INSTALLATION INSTRUCTIONS

GAS BUILT-IN OVEN

REGULAR AND SELF-CLEANING MODELS

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER

IMPORTANT NOTE TO INST ALLER: BEFORE YOU BEGIN - READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY.

BE SURE TO LEAVE THESE INSTRUCTIONS WITH THE CONSUMER.

IMPORTANT NOTE TO CONSUMER: KEEP THESE INSTRUCTIONS WITH YOUR USE AND CARE BOOK FOR FUTURE

REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

SAVE THESE INSTRUCTIONS FOR LOCAL INSPECTORS.

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or the gas supplier.

IMPORT ANT SAFETY INSTRUCTIONS

NO ATTEMPT SHOULD BE MADE TO

OPERATE BUILT-IN OVEN DURING A

POWER FAILURE.

IMPORTANT

Remove all packing material and literature from the oven

and broiler compartments before connecting gas and

electrical supply.

A WIRING DIAGRAM FOR THIS

APPLIANCE IS ENCLOSED IN THE

ENVELOPE OVER THE APPLIANCE.

318201502 (9810) Rev. APrinted in Canada

Installation of this appliance must conform with local codes, or in

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1 - latest edition.

This appliance has been design certified by the American Gas

Association. As with any appliance using gas and generating

heat, there are certain safety precautions you should follow.

You’ll find them in your Use and Care book. Read it carefully.

• Be sure your appliance is installed properly by qualified installer

or service technician.

• This appliance must be electrically grounded in accordance

with local codes, or in their absence, with the National

Electrical Code ANSI/NFPA No. 70-latest edition. See Grounding Instruction on page 3.

• The installation of appliances designed for manufactured

(mobile) home installation must conform with Manufactured

Home Construction and Safety Standard, Title 24CFR, Part

3280 [Formely the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD (Part 280)] or when such

standard is not applicable, the Standard for Manufactured

Home Installation 1982 (Manufactured Home Sites, Communities and Set-ups), ANSI Z225.1/NFPA 501A-latest edition, or

with local codes.

IMPORTANT SAFETY INSTRUCTIONS

• Be certain all packing materials are removed from the unit

before operating, to prevent fire or smoke damage should

the packing material ignite.

• Do not leave children alone in the kitchen when the

appliance is in use. They should not be allowed to sit or

stand on any part of the appliance, as injury or burns could

result. Keep children from touching the oven door or glass

window when the appliance is operating, as the door or

window could get hot enough to cause serious burns.

• Caution: Do not store items or food of interest to children

in cabinets above the appliance. Children could be

seriously burned or injured if they climb on an appliance to

reach these items.

• Remove broiler tray and other utensils from oven before

using the self-clean cycle.

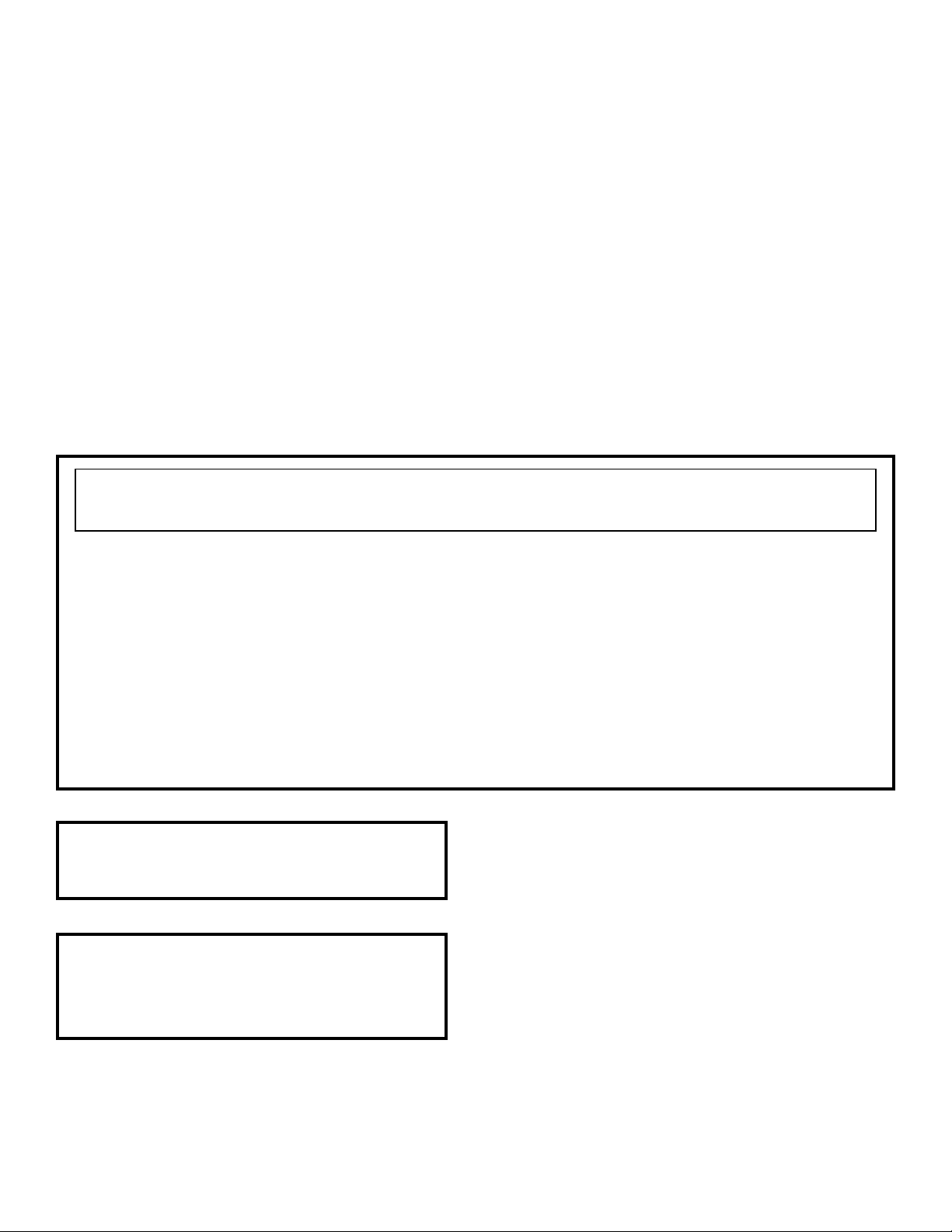

DIMENSIONS AND CLEARANCES

This unit is designed to fit various cutout sizes from

a minimum of 37 1/2” to 39”. See page 4 for proper

height adjustment.

• Do not use the oven as a store space. This creates a

potentially hazardous situation.

• The appliance requires fresh air for proper burner combustion. Do not obstruct the flow combustion air at the oven

vent or around the base or beneath the lower front panel

of the appliance. Avoid touching the event openings or

nearby surfaces, as they may become hot.

• Remember, your oven is not designed to heat your

kitchen. Such abuse could result in fire and/or damage to

the unit and will void your warranty .

• Do not store or use gasoline or other flammable vapors

and liquids near this or any other appliance. Explosions or

fires could result.

ADDITIONAL SAFEGUARDS

• Do not install wall oven beneath the work counter .

• The flue discharge shall not be located below the

36 inch level.

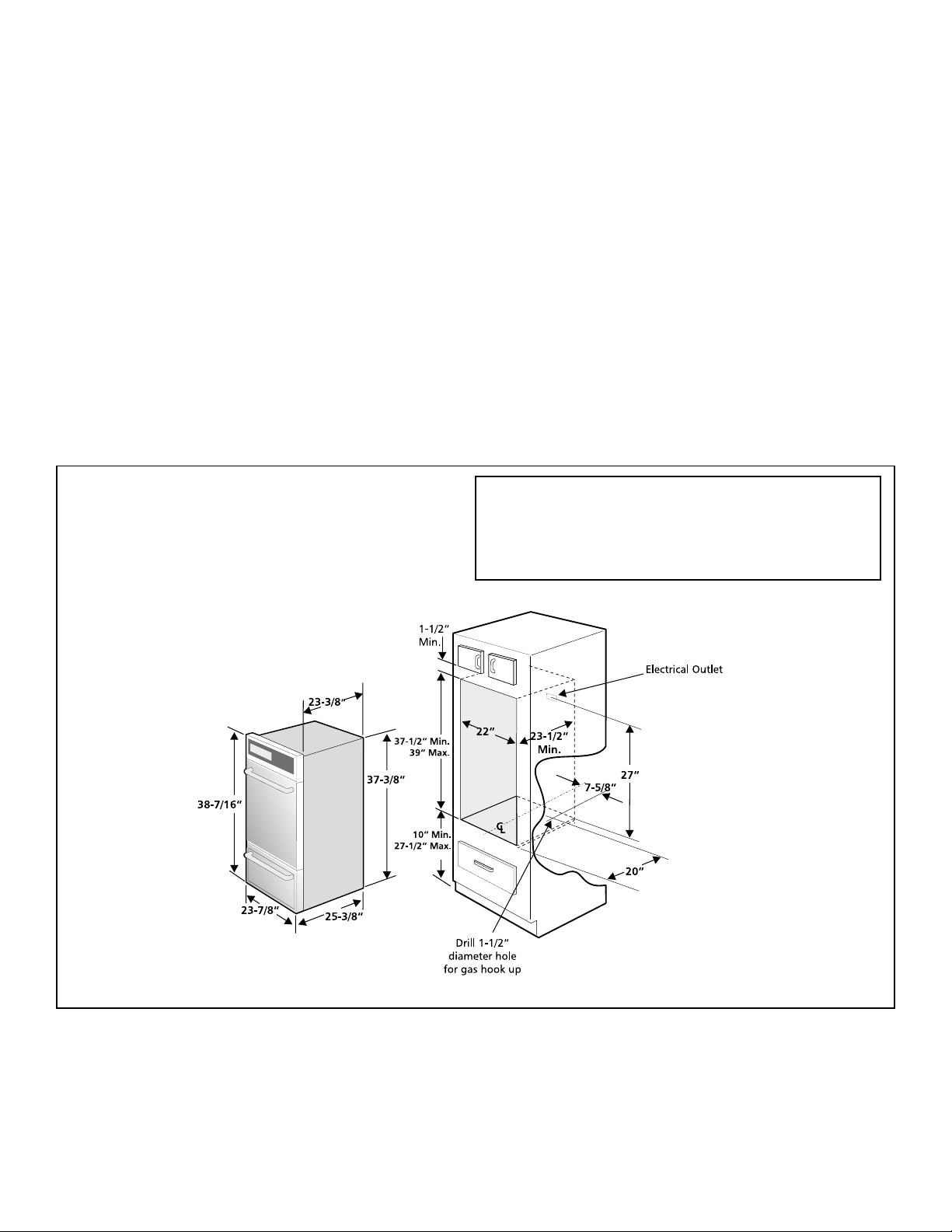

Allow at least 19 3/8” clearance for complete oven

door opening as shown in FIGURE 1.

2

ALTERNATE CONSTRUCTION

Installation instructions for installing a 1 1/2 cavity

oven into an existing 2 cavity opening with dimensions 42 1/8” H. by 22 1/2” W.

2”

22 1/2”

42-1/8”

3”

1”

PROVIDE ADEQUA TE GAS SUPPLY

This oven is designed to operate on natural gas at 4” of

manifold pressure or on LP gas at 10” of manifold pressure.

It is shipped from the factory set for natural gas. If it is to be

used with LP gas, adjustments described on page 5 must be

made.

A convertible pressure regulator is connected in series with

the manifold of the oven and must remain in series with the

supply line regardless of whether natural or LP gas is being

used.

FOR PROPER OPERA TION, THE MAXIMUM INLET PRESSURE

TO THE REGULATOR MUST BE NO MORE THAN 14” OF

WATER COLUMN PRESSURE.

For checking the regulator, the inlet pressure must be at

least 1” (or 3.4 KPA) greater than the regulator manifold

pressure setting. If the regulator is set for 4” of manifold

pressure, the inlet pressure must be at least 5”. If the

regulator is set for 10”, the inlet pressure must be at least

11”.

1. Height adjuster - lower height adjuster 1”.

2. If width opening is too wide to secure unit to cabinet with

mounting screws, add filler strips.

3. 2” x 4” (

standard 1-1/2” x 3-1/2”

) 22” minimum - stand

upright and flush with front cabinet. Secure to floor or

wall.

4. Lower trim (not shown) - overlap cabinet front (at bottom

of cutout) 1/4” minimum.

19-3/8”

MINIMUM

REQUIREMENT

FOR

COMPLETE

OVEN DOOR

OPENING.

Figure 1

SIDE

VIEW

NORMAL INSTALLATION STEPS

CONSTRUCTION REQUIREMENTS

• Cabinet or wall opening must be 22” wide, 23 1/2”depth

from outside face of cabinet to rear of opening, and

37 1/2”. Corners must be square.

• Floor of cabinet must be able to support 150 pounds and

must be flush with bottom of opening.

The recess in which an oven or broiler unit is installed

shall be constructed so as to provide a complete

closure around the recessed portion of the appliance,

and that any openings around gas and electric service

outlets shall be closed at the time of installation.

The gas supply line to the oven should be 1/2” or 3/4” pipe.

ELECTRICAL GROUNDING INSTRUCTIONS

WARNING:

This appliance is equipped with a three-prong grounding plug

for your protection against shock hazard and must be plugged

directly into a properly grounded receptacle. Do not cut or

remove grounding prong from this plug.

Use a properly polarized and grounded three-hole receptacle as is required by the National Electrical Codes on all

new construction.

Where a standard two-prong wall receptacle is encountered,

it is the personal responsibility and obligation of the

consumer to have it replaced with a properly grounded

three-prong wall receptacle.

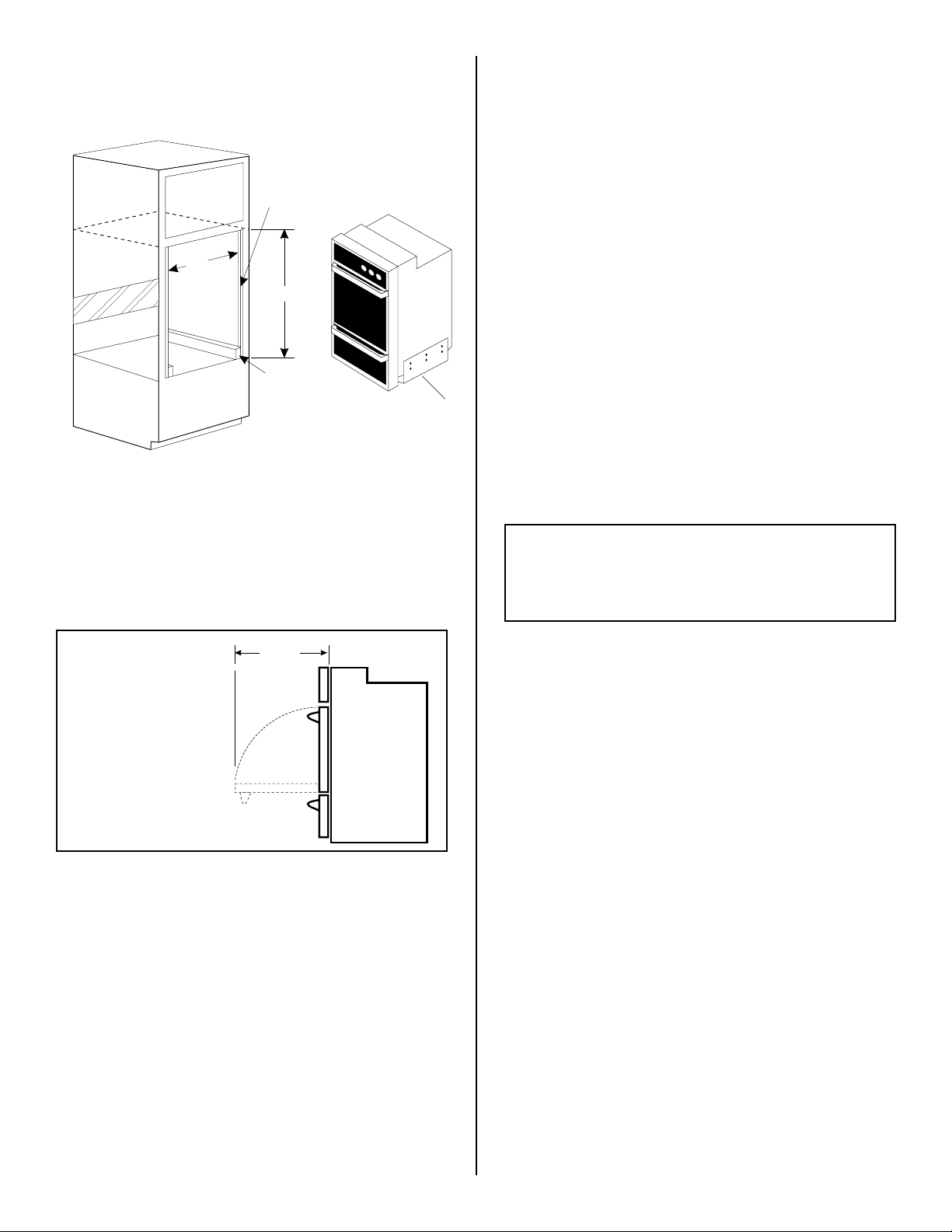

INSTALLATION

Remove and lay aside the lower vent grille that is taped to

the outer side panel of the oven. The grille will be fastened

to the lower front of the cabinet after it has been installed in

the cabinet.

Insert appliance into cut-out. Screws in the miscellaneous

parts bag are provided for fastening the front frame on the

appliance to the cabinet. The mounting holes in the front

frame of appliance may be used as a template to locate the

appliance mounting screw holes.

To fasten the appliance to the cabinet (see figure 2):

Use screws for mounting the appliance in the mounting

holes on each side of the oven frame, above the door.

To fasten the lower oven grille under the oven:

1. After oven has been adjusted to desired height, align

grille.

2. Mount grille to bottom of cabinet using 2 screws from the

miscellaneous parts bag.

3

MTG. SCREW

MTG. SCREW

LOWER VENT GRILL

MTG. SCREW

MTG. SCREW

OVEN DOOR

OVEN BOTTOM

EXTENSION

PANEL

Figure 2

HEIGHT ADJUSTMENT ON OVEN

There is a 1 1/2” height adjustment on these models. (see

figure 3) With this adjustment and a 1/2” trim overhang, a

unit can be installed in existing openings 37 1/2” to 39”

high.

ADJUSTMENT

HOLES

EXTENSION

PANEL

MOUNTING

SCREWS

Figure 3

Figure 4

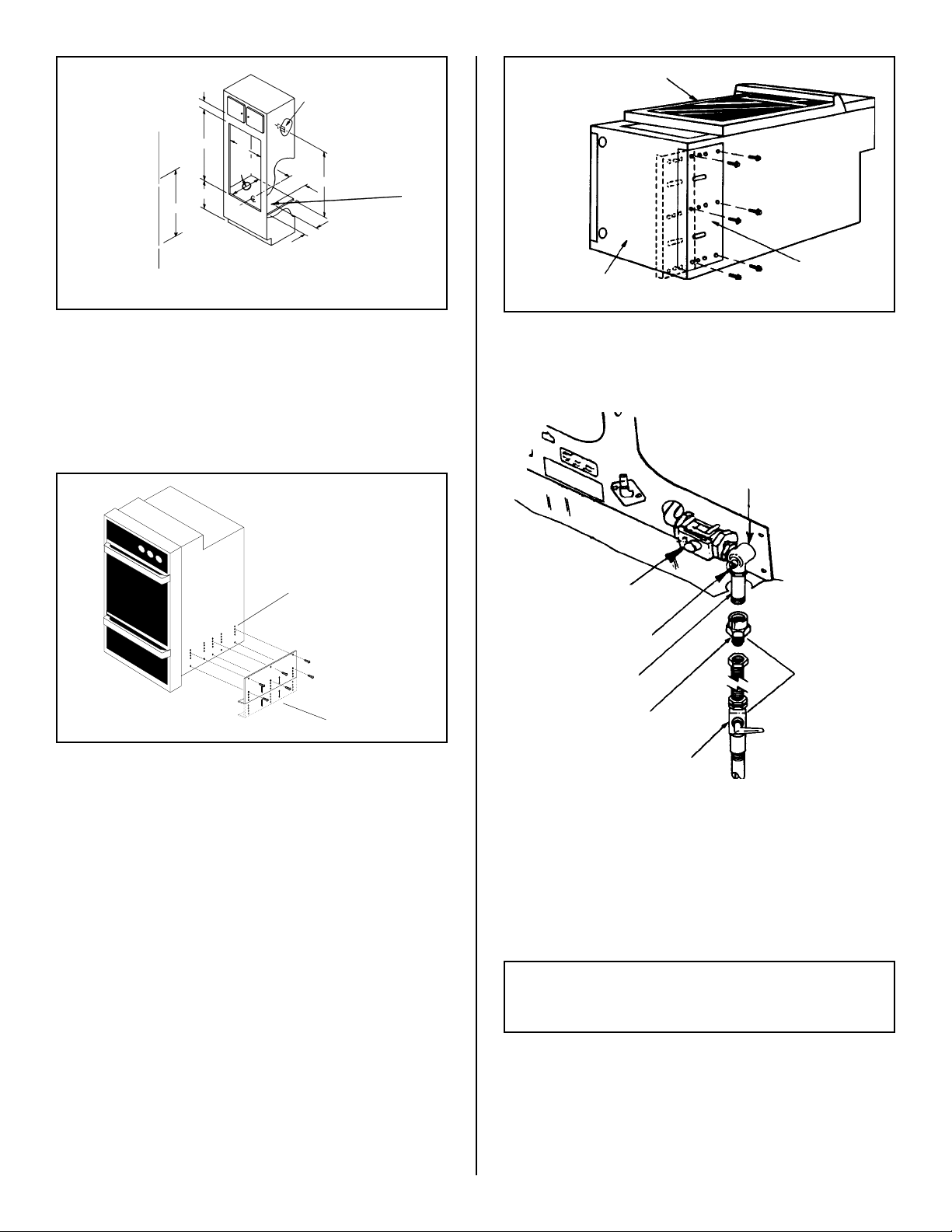

CONNECT THE OVEN TO GAS

SHUT-OFF

VALVE

PRESSURE REGULATOR

SHUT-OFF VALVE

3/8” NIPPLE

ADAPTOR OR UNION

EXTERNAL

SHUT-OFF VALVE

SOLID PIPE

OR FLEX

CONNECTOR

To adjust oven height:

A. Lay oven on its back. (see figure 4).

B. Remove the 6 screws that fasten the side extension

panel to the bottom sides of the oven.

C. Move each panel down to the position that increase

the oven height to fit your opening. Each position changes

oven height approximately 1/2”.

D. Line up the appropriate holes in the side extension

panels and sides of the oven. Replace the 6 screws.

E. Proceed with oven installation. Return oven to upright

position.

4

Figure 5

If flexible gas connector is used, gas line must be

AGA design certified.

Install a manual shutoff valve in the gas line in an easily

accessible location outside of the oven. Be sure you know

how and where to shut off gas supply to the oven.

IMPORTANT: A pipe joint sealant resistant to the action

of LP gas, must be employed on the pipe connections.

Check for leaks. After connecting the oven to gas, check

the system for leaks with a manometer. If a manometer is

not available, turn the gas supply on to the oven and use a

liquid leak detector at all joints and connections to check for

leaks.

Tighten all connections if necessary to prevent gas

leakage in the oven or supply line.

CAUTION: DO NOT USE A FLAME TO CHECK FOR

GAS LEAKS.

Do not remove the pressure regulator.

Disconnect this oven and its individual shutoff valve

from the gas supply piping system during any pressure

testing of that system at test pressures greater than 1/2 psig.

Isolate the oven from the gas supply piping system, by

closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig.

CHECK THE IGNITERS

Operation of electric igniters should be checked after oven

and supply line connectors have been carefully checked for

leaks and oven has been connected to electric power.

OVEN IGNITER SYSTEM

Close the door and turn the OVEN TEMP knob to 300°F. In

approximately 60 seconds, the burner should ignite and stay

on until oven reaches 300°F. Burner should then cycle on and

off to maintain an average temperature of approximately

300°F.

HOW TO CONVERT THE OVEN FOR USE

WITH LP GAS

CONVERT THE PRESSURE REGULA TOR

Do not remove the pressure regulator.

Remove broiler or storage drawer by pulling drawer out to

stops. Lift drawer front to clear stops and pull out.

GASKET

SMALL END TOWARDS

REGULATOR FOR

NATURAL GAS

ENLARGED END

TOWARDS REGULATOR

FOR L.P. GAS

Figure 6

ADJUST OVEN BURNER ORIFICE

FOR LP GAS:

AIR SHUTTER

OVEN BURNER

SPUD

Figure 7

Using 1/2” wrench, turn down the adjustable spud which injects

gas into the oven burner. Turn this spud until snug against the

LP metering pin. This will be approximately 2-1/2 turns. Do not

overtighten. See figure 7.

Pin

Nat.

L.P.

Pin

Spud

Locate pressure regulator on lower back wall and convert as

shown in Figure 6.

1. Remove the cap from the pressure r egulator.

2. Remove the plunger from the cap.

3. Turn the plunger upside down with the enlarged end

down.

4. Replace the plunger back into the cap. “LP” should be

visible on the explosed end of plunger .

5. Replace the cap with gasket on regulator.

NOTE: THE TYPE OF GAS PRESSURE THE REGULATOR

IS SET FOR INDICATED ON THE TOP OF THE PLUNGER

Figure 8

Nat.

Spud

AIR SHUTTER

L.P.

WAIST-HIGH

BROILER SPUD

ADJUST BROIL BURNER ORIFICE FOR LP

GAS (Self Cleaning Models Only):

Using 1/2” wrench, turn down the adjustable spud which injects

gas into the oven burner. Turn this spud until snug against the

LP metering pin. This will be approximately 2-1/2 turns. Do not

overtighten. See figure 8.

5

ADJUST THE OVEN/BROILER BURNER

FLAME

CAUTION: POWER FAILURE

Adjust the air shutter. It is

located on the venturi

tube, which sets on the

hood of the valve, and is

locked in place with a

Phillips head screw. If it

needs adjusting, loosen

the screw and rotate the

shutter to allow more or

less air into the burner

tube. See Figure 8

To determine if the oven

burner flame is proper,

observe the flame. It

should be steady with approximately 1” blue

cones and the fame

should not extend out

over the edges of baffle. For LP gas, this will most likely

occur when the air adjustment shutter is completely open.

See Figure 9.

T urn OVEN TEMP knob to 300°F and allow oven to cycle on

and off.

To replace broiler drawer or lower bottom, reverse steps

taken for removal. Replace oven rack and/or broiler pan.

AIR

ADJUSTMENT

SHUTTER

Figure 8

Figure 9

LOOSEN

DO NOT attempt to operate the oven in the event

of a power failure. If a power failure should occur

during operation, turn the oven control to the off

position. Failure to turn the oven control off will

result in oven operation upon resumption of

power to the unit.

SERIAL PLATE LOCATION

The Serial Plate is located on the left side inner trim of the

oven.

When ordering parts for or making inquiries about your appliance, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate on

your appliance. Refer to the Owner’s Manual for complete

instructions.

Y our serial plate also tells you the ratings of the burners

and type of fuel and pressure the appliance was adjusted

for when it left the factory .

BEFORE YOU CALL FOR SERVICE

Check to make sure the house fuses or circuit breaker for

your oven are not blown or open.

NOTE: Refer to Owner’s Guide for operating instructions and cleaning instructions.

CARE CLEANING AND MAINTENANCE

If removing the unit is necessary for cleaning or maintenance, shut off gas supply. Disconnect the gas supply line.

Remove installation screws from front frame and lower

grille. Pull out only as far as necessary to disconnect the

electric supply line. After disconnecting the gas and electric

supply, finish removing the unit for servicing and cleaning.

Reinstall in reverse order making sure to level the appliance

and check gas connection for leaks.

WARNING: Stepping, leaning or sitting on the

doors or drawers of this appliance can result in

serious injuries and also cause damage to the

appliance.

AFTER INSTALLATION IS COMPLETE MAKE SURE ALL

CONTROLS ARE LEFT IN THE OFF POSITION.

Reset all controls to the “OFF” position after using a

programmable timing operation.

6

INSTRUCCIONNES PARA LA INSTALACIÓN

HORNO EMPOTRADO A GAS

MODELOS REGULARES Y AUTOLIMPIADORES

LA INST ALACIÓN Y EL SERVICIO DEBEN SER REALIZADOS POR UN INSTALADOR CALIFICADO.

AVISO IMPORTANTE ANTES DE EMPEZAR - LEA CON ATENCIÓN TODAS ESTAS INSTRUCCIONES.

PARA EL INSTALADOR: NO SE OLVIDE DE DEJAR ESTAS INSTRUCCIONES CON EL USUARIO.

AVISO IMPORTANTE GUARDE ESTAS INSTRUCCIONES CON EL LIBRO DE MANTENIMIENTO Y UTILIZACIÓN PARA

PARA EL USUARIO: FUTURAS REFERENCIAS.

SIGA TODAS LAS INDICACIONES Y LOS CÓDIGOS VIGENTES.

GUARDE ESTAS INSTRUCCIONES PARA LOS INSPECTORES LOCALES.

ADVERTENCIA: Si todas las instrucciones de éste manual no son observadas a la letra, se puede

ocurrir incendios o explosiones que pueden causar daños materiales, lesiones o la muerte.

- No almacene o utilice gasolina u otros vapores y líquidos inflamables cerca de este o

cualquier otro artefacto.

- QUE HACER SI HAY FUGAS DE GAS

• No intente de encender ningún artefacto.

• No toque ningún interruptor eléctrico; no utilice ningún aparato telefónico en

su edificio.

• Llame inmediatamente el abastecedor de gas desde el telefónico de un vecino.

Siga las instrucciones del abastecedor de gas.

• En caso que no puede contactar el abastecedor de gas, llame al departamento

de bomberos.

- La instalación y el servicio tëcnico deben ser realizados por un instalador

calificado, por un servicio tëcnico certificado o por el abastecedor de gas.

NO TRAIGA DE PONER EL HORNO

EMPOTRADO EN FUNCIONAMIENTO DURANTE UN CORTE DE ENERGÍA.

IMPORTANTE

Retire todos los artículos de embalaje y folletos de la

cocina antes de realizar la conexiones de gas y

eléctricas a la cocina.

SE ADJUNTA EL DIAGRAMA DE

CABLES DE ESTA COCINA EN EL

SOBRE CON EL CATÅLAGO.

en Canadá

318201502 (9810) Rev. AImpreso

INSTRUCCIONES DE SEGURIDAD IMPORT ANTES

La instalación de esta cocina debe realizarse en

conformidad con los códigos locales o, si éstos no existen,

con el National Fuel Gas Code ANSI Z223.1 - última edición.

El diseño de esta cocina cuenta con la aprobación de la

American Gas Association. Al igual que todos los artefactos

a gas que generan calor , deben seguirse ciertas medidas de

seguridad. Vienen con el Manual de uso y mantenimiento.

Lea el manual atentamente.

• Asegure que la cocina sea instalada correctamente por un

instalador o técnico calificado.

• La cocina debe conectarse eléctricamente a tierra de

acuerdo con los códigos locales o, de no existir, con el

código eléctrico ANSI/NFP A No. 70 - última edición. Mir e

las instrucciones de conexión a tierra en la página 3.

• La instalación de unidades diseñadas para casas

(movibles) deben cumplir con los estandares de “Manufactured Home Construction and Safety Standard, title 24

CFR part 3280”. Anteriormente “The Federal Standard

for Mobile Home Construction and Safety title 24. HUD

(Part 280)”. O cuando estos estandares no sean

aplicables: “The Standard for Manufactured Home Installation 1982, (Manufactured Home Sites, Communities

and set-ups), ANSI Z225. NFP A - 501 A”, última edición o

códigos y regulaciones locales.

INSTRUCCIONES DE

SEGURIDAD IMPORTANTES

• Asegurese de remover todo el material de embalaje del

aparato antes de hacerlo funcionar, para evitar fuego o

daños por humo, en caso que el material de embalaje se

encendió.

• No permita que los niños estén solos en la cocina cuando

la estufa esté en uso. No les permita sentarse o pararse

en ninguna parte de la estufa, pues podrían lastimarse o

quemarse. Asegúrese de que no toquen la puerta del

horno o la ventana de vidrio cuando el horno esté en uso,

ya que éstas partes se calientan lo suficiente como para

causar quemaduras serias.

• Aviso: No almacene alimentos u otros objetos de interés

para los niños en alacenas ubicadas encima de la estufa o

en la guarda posterior de esta. Los niños pueden

quemarse o lastimarse seriamente si se suben en la estufa

para alcanzar estos objetos.

DIMENSIONES Y ESPACIOS LIBRES

Esta unidad esta diseñada para ajustarse a varios

tamaños de cortes, desde un mínimo de 37-1/2”

hasta 39” para modelos con 1-1/2 cavidades o de

50-1/4” hasta 51-3/4” para modelos con 2 cavidades.

Mire la pagina 4 para la abertura correcta.

• Remueve la bandeja del asador y otros utensilios antes de

usar el ciclo de limpieza a si mismo.

• No use el horno como espacio de almacenamiento. Esa

situación puede ser peligrosa.

• La estufa requiere aire fresco para que el quemador haga

la combustión adecuadamente. No obstruya la circulación

de aire de combustión en las ventilaciones del horno, ni

alrededor de la base, ni debajo del tablero frontal de la

estufa. Evite tocar las aberturas de ventilación y las

superficies cercanas pues éstas pueden calentarse.

• Recuerde, su horno no ha sido diseñado para calentar la

cocina. Este abuso puede causar un incendio o daño de la

unidad y anularía la garantía.

• No guarde o haga uso de gasolina o otros vaporos y

líquidos inflamables acerca de esté o cualquier aparato.

Se puede resultar en incendios o explosiónes.

MEDIDAS DE SEGURIDAD ADCIONALES

• No instale horno de pared debajo de la mesa de

trabajo.

• La salida de descarga no debe estar por debajo de

36”de altura.

PERFORACIÓN

DE 1-1/2”

PARA

CONEXIÓN

DE GAS

SALIDA

ELECTRICA

Medida mínima requisita para que la puerta del horno se

abre completamente, como se muestra en la FIGURA 1.

2

ALTERNATIVA DE CONSTRUCCION

Instrucciónes para instalar un horno de 1-1/2 cavidades en una

abertura existente para horno de 2 cavidades con dimensiónes

de 42-1/8” de alto por 22-1/2” de ancho.

2”

22 1/2”

1. Ajuste de altura - ajuste inferior de altura de 1”.

2. Si la abertura es demasiodo ancha para fijar la unidad al gabinete

con tornillos de montaje, ajuste con las tiras de relleno.

3. 2” x 4” (

nivele con el frente del gabinete. Asegure al suelo o al pared.

4. Moldura inferior (no se muestra) - monte al menos 1/4” sobre el

frente del gabinete (en parte inferior de abertura).

1-1/2” x 3-1/2”

standard) 22” mínimo - pare al derecho,

42-1/8”

3”

19-3/8”

PROVEA UN ADECUADO SUMINISTRO DE GAS

Esta cocina ha sido diseñada para utilizar gas natural de 4” de presión

múltiple, o para utilizar gas PL/Propano de 10” de presión múltiple.

De fábrica viene para usarse con gas natural. Para que se pueda

usar con gas PL/propano, siga las instrucciones de la página 5.

Un regulador de conversión de presión en serie esta conectado con el

múltiple del horno, y debe permanecer en serie con la línea de

suministro de gas, no importa si esta usando gas natural o gas

PL/propano.

PARA QUE MANEJO CORRECTO, LA PRESIÓN DE ENTRADA

MÁXIMA HACIA EL REGULADOR NO DEBE EXCEDER 14” DE

PRESIÓN DE LA COLUMNA DE AGUA.

Para controlar el regulador, la presión de entrada debe ser de al

menos 1” (o 3.4 KPA) mayor que el ajuste de la presión del múltiple

del regulador. Si el regulador se ajusta a 4” de la presión del

múltiple, la presión de entrada debe de ser de al menos 5”. Si el

regulador se ajusta a 10” de la presión del múltiple, la presión de

entrada debe de ser de al menos 11”.

La línea de suministro de gas por el horno deberá tener un tubo de

1/2” o de 3/4”.

1”

INSTRUCCIONES P ARA INST ALACION DE TIERRA

ADVERTENCIA:

Para su protección contra choques eléctricos este aparato ha sido

equipado con un enchufe de tres patas con conexión a tierra

apropiada. No remueva la pata redonda de tierra de este enchufe.

Use un toma de tres huecos, polarizado y con una tierra

correctamente instalada como lo requiere el “National Electric Codes”

para toda nueva construcción.

Dónde se encuentre un toma standard de dos patas, será responsabilidad personal y obligación del comprador reemplazarlo por un

toma de tres patas conectado a tierra.

MEDIDA MÍNIMA

REQUISITA PARA

QUE LA PUERTA

DEL HORNO

SE ABRE

COMPLETAMENTE

Figura 1

VISTA

LATERAL

INSTRUCCIONES PARA UNA

INST ALACIÓN NORMAL

REQUISITOS DE CONSTRUCCIÓN

• La abertura del gabinete o de la pared debe ser de 22 pulgadas de

ancho, 23 y 1/2 pulgadas de profundidad desde la cara exterior de

gabinete hasta la parte posterior de la abertura, y 37 y 1/2. Las

esquinas deben estar cuadradas.

• El piso del gabinete debe soportar una carga de 150 libras y debe

estar nivelado con el fondo de la abertura.

El soporte en el cual un horno o un asador es instalado deberá

ser construido de tal manera que proporcione un cerramiento

total alrededor de la parte apoyada del electrodoméstico.

Además, cualquier abertura alrededor de las entradas de gas o

de electricidad debe ser sellada al momento de la instalación.

INSTALACIÓN

Retire y ponga a un lado la rejilla baja de ventilación que está

pegada a la parte exterior del panel del horno. La rejilla será fijada

a la parte de baja del frente del gabinete después de que éste haya

sido instalado en el gabinete.

Inserte el electrodoméstico en la abertura. Para atornillar el marco

frontal del electrodoméstico en el gabinete, encontrará los tornillos

en la bolsa de partes varias. Los huecos de montaje en el frente

del marco del electrodoméstico pueden ser usados como una

plantilla para localizar los huecos para los tornillos para el montaje

del electrodoméstico.

Para fijar el electrodoméstico al gabbinete (ver figura 2)

Utilice los tornillos para el montaje del elctrodoméstico en los

huecos de montaje en cada lado del marco frontl del horno, por

debajo de la puerta del horno.

Para fijar la rejilla inferior del orno bajo el horno:

1. Después de que el horno haya sido ajustado a la altura deseada,

alinee la rejilla.

2. Monte la rejilla al fondo del gabinete usando 2 tornillos de la bolsa

de partes varias.

3

TORNILLOS DE

MONTAJE

PUERTA DEL HORNO

TORNILLOS DE

MONTAJE

REJILLA PARA LA

VENTILACIÓN POR

ABAJO

TORNILLOS

DE MONTAJE

TORNILLOS DE

MONTAJE

Figura 2

AJUSTE DE AL TURA DEL HORNO

Este modelos de horno cuenta con un ajuste de altura de 1-1/2”

(ver figura 3). Con este ajuste y la pestaña de 1/2” el horno puede

ser instalado en aberturas existentes de 37-1/2” a 39” de altura.

PERFERACIONES PARA

AJUSTAR

PANEL DE

EXTENSIÓN

TORNILLOS DE

MONTAJE

PANEL DE

FONDO DEL HORNO

EXTENSIÓN

Figura 4

CONEXION DEL HORNO AL SUMINISTRO DE GAS

VALVULA

DE CIERRE

REGULADOR DE PRESION

VALVULA DE CIERRE

TUBERÍA

3/8 NIPLE

ADAPTOR O UNION

RIGIDA O

CONECTOR

FLEXIBLE

Figura 3

Para ajustar la altura del horno:

A. Coloque el horno sobre su parte posterior (ver figura 4).

B. Remueva los 6 tornillos que aseguran el panel lateral de

extensión a la partes laterales inferiores del horno.

C. Mueva cada panel hasta la posición que mejor ajuste la

altura del horno al tamaño de su abertura. Cada posición

cambia la altura del horno aproximadamente 1/2”.

D. Alinée los orificios del panel lateral de extensión con los

de las paredes laterales del horno. Vuelva a colocar los 6 tornillos.

E. Proceda con la instalación del horno. Vuelva a colocar el

horno sobre su base.

4

VALVULA EXTERIOR

DE CIERRE

Figura 5

Si se utiliza conector de gas flexible, la linea de gas deberá

ser de diseño AGA certificado.

Instale una válvula de cierre manual en un sitio de fácil

acceso en la parte exterior del horno. Asegúrese de saber de

dónde y como cerrar el suministro de gas del horno.

IMPORTANTE: En las uníones de la tuberia debe usarse

un sellante de uníon de tuberia que sea resistente a la acción

del gas LP.

Verifique si hay fugas. Luego de conectar la cocina al gas,

verifique el sistema con un manómetro. Si no cuenta con este

instrumento, dé la vuelta al suministro de gas de la cocina y

utilice un detector de fugas líquidas en todas las articulaciones y

conexiones para verificar si existen fugas.

Ajuste todas las conexiones en caso que sea necesario, para

evitar fugas de gas en la cocina o en el tubo de suministro de

gas.

AVISO: NO USE NINGÚN TIPO DE LLAMA PARA

VERIFICAR SI HAY FUGAS DE GAS.

No remueva el regulador de presión.

Desconecte la cocina y su válvula de cierre individual del

sistema de tubería del suministro de gas durante cualquier

ensayo de presión del sistema en ensayos de presión superiores

a 1/2 psig.

Aparte la cocina del sistema de tubería del suministro

de gas, cierrando su válvula de cierre individual manual,

durante cualquier ensayo de presión del systema de suministro

de gas en ensayos iguales o inferiores a 1/2 psig.

VERIFIQUE LOS DISPOSITIVOS DE ENCENDIDO

La manipulación de los dispositivos de encendido eléctrico

deberá verificarse tras haber revisado detenidamente la cocina y

los conectores del tubo del suministro de fugas y tras haber

conectado la cocina al suministro eléctrico.

SISTEMA DE ENCENDIDO DEL HORNO

Cierre la puerta del horno y gire el boton de OVEN TEMP

(temperatura del horno) a 300°F. En 60 segundos aproximadamente, el quemador debe prender y permanecer encendido

hasta que el horno alcance 300°F. El quemador seguirá

alternando entre encendido y apagado para mantener una

temperatura promedia de aproximadamente 300°F.

COMO CONVERTIR LA COCINA PARA

QUE SE PUEDA USAR CON GAS LP/

PROPANO

CONVIERTA EL REGULADOR DE PRESIÓN

No remueva el regulador de presión

Remueva el asador o el cajón de almacenamiento halandolo

hacia afuera hasta los topes, luego saque hacia afuera.

Localice el regulador de presión en la parte inferior de la pared

trasera y modifique como se muestra en la figura 8.

1. Remueva la tapa del regulador de presión.

2. Remueva el pistón de la tapa.

3. Dé la vuelta al pistón, poniendo la grande extremidad hacia

abajo.

4. Vuelva a poner el pistón dentro de la tapa. Las letras “LP”

deben de estar visibles en la extremidad descubierta del

pistón.

5. Vuelva a poner la tapa del regulador.

JUNTA

PEQUEÑA EXTREMIDAD

HACIA EL REGULADOR

PARA GAS NATURAL

GRANDE EXTREMIDAD

HACIA EL REGULADOR

PARA GAS LP

Pasador

Figura 6

AJUSTE DEL ORIFICIO DEL

QUEMADOR DEL HORNO P ARA

GAS LP:

Obturador de aire

Junta en forma

de bellota del

quemador

Figura 7

L.P.

Nat.

Junta en

forma de

Usando una llave de 1/2 pulgada, giro hacia abajo la junta en

forma de bellota ajustable que inyecta gas al quemador del

horno. Gire esta junta en forma de bellota hasta que ajuste

contra el pasador medidor de L.P. Esto será aproximadamente 2

1/2 vueltas. No lo apriete damasiado. Ver Figura 7.

Pasador

Figura 8

Nat.

Junta en

forma de

bellota

Obturador de aire

L.P.

Junta en forma de

bellota de la parrilla

bellota

NOTA: EL TIPO DE PRESIÓN DE GAS PARA EL CUAL HA

SIDO CALIBRADO EL REGULADOR ESTA INDICADO EN LA

PARTE SUPERIOR DEL PISTÓN.

AJUSTE DEL ORIFICIO DEL QUEMADOR

DEL ASADOR PARA GAS L.P.

(modelos autolimpiadores solamente):

Usando una llave de 1/2 pulgada, gire hacia abajo la junta en

forma de bellota ajustable que inyecta gas al quemador del

horno. Gire esta junta en forma de bellota hasta que ajuste

contra el pasador de medición de L.P. Esto será aproximadamente 2 1/2 vueltas. No lo apriete demasiado. Ver figura 8.

5

AJUSTE DE LA LLAMA DEL

QUEMADOR DEL HORNO/ASADOR

Ajuste el obturador de aire.

Esté está localizado en el

vénturi, jundo a la capucha

de la válvula y es fijado en

su lugar pour un tornillo

con cabeza tipo Phillips. Si

éste necesita ajuste, afloje

el tornillo y rote el obturador para permitir más o

menos aire en el tubo del

quemador. Ver Figura 8.

Para determinar si la llama

del quemador del horno es la

apropiada, observe la llama.

Esta debe estar estable

formando conos azules de 1

pulgada aproximadamente.

La llama no debe extenderse

por encima de los bordes del

resonador. Para gas LP, ésto

ocurre más frecuentemente cuando el obturador de ajuste

de aire está completamente abierto. Ver figura 9.

Ponga el botón de OVEN TEMP (temperatura del horno) en

300°F, y permita que el horno alterne entre “on” y “off”

(prendido y apagado).

OBTURADOR

DE AIRE

Figura 8

Figura 9

FLOJO

AVISO: CORTE DE ENERGÍA ELÉCTRICA

NO TRATE de usar el horno de encendido eléctrico

durante un corte de energía . En caso de un corte de

energía eléctrica cuando el horno esta en funcionamiento coloque todos los controles en posición

APAGADO. El reestablecimiento del servicio eléctrico

cuando los controles del horno están en cualquier posición

diferente a APAGADO causaría el encendido automático del

quemador del horno.

MODELO Y UBICACIÓN DEL NÚMERO DE SERIE

La placa de numero de serie está ubicada en el lado de abajo

del armazón del horno.

Asegúrese de incluir el modelo, número de serie y el número o

letra del lote que se encuentran en la placa de serie de su

estufa, en todo pedido de partes o solicitud de información

acerca de su estufa.

La placa de número de serie también indica las especificaciones

de los quemadores, el tipo de combustible y la presión para la

cual fué ajustada la estufa en la fábrica.

ANTES DE LLAMAR

AL SERVICIO TÉCNICO

Verifique que los fusibles de la casa no se hayan fundido o el

cortacircuitos del horno no hayan saltado o abierto.

Para volver a colocar el cajón o el fondo inferior del asador,

siga en forma inversa los poasos tomados para retirarlo.

Vuelva a colocar la parrilla del horno y/o la bandeja del asador.

NOTA: Consulte el Manual de usuario para las

instrucciones de funcionamiento y limpieza.

CUIDADO, LIMPIEZA

Y MANTENIMIENTO

Cierre el suministro de gas en caso de ser necesario remover la

unidad para su limpieza o reparación. Desconecte la linea de

suministro de gas. Remueva los tornillos de instalación del

marco frontal y la parrilla inferior. Hale hacia afuera apenas lo

necesario para poder desconectar del toma eléctrico. Después

de desconectar del suministro eléctrico y de gas, termine de remover la unidad para su limpieza o mantenimiento. Reinstale

siguiendo el procedimiento inverso. Asegúrese de nivelar la

estufa y verificar que no halla escapes en la conexión de gas.

ADVERTENCIA: Pararse, apoyarse o sentarse en las

puertas o cajones de esta estufa puede causar serias

lesiones personales y también puede dañar la estufa.

CUANDO SE HAN REALIZADO TODOS LOS SISTEMAS DE

CONEXIÓN ASEGURESE QUE TODOS LOS CONTROLES

ESTÁN EN LA POSICIÓN DE APAGADO (OFF).

Vuelva a colocar todos los controles en la posición de

“off” (apagado) después de utilizar el funcionamiento de

programación cronometrada.

6

Loading...

Loading...