Page 1

INSTALLATION INSTRUCTIONS FOR FREESTANDING ELECTRIC RANGE

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

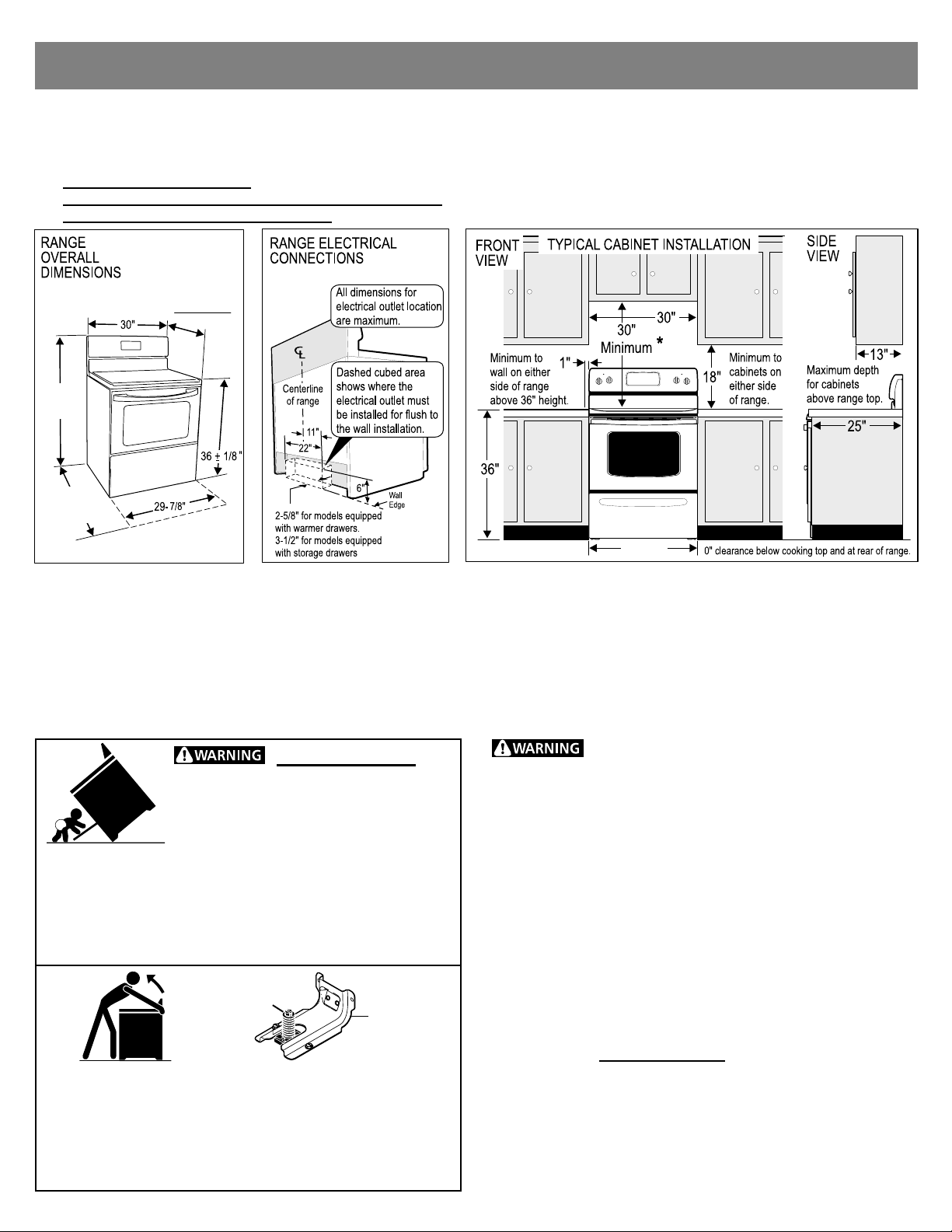

Clearances and Dimensions

1.

Provide adequate clearances between the range and adjacent combustible surfaces.

2. Location—Check location where the range will be installed. Check for proper electrical supply, and the stability of the floor.

3. Dimensions that are shown must be used. Given dimensions provide minimum clearance. Contact surface must be solid and level.

29 1/4” with

door handle

25-3/4”

48”

maximum

49”

door open

maximum

Fig. 1

*30" MINIMUM CLEARANCE BETWEEN THE TOP OF THE COOKING SURFACE AND THE BOTTOM OF AN UNPROTECTED WOOD OR

METAL CABINET; OR 24" MINIMUM WHEN BOTTOM OF WOOD OR METAL CABINET IS PROTECTED BY NOT LESS THAN 1/4" FLAME

RETARDANT MILLBOARD COVERED WITH NOT LESS THAN NO. 28 MSG SHEET STEEL, 0.015" STAINLESS STEEL, 0.024" ALUMINUM OR

0.020" COPPER. 0" CLEARANCE IS THE MINIMUM FOR THE REAR OF THE RANGE. FOLLOW ALL DIMENSION REQUIREMENTS PROVIDED

ABOVE TO PREVENT PROPERTY DAMAGE, POTENTIAL FIRE HAZARD, AND INCORRECT COUNTERTOP AND CABINET CUTS.

TO ELIMINATE THE RISK OF BURNS OR FIRE BY REACHING OVER HEATED SURFACE UNITS, CABINET STORAGE SPACE LOCATED ABOVE

THE SURFACE UNITS SHOULD BE AVOIDED. IF CABINET STORAGE IS TO BE PROVIDED, THE RISK CAN BE REDUCED BY INSTALLING A

RANGE HOOD THAT PROJECTS HORIZONTALLY A MINIMUM OF 5" BEYOND THE BOTTOM OF THE CABINETS.

Fig. 2

Fig. 3

30"

IMPORTANT SAFETY INSTRUCTIONS

Tip Over Hazard

• A child or adult can tip the range and

be killed.

• Verify the anti-tip device has been

installed to floor or wall.

• Ensure the anti-tip device is re-engaged when the range

is moved to floor or wall.

• Do not operate the range without the anti-tip device in

place and engaged.

• Failure to follow these instructions can result in death or

serious burns to children and adults.

Range

leveling leg

To check if the anti-tip bracket is installed properly, use both

arms and grasp the rear edge of range back. Carefully

attempt to tilt range forward. When properly installed, the

range should not tilt forward.

Refer to the anti-tip bracket installation instructions

supplied with your range for proper installation.

Anti-Tip

bracket

exactly, a fire or electrical shock may result causing property

damage, personal injury or death.

Important Notes to the Installer:

• Read all instructions contained in these installation

instructions before installing range.

• Remove all packing material from the oven compartments

before connecting the gas & electrical supply to the range.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

Important Notes to the Consumer:

Keep these instructions with your owner's guide for future

reference.

• As when using any appliance generating heat, there are

certain safety precautions you should follow. These are

listed in the Use & Care Guide, read it carefully.

• Be sure your range is installed and grounded properly by a

qualified installer or service technician.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• To eliminate the need to reach over the surface elements,

cabinet storage space above the elements should be

avoided.

1

If the information in this manual is not followed

p/n 316454912 rev C

Español - Páginas 5-8

Page 2

INSTALLATION INSTRUCTIONS FOR FREESTANDING ELECTRIC RANGE

BEFORE STARTING - Tools You Will Need

For leveling legs and Anti-Tip Bracket:

• Adjustable wrench or channel lock pliers

• 5/16" Nutdriver or Flat Head Screwdriver

• Electric Drill & 1/8" Diameter Drill Bit

(Masonry Drill Bit if installing in concrete)

For electrical supply connection:

• 1/4" & 3/8" Socket driver or Nutdriver

Additional Materials You Will Need:

• Power Supply Cord or

• Copper Electrical Wiring & Metal Conduit

(for hard wiring)

NORMAL INSTALLATION STEPS

1. ANTI-TIP BRACKET INSTALLATION INSTRUCTIONS -

IMPORTANT SAFETY WARNING

To reduce the risk of tipping of the range, the range must be

secured to the floor by properly installed Anti-Tip Bracket and

screws packed with the range. Failure to install the anti-tip

bracket will allow the range to tip over if excessive weight is

placed on an open door or if a child climbs upon it. Serious

injury might result from spilled hot liquids or from the range

itself.

If range is ever moved to a different location, the Anti-Tip

Bracket must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the floor or wall. When installed to the wall,

make sure that screws completely penetrate dry wall and are

secured in wood or metal. When fastening to the floor or wall,

be sure that screws do not penetrate electrical wiring or

plumbing.

1a. Locate the Bracket using the Template - (Bracket

may be located on either the left or right side of the range. Use

the information below to locate the bracket if template is not

available).

Mark the floor or wall where

left or right side of the range

will be located. If rear of

range is against the wall or

no further than 1-1/4" from

wall when installed, you may

use the wall or floor mount

method. If molding is

installed and does not allow

the bracket to fit flush against the wall, remove molding or

mount bracket to the floor. For wall mount, locate the bracket by

placing the back edge of the template against the rear wall and

the side edge of template on the mark made referencing the

side of the range (See Fig. 4). Place bracket on top of template

and mark location of the screw holes in wall. If rear of range is

further than 1-1/4" from the wall when installed, attach bracket

to the floor. For floor mount, locate the bracket by placing back

edge of the template where the rear of the range will be

located. Mark the location of the screw holes, shown in

template.

Fig. 4

1b. Drill Pilot Holes & Fasten Bracket - Drill a 1/8" pilot

hole where screws are to be located. If bracket is to be

mounted to the wall, drill pilot hole at an approximate 20°

downward angle (See Fig. 5).

If bracket is to be mounted to masonry or ceramic floors, drill a

3/16" pilot hole 1-3/4" deep. The screws provided may be used

in wood or concrete material. Use a 5/16" nut-driver or flat

head screwdriver to secure the bracket in place (See Fig. 6).

1c. Level and Position Range - Level range by adjusting

the (4) leveling legs with a wrench. Note: A minimum

clearance of 1/8" is required between the bottom of the range

and the leveling leg to allow room for the bracket. Use a spirit

level to check your adjustments. Slide range back into position

(See Fig. 7). Visually check that rear leveling leg is inserted

into and fully secured by the Anti-Tip Bracket by removing lower

panel or storage drawer. For models with a Warmer Drawer or

broiler compartment, grasp the top rear edge of the range and

carefully attempt to tilt it forward.

Fig. 5

Fig. 7

Fig. 6

2. ELECTRICAL CONNECTION REQUIREMENTS - This

appliance must be properly installed and grounded by a

qualified technician in accordance with the National Electrical

Code ANSI/NFPA No. 70 -- latest edition -- and Local Electrical

Code requirements.

This appliance may be connected by means of "permanent

wiring" or power supply cord kit."

When installing permanent wiring, do not leave excess wire in

range compartment. Excess wire in the range compartment

may not allow the rear access cover to be replaced properly

and could create a potential electrical hazard if wires become

pinched. Connect only as instructed under "Permanent Wire

Connections" in Step 4c. When using flexible conduit or range

cable use flex connector or range cable strain relief (Fig. 11).

2a. Models with factory connected power supply cord.

NOTE: Some models may have a factory installed

three (3) conductor power supply cord.

Mobile home installations, new branch circuit installations

(1996NEC) or areas where local codes do not permit

grounding through neutral require a four (4) conductor power

supply cord kit rated at 125/250 volts minimum and marked for

use with ranges.

See range connection opening size chart (Figs. 9 & 10) for

cord kit ampere rating information. Terminals on end of wires

must be either closed loop or open-end spade lugs with

upturned ends.

2

Page 3

INSTALLATION INSTRUCTIONS FOR FREESTANDING ELECTRIC RANGE

2b. MODELS REQUIRING POWER SUPPLY CORD KIT.

RISK OF FIRE OR ELECTRICAL SHOCK MAY OCCUR IF AN

INCORRECT SIZE RANGE CORD KIT IS USED, THE

INSTALLATION INSTRUCTIONS ARE NOT FOLLOWED OR

STRAIN RELIEF BRACKET IS DISCARDED.

This appliance may be connected by means of a power supply

cord. Only a power supply cord kit rated at 125/250 volts

minimum, and marked for use with ranges shall be used. See

Fig. 10 for cord kit ampere rating information. Cord must have

either three (3) or four (4) conductors (See Fig. 8). Terminals

on end of wires must be either closed loop or open-end spade

lugs with upturned ends. Cord must have strain relief properly

installed. See Steps 4a. for 4-Wire or 4b. for 3-Wire

connections.

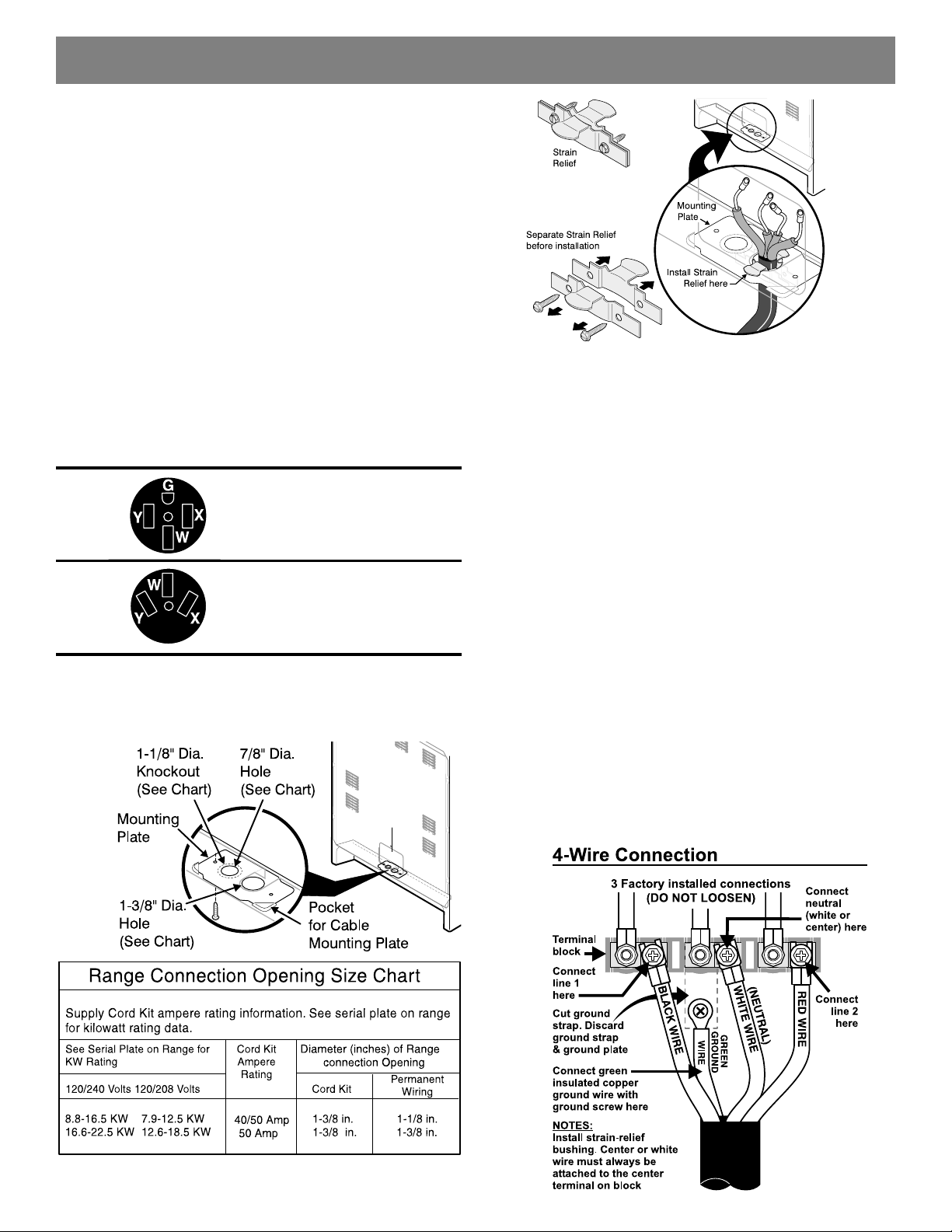

Fig. 11

3. ELECTRICAL CONNECTION TO RANGE.

The Rear Access Cover must be removed (Fig 9). To remove,

loosen center screw (one screw) and remove cover. The

terminal block will then be accessible.

3 & 4 - Wire electrical wall Receptacle types &

recommended mounting orientation on wall

Required for new and

remodeled installations

4-Wire Wall

receptacle (14-50R)

Allowed for

existing installations

3 Wire Wall

receptacle (10-50R)

Fig. 8

NOTE: Range is shipped from factory with 1-3/8" dia. hole as

shown. To use either 7/8" dia. hole or 1-1/8" dia. knockouts

refer to Fig. 9.

Rear

Access

Cover

4A. POWER CORD CONNECTIONS

(4-Wire Connection Instructions - Refer to Fig.12)

Before wiring the range review the suggested power source

location drawing in Fig. 3. If connecting to a 4-Wire electrical

system (new branch-circuit or mobile home requires 4-Wire

connection):

1. Follow the manufacturer’s installation instructions

supplied with the strain relief and install (Also see Figs. 9,

10 & 11).

2. Insert the end connectors for Line 1, Line 2 and Neutral

and tighten securely to the terminal block.

IMPORTANT NOTE: DO NOT LOOSEN the factory installed

nut connections which secure the range wiring to the

terminal block. Electrical failure or loss of electrical

connection may occur if these 3 nuts are loosened or

removed.

3. You must disconnect the ground strap. Remove the

factory installed ground screw & plate to release the

copper ground strap from the frame of the appliance. Cut

and discard the copper ground strap & plate. KEEP the

ground screw.

4. Connect the ground wire (Green) lead with the eyelet to

the frame of the appliance with the ground screw using the

same hole in the frame where the ground screw was

originally installed (See Fig. 12).

5. Make sure all screws are tightened securely and replace

the rear access cover (See Fig. 9).

Fig. 9

Fig. 10

Fig. 12

3

Page 4

INSTALLATION INSTRUCTIONS FOR FREESTANDING ELECTRIC RANGE

or 4B. POWER CORD CONNECTIONS

(3-Wire Connection Instructions . For existing installations ONLY Refer to Fig. 13).

1. Follow the manufacturer’s installation instructions supplied with the

strain relief and install (Also see Figs. 9, 10 & 11).

2. Insert the end connectors for Line 1, Line 2 and Neutral and tighten

securely to the terminal block (See Fig. 13).

IMPORTANT NOTE: DO NOT LOOSEN the factory installed nut

connections which secure the range wiring to the terminal block.

Electrical failure or loss of electrical connection may occur if these 3 nuts

are loosened or removed.

3. Make sure all connections are tightened securely and replace the rear

access cover (See Fig. 9).

Grounding Instructions (3-Wire Connections only): A ground strap is

installed on this range which connects the center terminal of the terminal

block (Neutral) to the range chassis. The ground strap is connected to the

range by the center, lowest screw (See Fig. 13). The ground strap must not

be removed unless National, State or Local Codes do not permit use of a

ground strap.

NOTE: If the ground strap is removed for any reason, a separate ground wire

must be connected to the separate ground screw attached to the range

chassis and to an adequate ground source.

Fig. 13

4c. 3 & 4-WIRE PERMANENT WIRE CONNECTIONS.

3 - Wire Permanent Connection - follow Steps 1,2 & 5 below.

4 - Wire Permanent Connection - follow Steps 1 thru 5 below.

Before wiring the range, review the suggested power source location

drawings in Fig. 3. If connecting to a 4-Wire electrical system (new branchcircuit or mobile home requires 4-Wire connection):

1. (3 & 4 - Wire Permanent Connections) Follow the manufacturer’s

installation instructions supplied with the strain relief and install.

2. (3 & 4 - Wire Permanent Connections) Strip insulation away from the

ends of the permanent wiring for Line 1, Line 2, Neutral (also strip ground

wire on 4-Wire Connections). Tighten all 3 wire leads to the terminal

block (Follow wire locations shown in Fig. 14).

IMPORTANT NOTE: DO NOT LOOSEN the factory installed nut

connections which secure the range wiring to the terminal block.

Electrical failure or loss of electrical connection may occur if these 3 nuts

are loosened or removed. NOTE: For 3-Wire Permanent Connections

skip Steps 3 & 4 and continue with Step 5.

3. (4-Wire Permanent Connection ONLY) Disconnect the ground strap.

Remove the factory installed ground screw & plate to release the factory

installed copper ground strap from frame of the appliance. Cut and

discard the copper strap from the terminal block. KEEP the ground screw,

ground plate and go to Step 4.

4. (4-Wire Permanent Connection ONLY) Connect the ground wire lead

(Green) to the frame of the appliance using the ground screw & plate as

shown in Fig. 15. Be sure to install using the same hole in the frame

where the ground screw was originally installed.

5. (3 & 4 - Wire Permanent Connections) Make sure all connections are

tightened securely and replace the rear access cover (See Fig. 9).

NOTE: Non-terminated field wire compression connections must be set at

22 in./lbs. or greater. Always use 10 gauge wire or larger.

5. CAREFULLY SLIDE RANGE INTO FINAL LOCATION.

Be sure to provide all the adequate clearances and dimensions shown in Figs.

1, 2 & 3 before moving appliance into final location.

Fig. 14

Note: Non-terminated field wire compression

connections must be set at approximately 22in./

lbs. Always use 10 ga. wire or larger.

Fig. 15

Serial Plate Locations:

Carefully slide range into final position while inserting rear leveling leg into and

FULLY ENGAGING THE ANTI-TIP BRACKET (See Fig. 7). Make sure the power

cord folds into the remaining open floor area behind the range Warmer or storage

drawer. Be sure to check the level of the range.

4

Serial plate is located on the lower right front frame

of the appliance. Alternate location may be under

cooktop.

Page 5

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA ELECTRICA DE 30"

LA INSTALACION Y EL SERVICIO DEBEN SER EFECTUADOS POR UN INSTALADOR CALIFICADO.

IMPORTANTE: CONSERVE ESTAS INSTRUCCIONES PARA USO DEL INSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y CONSERVE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

Espacios Libres y Dimensiones

1. Provea espacios libres adecuados entre la estufa y las superficies combustibles adyacentes.

2. Ubicación – Revise el lugar donde será instalada la estufa. Verifique el suministro de energía eléctrica y la estabilidad del piso.

3. Es esencial que se usen las dimensiones que se muestran. Las dimensiones indicadas proveen los espacios libres mínimos. La

superficie de contacto debe ser firme y nivelada.

30"

Fig. 1

*ESPACIO LIBRE MINIMO DE 30" ENTRE LA CUBIERTA DE COCINAR DE LA ESTUFA Y LA PARTE INFERIOR DE UN ARMARIO DE METAL O DE MADERA NO

PROTEGIDO; O 24" MINIMO CUANDO LA PARTE INFERIOR DE UN ARMARIO DE METAL O DE MADERA ESTA PROTEGIDA CON CARTON RETARDANTE A

LAS LLAMAS DE NO MENOS DE 1/4" CUBIERTO CON CHAPA DE ACERO NO INFERIOR AL No. 28 MSG, ACERO INOXIDABLE DE 0.015", ALUMINO DE

0.024" O COBRE DE 0.020". EL ESPACIO LIBRE DE 0" ES EL MINIMO PARA LA PARTE TRASERA DE LA ESTUFA. SIGA TODAS LAS DIMENSIONES

INDICADAS ANTERIORMENTE PARA EVITAR DAÑOS MATERIALES, RIESGOS DE INCENDIO Y CORTES INCORRECTOS DE LOS ARMARIOS Y DE LAS

MESADAS.

PARA ELIMINAR EL RIESGO DE QUEMADURAS O INCENDIOS AL PASAR SOBRE LOS ELEMENTOS CALIENTES, SE DEBE EVITAR COLOCAR

ARMARIOS DE ALMACENAMIENTO SOBRE LA ESTUFA. SI SE INSTALAN ARMARIOS SOBRE LA ESTUFA, SE PUEDEN REDUCIR TALES RIESGOS

INSTALANDO UNA CAMPANA EXTRACTORA QUE SE PROYECTE HORIZONTALMENTE UN MINIMO DE 5" MAS AFUERA DE LA PARTE INFERIOR DE

LOS ARMARIOS.

Fig. 2

Fig. 3

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

WARNING:

• Un niño o adulto puede volcar la estufa y acabar

muerto.

• Verifique que se haya instalado el dispositivo

antivuelco en el piso o en la pared.

• Asegúrese de que el dispositivo antivuelco se haya reacoplado cuando

mueva la estufa sobre el piso o a la pared.

• No utilice la estufa sin el dispositivo antivuelco instalado y acoplado.

• Si no se siguen estas instrucciones, se puede provocar la muerte o

quemaduras graves en niños y adultos.

Tornillo nivelador

de la estufa

Para verificar si el soporte antivuelco está instalado correctamente,

sostenga el borde trasero de la parte trasera de la estufa usando ambos

brazos.

Intente inclinar la estufa hacia adelante con cuidado. Si está instalada

correctamente, la estufa no debería inclinarse hacia adelante. Consulte

las instrucciones de instalación del soporte antivuelco

proporcionadas con la estufa para instalarlo adecuadamente.

Riesgo de volcamiento

Soporte

antivuelco

este manual, se puede producir un incendio o un choque eléctrico que

cause daños materiales, lesiones corporales o fatales.

Notas Importantes para el Instalador

• Lea todas las instrucciones indicadas en estas instrucciones de

instalación antes de instalar la estufa.

• Saque todo el material de empaque del compartimiento del

horno antes de conectar el suministro de gas y de electricidad a

la estufa.

• Observe todos los códigos y reglamentos vigentes.

• Asegúrese de dejar estas instrucciones con el usuario.

Aviso importante al consumidor

Mantenga estas instrucciones con su Guía de Uso y Cuidado para

referencia futura.

• Al igual que con cualquier electrodoméstico que genere calor,

existen ciertas precauciones de seguridad que usted debe

seguir. Tales precauciones se encuentran en la

Cuidado, léala atentamente.

• Asegúrese de que la estufa esté bien instalada y sea puesta a

tierra en forma debida por un instalador calificado o un técnico de

servicio.

• Asegúrese de que el revestimiento de la pared alrededor de la

estufa pueda resistir el calor generado por la estufa.

• Para eliminar la necesidad de tener que pasar sobre los

elementos, se recomienda no instalar armarios arriba los

elementos de la cubierta de la estufa.

Si no se sigue estrictamente la información de

Guía de Uso y

5

English - Pages 1-4

Page 6

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA ELECTRICA DE 30"

ANTES DE COMENZAR

Herramientas Necesarias

Para los tornillos niveladores y soporte antivuelco:

• Llave ajustable o pinzas ajustables

• Llave de tuerca de 5/16" o destornillador

de punta plana

• Taladro eléctrico y broca de 1/8" de diám. (broca para taladro de

mampostería si está instalando en concreto)

Para la conexión al suministro eléctrico:

• Llave de cubo o llave para tuercas de ¼”

y 3/8"

Materiales adicionales que usted necesitará:

• Cordón eléctrico o

• Cableado eléctrico de cobre y conducto

de metal (para el cableado)

PASOS DE LA INSTALACION NORMAL

1. INSTRUCCIONES PARA LA INSTALACION DEL SOPORTE

ANTIVUELCO

- ADVERTENCIA DE SEGURIDAD IMPORTANTE

Para reducir el riesgo de que la estufa se vuelque, es necesario

asegurarla al piso instalando el soporte antivuelco y los tornillos

suministrados con la estufa. Si no se instala el soporte antivuelco,

la estufa se puede volcar si un niño se sube a ella. Se pueden

ocasionar lesiones graves causadas por los líquidos calientes

derramados o por la estufa misma.

Si la estufa es movida a otro lugar, el soporte antivuelco debe

también ser movido e instalado en la estufa.

Las instrucciones son adecuadas para la instalación en pisos de

madera o cemento sujeto ya sea en el piso o en la pared. Cuando

se instala en la pared, asegúrese de que los tornillos penetren

completamente en la misma y que estén asegurados en madera

o metal. Cuando se asegura al piso o en la pared, asegúrese de

que los tornillos no penetren ningún cableado eléctrico o plomería.

1a. Ubicación del soporte

utilizando la plantilla

soporte puede ser ubicado ya

sea en el lado izquierdo o

derecho de la estufa. Use la

información indicada a

continuación para colocar el

soporte si no se dispone de la

plantilla.

Marque el piso o la pared donde se colocará el costado izquierdo o

derecho de la estufa. Si la parte trasera de la estufa será colocada

contra la pared o a no más de 1-1/4" de la pared cuando ya esté

instalada, usted puede usar el método de instalación en el piso o en

la pared. Si tiene moldura instalada y ésta no permite que el soporte

quede a ras contra la pared, retire la moldura o instale el soporte en

el piso. Para el montaje en la pared, ubique la plantilla colocando el

borde trasero de la plantilla contra la pared trasera y el borde lateral

de la plantilla en la marca hecha indicando el costado de la estufa

(Ver Fig. 4). Coloque el soporte sobre la plantilla y marque la

ubicación de los agujeros de los tornillos en la pared. Si la parte

trasera de la estufa está a más de 1-1/4" de la pared cuando ya está

instalada, instale el soporte en el piso. Para el montaje en el piso,

ubique el soporte colocando el borde trasero de la plantilla donde

quedará ubicada la parte trasera de la estufa. Marque la ubicación de

los agujeros de los tornillos mostrados en la plantilla.

- (El

Fig. 4

1b. Taladre agujeros pilotos e instale el soporte - Taladre un

agujero piloto de 1/8" donde se vayan a instalar los tornillos. Si el

soporte va a ser instalado en la pared, taladre un agujero piloto en un

ángulo descente de aproximadamente 20° (Ver Fig. 5).

Si el soporte va a ser instalado en pisos de mampostería o de

cerámica, taladre un agujero piloto de 3/16" y 1-3/4" de profundidad.

Los tornillos provistos pueden ser usados en materiales de madera

o concreto. Use una llave de tuerca de 5/16" o un destornillador de

punta plana para asegurar el soporte en su lugar (Ver Fig. 6).

1c. Nivele y ubique la estufa – Nivele la estufa ajustando los

cuatro (4) tornillos niveladores con una llave. NOTA: Se debe dejar un

espacio libre mínimo de 1/8" entre la parte inferior de la estufa y los

tornillos niveladores a fin de dejar espacio para instalar el soporte.

Use un nivel de burbuja de aire para verificar los ajustes. Deslice la

estufa de nuevo a su lugar (Ver Fig. 7). Verifique visualmente si el

tornillo nivelador trasero está insertado y firmemente asegurado por

el soporte antivuelco retirando el panel inferior o la gaveta de

almacenamiento. Para los modelos con una gaveta calentadora o

compartimiento asador, sujete la estufa desde el borde superior

trasero y trate de inclinarla hacia adelante cuidadosamente.

INSTALACIÓN DEL SOPORTE

(MONTAJE EN LA PARED O EN EL PISO)

Tornillo

nivelador

de la estufa

Parte trasera

Montaje en

el piso

11/16"

Costado

de la

estufa

Soporte

antivuelco

Fig. 5

Fig. 7

Máx.

1-1/4"

Montaje en

la pared

INSTALACIÓN DEL SOPORTE

(MONTAJEENEL PISO SOLAMENTE)

Tornillo

nivelador

Placa

mural

Montaje en

el piso

Deslice la

estufa

hacia atrás

Fig. 6

de la estufa

Parte trasera

Soporte

antivuelco

Más de

1-1/4"

Pared

2. REQUERIMIENTOS ELECTRICOS DE CONEXION - Este

artefacto debe ser instalado y puesto a tierra en forma correcta por

un técnico calificado de acuerdo con el Código Nacional de

Electricidad ANSI/NFPA No. 70 -- última edición -- y los

requerimientos del código local de electricidad.

Este artefacto debe ser conectado mediante “cableado

permanente” o el “Juego de Cable de Alimentación Eléctrica.”

Cuando instale el cableado permanente, no deje el exceso de

cable en el compartimiento de la estufa. El exceso de cable en el

compartimiento de la estufa puede impedir que la tapa de acceso

sea reinstalada en forma debida y podría crear un riesgo eléctrico

potencial si los alambres son apretados. Conecte solamente

como se indica en la sección “CONEXIONES DEL CABLEADO

PERMANENTE” en el Paso 4c. Cuando use tubo flexible o cable

de estufa, use un sujetacable o conector flexible (Ver Fig. 11).

2a. Modelos con el cordón eléctrico conectado en la

fábrica. NOTA: Algunos modelos vienen equipados con

cordón eléctrico de tres (3) conductores instalado en la

fábrica.

La instalación en casas rodantes, en instalaciones de circuitos de

derivación (1996NEC) o en áreas donde los códigos locales no

permitan la puesta a tierra a través del conductor neutro, se debe

usar un juego de cordón eléctrico de cuatro (4) conductores para

125/250 voltios mínimo y marcado para uso con estufas.

6

Page 7

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA ELECTRICA DE 30"

Consulte la Tabla del Tamaño de la Abertura de Conexión de la

Estufa (Figs. 9 y 10) para la información sobre los amperes del

juego de cordón. Los bornes en los extremos de los almabres

deben ser de anillo cerrado u horquillas abiertas con extremos

dirigidos hacia arriba.

2b. MODELOS QUE REQUIEREN EL JUEGO DE

CABLE DE ALIMENTACION ELECTRICA

PUEDE OCURRIR RIESGO DE INCENDIO O CHOQUE ELECTRICO

SI SE USA UN JUEGO DE CABLE DE ESTUFA DE CALIBRE

INCORRECTO, SI NO SE SIGUEN LAS INSTRUCCIONES DE

INSTALACION O SI NO SE USA EL SOPORTE DEL SUJETACABLES.

Este artefacto puede ser conectado mediante un cable de

alimentación eléctrica. Se debe usar solamente un juego de cable de

alimentación eléctrica para 125/250 voltios mínimo y marcado para

uso con estufas. Ver Fig. 10 para la información sobre la potencia

nominal en amperios del juego de cable. El cable debe tener ya sea

tres (3) o cuatro (4) conductores (Ver Fig. 8). Los bornes en los

extremos de los cables deben ser ya sea en bucle cerrado o

terminales de horquilla con los extremos girados hacia arriba. El

cable debe tener un sujetacable debidamente instalado. Ver Paso 4a.

para cables tetrafilares o 4b. para cables trifilares.

3. CONEXION ELECTRICA A LA ESTUFA.

Se debe retirar la cubierta de acceso trasera (Fig. 9). Para retirar,

afloje el tornillo central (un tornillo) y retire la cubierta de acceso.

Así se puede tener acceso al tablero de bornes.

3 y 4 - Tipos de tomacorrientes murales eléctricos trifilares o

tetrafilares y orientación recomendada del montaje en la pared

Requerido para instalaciones

nuevas y remodeladas

Tomacorriente mural tetrafilar

Permitido para instalaciones

Tomacorriente mural tetrafilar

Fig. 8

NOTA: La estufa es embarcada de la fábrica con un agujero de 13/8" de diámetro como se muestra. Para usar ya sea el agujero de

7/8" de diámetro o los discos removibles de 1-1/8" de diámetro.

Ver la Fig. 9.

Disco removible

de 29mm de diám.

(Ver Tabla)

Placa de

montaje

Agujero de

35 mm de diám.

(Ver Tabla)

Fig. 9

Tabla del Tamaño de la Abertura de Conexión de la Estufa

Informació sobre la potencia nominal en amperios del Juego de Cable de

Alimentación. Ver la placa de serie en la estufa para los datos sobre la

potencia nominal en kilovatios.

Ver la placa de serie en la

estufa para la potencia

nominal en kilovatios

120/240 Voltios 120/208 Voltios

8,8-16,5 KW 7,9-12,5 KW

16,6-22,5 KW 12,6-18,5 KW

Fig. 10

(14-50R)

existentes

(10-50R)

Agujero de

22 mm de diám.

(Ver Tabla)

Potencia

Nominal del

Juego de

cable

40/50 Amp.

50 Amp.

Cubierta

de

acceso

trasera

Cavidad para la

placa de montaje

del cable

Diámetro (pulg.) de la

Abertura de Conexión de la

Juego de

cable

1-3/8"

1-3/8"

Estufa

Cableado

Permanente

1-1/8"

1-3/8"

Sujetacable

Separe el

sujetacable antes

de la instalación

Placa de

montaje

Instale

aquí el

sujetacable

Fig. 11

4A. CONEXIONES DEL CORDON DE ALIMENTACION

(Instrucciones para Conexión Tetrafilar - Consulte la Fig.12)

Antes del cableado de la estufa, revise los dibujos de las ubicaciones

sugeridas para la fuente de alimentación en la Fig. 3. Si se va a

conectar a un sistema eléctrico tetrafilar (los circuitos de derivación

nuevos o las casas rodantes requieren conexión tetrafilar):

1. Siga las instrucciones de instalación del fabricante

suministradas con el sujetacable e instale (Además vea las

Figs. 9, 10 y 11).

2. Inserte los conectores de extremo para la Línea 1, Línea 2 y

Neutro y apriete firmemente en el tablero de bornes.

NOTA IMPORTANTE: NO AFLOJE las conexiones de tuerca

instaladas en la fábrica que aseguran el cableado de la estufa

en el tablero de bornes. Se puede producir una falla eléctrica

o pérdida de la conexión eléctrica si estas 3 tuercas son

aflojadas o retiradas.

3. Usted debe desconectar la cinta de conexión a tierra. Retire

el tornillo y placa de tierra instalada en la fábrica para soltar la

cinta de conexión a tierra de cobre del marco del

electrodoméstico. CONSERVE el tornillo de tierra.

4. Conecte el alambre de puesta a tierra (Verde) con el ojal en el

marco del electrodoméstico con el tornillo de tierra usando el

mismo agujero del marco donde estaba originalmente

instalado el tornillo de tierra (Ver Fig. 12).

5. Asegúrese de que todas las tuercas estén firmemente

apretadas y vuelva a colocar la cubierta de acceso trasera (Ver

Fig. 9).

Conexión Tetrafilar

Conexiones instaladas en la fábrica

Tablero de

bornes

Conecte

Línea 1

aquí

Corte la cinta

de conexión a

tierra. Descarte la cinta y

la placa de conexión a

tierra

Conecte aquí

el alambre de cobre verde

aislado de puesta a tierra

con el tornillo de tierra

NOTAS:

Instale el buje sujetacable.

El alambre central o

blanco debe estar siempre

instalado en el borne

central del tablero de

bornes.

(NO AFLOJAR)

ALAMBRE

NEGRO

ALAMBRE

(NEUTRO)

BLANCO

Conecte aquí el

alambre neutro

(blanco o

central)

ALAMBRE

Conecte

Línea 2

aquí

ROJO

Fig. 12

7

Page 8

INSTRUCCIONES DE INSTALACION PARA LA ESTUFA ELECTRICA DE 30"

o 4B. CONEXIONES DEL CORDON DE ALIMENTACION

Instrucciones para conexión trifilar (para instalaciones existentes SOLAMENTE Consulte la Fig. 13).

1. Siga las instrucciones de instalación del fabricante suministradas con el sujetacable e

instale (Además vea las Figs. 9, 10 y 11).

2. Inserte los conectores de extremo para la Línea 1, Línea 2 y Neutro y apriete firmemente

en el tablero de bornes.

NOTA IMPORTANTE: NO AFLOJE las conexiones de tuerca instaladas en la fábrica que

aseguran el cableado de la estufa en el tablero de bornes. Se puede producir una falla

eléctrica o pérdida de la conexión eléctrica si estas 3 tuercas son aflojadas o retiradas.

3. Asegúrese de que todas las conexiones estén firmemente apretadas y vuelva a colocar la

cubierta de acceso trasera (Ver Fig. 9).

Instrucciones para la Puesta a Tierra (para conexiones trifilares solamente):

Esta estufa tiene instalada una cinta de conexión a tierra que conecta el borne central del

tablero de bornes (neutro) al chasis de la estufa. La cinta de conexión a tierra está conectada a

la estufa mediante el tornillo central más inferior (Ver Fig. 13). La cinta de conexión de tierra

no debe retirarse a menos que el código nacional, estatal o local no permitan el uso

de una cinta de conexión a tierra. NOTA: Si por cualquier motivo se retira la cinta de

conexión a tierra, se debe conectar un alambre de tierra separado al tornillo de tierra instalado

en el chasis de la estufa y a una tierra adecuada.

4c. CONEXIONES DEL CABLEADO PERMANENTE TRIFILAR Y TETRAFILAR.

3 - Conexión trifilar permanente - siga los pasos 1, 2 y 5 incluidos a

continuación.

4 - Conexión tetrafilar permanente - siga los pasos 1 al 5 que se encuentran

PARA conexiones permanentes trifilares y tetrafilares)

más abajo.

Antes del cableado de la estufa, examine los dibujos de la ubicación sugerida

para la fuente de alimentación en la Fig. 3. Si está conectando a un sistema

eléctrico tetrafilar, (un circuito de derivación nuevo o casa rodante requieren

conexión tetrafilar):

1. (Conexiones permanentes trifilares y tetrafilares) Siga las

instrucciones de instalación del fabricante suministradas con el

sujetacable e instale.

2. (Conexiones permanentes trifilares y tetrafilares) Desforre el

aislamiento de los extremos del cableado permanente para la Línea 1,

Línea 2, Neutro (además desforre el alambre de conexión a tierra en las

conexiones tetrafilares). Apriete los 3 conductores hacia el tablero de

bornes (Siga las ubicaciones de los alambres que se muestran en la Fig.

14).

NOTA IMPORTANTE: NO AFLOJE las conexiones de tuerca instaladas

en la fábrica que aseguran el cableado de la estufa en el tablero de

bornes. Se puede producir una falla eléctrica o pérdida de la conexión

eléctrica si estas 3 tuercas son aflojadas o retiradas. NOTA: Para las

conexiones permanentes trifilares omita los Pasos 3 y 4 y

continúe con el Paso 5.

3. (Conexión permanente tetrafilar SOLAMENTE) Desconecte la cinta

de conexión a tierra. Retire el tornillo y placa de tierra instalada en la

fábrica para soltar la cinta de conexión a tierra de cobre del marco del

electrodoméstico. CONSERVE el tornillo de tierra, la placa de tierra y siga

NOTA: Los campos de la compresión de las conexiones de los cables no

terminadas deben ser usadas utilizando un cable de 10 ga. o más grande y

ajustarlos a aproximadamente 22 libras por pulgadas.

con el Paso 4.

4. (Conexión permanente tetrafilar SOLAMENTE) Conecte el alambre

terminal de puesta a tierra (Verde) al marco del electrodoméstico

Conexión permanente tetrafilar SOLAMENTE

usando el tornillo y la placa de conexión a tierra, como se muestra en la

Fig. 15. Asegúrese de instalarlo usando el mismo agujero del marco

donde estaba originalmente instalado el tornillo de tierra.

5. (Conexiones permanentes trifilares y tetrafilares) Asegúrese de

que todas las tuercas estén firmemente apretadas y vuelva a colocar la

cubierta de acceso trasera (Ver Fig. 9).

PLACA DE

CONEXION

A TIERRA

NOTA: Las conexiones de compresión no terminadas del cableado de campo

deben ser ajustadas a aproximadamente 22 pulg./lbs.

5. DESLICE CON CUIDADO LA ESTUFA HASTA SU LUGAR

DEFINITIVO.

TORNILLO DE

CONEXION A

TIERRA

Asegúrese de proveer todos los espacios libres adecuados y las

dimensiones mostradas en las Figs. 1, 2 y 3 en la Página 1 antes de mover la

estufa a su lugar definitivo.

Ubicación de la placa de serie:

Deslice cuidadosamente la estufa hacia la abertura del gabinete a la vez que

inserta el tornillo nivelador trasero en el SOPORTE ANTIVUELCO

VERFICANDO QUE QUEDE BIEN ENGANCHADO (Ver Fig. 7). Asegúrese de

que el cordón de alimentación quede plegado en el resto del área abierta del

piso detrás de la gaveta de almacenamiento o gaveta calentadora de la

Ubicación de la placa de serie:

estufa. Asegúrese de verificar la nivelación de la estufa.

8

Conexión Trifilar

Conecte

Línea 1

aquí

Tablero de

bornes

CINTA DE

CONEXION

A TIERRA

TORNILLO

Y PLACA

DE TIERRA

NOTAS:

Instale el buje

sujetacable. El alambre

central o blanco debe

estar siempre instalado

en el borne central del

tablero de bornes.

APRIETE LOS 3 CABLES TERMINALES

Línea 1

Conexiones instaladas en la fábrica

(NO AFLOJAR)

ALAMBRE

NEGRO

Neutro

PLACA DE CONEXION A TIERRA

TORNILLO DE CONEXION A TIERRA

CINTA DE CONEXION

DE TIERRA

TIERRA

CABLE

TERMINAL DE

CONEXION

A TIERRA

ALAMBRE

(NEUTRO)

BLANCO

Tablero de bornes

Línea 2

Fig. 15

ROJO

TIERRA

APROPIADA

PARA

CONEXION

PERMANENTE

TETRAFILAR

La placa de serie está ubicada

en el costado derecho del marco

delantero inferior del

electrodoméstico.

Conecte el

alambre

neutro

(blanco o

central)

ALAMBRE

Conecte

Línea 2

aquí

Fig. 13

Fig. 14

Loading...

Loading...