Frigidaire FEB30T7DCB Data Sheet

SERVICE DATA SHEET 318047305 (0406) Rev. B

Electric Double Wall Ovens with Electronic Oven Control

NOTICE

This service data sheet is intended for use by persons having electrical and mechanical training and a level of

knowledge of these subjects generally considered acceptable in the appliance repair trade. The manufacturer

cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the use of

this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing practices be

observed. The following are some, but not all, examples of safe practices.

1. Do not attempt a product repair if you have any doubts as to your ability to complete it in a safe and

satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric outlet, trip circuit breaker to Off, or

remove fuse.

3. Never interfere with the proper installation of any safety device.

4. USE ONLY REPLACEMENT PARTS SPECIFIED FOR THIS APPLIANCE. SUBSTITUTIONS MAY DEFEAT

COMPLIANCE WITH SAFETY STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN OR GREEN WITH YELLOW STRIPES.

Ground leads are not to be used as current carrying conductors. IT IS EXTREMELY IMPORTANT THAT THE

SERVICE TECHNICIAN REESTABLISH ALL SAFETY GROUNDS PRIOR TO COMPLETION OF SERVICE. FAILURE

TO DO SO WILL CREATE A POTENTIAL HAZARD.

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, high-temperature

components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately spaced away from

all metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely reassembled.

• All panels are properly and securely reassembled.

1

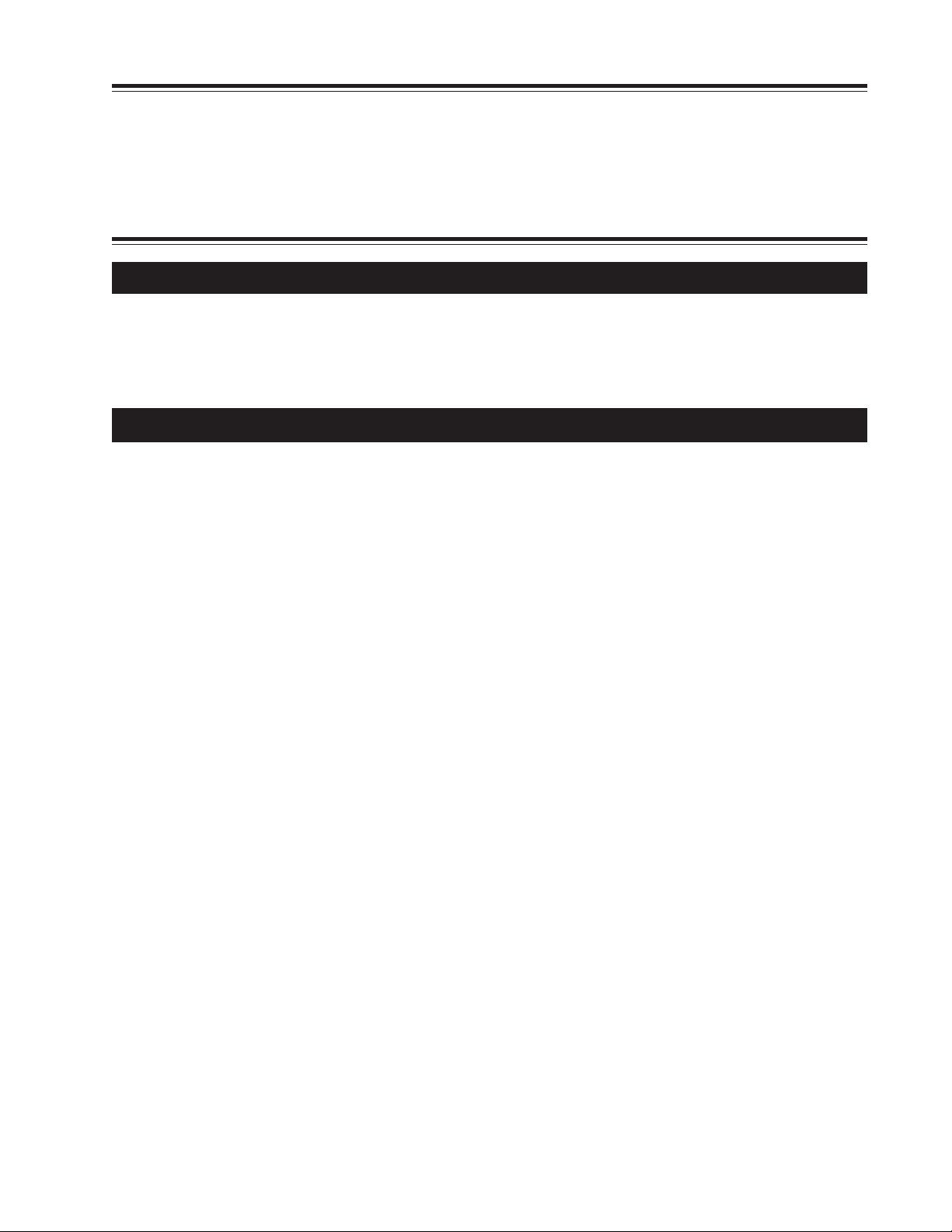

ELECTRONIC OVEN CONTROL (EOC)

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PREBAKE

ON TIMER

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PREBAKE

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PREBAKE

ONTIMER

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PREBAKE

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PREBAKE

ONTIMER

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PREBAKE

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PRE-

BAKE

ONTIMER

CONV

DELAY

CLEAN

BROIL

TIMED

LOCK

PRE-

BAKE

1. The EOC offers Bake, Broil, Preheat (some models), Speed Bake (some models), Convection Bake and Convection

Roasting modes (some models),Timed and Delayed Baking, and Cleaning functions.

2. Convection operates with an element and a fan dedicated to convection (some models).

3. This EOC has a touch sensitive membrane.

4. The EOC includes a display board and a relay board.

NOTE: The EOC is not field repairable. Only temperature settings can be changed. See oven calibration.

NOTE: Appearance may vary depending on model.

Select

Clean

Lower OvenUpper Oven

Speed

bake

Keep

warm

C

ONV

B

AKE

heat

Bake

Broil

S

TART

F

LEX

C

LEAN

O

VEN

L

IGHT

N/OFF

O

Lower Oven

Pre

Speed

clean

Clean

Lower Oven

Bake

Warm&

Hold

C

ONV

R

OAST

Speed

clean

Clea n

Maxx

clean

S

LOW

C

OOK

D

ELAY

S

TART

Bake

time

Start

time

C

3

C

ONV

ONVERT

warm

Broil

STOP

Clear

Oven

Lockout

L

OWEROVEN

W

ARM

H

OLD

O

VENCOOK

T

IME

IMEDOVEN

T

Bake

time

Start

time

Keep

Oven

light

Cook

Time

Delay

Start

B

AKEBROIL

P

RE

&

H

EAT

S

TOP

C

LEAR

VEN

O

L

OCKOUT

Oven

light

Clear

/Off

Controls

START

Clear

/Off

Controls

START

Upper Oven

P

Bake

Warm &

Select

Clean

Hold

U

PPEROVEN

C

ONV

B

AKE

C

ONV

C

ONV

C

ONVERT

R

OAST

F

LEX

S

LOW

C

LEAN

C

OOK

O

VEN

O

D

ELAY

L

IGHT

S

TART

ON/O

FF

3

W

ARM

H

VENCOOK

T

IMEDOVEN

T

STOP

Clear

Oven

Lockout

B

&

OLD

IME

Delay

S

TART

AKEBROIL

P

RE

H

EAT

S

TOP

C

LEAR

VEN

O

L

OCKOUT

Time

Start

Cook

Broil

Upper Oven

Conv

Pre

Speed

Bake

bake

heat

clean

Conv

Bake

Speed

bake

Keep

warm

Clea n

Maxx

Broil

clean

Bake

Speed

time

clean

Start

Clean

time

convert

Conv

roast

Bake

Broil

time

Start

time

Keep

warm

Oven

light

Clear

/Off

Controls

START

Clear

/Off

Controls

Oven

START

light

AM

R

B

PM

CONV

BROIL

PRE-

DELAY

TIMED

BAKE

ON

CLEAN OVEN

CLEAN

LOCK

P

R

B

CONV

BROIL

DELAY

TIMED

CLEAN

LOCK

C

LOCK

Even-Cook Convection Ovens

P

R

B

CONV

BROIL

DELAY

TIMED

CLEAN

LOCK

UPPER OVEN LOWER OVEN

123

6

789

Speed Bake Ovens

P

AM

R

B

PM

CONV

BROIL

PRE-

DELAY

TIMED

BAKE

ON

CLEAN OVEN

CLEAN

LOCK

UPPER OVEN LOWER OVEN

Clock

P

R

B

CONV

BROIL

PRE-

DELAY

TIMED

1

1

Add 1

Minute

2

STOPON TIMER

2

STOPON TIMER

P

R

B

CLEAN

Timer

On/Off

BAKE

ON

CLEAN

LOCK

P

R

B

CONV

BROIL

PRE-

DELAY

TIMED

BAKE

ON

CLEAN

LOCK

ADD1

M

INUTE

K

ITCHEN

T

IMER

N/OFF

O

P

R

B

CONV

BROIL

DELAY

TIMED

BAKE

CLEAN

LOCK

4

5

0

CONV

BROIL

PRE-

DELAY

TIMED

BAKE

ON

LOCK

PRE-

ON

Clock

Timer

Conv

bake

Conv

convert

Conv

roast

On/Off

Bake

Broil

2

1

STOP ON TIMER

Timer

Set/Off

AM

PM

PREBAKE

ON

CLEAN OVEN

AM

PM

PREBAKE

ON

CLEAN OVEN

2

1

STOPON TIMER

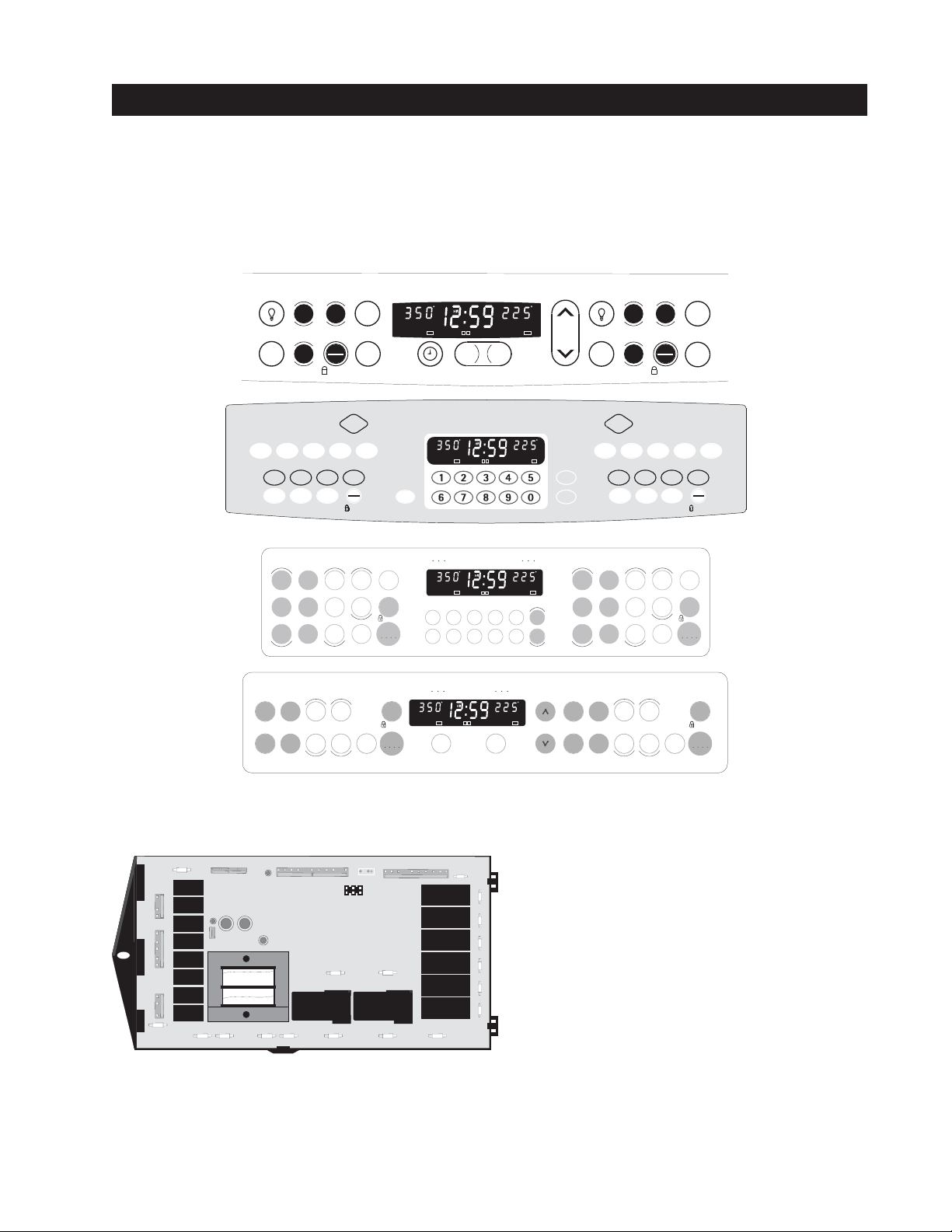

Electronic oven control relay board Relay Board Legend:

P19

1

3

P

J1

A

B

C

3

3

P

D

E

F

2

3

P

G

H

P34

P20P21

P28

P26

P25

I

P27

P29

P24

J

P17

P2

P

P3

O

P4

N

P9

M

P10

L

P11

K

P1 P18P23P8P22

A. Lower MDL relay

B. Lower convection fan relay

C. Lower cooling fan relay

D. Upper MDL relay

E. Upper convection fan relay

F. Upper cooling fan relay

G. Upper light relay

H. Lower light relay

I. Lower DLB relay

J. Upper DLB relay

K. Lower convection relay

L. Lower bake relay

This relay serves to energize the upper and lower oven

heating elements, convection and door lock motors, and

oven lamp. It also powers the display board.

M. Lower broil relay

N. Upper convection relay

O. Upper bake relay

P. Upper broil relay

2

ELECTRONIC OVEN CONTROL (continued)

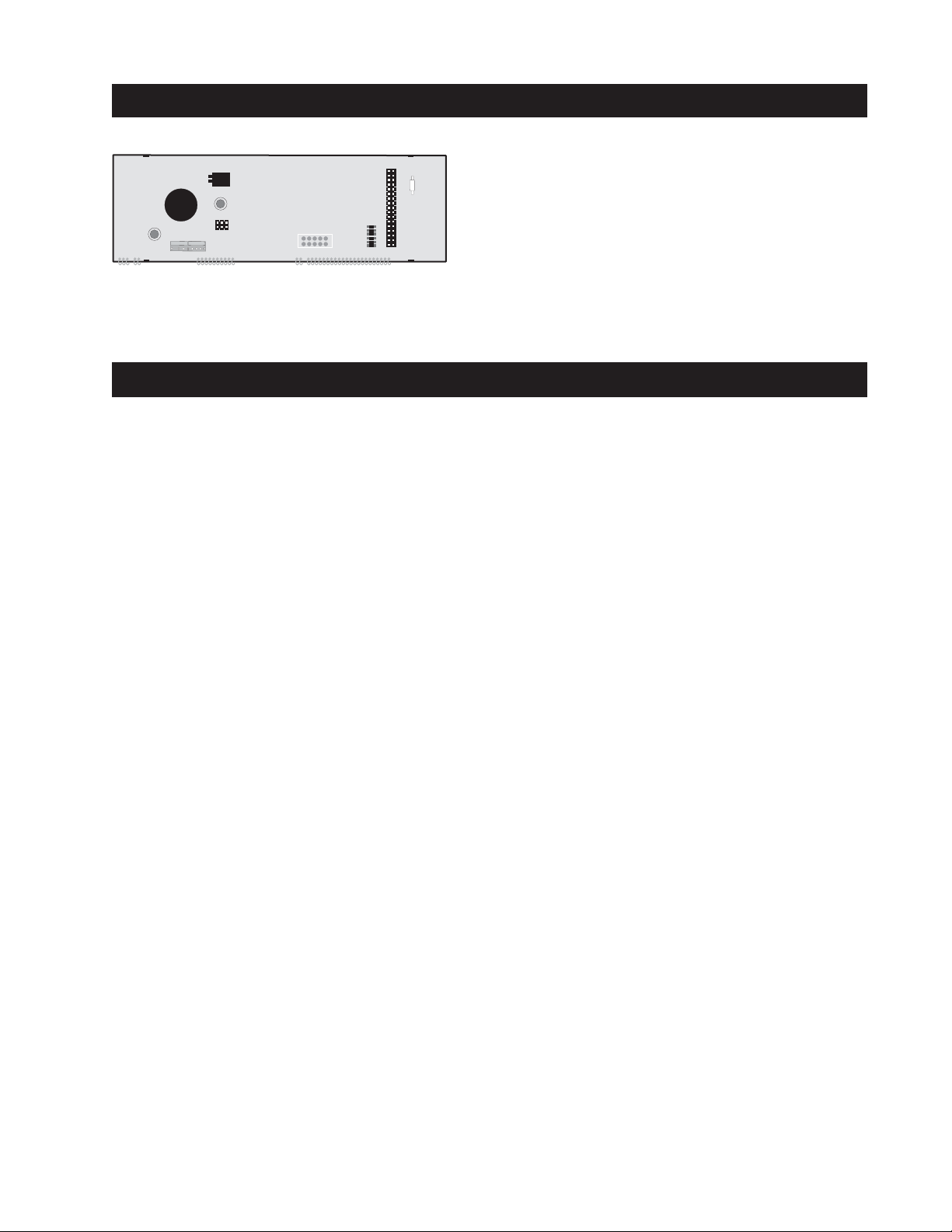

Electronic oven control display board

P3

P8

P4

P1

P2

P1 connector: This 9 pin connector is connected to the relay board.

P3 connector: This 1 or 2 X 17 pin connector is connected to the keyboard.

P4 connector: This 6 pin connector is used for Micro programming.

OVEN ELEMENT - OPERATION

Baking mode -First rise: Bake element is on 40 seconds per minute.

Broil element is on 19 seconds per minute.

-Normal baking: Bake element is on between 40 and 42 seconds per minute.

Broil element is on between 5 and 8 seconds per minute.

Broiling mode Broil element is on for 60 seconds per minute.

Convection mode -First rise: Bake element is on 40 seconds per minute.

Broil element is on 19 seconds per minute.

-Convection baking: Convection element is on for 60 seconds per minute.

Convection Roast -First rise: Bake element is on 40 seconds per minute.

Broil element is on 19 seconds per minute.

-Convection roast: Bake element is on for 50 seconds per minute.

Broil element is on for 9 seconds per minute.

Clean mode: Bake element is on for 60 seconds per minute

and broil element is off.

-Models with hidden Bake element is on for 20 seconds per minute.

bake: Broil element is on for 40 seconds per minute.

NOTE: SELF-CLEANING CYCLE CANNOT BE STARTED IF THE OTHER OVEN IS IN OPERATION, AND

YOU CANNOT OPERATE THE SECOND OVEN IF THE OTHER OVEN IS ON A SELF-CLEANING

CYCLE.

3

TERMINAL BOARD CONNECTORS

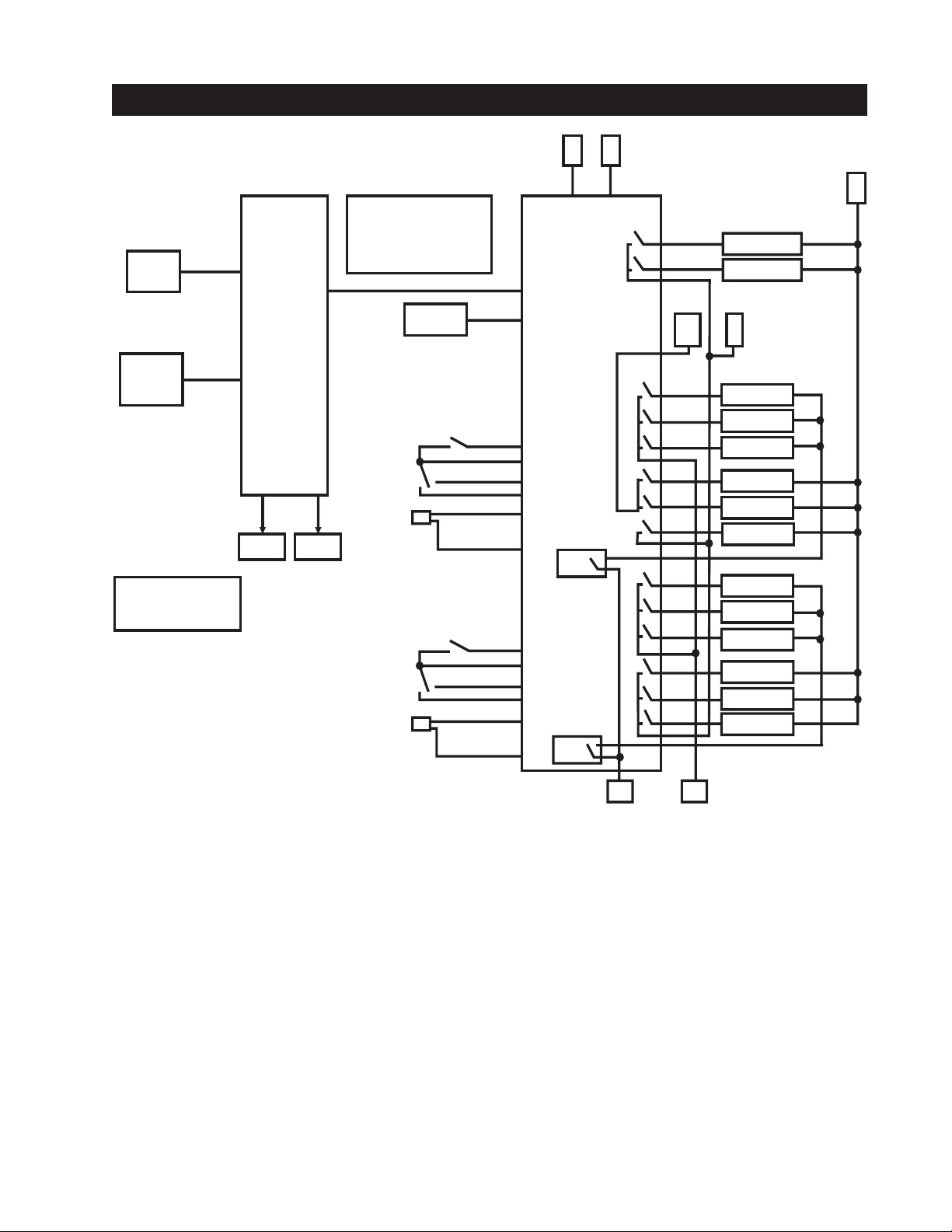

P1 & J1 Pin Designations:

KEYBOARD

*Micro

Programming

* Micro Programming

1 - MISO 2 - +5V

3 - SCK 4 - MOSI

5 - Reset 6 - GND

P3 (2x17 pins)

P4 (6 pins)

Display

Board

Flash

and

eeprom

Display Beeper

1- Filament 1

2- Filament 2

3- Ground

4- Vdisp

P1 (9 pins) J1 (9 pins)

Door 1 Position

Door Lock 1 Common

Door 1 Unlock

Door 2 Position

Door Lock 2 Common

Door 2 Unlock

5- RS485 Comm1

6- Rs485 Comm2

7- +12V

8- Not used

9- Second PB

*Micro

Programming

Door 1 Lock

RTD 1

RTD Common 1

Door 2 Lock

RTD 2

RTD Common 2

P29 (6)

P27-5

P27-3

P27-6

P27-7

P27-9

P27-10

P28-4

P28-3

P28-6

P28-7

P28-8

P28-9

N

P23

Power

Board

Flash

DLB

K1

DLB

K8

P22

P20

P25

P8

L

1

P24

P1

P21

P33-7

P31-4

L1 L1

P32-1

OR P34

P2

P3

P4

P17

P32-3

P33-1

P33-2

P9

P10

P11

P18

P33-4

P31-1

P31-2

Upper MDL (K13)

Lower MDL (K16)

P33-5 OR P19

Upper Broil

(K2)

Upper Bake

(K3)

Upper Conv Ring

(K4)

Lower Light

(K5)

Upper Light

(K6)

Upper Cooling Fan

(K7)

Lower Broil

(K9)

Lower Bake

(K10)

Lower Conv Ring

(K11)

Upper Conv Fan

(K12)

Lower Cooling Fan

(K14)

Lower Conv Fan

(K15)

N

L 2

L 1

4

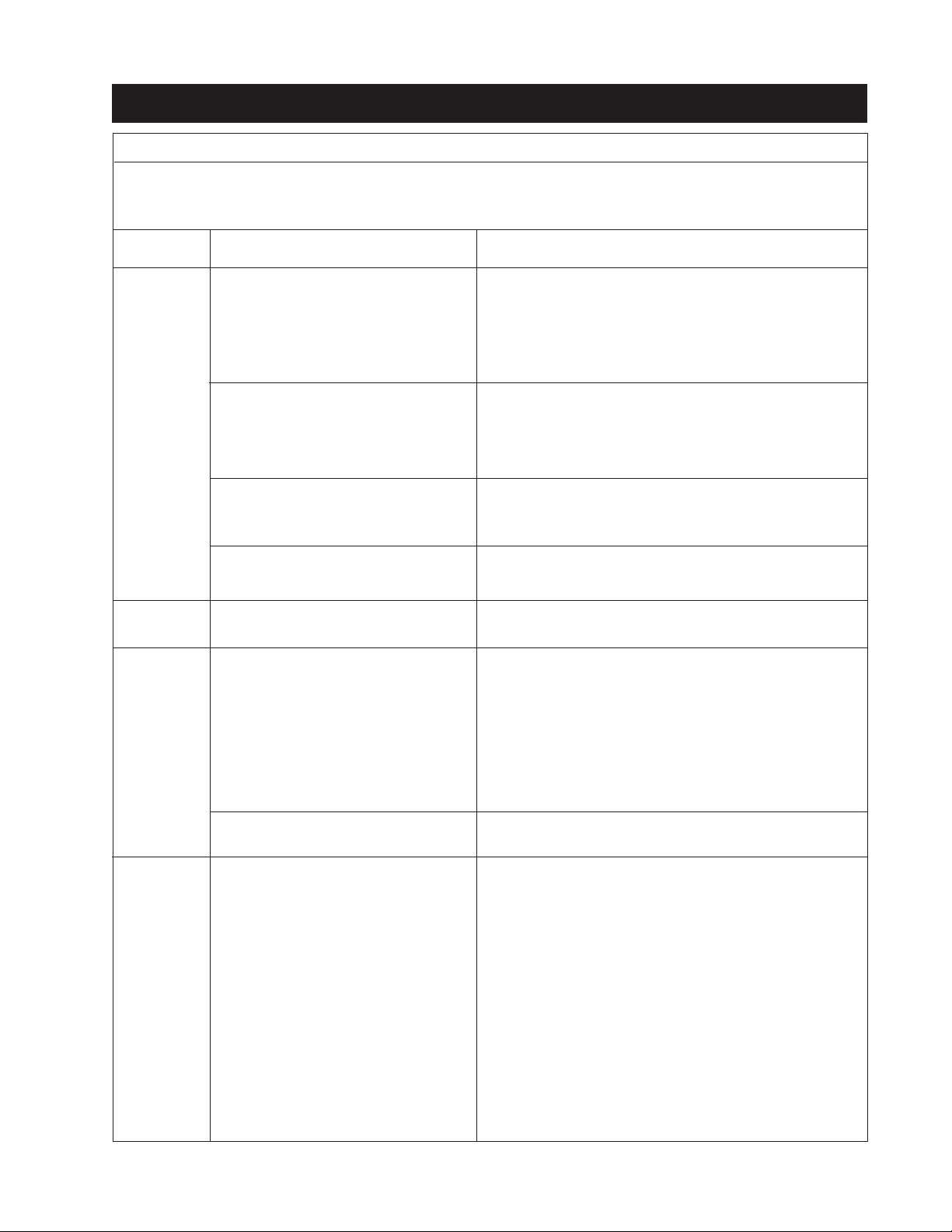

ELECTRONIC OVEN CONTROL (FAULT CODES)

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Note: Only four fault codes series are displayed by this control “F1”, "F2", "F3" and “F9”. Generally speaking “F1” implies

a control failure, “F2” a bad communication between display board and relay board, “F3” an oven probe problem, and “F9”

a latch motor problem.

Fault Code

Series

F1

Likely Failure Condition/Cause

(F10) Control has sensed a potential

runaway oven condition. Control

may have shorted relay, RTD sensor

probe may have a gone bad.

Suggested Corrective Action

Press Clear or Cancel key.

Check RTD sensor probe and replace if necessary. If oven is

overheating, disconnect power. If oven continues to oveheat

when power is reapplied, replace EOC. Severe overheating may

require the entire oven to be replaced, should damage be

extensive.

F2

F3

F9

(F11) Shorted Key: a key has been

detected as pressed (for more than

the debounce period) will be

considered a shorted key alarm

and will terminate all oven activity.

(F13) Control's internal checksum may

have become corrupted.

(F14) Relay watchdog failure.

(F20) Bad communication between

display board and relay board.

(F30) Open RTD sensor probe/ wiring

problem. Note: EOC may initially

display an "F10", thinking a

runaway condition exists.

(F31) Shorted RTD sensor probe / wiring

problem. Note: "F31" is displayed

when oven is in active mode or an

attempt to enter an active mode is

made.

(F32) Key loop is detected as an open

cicuit.

(F90 Door motor mechanism failure.

and

F95)

Press Clear or Cancel key.

Press Clear or Cancel key.

Disconnect power, wait 30 seconds ad reapply power. If fault

returns upon power-up, replace EOC.

Press Clear or Cancel key.

Replace Relay board.

Press Clear or Cancel key.

Verify connections between 2 boards (P1 and J1).

Press Clear or Cancel key.

Check wiring in probe circuit for possible open condition.

Check RTD resistance at room temperature (compare to probe

resistance chart). If resistance does not match the chart, replace

the RTD sensor probe.

Let the oven cool down and restart the function

Press Clear or Cancel key.

Verify if the the keyboard is connected (P3).

Press CLEAR key.

If CLEAR key does not eliminate problem, turn off power for

30 seconds, then turn on power.

Check wiring of Lock Motor, and Lock Switch and Door Switch

circuits.

Unplug the lock motor from the board and apply power (L1)

directly to the Lock Motor. If the motor does not rotate, replace

Lock Motor Assembly.

Check Lock Switch A for proper operation (do they open and

close, check with ohmmeter). The Lock Motor may be powered

as in above step to open and close Lock Switch. If the Lock

Switch is defective, replace Motor Lock Assembly.

If all above steps fail to correct situation, replace EOC.

5

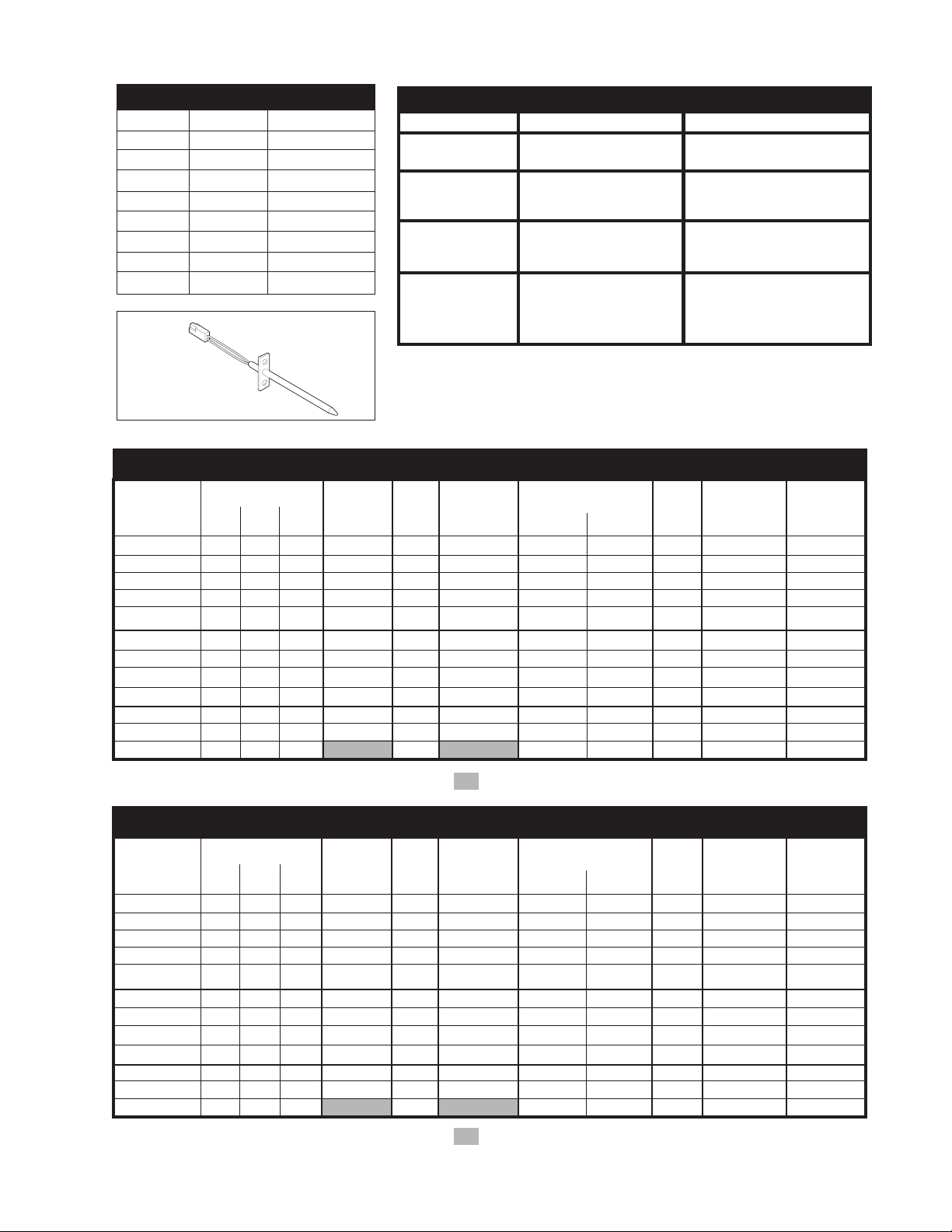

RTD SCALE

Temp. °F Temp. °C Resistance (ohms)

32 ± 1.9 0.0 ± 1.1 1000 ± 4.0

75 ± 2.5 23.9 ± 1.4 1091 ± 5.3

250 ± 4.4 121.1 ± 2.4 1453 ± 8.9

350 ± 5.4 176.7 ± 3.0 1654 ± 10.8

450 ± 6.9 232.2 ± 3.8 1852 ± 13.5

550 ± 8.2 287.8 ± 4.6 2047 ± 15.8

650 ± 9.6 343.3 ± 5.3 2237 ± 18.5

900 ± 13.6 482.2 ± 7.6 2697 ± 24.4

OVEN

TEMPERATURE

SENSOR

UPPER OVEN CIRCUIT ANALYSIS MATRIX

ELEMENTS

Bake

Broil

Conv. Bake

Conv. Roast

Clean

Locking

Locked

Unlocking

Unlocked

Light

Door Open

Door Closed

Bake

P3

X

X

X

X

Broil

P2

X*

X

X*

Conv.

P4

X

Conv.Fan

P33-4

ELECTRICAL RATING

27" 30"

KW rating

240/208 8.2/6.2 8.2/6.2

Bake Element Vary depending on model:

Wattage 2300W/17820W or 3400W/2554W

Broil Element 3400W/2554W Vary depending on model:

Wattage 2750W/2065W or

Convection Vary depending on model: Vary depending on model:

Element No convection element No convection element

Wattage or 350W element or 350W element

Light

Door Motor

P33-1

X

X

X

X

P33-7

X

X

2700W/2028W

Lock Motor Switches

P27-3

&

P27-7

NC

NO

NO

NC

P27-3

A

&

P27-6

NO

NC

NC

NO

DLB

L2 out

P24

X

X

X

X

X

4000W/3004W

2500W element

Door Switch

P27-5 / P27-3

COM-NO

X

Cooling

Fan

P33-2

Low Speed

Low Speed

Low Speed

Low Speed

Low & High

Speed

* Denotes Top heat Relay will operate in this condition only

LOWER OVEN CIRCUIT ANALYSIS MATRIX

ELEMENTS

Light

Door Motor

P32-3

X

X

P31-4

X

Bake

Broil

Conv. Bake

Conv. Roast

Clean

Locking

Bake

P10

X

X

X

X

Broil

P9

X*

X

X*

Conv.

P11

X

Conv.Fan

P31-2

Locked

Unlocking

X

Unlocked

Light

Door Open

X

X

Door Closed

* Denotes Top heat Relay will operate in this condition only

Lock Motor Switches

P28-3

&

P28-7

NC

NO

NO

NC

6

Door Switch

P28-3

A

&

P28-6

NO

NC

NC

NO

DLB

L2 out

P25

X

X

X

X

X

P28-3 / P28-4

COM-NO

X

Cooling

Fan

P31-1

Low Speed

Low Speed

Low Speed

Low Speed

Low & High

Speed

Loading...

Loading...