Page 1

All about the

Installation

of your

Split Type Room Air Conditioner

Refer to Page 2 for table of contents.

www.frigidaire.com USA 1-866-942-1567

2020323B2335 (June 2009)

www.frigidaire.ca Canada 1-866-942-1567

Page 2

Welcome to the world of

simple handling and no worries

Thank you for choosing Frigidaire. This manual contains all of the information

required to guarantee your safety and the appropriate use of your air

conditioner.

Please read all of the instructions before using the air conditioner and keep

this manual for future reference.

We know you will enjoy your new air conditioner and thank you for choosing

our product.

We hope you will consider us for future purchases.

Environmental advices

The packaging material used is recyclable. We

recommend that you separate plastic, paper and

cardboard and give them to recycling companies.

If you need to dispose of this appliance in the

future, do not throw it away with the rest of your

domestic garbage.

01

Attention!!

The air conditioner that you have bought may be slightly different from

the one illustrated in this manual. Please refer to the information related

to the model you have.

This air conditioner is for domestic use only. It is not recommended for

heavy commercial or industrial use.

Welcome

Page 3

Contents

01. Welcome..........................................................................................01

02. Environmental advices........................................................................01

03. Contents...........................................................................................02

04. Safety precautions.............................................................................

05. Installation:

5.1 Choosing the installation site.................................................04

5.2 Parts list..............................................................................06

5.3 Indoor unit installation.......................................................... 08

5.4 Outdoor unit installation....................................................... 12

5.5 Refrigerant piping connection................................................14

5.6 Electrical work.....................................................................16

5.7 Purging the system............................................................... 20

5.8 Electrical safety....................................................................23

5.9 Gas leak check....................................................................23

5.10 Initial operation test..............................................................24

03

Contents

02

Page 4

Safety precautions

This appliance must be installed by a qualified licensed HVAC

technician in accordance with all applicable codes. All electrical

connections should be performed by a licensed electrician.

Manufacturer's warranty will be voided with failure to comply.

Incorrect Handling could result in Serious Injury or Death!

1. Do not attempt to install the split air

conditioner by yourself.

2. This air conditioner contains no

user-serviceable parts. Always call

an authorized Electrolux servicer

for repairs.

3. When moving the air conditioner,

always call an authorized Frigidaire

servicer for disconnection and reinstallation.

4. Do not insert fingers or place

objects into the discharge area in

the front of the indoor unit.

5. Do not insert fingers or place

objects into the discharge area in

the front of the outdoor unit.

6. Do not start or stop the air

conditioner by turning off the power

at the electrical box.

7. In the event of a malfunction (sparks,

burning smell, etc.) immediately

power off unit and call an

authorized Frigidaire servicer.

8. Do not operate the air conditioner

with wet hands.

9. Do not drink any water or

condensation that is drained from

the air conditioner.

10

.Provide occasional ventilation

during use. Do not direct airflow

at fire places or other heat related

sources as this could cause flare

ups or make units run excessively.

11. Do not climb on or place objects

on the outdoor unit.

12. Do not hang objects off the indoor

unit.

13. Do not place objects containing

water on the indoor and/or

outdoor units.

14. Turn off the air conditioner at the

power source when it will not be

used for an extended period of

time.

15. Periodically check the condition of

the outdoor unit’s installation base

for any damage.

16. Do not apply heavy pressure to

the coil fins of the indoor and/or

outdoor units.

17. Operate the indoor unit with air

filters in place.

18. Do not block or cover the intake

grille, discharge area and outlet

ports.

19. Ensure that any electrical/

electronic equipment is 36” away

from the indoor unit and outdoor

unit.

20. Do not use or store flammable

gases near the indoor and/or

outdoor units.

03

Satety precautions

Page 5

Choosing the installation site

Installation Warnings

1. Carefully read the installation manual before beginning.

2. Follow each step as shown.

3. Observe all local, state and national electric codes. This appliance must

be installed by a qualified licensed HVAC technician in accordance with

all applicable codes. All electrical connections should be performed

by a licensed electrician. Failure to comply will result in a void of the

manufacturer's warranty.

4. Pay attention to all safety notices.

Precautions for Installation

Installation at the following sites may cause problems. If you must inevitably

install the unit at one of these sites, please consult your local distributor

beforehand:

1. Sites with machine oil.

2. Sites with a high concentration of salinity, such as coastal areas.

3. Sites with sulfuric gas, such as hot water springs.

4. Sites with high frequency equipment, such as wireless equipment, welding

machines and medical installations.

5. Sites with flammable gases or volatile material.

6. Sites with special environmental conditions.

7. Laundry rooms.

Choosing the installation site

04

Page 6

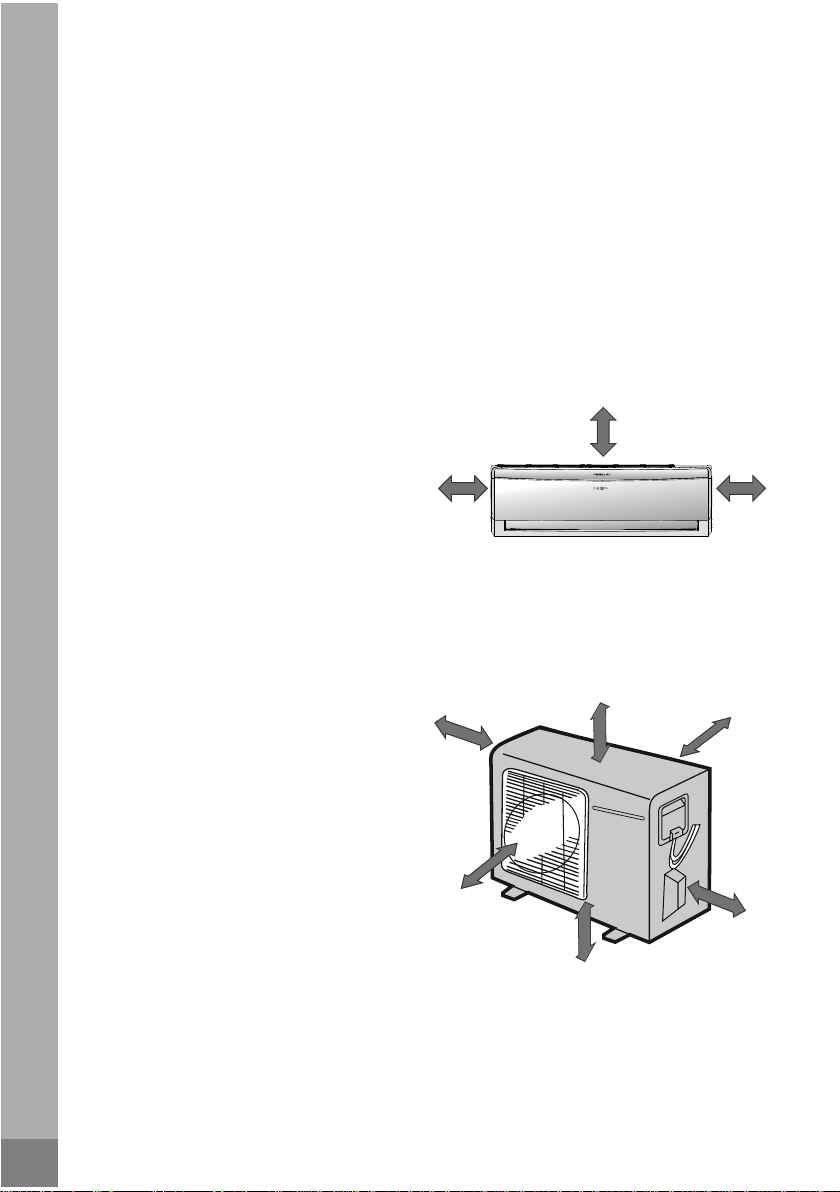

Indoor Unit

1. Install unit where air flow will not

be obstructed.

2. The installation location must

support the weight of the indoor

unit.

3. The site must be easily accessible

for maintenance and replacement

of the air filter.

4. The installation location must allow

for the necessary space around the

indoor unit, as shown in the figure

1.1.

5. There should be at least 3 feet (1

meter) between the unit and radio

or television devices. It is ideal that

the unit be installed at the center of

the wall.

6. The indoor unit must be kept away

from fire, smoke and flammable

gases.

Outdoor Unit

1. The outdoor unit must be installed

at a convenient site that is not

exposed to strong winds. The site

should be dry and well ventilated.

2. The site must support the weight

of the outdoor unit and allow for

vertical installation.

3. The site must be kept away from

flammable gases.

4. The site must provide enough space

around the unit, as shown in figure

1.2.

5. Children must not be able to access

the installation site.

7. We recommend the indoor unit to

be installed as high up as possible

on the inside wall (minimum of 7

feet high), always leaving a space

of at least 6" between the top of the

indoor unit and the ceiling.

8. The installation location must

allow for the easy removal of the

connector pipe and drain hose.

9. The unit must be installed at a

location protected from direct

sunlight.

More

than 6"

More

than 6"

More

than 12"

Figure 1.1

More

than 8.5"

More

than 6"

More

than 12"

06

More

than 78"

More

than 2"

Figure 1.2

More

than 18.5"

05

Choosing the installation site

Page 7

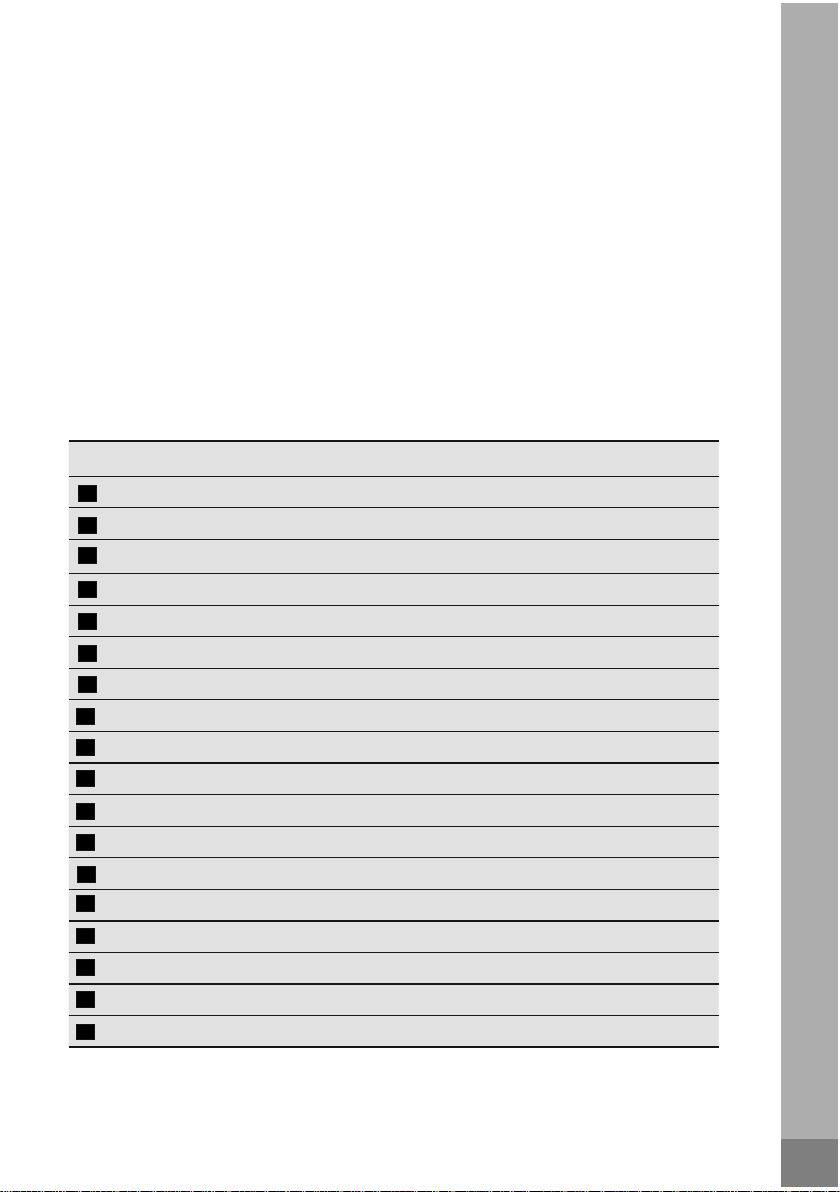

Part Lists

Tools needs for installation

1. Level gauge

2. Screw driver

3. Electric drill

4. Hole core drill (ø55mm /

ø70mm)

5. Flaring tool set

6. Specied torque wrenches

7. Spanner (half union)

8. A glass of water

9. Hexagonal wrench (4mm)

10. Gas-leak detector

11. Vacuum pump

12. Gauge manifold

13. Users manual

14. Thermometer

15. Multimeter

16. Pipe cutter

17. Measuring tape

Accessories

Number Name of Accessories Quantity

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Note: Other necessary parts for the installation, besides the above mentioned, must

be provided by the customer/installer.

Indoor unit mounting plate 1

Clip anchor Not supplied

Self-tapping screw A ST3.9X25 5-8

Remote control 1

Remote control holder (Optional) 1

Screw for remote holder ST2.9X10 (Optional) 2

Battery (AAA 1.5V) 2

Insulation material Not supplied

Connection piping assembly(Optional) 1

Insulation hose for refrigerant piping Not supplied

Drain hose Not supplied

Wall clamp Not supplied

Connection power cable Not supplied

Drain connector (Heat Pump model only) 1

Drain plug (Heat Pump model only) (Optional) 2-3

Thermal insulating pipe for extending drain hose 1

Flare nut (for suction pipe) (Optional) 1

Flare nut (for liquid pipe) (Optional) 1

Part list

06

Page 8

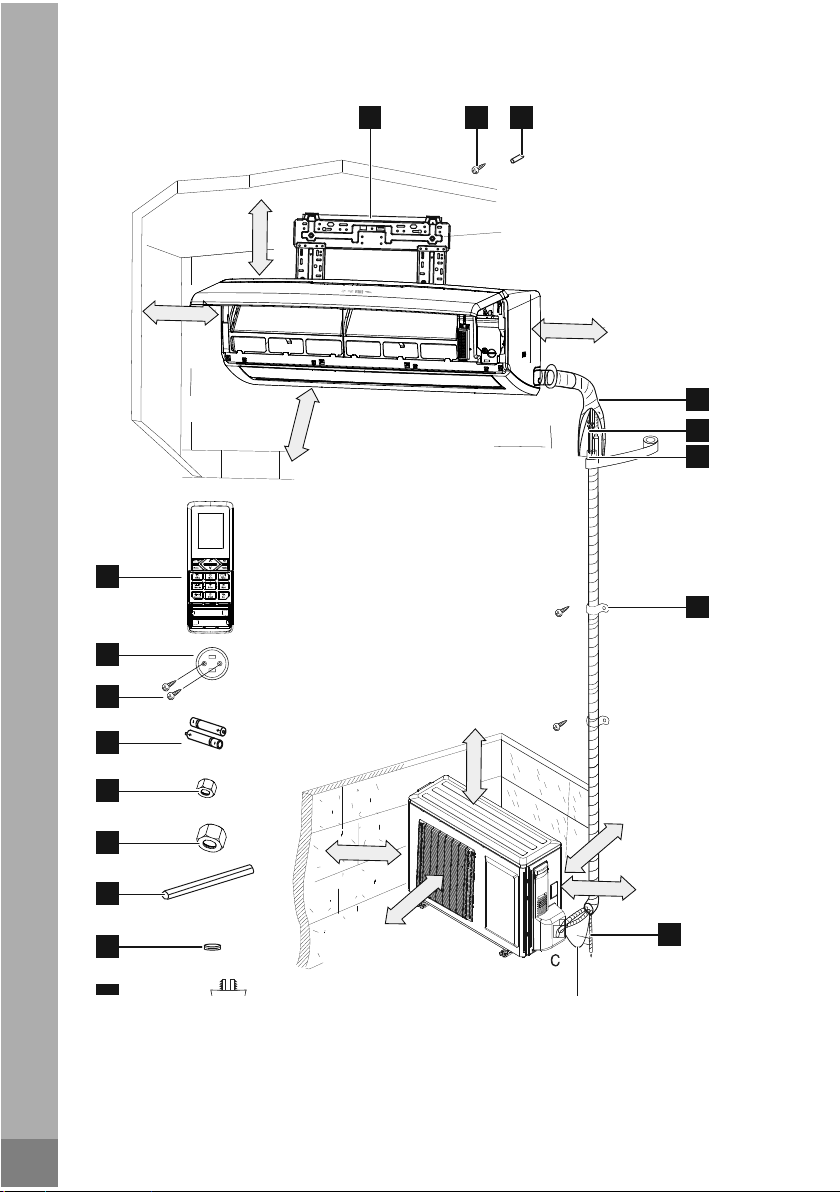

Product Description

1 23

Indoor

Unit

4

5

6

7

18

17

16

15

Space to the ceiling

15cm above

Space to the wall

15cm above

3m above

Air outlet side

Space to the wall

30cm above

Air outlet side

Space to obstruction

2m above

Space to the wall

50cm above

15cm above

8

9

10

11

Air inlet side

30cm above

50cm above

Space to the wall

12

07

NOTE

All the pictures in this manual are for explanation purposes only. The actual

shape of the indoor unit you purchased may be slight different on front panel

and display window.The actual shape shall prevail.

Part list

Page 9

Indoor unit installation

Wall mounting brackets and dimensions

Indoor unit outline

6" or more

from the wall

Refrigerant pipe

hole (right) Ø 2.56"

Indoor unit outline

6" or more

from the wall

Refrigerant pipe

hole (right) Ø 2.56"

6" or more from

the ceiling

4.21"

3.39"

Wall mounting bracket

4.21"

3.39"

6" or more

from the wall

B

Refrigerant pipe

hole (right) Ø 2.56"

A

%WXV$%

6" or more from

the ceiling

Wall mounting bracket

A

6" or more

from the wall

B

Refrigerant pipe

1.58''

7.91''

=18000 Btu's (A:36.97" B:11.73")

1.58''

hole (right) Ø 2.56"

5.31''

Indoor unit outline

6" or more

from the wall

Refrigerant pipe

hole (right) Ø 2.56"

6" or more fr

the ceiling

om

Wall mounting bracket

A

B

1.97''

3.94'' 4.88''

=22000 Btu's

(A:39.69" B:12.40")

Indoor unit installation

6" or more

from the wall

1.97''

Refrigerant pipe

hole (right) Ø 2.56"

08

Page 10

om

,QGRRUXQLWRXWOLQH

RUPRUH

IURPWKHZDOO

RUPRUHIU

WKHFHLOLQJ

B

5HIULJHUDQWSLSH

KROHULJKW

1.97''

3.94'' 4.88''

%WXV

$%

Installing the Wall Mounting Bracket

:DOOPRXQWLQJEUDFNHW

A

RUPRUH

IURPWKHZDOO

1.97''

5HIULJHUDQWSLSH

KROHULJKW

1. Install the wall mounting bracket

horizontally over the structural

parts on the wall using the spaces

the wall with eight A type screws.

4. At all times securing to the wall

studs is recommended.

indicated on the bracket, as shown

in figure 1.3.

2. In the case of tiled, concrete or

Wall mounting bracket

similar walls, create 13/64"

diameter holes. Place anchor

supports for the appropriate

assembly screws.

3. Install the wall mounting bracket to

Figure 1.3

Attention!!!

Fit the wall mounting bracket and drill holes in the wall according to the

wall structure and corresponding mounting points on the wall mounting

bracket (Dimensions are in “inches” unless otherwise stated).

Drilling the Hole

Indoor unit

1. Determine the position of the

hole for the pipes using the wall

mounting bracket and drill the

pipe hole so that it is tilted slightly

downward.

2. Always use a pipe cover with an

opening when drilling.

Wall

Outdoor unit

28"

0.2"-0.

09

Indoor unit installation

Page 11

Connective pipe and drainage installation

Connective pipe

1. For the left-hand and right-hand

piping, remove the pipe cover from

the side panel. The pipe cover can

be kept as it may be used when

relocating the air conditioner to any

other place.

2. For the rear-right-hand and rearleft-hand piping, install the piping

as shown in figure 1.4. Bend the

connective pipe to be laid at a

height of 1-11/16" or less from the

wall. Fix the end of the connective

pipe.

Drainage

1. Run the drain hose sloping

downward. Do not install the drain

hose as illustrated in figure 1.5.

2. When connecting extension drain

hose, insulate the connecting part

of extension drain hose with a

shield pipe, do not let the drain

hose slack.

Pipe cover

(right)

Right piping

Indoor unit

outline

Pipe

holder

Rear right

piping

Figure 1.4

Connective

pipe

Do not block

water flow

by a rise.

Do not put the end

of drain hose into water.

Pipe cover

(left)

Left piping

Rear left

piping

"

1-11/16

Do not block

water flow

by a rise.

Fastening the Indoor Unit

1. Pass the piping through the hole in

the wall.

2. Put the upper claw at the back of

the indoor unit on the upper hook

of the wall mounting bracket, move

the indoor unit from side to side to

see that it is securely hooked.

Figure 1.5

Upper hook

Lower hook

Indoor unit installation

10

Page 12

3. Piping can easily be made by lifting

the indoor unit with a cushioning

material between the indoor unit

and the wall.

4. Push the lower part of the indoor

unit up on the wall, Then move the

indoor unit from side to side, up

and down to check if it is hooked

securely.

Piping and wrapping

Cushioning

material

1. Bundle the tubing, connecting

cable, and drain hose with tape

Indoor unit

securely and evenly as shown in the

sideward figure.

2. Because the condensed water from

Cable

connection

rear of the indoor unit is gathered

in ponding box and is piped out of

room, do not put anything else in

Drain hose

the box.

Attention!!

1. Connect the indoor unit first, then the outdoor unit.

2. Be careful not to let the drain hose slack.

3. Both of the auxiliary piping should be heat insulated.

4. Be sure that the drain hose is located at the lowest side of the

bundle. Locating at the upper side may cause drain pan to overflow

inside the unit.

5. Never intercross nor intertwist the power wire with any other wiring.

6. Run the drain hose sloped downward to drain out the condensed

water smoothly.

Ponding

box

Pipe room

Connective

pipe

Wrapping

belt

11

Indoor unit installation

Page 13

Outdoor unit installation

1. Install the outdoor part of the unit

on a flat surface to avoid excess

noise and vibration. A condenser

pad is recommended.

2. Direct the air vent toward an area

without obstacles.

3. Install the unit at the site where

it is exposed to as little wind as

possible, especially in areas where

it is frequently windy.

4. If the installation site is exposed to

heavy winds, such as in coastal

areas, place the unit along the

widest part of the wall or use

protective plates.

5. Be sure there is no obstacle which

blocks exhausting air, including

schrubs or bushes.

Strong wind

Settlement of outdoor unit. Anchor the

outdoor unit tightly and horizontally

on a concrete or flat mount with a

bolt and nut 2/5" or 5/16" diameter

(Purchased separately).

Capacity (BTU/h)

Outdoor unit dimension inch(WxHxD)

33-9/25 x 21-6/25 x 12-3/5

12000

18000

22000

28000

33600

26000

34400

33-9/25 x 23-6/25 x 12-3/5

37-3/5 x 27-3/5 x 15-3/5

38-3/5 x 31-1/10 x 16-3/5

38-3/5 x 31-1/10 x 16-3/5

38-3/5 x 31-1/10 x 16-3/5

38-3/5 x 31-1/10 x 16-3/5

42-4/5 x 43-4/5 x 17-3/10

Air inlet

Air

inlet

Air outlet

A (inch) B (inch)

21-6/259000

22-2/25

24-6/25

26-4/25

26-4/25

26-4/25

26-4/25

31-3/25

11-7/25

14-4/25

15-9/25

17-7/25

17-7/25

17-7/25

17-7/25

18-3/25

Outdoor unit installation

12

Page 14

Condensate drainage of outdoor unit

(cooling only excluded)

The condensate and defrosting water produced during heating in the outdoor

unit can be properly discharged by drainage pipe.

Installation method: Insert the drain connection into one of the holes of the

chassis and then connect drainage pipe with drain nozzle. Insert drainage plugs

(with different appearance) into the other holes.

Drain

connection

13

Outdoor unit installation

Chassis

Drainage Plug

Page 15

Refrigerant piping connection

Unit comes with 25' tubing bundle. It is not recommended to cut. If too long,

loop for excess.

Note:

Keep original bend so not kinking of the tube occurs.

Flaring work

Main cause for refrigerant leakage is

due to defect in the flaring work.

Carry out correct flaring work using

the following procedure:

1. Cut the pipes and the cable.

A) Use the piping kit accessory or

pipes purchased locally.

B) Measure the distance between

the indoor and the outdoor unit.

C) Cut the pipes a little longer than

the measured distance.

D) Cut the cable 5ft longer than the

pipe length.

2. Burr removal

A) Completely remove all burrs from

the cut cross section of pipe/

tube.

B) Put the end of the copper tube/

pipe in a downward direction

as you remove burrs in order to

avoid dropping burrs into the

tubing.

3. Put nut on.

Remove flare nuts attached to

indoor and outdoor unit, then

put them on pipe/tube having

completed burr removal. (It is not

possible to put them on after flaring

work)

Pipe

Correct

Point

down

Cooper tube

Wrong

Oblique Roughness Burr

Pipe

Reamer

Flare nut

Refrigerant piping connection

14

Page 16

4. Flaring work.

Firmly hold copper pipe in a die in

the dimension shown in the table

below.

Bar

Copper

pipe

Max.

0.051

0.063

0.071

0.095

A (inch)

Min.

0.028

0.039

0.039

0.087

OUTER

DIAMETER (inch)

1/4

3/8

1/2

5/8

Connection Adjustment

1. Align the pipes to be connected.

2. Screw the flare nut with your

fingers, and then tighten it with a

spanner and torque wrench, as

shown in figure 1.6.

Caution:

Excessive twisting may break

the nut, depending on the installation

conditions.

Handle

Clamp

handle

Indoor unit

tubing

Figure 1.6

Yoke

Red arrow mark

Pipings

Flare

nut

OUTER TIGHTENING ADDITIONAL TIGHTENING

DIAMETER (inch)

1/4

3/8

1/2

5/8

15

Refrigerant piping connection

TORQUETORQUE (lbf.in)

139 174

260 304

434 477

651 694

(lbf.in)

Page 17

Electrical work

Electric safety regulations for the initial installation

1. If there is serious safety problem

about the power supply, the

technicians should refuse to install

the air conditioner and explain

to the client until the problem is

solved.

2. Power voltage should meet the

requirements in table 2.1.

3. Over current protection and

circuit disconnect should meet

the requirements in table 2.1 and

the applicable local and national

electrical codes.

Electrical Data Table 2.1

System

Operating

Capacity

(BTU/h)

9000 208/230-1-60 187/253 6.60 / 0.14

12000 208/230-1-60 187/253 6.60 / 0.14

18000 208/230-1-60 187/253 12.08 / 0.49

22000 208/230-1-60

28000 208/230-1-60

33600 208/230-1-60

26000 208/230-1-60

34400 208/230-1-60

Voltage

Volts-Ph.-

Freq

Voltage

(Min/Max)

RLA LRA FLA

14.67 / 0.65

187/253

13.50 40 0.45

187/253

17.50 67 0.73 40

187/253

15.82 / 0.59

187/253

15.60 / 0.82

187/253

Outdoor FanCompressor Indoor Fan

4. Ensure the air conditioner is

grounded well.

5. All wiring must comply with local

and national electrical codes and

be installed by qualified and skilled

electricians.

6. An individual branch circuit used

only for this air conditioner must be

available. See table 2.1.

MIN. Circuit

Ampacity

Watts

(MCA)

21

/

Output

Volts FLA

Watts

208/230V-AC

30

208/230V-AC

30

208/230V-AC

60

208/230V-AC

90 0.38 92 20

208/230V-AC

120 0.40 40 20

208/230V-AC

170 0.47 60 24

/

90 / /

170 / 21

/

Output

0.36 20 9 15

0.36 20 9 15

0.24 20 16

Max. Fuse/Circuit

Breaker

Amps(MOP)

25

30

30

35

35

Connecting (Power and Control Cable)

s7KHPDLQSRZHULVVXSSOLHGWRWKHRXWGRRUXQLW7KHILHOGVXSSOLHGFRQQHFWLQJ

cable from the outdoor unit to indoor unit consists of four wires and provides

the power for the indoor unit as well as the communication signal and ground

between the outdoor and indoor unit. Two wires are high voltage AC power,

one is low voltage DC signal and one is a ground wire.

s&RQVXOWORFDOEXLOGLQJFRGHV1(&1DWLRQDO(OHFWULFDO&RGHRU&(&

(Canadian Electrical Code) for special requirements.

Electrical work

16

Page 18

Connect the cable to the indoor unit

1. The inside and outside connecting

cable can be connected without

removing the front grille.

2. Connecting cable between indoor

unit and outdoor unit shall be

approved polychloroprene sheathed

flexible type cord.

3. Lift the indoor unit panel up,

remove the electrical box cover by

loosening the screw.

4. Ensure the wire color of the outdoor

terminal and indoor terminal

correspond respectively.

5. Wrap the cable not connected to

the terminal block with insulation

tape so that they will not come

in contact with any electrical

components. Secure the cable onto

the control board with the cord

clamp.

Cable

Code wire

Electrical box

cover

Terminal block of indoor unit

N(1) 2 3

0.39"

17

Electrical work

1.57"

To Outdoor Unit

Page 19

Connect the cable to the outdoor unit

1. Remove the electrical control board

cover from the outdoor unit by

loosening the screw.

2. Connect the connective cables to

the terminals as identified with their

respective matched numbers on

the terminal block of indoor and

outdoor units. The connective cable

to power supply shall be approved

polychloroprene sheathed flexible

cord.

3. Secure the cable onto the control

board with the cord clamp.

4. To prevent the ingress of water,

form a loop of the connective cable

as illustrated in the installation

diagram of indoor and outdoor

units.

5. Insulate unused cords (conductors)

with PVC-tape. Process them so they

could not touch any electrical or

metal parts.

Cover

Screw

Single split terminal block

Indoor unit A Indoor unit B Indoor unit C Indoor unit D Indoor unit E

L1 L2

Indoor unit A Indoor unit B Indoor unit C

L1 L2

26000 Btu/h Multi split terminal block

33400 Btu/h Multi split terminal block

Electrical work

18

Page 20

Caution

After the confirmation of the above conditions, prepare the wiring as follows:

1. Never fail to have an individual power circuit specifically for the air

conditioner. As for the method of wiring, be guided by the circuit diagram

posted on the inside of control cover.

2. The screws which fasten the wiring in the casing of electrical fittings are liable

to come loose from vibrations to which the unit is subjected during the course

of transportation. Check them and make sure that they are all tightly fastened.

(If they are loose, it could cause burn-out of the wires.)

3. Specification of power source.

4. Confirm that electrical capacity is sufficient.

5. See to that the starting voltage is maintained at more than 90 percent of the

rated voltage marked on the name plate.

6. Confirm that the cable thickness is as specified in the power source

specification.

7. Always install an earth leakage circuit breaker in a wet or moist area.

8. The following would be caused by voltage drop: vibration of a magnetic

switch, which will damage the contact point, fuse breaking, disturbance of the

normal function of the overload protector.

9. The means for disconnection from a power supply shall be incorporated in the

fixed wiring and have an air gap contact separation of at least 1/8" in each

active (phase) conductors.

Purging the system

Air and moisture in the refrigeration system have undesirable effects as indicated

below:

1. Pressure in the system rises.

2. Operating current rises.

3. Cooling or heating (only for models with heating function) efficiency drops.

4. Moisture in the refrigerant circuit may freeze and block capillary tubing.

5. Water may lead to corrosion of parts in the refrigeration system.

Therefore, the indoor unit and tubing between the indoor and outdoor unit must

apply leakage test and be evacuated to remove any noncondensables and

moisture from the system.

19

Electrical work

Page 21

Purging the system with a vacuum pump

1. Check that each tube (both liquid and gas side tubes) between the indoor and

outdoor units have been properly connected and all wiring for the test run

has been completed. Remove the service valve caps from both the gas and

the liquid side on the outdoor unit. Note that both the liquid and the gas side

service valves on the outdoor unit are kept closed at this stage.

2. When relocating the unit to another place, perform evacuation using vacuum

pump.

3. Oil trap should be installed every 16'-25' (no oil trap needed when outdoor

unit installed at a lower place than indoor unit).

4. Pipe length and refrigerant amount for single split type air conditioner .

(see tabel 2.2)

Indoor unit

Outdoor unit

(A)

(B)

Indoor unit

Outdoor unit

Oil trap

(A)

Piping length under 16' Piping length 16' or more

Table 2.2

Cooling capacity

(BTU/h)

9000 Heat Pump

12000

18000

18000

22000

22000

28000

33600

System

Heat Pump

Cooling Only

Heat Pump

Cooling Only

Heat Pump

Heat Pump

Heat Pump Use vacuum pump.25'~98'

Connective pipe

length (A)

25'~49' 16'

25'~66'

25'~82'

25'~82'

25'~82'

25'~82'

25'~98'

Max height

difference (B)

33'

33'

33'

33'

33'

66'

66'

Air purging

Use vacuum pump.

Use vacuum pump.

Use vacuum pump.

Use vacuum pump.

Use vacuum pump.

Use vacuum pump.

Use vacuum pump.

Additional amount of

refrigerant to be charged

R410a: 0.22ozs/ft (Pipe length-25')

R410a: 0.22ozs/ft (Pipe length-25')

R410a: 0.16ozs/ft (Pipe length-25')

R410a: 0.22ozs/ft (Pipe length-25')

R410a: 0.16ozs/ft (Pipe length-25')

R410a: 0.54ozs/ft (Pipe length-25')

R410a: 0.54ozs/ft (Pipe length-25')

R410a: 0.54ozs/ft (Pipe length-25')

(B)

Purging the system

20

Page 22

5. Pipe length and refrigerant amount for multi split type air conditioner.

(see tabel 2.3)

Table 2.3

Cooling capacity

(BTU/h)

26000

Connective pipe

length (Lx)

25'~66'

(x=1, 2, 3)

Max connective pipe

total length (H1)

197'

(H1=L1+L2+...+Lx, x≤3)

Max height

difference (H2)

50'

Air purging

Use vacuum pump.

Additional amount of

refrigerant to be charged

R410a: 0.22ozs/ft (Pipe length-82')

34400

H1

25'~82'

(x=1, 2, 3, 4, 5)

Outdoor unit

246'

(H1=L1+L2+...+Lx, x≤5)

50'

Use vacuum pump.

L4L3L2 L5L1

R410a: 0.22ozs/ft (Pipe length-131')

Lx

baedc

Indoor unit

Caution in handling the packed valve integrated in the

outlets of outdoor unit.

1. Operation of opening packed valve: Open the valve stem until it hits against

the stopper. Do not try to open it further.

2. Operation of closing packed valve: Securely tighten the valve stem with a

special tool. Then securely tighten the valve stem cap with a spanner or the

like. Refer to the table on page 17 for valve cap tightening torque.

Note:

There is a charging port integrated in the low side outlet, but not in the

high side outlet. The low side outlet is shown in the sketch map below.

A

B

Packed valve

21

Purging the system

Refrigerant

Indoor unitOutdoor unit

Gas

Valve body

C

D

Charge port

Half union

Flare nut

Cap

Valve stem

Stopper

Page 23

When using the vacuum pump

For method of using a manifold valve, refer to its operation manual.

1. Completely tighten the flare nuts at

connection point A, B, C and D.

Connect valve core removal tool

to the charging port, then connect

vacuum hose to valve core tool.

Open the schrader valve.

Note: The schrader valve is inside the

charging port.

2. Connect the other charge hose

of manifold valve to the vacuum

pump.

3. Fully open the Low Side handle of

the manifold valve.

4. Operate the vacuum pump to

evacuate. After starting evacuation,

slightly loose the flare nut of the

Low Side valve on the gas pipe

side and check if the air is entering

(Operation noise of the vacuum

pump changes and a compound

meter indicates 0 instead of

minus), then tighten the flare nut.

The procedure verifies if there are

blocks inside the tubes.

5. Make evacuation for 15 minutes or

more and check that the compound

meter indicates -7-3/5 x 10

Microns Hg (-1x10 Pa). After the

evacuation is completed, fully close

the Low Side handle of the manifold

valve and stop the operation of the

vacuum pump.

6. Turn the stem of the packed valve

B about 45

o

counterclockwise

for 6~7 seconds after the gas

comes out, then tighten the flare

nut again. Make sure the pressure

display in the pressure indicator is

Indoor unit

Outdoor unit

Manifold Valve

-76cm/Hg

Low Side

Charge Hose

Vacuum pump

Charge

Hose

High Side

a little higher than the atmospheric

pressure. This procedure verifies

if the refrigerant goes through the

tubes correctly.

7. Close the schrader valve, then

remove the valve core tool. Replace

the charging port cap.

8. Fully open the packed valve stems B

and A.

9. Securely tighten the cap of the

packed valve.

Purging the system

22

Page 24

Electrical safety

Perform the electric safety check after completing installation:

1. Insulated resistance: The insulated resistance must be more than 2M.

2. Grounding work: After finishing grounding work, measure the grounding

resistance by visual detection and grounding resistance tester. Make sure the

grounding resistance is less than 4.

3. Electrical leakage check (performing during test running): During test

operation after finishing installation, the serviceman can use the electric

probe and multimeter to perform the electrical leakage check. Turn off the unit

immediately if electrical leakage happens. Check and find out the solution

ways till the unit operates properly.

Gas leak check

Soap water method

Apply a soap water or a liquid

neutral detergent on the indoor unit

connection or outdoor unit connections

by a soft brush to check for leakage

of the connecting points of the piping.

If bubbles come out, the pipes have

leakage point.

Leak detector

Use the leak detector to check for

leakage.

Caution

A: Low side valve, B: High side valve

valve C and D are ends of indoor unit

connection.

indoor unit

check point

Cover

Outdoor unit

check point

23

Electrical safety & Gas leak check

Page 25

Initial operation test

Perform test operation after completing gas leak check at the flare nut

connections and electrical safety check.

1. Connect the power, press the ON/OFF button on the remote controller to turn

the unit on.

2. Use the MODE button to select COOL, HEAT (Only for models with heating

function), AUTO and FAN to check if all the functions work well.

3. When the ambient temperature is too low(lower than 63

be controlled by the remote controller to run in cooling mode, manual

operation can be taken. Manual operation is used only when the remote

controller is disable or maintenance necessary.

o

F), the unit cannot

Auto/OFF

Manual control button

Initial operation test

24

Loading...

Loading...