Frigidaire FGEW3065PD Installation Manual

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

Resistance (ohms)

1000 ± 4.0

1091 ± 5.3

1453 ± 8.9

1654 ± 10.8

1852 ± 13.5

2047 ± 15.8

2237 ± 18.5

2697 ± 24.4

Open circuit/infinite resistance

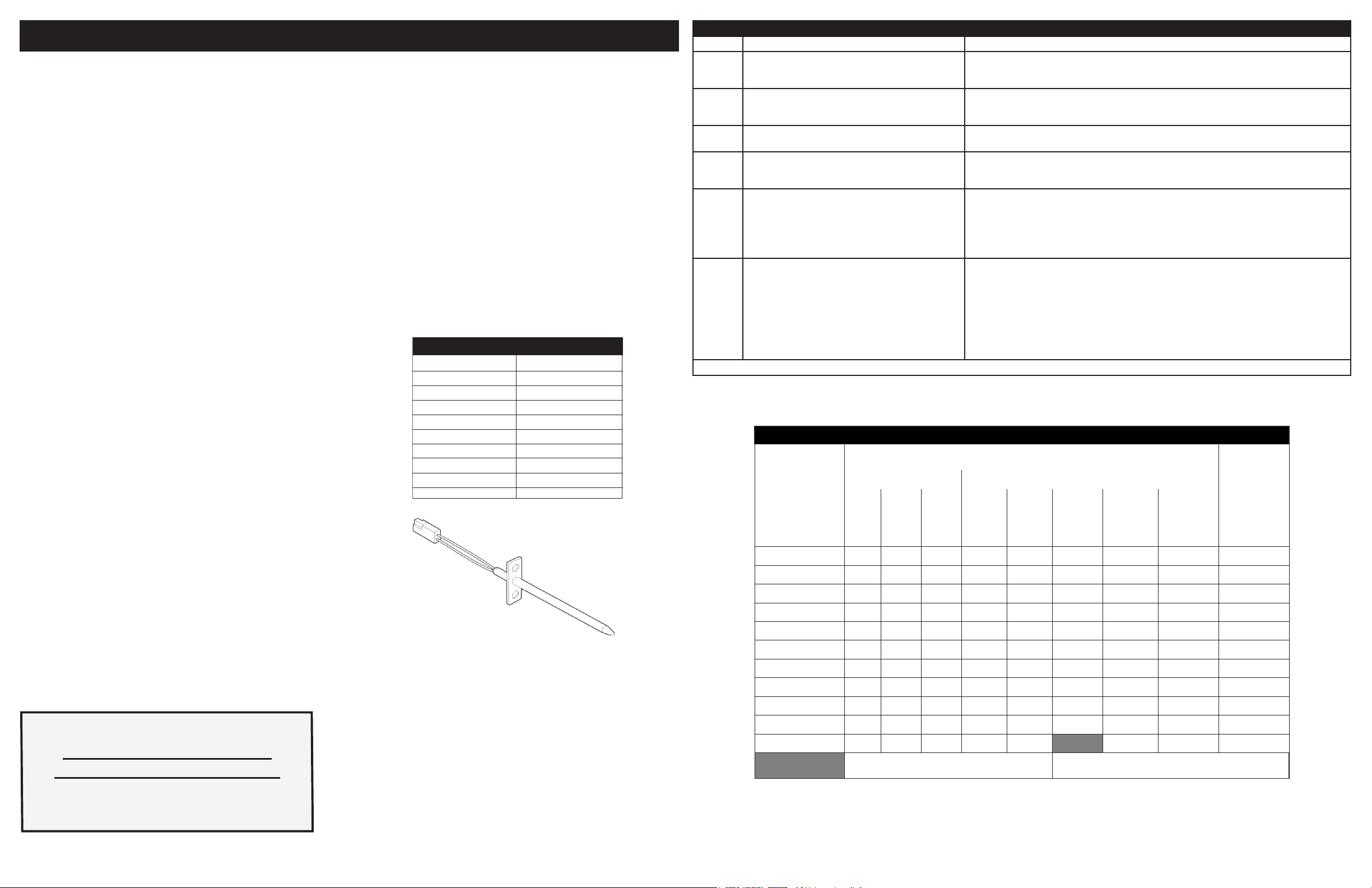

RTD SCALE

Temperature °F (°C)

32 ± 1.9 (0 ± 1.0)

75 ± 2.5 (24 ± 1.3)

250 ± 4.4 (121 ± 2.4)

350 ± 5.4 (177 ± 3.0)

450 ± 6.9 (232 ± 3.8)

550 ± 8.2 (288 ± 4.5)

650 ± 9.6 (343 ± 5.3)

900 ± 13.6 (482 ±7.5)

Probe circuit to case ground

Resistance Temperature Detector

SERVICE DATA SHEET

Appliance with 5xx Electronic Oven Control

NOTICE: This service data sheet is intended for use by persons having electrical

and mechanical training and a level of knowledge of these subjects generally

considered acceptable in the appliance repair trade. The manufacturer cannot

be responsible, nor assume any liability, for injury or damage of any kind arising

from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important

that safe servicing practices be observed. The following are some, but not all,

examples of safe practices.

1. Do not attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric

outlet, trip circuit breaker to Off, or remove fuse.

3. Never interfere with the proper installation of any safety device.

4. Use only replacement parts specied for this appliance. Substitutions may

not comply with safety standards set for home appliances.

5. Grounding: The standard color coding for safety ground wires is green

or green with yellow stripes. Ground leads are not to be used as current

carrying conductors. It is extremely important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a potential hazard.

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are ade-

quately spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and se-

curely reassembled.

• All panels are properly and securely reassembled.

OVEN CALIBRATION

Set the electronic oven control for normal baking at 350°F. Allow oven to preheat

to set temperature. Obtain an average oven temperature after a minimum of ve

cycles. Press the STOP key to end the Bake mode.

TEMPERATURE ADJUSTMENT

1. While in a non-cooking mode, press and hold the Bake key for 6 seconds.

2. The current calibration offset (temperature adjustment) should appear in the

temperature display.

3. Use the number keys (0-9) to enter the desired amount of adjustments (up

to 35°F).

4. Press the Self Clean key to change the sign of the adjustment to a (-), if

necessary. A positive adjustment will not display a sign.

5. Once the desired adjustment (-35° to 35° F) has been entered, press the

Start key to accept the change or the Cancel key to reject the change.

Note: Changing calibration affects all Baking modes. The adjustments made will

not change the self-cleaning temperature.

2-SPEED COOLING FAN

The EOC controls the speed of the cooling fan. The cooling fan is activated at

low speed during any cooking function and will remain on until the oven is cooled

down. The high speed is activated during the broil (with open door) and during

clean cycles only when the temperature is above apporximately 575°F/302°C.

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Code Condition / Cause Suggested Corrective Action

F10 Control has sensed a potential runaway oven con-

F11 Shorted Key: A key has been detected as pressed

F13 Control’s internal checksum may be corrupted. • Press CLEAR key. - Disconnect power, wait 10 seconds, and reapply power. If fault

F14 Misconnected at cables. No communication be-

F30

or

F31

F90

F94

Note: Generally speaking, F1X implies a control failure, F3X an oven probe problem, and F9x a latch motor problem.

dition, control may have shorted relay, and/or RTD

sensor probe may have gone bad.

(for a long period). Will be considered a shorted key

alarm and will terminate all oven activity.

tween oven and controls.

Open RTD sensor probe/ wiring problem. Note: EOC

may initially display an “F10,” thinking a runaway

condition exists.

Shorted RTD sensor probe /wiring problem.

to

Door motor mechanism failure.

Check RTD sensor probe and replace, if necessary. If oven is overheating, disconnect power.

If oven continues to overheat when power is reapplied, replace the Electronic Oven Control

(EOC).

1. Press STOP key.

2. If the problem persists, replace the EOC.

returns upon power-up, replace EOC.

1. Disconnect power. Verify the at cable connection between the touch panel or membrane

and the EOC on P12 and P13.

2. If the problem persist, replace the EOC.

1. Check wiring in probe circuit for possible open or short condition.

2. Check RTD resistance at room temperature (compare to probe resistance chart). If resistance does not match the chart, replace the RTD sensor probe.

3. Let the oven cool down and restart the function.

4. If the problem persists, replace the EOC.

1. Turn off power for 10 seconds, then turn on power. Test the door latch again (try to start a

Clean cycle).

2. If it fails, check wiring of Lock Motor, Lock Switch and Door Switch circuits.

3. Unplug the lock motor from the board and apply power (L1) directly to the Lock Motor. If

the motor does not rotate, replace Lock Motor Assembly.

4. Check Lock Switch for proper operation (do the contacts open and close, check with ohm-

meter). The Lock Motor may be powered as in above step to open and close Lock Switch.

If the Lock Switch is defective, replace Motor Lock Assembly.

5. If all above steps fail to correct situation, replace the EOC.

p/n 807153903 Rev A (16/07)

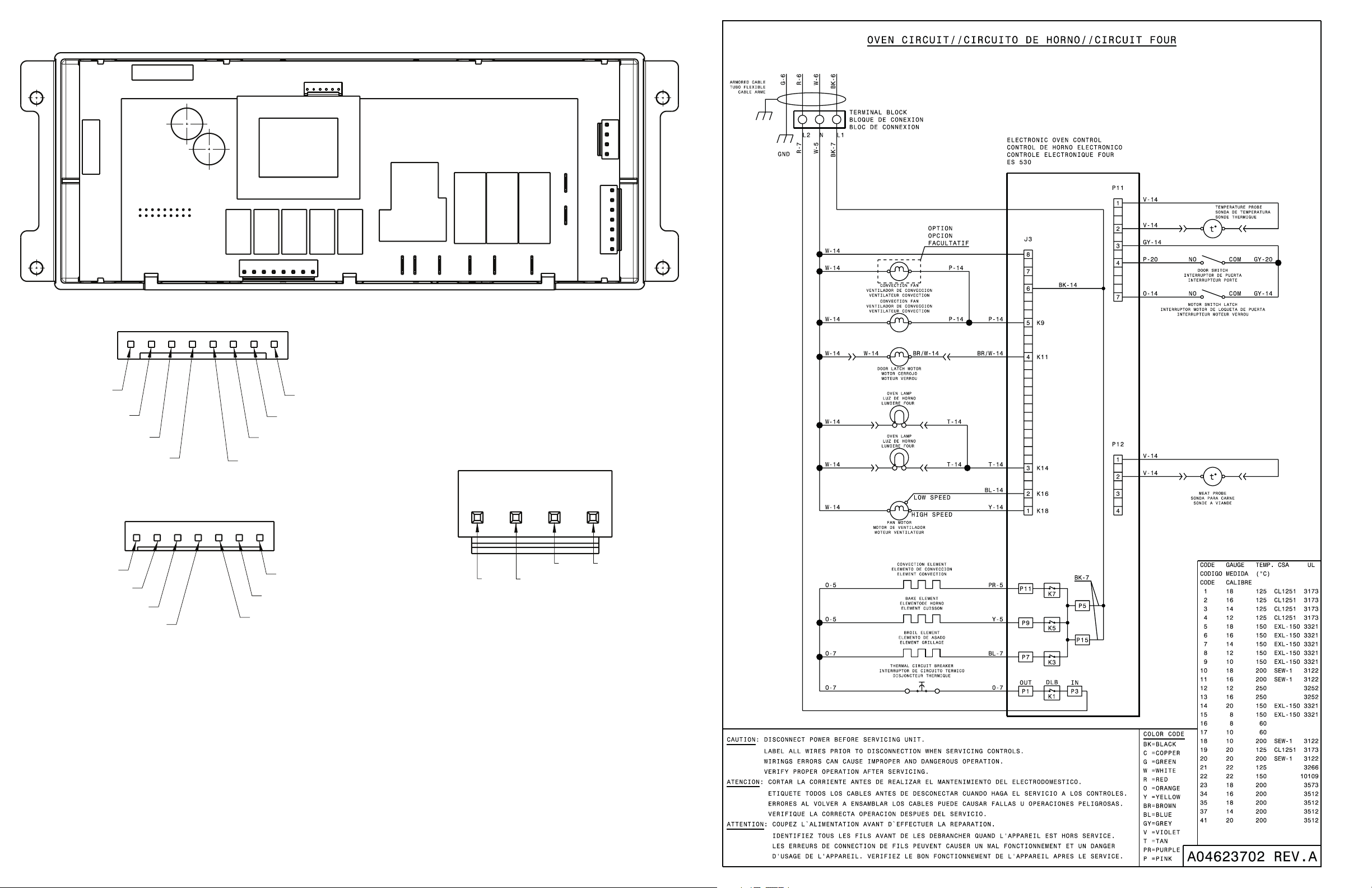

OVEN CIRCUIT ANALYSIS MATRIX

ON RELAY BOARD ON DISPLAY

ELEMENTS

Bake P9BroilP7Conv.

P11

Preheat X X X X X

Bake X X X* X* X

Broil X X X

Convection Bake X X X X X

Convection Roast X X X X X

Convection Broil X X X

Clean X X X X

Locking/Unlocking X

Light X

Door Open X

Door Closed X

=Relay will operate only in this condition *Convection element and fan are used for the rst ride of

Light

J3-3

Conv.

Fan

P2-7

Door

Motor

3-4

temperature

Low Speed

Cooling

Fan

J3-2

High Speed

Cooling Fan

J3-1

BOARD

Door Switch

P11-4/P11-3

J3 HEADER

DOOR SWITCH

P2 HEADER

K9 K11 K14 K16 K18

J3 HEADER

K1 K7 K5 K3

P3

P17 P1

P11

P9

P7

P15

P5

P12 MEAT PROBE

CONNECTOR

P11 HEADER

J3 CONNECTIONS

8

76

N

NC

L1

NC OR CONVECTION FAN

P11 CONNECTIONS

7

6

MOTOR DOOR

LATCH SWITCH

NC

NC

54

5

43

3

2

1

COOLING FAN HI

COOLING FAN LOW

OVEN LIGHT

MOTOR DOOR LATCH MDL

2

1

TEMPERATURE PROBE

TEMPERATURE PROBE

EXTERNAL SWITCH RETURN

P1 - L2 OUT

P3 - L2 IN

P5 - L1 INPUT

P7 - BROIL

P9 - BAKE

P11 - CONV ELEMENT

P15 - L1 INPUT

P17 - L2 IN

P12 MEAT PROBE CONNECTOR

GND

234

MEAT_PRB2

GND

1

MEAT_PRB1

Loading...

Loading...