Page 1

Installation Instructions

For Heavy Duty

Please read ALL instructions before installing. Two people are

recommended to install this product. Ifa new electrical outlet

is required, have the outlet installed by a qualified electrician

before installing unit. See#5 in Preliminary Instructions

following.

Preliminary Instructions

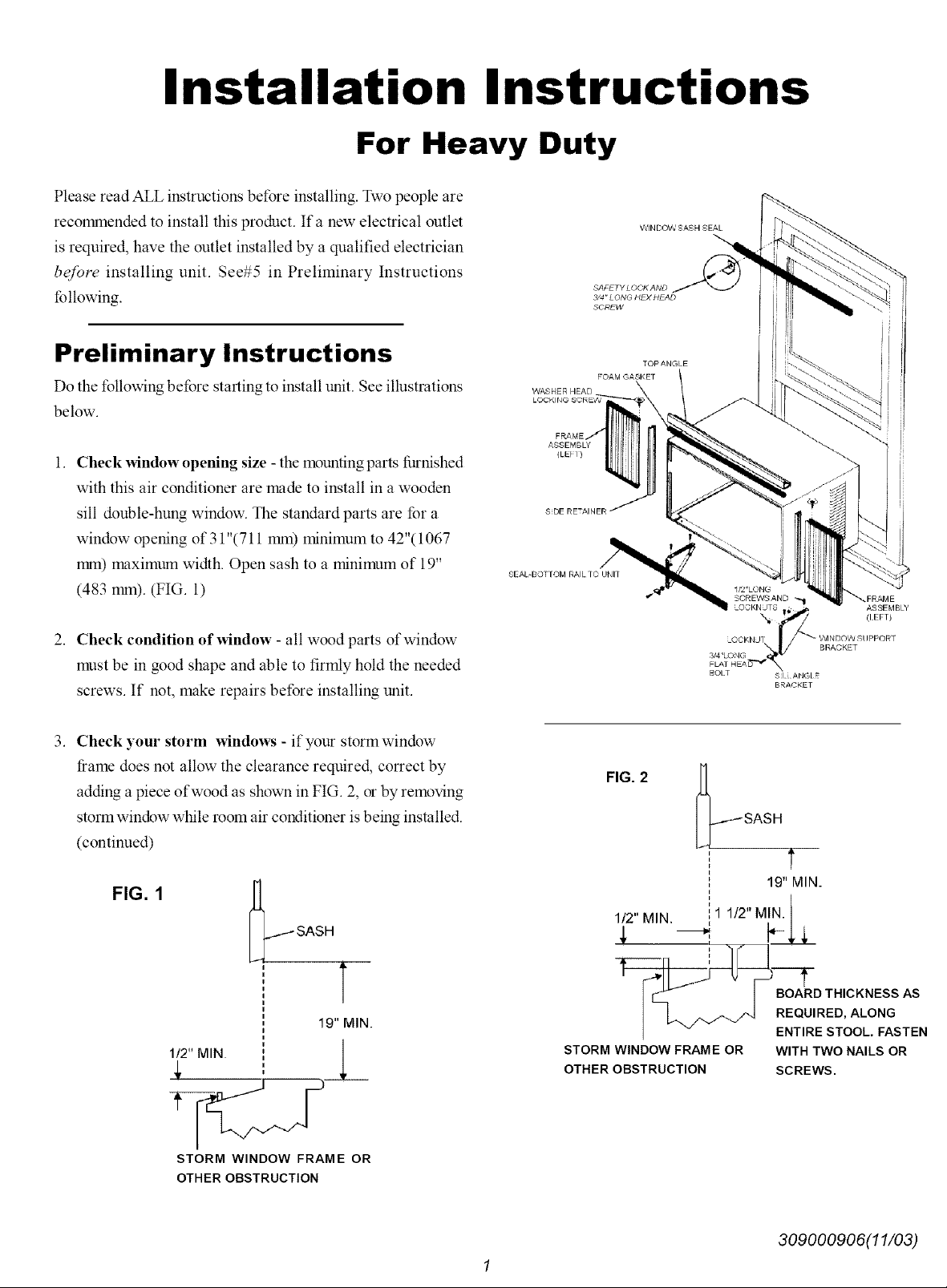

WINDOW SASH SEAL

3/4" LONG HE)( HEAD

SCREW

Do the following before starting to install unit. See illustrations

below.

1. Check window opening size - the mounting parts furnished

with this air conditioner are made to install in a wooden

sill double-hung window. The standard parts are for a

window opening of 31 "(711 mm) minimum to 42"( 1067

rc_n) maximum width. Open sash to a minimum of 19"

(483 mm). (FIG. 1)

2. Check condition of window - all wood parts of window

must be in good shape and able to firmly hold the needed

screws. If not, make repairs before installing unit.

3. Check your storm windows - if your storm window

frame does not allow the clearance required, correct by

adding a piece of wood as shown in FIG. 2, or by removing

storm window while room air conditioner is being installed.

(continued)

FIG. 1

_ SASH

WASHERHEAD

FRAME

ASSEMBLY

(LEII)

SDE RETAINER

SEAL-BOI tOM RAIL TC UNIT

I/2'LOFIG

SCREWS AND "_i FRAME

O_'KN JTS _ ASSEMBLY

OCKNJ [ _ WINDOW _!IPPORT

3/4 'LONG

D_____ " BRACKET

BOLT SI ANGI

FIG. 2 [_SASH

112"MIN 1 1/2"MIN.

\._ _#W-! (lEFT)

BRACKET

1

19" MIN_

T

19" MIN.

STORM WINDOW FRAME OR

OTHER OBSTRUCTION

ENTIRE STOOL. FASTEN

STORM WINDOW FRAME OR WITH TWO NAILS OR

OTHER OBSTRUCTION SCREWS.

309000906(11/03)

Page 2

4. CHECK FOR ANYTHING THAT COULD BLOCK

AIRFLOW - check area outside of window for things

such as shrubs, trees, or awnings. Inside, be sure

furniture, drapes, or blinds will not stop proper airflow.

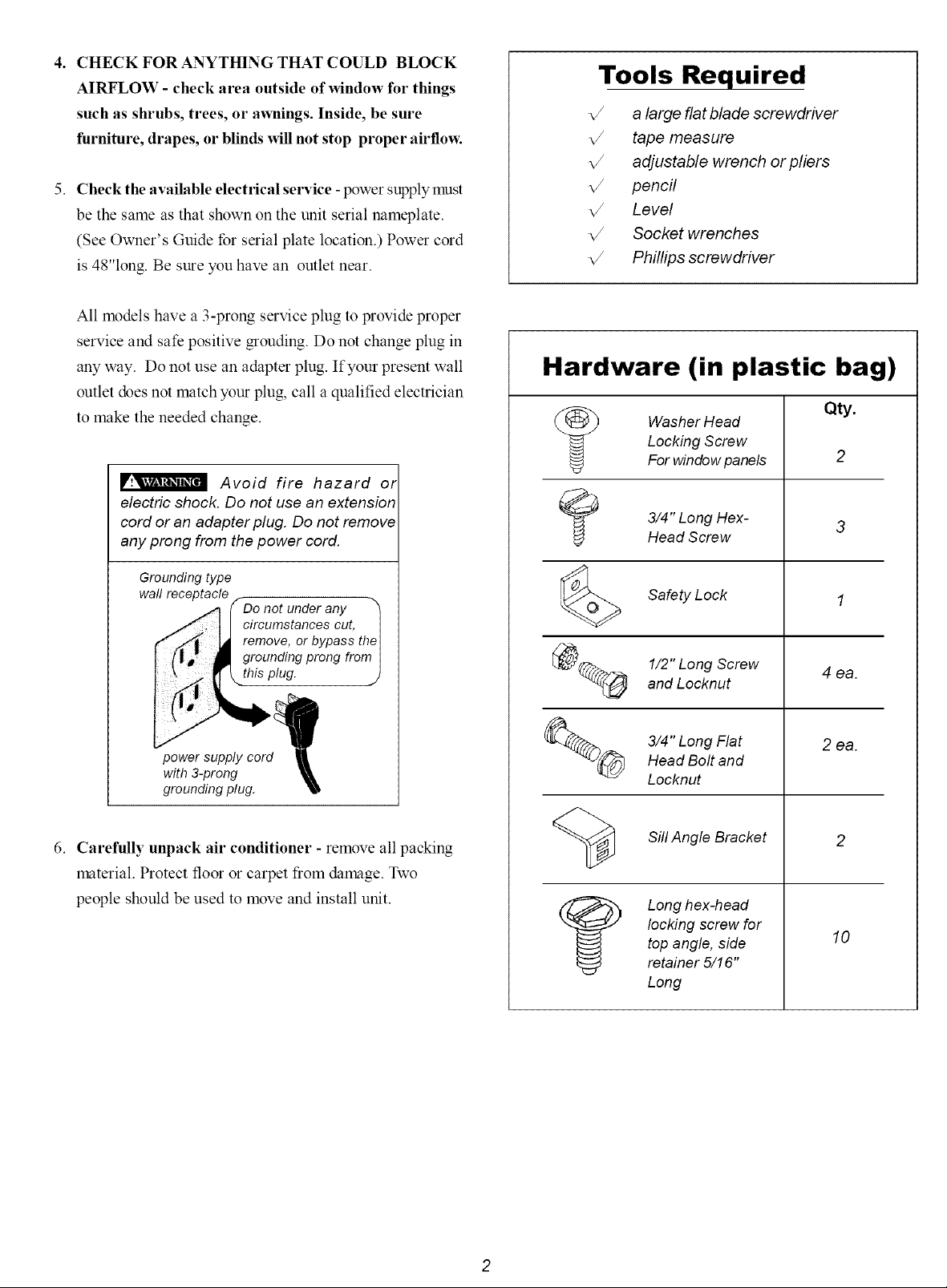

5. Check the available electrical service -power supply must

be the same as that shown on the unit serial nameplate.

(See Owner's Guide for serial plate location.) Power cord

is 48"long. Be sure you have an outlet near.

All models have a 3-prong service plug to provide proper

service and safe positive grouding. Do not change plug in

any way. Do not use an adapter plug. If your present wall

outlet does not match your plug, call a qualified electrician

to make the needed change.

Avoid fire hazard or

electric shock. Do not use an extension

cord or an adapter plug. Do not remove

any prong from the power cord.

Tools Required

a large flat blade screwdriver

tape measure

adjustable wrench or pliers

pencil

Level

Socket wrenches

Phillips screwdriver

Hardware (in plastic bag)

Locking Screw

Washer Head

For window panels

ft

3/4 Long Hex-

Head Screw

Grounding type

wall receptacle

/_, tl circumstancescut,I

r" _ _ remove,orbypasstheI

I (l', lP groundingprongfromI

power supply cord_

with 3-prong

grounding plug.

6. Carefully unpack air conditioner - remove all packing

material. Protect floor or carpet from damage. Two

people should be used to move and install unit.

Safety Lock

@_ 1/2"LongScrew

%_ 3/4" Long FlatHead Bolt and

and Locknut

Locknut

Sill Angle Bracket

locking screw for

top angle, side

Long hex-head

retainer 5/16"

Long

4 ea.

2 ea.

10

Page 3

Window Mounting

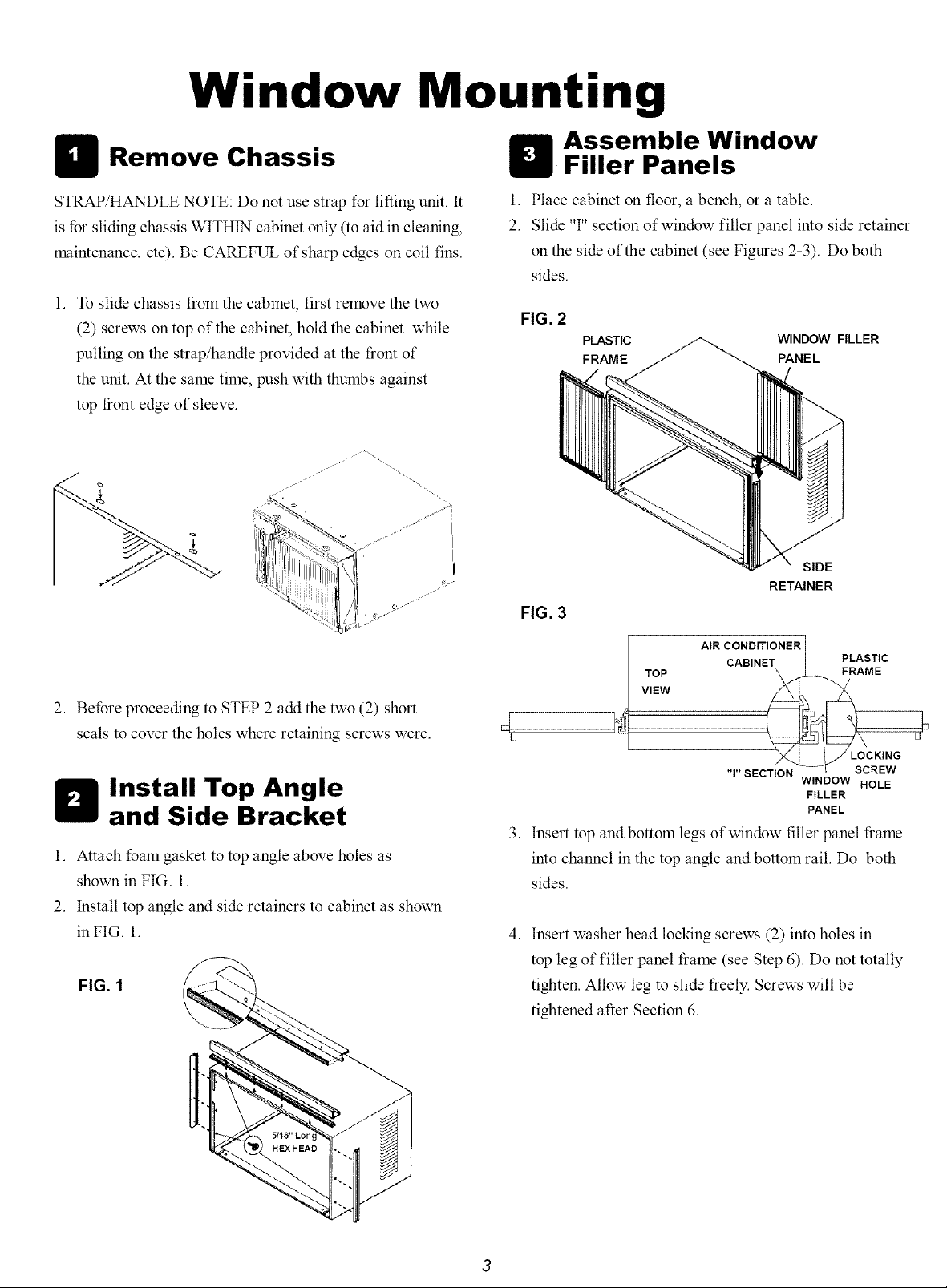

Remove Chassis

STRAP/HANDLE NOTE: Do not use strap for lifting unit. It

is for sliding chassis WITHIN cabinet only (to aid in cleaning,

maintenance, etc). Be CAREFUL of sharp edges on coil fins.

1. To slide chassis from the cabinet, first remove the two

(2) screws on top of the cabinet, hold the cabinet while

pulling on the strap/handle provided at the front of

the unit. At the same time, push with thumbs against

top front edge of sleeve.

T'h"_-_ ~_%..... !i

ii:ii!!!!!iiil]'i/i:i['_l I

,= <_ji=t .=

2. Before proceeding to STEP 2 add the two (2) short

seals to cover the holes where retaining screws were.

Assemble Window

Filler Panels

1. Place cabinet on floor, a bench, or a table.

2. Slide 'T' section of window filler panel into side retainer

on the side of the cabinet (see Figures 2-3). Do both

sides.

FIG. 2

PLASTIC WINDOW FILLER

FRAME PANEL

SIDE

RETAINER

FIG. 3

AIR CONDITIONER

TOP ...... FRAME

Vl EW

CABINI _ PLASTI

Install Top Angle

and Side Bracket

1. Attach foam gasket to top angle above holes as

shown in FIG. 1.

2. Install top angle and side retainers to cabinet as shown

in FIG. 1.

FIG. 1

'T' SECTION

.

Insert top and bottom legs of window filler panel frame

WINDOW HOLE

FILLER

PANEL

into channel in the top angle and bottom rail. Do both

sides.

.

Insert washer head locking screws (2) into holes in

top leg of filler panel frame (see Step 6). Do not totally

tighten. Allow leg to slide freely. Screws will be

tightened after Section 6.

Page 4

Place Cabinet in

Window

Install Support

Bracket

1. Open window and mark

center of window stool.

2. Place cabinet in window with bottom stool angle firmly

seated over window stool as shown. Bring window

down temporarily behind top angle to hold cabinet in

place.

1. Hold each support bracket flush against outside of sill,

and tight to bottom of cabinet as shown below. Mark

brackets at top level of sill, and remove.

4

MARK

|........ 1/2" LONG SCREWS

LEFT\. _/AND LOCKNUTS

LOC UTg" ,. !

3. Shift cabinet left or right as needed to line up center of

cabinet on center line marked on stool.

4. Fasten cabinet to window stool with 2 screws into

holes.(You may wish to pre-drill pilot holes.)

5. Add bottom rail seal over screws to window stool.

I

Rail Seal

L Bottom

_\. ./

"\ // --

FLAT HEAD BOLT <_@b,_/

2 EACH REQ'D FOR EACH

SUPPORT BRACKET

2. Assemlle sill angle bracket to support brackets at the

marked position, as shown. Hand tighten, but allow

for any changes later.

3. Install support brackets (with sill angle brackets

attached) to correct hole in bottom of cabinet as shown.

4. Tighten all 6 bolts securely.

l/2"long screws

andlocknuts

I (_/_/_//3/4"LONG HEX- I

_.._/HEADSCREW

Page 5

Extend Window Filler

Panels

1. Carefully raise window to expose filler panel locking

screws. Loosen screws so filler panels slide easily.

2. Extend panels to fill window opening completely.

Tighten lockin_ screws on top.

3. Close window behind top angle.

Install Chassis into

Cabinet and Install

Front to Unit

1. Lift chassis and carefully slide it into installed cabinet.

2. _ DO not push on controls OR finned coils.

3. Be sure chassis is firmly seated towards rear of

cabinet.

4. Refer to Owner's Guide for front installation.

Install Window Lock

and Sash Seal

1. Trim sash seal to fit window width. Insert into space

between upper and lower sashes.

)OW SASH SEAL

2. Attach right angle safety lock as shown.

/_ y ---_. 3,4",onghex-

"/// _) -- head screw

Page 6

Thru-The-Wall Installation

NOTE: Consult local building codes prior to installation,

or a qualified carpenter.

Select Wall Location

This air conditioner has a slide-out chassis, so it canbe installed

through an outside wall up to 12" thick. IMPORTANT: Side

louvers must never be blocked.

NOTE: All parts neede for Thru-The-Wall Installation are

provided, except a wood frame, shims, and 10 wood screws (#

10-1" long minimum). Select a wall surface that:

1. does not support major structural loads such as the frame

construction at ends of windows, and under truss-bearing

points, etc.

2. does not have plumbing or wiring inside.

3. is near existing electrical outlets, or where another outlet

can be installed.

4. Paces, and is not blocked to the area to be cooled.

5. allows unblocked airflow from rear sides and end (outside)

of installed air conditioner.

Prepare Wall

1. Prepare wall in frame construction (including brick and

stucco veneer). Working from inside the room, find wall

stud nearest the center of area where air conditioner will

be installed (by sounding wall, or by magnetically inding

nails).

2. Cut or knock out a hole on each side of center stud.

3. Measure between inside edges ofeve_T other stud as shown

in FIG. 1.

Carefully measure and cut an opening with t he following

dimensions. See FIGS. 1 and 2.

WIDTH "X" = 26-3/4" (67.9cm) plus twice the thickness

of framing material used.

HEIGHT "Y" = 18-7/8" (47.9cm) plus twice the

thickness of fiaming material used.

FIG. 2

Y

UP TO

8-1/2"

4. Build a wooden sleeve with the INSIDE dimensions of

26-3/4" (67.9cm) in width and 18-7/8" (47.9cm) in height.

Frame depth should be the same as wall thickness. Fill in

the space from the opening to the studs with wood spacers,

as shown.

5. Nail frame to spacers to spacers with front flush with

drywall.

IE

FIG. 1

3-3/8" MIN

(8.6 cm)

Page 7

NOTE: If wall thickness is 8-1/2" or more, add aluminum

flashing over bottom of frame opening to assure no water can

enter area between inner and outer wall.

FIG. 2

1" LONG

WOOD SCREW

OPTIONAL: Support brackets may be used. Installation

brakcets are recommended for walls under 5" thick.

ALUMINUM FLASHING

OVER BOTTOM OF FRAME

OVER

81/2"

Prepare and Install

Cabinet

I. Slide chassis from cabinet. Refer back to Step l of

Window Mounting.

2. Place cabinet into opening with bottom rail resting firmly

on bottom board of wooden frame.

3. Position cabinet to achieve proper slope for water removal.

(See FIG. 1 below.)

FIG. 1

3/4" PLUS

THICKNESS

SEE PARA 5

Refer to Step 4 of Window Mounting for assembly of support

brackets. A wooden strip nailed to the outside wall should be

used in coniunction with sill support angle brackets.

brakcet

Wooden strip

5. Screw or nail cabinet wooden frame using shims if frame

is oversized, to eliminate distortion. Remember to maintain

proper slope as described in Step 3.

TO

3/8"

F"

LEVEL

4. Secure bottom rail to wood frame with two large wood

screws 1"(2.5 cm) long using the tow holes in the bottom

of the channel resting on frame. (See FIG. 2 following)

6. Install chassis into cabinet by following all steps in Step

8 of Window Mounting. (continued)

Page 8

OPTIONAL: Caulking and installation of trim on interior wall

may be done. You can buy wood from your local lumber or

hardware supply. On the outside, caulk openings around top

and sides of cabinet, and all sides ofwtx_d sleeve to the opening.

NOTE: See Step 7, Item 3 of Window Mounting Instructions

for bottom rail seal location.

Masonry Construction

1. Cut or build a wall opening in the masonry wall similar

to the frame construction (refer to Step 2 of Tbau-the-

Wall Installation for a wall thickness _eater than 8-1/

2").

2. Secure cabinet in place using masom 7 nails, or the right

masom 7 anchor screws. (Another way to do this is to build

an in-between frame of 2x4's as shown in the Step 2 Prepare

Wall illustrations-but make it double framed on either

side, and install between n_soru 7 wall opening and cabinet.

Frame must be securely anchored to masom 7 wall

opening) This way gives very good louver clearance on

either side of cabinet.

3. Install a lintel to support masom 7 wall above cabinet.

Existing holes in cabinet can be used and/or additional

holes can be &illed to fasten cabinet at various positions.

Be sure that side louver clearance is in accordance with

Step 1 above.

4. Install exterior cabient support brackets as shown in

Step 2 of Tinu-the-Wall Installation. Caulk or flash if

nee&, to provide a wether-tight seal around top and

sides of cabinet.

5. To complete installation, apply wood trim molding

around room side projection of cabinet.

Loading...

Loading...