Page 1

BEER COOLER

6.1 CU FT

170 L

TABLE OF CONTENTS

Important Safety Instructions.....................1

Unpacking and Setup................................4

Features at a Glance.................................5

Assembly and Installation..........................6

Door Removal Instructions........................12

Temperature Controls................................13

USER MANUAL

EFRB200,EFRB200C

Helpful Hints.................................................14

Energy Saving Tips.......................................15

Vacation and Moving Tips.............................15

Normal Operating Sounds and Sights..........15

Care and Cleaning........................................16

Before You Call.............................................17

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

Please read all instructions before using this unit.

FOR YOUR SAFETY

• DO NOT store or use gasoline, or other flammable liquids in the vicinity of this or any other

appliance. Read product labels for warnings regarding flammability and other hazards.

• DO NOT operate the appliance in the presence of explosive fumes.

• Remove all staples from the carton. Staples can cause severe cuts, and also destroy finishes

if they come in contact with other appliances or furniture.

DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey

all safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious minjury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

IMPORTANT indicates installation, operation or maintenance information

which is important but not hazard-related.

INSTALLATION CHECKLIST

Doors

Door seals completely to cabinet on all sides

Door is level across the top

Leveling

Unit is level, side-to-side and tilted 1/4” (6 mm)

front-to-back

Cabinet is setting solid on all corners

Electrical Power

House power turned on

Appliance plugged in

Final Checks

Shipping material removed

Appliance temperatures set

Registration card sent in

CHILD SAFETY

Destroy or recycle the carton, plastic bags, and any exterior wrapping material immediately after

the appliance is unpacked. Children should NEVER use these items to play. Cartons covered

with rugs, bedspreads, plastic sheets or stretch wrap may become airtight chambers, and can

quickly cause suffocation.

1

Page 3

PROPER DISPOSAL OF YOUR APPLIANCE

RISK OF CHILD ENTRAPMENT

Child entrapment and suffocation are not problems of the past. Junked or abandoned

appliances are still dangerous – even if they will sit for “just a few days.” If you are getting rid of

your old appliance, please follow the instructions below to help prevent accidents.

PROPER DISPOSAL OF APPLIANCE

We strongly encourage responsible appliance recycling/disposal methods. Check with your

utility company or visit www.energystar.gov/recycle for more information on recycling your old

appliance.

BEFORE YOU THROW AWAY YOUR OLD APPLIANCE:

• Remove doors.

• Leave shelves in place so children may

not easily climb inside.

• Have refrigerant removed by a qualified

service technician.

WARNING These guidelines must be followed to ensure that safety

mechanisms in this unit will operate properly.

ELECTRICAL INFORMATION

• The appliance must be plugged into its own dedicated 115 Volt, 60 Hz., AC only electrical

outlet. The power cord of the appliance is equipped with a three-prong grounding plug for

your protection against electrical shock hazards. It must be plugged directly into a properly

grounded three prong receptacle. The receptacle must be installed in accordance with local

codes and ordinances. Consult a qualified electrician. Avoid connecting keg cooler to a Ground

Fault Interruptor (GFI) circuit. Do not use an extension cord or adapter plug.

• If the power cord is damaged, it should be replaced by an authorized service technician to

prevent any risk.

• Never unplug the appliance by pulling on the power cord. Always grip the plug firmly, and pull

straight out from the receptacle to prevent damaging the power cord.

• Unplug the appliance before cleaning and before replacing a light bulb to avoid electrical shock.

• Performance may be affected if the voltage varies by 10% or more. Operating the appliance

with insufficient power can damage the compressor. Such damage is not covered under your

warranty.

• Do not plug the unit into an electrical outlet controlled by a wall switch or pull cord to prevent

the unit from being turned off accidentally.

IMPORTANT Turning the Temperature Control to

“OFF” turns off the compressor and prevents your

appliance from cooling, but does not disconnect the

power to the other electrical components. To turn off

power to your appliance you must unplug the power

cord from the electrical outlet.

2

Page 4

WARNING

CO2 CANISTER SAFE HANDLING

• CO

canisters must be handled with extreme care. They contain potentially

2

hazardous high pressure compressed gas. Make sure you read and understand all of

these instructions before installation.

• Never attempt to refill a CO2 cylinder yourself. They can be refilled at locations such

as welding supply shops, party stores, fire supply shops, or where kegs are purchased.

• ALWAYS connect CO2 gas canisters to a pressure regulator.

• NEVER drop or throw the CO2 canister.

• NEVER connect gas canister directly to keg.

• ALWAYS keep CO2 canisters in a cool place (21.5°C(70°F) or less) and away from heat.

• In case of CO2 leakage, ventilate and evacuate the area immediately.

• ALWAYS keep canister secured in an upright position.

• Check the Department of Transportation (D.O.T.) test date on the canister neck and do

not use if older than five (5) years.

• Return outdated canister to your gas supplier for one that is within the time limit.

3

Page 5

UNPACKING AND SETUP

This Use and Care Manual provides specific assembly, operating and maintenance instructions

for your model. Use the keg cooler only as instructed in this Use and Care Manual. Before

starting the keg cooler, follow these important first steps.

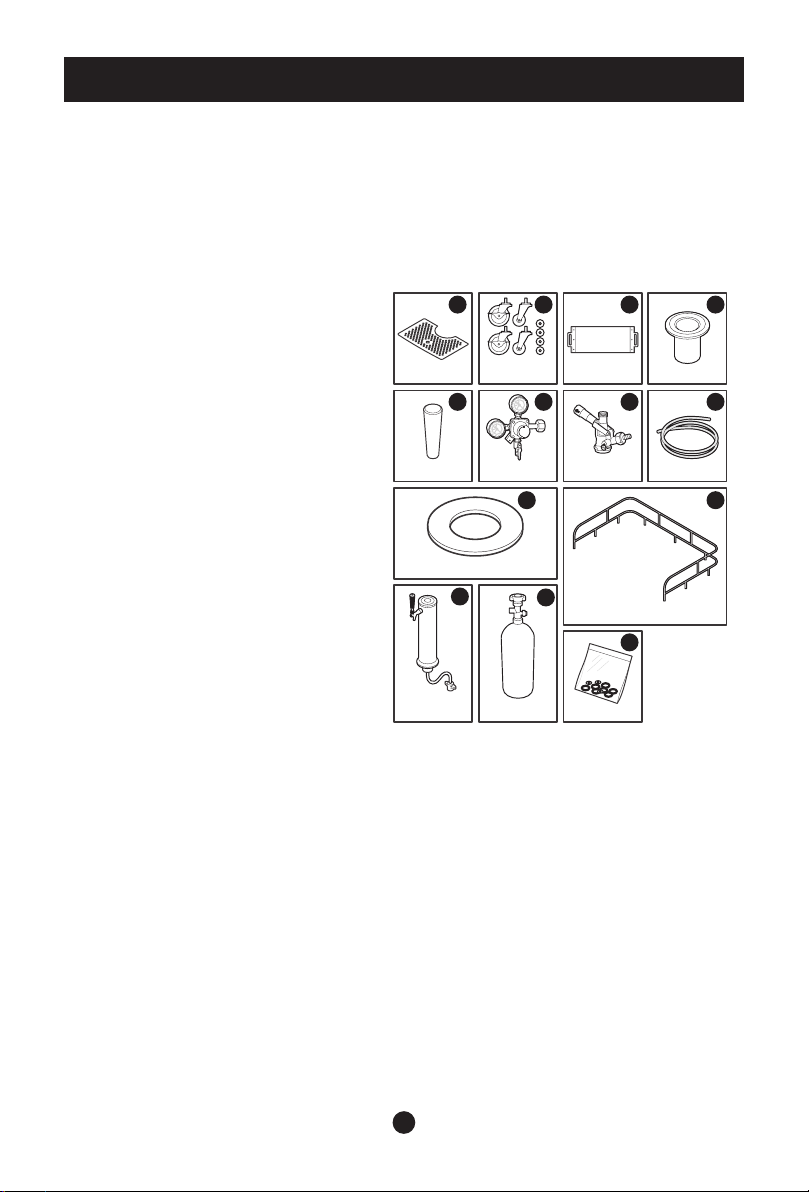

PARTS

Your keg cooler comes with several small boxes that contain all the required parts and

accessories. Check to make sure that you have received all of the components listed below.

BEVERAGE DELIVERY KIT BOX

(1) Drip Tray

(2) Casters and Washers

(3) Retaining Strap

(4) Hole Plug

(5) Faucet Knob

(6) CO2 Regulator (with plastic washer)

(7) Keg Coupler

(8) Small Hose (Gas Line)

(9) Rubber Gasket (Black)

(For bottom of Dispensing Tower)

(10) Guard Rail

(11) Dispenser Tower (with faucet)

(12) CO2 Canister (Empty)

(13) Bag of spare parts

(replacement seals and washers)

1 piece

4 pieces

1 piece

1 piece

1 piece

1 piece

1 piece

1 piece

1 piece

1 piece

1 piece

1 piece

1 bag

Drip Tray

Faucet Knob

Rubber Gasket

Dispenser

Tower

1

Casters and

Washers

5

C0 Regulator

2

9

11 12

C0 Canister

2

2

6

Retaining Strap

Keg Coupler

Spare Parts

3

Hole Plug

7

Small Hose

11

Guard Rail

13

NOTE

The box comes with a “D System” type Keg Coupler (7). Depending on your choice of beer,

you may require a different Keg Coupler (7). Check with your local beer distributor to

determine which type of system you need, and order additional Keg Couplers as needed.

4

8

10

4

Page 6

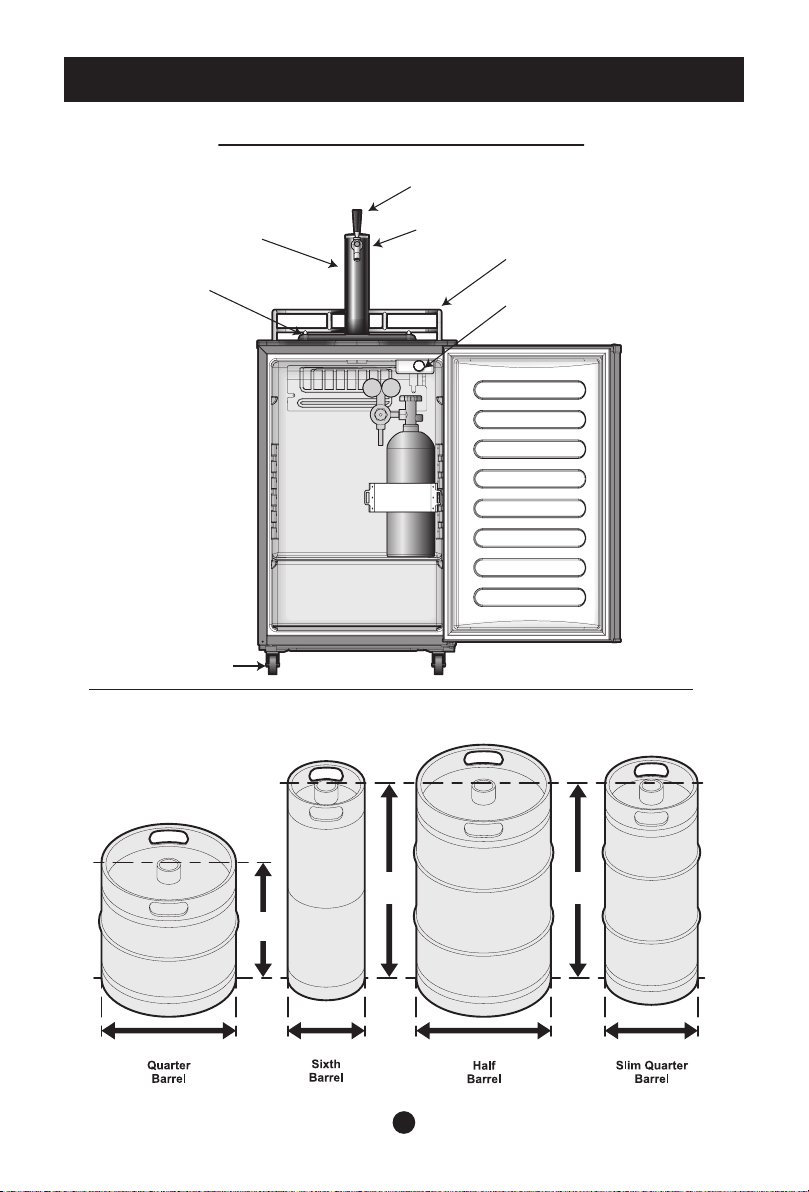

FEATURES AT A GLANCE

Faucet Handle

Features may vary according to model

Dispensing Tower

Drip Tray

Casters (x4)

Faucet

Top Rail

Temperature Control

Standard Keg Sizes for this Cooler

59.4 cm

(23-3/8 in.)

35.2 cm

(13-7/8 in.)

41.0 cm (16-1/8 in.) 41.0 cm (16-1/8 in.)

23.5 cm (9-1/4 in.)

5

59.4 cm

(23-3/8 in.)

28.3 cm (11-1/8 in.)

Page 7

ASSEMBLY AND INSTALLATION

This Use and Care Guide provides specific operating instructions for your model. Use this unit

only as instructed in this Use and Care Guide. Before starting the unit, follow these important

first steps.

LOCATION

• Choose a place that is near a grounded electrical outlet. Do not use an extension cord or an

adapter plug.

• If possible, place the unit out of direct sunlight and away from the range, dishwasher or other

heat sources.

• For optimum performance, this product should only be used indoors under normal ambient

conditions.

• The appliance must be installed on a floor that is level and strong enough to support a fully

loaded unit.

• If the appliance has been placed in a horizontal or tilted position for any period of time, please

wait at least 24 hours before plugging the unit in.

INSTALLING THE CASTERS

Follow the steps below to install the casters.

1. Empty the inside of the cabinet completely and lay the Keg Cooler down on its side.

We recommend that you place a piece of cardboard or cloth underneath the cabinet to prevent

dents or scratches.

2. Insert the casters into the holes on the bottom corners of the cabinet. Tighten each caster by

turning the head of the bolts clockwise with a wrench (not provided in the kit).

3. Once all four casters have been tightened, stand the cabinet in its upright position.

NOTE: Two of the casters include locking mechanisms to ensure the unit does not

slide on hard floors. These two locking casters should be fastened at the front end

of the unit, with the unlocked casters fastened on the rear end.

INSTALLING THE BEER TAP

There are notches on the bottom of the dispensing tower that line up with grooves inside the

opening on the top of the Keg Cooler. Align the dispensing tower with the opening on the top of

the unit, then place inside and twist clockwise until secure. Use four screws to fasten the beer tap.

Pay attention to use the thin black gasket (9) for assembly (see illustration). If you find this to be

a tight fit, apply some soapy water to the gasket to make the tower easier to twist into place.

Also see illustration showing hose connections to CO2 regulator to the beer tap.

6

Page 8

INSTALLING THE GUARDRAIL

Follow the steps below to install the guardrail.

1. Place the guard rail on top of the cabinet.

2. Align all support feet of the guardrail with the holes on the top of the unit and press down into

place.

CAUTION: Do not install the unit where the temperature will drop below 13°C

(55°F) or rise above 32°C (90°F). The compressor will not be able to maintain

proper temperatures inside the unit.

INSTALLATION

Installation clearances

• Allow the following clearances for ease of installation, proper air circulation, and electrical

connections:

Sides and Top 12.7 cm (5 inches)

Back 12.7 cm (5 inches)

NOTE: If your unit is placed with the door hinge side against a wall, you may have

to allow additional space so the door can be opened wider.

LEVELING

All four casters of your unit must rest firmly on a solid floor. Use adjustable wrench to adjust

leveling screws.

CAUTION: do not attempt to move or relocate the keg cooler with a keg inside.

REGULATOR INSTALLATION

• Check to ensure plastic washer is inside the hex nut.

• Fasten the CO2 regulator (6) to the CO2 canister (12). Place

the regulator to the right of the tank.

• Tighten the hex nut securely. DO NOT over tighten. Over-

tightening may damage the gasket in the nut of the regulator.

SMALL CO2 HOSE TO REGULATOR CONNECTION

• Attach wing nut on end of small hose (8) to fitting at bottom of regulator (6).

7

Page 9

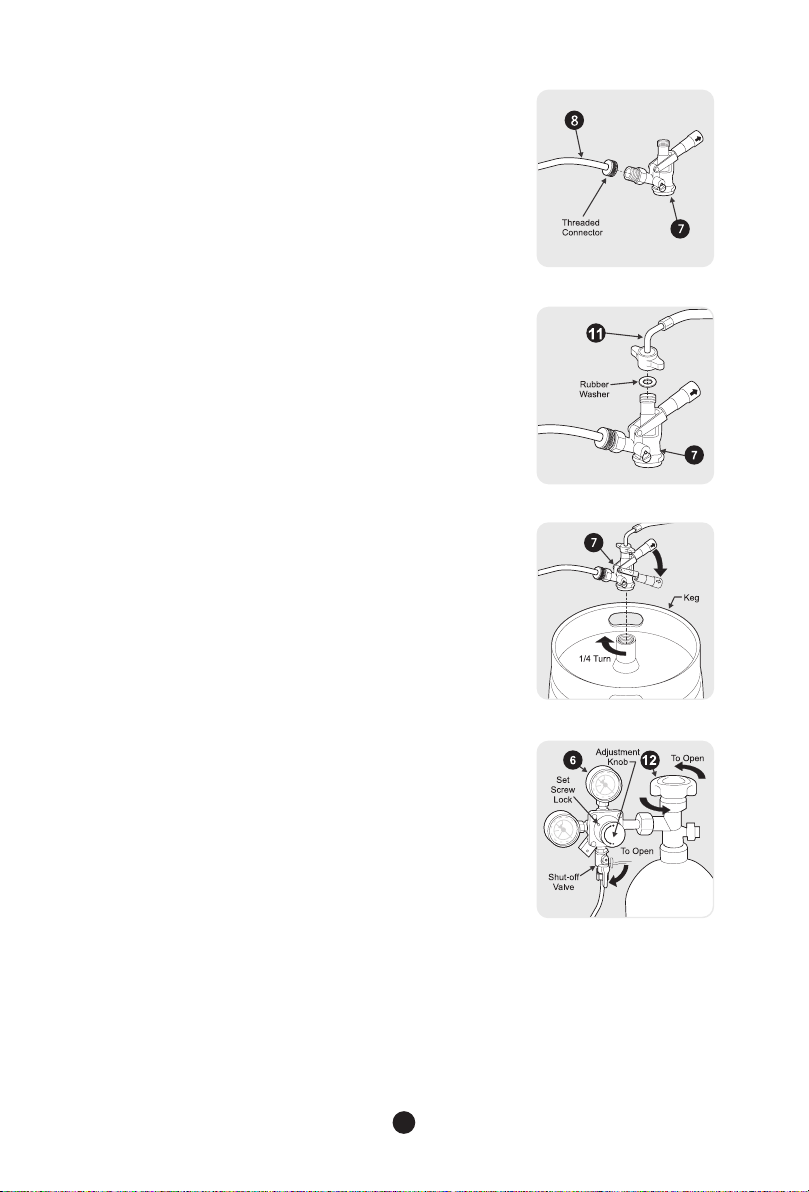

SMALL CO2 HOSE TO COUPLER CONNECTION

• Secure other end of small hose (8) to the threaded

end of keg coupler (7) as shown. Be sure to fully

tighten fitting.

NOTE: Depending on your choice of beer, you may require a

different keg coupler (7). Check with your local beer

distributor to determine which type of system you need, and

order additional keg couplers as needed.

CLEAR HOSE TO COUPLER CONNECTION

Place one of the supplied rubber washers inside

the wing nut on the one end of the clear hose

(beverage delivery line) and attach to keg coupler

(7). Be sure to tighten the nut securely to prevent

leakage. DO NOT overtighten. Overtightening may

damage the gasket in the nut.

COUPLER TO KEG INSTALLATION

• Align locks on keg coupler (7) with housing on

top of keg and push down on the keg coupler (7).

Make sure top handle is in the up position.

• Turn the tap head handle clockwise 1/4 turn. The

tap head is now secured to the keg.

• Pull the tap handle out and push down until it locks

into place to open the port in the keg.

DELIVERY HOSE PRESSURIZATION

• Open the CO2 canister valve all the way by turning

counterclockwise until it stops. This valve seals

at both the fully open and fully closed positions.

Failure to completely open or close the valve could

result in premature loss of CO2 pressure.

• Open the regulator shut-off valve by moving it to

the 6 o’clock position.

• Check gauge pressure. Adjust the regulator

adjustment knob Knob as necessary until the pressure

reads between 12 to 14 psi. You may first need to

loosen set screw located behind knob. After setting

regulator to correct pressure, set screw may be retightened

to lock knob in place.

8

Page 10

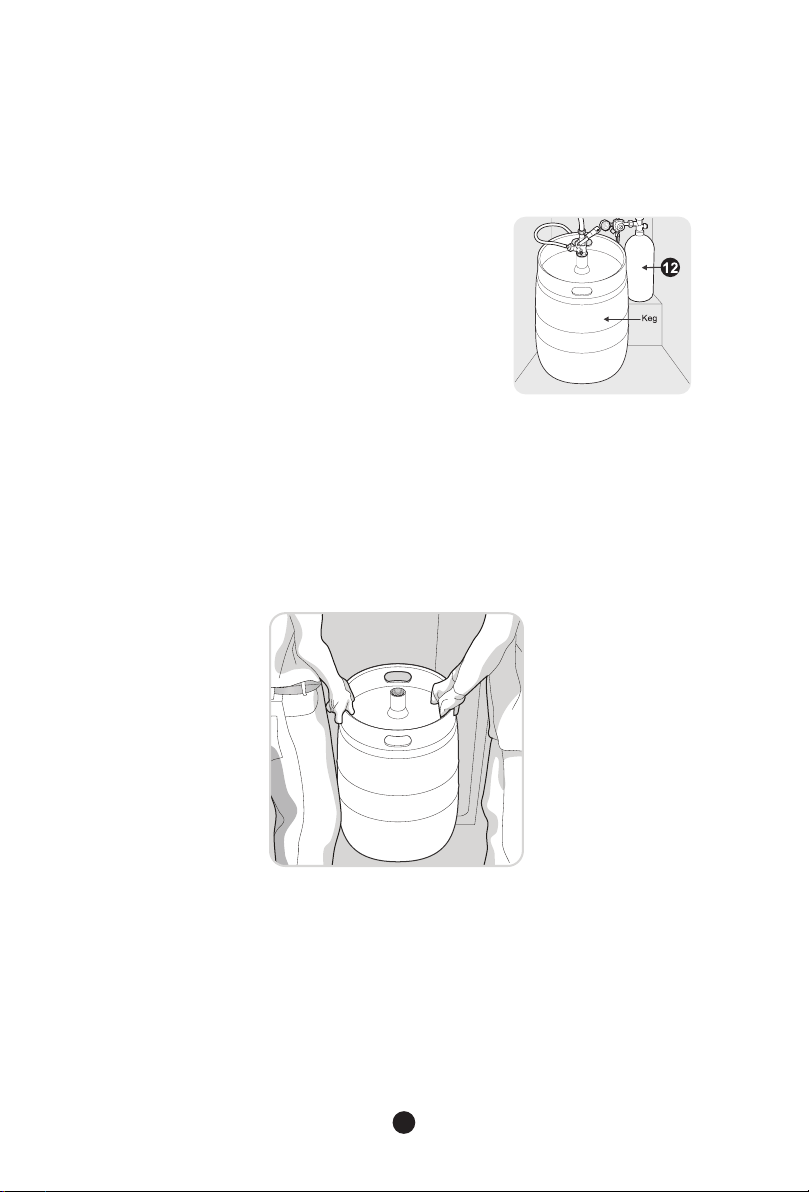

CO2 CANISTER TO CABINET INSTALLATION

• Lift and place the CO2 canister (12) with the CO2 regulator (6) on the shelf at rear right hand

corner of cabinet. It is important that the canister be kept in an upright position to operate

efficiently. Hook one end of retaining strap (3) over metal bracket at rear, then stretch around

canister and hook other end over front bracket.

KEG TO CABINET INSTALLATION

• Place the keg on the support shelf and push

back next to the CO2 canister (12) (See TIPS ON

INSTALLING KEG TO THE CABINET) inside the

cabinet as shown.

WARNING

SAFE KEG HANDLING

• Installing the keg to the cabinet is a two-person team effort. NEVER lift a full keg alone.

Doing so may cause severe injury.

• With the door fully open and the help of another person, lift the keg vertically on both

sides until the keg is higher than the keg support shelf.

• Set the edge of the keg on top of the plastic protective plate located on top of keg

support shelf. Slide the keg back until it is fully inside the cabinet.

• Care must be taken to avoid damage to the temperature control and shelf tower located

in the cabinet.

NOTE: The above illustration does not show the tap installed for clarity of installation.

9

Page 11

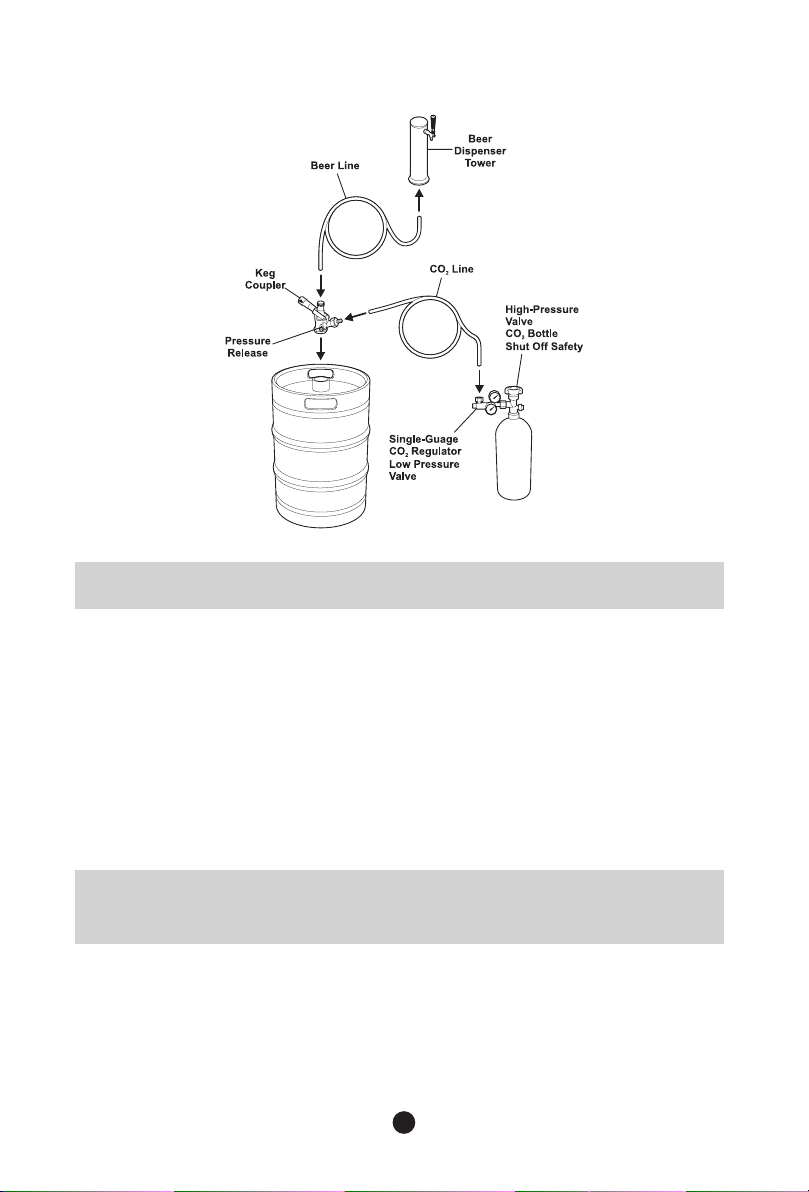

DELIVERY HOSE ARRANGEMENT

NOTE: Failure to route hoses properly may cause the hose to become kinked or

caught in door.

OPERATING YOUR KEG COOLER

• Make sure that the keg cooler is plugged in properly to a 115V, 60Hz AC only electrical outlet.

• Make sure that the drip tray and sump are secured under the faucet.

• Start with a clean beverage glass that has been wetted in cold water. Place the glass at a 45º

angle, 2.5 cm (1 in.) below the faucet. Do not let the glass touch the faucet. Open the faucet

all the way.

• After the glass has reached half full, gradually bring the glass to an upright position.

• Let the remaining beverage run straight down the middle. This insures proper release of CO

by producing a 1.9 to 2.5 cm (3/4 to 1 in.) foam head.

• Close the faucet completely and quickly.

2

NOTE: It is normal to see condensation forming around the faucet. This

condensation is caused by the temperature difference between the cold beverage

and the inner surfaces of the faucet when beverage is being drawn through the line.

10

Page 12

HOW TO REPLACE AN EMPTY CO2 CANISTER

• Remove hoses from routing clips.

• Remove the keg, then remove CO2 canister.

• Close the canister valve of the empty canister by turning clockwise until it stops.

• Close the regulator shut-off valve by moving it to the 9 o’clock position.

• Carefully remove regulator from the empty CO2 canister by loosening the nut with an

adjustable wrench. Check the condition of the gasket inside the nut and replace if necessary.

• Return canister to your local carbonic gas source for filling. (We suggest looking in your yellow

pages under “Carbonic Gas.” Sources of CO2 vary from community to community but it is often

available at welding supply stores and beverage distributors.)

• Remove dust cap from new canister nut, if any.

• With the canister valve still in closed position, reattach the regulator to the new canister using

an adjustable wrench. Ensure the plastic washer is inside of the nut. Tighten nut until it feels

snug but be careful not to overtighten as you will damage the gasket inside the stem nut.

• Check to make sure that the braided gas line hose is still securely attached to the regulator.

• Open the canister valve all the way by turning counter-clockwise until it stops. This valve seals

at both the fully open and fully closed positions. Failure to completely open or close the valve

could result in premature loss of CO2 pressure.

• Open the regulator shut-off valve by moving it down to the 6 o’clock position.

• Check gauge pressure. Adjust the regulator adjustment screw as necessary until the pressure

reads between 12 to 14 psi. Tighten the adjustment lock nut.

• Replace keg and route hose clips.

11

Page 13

DOOR REMOVAL INSTRUCTIONS

NOTE: The direction in which your unit door opens (door swing) can be reversed,

from left to right or right to left, by moving the door hinges from one side to the

other. Reversing the door swing should be performed by a qualified person.

IMPORTANT: Before you begin, turn the unit temperature control to “OFF” and

remove the electrical power cord from the wall outlet. Remove any food from door

shelves.

DOOR REMOVAL AND REVERSAL INSTRUCTIONS:

1 Remove dispensing tower from unit.

2 Remove three (3) screws at rear edge of top cover, then lift up at rear and slide forward to

remove cover (see Figure A).

3 Remove two (2) screws from top door hinge and lift up out of door bushing (see Figure B).

6 Re-install door with LH bushing placed over hinge pin.

7 Re-install top hinge on opposite corner of cabinet and then assemble top cover in reverse

order of Step 2.

12

Page 14

TEMPERATURE CONTROLS

COOL DOWN PERIOD

For proper operation, allow the unit to operate with the door closed for at least 12 hours before

placing the keg inside.

KEG COOLER CONTROLS

Temperature control

This rotary control is the primary control for the refrigerated compartment temperature. If the

unit is too warm, adjust this control in the “Max” direction. If the unit is too cold, adjust this

control in the “Min” direction.

TEMPERATURE SETTING AND ADJUSTMENT

For beer storage, the recommended initial setting is “Med.” Under most conditions,

this setting will provide for dispensed beer between 1-3 ºC (34-38 ºF) You may adjust as

required to suit your individual taste and the keg cooler operating conditions. After a control

adjustment, always allow 24 hours for the beer to stabilize at the new temperature before

making additional adjustments.

IMPORTANT: Turning the unit temperature control to “OFF” turns off the

compressor, but does not disconnect the power to the light bulb and other electrical

components. To turn off power to your unit, you must unplug the power cord from

the wall outlet.

NOTE: When purchasing a beer keg, always purchase a keg cold ( <3 ºC (38 ºF)),

transport as quickly as possible, and get it installed in the cold unit within two (2)

hours. Under most conditions, these guidelines will allow serving of properly

cooled beerwithin 24 hours. Purchasing a keg at a temperature above 3 ºC (38 ºF),

and/or exposure to elevated temperatures longer than two (2) hours will require

additional time for the beer to be cooled to optimum serving temperature.

13

Page 15

HELPFUL HINTS

PARTS OF A CO2 REGULATOR

(A) Low Pressure Gauge

(B) Adjustment Knob

(C) Adjustment Lock Set Screw

(D) Shut-off Valve

(E) CO2 Nut (used to connect to CO2 canister)

(F) High Pressure Gauge

BEER STORAGE TEMPERATURE

• Draft beer is not pasteurized, so it must be kept cold, preferably at 3 ºC (38 ºF). Temperatures

above 3 ºC (38 ºF) may cause the beer to become wild, turn sour and cloudy.

RECOMMENDED KEG HANDLING

• Be sure the keg is cold when you purchase it.

• Transfer keg from place of purchase and install in keg cooler in two (2) hours or less.

• After the keg is installed in the keg cooler, allow 24 hours for beverage to reach recommended

temperature.

• If the keg is exposed to ambient temperatures longer than two (2) hours, additional cooling

time will be required before beverage will reach recommended temperature.

TYPICAL BEER SERVING EQUIVALENTS

¼ Keg ½ Keg

Grams/Ounces 28123g/992

56245g/1984

Litres/Gallons

29 L / 7.75 gal

58 L / 15.5 gal.

Cases (355 mL

(12 oz.) bottles)

Weight (full)

CAUTION: DO NOT attempt to move or relocate this keg cooler with a keg inside.

3 3/8 (82 bottles)

37 kg / 82.5 lb. 75 kg / 165 lb

14

6 3/4 (165 bottles)

Page 16

ENERGY SAVING TIPS

• Install the keg cooler in the coolest part of the room, out of direct

sunlight and away from heating ducts or registers. Do not place the keg

cooler next to heat-producing appliances such as a range, oven, or

dishwasher.

• Do not overcrowd the keg cooler or block cold air vents. Doing so

causes the keg cooler to run longer and use more energy.

• Organize the keg cooler to reduce door openings. Remove as many

items as needed at one time and close the door as soon as possible.

VACATION AND MOVING TIPS

Vacation and Moving Tips

Short Vacations

Long Vacations • Remove all food and ice if you will be gone one month or more.

Moving • NEVER MOVE KEG COOLER WITH KEG INSIDE.

• Leave keg cooler operating during vacations of three (3) weeks or less.

• Use all perishable items from keg cooler compartment.

• Turn controls to the OFF position and disconnect power.

• Clean interior thoroughly.

• Leave door open to prevent odours and mould build-up. Block door open if necessary.

• If using handcart, load from side.

• Adjust leveling legs all the way up to protect

• Pad cabinet to avoid scratching surface.

surface during sliding or moving.

NORMAL OPERATING SOUNDS AND SIGHTS

UNDERSTANDING THE SOUNDS YOU MAY HEAR

Your new, high-efficiency keg cooler may introduce unfamiliar sounds. These sounds normally

indicate your keg cooler is operating correctly. Some surfaces on floors, walls, and kitchen

cabinets may make these sounds more noticeable.

NOTE: Rigid foam insulation is very energy efficient, but is not a sound insulator.

Following is a list of major components in your keg cooler and the sounds they can cause:

Evaporator Refrigerant through the evaporator may create a boiling or gurgling sound.

Electronic control and automatic defrost control These parts can produce a snapping or

clicking sound when turning the cooling system on and off.

Compressor Modern, high-efficiency compressors run much faster than in the past. The

compressor may have a high-pitched hum or pulsating sound.

Drain pan (not removable) You may hear water dripping into the drain pan during the defrost

cycle.

15

Page 17

CARE and CLEANING

PROTECTING YOUR INVESTMENT

Keeping your keg cooler clean maintains appearance and prevents odour build-up. Wipe up any

spills immediately and clean the keg cooler at least twice a year. When cleaning, take the

following precautions:

• Never use CHLORIDE or cleaners with bleach to clean stainless steel.

• Do not wash any removable parts in a dishwasher.

• Always unplug the electrical power cord from the wall outlet before cleaning.

• Remove adhesive labels by hand. Do not use razor blades or other sharp instruments which

can scratch the appliance surface.

• Do not remove the serial plate.

Do not use abrasive cleaners such as window sprays, scouring cleansers, brushes, flammable

fluids, cleaning waxes, concentrated detergents, bleaches or cleansers containing petroleum

products on plastic parts, interior doors, gaskets or cabinet liners. Do not use paper towels,

metallic scouring pads, or other abrasive cleaning materials or strong alkaline solutions.

NOTE: If you set your temperature controls to turn off cooling, power to lights and

other electrical components will continue until you unplug the power cord from the

wall outlet.

CAUTION: 1.Pull the keg cooler straight out to move it. Shifting it from side to side

may damage flooring. Be careful not to move the keg cooler beyond the plumbing

connections. 2.Damp objects stick to cold metal surfaces. Do not touch refrigerated

surfaces with wet or damp hands.

IMPORTANT: If you store or move your keg cooler in freezing temperatures, be sure

to completely drain the water supply system. Failure to do so could result in water

leaks when the keg cooler is put back into service. Contact a service representative

to perform this operation.

Part What To Use Tips and Precautions

Interior and Door

Liners

Door Gaskets • Soap and water Wipe gaskets with a clean soft cloth.

Drawers and Bins • Soap and water Use a soft cloth to clean drawer runners and tracks.

Exterior and

Handles

Exterior and

Handles

(Stainless Steel

Models Only)

• Soap and water

• Baking soda and water

• Soap and water

• Non-abrasive glass cleaner

• Soap and water

• Stainless steel cleaners

Use 30 mL (2 tbsp) of baking soda in 945 mL (1 qt.) of warm water. Be sure

to wring excess water out of sponge or cloth before cleaning around

controls, light bulb or any electrical part.

Do not use commercial household cleaners containing ammonia, bleach or

alcohol to clean handles. Use a soft cloth to clean smooth handles. DO

NOT use a dry cloth to clean smooth doors.

Never use CHLORIDE or cleaners with bleach to clean stainless steel.

Clean stainless steel front and handles with non-abrasive soapy water and

a dishcloth. Rinse with clean water and a soft cloth. Use a non-abrasive

stainless steel cleaner. These cleaners can be purchased at most home

improvement or major department stores. Always follow manufacturer’s

instructions. Do not use household cleaners containing ammonia or bleach.

NOTE: Always clean, wipe and dry with the grain to prevent

scratching. Wash the rest of the cabinet with warm water and mild liquid

detergent. Rinse well, and wipe dry with a clean soft cloth.

16

Care and Cleaning Tips

Page 18

BEFORE YOU CALL

CONCERN POTENTIAL CAUSE COMMON SOLUTION

RUNNING OF KEG COOLER

Keg cooler does not

run.

Keg cooler runs too

much or too long.

Interior keg cooler tem perature is too cold.

Interior keg cooler

temperature is too

warm.

Keg cooler external

surface temperature is

warm.

WATER/MOISTURE/FROST INSIDE KEG COOLER

Moisture collects on

inside of keg cooler

walls.

WATER/MOISTURE/FROST OUTSIDE KEG COOLER

Moisture collects on

outside of keg cooler

walls.

ODOUR IN KEG COOLER

Unpleasant odours. • Interior needs to be cleaned. • Clean interior with sponge, warm water, and baking soda.

DOOR PROBLEMS

Door will not close. • Keg cooler is not level. • This condition can force the cabinet out of square and

• Keg cooler is plugged into a

circuit that has a ground fault

interrupt.

• Temperature control is in the

“O” position.

• Keg cooler may not be plugged

in, or plug may be loose.

• House fuse blown or tripped

circuit breaker.

• Power outage.

• Room or outside weather is

hot.

• Keg cooler has recently been

disconnected for a period of time.

• Doors are opened too frequently

or too long.

• Keg cooler door may be slightly

open.

• Temperature control is set too

low.

• Keg cooler gasket is dirty, worn,

cracked, or poorly

• Temperature control is set too

low.

• Temperature control is set too

warm.

• Door is kept open too long or is

opened too frequently.

• Door may not be seating properly.

• Keg cooler has recently been

disconnected for a period of time.

• The external walls can be as

much as -1

than room temperature.

• Weather is hot and humid.

• Door may not be seating

properly.

• Door is kept open too long or

opened too frequently.

• Door may not be seating

properly, causing the cold air

from inside the keg cooler to

meet warm moist air from the

outside.

fitted.

O

C (30 OF) warmer

• Use another circuit. If you are unsure about the outlet,

have it checked by a technician.

• See SETTING THE TEMPERATURE CONTROL section.

• Ensure plug is tightly pushed into outlet.

• Check/replace fuse with a 15 amp time-delay fuse. Reset

circuit breaker.

• Check house lights. Call local electric company.

• It’s normal for the keg cooler to work longer under these

conditions.

• It takes four (4) hours for the keg cooler to cool down

completely.

• Warm air entering the keg cooler causes it to run more.

Open door less often.

• See DOOR PROBLEMS section.

• Adjust temperature control to warmer setting. Allow

several hours for temperature to stabilize.

• Clean or change gasket. Leaks in door seal will cause keg

cooler to run longer in order to maintain desired temperatures.

• Adjust temperature control to a warmer setting. Allow

several hours for temperature to stabilize.

• Adjust temperature control to a colder setting. Allow

several hours for the temperature to stabilize.

• Warm air enters the keg cooler every time the door is

opened. Open the door less often.

• See DOOR PROBLEMS section.

• It takes four (4) hours for the keg cooler to cool down

completely.

• This is normal while the compressor works to transfer heat

from inside the keg cooler.

• This is normal.

• See DOOR PROBLEMS section.

• Open the door less often.

• See DOOR PROBLEMS section.

misalign the door. Level the unit .

certified

17

Page 19

CONCERN POTENTIAL CAUSE COMMON SOLUTION

SOUND AND NOISE

Louder sound levels

whenever keg cooler

is on.

Longer sound levels

when compressor

comes on.

Popping or cracking

sound when compressor comes on.

Bubbling or gurgling

sound like water boil ing.

Vibrating or rattling

noise.

Snapping noise. • Temperature control turning keg

COMMON DRAFT PROBLEMS

WILD BEER - Beer,

when drawn, is all

foam, or too much

foam and not enough

liquid beer.

FLAT BEER - Foamy

head disappears

quickly; beer lacks

usual zestful brewery

fresh flavour.

CLOUDY BEER - When

beer in glass appears

hazy, not clear.

• Modern keg coolers have in-

creased storage capacity and

more stable temperatures. They

require a high-efficiency compres-

sor.

• Keg cooler operates at high

pressure during the start of the

cycle.

“ON”

• Metal parts undergo expansion

and contraction, as in hot water

pipes.

• Refrigerant (used to cool keg

cooler) is circulating throughout

the system.

• Keg cooler is touching the wall. • Move keg cooler slightly away from the wall.

cooler on and off.

• Beer drawn improperly.

• Creeping regulator.

• Applied pressure is set too high.

• Hot spots in line.

• Tapped into a warm keg (should

be 1.1

°C-3.5°C(34°F-38°F)

• Centre malfunctioning.

• Faucet is in bad, dirty or worn

condition.

• Dirty glasses.

• Applied pressure is set too low.

• CO

is cut off.

2

• Beer too cold.

• Loose tap or vent connections.

• Sluggish regulator.

• Frozen or near frozen beer.

• Unrefrigerated beer for long periods

of time.

• Dirty glasses.

• Dirty faucet.

• Unrefrigerated foods placed on top

of cold keg.

• This is normal. When the surrounding noise level is low, you

might hear the compressor running while it cools the interior.

• This is normal. Sound will level off or disappear as the keg

cooler continues to run.

• This is normal. Sound will level off or disappear as the keg

cooler continues to run.

• This is normal.

• This is normal.

• Make sure faucet is opened all the way. Close quickly when

done.

• Replace with a new regulator.

• Readjust regulator to a lower pressure until foam subsides.

When pressure is properly set, you should be able to pour 10

oz. of beer in (5)five seconds.

• Make sure beer del

the interior of the keg cooler.

• Wait until keg cools down to proper temperature.

• Have keg cooler serviced to return it to proper operating

condition.

• Thoroughly clean faucet with recommended cleaning kit.

Replace all worn seals.

• Wash glasses using soap-free detergent.

• Increase pressure until beer at a rate of 2 oz. per

second.

• Do not turn off CO

ready to be removed.

• Increase temperature of keg cooler. See SETTING THE

TEMPERATURE CONTROL section.

• Check that coupler is properly installed in keg.

• Replace regulator.

• Return keg to place of purchase and exchange for one that

has been properly refrigerated.

• Exchange keg for fresh one.

• Wash glasses using soap-free detergent.

• Clean faucet with recommended cleaning kit.

• Remove items from atop k

erator.

ivery line is not pinched and is fully inside

flows

supply line to keg until keg is empty and

2

eg and place in a separate refrig-

18

Page 20

DANGER – Risk Of Fire Or Explosion. Flammable Refrigerant

Used. To Be Repaired Only By Trained Service Personnel.

Do Not Puncture Refrigerant Tubing

CAUTION – Risk Of Fire Or Explosion. Flammable Refrigerant

Used. Consult Repair Manual/Owner’s Guide Before Attempting

To Service This Product. All Safety Precautions Must be Followed

CAUTION – Risk Of Fire Or Explosion. Dispose Of Property In

Accordance With Federal Or Local Regulations. Flammable

Refrigerant Used

CAUTION – Risk Of Fire Or Explosion Due To Puncture Of

Refrigerant Tubing; Follow Handling Instructions Carefully.

Flammable Refrigerant Used

19

Page 21

Baril à bière

6.1 CU FT

170 L

TABLE DES MATIÈRES

Consignes de sécurité importantes............1

Déballage et montage................................4

Aperçu des caractéristiques.......................5

Assemblage et installation..........................6

Instructions pour le retrait des portes........12

Commandes de température.....................13

Conseils utiles............................................14

Manuel de l'utilisateur

EFRB200,EFRB200C

Conseils pour économiser l'énergie...................15

Conseils pour les vacances et les

déménagements................................................15

Bruits et éléments visuels d'un

fonctionnement normal......................................15

Entretien et nettoyage.......................................16

Avant de faire appel au service après-vente.....17

Page 22

CONSIGNES DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT : veuillez lire ces instructions au complet

avant d'utiliser l'appareil.

POUR VOTRE SÉCURITÉ

• N'entreposez PAS et n'utilisez pas d'essence ou tout autre liquide inflammable à proximité de cet

appareil ou de tout autre électroménager. Lisez les étiquettes d'avertissement du produit concernant

l'inflammabilité et les autres dangers.

• Ne faites PAS fonctionner l'appareil en présence de vapeurs explosives.

• Enlevez toutes les agrafes du carton. Les agrafes peuvent causer de graves coupures et

endommager les finis si elles entrent en contact avec d'autres appareils électroménagers ou meubles.

DÉFINITIONS

Voici le symbole d'alerte de sécurité. Il sert à vous mettre en garde contre les risques potentiels de

blessures corporelles. Respectez toutes les consignes de sécurité qui suivent ce symbole afin d'éviter

les blessures ou la mort.

La mention DANGER indique un danger imminent qui causera la mort ou des

blessures graves s'il n'est pas évité.

La mention AVERTISSEMENT indique une situation potentiellement dangereuse

qui, si elle n'est pas évitée, peut entraîner des blessures graves, voire la mort.

La mention ATTENTION signale la présence d'une situation

potentiellement dangereuse qui, si elle n'est pas évitée, est susceptible de

causer des blessures mineures ou moyennement graves.

La mention IMPORTANT indique des renseignements importants relatifs à

l'installation, au fonctionnement ou à l'entretien. Toutefois, ceux-ci n'impliquent

aucune notion de danger.

LISTE DE VÉRIFICATION POUR L'INSTALLATION

Portes

La porte se ferme hermétiquement sur la caisse

de tous les côtés

La porte est à niveau sur toute sa partie

supérieure

Mise à niveau

L'appareil est à niveau d'un côté à l'autre et

incliné de 6 mm (1/4 po) de l'avant vers l'arrière

Les quatre coins de la caisse reposent

fermement sur le plancher

Alimentation en électricité

Le système électrique de la maison

est sous tension

L'appareil est branché

Vérifications finales

Le matériel d'expédition a été enlevé

Les températures de l'appareil sont réglées

La carte d'enregistrement a été postée

SÉCURITÉ DES ENFANTS

Détruisez ou recyclez le carton, les sacs en plastique et tout autre matériau d'emballage externe

immédiatement après avoir déballé l'appareil. Les enfants ne devraient JAMAIS jouer avec ces articles.

Les boîtes de carton recouvertes de tapis, de couvre-lits, de feuilles de plastique ou de pellicule étirable

peuvent se transformer en chambres hermétiques et rapidement provoquer une suffocation.

1

Page 23

MISE AU REBUT APPROPRIÉE DE VOTRE APPAREIL ÉLECTROMÉNAGER

RISQUES D'ENFERMEMENT DES ENFANTS

Les dangers d'enfermement et de suffocation des enfants constituent un problème dont il faut

sérieusement tenir compte. Les appareils électroménagers abandonnés ou mis au rebut sont

dangereux, même si ce n'est « que pour quelques jours ». Si vous désirez vous défaire de votre

vieil appareil électroménager, veuillez suivre les instructions ci-dessous afin d'aider à prévenir

les accidents.

MISE AU REBUT APPROPRIÉE DE L'APPAREIL ÉLECTROMÉNAGER

Nous encourageons fortement les méthodes responsables de recyclage et de mise au rebut des

appareils électroménagers. Vérifiez auprès de votre entreprise de services publics ou visitez le site

www.energystar.gov/recycle pour de plus amples renseignements sur comment recycler votre vieil

appareil électroménager.

AVANT DE METTRE VOTRE VIEIL APPAREIL

ÉLECTROMÉNAGER AU REBUT :

• Enlevez les portes.

• Laissez les clayettes en place pour que les enfants ne puissent pas

grimper facilement à l'intérieur.

• Faites retirer le fluide frigorigène par un technicien en entretien

et en réparation qualifié.

AVERTISSEMENT vous devez suivre ces instructions pour que les mécanismes de

sécurité de cet appareil fonctionnent correctement.

INFORMATION CONCERNANT L'ÉLECTRICITÉ

• L'appareil doit être branché que dans sa propre prise électrique CA de 115 V et 60 Hz. Le cordon

d'alimentation de l'appareil est muni d'une fiche à trois broches avec mise à la terre pour vous

protéger contre les chocs électriques. Cette fiche doit être branchée directement dans une prise à

trois branches avec mise à la terre. La prise murale doit être installée conformément aux codes et

règlements locaux. Consultez un électricien qualifié. Évitez de brancher le refroidisseur de baril à

bière à un circuit muni d'un disjoncteur de fuite à la terre (GFI). N'utilisez pas de rallonge électrique

ou d'adaptateur.

• Si le cordon d'alimentation est endommagé, il doit être remplacé par un technicien en entretien et

réparation autorisé afin d'éviter tout accident.

• Ne débranchez jamais l'appareil en tirant sur le cordon d'alimentation. Tenez toujours la fiche

fermement en la tirant en ligne droite pour la retirer de la prise afin d'éviter d'endommager le cordon.

• Pour éviter les chocs électriques, débranchez l'appareil avant de le nettoyer ou de remplacer une

ampoule.

• Une tension variant de 10 % ou plus risque de nuire au rendement de l'appareil. Le fait de faire

fonctionner l'appareil avec une alimentation insuffisante peut endommager le compresseur. Un

tel dommage n'est pas couvert par votre garantie.

• Ne branchez pas l'appareil dans une prise commandée par un interrupteur mural ou un cordon de

tirage pour éviter que l'appareil ne soit accidentellement mis hors tension.

IMPORTANT Le fait de tourner la commande à la position

« OFF » met le compresseur hors fonction et

désactive les fonctions de refroidissement, mais ne coupe

pas l'alimentation des autres composants électriques. Pour

couper l'alimentation de votre appareil, vous devez débrancher

le cordon d'alimentation de la prise murale.

2

Page 24

AVERTISSEMENT

MANIPULATION SÉCURITAIRE DU CONTENANT DE CO

2

• Les contenants de CO2 doivent être manipulés avec beaucoup de prudence. Ils contiennent

un gaz comprimé haute pression potentiellement dangereux. Assurez-vous de lire et

comprendre ces instructions avant de procéder à l'installation.

• Ne jamais recharger une bouteille de CO

dans des endroits comme des magasins de matériel de soudure, d'accessoires de fêtes,

vous-même. Vous pouvez les faire recharger

2

de matériel de prévention des incendies ou là où l'on vend des barils à bière.

• TOUJOURS raccorder les contenants de CO

• Ne JAMAIS laisser tomber ou lancer le contenant de CO

• Ne JAMAIS raccorder un contenant de gaz directement au baril à bière.

• TOUJOURS entreposer les contenants de CO

les tenir loin des sources de chaleur.

• Si une fuite de CO

• TOUJOURS vous assurer que le contenant est en position verticale et qu'il ne peut tomber.

survient, bien aérer et évacuer la zone immédiatement.

2

à un régulateur de pression.

2

dans un endroit frais (21ºC/70º F ou moins) et

2

.

2

• Vérifiez la date du test du ministère des Transports sur le goulot du contenant et ne l'utilisez

pas si elle date de plus de cinq (5) ans.

• Retournez les contenants périmés à votre détaillant de produits gazeux pour vous en procurer

respectant les délais prescrits.

3

Page 25

DÉBALLAGE ET MONTAGE

Ce manuel d'utilisation et d'entretien contient des instructions d'assemblage, d'utilisation et d'entretien

spécifiques à votre modèle. N'utilisez le refroidisseur de baril à bière que conformément aux

instructions présentées dans ce Guide d'utilisation et d'entretien. Avant de mettre le refroidisseur de

baril à bière en marche, suivez ces premières étapes importantes.

PIÈCES

Votre refroidisseur de baril à bière est livré avec plusieurs petites boîtes contenant toutes les pièces

et accessoires requis. Assurez-vous d'avoir reçu tous les composants énumérés ci-dessous.

BOÎTE DE LA TROUSSE DE

DISTRIBUTION DE BOISSON

(1) Plateau d'égouttement

(2) Roulettes et rondelles

(3) Courroie de retenue

(4) Bouchon cache-trou

(5) Poignée du robinet

(6) Régulateur de CO

de plastique)

(7) Coupleur du baril

(8) Petit tuyau (conduite du gaz)

(9) Joint d'étanchéité en caoutchouc (noir)

(Pour le bas de la tour distributrice)

(10) Barre de retenue

(11) Tour distributrice (avec robinet)

(12) Contenant de CO

(13) Sac de pièces de rechange

(joints et rondelles de rechange)

(avec rondelle

2

(vide)

2

1 pièce

4 pièce

1 pièce

1 pièce

1 pièce

1 pièce

1 pièce

1 pièce

1 pièce

1 pièce

1 pièce

1 pièce

1 sac

REMARQUE

Dans la boîte se trouve un coupleur de baril de type « Système D » (7). Selon votre choix de

bière, vous pourriez avoir besoin d'un autre type de coupleur de baril (7). Vérifiez auprès de

votre distributeur de bière le type de système le plus approprié à vos besoins et, au besoin,

commandez des coupleurs de barils additionnels.

4

Page 26

APERÇU DES CARACTÉRISTIQUES

59,4 cm

(23-3/8 po)

35,2 cm

(13-7/8 po)

41,0 cm (16-1/8 po) 41,0 cm (16-1/8 po)

23,5 cm (9-1/4 po)

5

59,4 cm

(23-3/8 po)

28,3 cm (11-1/8 po)

Page 27

ASSEMBLAGE ET INSTALLATION

Ce guide d'utilisation et d'entretien contient des instructions d'utilisation propres à votre modèle.

N'utilisez cet appareil que conformément aux instructions présentées dans ce Guide d'utilisation et

d'entretien. Avant de mettre l'appareil en marche, suivez ces premières étapes importantes.

EMPLACEMENT

• Choisissez un emplacement près d'une prise électrique avec mise à la terre. N'utilisez pas de

rallonge électrique ou de fiche d'adaptation.

• Si possible, placez l'appareil à l'abri de la lumière directe du soleil, et loin de la cuisinière, du

lavevaisselle et de toute autre source de chaleur.

• Pour un rendement optimal, cet appareil ne doit être utilisé qu'à l'intérieur dans des conditions

ambiantes normales.

• L'appareil doit être installé sur un plancher qui est à niveau et assez solide pour le supporter

adéquatement quand il est rempli à pleine capacité.

• Si l’appareil a été mis en position horizontale ou inclinée pour une période de temps, quelle qu'elle

soit, veuillez attendre au moins 24 heures avant de le brancher.

INSTALLATION DES ROULETTES

Suivez les étapes ci-dessous pour installer les roulettes.

1. Videz entièrement l'intérieur de la caisse et couchez le refroidisseur de baril à bière sur le côté.

Nous vous recommandons de mettre un morceau de carton ou de tissu sous la caisse pour éviter

d'endommager ou de rayer la surface.

2. Insérez les roulettes dans les trous situés aux coins inférieurs de la caisse. Serrez chacune des

roulettes en tournant la tête des boulons vers la droite à l'aide d'une clé à molette (n'est pas fournie

dans la trousse de l'appareil).

3. Une fois les quatre roulettes fixées solidement, mettez la caisse en position verticale.

REMARQUE : deux des roulettes comprennent un mécanisme de blocage pour garantir que

l'appareil ne glisse pas sur les planchers dont les surfaces sont dures. Ces deux roulettes à

blocage doivent être fixées sur le bord avant de l'appareil, les deux autres sur le bord arrière.

INSTALLATION DU ROBINET À BIÈRE

Des encoches au bas de la tour distributrice s'alignent avec des rainures dans l'ouverture sur le dessus

du refroidisseur de baril à bière. Alignez la tour distributrice avec l'ouverture sur le dessus de l'appareil,

puis placez-la à l'intérieur et tournez vers la droite jusqu'à ce qu'elle soit bien fixée. Utilisez quatre vis

pour fixer le robinet de bière. Assurez-vous d'utiliser le mince joint d'étanchéité noir (9) lors de

l'assemblage (voir l'illustration). Si vous trouvez qu'il est difficile de le faire faute d'espace, mettez un

peu d'eau savonneuse

6

Page 28

INSTALLATION DE LA BARRE DE RETENUE

Suivez les étapes ci-dessous pour installer la barre de retenue.

1. Placez la barre de retenue sur le dessus de la caisse.

2. Alignez tous les supports de la barre de retenue avec les trous sur le dessus de l'appareil et

appuyez pour les insérez à leur place.

ATTENTION : n'installez pas l'appareil à un endroit où la température pourrait descendre en

dessous de 13 °C (55 °F) ou s'élever à plus de 32 °C (90 °F). Le compresseur ne pourrait pas

maintenir des températures appropriées à l'intérieur de l'appareil.

INSTALLATION

Dégagements pour l'installation

• Prévoyez les dégagements suivants pour une installation plus facile, une circulation d'airappropriée

et pour les raccordements électriques :

Côtés et dessus 13 cm (5 po)

Arrière 13 cm (5 po)

REMARQUE : si votre appareil est positionné contre un mur du côté des charnières, prévoir

plus d'espace pour permettre à la porte de s'ouvrir davantage.

MISE À NIVEAU

Les quatre roulettes de votre appareil doivent reposer fermement sur un plancher solide. Utilisez une

clé à molette pour régler la hauteur des vis de mise à niveau.

ATTENTION : n'essayez pas de déplacer ou de relocaliser le refroidisseur de baril à bière

quand il contient un baril à bière.

INSTALLATION DU RÉGULATEUR

• Assurez-vous que la rondelle de plastique est à l'intérieur de

Un écrou

hexagonal

l'écrou hexagonal.

• Fixez le régulateur de CO2 (6) au contenant de CO2 (12). Placez

le régulateur à la droite du réservoir.

• Serrez bien l'écrou hexagonal. Ne le serrez PAS trop fort. Le fait de

le serrer trop fort risquerait d'endommager le joint d'étanchéité

dans l'écrou du régulateur.

RACCORDEMENT DU PETIT TUYAU DE CO2 AU RÉGULATEUR

• Fixez l'écrou à oreilles de l'extrémité du petit tuyau (8) au raccord situé dans le bas du régulateur (6).

7

Page 29

RACCORDEMENT DU PETIT TUYAU DE CO2 AU

COUPLEUR

• Fixez l'autre bout du petit tuyau (8) à l'extrémité filetée du coupleur

du baril (7), tel qu'illustré. Assurez-vous de bien serrer le raccord.

REMARQUE : selon votre choix de bière, vous pourriez avoir besoin

d'un autre type de coupleur de baril (7). Vérifiez auprès de votre

distributeur de bière le type de système le plus approprié à vos

besoins et, au besoin, commandez des coupleurs de barils

additionnels.

RACCORDEMENT DU TUYAU TRANSPARENT AU

COUPLEUR

• Placez l'une des rondelles de caoutchouc fournies dans l'écrou à

oreilles de l'une des extrémités du tuyau transparent (8) (conduite

d'alimentation de la boisson) et fixez-le au coupleur du baril (7).

Assurez-vous de bien serrer l'écrou pour prévenir les fuites. Ne le

serrez PAS trop fort. Le fait de le serrer trop fort risquerait

d'endommager le joint d'étanchéité dans l'écrou.

INSTALLATION DU COUPLEUR AU BARIL

• Alignez les arrêts du coupleur du baril (7) avec l'embout sur le

dessus du baril et appuyez en poussant le coupleur du baril (7) vers

le bas. Assurez-vous que la poignée supérieure est en position levée.

• Faites pivoter la poignée du robinet vers la droite de 1/4 de tour. La

poignée du robinet est dorénavant fixée au baril.

• Tirez la poignée du robinet vers l'extérieur, puis poussez vers le bas

jusqu'à ce qu'elle s'enclenche à sa place en ouvrant l'orifice dans le

baril.

PRESSURISATION DU TUYAU D'ALIMENTATION

• Ouvrez la vanne du contenant de CO2 en la tournant vers la gauche

jusqu'au bout. Cette vanne est scellée quand elle est entièrement

ouverte ou entièrement fermée. Le fait de ne pas l'ouvrir ou de ne

pas la fermer entièrement pourrait provoquer une perte prématurée

de pression du CO2.

• Ouvrez le robinet d'arrêt du régulateur en le plaçant à la position

« 6 heures » (s'il s'agissait d'une horloge).

• Vérifier la pression sur l'indicateur de pression. Ajustez le bouton de

réglage du régulateur si nécessaire, jusqu'à ce que la pression se

situe entre 12 et 14 lb/po². Il est possible que vous ayez à desserrer la vis située derrière le bouton.

Une fois la pression ajustée correctement, vous pouvez resserrer la vis pour que le bouton de

commande soit verrouillé dans cette position.

8

Page 30

INSTALLATION DU CONTENANT DE CO2 À LA CAISSE

• Soulevez et placez le contenant de CO2 (12) auprès du régulateur de CO2 (6) sur la tablette située

dans le coin arrière droit de la caisse. Il est important de conserver le contenant en position verticale

pour qu'il fonctionne de manière efficace. Accrochez l'une des extrémités de la courroie de retenue (3)

au support en métal à l'arrière, puis étirez-la autour du baril en fixant l'autre bout au support avant.

INSTALLATION DU BARIL À LA CAISSE

• Placez le baril sur la clayette et poussez-le à côté du contenant

de CO2 (12) (voir les CONSEILS POUR L'INSTALLATION DU

BARIL À LA CAISSE) à l'intérieur de la caisse, tel qu'illustré.

CONSEILS POUR L'INSTALLATION DU BARIL À LA CAISSE

AVERTISSEMENT

MANIPULATION SÉCURITAIRE DU BARIL

• Pour installer un baril dans la caisse, il faut être deux. Ne soulevez JAMAIS un baril plein

seul. Vous pourriez vous blesser grièvement.

• En laissant la porte grande ouverte et avec l'aide d'une autre personne, soulevez le baril à la

verticale des deux côtés jusqu'à ce que le baril soit plus haut que la clayette qui le supportera.

• Placez le bord du baril sur le dessus du plateau de protection en plastique situé sur le dessus

de la clayette. Faites glisser le baril jusqu'au fond de la caisse.

• Il faut faire attention à ne pas endommager la commande de température et la tour de la

clayette dans la caisse.

REMARQUE: par souci de clarté, l'illustration ci-dessus ne montre pas le robinet installé.

9

Page 31

DISPOSITION DU TUYAU D'ALIMENTATION

Conduite

de bière

Tour

distributrice

de bière

Coupleur

du baril

Relâchement

de pression

Conduite de CO

Robinet basse

pression à

manomètre

du régulateur

de CO

2

2

Robinet haute

pression

fermeture de sécurité

pour bouteille de CO

2

ATTENTION : si les tuyaux ne sont pas correctement disposés, ils pourraient se tordre ou

rester coincés dans la porte.

FONCTIONNEMENT DE VOTRE REFROIDISSEUR DE BARIL À BIÈRE

• Assurez-vous que le refroidisseur de baril à bière est bien branché dans une prise électrique de

115 V, 60 Hz et 15 A, CA uniquement.

• Assurez-vous que le plateau d'égouttement et le puisard sont bien fixés sous le robinet.

• Commencez en utilisant un verre à boisson propre mouillé dans de l'eau froide. Placez le verre à un

angle de 45º, un pouce sous le robinet. Ne laissez pas le verre toucher le robinet. Ouvrez le

robinet entièrement.

• Une fois le verre à moitié rempli, ramenez peu à peu le verre en position verticale.

• Laissez le reste de la boisson couler directement au milieu du verre. Procéder ainsi permet de

garantir une distribution appropriée de CO2 en produisant de 1,9 à 2,5 cm (3/4 à 1 po)o de mousse

en surface.

• Fermez entièrement et rapidement le robinet.

REMARQUE : il est normal que de la condensation s'accumule autour du robinet. Cette

condensation est provoquée par les écarts de températures entre la boisson froide et les

parois intérieures du robinet quand la boisson circule dans la conduite.

10

Page 32

COMMENT REMPLACER UN CONTENANT DE CO2 VIDE

• Retirez les tuyaux des agrafes de cheminement.

• Retirez le baril, puis retirez le contenant de CO2.

• Fermez la vanne du contenant vide en la tournant vers la droite jusqu'au bout.

• Fermez le robinet d'arrêt du régulateur en le plaçant à la position « 9 heures » (s'il s'agissait d'une

horloge).

• Retirez avec précaution le régulateur du contenant de CO2 vide en desserrant l'écrou à l'aide d'une

clé à molette. Vérifiez la condition du joint d'étanchéité dans l'écrou et remplacez-le si nécessaire.

• Rapportez le contenant à votre détaillant de gaz carbonique local pour le faire recharger. (Nous vous

suggérons de chercher dans les pages jaunes sous la rubrique « Gaz carbonique ». Les fournisseurs

de CO2 varient d'un endroit à l'autre, on en retrouve toutefois souvent dans des magasins vendant

des articles de soudure ou chez les distributeurs de boissons.)

• Si nécessaire, retirez le capuchon antipoussière de l'écrou du nouveau contenant.

• Alors que le contenant est toujours fermé, refixez le régulateur au nouveau contenant à l'aide d'une

clé à molette. Assurez-vous que la rondelle de plastique est à l'intérieur de l'écrou. Serrez bien

l'écrou, mais faites attention à ne pas le serrer trop fort, car cela risquerait d'endommager le joint

d'étanchéité à l'intérieur de l'écrou de la tige.

• Assurez-vous que le tuyau tressé de la conduite de gaz est toujours solidement fixé au régulateur.

• Ouvrez entièrement la vanne du contenant en la tournant vers la gauche jusqu'au bout. Cette vanne

est scellée quand elle est entièrement ouverte ou entièrement fermée. Le fait de ne pas l'ouvrir ou

de ne pas la fermer entièrement pourrait provoquer une perte prématurée de pression du CO2.

• Ouvrez le robinet d'arrêt du régulateur en l'abaissant à la position « 6 heures » (s'il s'agissait

d'une horloge).

• Vérifier la pression sur l'indicateur de pression. Ajustez la vis de réglage du régulateur si nécessaire,

jusqu'à ce que la pression se situe entre 12 et 14 lb/po². Serrez l'écrou autofreiné d'ajustement.

• Remettez le baril et les agrafes de cheminement du tuyau.

11

Page 33

INSTRUCTIONS POUR LE RETRAIT DES PORTES

REMARQUE : il est possible d'inverser l'orientation de l'ouverture de la porte de votre appareil,

de gauche à droite ou de droite à gauche, en déplaçant les charnières d'un côté à l'autre.

L'inversion des portes doit être effectuée par une personne qualifiée.

IMPORTANT : avant de commencer, tournez la commande de température de l'appareil à «OFF»

et débranchez le cordon d'alimentation de la prise murale. Retirez tous les aliments des

tablettes de la porte.

DÉPOSE ET INVERSION DE LA PORTE :

1 Retirez la tour distributrice de l'appareil.

2 Retirez les trois (3) vis du bord arrière du revêtement supérieur, puis soulevez-le à l'arrière et

glissez-le vers l'avant pour l'enlever (voir la Figure A).

3 Retirez deux (2) vis de la charnière supérieure de la porte et soulevez la porte pour la retirer de la

bague (voir la Figure B).

4 Sortez la porte de la charnière en la tirant vers le haut.

5 Retirez la charnière inférieure du coin droit de la caisse et déplacez-la vers le côté opposé

(voir la Figure C).

6 Réinstallez la porte en alignant la bague du côté gauche avec la cheville de la charnière.

7 Réinstallez la charnière supérieure sur le côté opposé de la caisse et installez le revêtement

supérieur en suivant l'ordre inverse de l'étape 2.

12

Page 34

COMMANDES DE TEMPÉRATURE

PÉRIODE DE REFROIDISSEMENT

Pour un bon fonctionnement, laissez l'appareil fonctionner la porte close pendant au moins 12 heures

avant d'y mettre un baril à bière.

COMMANDES DU REFROIDISSEUR DE BARIL À BIÈRE

Commande de température

Ce bouton de commande rotatif est la commande principale de la température du compartiment

réfrigérateur. Si l'appareil est trop chaud, tournez cette commande vers la position « Max ». Si l'appareil

est trop froid, tournez cette commande vers la position « Min ».

RÉGLAGE ET AJUSTEMENT DE LA TEMPÉRATURE

Pour entreposer la bière, il est recommandé de régler au départ la température à cinq « Med ».

Dans la plupart des conditions, ce réglage permettra à la bière distribuée d'atteindre une température

entre 1 ºC et 3 ºC (34 ºF et 38 ºF). Vous pouvez régler la température en fonction de vos goûts

personnels et les conditions de fonctionnement du refroidisseur de baril à bière. Une fois la commande

ajustée, toujours attendre 24 heures pour permettre à la bière de se stabiliser à la nouvelle température

avant de faire d'autres ajustements.

IMPORTANT : le fait de tourner la commande de l'appareil à « OFF » met le compresseur hors

fonction, mais ne coupe pas l'alimentation de l'ampoule ni des autres composants électriques.

Pour couper l'alimentation de votre appareil, vous devez débrancher le cordon d'alimentation

de la prise murale..

REMARQUE : quand vous achetez un baril à bière, toujours l'acheter déjà froid (à moins de

3 ºC (38 ºF), le transporter le plus rapidement possible et l'installer dans l'appareil froid dans

les deux (2) heures suivantes. Dans la plupart des conditions, ces instructions permettront de

servir la bière à une température appropriée dans les 24 heures. Le fait d'acheter le baril à une

température supérieure à 3 ºC (38 ºF) ou de l'exposer à des températures élevées pendant plus

de deux (2) heures fera en sorte qu'il faudra plus de temps pour refroidir la bière à une

température optimale pour la consommation.

13

Page 35

CONSEILS UTILES

COMPOSANTS D'UN RÉGULATEUR DE CO

(A) Manomètre basse pression

(B) Bouton d'ajustement

(C) Vis de verrouillage pour ajustement

(D) Robinet d'arrêt

(E) Écrou du CO2 (utilisé pour raccorder le contenant de CO2)

(F) Manomètre haute pression

2

TEMPÉRATURE DE CONSERVATION DE LA BIÈRE

• La bière en baril à bière n'est pas pasteurisée, il faut donc la conserver au froid, de préférence à

3 ºC (38 ºF). Des températures de plus de 3 ºC (38 ºF) pourraient faire mousser la bière davantage,

la rendre aigre et trouble. (F) Manomètre haute pression

MANIPULATION RECOMMANDÉE DU BARIL

• Assurez-vous que le baril est froid quand vous l'achetez.

• Transférez le baril du lieu où vous l'avez acheté et installez-le dans le refroidisseur de baril à bière

dans les deux (2) heures suivantes ou moins.

• Une fois le baril installé dans le refroidisseur de baril à bière, attendez 24 heures afin de permettre à

la boisson d'atteindre la température recommandée.

• Si le baril est exposé à des températures ambiantes plus de deux (2) heures, il faudra le laisser se

refroidir plus longtemps pour atteindre la température recommandée. CONSEILS UTILES ATTENTION

N'essayez PAS de déplacer ou de relocaliser le refroidisseur de baril à bière quand il contient un baril

de bière. ÉQUIVALENCES HABITUELLES

ÉQUIVALENCES HABITUELLES DE QUANTITÉS DE BIÈRE

¼ de baril ½ baril

Onces 992

Litres/Gallons

Caisses (bouteilles de

355 mL (12 oz.))

29 L / 7,75 gal

3 3/8 (82 bouteilles)

1984

58 L / 15,5 gal

6 3/4 (165 bouteilles)

Poids (complet)

ATTENTION : n'essayez PAS de déplacer ou de relocaliser le refroidisseur de baril à bière

quand il contient un baril de bière.

37 kg / 82,5 lb 75 kg / 165 lb

14

Page 36

CONSEILS POUR ÉCONOMISER L'ÉNERGIE

• Installez le refroidisseur de baril à bière dans la partie la plus fraîche de la

pièce, à l'abri du soleil direct et loin des conduits d'air chaud ou des registres.

Ne placez pas le refroidisseur de baril à bière à côté d'appareils qui produisent

de la chaleur tels une cuisinière, un four ou un lave-vaisselle.

• Évitez de surcharger le refroidisseur de baril à bière ou de bloquer les évents

d'air froid. Ceci pourrait faire fonctionner le refroidisseur de baril à bière plus

longtemps et consommer plusd'énergie.

• Disposez les contenants dans le refroidisseur de baril à bière de façon à

limiter le nombre de fois où il faudra ouvrir la porte. Prévoyez de prendre

plusieurs articles à la fois et refermez immédiatement la porte.

CONSEILS POUR LES VACANCES ET LES DÉMÉNAGEMENTS

Vacances de courte

durée

Vacances plus

longues

Déménagement • NE JAMAIS DÉPLACER LE REFROIDISSEUR DE BARIL À BIÈRE QUAND IL

• Laissez le refroidisseur de baril à bière fonctionner pour des vacances de trois (3)

semaines ou moins.

• Ne laissez aucun aliment périssable dans le compartiment du refroidisseur de baril à bière.

• Si vous prévoyez être absent un mois ou plus, retirez tous les aliments et tous les glaçons.

• Tournez les commandes à la position OFF et débranchez le cordon d'alimentation.

• Nettoyez l'intérieur à fond.

• Laissez la porte ouverte pour empêcher l'accumulation d'odeurs et de moisissures.

Si nécessaire, bloquez la porte pour qu'elle reste ouverte.

CONTIENT UN BARIL À BIÈRE.

• Si vous utilisez un diable, chargez-le sur le côté.

•

le déménagement.

• Enveloppez la caisse pour éviter d'égratigner la surface.

BRUITS ET ÉLÉMENTS VISUELS D'UN FONCTIONNEMENT NORMAL

COMPRENDRE LES BRUITS QUE VOUS ENTENDEZ

Votre nouveau refroidisseur de baril à bière pourrait émettre des bruits qui ne vous sont pas familiers.

Ces bruits indiquent habituellement que votre refroidisseur de baril à bière fonctionne correctement.

Certaines surfaces, notamment le plancher, les murs et les armoires de cuisine, peuvent amplifier ces

bruits.

REMARQUE : l'isolant en mousse rigide est efficace pour conserver l’énergie, mais il n'est pas

destiné à servir d'isolant acoustique.

Voici la liste des principaux composants de votre refroidisseurde baril à bière et des sons qu'ils

peuvent émettre :

Évaporateur La circulation du fluide frigorigène dans l'évaporateur peut faire un bruit de

bouillonnement ou de gargouillement.

Commande électronique et commande de dégivrage automatique Ces pièces peuvent émettre un

déclic ou un cliquetis lorsque le système de refroidissement s'arrête ou se remet en marche.

Compresseur Les compresseurs modernes à haut rendement énergétique fonctionnent beaucoup plus

vite que les anciens compresseurs. Le compresseur peut émettre un ronronnement aigu ou des pulsations.

Plateau de dégivrage (inamovible) Vous pourriez entendre l'eau qui tombe dans le plateau de

dégivrage pendant le cycle de dégivrage.

Conseils pour les vacances et les déménagements

15

Page 37

ENTRETIEN ET NETTOYAGE

PROTÉGER VOTRE INVESTISSEMENT

Gardez votre refroidisseur de baril à bière propre pour préserver son apparence et empêcher

l'accumulation d'odeurs. Essuyez immédiatement tout renversement et nettoyez le refroidisseur de

baril à bière au moins deux fois par année. Lorsque vous effectuez ce nettoyage, prenez les

précautions suivantes :

• Ne jamais utiliser de CHLORURE ou de nettoyants avec agent de blanchiment pour nettoyer l'acier

inoxydable.

• Ne lavez aucune pièce amovible dans un lave-vaisselle.

• Vous devez toujours débrancher le cordon d’alimentation de la prise murale avant le nettoyage.

• Enlevez les étiquettes adhésives à la main. N'utilisez pas de lame de rasoir ou autre instrument

pointu pouvant égratigner

la surface de l'appareil.

• N'enlevez pas la plaque signalétique.

N'utilisez pas de nettoyant abrasif tel que du nettoyant pour les vitres, de la poudre à récurer, une brosse,

du liquide inflammable, de la cire nettoyante, du détersif concentré, un agent de blanchimentou du nettoyant

renfermant des produits à base de pétrole sur les pièces en plastique, les portes intérieures, les joints

ou les revêtements de la caisse. N'utilisez pas d'essuie-tout, de tampon à récurer métallique ou tout

autre matériau de nettoyage abrasif ou solution alcaline forte.

REMARQUE : si vous réglez la commande de température pour arrêter le système de

refroidissement, l'éclairage et les autres composants électriques continueront à fonctionner

jusqu'à ce que vous débranchiez le cordon d'alimentation de la prise murale..

ATTENTION : 1.Tirez le refroidisseur de baril à bière en ligne droite pour le déplacer. Le balancer

de gauche à droite pourrait endommager le plancher. Faites attention de ne pas déplacer le

refroidisseur de baril à bière au-delà de ce que permettent les raccordements de plomberie.

2 . Les objets humides collent aux surfaces de métal froides. Ne touchez pas aux surfaces

réfrigérées si vous avez les mains mouillées ou humides.

IMPORTANT : si vous entreposez ou déménagez votre refroidisseur de baril à bière dans des

températures sous le point de congélation, assurez-vous de vidanger complètement le système

d'alimentation en eau. Autrement, des fuites d'eau pourraient se produire lorsque vous

remettrez votre refroidisseur de baril à bière en marche. Adressez-vous à un représentant de

service après-vente pour faire effectuer cette opération.

Pièce Produits à utiliser Conseils et précautions

Intérieur et

revêtements de

porte

Joints de porte • Eau et savon Essuyez les joints avec un chiffon propre et doux.

Bacs et

compartiments

Extérieur et

poignées

Extérieur et

poignées

(modèles

en acier

inoxydable

seulement)

• Eau et savon

• Bicarbonate de soude et eau

• Eau et savon Utilisez un linge doux pour nettoyer les glissières et les rails des tiroirs.

• Eau et savon

• Nettoyant pour verre non

• Eau et savon

• Nettoyants pour acier

Conseils pour l'entretien et le nettoyage

Utilisez 30 mL (2 c. à table) de bicarbonate de soude dans 1 L (1 pinte)

d'eau chaude. Assurez-vous de bien essorer l'eau de l'éponge ou du

chiffon avant de nettoyer autour des commandes, de l'ampoule ou

de toute pièce électrique.

Pour nettoyer les poignées, n'utilisez pas de nettoyant ménager commercial

abrasif

inoxydable

à base d'ammoniaque, de javellisant ou d'alcool. Utilisez un linge doux

pour nettoyer les poignées. N'utilisez PAS de chiffon sec pour

nettoyer les portes lisses.

N'utilisez jamais de CHLORURE ni de nettoyant avec agent de

blanchiment pour

Nettoyez l'avant et les poignées en acier inoxydable avec de l'eau

savonneuse non abrasive et un linge à vaisselle. Rincez avec de l'eau

propre et un linge doux. Utilisez un nettoyant pour acier inoxydable

non abrasif. Ces nettoyants peuvent être achetés dans la plupart des

quincailleries et des grands magasins. Suivez toujours les directives du

fabricant. N'utilisez pas de nettoyant ménager à base d'ammoniaque ou

de d'agent de blanchiment.

REMARQUE : nettoyez, essuyez et asséchez toujours dans le sens

des stries pour éviter les égratignures. Lavez le reste de la caisse

avec de l'eau chaude et un détergent liquide doux. Rincez bien et essuyez

à sec avec un linge doux et propre.

16

nettoyer l'acier inoxydable.

Page 38

AVANT DE FAIRE APPEL AU SERVICE APRÈS-VENTE

PROBLÈME CAUSE POSSIBLE SOLUTION HABITUELLE

FONCTIONNEMENT DU REFROIDISSEUR DE BARIL À BIÈRE

Le refroidisseur de baril

à bière ne fonctionne

pas.

Le refroidisseur de

baril à bière fonctionne

trop souvent ou trop

longtemps.

La température

intérieure du

refroidisseur de baril à

bière est trop froide.

La température

intérieure du

refroidisseur de baril à

bière est trop chaude.

La température de la

surface externe du

refroidisseur de baril à

bière est élevée.

EAU/HUMIDITÉ/GIVRE À L'INTÉRIEUR DU REFROIDISSEUR DE BARIL À BIÈRE

De la condensation

se forme sur les

parois intérieures du

refroidisseur de baril à

bière.

EAU/HUMIDITÉ/GIVRE À L'EXTÉRIEUR DU REFROIDISSEUR DE BARIL À BIÈRE

De la condensation se

forme sur les parois

extérieures du refroidis seur de baril à bière.

ODEUR DANS LE REFROIDISSEUR DE BARIL À BIÈRE

Odeurs désagréables. • L'intérieur a besoin d'être nettoyé. • Nettoyez l'intérieur avec une éponge, de l'eau tiède et

PROBLÈMES DE PORTE

La porte ne ferme pas. • Le refroidisseur de baril à bière n'est pas

• Le circuit dans lequel le refroidisseur de

baril à bière est branché dispose d'un

disjoncteur de fuite de terre.

• La commande de température est en

position « O » (OFF).

• Le refroidisseur de baril à bière n'est pas

dans la prise murale.

• Un fusible est grillé ou un disjoncteur est

hors tension.

• Panne d'électricité.

• La température dans la pièce ou à

l'extérieur est chaude.

• Le refroidisseur de baril à bière a

récemment été débranché pendant un

certain temps.

• Les portes sont ouvertes trop souvent ou

trop longtemps.

• Il est possible que la porte du refroidisseur

de baril à bière soit entrouverte.

• Le réglage de la température est trop bas.

Le joint d'étanchéité du refroidisseur de baril

à bière est sale, usé, craquelé ou mal ajusté.

• Le réglage de la température est trop bas. • Ajustez la commande de température à un réglage plus

• Le réglage de la température est trop

chaud.

• La porte est ouverte trop longtemps ou

trop souvent.

• La porte se ferme peut-être mal.

• Le refroidisseur de baril à bière a récemment

été débranché pendant un certain temps.

• La température des parois extérieures

du refroidisseur de baril à bière peut être

jusqu'à 15 °C (30 °F) plus élevée que la

température ambiante.

• La température extérieure est chaude et

le niveau d'humidité est élevé.

• La porte se ferme peut-être mal.

• La porte est ouverte trop longtemps ou

trop souvent.

• La porte n'est peut-être pas bien fermée,

sant en sorte que de l'air froid provenant

fai

de l'intérieur du refroidisseur de baril à

bière entre en contact avec l'air chaud et

humide à l'extérieur.

à niveau.

• Branchez l'appareil dans un autre circuit. Si vous

• Consultez la rubrique AJUSTER LA COMMANDE DE

TEMPÉRATURE .

•

prise.

•

retardée de 15 A. Réinitialisez le disjoncteur.

•

fournisseur d'électricité local.

• Il est normal que le refroidisseur de baril à bière

fonctionne plus longtemps dans de telles conditions.

• Le refroidisseur de baril à bière a besoin d'environ

quatre (4) heures pour se refroidir complètement.

Le refroidisseur de baril à bière fonctionne davantage si

de l'air chaud y pénètre. Ouvrez la porte moins souvent.

• Consultez la rubrique PROBLÈMES DE PORTE.

• Ajustez la commande de température à un réglage plus

froid. Attendez quelques heures pour permettre à la

température de se stabiliser.

• Nettoyez ou remplacez le joint. Si le joint d'étanchéité

fuit, le refroidisseur de baril à bière doit fonctionner plus

longtemps pour maintenir la température désirée.

ttendez quelques heures pour permettre à la

chaud. A

température de se stabiliser.

• Ajustez la commande de température à un réglage plus