Page 1

SERVICE DA T A SHEET

Electric Range with Coil Cooktop (without EOC)

NOTICE - This service data sheet is intended for use by

persons having electrical and mechanical training and a

level of knowledge of these subjects generally

considered acceptable in the appliance repair trade.

The manufacturer cannot be responsible, nor assume

any liability for injury or damage of any kind arising

from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property

damage, it is important that safe servicing practices be

observed. The following are examples, but without limitation,

of such practices.

1. Before servicing or moving an appliance remove power

cord from electrical outlet, trip circuit breaker to OFF,

or remove fuse.

2. Never interfere with the proper installation of any safety

device.

3. GROUNDING: The standard color coding for safety

ground wires is GREEN or GREEN WITH YELLOW

STRIPES. Ground leads are not to be used as current

carrying conductors. It is extremely important that

the service technician reestablish all safety grounds

prior to completion of service. Failure to do so will

create a potential safety hazard.

4. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured

away from sharp edges, high-temperature components,

and moving parts.

• All uninsulated electrical terminals, connectors,

heaters, etc. are adequately spaced away from all metal

parts and panels.

• All safety grounds (both internal and external) are

correctly and securely reassembled.

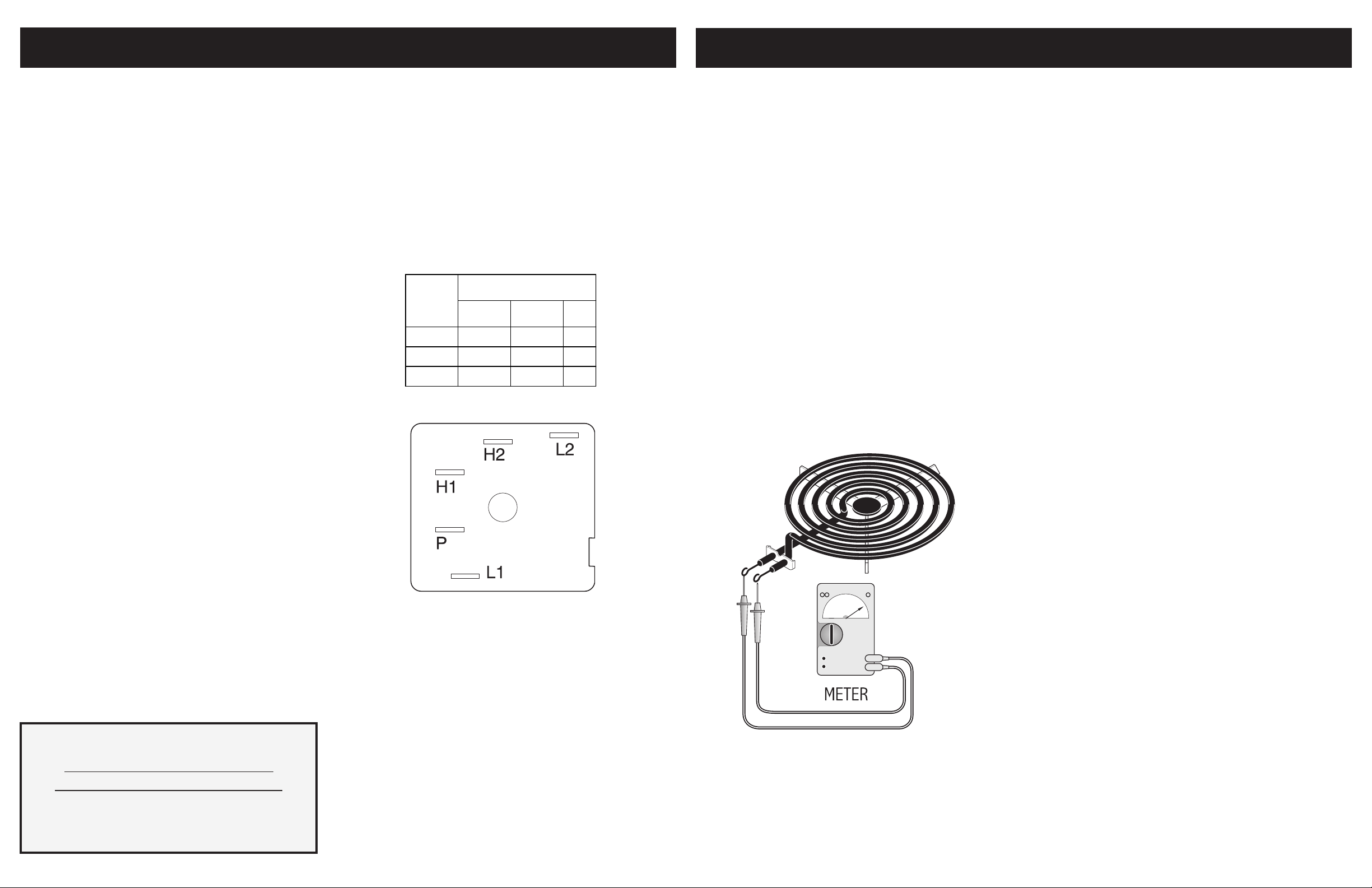

Surface Elements (Infinite) Switch

The surface elements and controls provide an infinite choice of heat

settings for cooking. Controls are safety type and must be pushed in

before turning. All surface controls are marked on the control panel for

their respective heating element. Power is supplied to the surface

elements through the infinite switch contacts L1-H1 and L2-H2.

Continuity tests can be performed on the infinite switch contacts. All

tests should be performed with power to the range disconnected, and

wiring removed from the switch. Set an ohmmeter on R X 1K scale

and check the contacts in the chart below (Fig. 1). The location of the

switch terminals is shown in Fig. 2.

Dial Posi tion

Contacts

OFF LO-MED HI

L1 - P O X X

L1 - H1 O X X

L2 - H2 O X - C X

Fig. 1

Indicator Light

If the elements heat up but the indicator light does not glow ,

check for voltage at the indicator terminals. 240 V AC should

be present at the indicator terminals. If voltage is present at

the indicator terminals, replace the indicator light. If no

voltage is present at the

indicator terminals, check for loose connections, broken

wiring, or open L1-P contact in the infinite switch.

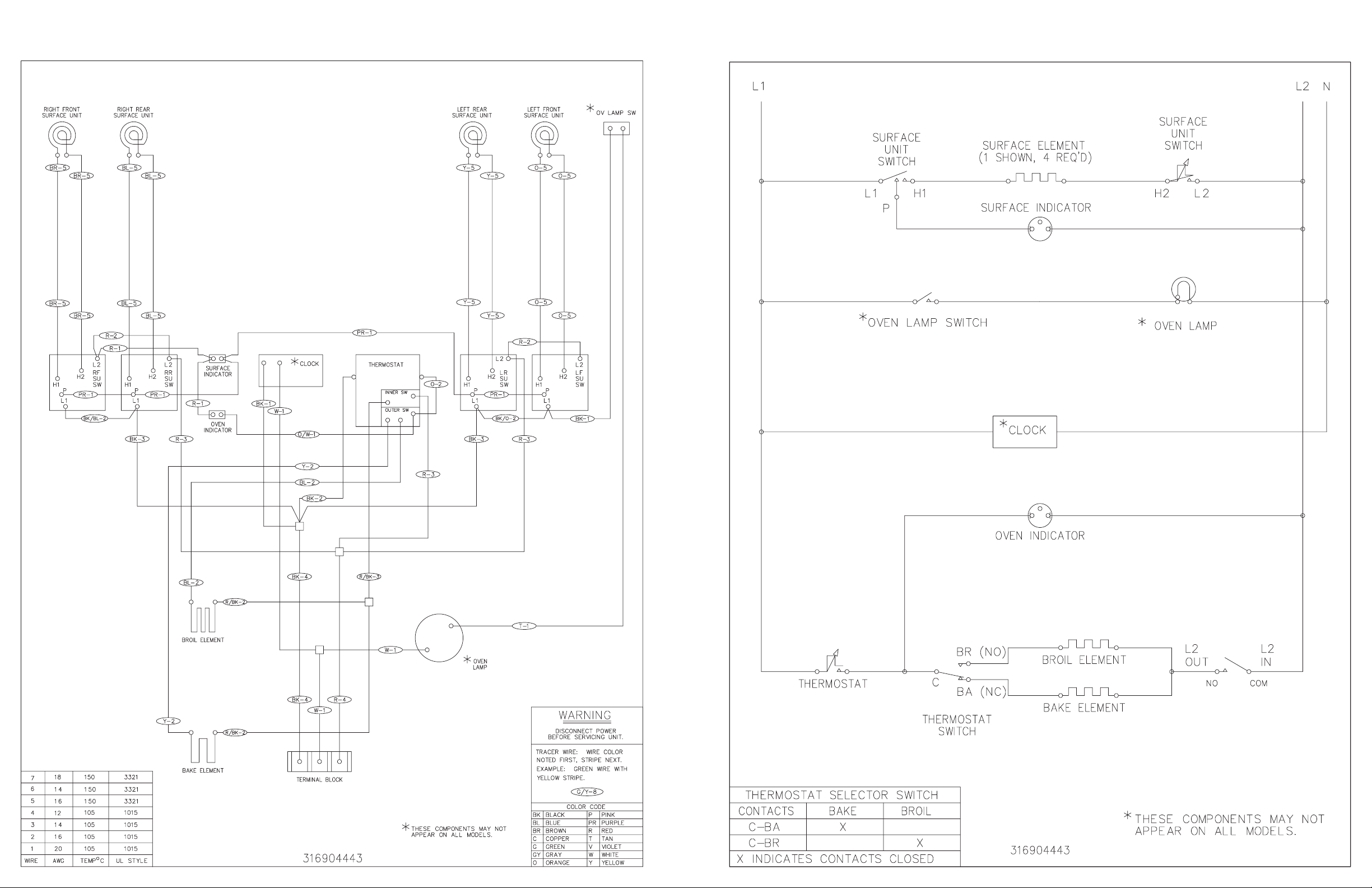

Surface Elements

If the heating element does not heat up, check for line

voltage at receptacle. Approximately 240 V AC should be

indicated at the

element receptacle with the infinite switch in the HI position.

If no voltage is indicated at receptacle, check for loose

connections, broken wiring, or a defective infinite switch. If

voltage is present at the receptacle terminals, check element

for continuity using procedures below.

1.Shut off power to range.

2.Remove element from receptacle.

3.Set ohmmeter to R X 10 scale and attach meter leads to

element. A low OHMS reading (continuity) should be indicated, and this reading may vary slightly on each element

tested. If infinite OHMS (open) is indicated, element must be

replaced (see Fig. 3).

Bake Element

If the bake element does not heat up, check for line voltage across

element terminals. Approximately 240 V AC should be indicated

across terminals. If no voltage is indicated across terminals, check

for broken wire between thermostat and element. Check thermostat.

If voltage is present at the element, check element for continuity

using procedures below.

1.Shut off power to range.

2.Remove wire leads from element terminals.

3.Set ohmmeter to R X 10 scale and attach meter leads to element.

A low OHMS reading (continuity) should be indicated. If infinite

OHMS (open) is indicated, element must be replaced.

Broil Element

If the broil element does not heat up, check for line voltage at

element terminals. Approximately 240 VAC should be indicated at

the element. If no voltage is indicated across terminals, check for

broken wire between thermostat and element. Check thermostat. If

voltage is present at the element, check element for continuity using

procedures below.

1.Shut off power to range.

2.Remove wire leads from element terminals.

3.Set ohmmeter to R X 10 scale and attach meter leads to element.

A low OHMS reading (continuity) should be indicated. If infinite

OHMS (open) is indicated, element must be replaced.

Thermostat Selector Switch

The temperature control is a combination thermostat and selector

switch assembly . The temperature control is performed by cycling

contacts in the thermostat.

The selection of bake or broil operation is done at the control dial.

The contacts C-BA are closed when a bake temperature is selected.

The contacts C-BR are closed when the broil function is chosen.

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

p/n 316904443 (1005)

Fig. 2

NOTE: During actual surface element operation, contacts L2-H2 will

cycle to maintain the correct heat setting. Contacts L1-P provide

power to the surface element indicator light.

If the infinite switch contacts are good, and the element does not heat,

check for voltage at the element receptacle. If no voltage is indicated,

check for broken wiring or loose connections. If voltage is indicated,

the problem is in the heating element.

Fig. 3

OHMS

Oven Indicator Light

The oven indicator light operates any time the thermostat selector

switch is placed in operation. It will cycle with the operation of the

cycling contacts in the thermostat (glows with contacts closed). It is

a 240 VAC indicator light.

Page 2

GENERAL TROUBLESHOOTING SCHEMATICGENERAL TROUBLESHOOTING DIAGRAM

Loading...

Loading...