Page 1

SERVICE DATA SHEET 318047301 (9704) Rev. C

Electric Double Wall Ovens with Electronic Oven Control (Robertshaw 5800 - 318010501)

NOTICE

This service data sheet is intended for use by persons having electrical and mechanical training and a

level of knowledge of these subjects generally considered acceptable in the appliance repair trade.

The manufacturer cannot be responsible, nor assume any liability, for injury or damage of any

kind arising from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing

practices be observed. The following are some limited examples of safe practices.

1. Do not attempt a product repair if you have any doubts as to your ability to complete it in a safe

and satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric outlet, trip circuit

breaker to Off, or remove fuse.

3. Never interfere with the proper installation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE. SUBSTITUTIONS

MAY DEFEAT COMPLIANCE WITH SAFETY STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN OR GREEN WITH

YELLOW STRIPES. Ground leads are not to be used as current carrying conductors. IT IS

EXTREMELY IMPORTANT THAT THE SERVICE TECHNICIAN REESTABLISH ALL SAFETY

GROUNDS PRIOR TO COMPLETION OF SERVICE. FAILURE TO DO SO WILL CREATE A

POTENTIAL HAZARD.

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, high-temperature

components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately spaced away from

all metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely reassembled.

• All panels are properly and securely reassembled.

1

Page 2

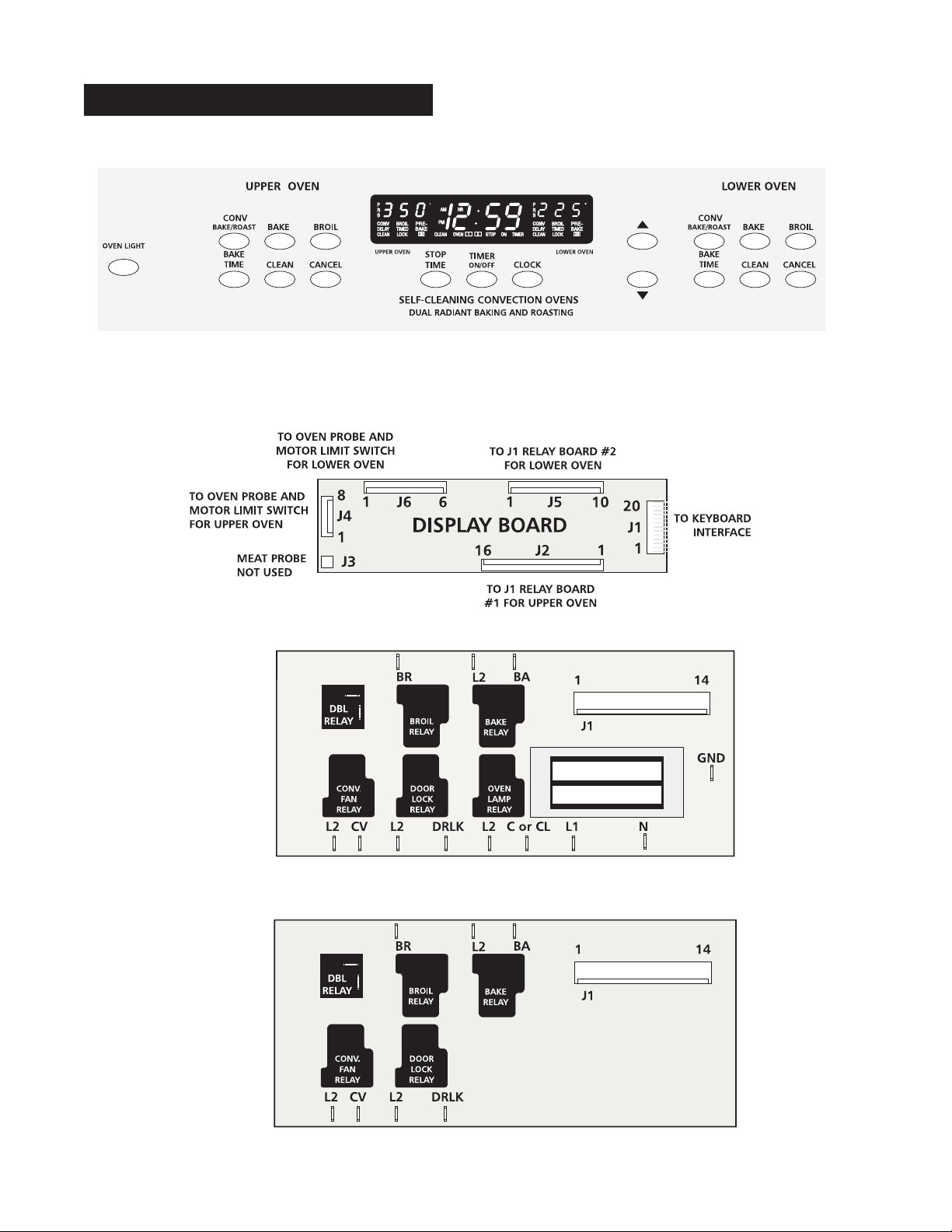

ELECTRONIC OVEN CONTROL

* Depending on model, shape of buttons or pads may vary.

RELAY BOARD #1

FOR UPPER OVEN.

RELAY BOARD # 2

FOR LOWER OVEN

TRANSFORMER

2

Page 3

ELECTRONIC OVEN CONTROL FOR DOUBLE WALL OVENS

The electronic oven control includes:

• a display board

• a relay board #1 and transformer for upper oven

• a relay board #2 for lower oven

DISPLAY BOARD UNIT

The display board unit includes 6 connectors (J1 to J6)

J1 connector: This 20 pin connector is connected to the keyboard (touch pads).

J2 connector: This 16 pin connector is connected to J1 in relay board #1 for upper oven. J2

serves to energize the upper oven relays (6 of) and to power the control display.

J3 connector: Unused

J4 connector: This 8 pin connector is connected to the upper oven probe and upper oven motor

limit switch.

J5 connector: This 10 pin connector is connected to J1 in relay board #2 for lower oven. J5 serves

to energize the lower oven relays (5 of).

J6 connector: This 6 pin connector is connected to lower oven probe and lower oven motor limit

switch.

RELAY BOARD #1 FOR UPPER OVEN

This relay board includes 6 relays and a transformer. These relays serve to energize the upper oven

heating elements, convection and door lock motors, and oven lamp. It also powers the display board.

Its 14 pin connector J1 is connected to J2 in the display board.

RELAY BOARD #2 FOR LOWER OVEN

This relay board includes 5 relays. These relays serve to energize the lower oven heating elements,

convection and door lock motors. Its 14 pin connector is connected to J5 in the display board.

OVEN ELEMENT - OPERATION

Baking mode -First rise: Broil element is on 30 seconds per minute.

Bake element is on 60 seconds per minute.

-Normal baking: Broil element is on 7 seconds per minute.

Bake element is on 50 seconds per minute.

Broiling mode Broil element is on for 60 seconds per minute.

Convection mode Bake element is on for 33 seconds per minute.

Broil element is on for 12 seconds per minute.

Clean mode: -First 10 minutes: Broil element is on for 42 seconds per minute

and bake element is off.

-After 10 minutes: Bake element is on for 60 seconds per minute

and broil element is off.

NOTE: SELF CLEANING CYCLE CANNOT BE STARTED IF THE OTHER OVEN IS IN OPERATION, AND

YOU CANNOT OPERATE THE SECOND OVEN IF THE OTHER OVEN IS ON A SELF CLEANING

CYCLE.

3

Page 4

ELECTRONIC OVEN CONTROL (FAULT CODES)

FAILURE MODES

F0 - ALARM (EEPROM OPTION)

This EEPROM selectable option enables the control to recognize a shorted key within approximately

32 seconds. This option has priority over shorted watchdog failure alarm F1.

F1 - ALARM

A failure is detected in the element relay watchdog protection circuits and will activate a "CANCEL"

feature. "F1" will be displayed in the time digits and the alarm will sound until the cancel key for the

oven is pressed or another function is selected.

F2 - ALARM

Occurs when cavity temperature exceeds the clean runaway temp in the clean mode or the cooking

runaway temp in a non-clean condition and will activate a "CANCEL" feature. "F2" will be displayed in

the digits for the affected cavity, and the alarm will sound until the CANCEL key for the oven is pressed

or another function is selected. This failure may be overridden by the F3 or F4 alarm.

F3- ALARM

Occurs when there is a short circuit in the oven temperature sensor for 16 temperature conversions in

a row and will activate a "CANCEL" feature. "F3" will be displayed in the digits for the affected oven

cavity, and the alarm will sound until the CANCEL key for the oven is pressed. The alarm will return in

16 seconds if the failure is still present.

F4 - ALARM

An open circuit in the oven temperature sensor for 16 temperature conversions in a row will activate a

"CANCEL" feature. "F4" will be displayed in the temp digits for the affected cavity, and the alarm will

sound until the CANCEL key for the affected oven is pressed. If the failure is present after cancel is

pressed, the alarm will not be reactivated unless a baking or cleaning function is attempted. The

opposite oven is unaffected with this alarm.

F6 - ALARM

A failure is detected in the EEPROM checksum comparison. This indicates the EEPROM checksum

and the calculated checksum are not the same. Only time of day and timer operation will be allowed in

the control.

F-7 ALARM

A failure detected in the clean lock/phase circuitry for 16 seconds in a row will activate a "CANCEL"

feature. "F7" will be displayed in the temp digits of the affected oven and the alarm will sound until

CANCEL for the affected oven is pressed or another function is selected. This test will be performed

constantly.

F-8 ALARM

Occurs when the door lock runs for 2 minutes without seeing either the lock or phase switch change

positions.

4

Page 5

TERMINAL BOARD CONNECTORS

(French translation included)

5

Page 6

CONVECTION BAKE MODE

The convection oven uses the addition of a fan to move the heated air already in the oven. Moving the

heated air helps to destratify the heat or cause uniform heat distribution. Longer cooking times can be

reduced by as much as 30%. The air is drawn in through a fan shroud located on the rear wall of the

oven. It is then discharged around the outer edges of this shroud. The air is circulated around the food

and then enters the shroud again. As with conventional electric ranges, there is still an oven vent which

discharges through the control panel vent opening.

To set the control in convection mode, follow these two steps:

1. Press the CONV. BAKE/ROAST pad.

2. Press the UP or DOWN arrow pads to select the desired temperature.

After 3 seconds, the oven will automatically start and the fan will begin to run. To cancel the convection

baking function, press the CANCEL pad.

NOTE: THE FAN RUNS CONTINUOUSLY WHILE IN THE CONVECTION MODE. THE FAN WILL

STOP IF THE DOOR IS OPENED WHILE CONVECTION BAKING/ROASTING. THE

HEATING ELEMENTS WILL CONTINUE TO OPERATE WITH THE DOOR OPEN.

CONVECTION MODE OVEN TEMPERATURES

Because heat is more evenly distributed during convection temperatures, foods can be cooked at lower

temperatures. In order to allow the consumer to bake per their existing methods using regular baking

recipes, there is an offset temperature of -25°F in the programming of the control. This means that when

the consumer sets the control for 375°F, the actual oven temperature is cycling at 350°F.

6

Page 7

CONVECTION CYCLING

When the control is set to the CONV. BAKE/ROAST function, the fan immediately comes on. The broil

and bake elements are energized for the first 12 seconds of every minute. For the next 21 seconds, only

the bake element is energized. Both elements are off the remaining 27 seconds. This cycle is repeated

for the duration of the cooking period.

Convection Cycle

NORMAL BAKE MODE

1

3

OFF

BAKE

1 = Broil & Bake 12 sec/min

2 = Bake 21 sec/min

3 = Both off 27 sec/min

Approximate Times

BAKE &

BROIL

BROIL

BAKE

OFF

2

During a normal bake mode, the oven uses top heat by cycling the broil element on for 7 seconds each

minute. Both elements use full power when they are on.

FAN RELAY

The fan motor runs continuously while in the convection mode unless the door is opened. If the fan does

not operate, check the following:

• Display illuminated on the electronic control.

• Voltage output between terminals L2 and CV on appropriate board.

• 240 Volts available at fan motor.

• Fan motor coil resistance 56.5 ohms ± 10%.

• Voltage input to fan relay coil during convection bake with door closed.

• Door/light switch.

7

Page 8

ADJUSTING OVEN TEMPERATURE

1. Push the BAKE pad.

2. Set the temperature to 550°F/288°C by pushing the UP arrow pad.

3. Within 2 seconds, push and hold the BAKE pad for approximately 5 seconds until the special 2

digit display appears. Release the BAKE pad.

The display now indicates the difference in degrees between the original factory temperature

setting and the current temperature setting. If the oven control has the original factory calibration,

the display will read "00".

4. The temperature can now be adjusted up or down 35°F/17°C, in 5°F/2.5°C increments, by pushing

the UP or Down arrow pads. Adjust the UP/DOWN arrow pads until the desired amount of offset

appears in the display. A minus sign (-) will appear before the number to indicate the oven will be

cooler by the displayed amount of degrees.

5. When you have made the desired adjustment, push the CANCEL pad to go back to the time of

day display.

NOTE:

CHANGING CALIBRATION EFFECTS BOTH CONVENTIONAL AND CONVECTION MODES.

FAN BLADE

The fan blade is mounted in the rear of the unit and has a "D" shaped opening. Only minimum clearance

exists between the oven back, fan blade, and fan shroud. Be careful not to bend blade when removing

or installing.

Access to the fan blade is gained by removing the fan shroud, held in place by three screws, from the

inside of the oven.

The fan blade is held in place with a hex nut that has left handed threads. When

removing this nut, gently hold the fan blade, and turn the nut clockwise. If one of the

blades becomes deformed, it may be bent back into shape using a flat surface as a

reference.

NOTE: IF THE FAN BLADE IS BENT AND MOTOR VIBRATIONS

INCREASE, THE NOISE MADE BY THE FAN WILL BE

GREATER.

8

Page 9

ELECTRICAL SPECIFICATIONS

ELECTRICAL RATING

30”

KW rating

240/208

Bale Element

Wattage

27”

8.2/6.2 9.0/6.8

2300W/1728W 3000W/2254W

Broil Element

Wattage

3400W/2550W 2750W/2065W

LOWER OVEN LIGHT SWITCH LOCATION /REMOVAL (Some Models)

On some double wall ovens, the light

switch for the lower oven is located on

the lower right-hand side of the oven. The

servicer must pull the oven out of the

cabinet to access it.

Removal/Replacement Procedure

1. Pull wall oven out from cabinet. (Light

switch access is on lower right-hand

side of wall oven.)

2. Remove screw securing cover plate to

side panel.

3. Remove two screws securing light

switch to oven insulation cover.

4. Gently pull switch out of opening to

access and remove wire leads.

5. Reverse procedure to replace switch.

9

Page 10

NOTES

SCHEMATIC DIAGRAM

10

Page 11

NOTES

11

Page 12

12

Loading...

Loading...