Frigidaire FAS184N2A, FAS226N2A, FAS185N2A, FAS186N2A, FAS256N2A Product Information And Technical Manual

...Page 1

Product Information

g

and Technical Guide

2004 Room Air Conditioners

Safe Servicing Practices 3

ATTENTION SERVICERS!

To get a helping hand, visit the

Frigidaire Web Site at:

http://www.frigidaire.com

User name: service

Password: tips

Model Specifications 4-7

Compressor Overloads 8

Restrictor Tube Data 8

Receptacle Codes 9

Product Dimensions 10

Thermostat Dia

Fan/Blower Diagrams 13-14

Wiring Diagrams 15-17

Troubleshooting 18-20

rams 11-12

5995413183

July 2004

Page 2

TABLE OF CONTENTS

Safe Servicing Practices ............................................................................................3

Model Specifications ..................................................................................................4-7

Compressor Overload Data .......................................................................................8

Restrictor Tube Data ..................................................................................................8

Receptacle Outlet Codes ...........................................................................................9

Product Dimensions ..................................................................................................10

Control Thermostat Location Diagrams ................................................................... 11-12

Slider Casement ......................................................................................................11

Compact Electronic Control .....................................................................................11

Compact Rotary .......................................................................................................11

Intermediate Top Control Rotary .............................................................................. 11

2004 Heavy Duty Thermostat Locations ..................................................................12

2004 Builder Thermostat Locations .........................................................................12

2004 Slider Thermostat Locations ...........................................................................12

Fan and Blower Location Diagrams .........................................................................13-14

Compact .................................................................................................................13

18.5” - No Side Louvers ........................................................................................... 13

Slider Casement ......................................................................................................13

Motor .....................................................................................................................14

Heavy Duty Top Control ...........................................................................................14

Heavy Duty Side Discharge .....................................................................................14

Wiring Diagrams .........................................................................................................15-17

A232012 .................................................................................................................15

309201101/02 ......................................................................................................... 16

309201102/02 ......................................................................................................... 16

309902101/01 ......................................................................................................... 17

Troubleshooting ......................................................................................................... 18-20

2

Page 3

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury or property damage, it is important that Safe Servicing

Practices be observed. The following are some limited examples of safe practices.

1. DO NOT attempt a product repair if you doubt your ability to complete it in a safe

and satisfactory manner.

2. Before servicing or moving an appliance

• Remove power cord from electrical outlet, trip circuit breaker to OFF position,

or remove fuse

• Turn off gas supply

• Turn off water supply

3. Never interfere with the proper operation of any safety device.

4. Use only OEM replacement parts cataloged for this appliance.

Substitutions may defeat compliance with safety standards set for home

appliances.

5. GROUNDING: The standard color coding for safety ground wires is GREEN, or

GREEN with YELLOW STRIPES. DO NOT use ground leads as current carrying

conductors. It is EXTREMELY important that the service technician reestablish all

safety grounds prior to completing service. Failure to do so will create an electrical

hazard.

6. Prior to returning the product to service, ensure that

• All electrical connections are correct and secure

• All electrical leads are properly dressed and secured away from sharp edges,

high-temperature components, and moving parts

• All non-insulated electrical terminals, connectors, heaters, etc. are adequately

spaced away from all metal parts and panels

• All safety grounds (both internal and external) are correctly and securely

connected

• All panels are properly and securely reassembled

WARNING

This service manual is intended for use by persons having electrical and mechanical training and

a level of knowledge of these subjects generally considered acceptable in the appliance repair trade.

Electrolux Home Products Inc. cannot be responsible, nor assume any liability, for injury or damage

of any kind arising from the use of this manual.

© 2004 Electrolux Home Products, Inc.

3

Page 4

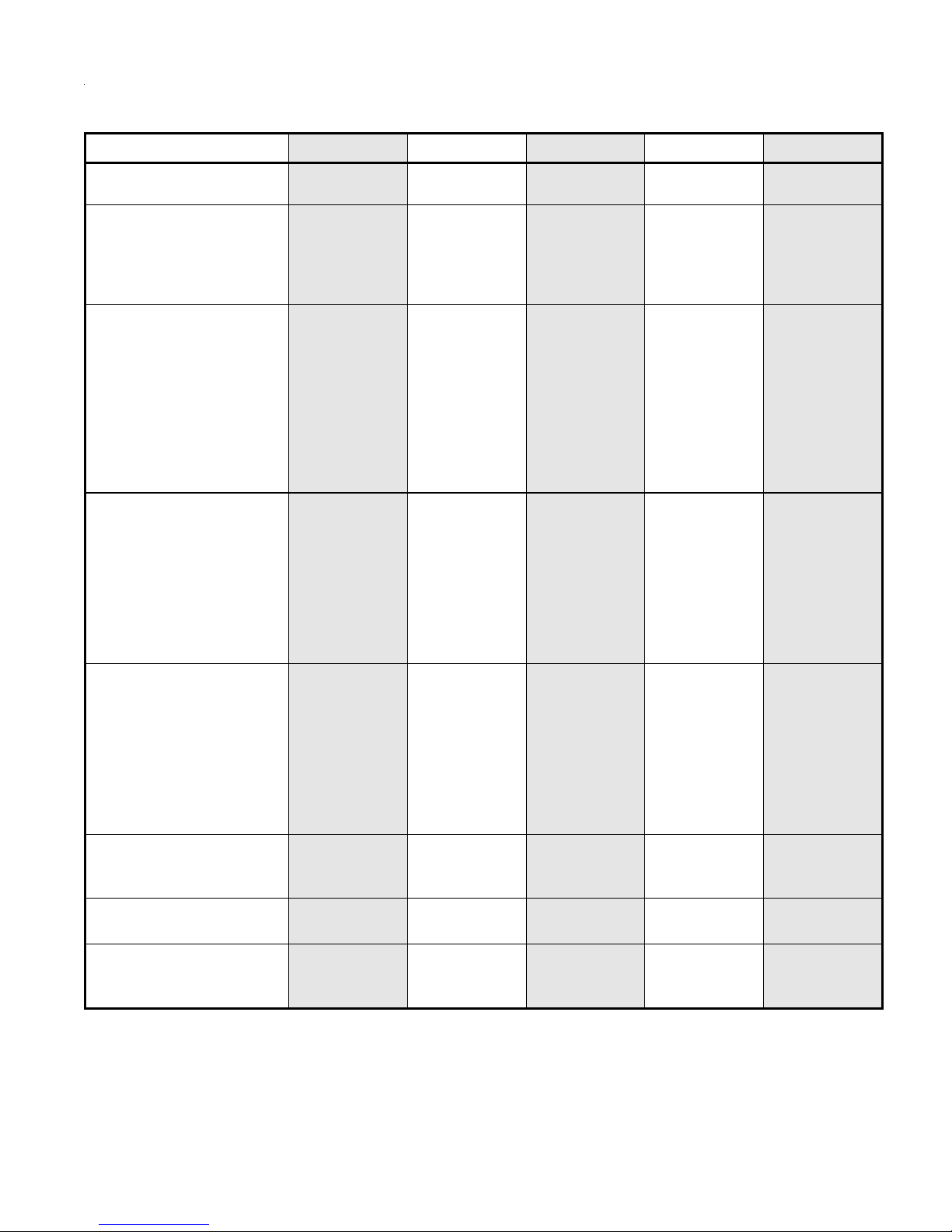

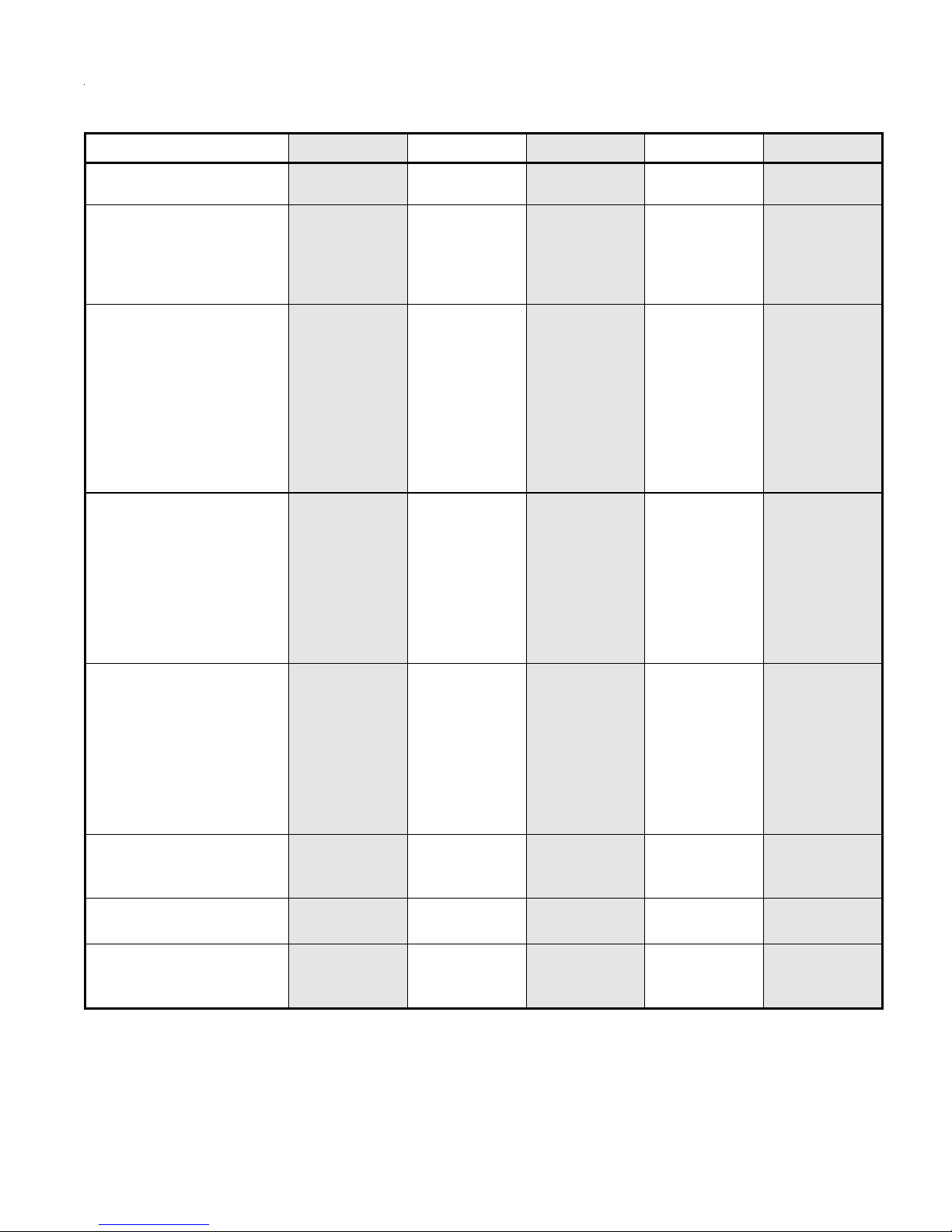

FRIGIDAIRE MODEL SPECIFICATIONS

Model FAS156N1A FAS184N2A FAS185N2A FAS186N2A FAS226N2A

Chassis Type

Capacity Features

BTU - Cooling

BTU - Heating

Moisture Removal

EER

Electrical Information

Voltage

Amps - Cooling

Amps - Heating

Watts - Cooling

Watts - Heating

Fuse/Breaker (Amps)

Receptacle Code

Wiring Diagram

Page #

Air Flow System

Capacitor-µ farads

Fan Motor Mfg.

Fan Motor Number

RPM/CMP (EVAP)

High

Medium

Low

Heat Only

Refrigeration System

Compressor Mfg.

Compressor Number

Compressor Type

Overload Protector

Capacitor-µ farads

Refrigerant Charge

Restrictor Tube

Thermostat Type

Installation Instructions

Kit Type

Part Number

Heavy Duty

Top Control

15100

-

3.5

10.7

115

12.5

-

1415

-

15

A

309902101

17

10/370

Heshan

309630615

980/530

-

810/400

-

LG

QK191CAB

Rotary

A363784

60/370

42

A112129

Electronic

A

309000906

Heavy Duty

Top Control

18000/17800

-

5.3

9.7

230/208

8.5/9.0

-

1860/1840

-

15

C

309902101

17

6/440

Heshan

309630613

975/500

-

775/400

-

LG

QJ258KAB

Rotary

A363771

25/440

31.75

A112138

Electronic

A

309000906

Heavy Duty

Top Control

18500/18200

-

5.5

10.7

230/208

7.8/8.5

-

1730/1700

-

15

C

309902101

17

6/450

Heshan

309630613

1000/480

-

800/380

-

LG

QJ250KBA-6A

Rotary

A363789

35/450

36

A112115

Electronic

A

309000906

Heavy Duty

Top Control

18500/18200

-

5.5

10.7

230/208

7.8/8.5

-

1730/1700

-

15

C

309902101

17

6/450

Heshan

309630613

1000/480

-

800/380

-

LG

QJ250KBA-6A

Rotary

A363789

35/450

36

A112115

Electronic

A

309000906

Heavy Duty

Top Control

22000/21600

-

6.5

9.4

230/208

10.5/11.4

-

2340/2300

-

15

C

309902101

17

7.5/450

Heshan

309630614

1115/550

-

925/470

-

LG

QP306KBA

Rotary

Internal

40/450

38.5

A112114

Electronic

A

309000906

Control Thermostat

Location Diagram

Condenser Fan and

Evaporator Blower

Location Diagram

Page 12 Page 12 Page 12 Page 12 Page 12

Page 14 Page 14 Page 14 Page 14 Page 14

4

Page 5

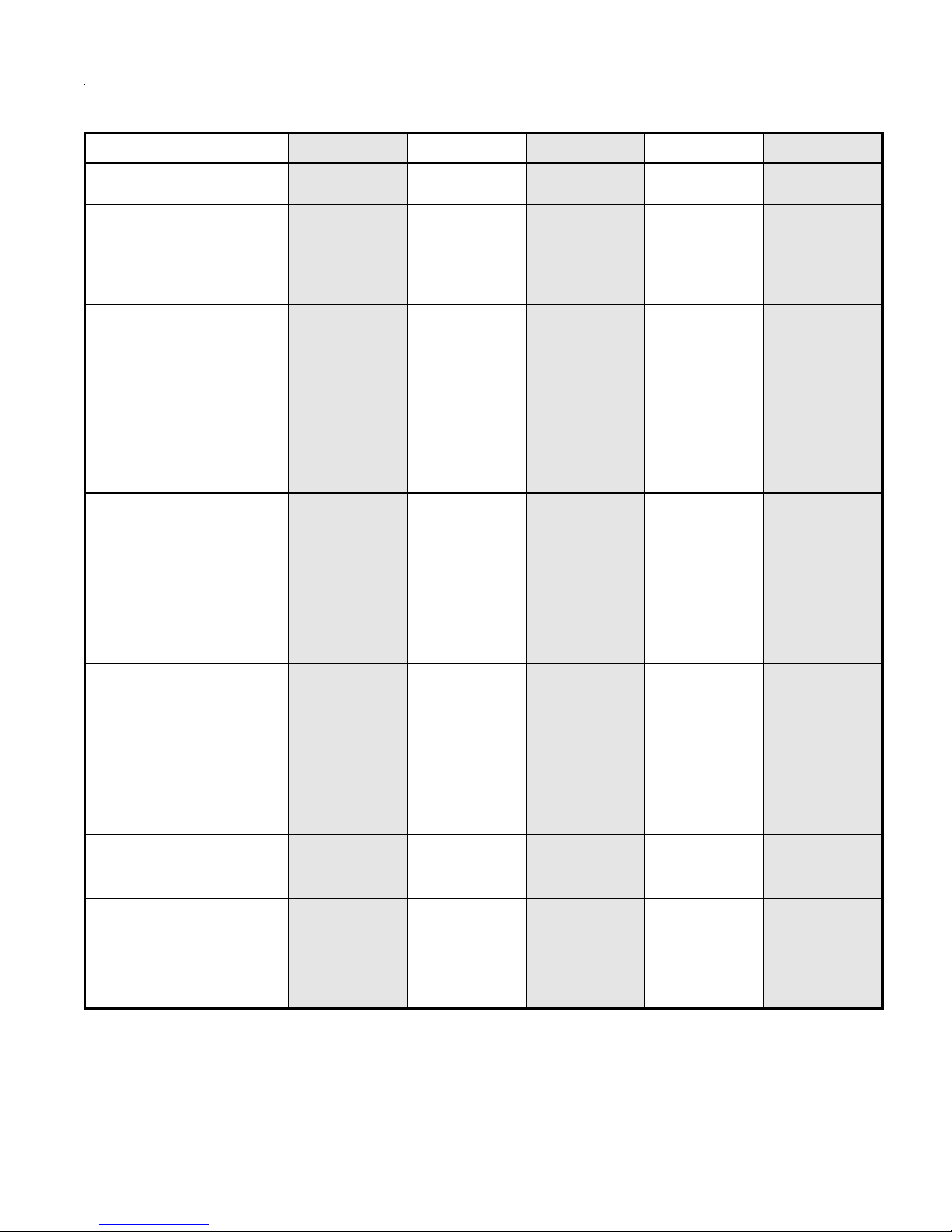

FRIGIDAIRE MODEL SPECIFICATIONS

Model FAS256N2A FAS296N2A FAH085N1T FAH08EN1T FAH105N1T

Chassis Type

Capacity Features

BTU - Cooling

BTU - Heating

Moisture Removal

EER

Electrical Information

Voltage

Amps - Cooling

Amps - Heating

Watts - Cooling

Watts - Heating

Fuse/Breaker (Amps)

Receptacle Code

Wiring Diagram

Page #

Air Flow System

Capacitor-µ farads

Fan Motor Mfg.

Fan Motor Number

RPM/CMP (EVAP)

High

Medium

Low

Heat Only

Refrigeration System

Compressor Mfg.

Compressor Number

Compressor Type

Overload Protector

Capacitor-µ farads

Refrigerant Charge

Restrictor Tube

Thermostat Type

Installation Instructions

Kit Type

Part Number

Heavy Duty

Top Control

25000/24700

-

7.6

9.4

230/208

12.0/13.0

-

2660/2630

-

20

D

309902101

17

7.5/450

Heshan

309630616

1145/590

-

925/470

-

LG

QP348KBB

Rotary

Internal

40/450

40.5

A112153

Electronic

A

309000906

Heavy Duty

Top Control

28500/28000

-

8.6

8.5

230/208

15.0/16.3

-

3365/3300

-

30

E

309902101

17

7.5/450

Heshan

309630616

1145/570

-

960/475

-

LG

QP425KAA

Rotary

Internal

45/450

41.3

A112156/57-59

Electronic

A

309000906

Builder Line Builder Line Builder Line

8000

-

1.8

9.4

115

7.5

-

850

-

15

A

309201101

16

10/370

Welling

309647503

1130/280

950/230

800/190

-

Matsushita

2R11S3R126A6A

Rotary

309205101

35/370

18.7

A112116

Electronic

T

309636002

8000

4200

1.8

9.4

115

7.5

12

850

1250

15

A

309201102

16

10/370

Welling

309647503

1130/280

950/230

800/190

-

Matsushita

2R11S3R126A6A

Rotary

309205101

35/370

18.7

A112116

Electronic

T

309636002

10000

-

2.8

9.4

115

10

-

1065

-

15

A

309201101

16

10/370

Welling

309647503

1130/280

950/240

800/210

-

LG

QK141CCA

Rotary

A363785

50/370

20.5

A112129

Electronic

T

309636002

Control Thermostat

Location Diagram

Condenser Fan and

Evaporator Blower

Location Diagram

Page 12 Page 12 Page 12 Page 12 Page 12

Page 14 Page 14 Page 14 Page 14 Page 14

5

Page 6

FRIGIDAIRE MODEL SPECIFICATIONS

Model FAH105N2T FAH10EN2T FAH124N2T FAH12EN2T FAK083N7V

Chassis Type

Capacity Features

BTU - Cooling

BTU - Heating

Moisture Removal

EER

Electrical Information

Voltage

Amps - Cooling

Amps - Heating

Watts - Cooling

Watts - Heating

Fuse/Breaker (Amps)

Receptacle Code

Wiring Diagram

Page #

Air Flow System

Capacitor-µ farads

Fan Motor Mfg.

Fan Motor Number

RPM/CMP (EVAP)

High

Medium

Low

Heat Only

Refrigeration System

Compressor Mfg.

Compressor Number

Compressor Type

Overload Protector

Capacitor-µ farads

Refrigerant Charge

Restrictor Tube

Thermostat Type

Installation Instructions

Kit Type

Part Number

Builder Line Builder Line Builder Line Builder Line Slider

Casement

10000/9800

-

2.8

9.4

230/208

4.7/5.1

-

1060/1045

-

15

C

309201101

16

6/450

Welling

309647501

1130/280

1010/240

880/210

-

LG

QK141KBE

Rotary

A363786

30/450

18.4

A112145

Electronic

T

309636002

10000/9800

10600/8600

2.8

9.4

230/208

4.7/5.1

15.5/14

1060/1045

3450/2800

20

D

309201102

16

6/450

Welling

309647501

1130/280

1010/240

880/210

-

LG

QK141KBE

Rotary

A363786

30/450

18.4

A112145

Electronic

T

309636002

12000/11700

-

3.6

9

230/208

5.9/6.4

-

1335/1300

-

15

C

309201101

16

7.5/450

Welling

309647502

1280/300

1130/260

975/230

-

LG

QK164KBC

Rotary

A363788

30/450

22.6

A112119

Electronic

T

309636002

12000/11700

10600/8600

3.6

9

230/208

5.9/6.4

15.5/14

1335/1300

3450/2800

20

D

309201102

16

7.5/450

Welling

309647502

1280/300

1130/260

975/230

-

LG

QK164KBC

Rotary

A363788

30/450

22.6

A112119

Electronic

T

309636002

8000

-

2.2

10.5

115

6.7

-

760

-

15

A

A232012

15

5/370

Heshan

309646002

1120/240

1000/210

940/190

-

Matsushita

2R11S3R126A2A

Rotary

309205101

35/370

20.11

A112124

Bulb

V

309625802

Control Thermostat

Location Diagram

Condenser Fan and

Evaporator Blower

Location Diagram

Page 12 Page 12 Page 12 Page 12 Page 11

Page 14 Page 14 Page 14 Page 14 Page 13

6

Page 7

FRIGIDAIRE MODEL SPECIFICATIONS

Model FAK103N1V FAK123N1V

Chassis Type

Capacity Features

BTU - Cooling

BTU - Heating

Moisture Removal

EER

Electrical Information

Voltage

Amps - Cooling

Amps - Heating

Watts - Cooling

Watts - Heating

Fuse/Breaker (Amps)

Receptacle Code

Wiring Diagram

Page #

Air Flow System

Capacitor-µ farads

Fan Motor Mfg.

Fan Motor Number

RPM/CMP (EVAP)

High

Medium

Low

Heat Only

Refrigeration System

Compressor Mfg.

Compressor Number

Compressor Type

Overload Protector

Capacitor-µ farads

Refrigerant Charge

Restrictor Tube

Thermostat Type

Installation Instructions

Kit Type

Part Number

Slider

Casement

10000

-

2.8

9.5

115

9.6

-

1050

-

15

A

A232012

15

15/370

Heshan

309646001

1400/305

1230/260

1050/210

-

LG

QK134CCA

Rotary

A363785

50/370

20.46

A112137

Bulb

V

309625802

Slider

Casement

12000

-

3.6

9.5

115

11.5

-

1260

-

15

A

A232012

15

15/370

Heshan

309646001

1400/305

1230/260

1050/210

-

LG

QK164CCA

Rotary

A363776

50/370

23.28

A112104

Bulb

V

309625802

Control Thermostat

Location Diagram

Condenser Fan and

Evaporator Blower

Location Diagram

Page 11 Page 11

Page 13 Page 13

7

Page 8

Compressor Overload Data

Part# Used With Compressor Supplier Part#

309260303 2R11S3R126A6A MRA98705

A363785 QK134CCA MRA12061-12056

A363785 QK141CCA MRA12061-12056

A363776 QK164CCA MRA12053-12057

A363784 QK191CAB MRA4720-12057

A363786 QK141KBE MRA12054-12056

A363788 QK164KBC MRA12124-12056

A363771 QJ258KAB MRA12044-12057

A363789 QJ250KBA MRA12107-12057

*Terminal to overload must withstand 10 pounds pull test.

Opening Temp

C°± 5 C°

150 61 50.5

150 61 50.5

150 61±9 C° 41.5

150 69 50.3

155±7 C° 69 14.5

155 69 19.0

160 61 29.0

150 69 27.3

Closing Temp

C°± 11 C°

Short Time Trip at 25 C°

Test Amp Opening Time-Sec

6-16

6-16

6-16

2-12

6-16

6-16

6-16

6-16

Restrictor Tube Data

Style#

Internal Diameter

Color Code

Length O.D.

I.D PSIG

A112114 Red 35.00 0.112 0.059 10 0.294 0.318

A112115 Red 40.00 0.112 0.059 10 0.274 0.296

A112129 Purple 45.00 0.097 0.046 25 0.261 0.283

A112138 Black 33.00 0.099 0.049 20 0.304 0.330

A112153 Blue 37.50 0.125 0.064 10 0.227 0.247

A112156 Black 38.19 0.099 0.049 20 0.352 0.382

A112157 Black 19.69 0.099 0.049 20 0.181 0.197

A112158 Black 23.62 0.099 0.049 20 0.218 0.236

A112159 Black 29.13 0.099 0.049 20 0.268 0.291

CFM Dry Air

Minimum Maximum

A112124 White 45.00 0.106 0.054 20 0.346 0.374

A112137 Purple 51.18 0.097 0.046 25 0.248 0.268

A112104 Black 45.00 0.099 0.049 20 0.258 0.280

A112116 White 40.00 0.106 0.054 20 0.366 0.396

A112129 Purple 45.00 0.097 0.046 25 0.261 0.283

A112145 Black 37.00 0.099 0.049 20 0.288 0.312

A112119 Black 35.00 0.099 0.049 20 0.296 0.320

8

Page 9

Receptacle Outlet Codes

Code A

115 Volts - 15 Amps

NEMA 5 - 15 TYPE

Code D

230 Volts - 20 Amps

NEMA 6 - 20 TYPE

Code B

115 Volts - 20 Amps

NEMA 5 - 20 TYPE

Power Supply Cord with

3-prong Grounding Plug

Code C

230 Volts - 15 Amps

NEMA 6 - 20 TYPE

Code E

230 Volts - 30 Amps

NEMA 6 - 30 TYPE

Grounding Type

Wall Receptacle

9

Page 10

Product Dimensions

Heavy Duty Slide Out Top Control

10

Page 11

Control Thermostat Location Diagrams

Slider Casement

Compact Rotary Control

Compact Electronic Control

Intermediate Rotary

Top Control

11

Page 12

Control Thermostat Location Diagrams

A

2004 Heavy Duty Thermostat Locations

15.1K 18K 22 K18.5K 28.5K25K

Freeze thermistor and freeze thermistor holder.

2004 Builder Thermostat Locations

8K and 10K12K

Freeze the rmistor and free ze

thermistor holder.

3.94"

Bracket-Evap

B

B

7.87"

ir thermistor and air thermistor h older(Place

3.75"

A

A

Section A-A

between 9th & 10th

rows up from t he bottom)

fin

Section B-B

insulation

fourth row from bottom

third row from bottom

second row from bottom

first row from bottom

12

fin

2004 Slider

Thermostat

Locations

fin

9th Row from bott om

8th Row from bott om

7th Row from bott om

6th Row from bott om

Retaining Clip

Retaining Clip

Page 13

Fan and Blower Location Diagrams

Compact

Slider Casement

18.5”

No Side Louvers

13

Page 14

Fan and Blower Location Diagrams

Heavy Duty

Top Control

COND. FAN

BLOWER WHEEL

To be fully seated

against motor shaft.

(bottom out on shaft)

BULKHEAD ASSY.

CLAMP SCREW

TORQUE TO

22-27 IN.LBS.

CONDENSER FAN

To be fully seated

against motor shaft.

(bottom out on shaft)

Motor Shaft

Clamp Clamp

Evaporator Side Condenser Side

Motor

SHROUD

& SEAL

ASSY.

SCREW (3) SHROUD/

BULKHEAD ASSY.

TORQUE TO 25 IN.LBS.

CLAMP

TORQUE TO

15-20 IN. LBS.

BLOWER

WHEEL

.300

FAN CLAMP

PUSH FAN BLADE

TILL END

OF FLAT

COND. FAN

.370

REF.

SLINGER RING

SHROUD

.560

SCROLL

.380

AIR SYSTEM

(H/D T/C)

Heavy Duty Side Discharge

14

Page 15

Wiring Diagrams

A232012

R

BL

BK

PLAIN (BROWN) - ORDINAIRE (BRUN)

(VENTILATEUR LENT)

(VENTILATEUR MOYEN)

(VENTILATEUR RAPIDE)

(REFROIDISSEMENT ÉLEVÉ)

(REFROIDISSEMENT MOYEN)

(REFROIDISSEMENT BAS)

BK

C

S

R

W

ALTERNATE INTERNAL

COMPRESSOR OVERLOAD

(AUTRE SURCHARGE

INTERNE DU COMPRESSEUR)

R

or (ou)

LO FAN

MED FAN

HI FAN

OFF

(ARRÊT)

HI COOL

MED COOL

LO COOL

RIBBED - BLUE

(RAYE - BLEU)

COLOR CODE

BL - BLUE (BLEU)

G - GREEN (VERT)

BK - BLACK (NOIR)

BR - BROWN (BRUN)

R - RED (ROUGE)

W - WHITE (BLANC)

A

L1

GND

(TERRE)

W

2

4

1

3

G

1

3

ROOM THERMOSTAT

4

2

(SÉLECTEUR)

SELECTOR SWITCH

COMPRESSOR

(COMPRESSEUR)

S

W

(THERMOSTAT DE LA PIÉCE)

BK

COMPRESSOR

OVERLOAD

(SURCHARGE DU

COMPRESSEUR)

BK

C

R

R

COMPRESSOR

CAPACITOR

(CONDENSATEUR

DU COMPRESSEUR)

START

ASSIST

(DÉMARREUR)

W

BR

FAN CAPACITOR

(CONDENSATEUR

DU VENTILATEUR)

FAN MOTOR

(MOTEUR DU

VENTILATEUR)

15

Page 16

A

RR

A

R

2

0

4

6

1

8

Heater Relay(Relais Du

Chauffage Electrique)

OR

OR

BK

BK

Heater(Chauffage

Electrique)

DAHT(Sonde Du

Chauffage

Electrique)

Eva p

Sensor(Sonde Anti Givre)

Room

Sensor(Sonde D' Ambiance)

G

(Vert)

HT

Relay

(Relais)

Connector(Connecteur)

OR

OR

GND

Wiring Diagrams

FH

Relay

(Relais)

Plain

(Brown)

Ord inai re(Bru n)

Ribbed

(Blue)

Raye(Bleu)

FM

Relay

(Rel ais)

AC- N

FL

Relay

(Relais)

4

3

W

Compressor

capacitor

(Condensateur Du

Compresseur)

BK

BK

SR

Compressor

(Compresseur)

N2

N1

Compressor

Relay(Relais

Du

Compresseur)

Compressor Overload

(Surcharge Du

Compresseur)

C

WOR Y

(O U)

R

Fan motor capacitor

(Condensateur Du

Ventilateur)

BR

MED

BL

HI

BK

Fan motor

(Moteur Du

Ventilateur)

R

LO

R

BK=Black(Noir)

BL=Blue(Bleu)

BR= Brown(B run)

G=Green(Vert)

OR=Orange(Orange)

R=Red(Rouge)

W=White(Blanc)

Y=Yellow(Jaune)

BK

C

S

R

W

lternate In ternal Overl oad

Compr essor

(Autre Surcharge

Interne D u Compresseur)

309201102/02

R

Evap

Sensor(Sonde Anti Givre)

Room

Sensor(Sonde D' Ambiance)

Connector(Connecteur)

G

GND

(Vert)

FH FL

FM

Relay

Relay

(Relais)

(Relais)

Plain

(Br own)

Ordinaire(Brun)

Ribbed

(Blu e)

Raye(Bleu)

AC-N N1

Relay

(Relais)

4

3

S

W

Compressor

(C ompre sseur )

Compressor

capacitor

(Condensateur Du

Compresseur)

N2

Compressor

Relay(Relais

Du

Compresseur)

Compressor Overload

(Surcharge Du

Compresseur)

R

R

Fan motor capacitor

(Condensateur Du

Ven t il at eur )

BR

MED

BL

HI

BK

Fan motor

(Moteur Du

Ven t il at eur )

R

LO

R

BK= Black(Noi r)

BL=Blue(Bleu)

BR =Bro wn(B run )

G=Green(Vert)

R=Red(Rouge)

W=White(Blanc)

Y=Yellow(Jaune)

BK

C

S

R

W

lternate Internal Overload

Compressor

(Autre Surcharge

Interne Du C ompresseur)

309201101/02

R

16

Page 17

Wiring Diagrams

(

)

J3210

Connector (Connecteur)

Evap

Sensor (Sonde

Anti Givre)

Room

Sensor

(Sonde D'

Ambiance)

Ion.

3

4

Compressor Relay (Relais Du

Compresseur)

Ionizer(Ion)

(Optional)

(Facultatif)

G

(Vert)

GND

Plain

(Brown)

Ordinaire(Brun)

Ribb ed

(Blue)

Raye( Bleu)

Fan(Ventilateur)

N

BK

BK

C

R

S

W

Compressor

(Compresseur)

Compressor

capacitor

(Condensateur Du

Compresseur)

Compressor Overload

(Surcharge Du

Compresseur)

WOR Y

(OU)

R

Fan motor capacitor

(Condensateur Du

Ventilateur)

BR

BK

G

(Vert)

GND

Fan motor

(Moteur Du

Ventilateur)

R

BK=Black(Noir)

BL=Blue(Bleu)

BR=Brown(Brun)

G=Green(Vert)

R=Red(Rouge)

W=White(Blanc)

Y=Yellow

Jaune

BK

C

S

R

W

Alternate Internal Ove rload

Compressor

(Autre Surcharge

Interne Du Compresseur)

R

309902101/01

17

Page 18

ROOM AIR CONDITIONERS TROUBLESHOOTING

CAUTION: Review Safe Servicing Practices in

the front of this manual before attempting

diagnostic procedures and repairs.

AIR CONDITIONER VOLTAGE LIMITS

ETALPEMAN

GNITAR

CAV511CAV5.301CAV5.621

CAV032CAV702CAV352

032/802CAV5.791CAV352

AIR CONDITIONER VOLTAGE LIMITS

Low voltage is a common cause of trouble in the operation

of any room air conditioner.

Improper voltage may cause one or more of the following

problems:

1. Unit will not start.

2. Compressor motor cycling on motor protector.

3. Premature failure of motor protector.

4. Blown fuses.

5. Premature failure of compressor or fan motor.

6. Noticable dimming of lights when air conditioner is

running.

7. Evaporator icing. Low voltage may reduce fan speed

resulting in inadequate air flow over evaporator, thereby

allowing it to ice up.

MUMINIM MUMIXAM

Low voltage can also be the direct result of inadequately

wired circuits, extension cords, or loose fuses and

connections to the power supply. Voltage may also be a

general condition in the area (a responsibility of the power

company).

All units will start and run on the minimum voltage stated

in the chart to the left, and will perform satisfactorily if the

voltage remains constant. Low voltage caused by defective

wiring will not remain constant under load.

To test for low voltage, use a reliable meter with sufficient

capacity to measure the required voltage. Take

measurements at the electric power entry point and at the

electric outlet serving the air conditioner. Take readings

with the unit off, while the unit is starting, and again while

the unit is running. The lowest reading should not drop

below the lowest value listed in the chart.

HIGH VOLTAGE

High voltage can be equally troublesome, causing motors

to overheat, cycle on their protectors, or break down

electrically. This problem can only be solved by the power

company.

ELECTRONIC CONTROL

This control is not repairable. If any component in the

control is defective, the entire control must be replaced.

IMPORTANT NOTICE: Repair or replace any

malfunctioning line voltage component before testing

or replacing the electronic control. DO NOT assume a

service problem is directly caused by the electronic

control system. A line voltage component (including

power cord and wiring) that has opened, shorted,

grounded or otherwise malfunctioned, may have created

a service problem.

SYMPTON POSSIBLE CAUSE

Fan motor will not run. 1. No power.

Fan motor runs intermittently. 1. Cycle on motor protector.

2. Power supply cord.

3. Selector switch.

4. Energy saving switch (if applicable).

5. Electronic control (if applicable).

6. Wire disconnected or connection loose.

7. Capacitor. (Discharge capacitor before testing.)

8. Defective fan motor windings.

9. Will not rotate. Fan blade hitting shroud or blower

wheel hitting scroll. (Motor cycles on overload.)

18

Page 19

SYMPTON POSSIBLE CAUSE

Fan motor noisy. 1. Condenser fan blade or evaporator blower

wheel.

2. Loose power clamp or set screw.

3. Worn bearings.

4. Grommets (if applicable).

Compressor will not run, but fan motor runs. 1. Voltage.

2. Wiring.

3. Selector switch.

4. Temperature control.

5. Capacitor. (Discharge capacitor before testing.)

6. Compressor.

7. Motor protector (external).

8. Motor protector (internal).

9. Electronic control (if applicable).

10. Hard starting.

Compressor cycles on motor protector. 1. Voltage.

2. Motor protector (external).

3. Motor protector (internal).

4. Fan motor.

5. Condenser air flow restriction.

6. Condenser fins damanged.

7. Capacitor.

8. Wiring.

9. Refrigerant system.

Insufficient cooling. 1. Low capacity.

2. Air filter.

3. Exhaust door open.

4. Unit undersized.

Excessive noise. 1. Evaporator blower wheel.

2. Condenser wheel.

3. Copper tubing.

4. Compressor internal noise.

5. Fan motor.

Excessive water or condensation. 1. Unit operating under extremely high humidity

conditions.

No cooling. 1. Refrigerant leak.

Unit is cooling but room is not cool. 1. Amps and watts.

2. Sealed refrigeration system.

Wattage decreases slowly until abnormally low. 1. Undercharged, restricted strainer or plugged

restrictor tube.

Wattage decreases immediately. 1. No refrigerant.

2. Compressor defective.

Wattage continuously high. 1. Refrigerant overcharge.

19

Page 20

SYMPTON POSSIBLE CAUSE

Evaporator coil partially frosted. 1. System low on refrigerant.

Evaporator completely iced. 1. Low outside temperature.

No heat. 1. No power.

2. Selector switch position.

3. Temperature control position.

4. Fan motor.

5. Heating element.

6. Selector switch.

7. Temperature control.

8. Terminals and connectors.

Fan motor will not rotate during heat cycle. 1. Thermostatic drain valve. (Water level control, if

(Heat/Cool models only.) applicable.)

20

Loading...

Loading...