Page 1

p/n 807880401 Rev A (1305)

SERVICE DATA SHEET

Electric Ranges with ES 300/305/306 Electronic Oven Controls

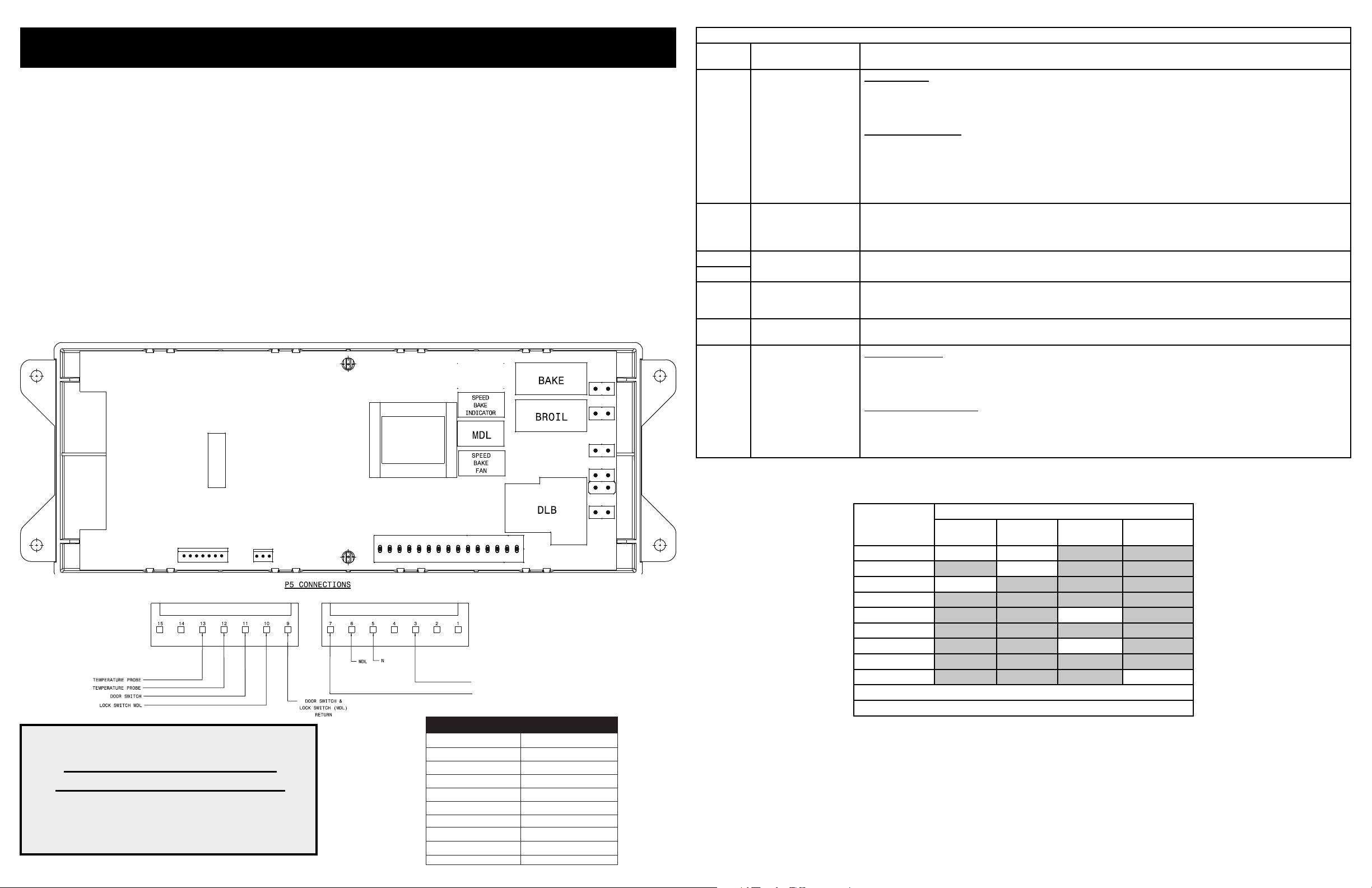

Electronic Oven Control (Rear View)

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

NOTICE - This service data sheet is intended for use by persons having

electrical and mechanical training and a level of knowledge of these

subjects generally considered acceptable in the appliance repair trade. The

manufacturer cannot be responsible, nor assume any liability for injury or

damage of any kind arising from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important

that safe servicing practices be observed. The following are examples, but without

limitation, of such practices.

1. Before servicing or moving an appliance remove power cord from electrical

outlet, trip circuit breaker to OFF, or remove fuse.

2. Never interfere with the proper installation of any safety device.

3. GROUNDING: The standard color coding for safety ground wires is GREEN

or GREEN WITH YELLOW STRIPES. Ground leads are not to be used as

current carrying conductors. It is extremely important that the service

technician reestablish all safety grounds prior to completion of service.

Failure to do so will create a potential safety hazard.

4. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges,

high-temperature components, and moving parts.

E.O.C. Control Connections

• All uninsulated electrical terminals, connectors, heaters, etc. are

adequately spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and

securely reassembled.

Oven Calibration

Set the electronic oven control for normal baking at 350°F. Obtain an

average oven temperature after a minimum of 5 cycles. Press Stop or

Clear to end bake mode.

Temperature Adjustment

1. Set EOC to bake at 550°F.

2. Within 5 seconds of setting 550°F, press and hold the bake pad for

approximately 15 seconds until a single beep is heard (longer may

cause F11 shorted keypad alarm).

3. Calibration offset should appear in the display.

4. Use the slew keys to adjust the oven temperature up or down 35°F in

5°F increments.

5. Once the desired (-35° to 35°) offset has been applied, press Stop or

Clear.

Note: Changing calibration affects normal Bake mode. The adjustments

made will not change the Self-Cleaning cycle temperature.

ELECTRONIC OVEN CONTROL FAULT CODE DESCRIPTIONS

Fault

Code

Likely failure condition/

cause

Suggested corrective action

F10

Runaway temperature.

Oven heats when no

cook cycle is programmed.

If Oven is cold:

1. If fault code is present with cold oven test oven temperature sensor probe circuit resistance. Use RTD scale found in

the tech sheet.

2. Replace probe or repair wiring connections if defective.

3. If temperature sensor probe circuit is good but fault code remains when oven is cold replace the EOC.

If Oven is overheating:

1. If oven is severely overheating/heating when no cook cycle is programmed test oven temperature sensor probe

circuit resistance using the RED scale found in the service tech sheet. Also verify that the temperature sensor probe

in properly installed in the oven cavity.

2. Disconnect power from the range, wait 30 seconds and reapply power. If oven continues to heat when the power is

reapplied, replace the EOC. NOTE: Severe overheating may require the entire oven to be replaced should damage

be extensive.

F11 Shorted keypad or selec-

tor switch.

1. Reset power supply to range - Disconnect power, wait 30 seconds and reapply power.

2. Check/reseat ribbon harness connections between touch panel and EOC.

3. Test keyboard circuits. Replace touch panel if defective.

4. If keyboard ciruits check good replace the EOC.

F12 EOC Internal software

error or failure.

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up, replace EOC.

F13

F30

Open oven sensor probe

circuit.

Check resistance at room temperature & compare to RTD Sensor resistance chart. If resistance is correct replace the

EOC. If resistance does not match the RTD chart replace RTD Sensor Probe. Check Sensor wiring harness between

EOC & Sensor Probe connector.

F31 Shorted oven sensor

probe circuit.

Check resistance at room temperature, if less than 500 ohms, replace RTD Sensor Probe. Check for shorted Sensor

Probe harness between EOC & Probe connector. If resistance is correct replace the EOC.

F90-F95 Door lock motor or latch

circuit failure.

If lock motor runs:

1. Test continuity of wiring between EOC and lock switch on lock motor assy. Repair if needed.

2. Advance motor until cam depresses the plunger on lock motor switch. Test continuity of switch contacts. If switch is

open replace lock motor assembly.

3. If motor runs and switch contacts and wiring harness test good, replace the EOC.

If lock motor does not run:

1. Test continuity of lock motor windings. Replace lock motor assembly if windings are open.

2. Test lock motor operation by using a test cord to apply voltage. If motor does not operate replace lock motor assy.

3. If motor runs with test cord check continuity of wire harness to lock motor terminals. If harness is good replace the

EOC.

CIRCUIT

ANALYSIS

MATRIX

EOC RELAYS

L1 to Bake L1 to Broil L1 to Motor

Door Latch

Door Switch

COM-NO

Bake/Time Bake X X*

Broil X

Clean X

Unlocked

Locking X

Locked

Unlocking X

Door Open

Door Closed X

NOTE: X = Check listed circuits * = Alternates with bake element

Please note that the warmer drawer feature is only on some models

COOLING FAN

COOLING FAN

RTD SCALE

Temperature °F (°C)

32 ± 1.9 (0 ± 1.0)

75 ± 2.5 (24 ± 1.3)

250 ± 4.4 (121 ± 2.4)

350 ± 5.4 (177 ± 3.0)

450 ± 6.9 (232 ± 3.8)

550 ± 8.2 (288 ± 4.5)

650 ± 9.6 (343 ± 5.3)

900 ± 13.6 (482 ±7.5)

Probe circuit to case ground

Resistance (ohms)

1000 ± 4.0

1091 ± 5.3

1453 ± 8.9

1654 ± 10.8

1852 ± 13.5

2047 ± 15.8

2237 ± 18.5

2697 ± 24.4

Open circuit/infinite resistance

Page 2

Page 3

p/n 807880402 Rev A (1305)

Electronic Oven Control (Rear View)

AVIS : Cette fi che de réparation est destinée à des personnes possédant une

formation en mécanique et en électricité ainsi qu'un niveau de connaissance de

ces domaines jugé généralement acceptable dans le secteur de la réparation. Le

fabricant ne peut être tenu responsable des blessures ou des dommages que

l'utilisation de cette fi che pourrait entraîner.

PROCÉDURES D'ENTRETIEN SÉCURITAIRES

L'observation de procédures d'entretien sécuritaires est importante pour éviter

les blessures ou les dommages matériels. La section suivante présente quelques

exemples de procédures d'entretien sécuritaires.

1. Avant de réparer ou de déplacer l'appareil, débranchez-le, mettez le disjoncteur

du circuit à la position ARRÊT ou enlevez le fusible.

2. Ne modifi ez jamais l'installation d'un dispositif de sécurité.

3. MISE À LA TERRE : Le code de couleur standard des fi ls de mise à la terre

est VERT ou VERT RAYÉ JAUNE. Les fi ls de mise à la terre ne doivent pas

être utilisés comme fi ls de transport. Il est extrêmement important que le

technicien en entretien rétablisse toutes les prises de terre de sécurité

avant d'effectuer la réparation. Le non-respect de cette consigne peut

entraîner un risque d'accident.

4. Avant de remettre l'appareil en service, assurez-vous que :

• Toutes les connexions électriques sont en bon état et sécuritaires.

• Tous les conducteurs sont couverts et à l'abri de rebords coupants, de

composants qui atteignent de hautes températures et de pièces mobiles.

• Tous les éléments chauffants, connecteurs, bornes non isolées, etc.

sont à une distance adéquate de panneaux ou de pièces métalliques.

• Toutes les prises de terre de sécurité (à l'intérieur de l'appareil et à

l'extérieur) ont été correctement remises en place.

Calibration du four

Réglez le régulateur électronique de four pour une cuisson normale à 177 ºC

(350 ºF). Vous devez obtenir une température moyenne de four après

5 cycles. Appuyez sur Stop/Clear/Cancel pour arrêter la cuisson.

Réglage de la température

1. Réglez le régulateur pour une cuisson à 288 °C (550 °F).

2. Dans les 5 secondes suivant le réglage à 288 °C (550 °F), appuyez sur la

touche de cuisson et maintenez-la enfoncée pendant 15 secondes jusqu'à

ce que vous entendiez un bip (la maintenir enfoncée plus longtemps

pourrait faire retentir l'alarme de court-circuit du clavier F11).

3. L'écart de calibration devrait s'affi cher.

4. Utilisez les touches à incrément pour augmenter ou diminuer la

température du four de 19 °C (35 °F) par intervalles de 1 °C (5 °F).

5. Une fois que l'écart désiré est réglé (-37 à 2 °C / -35 à 35 °F), appuyez sur

Stop/Clear/Cancel.

Remarque : La modifi cation de la calibration s'applique au mode de

cuisson normal. Les ajustements n'affectent pas la température du cycle

d'autonettoyage.

DESCRIPTIONS DES CODES D'ANOMALIE DU RÉGULATEUR ÉLECTRONIQUE DE FOUR

Code

d'anomalie

Cause probable du

problème

Mesure corrective suggérée

F10

Emballement de la

température.

Le four chauffe lorsqu'aucun

cycle de cuisson n'est

programmé.

Si le four est froid :

1. Si un code d'erreur apparaît lorsque le four est froid, vérifi ez la résistance du circuit de la sonde du détecteur de température du four.

Servez-vous de l'échelle du détecteur de température à résistance se trouvant sur la fi che technique.

2. Remplacez la sonde ou réparez les raccordements de fi ls, s'ils sont défectueux.

3. Si le circuit de la sonde du détecteur de température semble correct, mais que le code d'erreur réapparaît pendant que le four est froid,

remplacez le régulateur électronique de four.

Si le four surchauffe :

1. Si le four chauffe/surchauffe de façon excessive alors qu'aucun programme de cuisson n'est sélectionné, vérifi ez la résistance du circuit

de la sonde du détecteur de température du four au moyen de l'échelle du détecteur de température à résistance se trouvant sur la fi che

technique d'entretien. Vérifi ez également si la sonde du détecteur de température est correctement installée dans la cavité du four.

2. Coupez l'alimentation électrique de la cuisinière, attendez 30 secondes, puis rebranchez l'appareil. Si le four chauffe toujours lorsque

l'alimentation est rebranchée, remplacez le régulateur électronique de four. REMARQUE : Le four doit être remplacé au complet si une

surchauffe excessive a causé des dommages importants.

F11 Court-circuit du clavier ou du

sélecteur.

1. Réinitialisation de l'alimentation à la cuisinière - Coupez l'alimentation, attendez 30 secondes, puis rebranchez l'appareil.

2. Vérifi ez et replacez les connexions du câble-ruban entre le panneau tactile et le régulateur électronique de four.

3. Testez les circuits du clavier. Remplacez le panneau tactile, s'il est défectueux.

4. Si les circuits du clavier semblent fonctionner correctement, remplacez le régulateur électronique de four.

F12 Erreur logicielle interne ou

défectuosité du régulateur

électronique de four.

Coupez l'alimentation électrique, attendez 30 secondes, puis rebranchez l'appareil. Si le problème n'est pas réglé, remplacez le régulateur

électronique de four.

F13

F30 Circuit de la sonde du four

ouvert.

Vérifi ez la résistance à la température de la pièce et comparez-la au tableau de résistance de la sonde du détecteur de température à

résistance. Si la résistance est correcte, remplacez le régulateur électronique de four. Si la résistance ne correspond pas au tableau de

résistance de la sonde du détecteur de température à résistance, remplacez la sonde. Vérifi ez le faisceau électrique entre le régulateur

électronique de four et le connecteur de la sonde.

F31 Court-circuit du circuit de la

sonde du four.

Vérifi ez la résistance à la température ambiante. Si elle est inférieure à 500 ohms, remplacez la sonde du détecteur de température à

résistance. Vérifi ez s'il y a un court-circuit au niveau du faisceau de la sonde, entre le régulateur électronique du four et le connecteur de la

sonde. Si la résistance est correcte, remplacez le régulateur électronique de four.

F90-F95 Défaillance du circuit du

moteur de verrouillage ou

du loquet.

Si le moteur du loquet fonctionne :

1. Vérifi ez la continuité du câblage entre le régulateur électronique de four et l'interrupteur du loquet du moteur de verrouillage. Réparez au besoin.

2. Faites avancer le moteur jusqu'à ce que la came appuie sur le poussoir du moteur de verrouillage. Vérifi ez la continuité des contacts

d'interruption. Si le contacteur est ouvert, remplacez le moteur de verrouillage.

3. Si le moteur de verrouillage fonctionne et que les tests des contacts d'interruption et du faisceau ne révèlent aucune anomalie,

remplacez le régulateur électronique de four.

Si le moteur de verrouillage ne fonctionne pas :

1. Vérifi ez la continuité des bobines du moteur de verrouillage. Si les bobines sont ouvertes, remplacez le moteur de verrouillage.

2. Vérifi ez le fonctionnement du moteur de verrouillage en utilisant un câble de test pour appliquer la tension. Si le moteur de verrouillage

ne fonctionne pas, remplacez-le.

3. Si le moteur fonctionne avec le câble de test, vérifi ez la continuité entre le faisceau et les bornes du moteur. Si le faisceau fonctionne

correctement, remplacez le régulateur électronique de four.

TABLEAU

D'ANALYSE

DU CIRCUIT

RELAIS DU RÉGULATEUR ÉLECTRONIQUE DU FOUR

L1 à cuisson L1 à gril L1 au loquet

du moteur de

la porte

Interr. de porte

COM-NO

Cuisson au four/

durée de cuisson

XX*

Gril X

Nettoyage X

Déverrouillé

Verrouillage X

Verrouillé

Déverrouillage X

Porte ouverte

Porte fermée X

REMARQUE : X = Vérifi er les circuits énumérés * = Alterne avec l'élément de

cuisson au four

FICHE DE RÉPARATION

Cuisinières électriques avec régulateur de four électronique ES 300/305/335/336

CUISSON

LOQUET

MOTORISÉ DE

LA PORTE

GRIL

DBL

SONDE DE TEMPÉRATURE

SONDE DE TEMPÉRATURE

INTERR. DE PORTE

INTERRUPTEUR DE

VERROUILLAGE (MDL)

IMPORTANT

N’ENLEVEZ P

DÉTR

UISEZ P

CONTIENT LES SCHÉMAS DE CÂBLAGE ET

LES INFORMATIONS DE RÉPARATION

REMETTRE LE CONTENU

AS CE SAC OU NE

AS SON CONTENU

DANS LE SAC

P5 CONNEXIONS

MOTEUR DE

VERROUILLAGE

RETOUR DE L’INTERR.

DE LA PORTE ET DU

VERROUILLAGE (MDL)

VENTILATEUR DE REFROIDISSEMENT

VENTILATEUR DE REFROIDISSEMENT

ÉCHELLE DU DÉTECTEUR DE TEMPÉRATURE

Température °F (°C)

32 ± 1,9 (0 ± 1,0)

75 ± 2,5 (24 ± 1,3)

250 ± 4,4 (121 ± 2,4)

350 ± 5,4 (177 ± 3,0)

450 ± 6,9 (232 ± 3,8)

550 ± 8,2 (288 ± 4,5)

650 ± 9,6 (343 ± 5,3)

900 ± 13,6 (482 ±7,5)

Circuit de la sonde mise à la

terre à la caisse

À RÉSISTANCE

Résistance (ohms)

Circuit ouvert/résistance infinie

1 000 ± 4,0

1 091 ± 5,3

1 453 ± 8,9

1 654 ± 10,8

1 852 ± 13,5

2 047 ± 15,8

2 237 ± 18,5

2 697 ± 24,4

Page 4

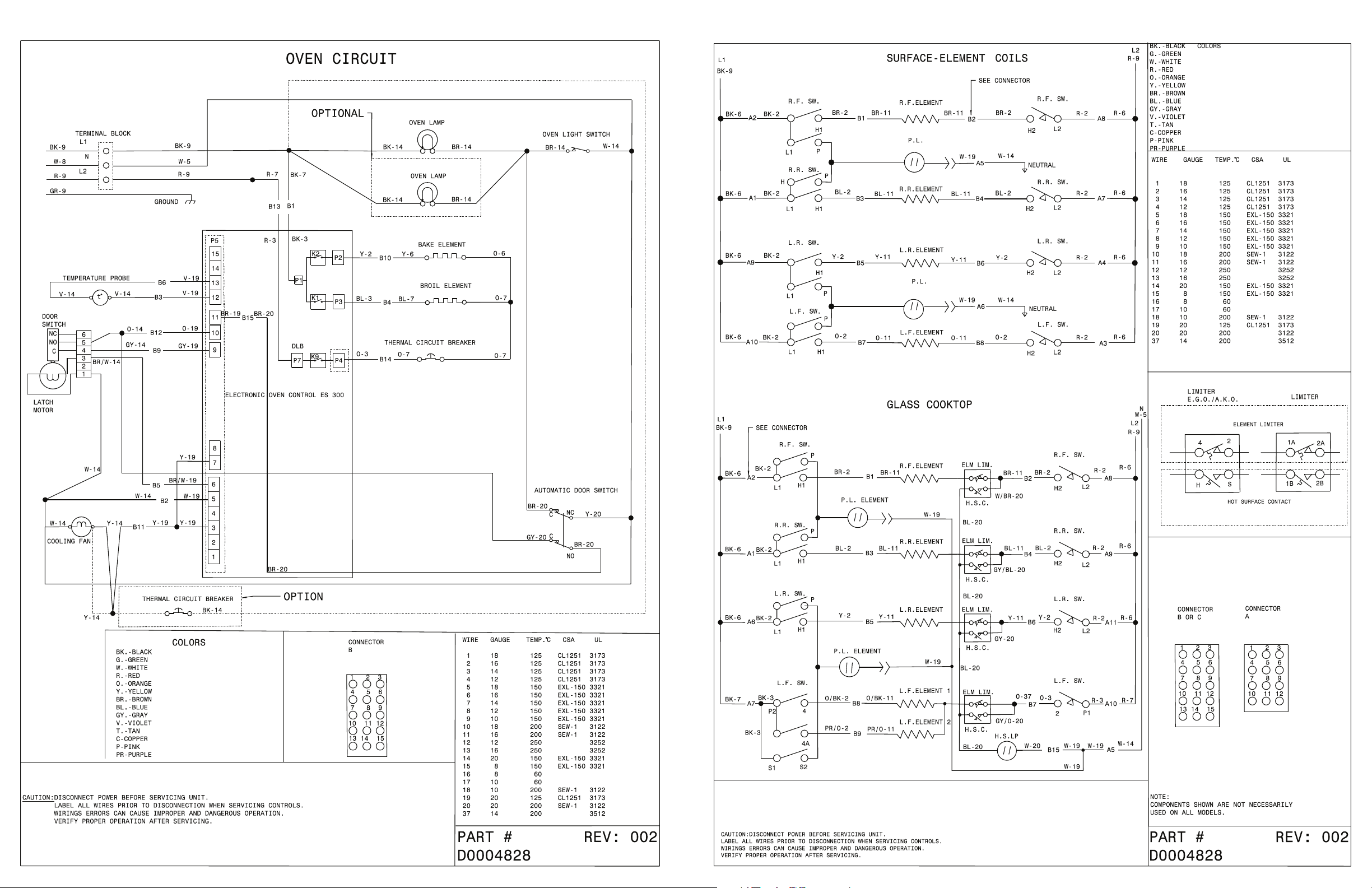

Loading...

Loading...