Page 1

SERVICE DATA TECH SHEET

Gas Free-Standing Ranges with Venturi Burner System

Before servicing, disconnect electrical supply

at circuit breaker, fuse or power cord.

This service data sheet is intended for use by

persons having electrical and mechanical training and a level of

knowledge of these subjects generally considered acceptable

in the appliance repair trade. The manufacturer cannot be

responsible, nor assume any liability, for injury or damage of

any kind arising from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important

that safe servicing practices be observed. The following are examples, but without

limitation, of such practices.

1. Before servicing or moving an appliance remove power cord from electrical

outlet, trip circuit breaker to OFF, or remove fuse.

2. Never interfere with the proper installation of any safety device.

3. GROUNDING: The standard color coding for safety ground wires is GREEN

or GREEN WITH YELLOW STRIPES. Ground leads are not to be used as

current carrying conductors. It is extremely important that the service

technician reestablish all safety grounds prior to completion of

service. Failure to do so will create a potential safety hazard.

4. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately

spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely

reassembled.

Gas Regulator & Shut-off Valve Location

The gas regulator is located on the back of the appliance (See Fig.1).

The shut-off valve is located on the gas regulator as shown (Fig. 2).

After properly installing or if converting the appliance to L.P. Gas, be

sure to set the shut-off valve back to the “ON” position before operating.

Fig. 1

Fig. 2

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

p/n 316904011 (0907)

Surface Burner Heads

Lighter

Ports

Flash Tube

Assemby

Charge Ports

Surface Burner System

Spark

Electrodes

Surface Gas Valves & Air Shutter

Air Shutter adjustment

Venturi

Air

Shutters

Fig. 4

Surface Burner Flame Adjustments

1. The air shutter adjustment for each of the 4 surface burners is located

at the open end of the venturi tube near the valve gas orifice (See Fig.

4). Should the air shutter need adjustment, rotate the air shutter to

allow more or less air into the burner tube. If the air is properly adjusted,

the flame will be steady, relatively quiet, and have approximately 1/2"

sharp blue cone (usually the center of air shutter's adjustment). If the

flame is yellow in color, increase air shutter opening size. If the flame

is a distinct blue but lifting away from the burner, reduce the air shutter

opening size.

2. Check gas pressure with all burners ON (See Check the Regulator

Inlet & Outlet).

Surface Burner Troubleshooting

Check the Regulator Inlet & Outlet -

Check gas pressure to manifold or surface burner. Ranges should be

checked under maximum flow (all burners turned ON and with changes

in flow). The outlet of ranges using Natural Gas should check 4” WCP;

ranges on LP gas 10” WCP. If gas pressure is incorrect check inlet supply

to gas regulator. Inlet pressure should be at least 1” WCP above outlet

pressure. If pressure at inlet of the gas regulator exceeds 8” WCP Natural

Gas or 11” WCP LP gas, the gas supplier should be contacted.

Surface Burners Slow to Ignite or Not Igniting -

1. Check for spark at the 2 surface spark electrodes. If the spark

electrodes are operating, go to step 2 below. If the spark electrodes

are not operating, go to step 5 below.

2. Check gas pressure with all surface burners turned ON (See

Check the Regulator Inlet & Outlet).

3. Clean surface burner head charge ports & lighter ports. The ports may

be cleaned using a strand of wire or some similar object. DO NOT

ENLARGE BURNER PORTS when cleaning (See Fig. 3).

4. Check alignment of burner flash tube assemblies (See Fig. 3).

5. Disconnect power & turn OFF power to the appliance. Remove the

panel at the top right rear of the range that covers the spark module.

6. Reconnect electrical power. Turn one of the surface burner valves to

“LITE” and check between “L” and “N” on the spark module for 120

VAC. If the meter reads 120 VAC, go to step 7. If the meter reads 0

VAC, check the wiring to and from the surface burner switches and the

surface burner switches. Note: It is unlikely that all 4 surface burner

switches will fail simultaneously since the surface burner switches are

wired in parallel.

7. Listen to the spark module. If a snapping sound is heard and the

surface electrodes are not arcing, the high voltage lead to surface

electrodes is open. If the snapping sound is not heard go to step 8.

Spark

Wire

leads to

Spark

Module

Gas

Valve

Orifice

Fig. 5

Caps

Surface

Gas

Burner

Valve

Surface

Burner &

Venturi

Spark

switches

Manifold

Valve

screw

8. Disconnect electrical power and remove the 2 wires from output

terminals 1 & 2. Using an Ohm Meter check the high voltage wiring

between the spark module and the burner electrodes for a short to the

chassis. If no shorted wiring is found replace the spark module.

Oven Burner Troubleshooting

The oven burner is ignited by an electronic glowbar ignition system. The

ignition circuit consists of the oven thermostat, the oven igniter and the

oven safety valve. These 3 components are wired in series. The most

important points to know about the oven ignition system are:

1. The oven igniter resistance decrease as the igniter surface temperature

increases.

2. The gas safety valve operates by current not voltage.

From a cold start, the oven igniter needs 30-60 seconds with voltage

applied, to reduce its electrical resistance enough to provide a minimum

of 2.9 amps of current flow in the series circuit. This is the required current

flow needed for the gas safety valve to open to supply gas to the oven

burner. NOTE: The oven igniter needs 2.9 amps or greater to the open

gas safety valve.

The oven igniter should provide a steady current flow of between 3.2 to 3.6

amps in the circuit. At that point the oven igniter temperature is between

1800° to 2500°F. The oven igniter will remain energized at all times during

burner operation. If the oven igniter glows red but does not draw at least

2.9 amps, the fault is usually with the oven igniter, not the oven safety

valve. If the oven igniter does not glow check the thermostat and circuit

wiring for an open circuit. NOTE: Be sure that the oven shut-off valve lever

located on the gas regulator is set to ON position (See Fig. 1).

Oven Burner Will Not Cycle Off -

1. Disconnect electrical power from appliance. If the oven burner does

not cycle OFF, the gas safety valve is defective. If the oven burner

cycles OFF go to step 2.

2. Check polarity to the appliance. If polarity is incorrect, check range

wiring for a short to chassis. If polarity is correct go to step 3.

3. Allow oven to heat to 300°F, disconnect power and lift the cooktop to

obtain access to the oven thermostat. Set the oven thermostat to

200°F and remove wires from the oven thermostat.

4. Check across the thermostat terminals with an Ohm Meter. If the

meter reads continuity, the oven thermostat is defective.

Oven Burner System

Spark

Spark

Module

Module

Wiring

Gas Safety

Valve

Gas Valve

Cover

Increase gas volume

for Natural Gas

Fig. 7

Oven Burner Adjustments

1. Check orifice hood

adjustment on the oven

safety valve to be sure it is

adjusted for the type of gas

supplied to the range

(Natural or LP - See Fig. 7).

2. Check the oven safety valve

orifice hood for straight

injection of gas into the oven

burner. If the orifice hood is

tipped, the oven burner will

not draw in air properly.

3. Check air shutter

adjustments on oven burner

(See Fig. 8).

4. Check gas pressure (as

described earlier).

Air

Shutter

Orifice

Hood

Air

Shutter

Lock

Screw

Oven Igniter

Oven

Burner

Fig. 6

SpudPin

Decrease gas

volume

for LP Gas

Air

Shutter

Fig. 8

Flame

Spreader

Burner

Support

Oven

Burner

Tube

Orifice

Hood

Oven Calibration -

1. Place the probe for the oven tester in the center of the oven.

2. Turn thermostat to 350°F and allow it to cycle 3 times. Record the

temperatures at the highest and lowest point of the third cycle and

determine the average.

3. If the average temperature does not fall within 330° to 390°F,

replace the oven thermostat.

Natural Gas BTU Ratings

This appliance is factory preset for use with Natural Gas with a 9,000

BTU rating for each surface burner and 18,000 BTU rating for the oven

burner. NOTE: For operation at elevations above 2000 ft., appliance

rating shall be reduced at the rate of 4 percent for each 1000 ft. above

sea level.

Page 2

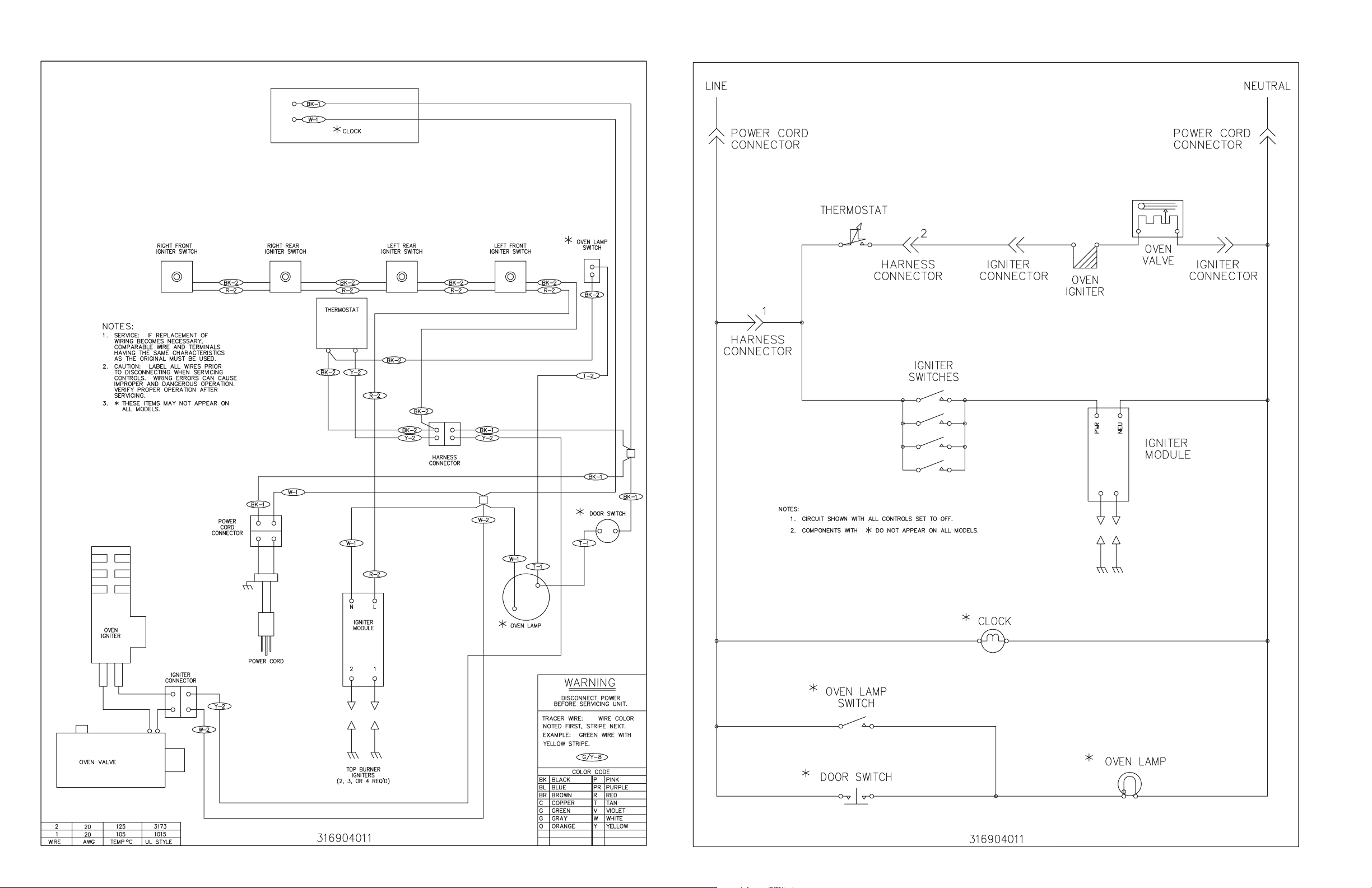

General Troubleshooting Wiring Diagram General Troubleshooting Wiring Schematic

Loading...

Loading...