Electronic Oven Control (EOC) Fault Code Descriptions

Code Condition / Cause Suggested Corrective Action

F10 Control has sensed a potential runaway oven con-

dition, control may have shorted relay, and/or RTD

sensor probe may have gone bad.

Check RTD sensor probe and replace, if necessary. If oven is overheating, disconnect

power. If oven continues to overheat when power is reapplied, replace the Electronic Oven

Control (EOC).

F11 Shorted Key: A key has been detected as pressed

(for a long period). Will be considered a shorted key

alarm and will terminate all oven activity.

1. Press STOP key.

2. If the problem persists, replace the EOC.

F13 Control’s internal checksum may be corrupted. • Press CLEAR key. - Disconnect power, wait 10 seconds, and reapply power. If fault

returns upon power-up, replace EOC.

F14 Misconnected fl at cables. No communication be-

tween oven and controls.

1. Disconnect power. Verify the fl at cable connection between the touch panel or mem-

brane and the EOC on P12 and P13.

2. If the problem persist, replace the EOC.

F30

or

F31

Open RTD sensor probe/ wiring problem. Note: EOC

may initially display an “F10,” thinking a runaway

condition exists.

Shorted RTD sensor probe /wiring problem.

1. Check wiring in probe circuit for possible open or short condition.

2. Check RTD resistance at room temperature (compare to probe resistance chart). If

resistance does not match the chart, replace the RTD sensor probe.

3. Let the oven cool down and restart the function.

4. If the problem persists, replace the EOC.

F90

to

F94

Door motor mechanism failure.

1. Turn off power for 10 seconds, then turn on power. Test the door latch again (try to

start a Clean cycle).

2. If it fails, check wiring of Lock Motor, Lock Switch and Door Switch circuits.

3. Unplug the lock motor from the board and apply power (L1) directly to the Lock Mo-

tor. If the motor does not rotate, replace Lock Motor Assembly.

4. Check Lock Switch for proper operation (do the contacts open and close, check with

ohmmeter). The Lock Motor may be powered as in above step to open and close

Lock Switch. If the Lock Switch is defective, replace Motor Lock Assembly.

5. If all above steps fail to correct situation, replace the EOC.

Note: Generally speaking, F1X implies a control failure, F3X an oven probe problem, and F9x a latch motor problem.

Service Data Sheet

Appliance with Electronic Oven Control

NOTICE: This service data sheet is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects generally consid-

ered acceptable in the appliance repair trade. The manufacturer cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the use

of this data sheet.

IMPORTANT NOTE: This unit includes an EOC (electronic oven control). This board is not fi eld-repairable.

Safe Servicing Practices

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing practices be observed. The following are some, but not all, exam-

ples of safe practices.

1. Do not attempt a product repair if you have any doubts as to your ability to complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric outlet, trip circuit breaker to Off, or remove fuse.

3. Never interfere with the proper installation of any safety device.

4. Use only replacement parts specifi ed for this appliance. Substitutions may not comply with safety standards set for home appliances.

5. Grounding: The standard color coding for safety ground wires is green or green with yellow stripes. Ground leads are not to be used as current carrying con-

ductors. It is extremely important that the service technician reestablish all safety grounds prior to completion of service. Failure to do so will create a potential

hazard.

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, high-temperature components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely reassembled.

• All panels are properly and securely reassembled.

Oven Calibration

Set the electronic oven control for normal baking at 350°F. Allow oven to preheat to set temperature. Obtain an average oven temperature after a minimum of fi ve

cycles. Press the STOP key to end the Bake mode.

Temperature Adjustment

1. While in a non-cooking mode, press and hold the Bake key for 6 seconds.

2. The current calibration offset (temperature adjustment) should appear in the temperature display.

3. Use the number keys (0-9) to enter the desired amount of adjustments (up to 35°F).

4. Press the Self Clean key to change the sign of the adjustment to a (-), if necessary. A positive adjustment will not display a sign.

5. Once the desired adjustment (-35° to 35° F) has been entered, press the Start key to accept the change or the Cancel key to reject the change.

Note: Changing calibration affects all baking modes. The adjustments made will not change the self-cleaning temperature.

2-Speed Cooling Fan

The EOC controls the speed of the cooling fan. The cooling fan is activated at low speed during any cooking function and will remain on until the oven is cooled down.

The high speed is activated during the broil (with open door) and during clean cycles only when the temperature is above apporximately 575°F/302°C.

p/n 807153901 Rev A (13/1)

Data Sheet Abbreviations and Terminology

EOC - Electronic Oven Control

LED - Light-Emitting Diode

MDL - Motor Door Latch

DLB - Double Line Break

RTD - Resistance Temperature Detector/Oven Probe

REPLACE CONTENTS IN BAG

OR DESTROY THE CONTENTS

DO NOT REMOVE THIS BAG

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

IMPORTANT

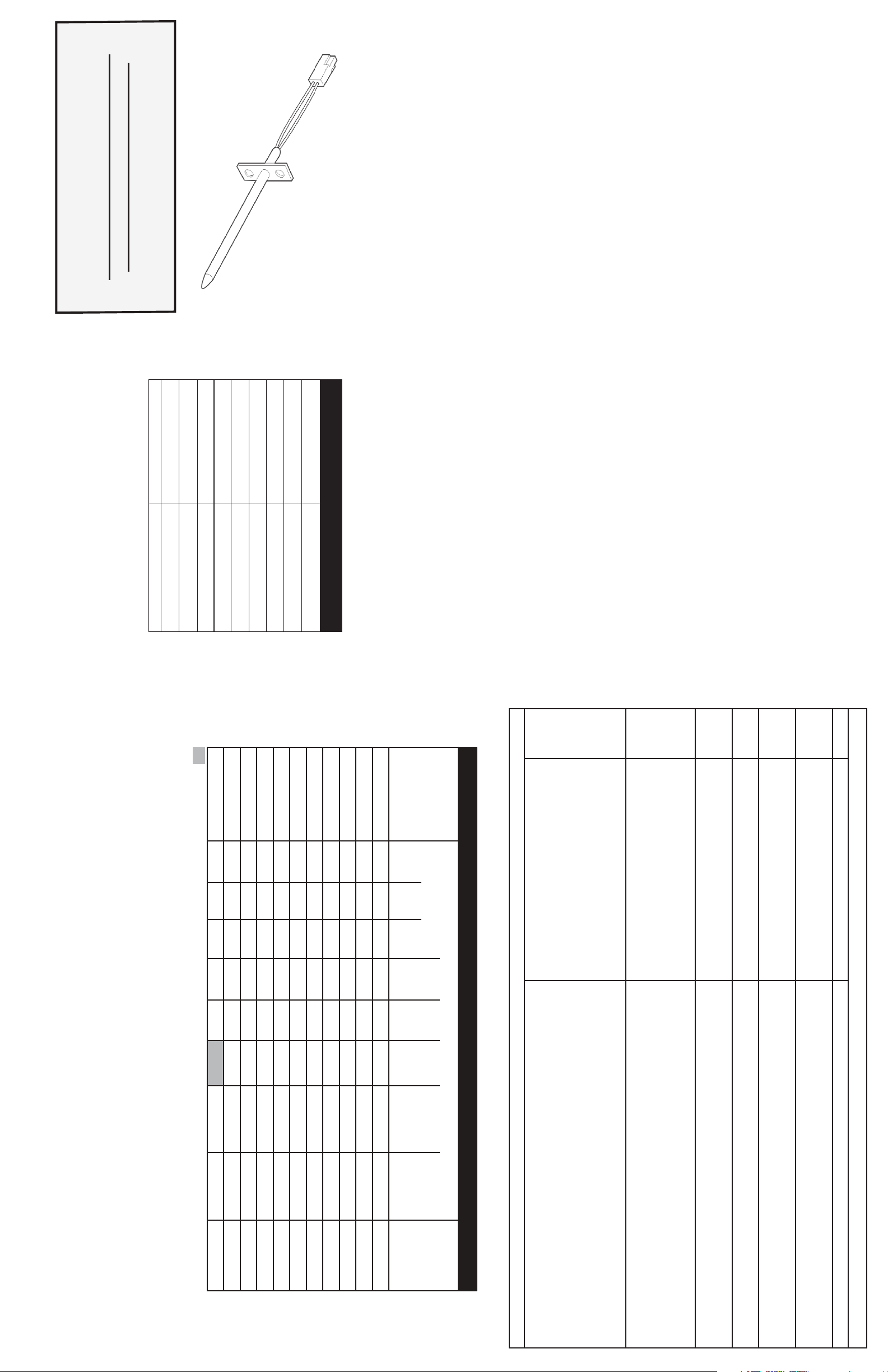

Resistance Temperature Detector

Probe circuit to case ground

900 ± 13.6 (482 ±7.5)

650 ± 9.6 (343 ± 5.3)

Open circuit/infinite resistance

2697 ± 24.4

2237 ± 18.5

450 ± 6.9 (232 ± 3.8)

550 ± 8.2 (288 ± 4.5)

1852 ± 13.5

2047 ± 15.8

250 ± 4.4 (121 ± 2.4)

350 ± 5.4 (177 ± 3.0)

1654 ± 10.8

1453 ± 8.9

75 ± 2.5 (24 ± 1.3)

Temperature °F (°C)

32 ± 1.9 (0 ± 1.0)

RTD SCALE

Resistance (ohms)

1000 ± 4.0

1091 ± 5.3

Locking / Unlocking X

Light X

Door Open X

Door Closed X

Relay will operate in this condition only * Convection element and fan are used for the first rise of temperature.

Convection Broil X X X

Clean X X X X

Convection Roast X X X X X

Broil X X X

Convection Bake X X X X X

Bake X X X* X* X

Preheat X X X X X

Bake

P9

ELEMENTS

Broil

P7

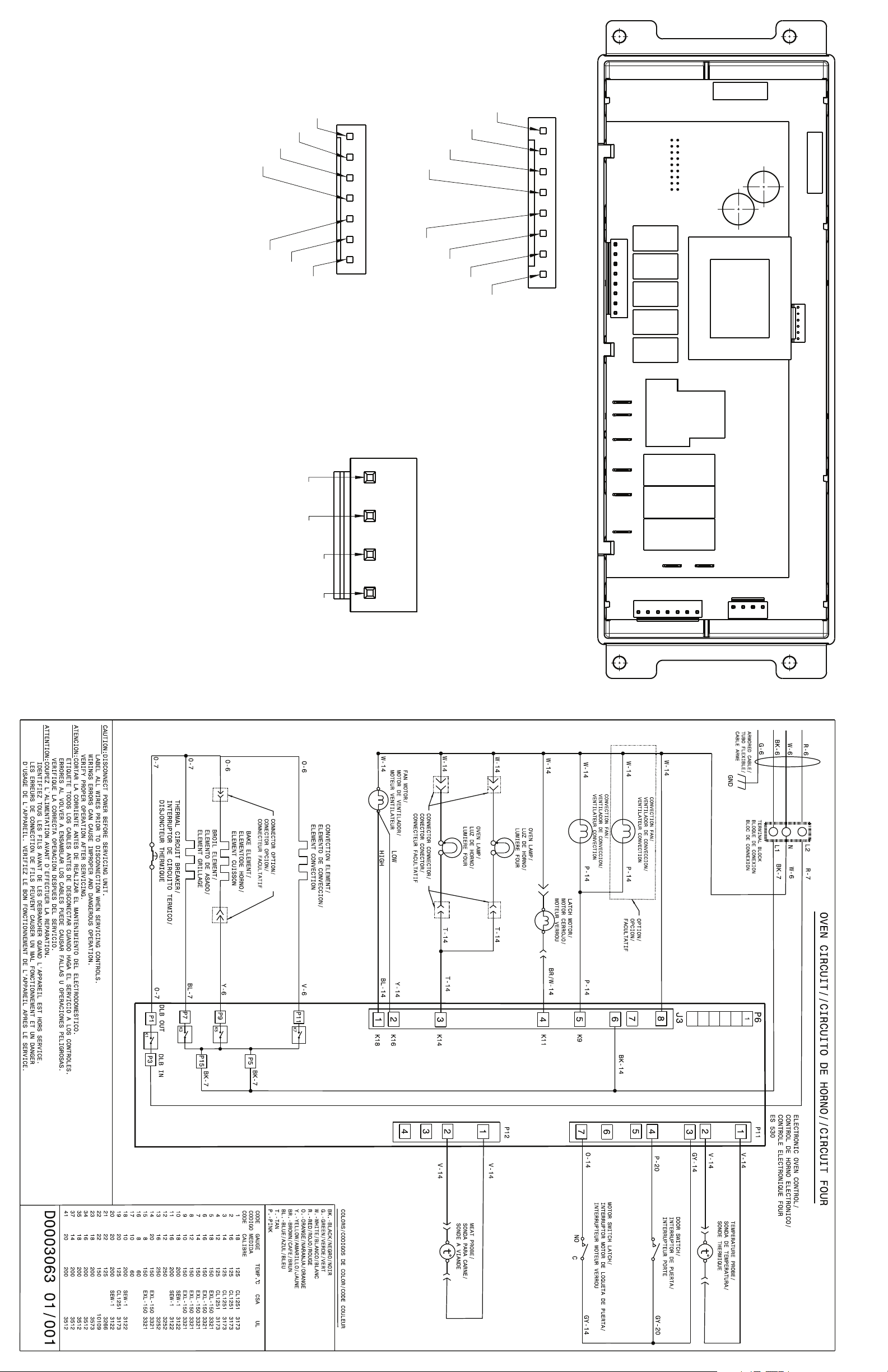

OVEN CIRCUIT ANALYSIS MATRIX

Conv.

P11

Oven

Light

J3-3

P2-7

Fan

Conv.

On Relay Board On Display

Motor

Door

J3-4

Cooling Fan

Low Speed

J3-2

Cooling Fan

High Speed

J3-1

P11-4 / P11-3

Door Switch

Board

General Troubleshooting Schematic

LATCH SWITCH

DOOR SWITCH

NC

NC

MOTOR DOOR

7

P11 CONNECTIONS

6

5

43

NC OR CONVECTION FAN

N

NC

L1

8

76

54

J3 CONNECTIONS

J3 HEADER

2

EXTERNAL SWITCH RETURN

1

TEMPERATURE PROBE

TEMPERATURE PROBE

4

GND

MEAT_PRB2

23

GND

3

MOTOR DOOR LATCH MDL

OVEN LIGHT

2

1

COOLING FAN LOW

COOLING FAN HI

P12 MEAT PROBE CONNECTOR

P1 - L2 OUT

P3 - L2 IN

P5 - L1 INPUT

P7 - BROIL

P9 - BAKE

P11 - CONV ELEMENT

P15 - L1 INPUT

P17 - L2 IN

K9 K11 K14 K16 K18

J3 HEADER

P3

P17 P1

P11

P9

P7

P5

P2 HEADER

K1 K7 K5 K3

P15

MEAT_PRB1

1

P11 HEADER

P12 MEAT PROBE

CONNECTOR

Description des Codes d’Erreur

Code Condition / Cause Action corrective suggérée

F10 La commande a décelée une condition possible

d’emballement, la commande présente un relais en

court-circuit, et (RTD) mauvais fonctionnement de la

sonde.

Vérifi ez la sonde RTD et remplacez-la, si nécessaire. Si le four surchauffe, débranchez-le.

Si le four continue de surchauffer, remplacez le contrôleur de four électronique.

F11 Touche en court-circuit: Si la commande détecte

qu’une touche est appuyée pendant une longue péri-

ode de temps. Elle sera considérée en court-circuit.

La commande génère un signale sonore et éteint le

four.

1. Appuyez sur ANNULER.

2. Si le problème persiste, remplacez le EOC.

F13 La mémoire interne de la commande est corrompue. • Appuyez sur ANNULER. Coupez le courant, attendez 10 secondes, et rétablissez le

courant. Si l’erreur réapparaît, remplacez le EOC.

F14 Câbles plats mal branchés. No communication pas

entre le four et les contrôleurs.

1. Coupez le courant électrique. Vérifi ez la connexion du câble plat entre le panneau

des touches et le panneau EOC à la tige P12 et P13.

2. Si le problème persiste, remplacez le EOC.

F30

ou

F31

Problème avec le fi lage de sonde ou fi lage ouvert.

Note: EOC affi che initialement le code “F10”, signifi -

ant qu’il décèle une condition d’emballement.

Court circuit de la sonde/problème de fi lage.

1. Vérifi ez si le fi lage de la sonde qu’il n’est pas en court-circuit.

2. Vérifi ez la résistance RTD à la température de la pièce (comparez la valeur avec

le tableau). Si celle-ci ne concorde pas avec le tableau, remplacez le senseur de la

sonde RTD.

3. Laissez refroidir le four et redémarrez la fonction.

4. Si le problème persiste, remplacez le EOC.

F90

à

F94

Système de verrouillage de porte défectueux.

1. Coupez le courant électrique pendant 10 secondes et réappliquez le courant par la

suite.

2. Vérifi ez le fi lage du moteur verrou, de l’interrupteur et le circuit de l’interrupteur de la

porte.

3. Débranchez le moteur du EOC et branchez (L1) directement au moteur. Si le moteur

ne tourne pas, remplacez l’assemblage du moteur.

4. Vérifi ez si les interrupteurs fonctionnent correctement. (Est-ce qu’il permet de fermer

et d’ouvrir la porte? Vérifi ez avec un ohm mètre). Le moteur verrou doit être réactivé

tel qu’indiqué à l’étape précédente afi n que l’interrupteur s’ouvre et se ferme. Si

l’interrupteur verrou est défectueux, remplacez-le.

5. Si toutes les étapes mentionnées ci-haut ont échouées, remplacez le EOC.

Note: Généralement F1X signifi e un problème avec le contrôleur, F3X un problème avec la sonde, et F9X un problème avec le moteur verrou de la porte.

Feuillet de Données Techniques

Électroménager avec commande de four électronique

AVIS: Cette feuille de données d’entretien est destinée aux personnes ayant reçu une formation en électricité et en mécanique, et qui possèdent un niveau de con-

naissance jugé acceptable dans l’industrie de réparation des appareils électroménagers. Le fabricant ne peut être tenu responsable, ni assumer aucune responsabil-

ité, pour toute blessure ou dommage de quelque nature que ce soit pouvant résulter de l’utilisation de cette feuille de données.

NOTEs IMPORTANTES: Cet appareil inclut un contrôleur de four électronique. Le tableau de contrôle n’est pas réparable sur place.

Pratiques d’entretien Sécuritaires

Pour éviter tout risque de blessure et/ou dommage matériel, il est important que des pratiques d’entretien sécuritaires soient suivies. Voici quelques exemples de

pratiques sécuritaires.

1. N’essayez jamais de réparer un appareil si vous ne croyez pas avoir les compétences nécessaires pour le faire de manière satisfaisante et sécuritaire.

2. Avant de procéder au service d’entretien ou de déplacer tout appareil ménager, débranchez le cordon d’alimentation de la prise électrique, réglez le disjoncteur

de circuit à OFF, ou enlevez le fusible et fermez le robinet d’alimentation en gaz.

3. N’entravez jamais l’installation adéquate de tout dispositif de sécurité.

4. Utilisez que les pièces de remplacement énumérées dans le catalogue pour cet appareil. La moindre substitution risque de ne pas être conforme aux normes de

sécurité établies pour les appareils électroménagers.

5. Mise à la Terre: La couleur de codage standard des conducteurs de mise à la terre de sécurité est verte ou verte à barres jaunes. Les conducteurs de mise à

la terre ne doivent pas être utilisés comme conducteurs de courant. Il est d’une importance capitale que le technicien d’entretien complète toutes les mises à la

terre de sécurité avant de terminer le service. Si cette recommandation n’est pas suivie à la lettre, il en résultera des risques pour les personnes et les biens.

6. Avant de retourner le produit au service de réparation ou d’entretien, assurez-vous que:

• Toutes les connexions électriques sont correctes et sécuritaires.

• Tous les conducteurs électriques sont correctement préparés et à l’abri des bords tranchants, des composants à température élevée, et des parties mo-

biles.

• Toutes les bornes électriques, connecteurs, réchauffeurs, etc. dénudés sont espacés convenablement loin de toute pièce en métal et des panneaux.

• Toutes les mises à la terre de sécurité (interne et externe) sont correctement ré-assemblées de façon sécuritaire.

• Tous les panneaux sont correctement et fermement remontés.

Étalonnage du Four

Réglez le régulateur électronique de four pour une cuisson normale à 350 ºF (177 ºC). Comptez-vous de four préchauffer choisir températures. Vous devez obtenir

une température moyenne de four après 5 cycles. Appuyez sur la touche Stop (arrêt) pour mettre fi n au mode de cuisson.

Réglage de la Température

1. Assurez-vous de ne sélectionner aucun mode de cuisson, puis appuyez sur la touche Bake (cuisson au four) et maintenez-la enfoncée pendant 6 secondes.

2. L’affi cheur de température indique l’écart actuel de calibration (ajustement de température).

3. Utilisez les touches numériques (0 à 9) pour entrer l’ajustement désiré (jusqu’à 35 ºF/19 ºC).

4. Appuyez sur la touche Self Clean (autonettoyage) pour ajouter le symbole à (-) à l’ajustement, si nécessaire. Aucun signe n’apparaît si l’ajustement est positif.

5. Lorsque vous avez fait le réglage désiré (-35 à 35 ºF / -18 à 18 ºC), appuyez sur la touche Start (mise en marche) pour confi rmer le choix ou Cancel (annuler)

6. pour l’annuler.

Remarque: La modifi cation de la calibration affecte tous les modes de cuisson. Les ajustements n’infl uent pas sur la température du cycle d’autonettoyage.

2-Vitesse Ventilateur rafraîchissant

Les contrôleurs de four électronique dirige vitesse de le ventilateur rafraîchissant. Le ventilateur rafraîchissant activer à basse vitesse vitesse pendant une cui-

sson fonction, et il reste allumé jusqu’à ce que du four refroidir. Le haut débit activer pendant grillage (avec la porte ouverte) et pendant clean cycles seul quand la

température est plus que approximativement 575ºF/302ºC.

p/n 807153901 Rev A (13/1)

Abréviation et terminologie de la fi che technique

DLB - Ligne Double interrompue

EOC - Contrôleur de four électronique

LED - Diode électroluminescente

MDL - Moteur verrou de la porte

RTD - Sonde de température

PS - Carte d’alimentation électrique (PS1, PS2, etc)

TCO - Coupe-circuit thermique (aussi «disque thermique» ou «limiteur thermique»)

VSC - Commande de vitesse variable

TABLEAU D’ANALYSE DU CIRCUIT

À Bord Du Relais Conseil Sur

L’affi chage

ELEMENTS

Cuire

P9

Griller

P7

Conv.

P11

Lampe

J3-3

Vent. Á

Conv

P2-7

Interr. De

porte 3-4

Vent.

Basse

Vitesse

J3-2

Vent. Haute

Vitesse

J3-1

Interrupteur de

porte

P11-4/P11-3

Préchauffage X X X X X

Cuire X X X* X* X

Griller X X X

Cuire á conv. X X X X X

Rôtissage á conv. X X X X X

Griller á conv. X X X

Nettoyer X X X X

Verrouil./deverrouil. X

Lampe X

Porte ouverte X

Porte fermée X

=Relais fonctionnera dans cette seule condition *Alterne avec l’élément de cuisson au four

DANS LE SAC

DÉTR

N’ENLEVEZ P

CONTIENT LES SCHÉMAS DE CÂBLAGE ET

LES INFORMATIONS DE RÉPARATION

REMETTRE LE CONTENU

UISEZ P

IMPORTANT

AS SON CONTENU

AS CE SAC OU NE

Circuit de la sonde mise à la

900 ± 13,6 (482 ±7,5)

650 ± 9,6 (343 ± 5,3)

terre à la caisse

Circuit ouvert/résistance infinie

2 697 ± 24,4

2 237 ± 18,5

550 ± 8,2 (288 ± 4,5)

2 047 ± 15,8

450 ± 6,9 (232 ± 3,8)

1 852 ± 13,5

350 ± 5,4 (177 ± 3,0)

1 654 ± 10,8

250 ± 4,4 (121 ± 2,4)

1 453 ± 8,9

75 ± 2,5 (24 ± 1,3)

1 091 ± 5,3

Température °F (°C)

32 ± 1,9 (0 ± 1,0)

ÉCHELLE DU DÉTECTEUR DE TEMPÉRATURE

À RÉSISTANCE

Résistance (ohms)

1 000 ± 4,0

Schéma de dépannage général

É

É

À

É

INTERRUPTEUR

DE PORTE

NC

NC

INTERRUPTEUR DU

LOQUET MOTORISÉ

DE LA PORTE

7

P11 CONNEXIONS

6

5

43

NC O VENT.CONVECTION

N

NC

L1

8

76

54

J3 CONNEXIONS

J3 HEADER

D

TECTEUR DE TEMP

RATURE

R

SISTANCE

2

RETOUR DE L’INTERR, EXTERNE

1

MDL

SONDE DE TÉMP

SONDE DE TÉMP

P12 SONDE THERMIQUE CONNECTEUR

4

GND

SONDE THERM 2

23

GND

LAMPE DU FOUR

VENT. BASSE

VENT. HAUTE

P7 - GRIL

P9 - CUISSON

P11 - ÉLÉMENT DE CONV

P15 - L1 INPUT

P17 - ENTRÉE L2

3

2

1

P1 - SORTIE L2

P3 - ENTRÉE L2

P5 - L1 INPUT

K9 K11 K14 K16 K18

J3 HEADER

P3

P17 P1

P11

P9

P7

P5

P2 HEADER

K1 K7 K5 K3

P15

SONDE THERM 1

1

P12 SONDE THERMIQUE

CONNECTEUR

P11 HEADER

Loading...

Loading...