Frigidaire FFLG3900UW, FFLE3900UW Installation Manual

LAUNDRY CENTER TECH DATA SHEET

1

3

8

9

6

11

12

13

153781311

4261210

9

This information is intended for Qualied Technicians Only.

Table Of Contents

Washer Diagnostic Mode ....................................................2

Washer Error Codes ...........................................................3

Washer Troubleshooting Tests ............................................4

Washer Error Display .........................................................5

Dryer Diagnostic Mode .......................................................6

Dryer Error Codes .............................................................7

Dryer Error Display ............................................................8

Wiring Diagram - Electric .................................................27

Wiring Diagram - Gas .....................................................28

1

WARNING

The information within this manual is intended for Qualied

Service Technicians Only.

• DO NOT reach into the appliance while the tub or drum is

spinning.

• Disconnect power before servicing machine.

• Certain internal parts are intentionally not grounded and may

present a risk of electric shock only during servicing.

WARNING

Safety items throughout this manual are labeled with a WARNING or CAUTION based on the risk type as described below:

WARNING indicates a potentially

WARNING

CAUTION

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury.

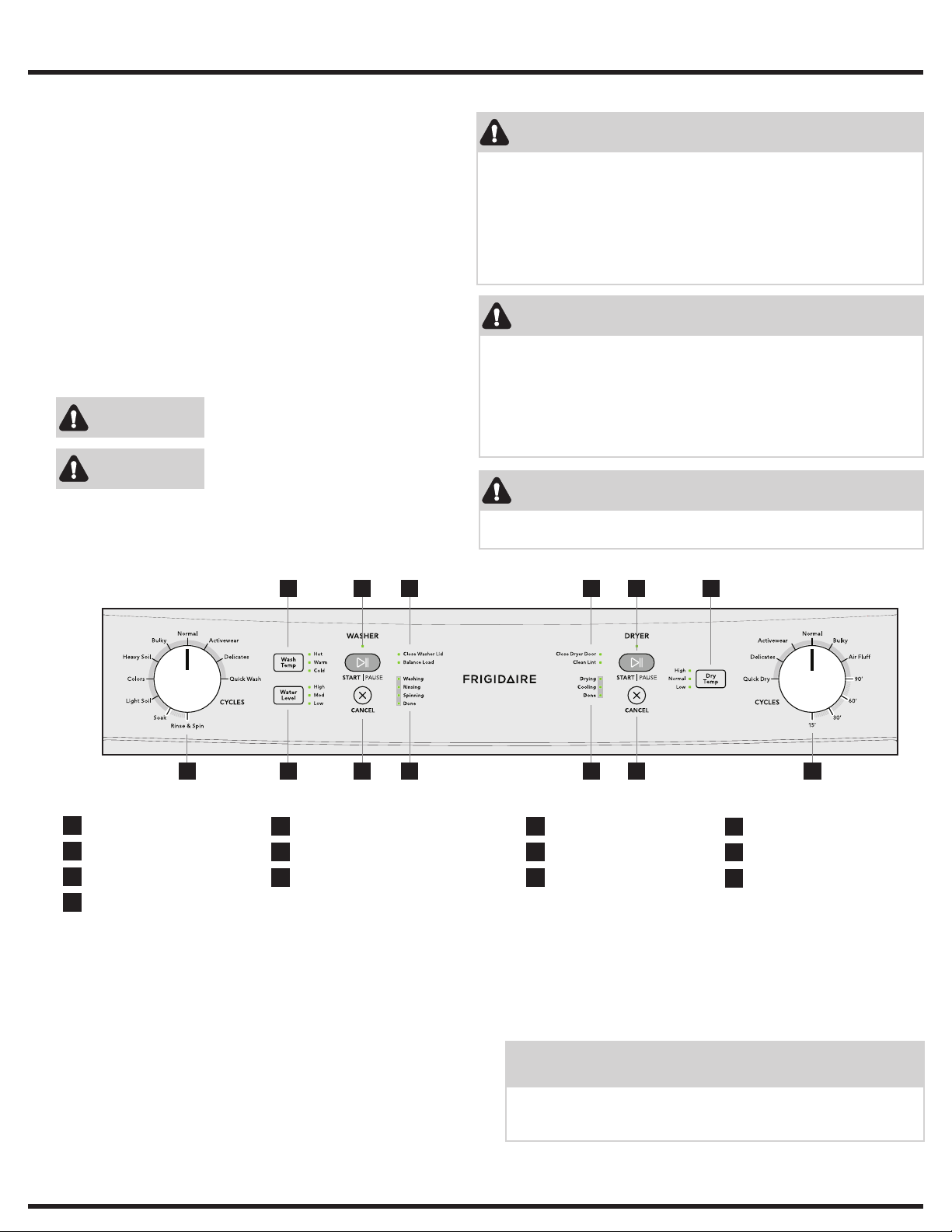

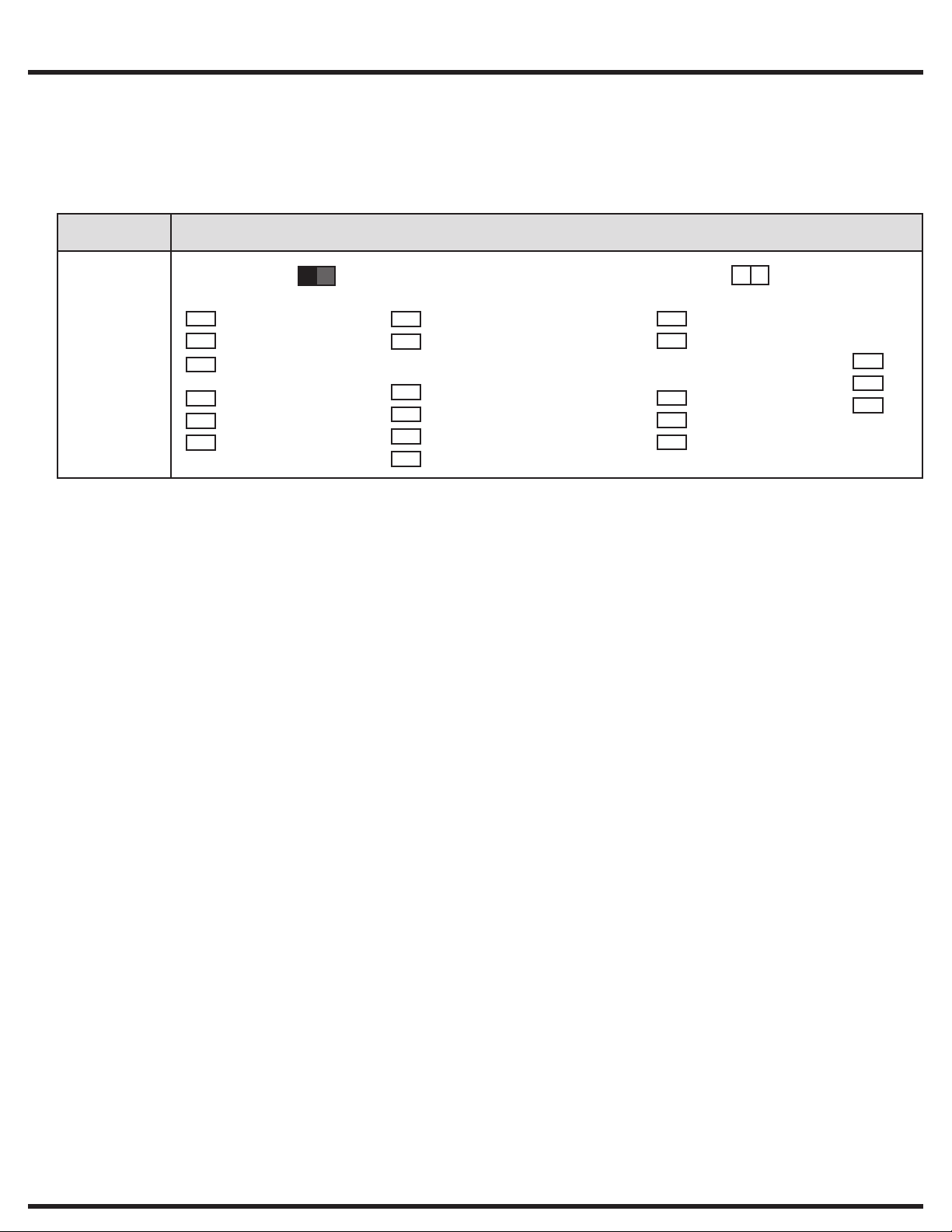

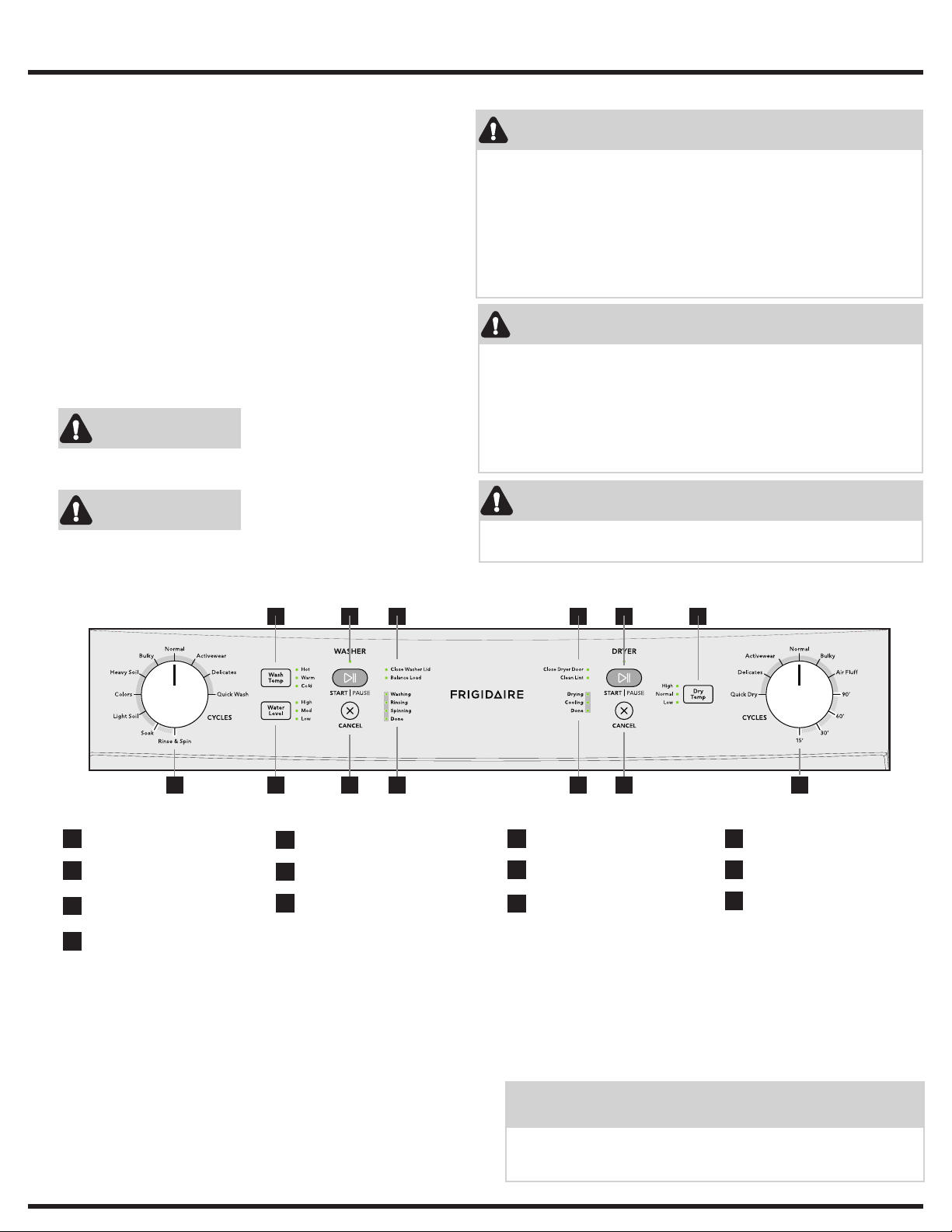

Laundry Center User Interface

FIRE HAZARD

A clothes dryer produces combustible lint. The cabinet interior of

the dryer, lint lter housing, and exhaust duct should be cleaned

approximately every 18 months by a qualied servicer. An excessive

amount of lint build-up in these areas could result in inefcient drying

and possible FIRE. See the Care and Cleaning section of the Use &

Care instructions.

CAUTION

Unless otherwise directed, disconnect electrical current before

servicing.

Washer

2

4

Washer Diagnostic Mode

Entering Washer Diagnostic Mode:

1. Power OFF the unit by either turning the washer cycle selector

knob to CYCLES position (5 o’clock position) or unplugging the

unit.

2. Power back ON the unit by either rotating the washer cycle

selector knob or plugging in the unit.

3. Within 10 seconds of powering up, rotate the knob to the Rinse

& Spin cycle position.

4. Press and hold Wash Temp and CANCEL buttons

simultaneously until a beep is heard and LED lights start to blink

one by one.

USA 1-877-435-3287

Wash Cycle Selector

Wash Cycle Temperature

Wash Cycle Water Level

Wash Cycle START|PAUSE

5

Wash Cycle Cancel

Wash Cycle Advisory Lights

7

Wash Cycle Status

www.electroluxappliances.com

Dryer

Dry Cycle Selector

Dry Cycle Temperature

10

Dry Cycle START|PAUSE

Dry Cycle Cancel

Dry Cycle Advisory Lights

Dry Cycle Status

Exiting Diagnostic Mode:

To exit Diagnostic Mode and return to normal function, either press

and hold the Wash Temp and CANCEL buttons simultaneously

until the LED lights stop blinking or unplug the unit for a 10 full

seconds before plugging the unit back in.

NOTE

The unit will automatically exit Diagnostic Mode and return to

normal functionality if left unattended in diagnostic Mode for

more than 15 minutes.

A11271102 (1803)

Canada 1-800-265-8352

Close Lid

Unbalanced

Washing

START | PAUSE

Close Door

Clean Lint

Drying

Cooling

Done

High

Normal

Low

2

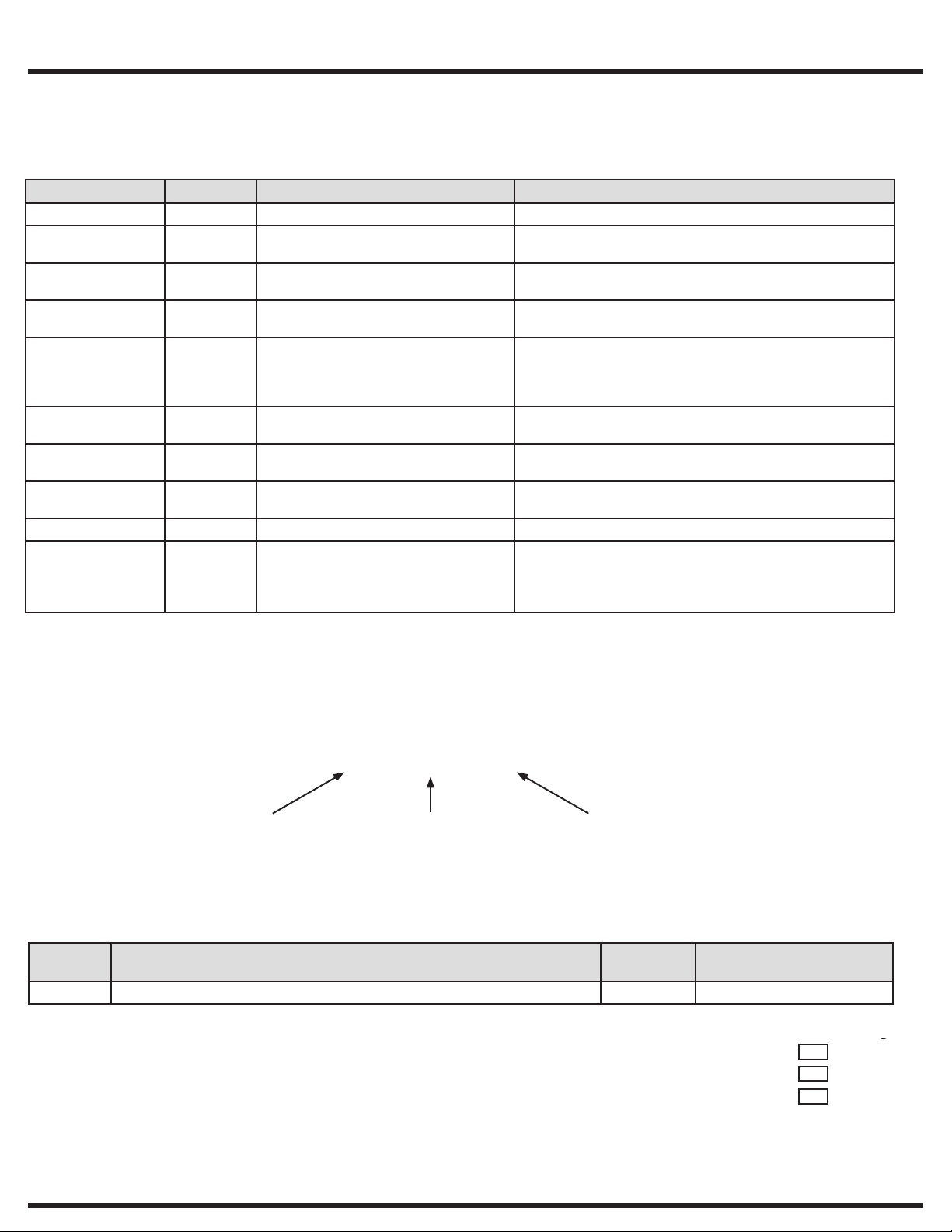

WASHER DIAGNOSTIC MODE

Washer Diagnostic Mode Tests

All tests should be performed with an empty tub. Any items left in the tub will cause a serious out-of-balance situation and potential

damage to the washer as it reaches higher spin speeds.

DIAGNOSTIC ID PROGRAM TEST/ACTIVATED COMPONENT TEST DESCRIPTION

1 Rinse & Spin LED Test, Button Test LEDs illuminate in sequence. Manually test buttons for tone.

2 Soak Lid Lock, Hot Valve and Clutch

3 Light Soil Lid Lock, Cold Valve, and Clutch

4 Colors

5 Heavy Soil Balance Switch

6 Bulky Lid lock, Drain Pump, and Clutch

7 Normal

8 Activewear Lid lock, Hot Valve, and Cold Valve

9 Delicates — — — —

10 Quick Wash Error code history

Lid Lock, Hot valve, Cold Valve, Clutch,

and Motor

Lid Lock, Pressure Sensor, Motor, and

Drain Pump

Lid Locks. Fill water via HOT valve to 140mm. Disengage

the clutch.

Lid Locks. Fill water via COLD valve to 140mm. Disengage

the clutch.

Lid locks. Fill water via HOT and COLD valves to 20mm.

Agitate for 4 mins.

Out of balance switch test. Move the drum against the tilt

switch 2 times in 10 seconds. If tilt switch is working, the

WASHER RED LED, Close Washer Lid LED and Balance

Load LED will be ON simultaneously.

Lid locks. Drain water until empty. Engage and disengage

the clutch 1 time.

Lid locks. Spin for 25 seconds while draining water from

tub.

Lid Locks. Fill water using both HOT and COLD valve for 5

mins. Complete test 6 or 7 to drain water from the tub.

Check last 3 error codes

• If START|PAUSE LEDs are not blinking there is no error.

• If START|PAUSE LEDs are blinking refer to Washer

Error Code Table.

Understanding Error Codes

In Washer Diagnostic Mode, error codes are indicated by a pattern of blinking RED and GREEN LEDs above the WASHER START|PAUSE

button. The LEDs will blink rst RED then GREEN, to provide the two digit error code number. These blinking lights can then be translated

into error codes that are listed in the chart on the following page and can help pinpoint the problem with the washing machine. The number

of times a light blinks corresponds with the digit or character it represents. Blinking 1 through 9 times will represent the corresponding digit.

Blinking 10 times =A, 11=B, 12=C, 13=D, 14=E, 15=F.

An Error Code looks like this:

E 4 2

This letter “E” designates

that this is an Error Code.

Looking at the Washer Error Code Table on the following page, E42 refers to a Door Lock Error.

Error

Code

E42 Door lock device failure No Refer to test (6)

If your washing machine has multiple errors, the display will communicate up to three error codes.

• The GREEN LED light for Done will be illuminated while the rst error code is being communicated.

• The GREEN LED light for Spinning will be illuminated while the second error code is being communicated.

• The GREEN LED light for Rinsing will be illuminated while the third error code is being communicated.

Reset Washer Error Code History in Diagnostic Mode:

Rotate the washer cycle selector knob to the Quick Wash position (position 10) and press and hold Wash Temp and CANCEL buttons

simultaneously until UI stops displaying error code.

Error Description Display

The rst digit is the area of error. This digit

is determined by counting how many times

the LED over the START|PAUSE button

blinks RED. In this example the LED will

blink RED four times.

The second digit is the type of error.

This digit is determined by counting how many times the LED over

the START|PAUSE button blinks

GREEN.

Next Step

Notication

3

2

1

Rinsing

Spinning

Done

WASHER ERROR CODES

Recalling Last Error Code:

From any cycle position, press and hold Wash Temp and CANCEL buttons for 15 seconds to display the last error code.

Washer Error Code Table

3

Error

Code

E11 Fill time too long Yes Refer to test (1)

E13 Water leak in tub or in pressure sensor No Refer to test (2)

E21 Water not pumping out fast enough Yes Refer to test (3)

E23 Drain triac error No Refer to test (3)

E24 Drain triac error sensing No Refer to test (3)

E31 Electronic pressure switch error No Refer to test (4)

E32 Pressure sensor calibration problem No Refer to test (4)

E35 Pressure sensor indicates water overll No Refer to test (5)

E41 Control board thinks the door switch is open Yes Refer to test (6)

E42 Door lock device failure No Refer to test (6)

E44 Door closed sensing failure No Refer to test (6)

E45 Line door sensing failure No Refer to test (6)

E51 Motor triac error No Main board failure

E53 Motor triac sensing error No Main board failure

E54 Motor relay error No Main board failure

E91 User interface protocol incongruence error Yes Refer to test (11)

E92 User interface mother board protocol incongruence No Refer to test (11)

E93 Console or main board control problem (incompatible machine conguration) Yes Refer to test (11)

Error Description Display

Notication

Next Step

E94 Main board control problem (incompatible cycle conguration) Yes Refer to test (10)

E97 Console or main board control problem (incompatible cycle conguration) Yes Refer to test (11)

E9C User interface conguration problem Yes Refer to test (11)

EB1 Frequency of power out of limits Yes Refer to test (18)

EB2 Supply voltage too high (incoming voltage) Yes Refer to test (18)

EB3 Supply voltage too high (incoming voltage) Yes Refer to test (18)

EF5 Load unbalanced No Redistribute load and restart

EF6 Control reset No Refer to test (19)

EC6 Clutch error. Clutch positioning timeout reach or failure to stay in desired

position

EC7 Sensing that the clutch triac is out of limits No Clutch mechanism failure

No Clutch mechanism failure

Main board failure

Wire/connection problem

Main board failure

Wire/connection problem

4

Test Number Check/Test Activity Steps Correction

WASHER TROUBLESHOOTING TESTS

Test 1 1. Is the incoming water ow normal? Yes, go to step (4).

2. Are the incoming water faucets

turned on?

3. Is the incoming water pressure above

20 psi?

4. Does the ll water continue to enter

the washer?

5. Remove power from the washer. Did

the water ll stop?

6. Replace the pressure sensor. If this did not correct the problem, go to step 7.

7. Replace the main control board.

Test 2 1. Is the washer leaking water? Yes, correct water leak.

2. Is there an air leak in the pressure

sensor system?

3. Replace the pressure sensor. If this did not correct the problem, go to step (4).

4. Replace the main control board.

Test 3 1. Check the drain hose for restrictions. If there is a restriction, correct the problem.

2. Start the washer and check for 120

VAC at the drain pump.

Test 4 Inspect the wiring between the pressure

sensor and the main control board.

Test 5 1. Is the water level above 4.5 inches? Yes, go to step (2).

2. Does water enter the washer continuously?

3. Remove power from washer. Does the

water stop coming in?

4. Replace the pressure sensor switch.

Test 6 1. Is the loading door closed? No, close the door.

2. Can you hear the lock attempt to

close?

3. Check wire connection between door

lock and main control board.

Test 10 Communication problem. Check the

wiring between the main control board

and the motor control board.

Test 11 Communication problem. Check the

wiring between the main control board

and the user interface board.

Test 18 1. Check power in for voltage under

load.

2. Check power wiring to main board. Yes, x wiring or plug to main board.

3. Check wiring to motor board for short

to power or ground.

Test 19 Check wiring to main board. Unplug the

unit for 1 minute and retry.

No, go to step (2).

No, turn water faucets on.

Yes, go to step (3).

No, have customer correct pressure problem.

Yes, check for kinked or blocked incoming water hoses, clean the incoming

water screens. If problem still remains, replace water inlet valve assembly.

Yes - Go to step (5)

No - Go to step (6)

Yes - Go to step (6)

No - Replace the inlet valve assembly. If pressure switch checks good, go to

step (7). If pressure switch checks bad, replace pressure switch.

No, go to step (2).

Yes, correct the air leak problem.

No, go to step (3).

No restriction, go to step (2).

If reading zero, check wiring. If wiring good, replace main control board.

If reading 120 VAC, remove the pump and check for blockage. If blocked,

remove the restriction, if not, replace the pump.

If wiring defective, correct wiring.

If wiring OK, replace pressure sensor. If this does not correct the problem,

replace the main control board.

No, go to step (4).

Yes, go to step (3).

No, check air trap for clog, if not replace the main control board.

No, replace water valve assembly.

Yes, check wiring to valve assembly for shorts. If wiring is good, replace the

main control board.

Yes, go the step (2).

Yes, check the door strike. If good, replace the door

No, go the step (3)

If good, replace door lock. Then if problem is not xed, replace main control

board.

If wiring is bad, correct wiring problem.

If wiring is good, replace the main control board. If the problem is not

corrected, replace the user interface board

If wiring is bad, correct wiring problem.

If wiring is good, replace the user interface board. If the problem is not

corrected, replace the main control board.

Correct supply or branch circuit issues.

No problem go to step 2

No, go to step 3.

Yes, x problem.

No, replace the main board.

If problem is not corrected replace main control.

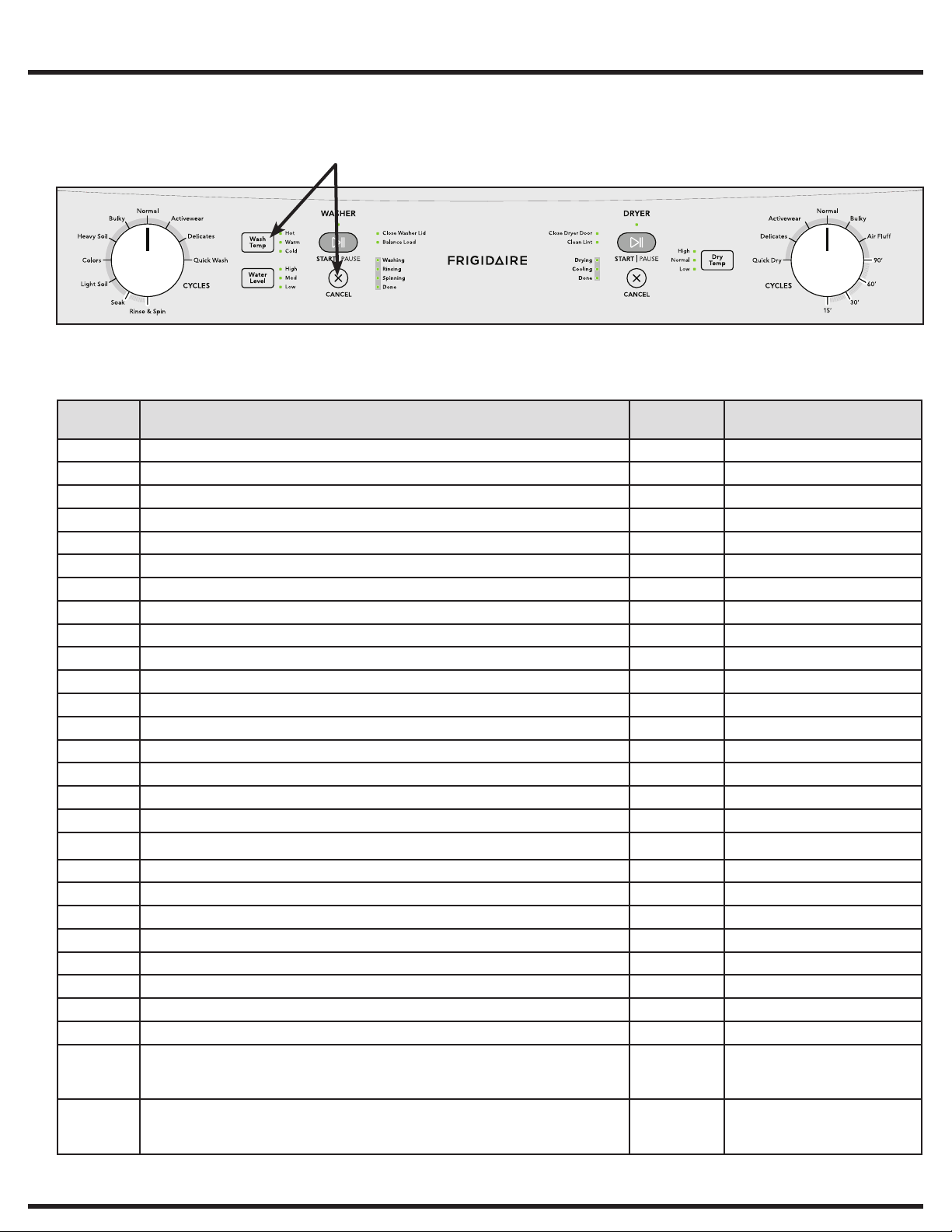

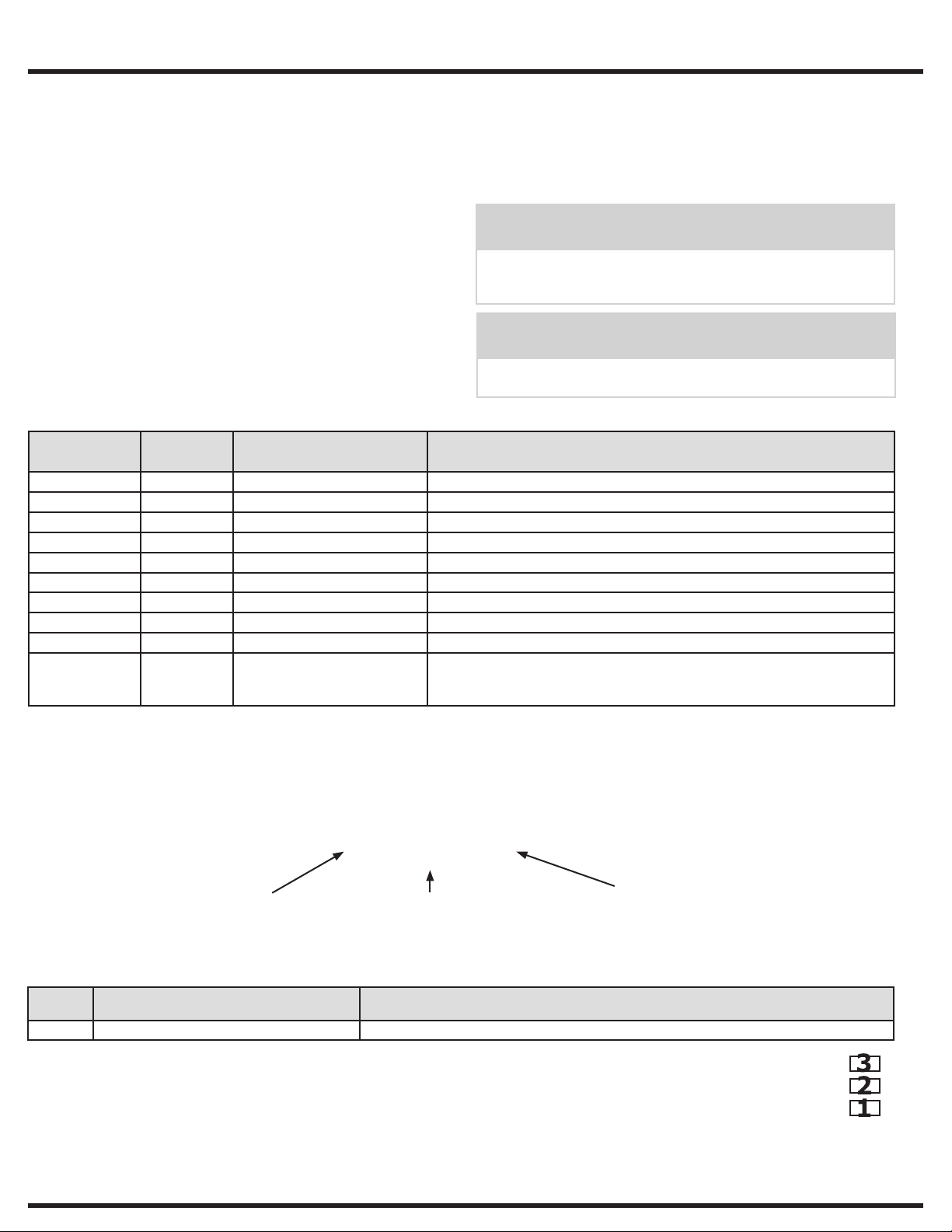

WASHER ERROR DISPLAY

5

Washer Error Display Pattern

The error is displayed with the WASHER START|PAUSE LED lights blinking RED and GREEN for 0.5 secs ON and 0.5 secs OFF with a 4.5

secs. pause between the sequences. The RED blinking LED light indicates the error family and the GREEN blinking LED light indicates the

error code. The LED lights will continue to blink until the user interacts with the unit (the UI should not go to sleep in error condition). The

RED blinking LED lights are shown in BLACK. The GREEN blinking LED lights are shown in GRAY.

Description LED Error Pattern

START | PAUSE

Hot

WASHER

ERROR

To determine an error code, look at the blinking START|PAUSE LED lights only. Additional blinking lights are not needed for determining

an error.

Warm

Cold

Max Fill

Med

Low

Close Lid

Unbalanced

Washing

Rinsing

Spinning

Done

Close Door

Clean Lint

Drying

Cooling

Done

START | PAUSE

High

Normal

Low

6

START | PAUSE

High

Normal

Low

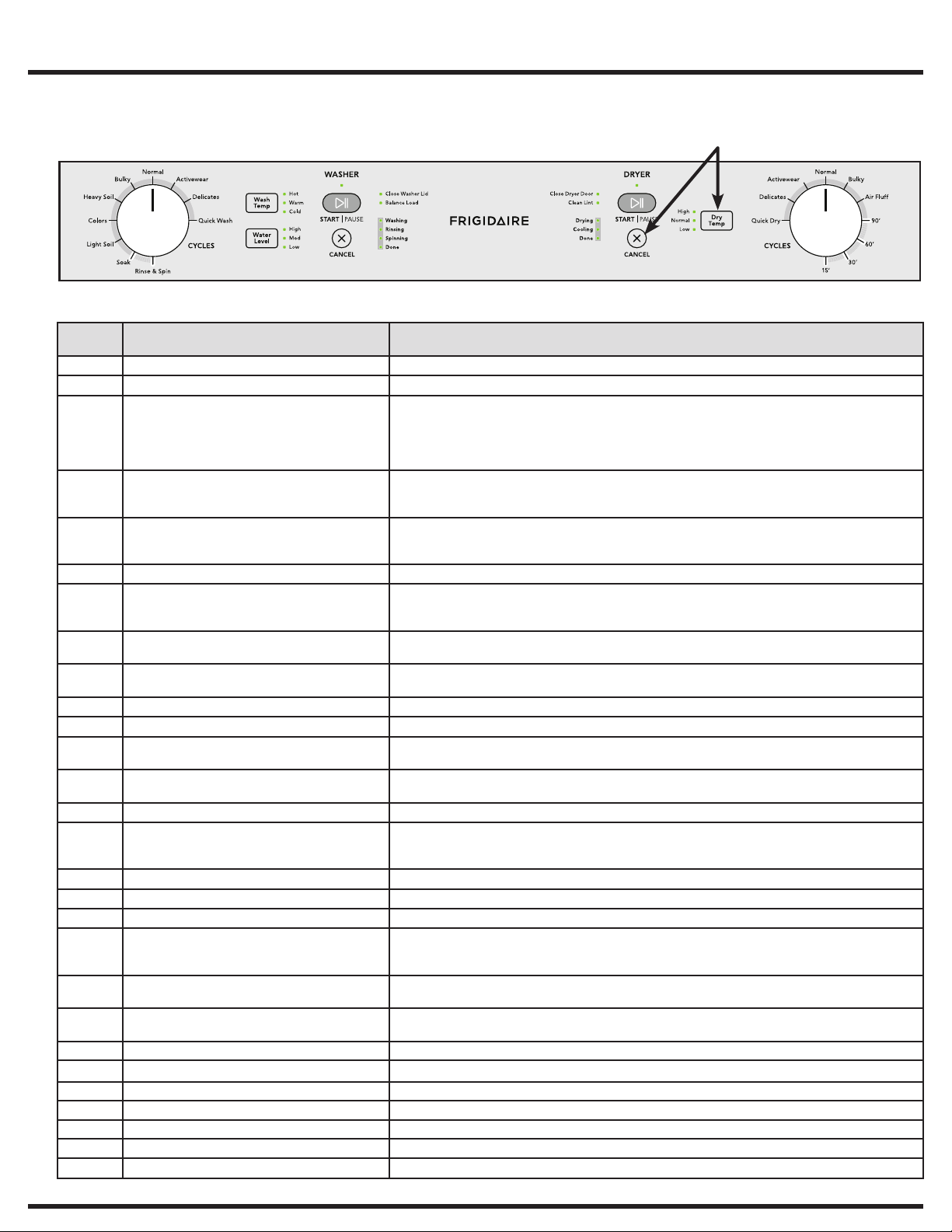

DRYER DIAGNOSTIC MODE

Dryer Diagnostic Mode

Entering Diagnostic Mode:

1. Power OFF the unit by either turning the DRYER cycle selector

knob to the CYCLES position (8 o’clock position) or unplugging

the unit.

2. Turn ON the unit.

3. Within 10 seconds of powering up, rotate the knob to the

Quick Dry position.

4. Press and hold DRY Temp and CANCEL buttons simultaneously

until a beep is heard and LED lights start to blink one by one.

5. Press the START|PAUSE button.

Exiting Diagnostic Mode:

To exit Diagnostic Mode and return to normal function, either press

and hold the Dry Temp and CANCEL buttons simultaneously until

the LED lights stop blinking or unplug the unit for a 10 full seconds

before plugging the unit back in.

NOTE

The unit will automatically exit Diagnostic Mode and return to

normal functionality if left unattended in diagnostic Mode for

more than 15 minutes.

NOTE

If the dryer door has been opened and closed, the START|PAUSE

button must be pressed to activate the motor and heater.

Diagnostic Mode Tests

All tests should be performed with an empty tub. Programs not shown do not have associated tests.

DIAGNOSTIC

ID

1 Quick dry Lights/ Buttons test LEDs illuminate in sequence. Manually test buttons for tone.

2 Delicates Motor Motor is driven for 10 mins

3 Activewear Motor, Heater and Thermistor Motor and Heater is driven for 10 mins.

4 Normal — — — —

5 Bulky — — — —

6 Air Fluff — — — —

7 90’ — — — —

8 60’ — — — —

9 30’ — — — —

10 15’ Error code history

PROGRAM

TEST/ACTIVATED

COMPONENT

TEST DESCRIPTION

Check last 3 error codes

• If START|PAUSE LEDs are not blinking there is no error.

• If START|PAUSE LEDs are blinking refer to Dryer Error Codes Table.

Understanding Error Codes

In Dryer Diagnostic Mode, error codes are indicated by a pattern of blinking RED and GREEN LEDs above the DRYER START|PAUSE but-

ton. The LEDs will blink rst RED then GREEN, to provide the two digit error code number. These blinking lights can then be translated into

error codes that are listed in the chart on the following page and can help pinpoint the problem with the dryer. The number of times a light

blinks corresponds with the digit or character it represents. Blinking 1 through 9 times will represent the corresponding digit. Blinking 10

times =A, 11=B, 12=C, 13=D, 14=E, 15=F.

An Error Code looks like this:

E 4 2

This letter “E” designates

that this is an Error Code.

Looking at the Dryer Error Code Table on the following page, E42 refers to a Door Lock Error.

Error

Code

E42 Door closed sensing error Door switch or wiring or sensing circuit on main board failure

If your dryer has multiple errors, the display will communicate up to three error codes.

• The GREEN LED light for Done will be illuminated while the rst error code is being communicated.

• The GREEN LED light for Cooling will be illuminated while the second error code is being communicated.

• The GREEN LED light for Drying will be illuminated while the third error code is being communicated.

Reset Dryer Error Code History in Diagnostic Mode:

Rotate the dryer cycle selector knob to the 15’ position (position 10) and press and hold Dry Temp and CANCEL buttons simultaneously

until UI stops displaying error code.

Error Description Possible Causes

The rst digit is the area of error. This digit is determined by counting how many times the LED

over the START|PAUSE button blinks RED. In

this example the LED will blink RED four times.

The second digit is the type of error.

This digit is determined by counting

how many times the LED over the

START|PAUSE button blinks GREEN.

Drying

Cooling

Done

DRYER ERROR CODES

Recalling Last Error Code:

From any cycle position, press and hold Dry Temp and CANCEL buttons for 15 seconds to display the last error code.

Dryer Error Code Table

Error

Code

E41 Door opened at cycle start Door open

E42 Door closed sensing error Door switch or wiring or sensing circuit on main board failure

E51 Drum motor relay error With line safe relay closed, motor sensing detects voltage on motor

E52 Drum motor start sensing error Motor relay driven but start sensing not congruent

E53 Drum motor centrifugal switch error Motor driven but sensing not congruent

E54 Drum motor sensing error Drum motor relay sensing circuit failure (main board failure)

E61 Heater relay error 1. Heater disconnected (wiring or connector failure)

E63 Heater short error 1. Heater sensing circuit failure (main board failure)

E64 Heater open error 1. Heater sensing circuit failure (main board failure)

E65 Thermostat open Heater thermostat trip

E67 Heater sensing error Heater sensing circuit failure (main board failure)

E71 NTC1 (OPEN) error 1. NTC open/disconnected

E72 NTC1 (SHORTED) error 1. NTC short

E91 User Interface protocol incongruence error User Interface mounted is not compatible with main board connected

E92 User Interface mother board protocol

E93 MCF checksum error Wrong machine conguration le in main board

E94 CCF checksum error Wrong cycle conguration le in main board

E97 Missing program on CTF error Software problem in main board

EB1 Power supply frequency out of range 1. Power supply problems

EB2 Power supply amplitude out of range (too

EB3 Power supply amplitude out of range (too

EB4 Line wiring error Wrong line wiring/connection

EF1 Ventilation blocked error Air ow duct clogged or blocked. Remove debris, clean and check one way vent operation

E9C User Interface conguration checksum error Software problem between main board and User Interface board

EBD Line safe relay short circuit error Line safe relay problem (main board failure)

EBE Line safe error Line safe relay problem (main board failure)

EBF Line safe sensing error Line safe sensing circuit failure (main board failure)

EF6 Safety reset error Main board fault

Error Description Possible Causes

1. Motor short circuit to ground (motor or wiring)

2. Electrical noise

3. Line safe relay problem (main board failure)

4. Motor relay open or short

1. Motor fault

2. Main board fault

1. Motor fault

2. Main board fault

2. Heater failure

3. Heater relay failure (open circuit)

2. Heater failure

2. Heater failure

2. Main board fault

2. Main board fault

incongruence

HIGH)

LOW)

1. Wiring failure

2. User Interface board failure

3. Main board failure

2. Wrong MCF

3. Main board failure

1. Power supply problems - too HIGH VOLTAGE

2. Main board failure

1. Power supply problems - too LOW VOLTAGE

2. Main board failure

7

8

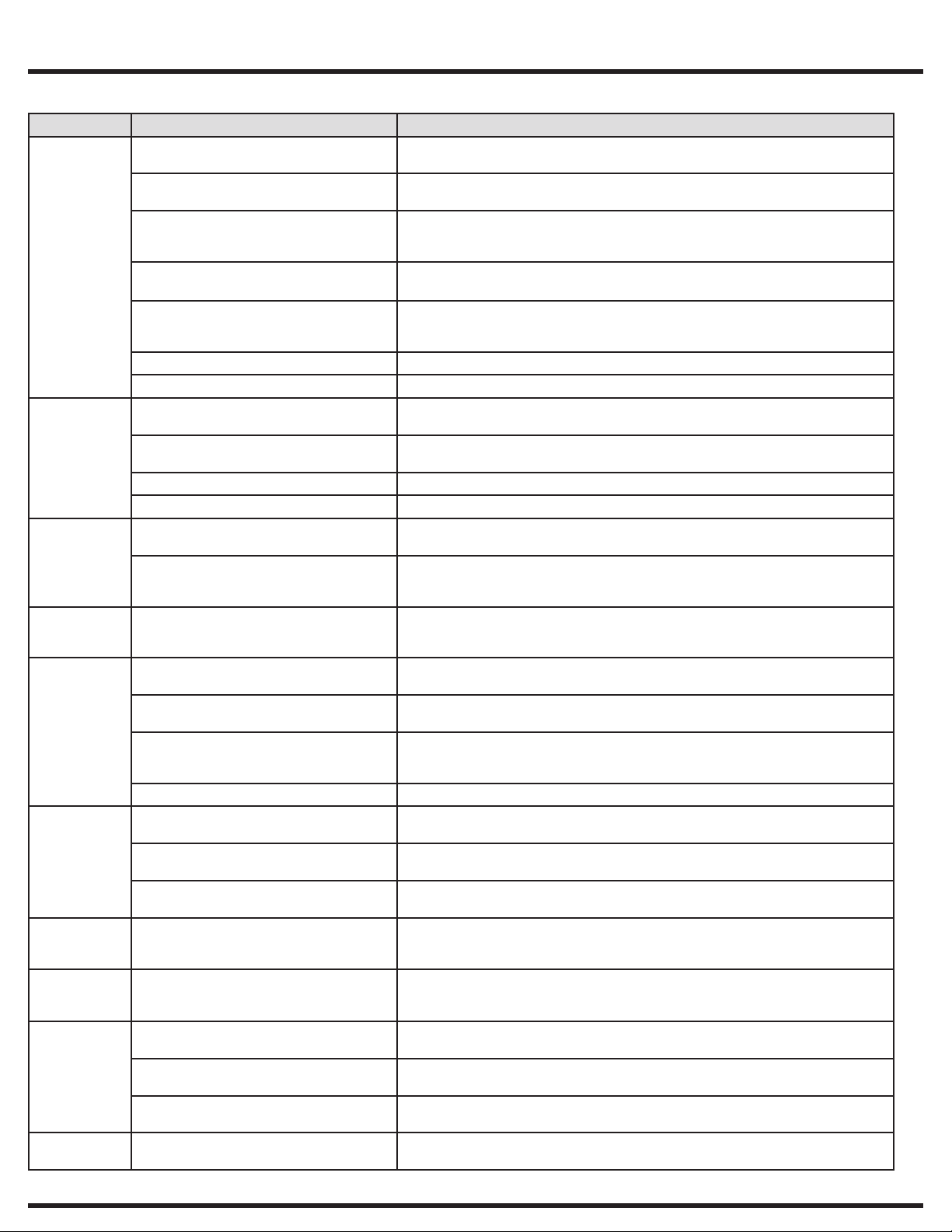

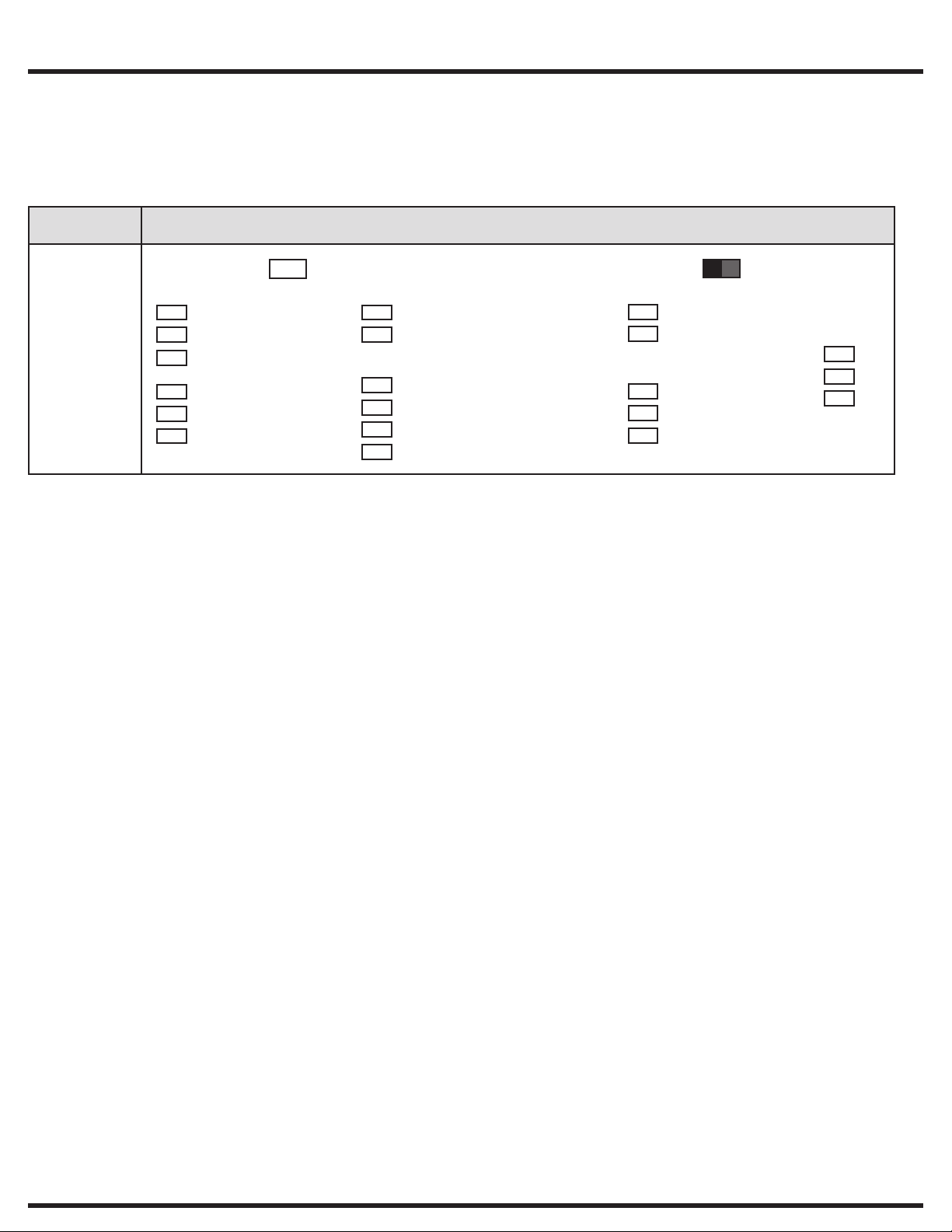

DRYER ERROR DISPLAY

Dryer Error Display Pattern

The error is displayed with the DRYER START|PAUSE LED lights blinking RED and GREEN for 0.5 secs ON and 0.5 secs OFF with a 2.5

secs pause between the sequences. The RED blinking LED light indicates the error family and the GREEN blinking LED light indicates the

error code. The LED lights will continue to blink until the user interacts with the unit (the UI should not go to sleep in error condition).

The RED blinking LED lights are shown in BLACK. The GREEN blinking LED lights are shown in GRAY.

Description LED Error Pattern

START | PAUSE

Hot

DRYER

ERROR

To determine an error code, look at the blinking START|PAUSE LED lights only. Additional blinking lights are not needed for determining

an error.

Warm

Cold

Max Fill

Med

Low

Close Lid

Unbalanced

Washing

Rinsing

Spinning

Done

Close Door

Clean Lint

Drying

Cooling

Done

START | PAUSE

High

Normal

Low

2

3

8

9

10

5

7

11

12

13

4261210

9

153781311

HOJA DE DATOS TÉCNICOS DEL CENTRO DE LAVADO

9

Esta información está dirigida solo a técnicos cualicados.

Índice

Modo de diagnóstico de la lavadora ..................................10

Códigos de error de la lavadora ........................................ 11

Pruebas de resolución de problemas de la lavadora ...........12

Pantalla de error de la lavadora ........................................14

Modo de diagnóstico de la secadora .................................15

Códigos de error de la secadora .......................................16

Pantalla de error de la secadora .......................................17

Esquema de cableado eléctrico .........................................27

Esquema de cableado para gas ........................................28

Los elementos de seguridad de este manual están marcados con

la etiqueta ADVERTENCIA o PRECAUCIÓN dependiendo del

tipo de riesgo según se describe a continuación:

ADVERTENCIA indica una

ADVERTENCIA

PRECAUCIÓN

situación potencialmente

peligrosa que, de no evitarse,

puede llegar a producir la muerte

o lesiones graves.

PRECAUCIÓN indica una

situación potencialmente

peligrosa que, si no se

evita, podría causar lesiones

personales leves o moderadas.

ADVERTENCIA

La información contenida en este manual está destinada

exclusivamente a técnicos de mantenimiento cualicados.

• NO meta la mano en el aparato si el tambor o la cuba están

girando.

• Desconecte la corriente antes de realizar el mantenimiento de la

máquina.

• Ciertos componentes internos no están puestos a tierra

intencionadamente y pueden suponer un peligro de descarga

eléctrica solo durante el mantenimiento.

ADVERTENCIA

PELIGRO DE INCENDIO

Las secadoras de ropa producen pelusa combustible. Un técnico

de mantenimiento cualicado debe limpiar el interior del cuerpo

de la secadora, la carcasa del ltro de pelusas y el conducto de

salida cada 18 meses aproximadamente. Una acumulación excesiva

de pelusa en estas zonas podría provocar un secado ineciente y

posibles INCENDIOS. Consulte la sección Cuidado y limpieza de las

instrucciones de uso y cuidado.

PRECAUCIÓN

Salvo indicación en otro sentido, desconecte la corriente eléctrica

antes de las tareas de servicio.

Interfaz de usuario del centro de lavado

Arandela

1

Selector de ciclo de lavado

Temperatura del ciclo

de lavado

Nivel de agua del ciclo

de lavado

Inicio/Pausa del ciclo

4

de lavado

Modo de diagnóstico de la lavadora

Acceso al modo de diagnóstico de la lavadora:

1. DESCONECTE la unidad girando el selector de ciclo de lavado a la

posición CYCLES (posición 5 en punto) o desenchufando la unidad.

2. CONECTE de nuevo la unidad girando el selector de ciclo de lavado

o enchufando la unidad.

3. Antes de transcurridos 10 segundos, gire el mando a la posición

del ciclo Rinse & Spin.

4. Puse y mantenga pulsados los botones Wash Temp y CANCEL

simultáneamente hasta que se escuche un pitido y las luces LED

comiencen a parpadear una a una.

EE. UU. 1-877-435-3287

Cancelar ciclo de lavado

Luces de aviso del ciclo

6

de lavado

Estado del ciclo de lavado

www.electroluxappliances.com

Secadora

Selector de ciclo de secado

Temperatura del ciclo

de secado

Inicio/Pausa del ciclo

de secado

Cancelar ciclo de secado

Luces de aviso del ciclo

de secado

Estado del ciclo de secado

Salir del modo de diagnóstico:

Para salir del modo de diagnóstico y volver al funcionamiento normal,

pulse y mantenga pulsados los botones Wash Temp y CANCEL

simultáneamente hasta que las luces LED dejen de parpadear,

o bien desenchufe la unidad durante 10 segundos antes de volver

a enchufarla.

NOTA

La unidad saldrá automáticamente del modo de diagnóstico y volverá

al funcionamiento normal si se deja en modo de diagnóstico sin

supervisión durante más de 15 minutos.

Canadá 1-800-265-8352

Loading...

Loading...