directives

de mise à la terre à la page 5.

• Avant d’installer la cuisinière dans un endroit

recouvert de linoléum ou de tout autre couvreplancher synthétique, s’assurer que le couvre-plancher

peut supporter une chaleur supérieure d’au moins

32,2°C (90°F) à la température de la pièce sans rétrécir,

se tordre ou changer de couleur. Ne pas installer la

cuisinière sur un tapis à moins de placer un revêtement

isolant en contre-plaqué de 0,64 cm (1/4 po) entre la

cuisinière et le tapis.

• S’assurer que le revêtement des murs qui entourent

la cuisinière peut supporter la chaleur qu’émet cet

appareil.

• Ne pas obstruer la circulation de l’air servant à la

combustion près de la grille d’aération ni autour de la

base ou sous le panneau avant de la cuisinière. Éviter

de toucher aux ouvertures d’aération ou aux surfaces

avoisinantes car elles peuvent devenir très chaudes pendant

le fonctionnement de la cuisinière. Cette cuisinière a besoin

d’air frais pour que la combustion soit adéquate.

Ne jamais laisser des enfants seuls

ou sans surveillance près d’un appareil électroménager

en marche. Dès que les enfants sont assez grands, leur

enseigner l’utilisation correcte et sécuritaire de tous les

appareils électroménagers. Ne jamais laisser la porte du four

ouverte lorsque aucun adulte ne se trouve à proximité.

Ne pas monter, s’appuyer ou

s’asseoir sur les portes ou les tiroirs de cette cuisinière;

cela pourrait entraîner des blessures graves et

endommager la cuisinière.

• Ne pas ranger des articles pouvant attirer des enfants

dans les armoires situées au-dessus de la cuisinière.

Les enfants pourraient se brûler gravement en grimpant sur

la cuisinière pour atteindre ces objets.

• Il est préférable de ne pas utiliser l’espace de

rangement situé au-dessus des brûleurs de surface

pour ne pas avoir à tendre les bras au-dessus de

ceux-ce.

• Ajuster l’intensité de la flamme des brûleurs de surface

de façon à ce qu’elle ne dépasse pas le bord de la

casserole. Les flammes trop vives présentent des dangers.

• Ne pas utiliser la cuisinière comme espace de

rangement. Cela pourrait présenter des dangers.

• Ne jamais utiliser la cuisinière pour réchauffer ou

chauffer la pièce. Il est dangereux d’utiliser la cuisinière

de façon prolongée sans une aération suffisante.

• Ne pas entreposer d’essence ou d’autres vapeurs ou

liquides inflammables à proximité de cet appareil ou

de tout autre appareil électroménager. Cela pourrait

entraîner une explosion ou un incendie.

• Remettre tous les boutons de commande à la position

«off» après avoir utilisé une fonction de la minuterie.

POUR LES MODÈLES AUTONETTOYANTS:

• Retirer la lèchefrite, la nourriture et tout autre

ustensile de cuisson avant de nettoyer la cuisinière.

Essuyer le surplus de saleté. Suivre les directives de

préparation au nettoyage contenues dans le Guide de

l’utilisateur.

• Contrairement à la cuisinière au gaz standard, LA

SURFACE DE CUISSON DE CETTE CUISINIÈRE N’EST PAS

AMOVIBLE. Ne pas tenter de retirer la surface de cuisson.

10

Page 11

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

NE PAS TENTER DE QUELQUE

FAÇON QUE CE SOIT D’UTILISER LE FOUR À ALLUMAGE

ÉLECTRIQUE PENDANT UNE PANNE D’ÉLECTRICITÉ. EN

CAS DE PANNE D’ÉLECTRICITÉ, REMETTRE TOUTES LES

COMMANDES DU FOUR À LA POSITION «OFF».

Si le thermostat du four restait allumé (position «ON»)

pendant une panne d’électricité, l’allumeur électrique

redémarrerait automatiquement le brûleur du four une fois

la panne rétablie.

Si la panne d’électricité survient après l’allumage de l’un

des brûleurs de surface, ce brûleur continuera de

fonctionner.

Pendant une panne d’électricité, les brûleurs de surface

peuvent être allumés à l’aide d’une allumette. Tenir une

allumette allumée au-dessus du brûleur, puis tourner

lentement le bouton vers la position d’allumage «LITE».

Faire preuve d’une grande prudence en allumant les

brûleurs de cette façon.

Avant l’installation

Outils requis

Pour mettre les pieds au niveau :

• Clé à douille (1 3/8 po hexagonale) ou pinces

multiprise

Pour le branchement du gaz :

• Clé à tuyau

Pour ajuster la flamme du brûleur :

• Tournevis Phillips® et tournevis à pointe plate

Pour convertir la cuisinière au gaz propane, suivre les directives

qui accompagnent la cuisinière ou l’ensemble de conversion

au propane.

NE PAS tenter de convertir cette cuisinière au gaz

propane sans l’ensemble de conversion qui accompagne la cuisinière

ou que l’on peut se procurer auprès d’un fournisseur de pièces.

1. Poser les amarres. (Se reporter à la page 16.)

2. Assurer une alimentation en gaz adéquate. Cet

appareil est conçu pour fonctionner sur une pression de

10,16 cm (4 po) produite par un distributeur de gaz naturel.

Un régulateur de pression ajustable est branché au distributeur;

ce régulateur DOIT être relié en série avec la conduite

d’alimentation en gaz. Si un ensemble de conversion au gaz

propane a été installé, suivre les directives qui accompagnent

l’ensemble en question pour convertir le régulateur de pression

à l’alimentation de gaz propane.

Il faut prendre grand soin pendant l’installation de la cuisinière de ne

pas obstruer la circulation de l’air servant à la combustion et à la

ventilation.

Pour que la cuisinière fonctionne correctement, la pression

d’admission maximum au régulateur ne doit pas dépasser 35,56 cm

(14 po) d’eau. La pression d’admission au régulateur doit être d’au

moins 2,54 cm (1 po) plus élevée que la pression au distributeur.

Par exemple, si le régulateur est réglé de façon à ce que la pression de

gaz naturel soit de 10,16 cm (4 po) au distributeur, la pression

d’admission doit être d’au moins 12,7 cm (5 po). Si le régulateur a

été converti à une alimentation en gaz propane et que la pression au

distributeur est de 25,4 cm (10 po), la pression d’admission doit être

d’au moins 27,94 cm (11 po).

Matériel additionnel requis

• Robinet d’arrêt de la conduite de gaz

• Mastic pour joints de tuyaux qui résiste à l’action

corrosive du propane

• Conduit en métal souple (1,27 cm (1/2 po) NPT sur

1,9 cm (3/4 po) ou 1,27 cm (1/2 po) d.i.) approuvé

AGA/CGA. Puisque les tuyaux rigides restreignent les

déplacements de la cuisinière, il est recommandé

d’utiliser ce conduit souple (1,2 m à 1,5 m de long).

• 2 adaptateurs à évasement (1,27 cm (1/2 po) NPT

sur 1,9 cm (3/4 po) ou 1,27 cm (1/2 po) d.i.) pour

brancher le conduit souple.

Étapes habituelles d’installation

Avant l’installation :

La cuisinière est conçue de façon à ne fonctionner que sur

une alimentation en gaz naturel. Toutefois, certains modèles

sont accompagnés de pièces et d’instructions de conversion.

D'autres modèles comportent un ensemble de conversion

au gaz propane no 80-8802-10 que vous pouvez vous

procurer auprès d'un détaillant.

La conduite d’alimentation en gaz doit être de 1,27 cm

(1/2 po) ou 1,9 cm (3/4 po) d.i.

Centre de

la cuisinière

17,78 cm

(7 po)

29,21 cm

58,42 cm

(23 po)

55,88 cm

(22 po)

17,78 cm

(7 po)

26,67 cm

(10 1/2 po)

ESPACE RECOMMANDÉ POUR LE

BRANCHEMENT DU TUYAU ET DU

ROBINET D’ARRÊT DANS LE

PLANCHER.

(11 1/2 po)

5,08 cm

(2 po)

48,26 cm

(19 po)

LA ZONE OMBRAGÉE

INDIQUE L’ESPACE

RECOMMANDÉ POUR LA

PRISE DE 120 V SUR LE MUR

ET L’ESPACE POUR LE

BRANCHEMENT DU TUYAU

ET DU ROBINET D’ARRÊT

DANS LE MUR.

Bord du mur

11

Page 12

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

3. Sceller les ouvertures. Sceller toute ouverture dans

le mur, derrière la cuisinière, et dans le plancher, sous la

cuisinière, une fois la conduite d’alimentation en gaz

installée.

4. Brancher la cuisinière à l’alimentation en

gaz. Pour prévenir les fuites, appliquer un mastic de joint

pour tuyaux sur les filets de tous les raccords mâles (filets

sur l’extérieur).

Ne pas permettre au régulateur de

tourner sur le tuyau pendant le serrement des pièces. Le

régulateur est situé dans l’espace indiqué ci-dessous.

Retirer le tiroir ou le panneau

pour accéder au régulateur

Emplacement du régulateur

de pression sur l’arrière de la

cuisinière

a) Poser un robinet d’arrêt manuel externe sur la conduite

d’alimentation en gaz dans un endroit facile d’accès à

l’extérieur de la cuisinière. S’assurer de savoir comment et

où couper l’alimentation en gaz de la cuisinière.

b) Poser un adaptateur à évasement de 1,27 cm (1/2 po) sur

le régulateur de pression.

c) Fixer le conduit de l’appareil à l’adaptateur à évasement relié

au régulateur.

d) Fixer un autre adaptateur à évasement au robinet d’arrêt

manuel externe.

e) Fixer le conduit de l’appareil à l’adaptateur à évasement relié

au robinet d’arrêt.

f) S’assurer que le robinet d’arrêt du régulateur de pression est

ouvert (position «ON»).

g) Vérifier s’il y a des fuites. Ouvrir l’alimentation en gaz de la

cuisinière et appliquer un détecteur de fuite liquide sur

tous les joints et les raccords de façon à déceler toute

fuite dans la conduite.

Ne pas utiliser une flamme vive pour

détecter les fuites de gaz.

Régulateur de pression

Conduit

souple de

l'appareil

Adaptateur à

évasement

Robinet d’arrêt

manuel externe

Alimentation en gaz

On

Off

Adaptateur à

évasement

Robinet d’arrêt

des modèles à allumage

électrique seulement.

S’assurer que le levier est

ouvert (position «On») une

fois l’installation terminée.

On

Off

Vérifier la pression de gaz du distributeur

Débrancher la cuisinière et son robinet d’arrêt distinct de la

canalisation de gaz pendant toute vérification de pression de

l’alimentation en gaz à des pressions qui dépassent 35,56 cm

(14 po) d’eau (environ 3,45 kPa (1/2 lb/po²)).

L’appareil doit être isolé de la canalisation de gaz par la

fermeture de son robinet d’arrêt manuel pendant toute

vérification de pression de la canalisation de gaz à des pressions

égales ou inférieures à 35,56 cm (14 po) d’eau (environ

3,45 kPa (1/2 lb/po²)).

S’il s’avère nécessaire de vérifier la pression de la canalisation

de gaz, brancher un manomètre (hydromètre) ou un autre

appareil de vérification de pression à l’orifice du brûleur de

surface arrière droit. Tenir un boyau en caoutchouc d’environ

0,6 cm (1/4 po) de diamètre intérieur relié à l’appareil de

vérification bien serré sur l’orifice. Ouvrir le robinet du brûleur.

Pour une vérification de pression fiable, faire fonctionner au

moins deux (2) autres brûleurs de surface pendant la

vérification. S’assurer que la pression d’alimentation en gaz

(pression d’admission) est supérieure d’au moins 2,54 cm

(1 po) à la pression du distributeur. La pression de

l’alimentation en gaz ne doit jamais être supérieure à

35,56 cm (14 po) d’eau. Lorsque la pression du distributeur

est bien ajustée au gaz naturel, elle est de 10,16 cm (4 po).

(Dans le cas du gaz propane, la pression du distributeur est de

25,4 cm (10 po)).

5. Lire les directives relatives au branchement

électrique ci-dessous et brancher la

cuisinière à l’alimentation électrique.

Avant le branchement, couper

l’alimentation électrique à la boîte de fusibles ou de

disjoncteurs ou au cordon d’alimentation.

Installation électrique : Dérivation distincte adéquatement

mise à la terre et polarisée avec disjoncteur ou fusible à

retardement de 15 A. Se reporter à la plaque signalétique pour

la tension recommandée.

Consignes de sécurité relatives aux cordons de rallonge :

En raison des risques que peuvent présenter les cordons de

rallonge dans certaines circonstances, nous recommandons

fortement de ne pas utiliser de cordon de rallonge avec la

cuisinière. Toutefois, si l’on décide tout de même d’utiliser un

cordon de rallonge, celui-ci doit être à 3 conducteurs, agréé

UL, mis à la terre et conçu pour le branchement d’appareils

électroménagers; il doit être en mesure de soutenir une tension

équivalente ou supérieure à l’ampérage de la dérivation. On

peut se procurer ce type de cordon de rallonge auprès de

l’agent de service après-vente agréé le plus proche.

LIRE ATTENTIVEMENT ! Pour votre

sécurité, cet appareil doit être convenablement mis à la terre.

12

Page 13

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

Mise à la terre

Le cordon d’alimentation électrique de cet appareil est pourvu

d’une fiche à 3 broches (mise à la terre) qui convient aux prise

murales standard à 3 ouvertures mises à la terre, et ce de façon

à minimiser les risques d’électrocution que pourrait présenter

cet appareil. Le consommateur doit faire vérifier la prise murale

et le circuit par un électricien agréé afin de s’assurer que la prise

est correctement mise à la terre et polarisée.

Méthode privilégiée

Il ne faut en aucun cas

couper, retirer ou

contourner la broche

de terre de cette fiche.

Prise murale

mise à la terre

Cordon

d’alimentation

avec fiche à 3

broches mise

à la terre

Lorsque la prise murale n’a que deux ouvertures, il incombe

au propriétaire de l’appareil de faire remplacer cette prise par

une prise à trois ouvertures convenablement mise à la terre.

IL NE FAUT EN AUCUN CAS COUPER OU RETIRER LA

BROCHE DE TERRE DU CORDON D’ALIMENTATION

ÉLECTRIQUE.

Fonctionnement des brûleurs de

surface

Cette cuisinière est pourvue de brûleurs scellés, comme le

montre l’illustration qui suit.

Couvercle du

brûleur

Languettes

de fixation

Base du

brûleur

Ouvertures de

fixation

6. Installation des pièces qui recouvrent le

brûleur

La cuisinière est pourvue d’anneaux de garniture ou de

cuvettes, ou encore de ces deux dispositifs. Installer les cuvettes

(certains modèles) et les anneaux de garniture (certains

modèles) comme suit :

Grille

Couvercle

du brûleur

Anneau de garniture

(certains modèles)

Cuvette du brûleur

(certains modèles)

Base du brûleur

Surface de cuisson

7. Brûleurs de surface à allumage électrique

Le fonctionnement de l’allumage électrique doit être vérifié une

fois que la détection de fuite dans les raccords de la cuisinière

et de la conduite d’alimentation a été effectuée et que la

cuisinière a été branchée à l’alimentation électrique. Pour

vérifier l’allumage, enfoncer et tourner un bouton d’allumage

de brûleur de surface à la position «LITE». On entend une

étincelle dans le dispositif d’allumage. Le brûleur de surface

devrait s’allumer si l’alimentation en gaz est reliée au brûleur.

Dans des conditions normales, chaque brûleur devrait s’allumer

dans les quatre (4) secondes une fois que l’air a été purgé des

conduites d’alimentation. Vérifier visuellement si le brûleur est

allumé. Une fois le brûleur allumé, le bouton de commande

doit être retiré de la position «LITE». Chaque brûleur est pourvu

d’un dispositif d’allumage distinct. Vérifier chacun des boutons

pour tester tous les brûleurs.

Électrode

Anneau de garniture (certains modèles)

ou cuvette du brûleur (certains modèles)

COMMANDE

À DEUX

POSITIONS

COMMANDE À

TROIS

POSITIONS

COMMANDE

À DÉBIT

LINÉAIRE

Remarque : Le style des robinets peut différer des styles

illustrés.

13

Page 14

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

8. Ajustement du réglage faible «LOW» du

robinet des brûleurs (commandes à débit linéaire

ou à trois positions seulement) :

CONDUITE

D’ALIMENTATION

EN GAZ

a) Tourner le bouton de commande à la position «LITE»

jusqu’à ce que le brûleur s’allume.

b) Tourner rapidement la commande à la POSITION LA PLUS

FAIBLE.

c) Si le brûleur s’éteint, ajuster le robinet de la façon

suivante :

Remettre le bouton de commande à la position «OFF». Retirer

le bouton de commande du brûleur, insérer un tournevis à lame

mince dans la tige creuse du robinet et saisir la vis à filets

interrompus. La taille de la flamme peut être augmentée ou

réduite par le réglage de cette vis. Ajuster la flamme jusqu’à

ce que le bouton de commande puisse être tourné rapidement

de la position «LITE» à la POSITION LA PLUS FAIBLE sans que

la flamme ne s’éteigne. La flamme doit être aussi petite que

possible sans s’éteindre.

Remarque : L’ajustement du mélange d’air n’est pas requis

pour les brûleurs de surface.

Une fois tout le matériel d’emballage et la documentation

sortis du four :

a) Régler le four sur CUISSON «BAKE» à 154°C (300°F). Se

reporter au Guide de l’utilisateur pour les directives de

fonctionnement.

b) Le brûleur du four devrait s’allumer dans les 60 secondes

qui suivent. S’assurer que la flamme est adéquate et

permettre au brûleur d’accomplir un cycle complet.

Refermer les boutons de commande (position «off»).

c) Si la cuisinière est pourvue d’un brûleur de grillage à

hauteur de la taille, régler le four sur GRILLAGE «BROIL».

Se reporter au Guide de l’utilisateur pour les directives de

fonctionnement.

d) Le brûleur de grillage devrait s’allumer dans les

60 secondes qui suivent. S’assurer que la flamme est

adéquate. Refermer les boutons de commande.

10. Obturateur d’air / brûleur du four

La flamme du brûleur du four mesure environ 2,5 cm (1 po)

(flamme intérieure de couleur bleue).

Brûleur à hauteur de

la taille (modèles

autonettoyants)

Déflecteur inférieur

du four (amovible)

Obturateur d’air

Fonctionnement des brûleurs du

four et ajustement du four

9. Brûleurs à allumage électrique

Le fonctionnement de l’allumage électrique doit être vérifié une fois

que la détection de fuite dans les raccords de la cuisinière et de la

conduite d’alimentation a été effectuée et que la cuisinière a été

branchée à l’alimentation électrique.

Le brûleur du four est pourvu d’un dispositif de contrôle électrique

ainsi que d’un dispositif d’allumage électrique. Si la cuisinière est

pourvue d’un brûleur de grillage à hauteur de la taille, ce brûleur

dispose également d’un dispositif d’allumage électrique. Ces

dispositifs de contrôle n’ont pas à être ajustés. Une fois le four prêt à

fonctionner, l’alimentation électrique se rend au dispositif d’allumage.

Ce dispositif «s’illumine» comme une ampoule électrique. Lorsque

le dispositif d’allumage atteint la température requise pour enflammer

le gaz, le robinet à commande électrique du four s’ouvre et la flamme

se forme sur le brûleur. Il faut de 30 à 60 secondes entre le moment

où le thermostat est allumé et l’apparition de la flamme sur le brûleur.

Lorsque le four atteint la température prévue, le dispositif d’allumage

s’éteint. La flamme du brûleur s’éteint dans les 20 à 30 secondes qui

suivent la fermeture du dispositif d’allumage. Pour maintenir une

température donnée dans le four, le cycle se poursuit tant que la

commande (ou le voyant) fonctionne.

Fond du four

(amovible)

Obturateur d’air

Pour déterminer si la flamme du brûleur du four est adéquate,

retirer le fond du four et le déflecteur, puis régler le four sur

CUISSON «BAKE» à 154°C (300°F).

Pour retirer le fond du four, enlever les vis de support situées

sur sa partie arrière. Le soulever par l’arrière, désengager son

devant du cadre avant du four, puis le tirer pour le sortir du

four. Retirer le déflecteur de façon à pouvoir observer la

flamme.

14

Page 15

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

Si la flamme est de couleur jaune, accroître l’ouverture de

l’obturateur d’air. (Se reporter au numéro 2 de l’illustration

qui suit.) Si la flamme est d’un bleu marqué, réduire l’ouverture

de l’obturateur d’air.

Pour ajuster la flamme, desserrer la vis de blocage (se reporter

au numéro 3 de l’illustration qui suit), ajuster l’obturateur d’air,

puis resserrer la vis de blocage. Remettre le fond du four en

place.

Tuyau du

brûleur

du four

Vis de blocage

Obturateur d’air

Capuchon

de l’orifice

11. Obturateur d’air / brûleur de grillage

(s’il y a lieu)

La flamme du brûleur du four mesure environ 2,5 cm (1 po)

(flamme intérieure de couleur bleue).

Pour déterminer si la flamme du brûleur de grillage est

adéquate, régler le four sur GRILLAGE «BROIL».

Si la flamme est de couleur jaune, accroître l’ouverture de

l’obturateur d’air. (Se reporter au numéro 2 de l’illustration

qui précède.) Si la flamme est d’un bleu marqué, réduire

l’ouverture de l’obturateur d’air.

Pour ajuster la flamme, desserrer la vis de blocage (se reporter

au numéro 3 de l’illustration qui précède), ajuster l’obturateur

d’air, puis resserrer la vis de blocage.

12. S’assurer que la cuisinière est au niveau

Mettre la cuisinière au niveau en plaçant un niveau à

l’horizontale sur une gille du four. Vérifier en diagonale d’avant

en arrière, puis mettre la cuisinière au niveau, soit en ajustant

les pieds de nivellement, soit en plaçant des cales sous les coins

au besoin.

13. Une fois l’installation terminée, s’assurer

que tous les boutons de commande sont

fermés (position «off»).

Emplacement des numéros de

modèle et de série

Dans le cas des fours émaillés, la plaque signalétique est située

sur le bord avant droit du cadre du four, dans le compartiment

du grilloir ou le tiroir de rangement.

Dans le cas des fours à nettoyage continu, la plaque

signalétique est située sur le bord avant droit du protecteur

de plancher situé dans le compartiment du grilloir.

Lorsqu’il faut commander des pièces ou poser des questions

sur la cuisinière, s’assurer de mentionner le numéro de modèle

et le numéro de série ainsi que le numéro de lot ou la lettre qui

figurent sur la plaque signalétique de la cuisinière.

La plaque signalétique indique également le calibre des

brûleurs, le type de carburant à utiliser et la pression préajustée

au moment où la cuisinière a quitté l’usine.

Avant de faire appel à un centre de

service

Lire le Guide de dépannage et les directives d’utilisation qui

figurent dans le Guide de l’utilisateur. Cela peut épargner du

temps et des dépenses inutiles. Le Guide de dépannage décrit

les problèmes courants qui ne sont pas causés par un vice de

fabrication ou de matériaux.

Se reporter à la garantie qui figure dans le Guide de l’utilisateur

pour connaître le numéro sans frais et l’adresse de notre service

à la clientèle. N’hésitez pas à nous appeler ou à nous écrire si

vous avez des questions au sujet de votre cuisinière ou pour

commander des pièces.

Entretien et nettoyage

Se reporter au Guide de l’utilisateur pour les directives de

nettoyage.

S’il faut déplacer la cuisinière pour la nettoyer ou la réparer,

fermer l’alimentation en gaz. Débrancher l’alimentation en

gaz et l’alimentation électrique. Si les sources de gaz et

d’électricité ne sont pas accessibles, soulever légèrement le

devant de la cuisinière et tirer. Tirer juste assez pour être en

mesure de couper l’alimentation en gaz et en électricité.

Poursuivre le déplacement de la cuisinière pour l’entretien ou

le nettoyage. Réinstaller la cuisinière dans l’ordre inverse en

s’assurant qu’elle est au niveau et qu’il n’y a pas de fuite dans

les raccords de la conduite de gaz. Se reporter au

paragraphe 5 de la page 8 pour savoir comment amarrer

correctement la cuisinière.

15

Page 16

NOTICE D’INSTALLATION DE LA CUISINIÈRE AU GAZ DE 76,2 CM (30 PO)

(Pour les modèles pourvus de brûleurs de surface scellés)

Directives d’installation des

amarres

Consigne de sécurité importante

Pour prévenir tout risque de basculement de la cuisinière, cet

appareil doit être fixé correctement au plancher à l’aide des

amarres et des vis qui l’accompagnent. Si les amarres n’étaient

pas installées, la cuisinière pourrait basculer si un poids excessif

était déposé sur la porte du four lorsque celle-ci est ouverte

ou qu’un enfant grimpait sur la porte. Des blessures graves

pourraient alors être causées par le renversement de liquides

chauds ou par la cuisinière elle-même.

Suivre les directives qui suivent pour installer les amarres.

Si la cuisinière doit être déplacée après son installation initiale,

les amarres doivent également être déplacées et réinstallées.

Pour s’assurer que l’installation a été effectuée correctement,

se reporter à l’étape 5.

Outils requis :

Tournevis à douille de 5/16 po ou tournevis à pointe plate

Clé à molette

Perceuse électrique

Foret de 3/16 po de diamètre

Foret à maçonnerie de 3/16 po de diamètre (si les amarres

doivent être installées dans du béton)

Directives d’installation des amarres

Les amarres se fixent au plancher sur l’arrière de la cuisinière de

façon à tenir les deux pieds de nivellement arrière. En attachant

les amarres au plancher, s’assurer que les vis ne percent pas de fil

électrique ni de conduite de plomberie. Les vis fournies

conviennent aussi bien au bois qu’au béton. Les amarres sont

fixées sur l’arrière de la cuisinière.

1. Déplier le gabarit en papier et le placer à plat sur le plancher

en ajustant bien les bords arrière et latéraux du gabarit sur

l’endroit précis où la cuisinière doit être installée. (Utiliser le

diagramme qui figure ci-dessous pour déterminer

l’emplacement des amarres si le gabarit n’est pas disponible.)

2. Tracer sur le plancher l’emplacement des quatre trous de

montage indiqués sur le gabarit. Pour faciliter l’installation,

des trous de guidage de 0,47 cm (3/16 po) de diamètre et

de 1,27 cm (1/2 po) de profondeur peuvent être percés dans

le plancher.

3. Retirer le gabarit et poser les amarres sur le plancher en

tournant les languettes vers le devant. Aligner les trous des

amarres avec les traits sur le plancher, puis attacher les

amarres à l’aide des quatre vis fournies. Les amarres doivent

être fixées à un plancher ferme. Si elles doivent être fixées à

un plancher en béton, percer d’abord des trous de guidage

de 0,47 cm (3/16 po) de diamètre à l’aide d’un foret à

maçonnerie.

4. Mettre la cuisinière au niveau en ajustant au besoin les quatre

pieds de nivellement à l’aide d’une clé. (Se reporter à la figure

1 ci-dessous.) Un espace minimum de 0,32 cm (1/8 po) est

requis entre le fond de la cuisinière et les pieds de nivellement

arrière pour les amarres.

5. Glisser la cuisinière en place en s’assurant que les pieds de

nivellement arrière sont bien immobilisés par l’extrémité des

amarres. Il peut être nécessaire de tourner légèrement la

cuisinière vers la gauche ou la droite en la poussant pour

permettre aux pieds de s’aligner sur les amarres. Retirer le

panneau inférieur ou le tiroir de rangement, ou encore ouvrir

le compartiment du grilloir pour inspecter les amarres. On

peut aussi saisir la partie supérieure de l’arrière de la cuisinière

pour faire basculer légèrement celle-ci vers l’avant de façon

à s’assurer qu’elle est bien ancrée.

Amarres en deux pièces (certains modèles)

12:00

GLISSER VERS

L’ARRIERE

UR

BORD ARRIERE DE

LA CUISINIERE OU M

ARRIÈRE

5,7 cm

(2 1/4 po)

16

AMARRES

7,3 cm

(2 7/8 po)

EMPLACEMENT

DU PANNEAU

LATERAL DE LA

CUISINIERE

Figure 1

12:00

Base de la cuisinière

Pied de

nivellement

Soulever

Abaisser

Page 17

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA DE GAS DE 30"(76,2cm)

(Para modelos con Quemadores Superiores Sellados)

LA INSTALACION Y EL SERVICIO DEBEN SER EFECTUADOS POR

UN INSTALADOR CALIFICADO.

IMPORTANTE: CONSERVE ESTAS INSTRUCCIONES PARA USO DEL

INSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y CONSERVE ESTAS INSTRUCCIONES PARA REFERENCIA

FUTURA.

Si la información contenida en este manual no

es seguida exactamente, puede ocurrir un incendio o

explosión causando daños materiales, lesión personal o la

muerte.

• TODAS LAS

PARA SU SEGURIDAD:

— No almacene ni utilice gasolina u otros vapores y líquidos

inflamables en la proximidad de éste o de cualquier otro

artefacto.

— QUE DEBE HACER SI PERCIBE OLOR A GAS:

• No trate de encender ningún artefacto.

• No toque ningún interruptor eléctrico; no use ningún

teléfono en su edificio.

• Llame a su proveedor de gas desde el teléfono de un

vecino. Siga las instrucciones del proveedor de gas.

• Si no logra comunicarse con su proveedor de gas, llame al

departamento de bomberos.

— La instalación y el servicio de mantenimiento debe

realizarlo un instalador calificado, la agencia de servicios

o el proveedor de gas.

ESTUFAS

PUEDEN

VOLCARSE.

• PUEDEN

RESULTAR

LESIONES

PERSONALES.

• INSTALE EL

DISPOSITIVO

ANTIVUELCO

EMPACADO

CON LA

ESTUFA.

• VEA LAS

INSTRUCCIONES

DE

INSTALACION.

Nota:

29-7/8" (75,88

cm) sin la

moldura

superior

29-15/16"

(76,04 cm) con

la moldura

superior

47 3/4"

121,28 cm

Máximo

44 3/8"

114,17 cm

Puerta abierta

Ver la nota

Espacios libres y dimensiones

1. Ubicación - Examine la ubicación donde va a instalar la estufa. Compruebe que la alimentación eléctrica y de gas sea

adecuada y compruebe la estabilidad del piso.

2. Las dimensiones que se muestran deben ser usadas. Las dimensiones dadas proporcionan el espacio mínimo necesario. La

superficie de contacto debe ser sólida y nivelada.

P/N 316002989 (9510)

25 3/8"

64,45 cm

36

91,44 cm

± 0,32 cm

DELANTERA

Mínimo hasta la pared

en cualquiera de los

lados de la estufa

por encima de

91,44 cm de altura.

+1/8"

91,44 cm

36"

VISTA

17

2"

5,08 cm

76,2 cm

30"

76,2 cm

Mínimo

30" (76,2 cm)

30"

VISTA

LATERAL

Mínimo hasta

los armarios en

18"

45,72 cm

cualquiera de

los lados de la

estufa.

0 cm de espacio debajo de la estufa y en la parte trasera.

Profundidad

máxima para

los armariospor

encima de la

cubierta de la estufa.

33 cm

25"

63,5 cm

13"

English—Pages 1-8

Français—Pages 9-16

Español—Pages 17-24

Page 18

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA DE GAS DE 30"(76,2cm)

(Para modelos con Quemadores Superiores Sellados)

Importantes notas para el instalador

1. Lea todas las instrucciones contenidas en estas instrucciones

para la instalación antes de instalar la estufa.

2. Saque todos los materiales de embalaje de los

compartimientos del horno antes de conectar la

alimentación de gas y electricidad a la estufa.

3. Observe todos los códigos y ordenanzas en vigor.

4. Asegúrese de dejar estas instrucciones al cliente.

Nota importante para el cliente

1. Guarde estas instrucciones con la guía del propietario para

referencia futura.

IMPORTANTES

INSTRUCCIONES DE

SEGURIDAD

La instalación de esta estufa debe estar conforme con los códigos

locales, o si no existen códigos locales, con el National Fuel Gas

Code (Código Nacional para Gases Combustibles), ANSI

Z223.1—la edición más reciente cuando se instala en los Estados

Unidos. Si se instala en Canadá, la instalación debe estar

conforme con CAN/CGA-B149.1 y CAN/CGA-B149.2.

El diseño de esta estufa ha sido certificado por la American Gas

Association (Asociación Norteamericana de Gas) y la Canadian

Gas Association (Asociación Canadiense de Gas). Igual que con

cualquier electrodoméstico que utiliza gas y genera calor, existen

ciertas precauciones de seguridad que deberá seguir. Las

encontrará en la

• Asegúrese de que su estufa sea instalada y puesta a tierra

debidamente por un instalador capacitado o un técnico

de servicio.

• Esta estufa debe ser puesta a tierra de acuerdo con los

códigos locales, o si no existen códigos locales, con el

National Electrical Code (Código Eléctrico Nacional),

ANSI/NFPA Nº 70 — la edición más reciente cuando se

instala en los Estados Unidos. Si se instala en Canadá, esta

estufa debe ser puesta a tierra de acuerdo con la Norma CSA

Standard C22.1, Canadian Electrical Code (Código Eléctrico

Canadiense), Parte 1. Vea las instrucciones para la puesta a

tierra en la página 5.

• Antes de instalar la estufa en un área cubierta con linóleo

o cualquier otro material de recubrimiento sintético para

pisos, asegúrese de que el recubrimiento para pisos

pueda soportar una temperatura de por lo menos 90°F

(32,2°C) por encima de la temperatura ambiente sin

encogerse, doblarse ni cambiar de color. No instale la estufa

encima de un alfombrado a menos que coloque una alfombrilla

o lámina aislante de madera chapada de 1/4 de pulgada (6,3

mm) de espesor entre la estufa y el alfombrado.

• Asegúrese de que el papel tapiz de paredes alrededor

de la estufa pueda soportar el calor generado por la

estufa.

Guía del Propietario. Léalas con atención.

• No obstruya el paso de aire de combustión en la rejilla

de ventilación del horno ni alrededor de la base ni debajo

del panel delantero inferior de la estufa. Evite tocar las

aberturas de ventilación o las superficies cercanas ya que

pueden calentarse cuando el horno esté en funcionamiento.

Esta estufa requiere aire fresco para la combustión adecuada

del quemador.

desatendidos en el área donde un electrodoméstico esté

en funcionamiento. Cuando los niños crezcan, enséñeles el

uso correcto y seguro de todos los electrodomésticos. No deje

nunca la puerta del horno abierta cuando la estufa esté

desatendida.

puertas o cajones de esta estufa puede provocar lesiones

de consideración y también puede dañar la estufa.

• No almacene artículos de interés para los niños dentro

de los armarios situados por encima de la estufa. Los niños

que se suban a la estufa para alcanzar artículos podrían resultar

gravemente quemados..

• Para eliminar la necesidad de colocarse sobre los

quemadores de la superficie, deben evitarse los armarios

por encima de los quemadores.

• Ajuste el tamaño de la llama del quemador de superficie

para que no sobrepase el borde del utensilio de cocina.

Las llamas excesivas son peligrosas.

• No use el horno para almacenar cosas. Esto crea una

situación peligrosa potencial.

• No use nunca su estufa para mantener un cuarto caliente

ni para calentarlo. El uso prolongado de la estufa sin

ventilación adecuada puede ser peligroso.

• No guarde ni utilice gasolina ni otros vapores y líquidos

inflamables en las cercanías de este o cualquier otro

electrodoméstico. Pueden ocurrir incendios o explosiones.

• Vuelva a colocar todos los controles en la posición de

“off” (apagado) después de haber utilizado una

operación con el programador.

PARA MODELOS CON LA CARACTERISTICA DE

AUTOLIMPIEZA:

• Saque la bandeja del asador, los alimentos y cualquier

otro utensilio antes de poner en marcha la autolimpieza.

Limpie el exceso de derrames de comida. Siga las instrucciones

para la limpieza previa en la

• A diferencia de las estufas a gas communes, LA

TAPA DE LA ESTUFA NO ES REMOVIBLE. No trate de sacar

la tapa.

No deje nunca a los niños solos o

Subirse, apoyarse o sentarse sobre las

Guía del Propietario.

18

Page 19

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA DE GAS DE 30"(76,2cm)

(Para modelos con Quemadores Superiores Sellados)

NO TRATE DE UTILIZAR EL ENCENDIDO

ELECTRICO DURANTE UNA FALLA DEL SUMINISTRO

ELECTRICO. COLOQUE TODOS LOS CONTROLES DEL

HORNO EN “OFF” (APAGADO) EN CASO DE UNA FALLA

ELECTRICA.

El encendedor eléctrico volverá a encender

automáticamente el quemador del horno cuando regrese

el suministro eléctrico si el control del termostato del

horno se dejó en la posición de “ON” (encendido).

Cuando ocurra una falla eléctrica durante el uso, los

quemadores de superficie continuarán funcionando.

Durante una falla eléctrica, los quemadores de superficie

pueden ser encendidos con una cerilla. Sujete una cerilla

encendida justo al lado del quemador y gire despacio la

perilla a la posición de LITE (encendido). Tenga

muchísimo cuidado cuando encienda los quemadores de

esta manera.

Antes de Comenzar

Herramientas necesarias

Para las patas niveladoras:

•

Herramienta para insertar casquillos (1-3/8" hex) o alicates

channel lock

Para la conexión de la alimentación de gas:

• Llave para tuberías

Para el ajuste de la llama del quemador:

•

Destornilladores Phillips® y plano

No trate de convertir esta estufa para ser

usada con propano líquido sin el juego de conversión provisto

con la estufa o el provisto por el distribuidor.

1. Instale el(los) soporte(s) antivuelco. (Vea la

página 24).

2. Provea un suministro de gas apropiado. Esta

unidad ha sido ajustada para operar con un múltiple de

admisión para gas natural de 4". Un regulador de presión

convertible esta conectado a la válvula distribuidora y

DEBE ser conectado en serie con la tubería de sumibistro

de gas. Si el juego de conversión a propano líquido ha sido

usado, siga las instrucciones provistas con el juego para

convertir el regulador de presión para uso con propano

líquido.

Se debe tener cuidado durante la instalación de la estufa para

no obstruir el flujo de combustión y la ventilación.

Para la operación apropiada, la máxima presión de entrada

al regulador no debe exceder la presión de una columna de

agua de 14 pulgadas. La presión de entrada al regulador

debe ser por lo menos 1 pulgada más grande que la válvula

distribuidora. Ejemplos: Si el regulador ha sido ajustado para gas

natural a 4 pulgadas de presión para la válvula distribuidora, la

presión de entrada debe ser por lo menos de propano 5 pulgadas;

si el regulador ha sido convertido a propano líquido a 10

pulgadas de presión para la válvula distribuidora, la presión de

entrada debe ser por lo menos de 11 pulgadas.

La tubería de suministro de gas debe ser de 1/2" o 3/4" D.I.

Materiales adicionales necesarios

• Válvula de cierre de la línea de gas.

• Sellador de juntas para tuberías que resista la acción del

propano líquido.

• Tubo conducto de metal flexible (1/2" NPT x 3/4" o

1/2" D.I.). Debe ser de diseño certificado AGA/CGA. Debido

a que la tubería rígida impide el movimiento de la estufa,

nosotros recomendamos el uso del conducto flexible (4 a 5

pies de longitud).

• (2)adaptadores para gas (1/2" NPT x 3/4" o 1/2" D.I.)

para conectar la estufa al conducto flexible.

Pasos Normales Para la Instalación

Antes de proceder

Su estufa ha sido ajustada para operar con gas natural

solamente. Algunos modelos son convertibles y vienen

equipados con las instrucciones y las partes necesarias para

efectuar la conversión. Otros modelos tienen un Equipo para

Conversión a LP/Propano, número 80-8802-10, disponible a

través de su distribuidor.

Para convertir su estufa para ser usada con propano

líquido, siga las instrucciones provistas con la estufa o

con el juego de conversión.

Línea central

de la estufa

AREA RECOMENDADA PARA PASAR LA

TUBERIA DE CONEXION A TRAVES DEL

PISO PARA LA VALVULA DE CIERRE.

AREA RECOMENDADA PARA EL

TOMACORRIENTE DE 120V EN

LA PARED DE ATRAS Y AREA

PARA PASAR LA TUBERIA DE

CONEXION A TRAVES DE LA

PARED Y PARA LA VALVULA DE

CIERRE, ES EL AREA EN

SOMBRA.

Borde de

la pared

19

Page 20

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA DE GAS DE 30"(76,2cm)

(Para modelos con Quemadores Superiores Sellados)

3. Selle las aberturas. Selle cualquier abertura en la

pared detrás de la estufa y en el piso debajo de la estufa

una vez que haya instalado la línea de alimentación de

gas.

4. Conecte la estufa a la alimentación de gas.

Para evitar fugas, ponga un sellador para juntas de tuberías

en todas las roscas macho (exteriores) de la tubería.

El regulador se encuentra en una de las dos ubicaciones que se

muestran a continuación.

No permita que el regulador gire sobre

la tubería cuando apriete los conectores. El regulador está

ubicado en el área mostrada más a bajo.

Saque el cajón/panel

para tener acceso

al regulador.

Verificación de la Presión de Gas en la Válvula Distribuidora

Desconecte la estufa y su válvula individual de cierre de la

tubería de suministro de gas durante toda prueba de presión del

sistema, con presiones más altas que 14" de columna de agua

(aproximadamente 1/2" lb./pulg.

2

).

El artefacto debe estar aislado de la tubería de suministro

de gas, lo cual se obtendrá cerrando la válvula individual de

cierre manual, durante toda prueba de presión de suministro del

sistema de gas, a presiones de prueba iguales o menores

que 14" de presión de columna de agua (aproximadamente

1/2" lb./pulg.

2

).

Si fuera necesario verificar la presión de gas de la válvula

distribuidora, conecte un manómetro (calibre de agua) u otro

dispositivo de presión al orificio trasero derecho del quemador

superior. Usando una manguera de goma con un diámetro

interior de aproximadamente 1/4", sostenga el tubo

apretadamente sobre el orificio. Coloque la válvula del quemador

en la posición "ON" (ABIERTA).

Para un control correcto de la presión, tenga dos quemadores

superiores encendidos. Asegúrese de que la presión de

suministro de gas (entrada) sea de por lo menos una pulgada

más alta que la presión especificada para la válvula distribuidora

de la estufa. La presión de suministro de gas no debe ser

nunca más alta que 14" por columna de agua. Cuando está

correctamente ajusta da para gas natural, la presión de la válvula

distribuidora es de 4". (Para propana líquido, la presión es 10".)

Ubicación del regulador de presión en la parte de

astrás de la estufa

a) Instale una válvula manual externa para el cierre del gas en

la tubería de suministro de gas, en un lugar que tenga fácil

acceso fuera de la estufa. Esté seguro de saber como y

cuando cerrar el suministro de gas a la estufa.

b) Instale un adaptador para gas de 1/2" al regulador de

presión.

c) Una el conducto flexible para artefactos al adaptador en el

regulador.

d) Instale un adaptador para gas a la válvula manual externa

de cierre.

e) Una el conducto flexible para artefactos al adaptador en la

válvula de cierre.

f) Asegúrese de que la válvula de cierre en el regulador de

presión esté en la posición "ON" (ABIERTA).

g) Controle que no haya pérdidas. Abra el suministro de gas a

la estufa y use un detector líquido de pérrdidas en todas las

juntas y conexiones para controlar que no haya pérdidas en

el sistema.

No use fuego para comprobar si hay fugas

de gas.

Conducto

Flexible

para

Artefactos

Adaptador

de gas

Válvula

Manual

Externa de

Cierre

Suministro de Gas

Regulateur de Presión

Adaptador de gas

Cerrada

Abierta

Abierta

Cerrada

Válvula de Cierre de Servicio.

Modelos con Sistema de

Encendido Eléctrico

Solamente.

Asegúrese de que la palanca

este en la posición abierta

cuando haya terminado la

instalación.

5. Lea más abajo los detalles para la conexión

eléctrica y conecte la electricidad a la estufa.

Antes de de reparar, desconecte el

suministro de corriente del disyuntor, fusibles o cordón

eléctrico.

Requisitos eléctricos: un circuito individual, que esté

correctamente puesto a tierra y protegido por un fusible de

tiempo diferido de 15 amperios. Vea la placa de serie para el

voltaje apropiado.

Precauciones para Cordones de Extensión: Por razones de

seguridad bajo ciertas condiciones, se recomienda no usar

cordones de extensión. Sin embargo si usted deci-diera usarlos,

es absolutamente necessario que sea un cordón de extensión

trifilar con conexión a tierra aprobado por UL con una capacidad

de conducción equivalente o superior a la del circuito. Estos

cordones de extensión pueden ser obtenidos localmente.