Page 1

INSTALLATION INSTRUCTIONS

ELECTRIC BUILT-IN

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER

SINGLE AND DOUBLE OVEN MODELS

IMPORTANT NOTE TO INSTALLER: Before you begin – read these

instructions completely and carefully. Be sure to leave these instructions with the consumer.

IMPORTANT NOTE TO CONSUMER: Keep these instructions with your

use and care book for future reference. Observe all gover ning codes

and ordinances. Save these instructions for local inspectors.

Your new wall oven has been designed to fit a wide variety of cutout

sizes to make the job of installing easier. The first step of your

installation should be to measure your current cutout dimensions and

compare them to the cutout dimension chart for your model shown on

page 2. You may find that little or no cabinet work will be necessary.

1. CARPENTRY

Refer to Figures 1 or 2 for the dimensions applicable to

your model oven, and the space necessary to receive the

oven. The oven support surface may be solid plywood or

similar material, however the surface must be level from

side to side and from front to rear.

2. ELECTRICAL REQUIREMENTS

OBSERVE ALL GOVERNING CODES

AND LOCAL ORDINANCES

IMPORTANT: SAVE THESE INSTRUCTIONS FOR

THE LOCAL ELECTRICAL INSPECTOR’S USE.

A. A three-wire or four-wire single phase 120/240 Volt,

60 Hz AC only electrical supply (or three-wire or fourwire 120/280 Volt if specified on nameplate) is required

on a separate circuit fused on both sides of the line

(time-delay fuse or circuit breaker is recommended). DO

NOT fuse neutral. The fuse size must not exceed the

circuit rating of the appliance specified on the

nameplate.

NOTE: Wire sizes and connections must conform with

the fuse size and rating of the appliance in accordance

with the National Electrical Code and local codes and

ordinances.

WARNING: AN EXTENSION CORD SHOULD NOT BE

USED WITH THIS APPLIANCE. SUCH USE MAY RESULT IN

A FIRE, ELECTRICAL SHOCK, OR OTHER PERSONAL

INJURY.

B. The appliance should be connected to the fused

disconnect (or circuit breaker) box through flexible

armored or non-metallic sheathed cable. The flexible

armored cable extending from the appliance should be

connected directly to the junction box. The junction box

should be located as shown in Figure 1 with as much

slack as possible remaining in the cable between the box

and the appliance, so it can be moved, if servicing is ever

necessary.

C. A suitable strain relief must be provided to attach

the flexible armored cable to the junction box.

- 1 -

318064300 (9806) Rev. B

Printed in Canada

Page 2

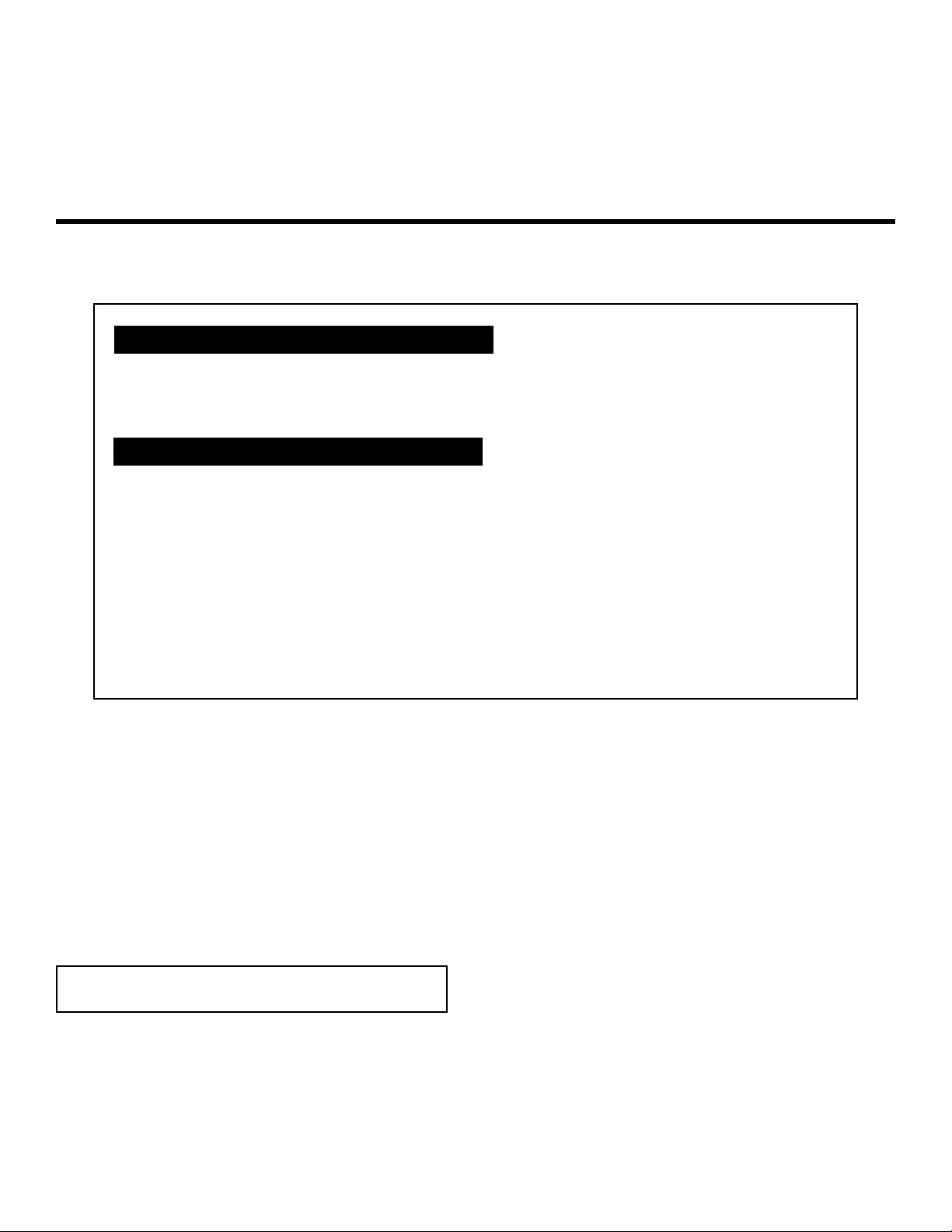

24” AND 27” SINGLE OVENS

C

1-1/2”

MIN.

Allow at least 19-3/8” clearance for complete oven door

opening as show in FIGURE 8.

DO NOT INSTALL THIS OVEN IN A BASE CABINET

WITH A COUNTERTOP ABOVE IT.

PRODUCT DIMENSIONS AND CABINET WIDTH

30-3/4”

D

B

28-1/32”

31”

*

A

25-3/8”

6’ CABLE

*

E

F

18” MINIMUM

24” AND 27” DOUBLE OVENS

CABLE

1-7/8”

MIN.

HOLE

FOR

3”

MAX.

ELECTRICAL

JUNCTION

BOX

FIGURE 1

MODEL

24” SINGLE OVEN

27” SINGLE OVEN

ABC

23-7/8” 21-11/16” 24” MIN.

26-7/8” 24-11/16” 27” MIN.

CUTOUT DIMENSIONS

MODEL D E F

24”

Min.

28-1/8” 22” 23-1/2”

SINGLE

OVEN

27”

Max.

30-1/8” 22-1/4” –

Min.

28-1/8” 24-7/8” 23-1/2”

SINGLE

OVEN

Max.

30-1/8” 25-1/4” –

Allow at least 19-3/8” clearance for complete oven door

opening as show in FIGURE 8.

49-1/4”

1-1/2”

MIN.

C

PRODUCT DIMENSIONS AND CABINET WIDTH

B

MODEL

D

47-3/4”

11-1/2”

A

25-3/8”

6’ CABLE

E

HOLE

FOR

CABLE

3”

F

1-7/8”

MIN.

MAX.

ELECTRICAL

JUNCTION

BOX

24” DOUBLE OVEN

27” DOUBLE OVEN

CUTOUT DIMENSIONS

MODEL D E F

24”

Min.

DOUBLE

OVEN

27”

Max.

Min.

ABC

23-7/8” 21-11/16” 24” MIN.

26-7/8”

27-1/8” **

24-11/16” 27” MIN.

48” 22” 23-1/2”

50” 22-1/4” –

48” 24-7/8” 23-1/2”

DOUBLE

OVEN

Max.

49-7/8” 25-1/4” –

** 27-1/8” on stainless steel models.

FIGURE 2

- 2 -

Page 3

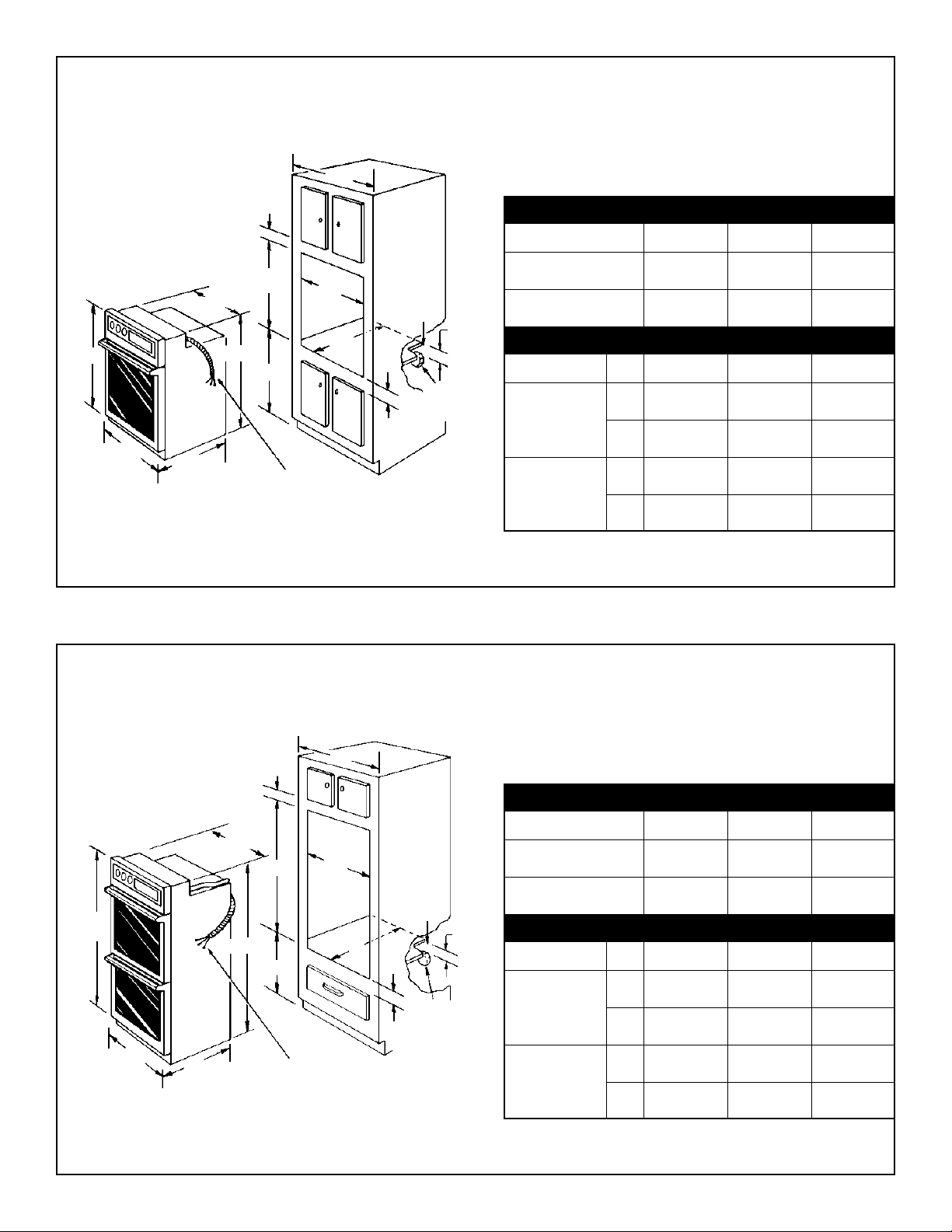

3. HEIGHT ADJUSTMENT ON OVEN

4. ELECTRICAL CONNECTION

Remove and lay aside the lower vent grille that is taped to

the outer side panel of the oven. The grille will be fastened

to the lower front of the oven after it has been installed in

the cabinet.

There is a 1-1/2” height adjustment on these models. (see

figure 4) With this adjustment and a 1/2” trim overhang, a

unit can be installed in existing openings 48” to 50” high

(double oven) or 28-1/8” to 30-1/8” (single oven).

ADJUSTMENT

HOLES

EXTENSION

PANEL

MOUNTING

SCREWS

It is the personal responsibility and obligation of the

customer to contact a qualified installer to assure that the

electrical installation is adequate and is in conformance

with the National Electrical Code and local code

ordinances.

ELECTRICAL GROUND IS REQUIRED

ON THIS APPLIANCE.

This appliance is equipped with copper lead wires. If

connection is made to aluminum house wiring, use only

special connectors which are approved for joining copper

and aluminum wires in accordance with the National

Electrical Code and local codes and ordinances.

This appliance is manufactured with a white neutral power

supply wire and a frame connected bare ground wire.

A. If local codes permit connection of the frame

grounding conductor to the neutral (white wire),

connect the bare wire and white wire from the supply

cable of the appliance together and to the neutral (white)

wire in the junction box. Connect the remaining wires

from the supply cable, matching colors to the wires in the

junction box.

Figure 4

To adjust oven height:

A. Lay oven on its back. (see figure 5)

B. Remove the 6 screws that fasten the side extension

panel to the bottom sides of the oven.

C. Move each panel down to the position that increases

the oven height to fit your opening. Each position changes

oven height approximately 1/2”.

D. Line up the appropriate holes in the side extension

panels and sides of the oven. Replace the 6 screws.

E. Proceed with oven installation. Return oven to upright

position.

OVEN DOOR

B. If used in mobile home or if local codes DO NOT

permit frame grounding to the neutral, separate the

white and bare ground wires that extend out of the end of

the supply cable of the appliance. Connect the white wire

from the supply cable to the neutral white wire in the

junction box. Connect the black wire from the supply

cable to the black wire in the junction box. Connect the

red wire from the supply cable to the red wire in the

junction box. The bare wire must now be used to ground

the appliance in accordance with local electrical codes.

Connect the bare copper ground wire to a grounded cold

water pipe* or to the grounded lead in the service panel.

Do not ground to a gas supply pipe. Do not connect to

electrical power supply until appliance is permanently

grounded. Connect the ground wire befor e turning on the

power. (see figure 6)

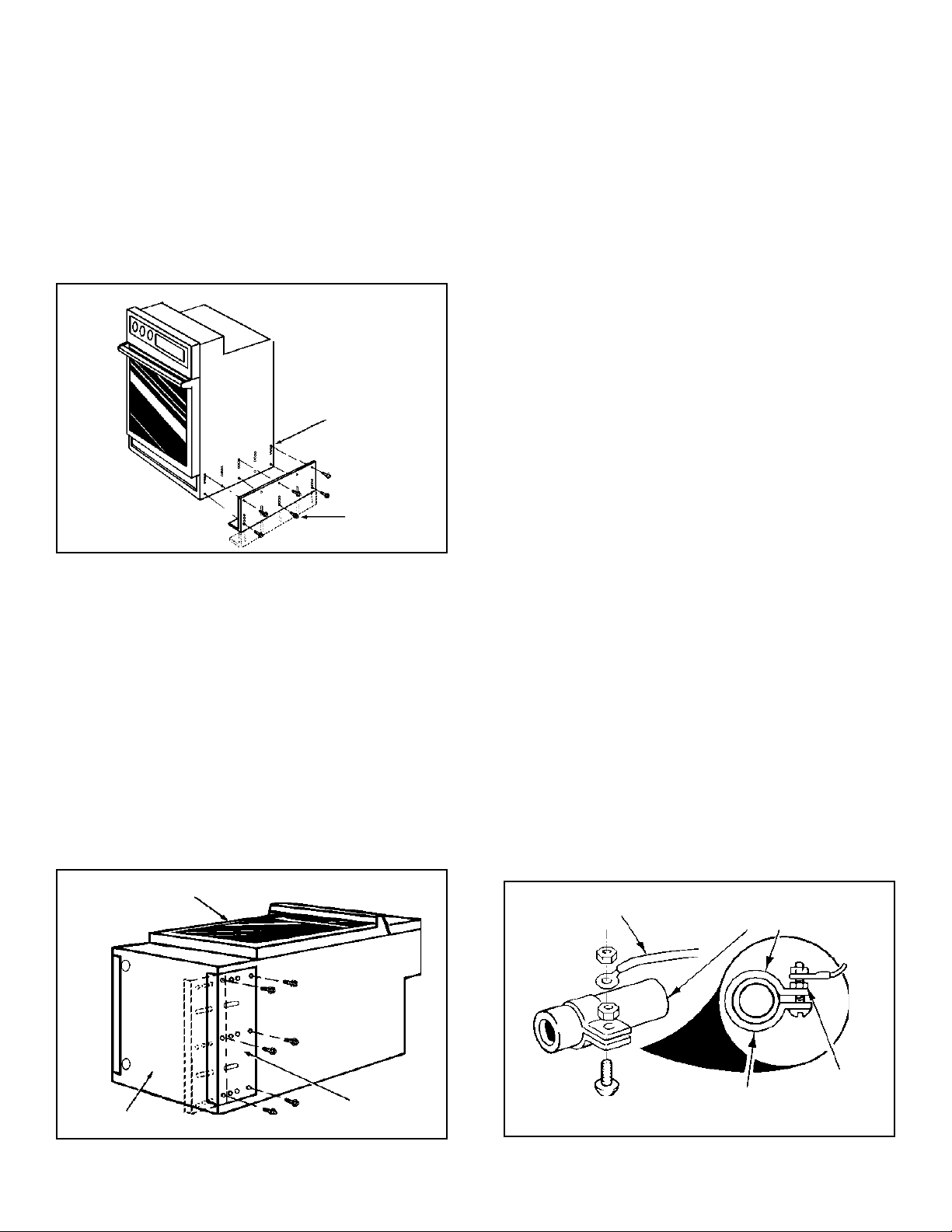

COPPER

GROUND WIRE

GROUNDED COLD

WATER PIPE

(REMOVE PAINT, ETC.)

OVEN

BOTTOM

Figure 5

EXTENSION

PANEL

- 3 -

GROUND CLAMP

(MUST BE TIGHT

ON PIPE)

Figure 6

TIGHTEN

NUTS FIRMLY

Page 4

CAUTION: If connecting to a four-wire electrical system

(mobile home) the appliance frame MUST NOT be

connected to the neutral wire of the four-wire electrical

system. Separate the white and bare wires that extend out

of the end of the supply cable of the appliance. Connect

the white, red and black wires from the supply cable,

matching the colors to the corresponding wires in the

junction box. Connect the bare ground wire from the

supply cable to the ground wire in the junction box.

6. CHECKING OPERATION

SINGLE AND DOUBLE OVEN MODELS

Some wall ovens have manually operated control knobs

to set the Clock and the oven Bake, Broil or Clean

functions. Refer to the Owner’s Guide supplied in the

literature package and check all controls for correct

operation.

* Cold water pipe must have metal continuity to electrical

ground and not be interrupted by plastic, rubber or other

electrically insulating connectors (including water meter or

pump) without adding a jumper wire at these connections.

5. INSTALLATION

Insert appliance into cut-out. Screws are provided for

fastening the front frame on the appliance to the cabinet.

The mounting holes in the front frame of appliance may be

used as a template to locate the appliance mounting screw

holes.

To fasten the appliance to the cabinetry:

1. Line up the 2 mounting holes on the grill with the

lower mounting holes on each side of the oven frame,

below the oven door. (see figure 7)

2. Use 2 screws from the miscellaneous parts bag to

secure the grill and appliance to the cabinetry.

3. Use the remaining 2 screws for mounting the appliance in the upper two mounting holes on each side of the

oven frame, above the door.

This wall oven may be equipped with an electronic oven

control. Each one of the electronic control functions have

been factory checked before shipping this appliance.

However, it is suggested that you verify the operation of

the electronic oven controls once more. For using the

electronic control refer to the Owner’s Guide. Follow the

setting instructions for the Clock, Timer, Bake, Broil,

Convection (some models) and Clean functions.

Bake – After setting the oven to 350°F for baking, the

lower oven element should become red.

Broil – When the oven is set to broil the upper oven

element should become red.

Clean – When the oven is set for a self-cleaning cycle, the

upper element should become red during the preheat

portion of the clean cycle. After reaching the self-cleaning

temperature, the lower heating element will be on and

should become red.

Convection (some models) – When the oven is set for

convection baking or roasting both the upper and the

lower oven heating elements will be on and the convection

fan will turn. The convection fan will stop turning when

the oven door is opened during convection baking or

roasting.

Figure 7

Figure 8

MTG. SCREW

LOWER

VENT GRILL

MINIMUM

REQUIREMENT

FOR

COMPLETE

OVEN DOOR

OPENING.

MTG.

SCREW

19-3/8”

SIDE

VIEW

IMPORTANT NOTE:

Some models have a small fan located inside the control

panel for additional cooling of the electrical and electronic

components. The fan will continue to turn after the oven

has been operating at high temperatures as is obtained

during oven self-cleaning.

SERIAL PLATE LOCATION

The Serial Plate is located along the side of the oven door in

the open position.

BEFORE YOU CALL FOR SERVICE

Check to make sure the house fuses or circuit breaker for

your oven are not blown or open.

- 4 -

Page 5

INSTRUCCIONES PARA LA INSTALACIÓN

HORNO ELÉCTRICO EMPOTRADO

LA INSTALACIÓN Y EL SERVICIO DEBE DE HACERLOS UN INSTALADOR CALIFICADO

DOBLE Y SENCILLO MODELOS DE HORNO

AVISO IMPORTANTE PARA EL INSTALADOR: Antes de empezar, lea con

atención todas estas instrucciones. No se olvide de dejar estas instrucciones

con el usuario.

AVISO IMPORTANTE PARA EL USUARIO: Guarde estas instrucciones con el

libro de mantenimiento y utilización para futuras referencias. Siga todos las

indicaciones y los códigos vigentes. Guarde estas instrucciones para los

inspectores locales.

Su horno de pared ha sido diseñado para adaptarse a un número diverso de

huecos con distintas medidas, y hacer el trabajo de instalación mas fácil. El

primer paso para su instalación debe de ser el de medir las dimensiones de la

apertura y compararlas con las que se indican en el cuadro de dimensiones del

hueco de la página número 2, para su modelo. Puede ocurrir que no sea casi

necesario hacer trabajo de carpintería.

1. CARPINTERÍA

Consulte las figuras 1 o 2 para conocer las dimensiones

pertinentes al modelo de su horno y al espacio necesario

en el que poner el horno. La superficie donde se va a

apoyar el horno debe de ser de madera contrachapada

solida o otro material similar y, sobre todo, la superficie

tiene que estar a nivel, de lado a lado, y de atrás hacia

adelante.

2. REQUISITOS ELÉCTRICOS

CUMPLA CON TODOS LOS CÓDIGOS EN VIGOR Y

TODOS LOS REGLAMENTOS LOCALES.

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES

PARA USO DEL INSPECTOR ELÉCTRICO LOCAL.

A. Para el suministro eléctrico solamente se necesita

corriente alterna con frecuencia de 60 Hz y fase única de

120/240 voltios suministrada por cable de tres o de

cuatro alambres (o si se especifica así en la placa,

corriente de 120/208 voltios suministrada con un cable

de tres o de cuatro alambres) en un circuito separado

con fusibles en ambos lados de la línea (se recomienda

un fusible de tiempo retardado o un cortacircuitos). NO

ponga un fusible en el hilo neutro. El tamaño del fusible

no tiene que exceder la capacidad del circuito necesario

para el electrodomestico y la cual se especifica en la

placa.

NOTA: El tamaño de los cables y de las conexiones debe

de estar en conformidad con el tamaño del fusible y con

la capacidad del electrodomestico y de acuerdo con el

Código Eléctrico Nacional y los códigos y reglamentos

locales.

AVISO: NO SE DEBE DE USAR UNA ALARGADORA PARA

ENCHUFAR ESTE ELECTRODOMESTICO. ESTO PODRÍA

RESULTAR EN UN FUEGO, UN CHOQUE ELECTRICO U

OTRO TIPO DE DAÑO PERSONAL.

B. Este electrodomestico debe conectarse a la caja de

fusibles (o de cortacircuitos), por medio de un cable

blindado flexible o un cable con forro no metálico. El

cable blindado flexible que va desde el electrodomestico

debe de estar conectado directamente a la caja de

empalme. La caja de empalme debe de estar localizada

en el lugar que se indica en la figura 1, dejando tanto

exceso de cable como sea posible entre la caja y el

electrodomestico, de forma que así el electrodomestico

se pueda mover fácilmente, si fuera necesario para hacer

una reparación.

C. Se debe de usar un conectador que reduzca la

tirantez de una forma adecuada para unir el cable

blindado flexible a la caja de empalme.

- 1 -

318064300 (9806) Rev. B

Impreso en Canadá

Page 6

HORNOS SENCILLOS

DE 24 Y 27 PULGADAS

MÍNIMO 1-1/2

PULGADAS

Deje por lo menos 19-3/8 pulgadas de espacio para

que la puerta se pueda abrir completamente, como se

indica en la figura 8.

NO INSTALE ESTE HORNO EN LA PARTE DE ABAJO

C

DE UN ARMARIO DE COCINA QUE TIENE UN

MOSTRADOR ENCIMA.

DIMENSIONES DEL APARATO Y ANCHURA DEL ARMARIO

D

B

25-3/8”

28-1/32”

31”

*

6 PIES DE CABLE

MÍNIMO 18 PULGADAS

*

30-3/4”

A

FIGURA 1

HORNOS DOBLOS

DE 24 Y 27 PULGADAS

MODELO

E

F

AGUJERO

PARA EL

CABLE

MÁXIMO

3

PULGADAS

HORNO SENCILLO

DE 24 PULGADAS

HORNO SENCILLO

DE 27 PULGADAS

MÍNIMO 17/8

PULGADAS

CAJA

ELÉCTRICA DE

EMPALME

MODELO D E F

HORNO

DIMENSIONES DEL HUECO

Mín.

ABC

23-7/8” 21-11/16” 24” MÍN.

26-7/8” 24-11/16” 27” MÍN.

28-1/8” 22” 23-1/2”

SENCILLO

DE 24”

HORNO

Máx.

30-1/8” 22-1/4” –

Mín.

28-1/8” 24-7/8” 23-1/2”

SENCILLO

DE 27”

Máx.

30-1/8” 25-1/4” –

Deje por lo menos 19-3/8 pulgadas de espacio para

que la puerta del horno se pueda abrir

completamente, como se indica en la figura 9.

49 1/4”

MÍNIMO 1-1/2

PULGADAS

B

D

47-3/4”

11-1/2”

A

25-3/8”

6 PIES DE CABLE

C

DIMENSIONES DEL APARATO Y ANCHURA DEL ARMARIO

MODELO

HORNO DOBLE

E

AGUJERO

PARA EL

CABLE

F

MÁXIMO

PULGADAS

DE 24 PULGADAS

HORNO DOBLE

DE 27 PULGADAS

3

DIMENSIONES DEL HUECO

ABC

23-7/8” 21-11/16” 24” MÍN.

26-7/8”

24-11/16” 27” MÍN.

27-1/8” **

MODELO D E F

CAJA

MÍNIMO

1-7/8

PULGADAS

ELÉCTRICA DE

EMPALME

HORNO

DOBLE

DE 24”

HORNO

Mín.

Máx.

Mín.

48” 22” 23-1/2”

50” 22-1/4” –

48” 24-7/8” 23-1/2”

DOBLE

FIGURA 2

DE 27”

** 27-1/8” para el modelo de acero inoxidable

- 2 -

Máx.

49-7/8” 25-1/4” –

Page 7

3. AJUSTE DE LA ALTURA DEL HORNO

Retire y deje a un lado la rejilla que está sujeta con cinta

adhesiva al panel exterior del horno. Esta rejilla se

sujetará a la parte baja frontal del horno, después de que

este se haya instalado en el armario.

En estos modelos hay 1 1/2 pulgadas de ajuste en la

altura (vea la figura 4). Con este ajuste y 1/2 pulgada del

borde que sobresale, el electrodomestico puede

instalarse en huecos de 48 a 50 pulgadas de alto (para

horno doble) o de 28 1/8 a 30 1/8 pulgadas (para horno

sencillo).

AGUJEROS

DE AJUSTE

TORNILLOS

DE MONTAJE

PARA AL

DE EXTENSIÓN

Figura 4

Para ajustar la altura del horno:

A. Ponga el horno apoyado en la parte trasera. (vea la

figura 5)

B. Quite los 6 tornillos que sujetan el panel de

extensión lateral a la parte inferior de los lados del

horno.

C. Mueva cada panel hacia abajo, hasta la posición que

aumenta la altura del horno para que se adapte a la

apertura que usted tiene. Cada posición cambia la altura

del horno 1/2 pulgada aproximadamente.

D. Alinee los agujeros apropiados en los paneles de

extensión y en los lados del horno. Vuelva a poner los 6

tornillos.

E. Proceda con la instalación del horno. Vuelva a poner

el horno en posición vertical.

PUERTA DEL HORNO

4. CONEXIÓN ELÉCTRICA

El usuario tiene la responsabilidad personal y la obligación

de utilizar un instalador calificado, para asegurar que la

instalación eléctrica está hecha de forma adecuada y está

conforme con el Código Eléctrico Nacional y con los

reglamentos locales.

EN ESTE ELECTRODOMESTICO SE NECESITA UN

CABLE DE TOMA A TIERRA.

Este electrodomestico viene equipado con cables de

conexión de cobre. Si estos tuvieran que conectarse a los

cables de aluminio de una casa, use solamente los conectores especiales aprobados para empalmes de cobre y

aluminio, de acuerdo con el Código Eléctrico Nacional y los

reglamentos y códigos locales.

Este electrodomestico se ha fabricado con un cable para el

suministro de energía que tiene un alambre neutro de color

blanco y un alambre pelado de toma a tierra conectado al

armazón exterior.

A. Si los códigos locales permiten la conexión del

conductor de toma a tierra del armazón al neutro

(alambre blanco), una el alambre pelado y el alambre

blanco del cable de suministro de energía del

electrodomestico juntos al cable neutro (blanco) en la caja

de empalme. Conecte los alambres restantes desde el cable

de suministro de energía, emparejando los colores con los

de los cables en la caja de empalme.

B.

Si este horno se va a usar en una casa sobre

ruedas o si los códigos locales no permiten que el

armazón este conectado al neutro de la toma a tierra,

separe el alambre blanco y el de toma a tierra pelado que

salen del final del cable de suministro de energía al

electrodomestico. Conecte el alambre blanco del cable de

suministro de energía al alambre blanco neutro en la caja de

empalme. Conecte el alambre negro del cable de suministro

de energía al alambre negro en la caja de empalme.

Conecte el alambre rojo del cable de suministro de energía

al alambre rojo de la caja de empalme. El alambre pelado

debe de usarse ahora para la toma a tierra del

electrodomestico de acuerdo con los códigos eléctricos

locales. Conecte el alambre de cobre pelado de toma a

tierra a una tubería de toma a tierra de agua fría* o al

alambre de toma a tierra en el panel de servicio. No conecte

la toma a tierra a una tubería de suministro de gas. No

conecte el suministro de energía eléctrica hasta que el

electrodomestico tenga su toma a tierra instalada

permanentemente. Conecte el alambre de toma a tierra

antes de enchufar por primera vez el electrodomestico. (vea

la figura 6)

CABLE DE TOMA A

TIERRA DE COBRE

CABLE DE TOMA A TIERRA A

LA TUBERÍA DE AGUA FRÍA

(QUITE LA PINTURA, ETC.)

PARTE DE ABAJO

DEL HORNO

Figura 5

PANEL DE

EXTENSIÓN

- 3 -

ARGOLLA PARA SUJETAR EL

CABLE DE TOMA A TIERRA

(DEBE DE ESTAR BIEN SUJETA A

LA TUBERÍA)

Figura 6

AJUSTE LAS

TUERCAS

FIRMEMENTE

Page 8

ADVERTENCIA: Si está conectado a un sistema eléctrico

de cuatro alambres (casa movible), el armazón del

eletrodomestico NO TIENE QUE estar conectado al alambre

neutro del sistema eléctrico de cuatro alambres. Separe el

alambre blanco y el alambre pelado que salen del extremo

final del cable de suministro de energía del

electrodomestico. Conecte el alambre blanco, el rojo y el

negro del cable de suministro de energía, emparejando los

colores con los alambres correspondientes en la caja de

empalme. Conecte el alambre pelado de toma a tierra

desde el cable de suministro de energía al alambre de toma

a tierra en la caja de empalme.

* La tubería de agua fría debe de tener una continuidad de

metal hasta la toma a tierra eléctrica y no puede estar

interrumpida por plástico, goma u otros conectores de

aislamiento eléctrico (incluyendo un manómetro o bomba

de agua) al menos que se instale un cable de conexión

alrededor de cada uno de estos puntos.

5. INSTALACIÓN

Coloque el electrodomestico en el hueco. Se proveen los

tornillos para sujetar el frente del armazón del

electrodomestico al armario. Los agujeros de montaje en la

parte frontal del armazón del electrodomestico pueden

usarse como una plantilla para situar los agujeros para los

tornillos de montaje del electrodomestico.

Para sujetar el electrodomestico al armario:

1. Alinee los dos agujeros de montaje en la rejilla con los

agujeros de montaje a cada lado de la parte inferior del

armazón del horno, debajo de la puerta del horno. (vea la

figura 7)

2. Use dos tornillos de la bolsa de piezas variadas para

asegurar la rejilla y el electrodomestico a los armarios.

3. Utilice los dos tornillos que quedan para montar el

electrodomestico en los dos agujeros de montaje a cada

lado de la parte superior del armazón del horno, encima de

la puerta.

6. VERIFICACIÓN DEL FUNCIONAMIENTO

MODELOS DE HORNO SENCILLO Y DOBLE

Algunos hornos de pared tienen botones para control

manual del reloj y de las funciones de Hornear, Asar o

Limpiezar. Mire la Guía del Usuario suministrada en el

paquete de información y verifique que todos los

controles funcionan correctamente.

Este horno de pared puede estar equipado con un

control electrónico para el horno. Cada una de las

funciones electrónicas ha sido verificada en la fabrica

antes de que el electrodomestico haya sido enviado. Sin

embargo, se sugiere que verifique el funcionamiento de

los controles electrónicos del horno una vez más. Para

saber como utilizar el control electrónico del horno mire

la Guía del Usuario y siga las instrucciones para poner en

funcionamiento el reloj, el minutero, el horno, el asador,

el horno de convección (solo en algunos modelos) y el

sistema de limpieza.

Hornear – Después de poner el horno a 350 F para

hornear, el elemento de la parte de abajo del hor no se

debe de ponerse rojo.

Asar – Cuando se pone el horno para asar, el elemento

de arriba del horno debe de ponerse rojo.

Limpiezar – Cuando el horno se pone en el ciclo para

que se limpie a si mismo, el elemento de arriba debe de

ponerse rojo durante la parte de pre-calentamiento del

ciclo de limpieza. Después de que llegue a la

temperatura adecuada de limpieza, el elemento de

calentamiento inferior se encenderá y debe de ponerse

rojo.

Horno de convección (solamente en algunos

modelos) – Cuando el horno se pone para hornear o

asar con convección, ambos elementos de

calentamiento, el superior y el inferior, se encenderán y

el ventilador de convección empezará a funcionar. El

ventilador de convección se parará cuando se abre la

puerta del horno cuando se está horneando o asando

con convección.

Figura 7

Figura 8

TORNILLO DE

MONTAJE

REJILLA PARA LA

VENTILACIÓN POR

DEL HORNO

COMPLETAMENTE.

MEDIDAS

MÍNIMAS

QUE SE

REQUIEREN

PARA QUE

LA PUERTA

SE PUEDA

ABRIR

ABAJO

TORNILLO

DE

MONTAJE

19-3/8”

VISTA

LATERAL

NOTA IMPORTANTE:

Algunos modelos tienen un ventilador pequeño situado

dentro del panel de control para enfriamiento adicional

de los componentes eléctricos y electrónicos. El

ventilador continuará funcionando después de que el

horno haya estado operando a una temperatura alta,

como a la que se llega cuando el horno se está

limpiando.

LOCALIZACIÓN DE LA PLACA

CON EL NÚMERO DE SERIE

La placa con el número de serie se puede encontrar en el

lado de la puerta del horno, cuando está abierta.

ANTES DE LLAMAR AL SERVICIO DE

REPARACIONES

Verifique que los fusibles de la casa no se hayan fundido

o el cortacircuitos del horno no haya saltado.

- 4 -

Loading...

Loading...