Frigidaire CGDS3065KF6, CGDS3065KF7, CPDS3085KF4, CPDS3085KF5, CPDS3085KF6 Installation Guide

...Page 1

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICALINSPECTOR"SUSE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire

or explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IFYOU SMELL GAS:

• Do not try to light any appliance.

Do not touch any electrkal switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor's phone. Follow the

gas supplier"s instructions.

If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

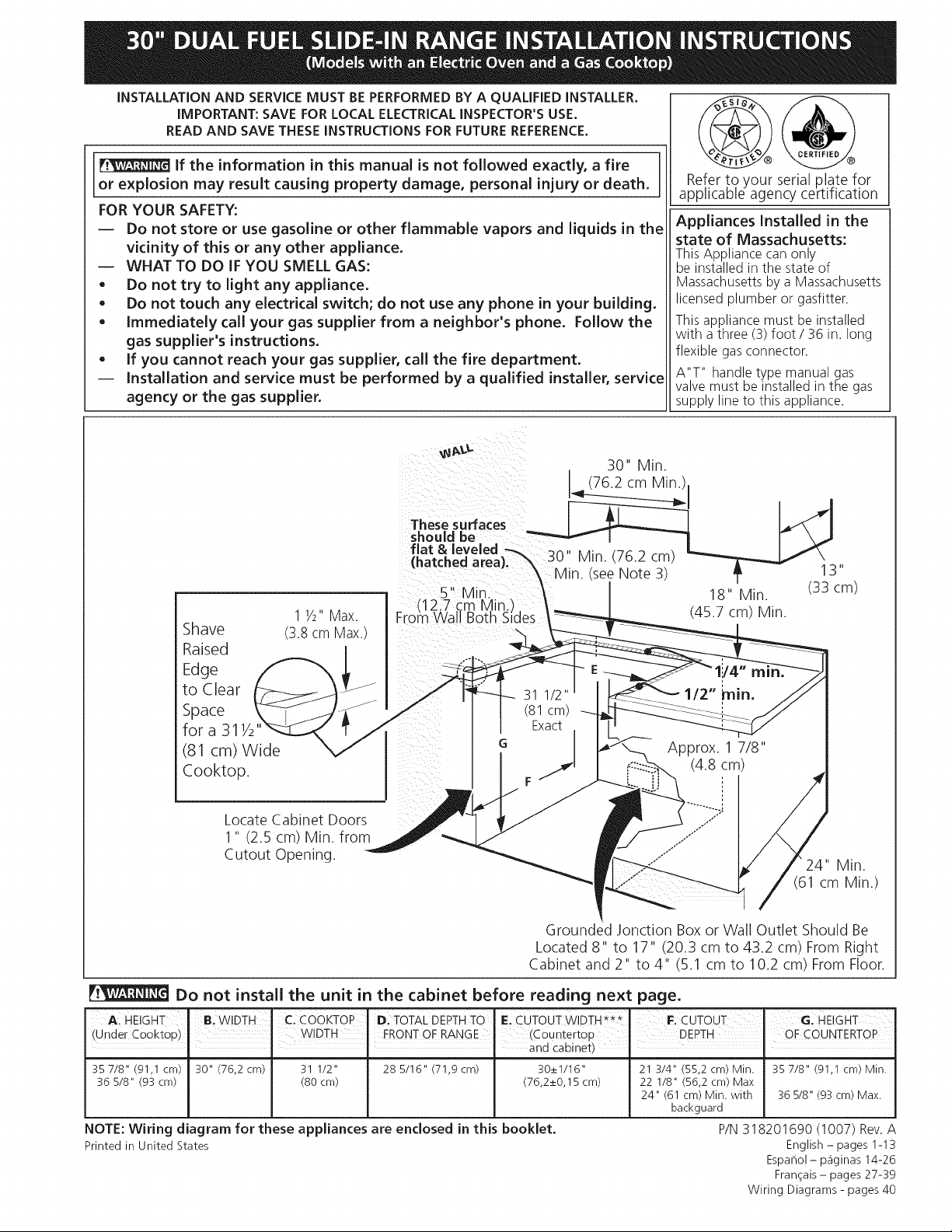

_LL

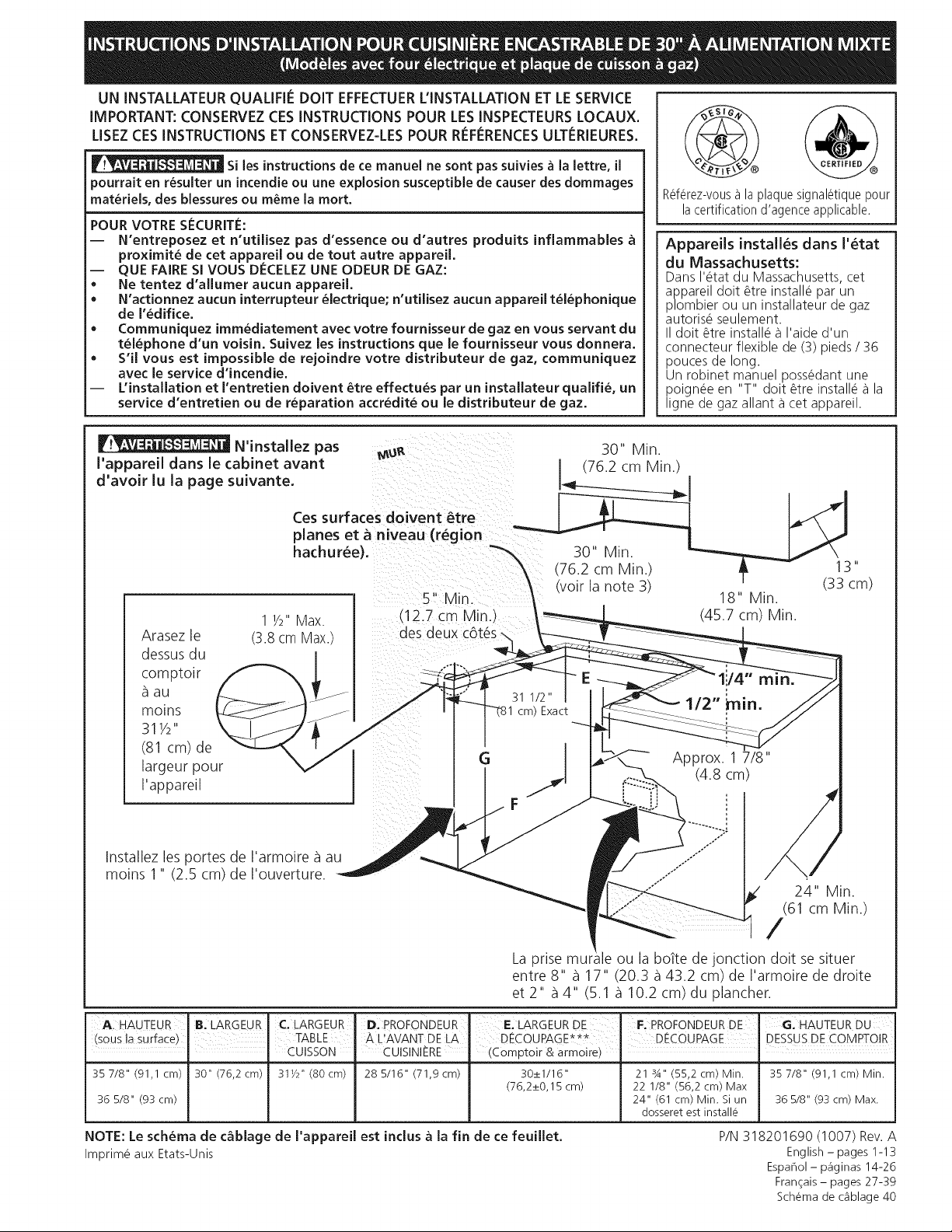

30" Min.

(76.2 cm Min.

These sutraces

should be

fiat

(hatched

30" Min. (76.2 cm)

Min. (see Note 3)

5" Min.

(12.7 cm Min.)

From Wall Both Sides

Shave

1 1/2"Max.

(3.8cm Max.)

Raised

Edge

to Clear

Space

fora 31_/2

I

31 1/2"

(81 cm)

Exact

(81 cm) Wide

Cooktop.

/ Approx. 1 718"(4.8 cm)

F

Refer to your serial plate for

applicable agency certitication

Appliances Installed in the

state of Massachusetts:

This Appliance can only

be installed in the state of

Massachusetts by a Massachusetts

licensed plumber or gasfitter.

This appliance must be installed

with a three (3) foot / 36 in. long

flexible gas connector.

A"T" handle type manual gas

valve must be installed in the gas

supply line to this appliance.

13"

18" Min.

(33 cm)

(45.7 cm) Min.

Locate Cabinet Doors

1" (2.5 cm) Min. from

Cutout Opening.

.......... 24" Min.

-' (61 cm Min.)

Grounded Jonction Box or Wall Outlet Should Be

Located 8" to 17" (20.3 cm to 43.2 cm) From Right

Cabinet and 2" to 4" (5.1 cm to 10.2 cm) From Floor.

Do not install the unit in the cabinet before reading next page.

A. HEIGHT B. WIDTH C. COOKTOP D. TOTAL DEPTH TO E. CUTOUTWDTH***' F:CUTOUT G. HEIGHT

(under C0oktop) I ERQNi-QF RANGE (C0untert0p DEPTH OF COUNTERTOP

35 718" (91,1 cm) 30" (76,2cm) 31 1/2" 28 5/16" (71,9cm) 30_+1/16"

36 5/8" (93 cm) (80 cm) (76,2_+0,15 cm)

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

Printed in United States

_ and Cabinet)

21 3/4" (55,2 cm) Min. 35 7/8" (91,1 cm) Min.

22 1/8" (56,2 cm) Max

24" (61 cm) Min. with 36 5/8" (93 cm) Max.

backguard

P/N318201690 (1007) Rev.A

English - pages 1-13

Espahol- p_iginas 14-26

Fran_ais - pages 27-39

Wiring Diagrams - pages 40

Page 2

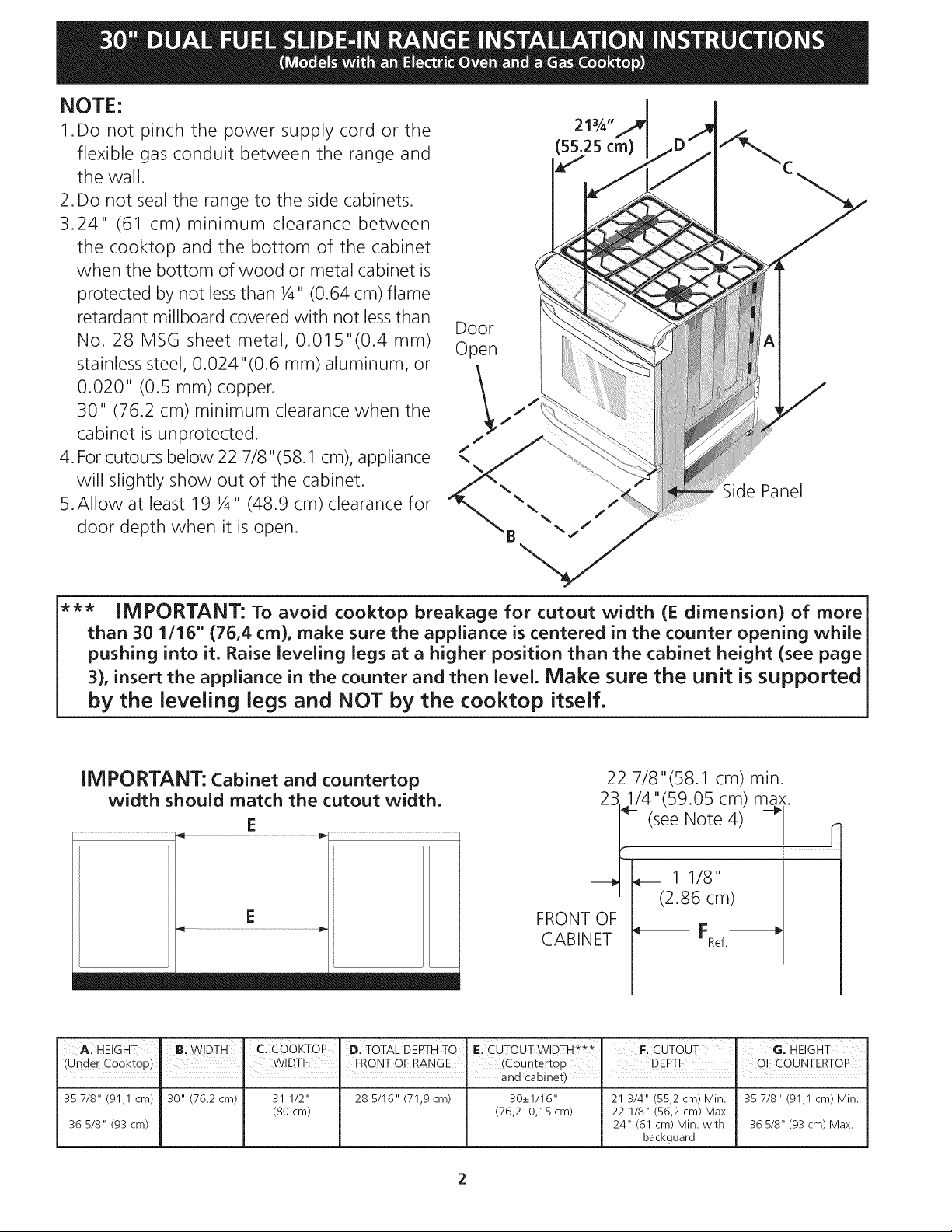

NOTE:

1. Do not pinch the power supply cord or the

flexible gas conduit between the range and

the wall.

2. Do not seal the range to the side cabinets.

3.24" (61 cm) minimum clearance between

the cooktop and the bottom of the cabinet

when the bottom of wood or metal cabinet is

protected by not lessthan ¼" (0.64 cm) flame

retardant millboard covered with not lessthan

No. 28 MSG sheet metal, 0.01 5"(0.4 ram)

stainless steel, 0.024"(0.6 ram) aluminum, or

0.020" (0.5 ram) copper.

30" (76.2 cm) minimum clearance when the

cabinet is unprotected.

4. Forcutouts below 22 7/8"(58.1 cm), appliance

will slightly show out of the cabinet.

5.Allow at least 19 ¼" (48.9 cm) clearance for

door depth when it is open.

I

Door

Open

Panel

*** IMPORTANT: To avoid cooktop breakage for cutout width (E dimension) of more

than 30 1/16" (76,4 cm), make sure the appliance is centered in the counter opening while

pushing into it. Raise leveling legs at a higher position than the cabinet height (see page

3), insert the appliance in the counter and then level. Make sure the unit is supported

by the leveling legs and NOT by the cooktop itself.

IMPORTANT: Cabinet and countertop

width should match the cutout width.

E

22 7/8"(58.1 cm) min.

23. 1/4"(59.05 cm) max.

F

F (see Note 4)

" (2.86 cm)

E

_ immmmmmmmml gmmmmmmmg

A HEIGHT ' B:WIDTH " C] CooKToP D. TOTAL DEPTH TO E. CUTOUTWIDTH***. F: CUTOUT I G: HEIGHT

(Under Cooktop) , WIDTH FRONTOF RANGE (Couotertop ] DEPTH OF COUNTERTOP

I ! ! I and cabinet) i i

35 7/8" (91,1 cm) 30"(76,2cm) 31 1/2" 28 5/16" (71,9cm) 30_+1/16" 21 3/4" (55,2cm) Min. 35 7/8" (91,1 cm) Min.

(80 cm) (76,2_+0,15 cm) 22 1/8" (56,2 cm) Max

36 5/8" (93 cm) 24" (61 cm) Min. with 36 5/8" (93 cm) Max.

FRONT OF

CABINET ,4_ FRef

-_1 _ 11/8" ,_

backguard

Page 3

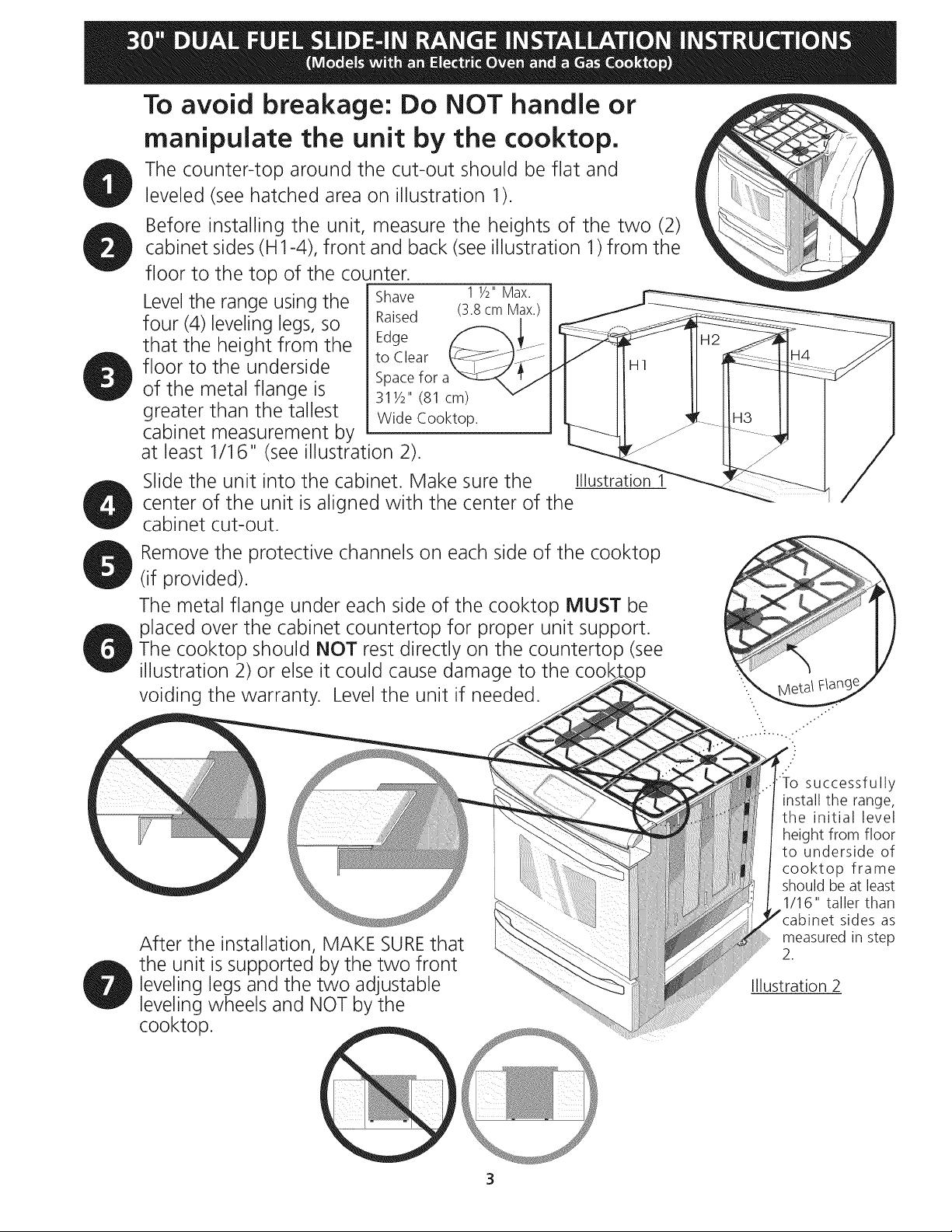

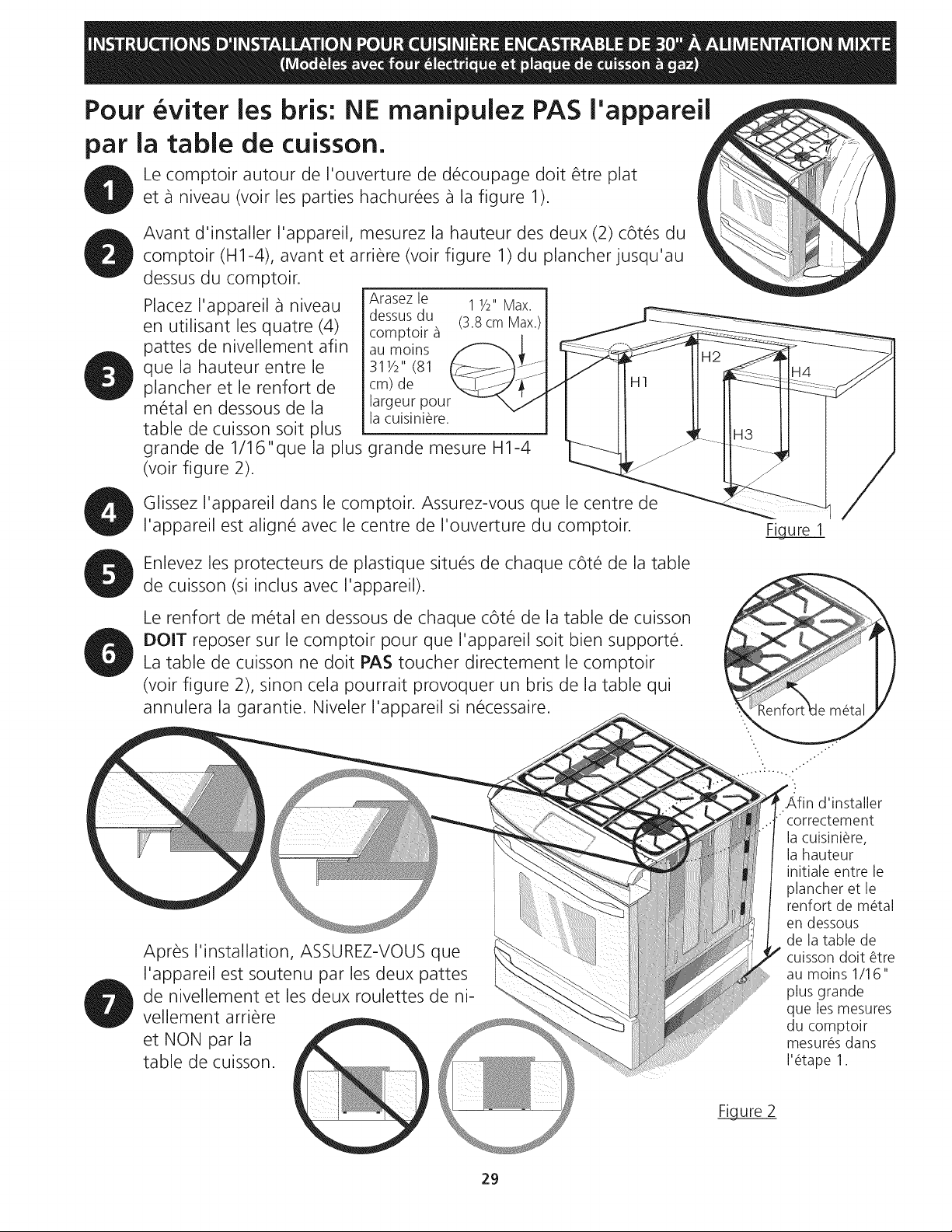

To avoid breakage: Do NOT handle or

manipulate the unit by the cooktop.

The counter-top around the cut-out should be flat and

leveled (see hatched area on illustration 1).

Before installing the unit, measure the heights of the two (2)

cabinet sides (H1-4), front and back (see illustration 1)from the

floor to the top of the counter.

Level the range using the

four (4)leveling legs, so

that the height from the

floor to the underside

of the metal flange is

greater than the tallest

cabinet measurement by

at least 1/16" (see illustration 2).

Slide the unit into the cabinet. Make sure the

center of the unit is aligned with the center of the

cabinet cut-out.

Remove the protective channels on each side of the cooktop

(if provided).

The metal flange under each side of the cooktop MUST be

placed over the cabinet countertop for proper unit support.

The cooktop should NOT rest directly on the countertop (see

illustration 2) or else it could cause damage to the

voiding the warranty. Level the unit if needed.

Shave

Raised

Edge

to Clear

Space for a

311/2" (81 cm)

Wide Cooktop.

Illustration 1

1

After the installation, MAKE SUREthat

the unit is supported by the two front

leveling legs and the two adjustable

leveling wheels and NOT by the

cooktop.

":1-osuccessfully

install the range,

the initial level

height from floor

to underside of

cooktop frame

should be at least

1/16" taller than

net sides as

measured in step

2.

Illustration 2

3

Page 4

important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Removeall packing material from the oven compartments

before connecting the gas and electrical supply to the

range.

3. Observe all governing codes and ordinances.

4. Besure to leave these instructions with the consumer.

5. Note: For operation at 2000 ft. elevations above see

level, appliance rating shall be reduced by 4 percent for

each additional 1000 ft.

important Note to the Consumer

Keep these instructions with your Owner's Guide for the

local electrical inspector's use and future reference.

IMPORTANT SAFETY

INSTRUCTION

_Jl_i_Co]d temperatures can damage the

electronic control. When using the appliance for the first

time, or when the appliance has not been used for an

extended period of time, be certain the unit has been

in temperatures above 32% (0°C) for at least 3 hours

before turning on the power to the appliance.

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1 / NFPA54 or CAN/ACG-B149.1

and CAN/ACG-B149.2.

This range has been design certified by CSA

international. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence, with

the National Electrical Code ANSI/NFPA No. 70---

latest edition in United States or with CSA Standard

C22.1, Canadian Electrical Code, Part I in Canada.

• The installation of appliances designed for

manufactured (mobile) home installation must conform

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

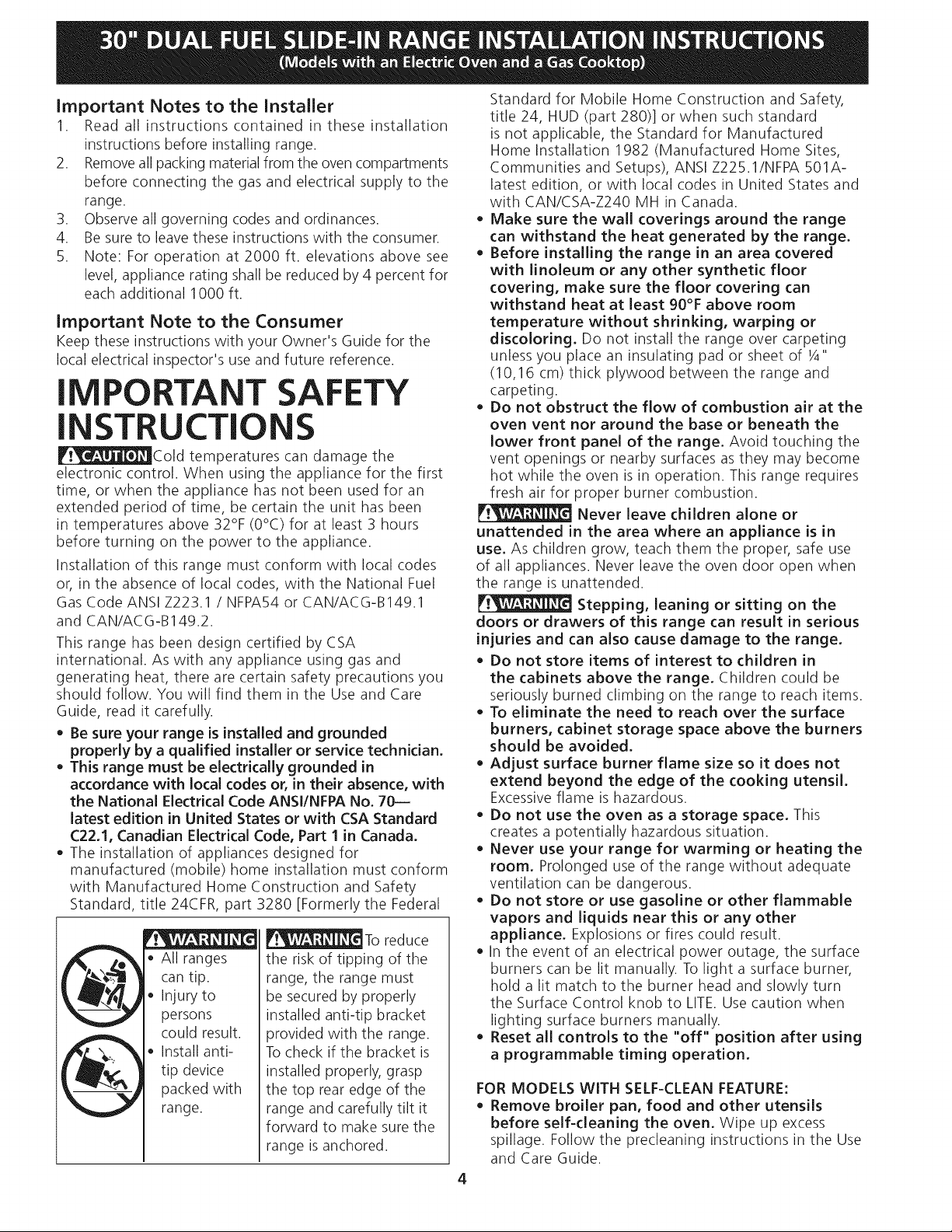

_To reduce

All ranges

can tip.

Injury to

persons

could result.

Install anti-

tip device

packed with

range.

the risk of tipping of the

range, the range must

be secured by properly

installed anti-tip bracket

provided with the range.

Tocheck if the bracket is

installed properly, grasp

the top rear edge of the

range and carefully tilt it

forward to make sure the

range is anchored.

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard

is not applicable, the Standard for Manufactured

Home Installation 1982 (Manufactured Home Sites,

Communities and Setups), ANSI Z225.1/NFPA 501A-

latest edition, or with local codes in United States and

with CAN/CSA-Z240 MH in Canada.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/4"

(10,16 cm) thick plywood between the range and

carpeting.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is in

use. As children grow, teach them the proper, safe use

of all appliances. Never leave the oven door open when

the range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in

the cabinets above the range. Children could be

seriously burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessiveflame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn

the Surface Control knob to LITE. Use caution when

lighting surface burners manually.

• Reset all controls to the "off" position after using

a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the Use

and Care Guide.

4

Page 5

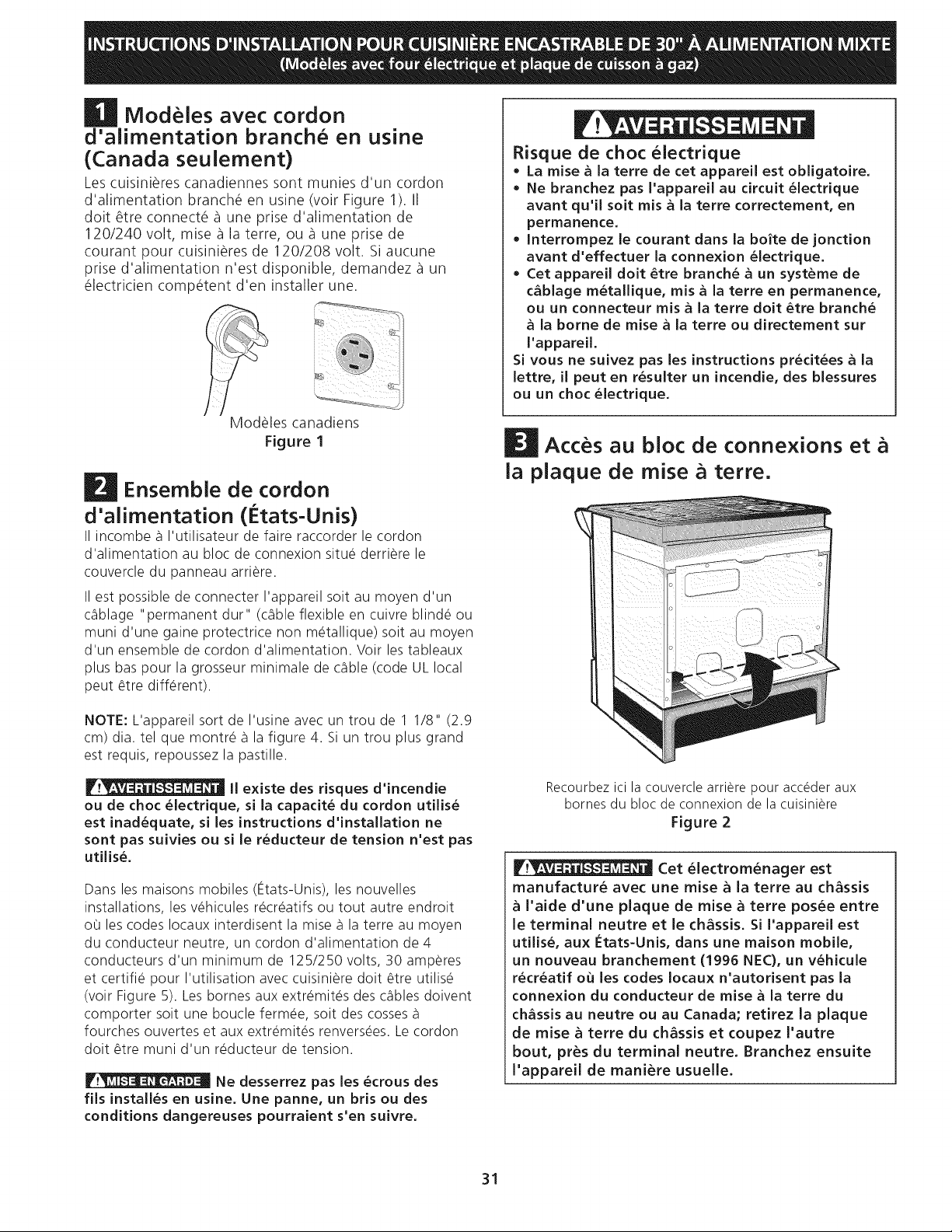

Factory Connected Power Supply

Cord (Canada only)

This range is equipped with a factory-connected power

cord (see Figure 1). Cord must be connected to a

grounded 120/240 volt or 120/208 volt range outlet. If

no outlet is available, have one installed by a qualified

electrician.

Canada Style

Figure 1

Power Supply Cord Kit (U.S.A.)

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

This appliance may be connected by means of

permanent "hard wiring"; flexible armored or

nonmetallic shielded copper cable (when local code

allow it) or by means of a power supply cord kit.

NOTE: Electric Slide-in Range is shipped from factory

with 1 1/8" (2.9 cm) dia. hole as shown on figure 4. If a

larger hole is required, punch out the knockout.

Risk of fire or electrical shock exists

if an incorrect size range cord kit is used, the

Installation Instructions are not followed, or the

strain relief bracket is discarded.

Electrical Shock Hazard

o Electrical ground is required on this appliance.

Do not connect to the electrical supply until

appliance is permanently grounded.

Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

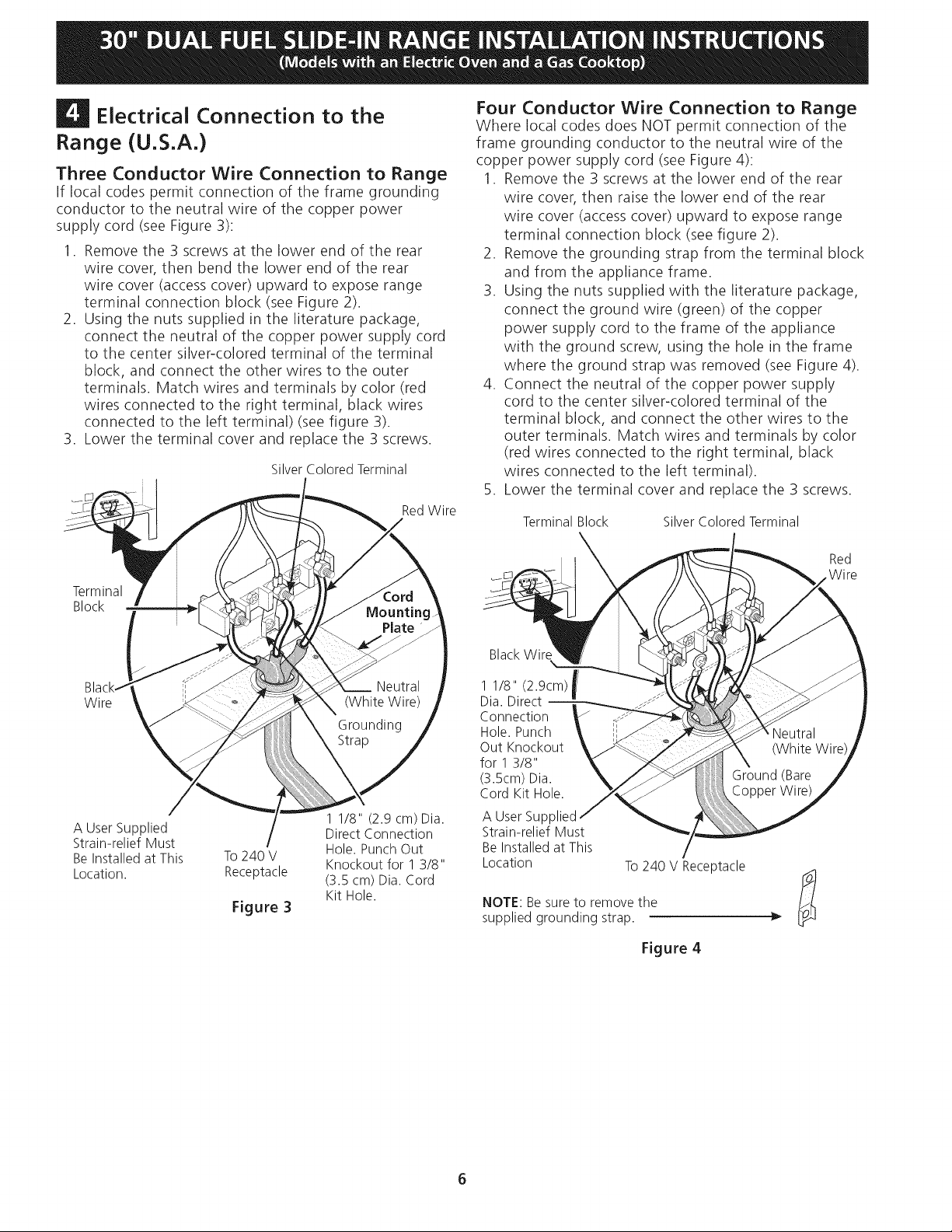

Access to Terminal Block &

Grounding Strap (U.S.A.)

For mobile homes, new installations or recreational

vehicles, use only a power supply kit designed for a

range at 125V/250V 30A recommended. Cord must have

either 3 (when local code permits grounding through

neutral) or 4 conductors. Terminal on end of wires must

be either closed loop or open spade lug with upturned

ends. Cord must have strain-relief clamp.

Do not loosen the nuts which secure

the factory=installed range wiring to terminal block

while connecting range, Electrical failure or loss of

electrical connection may occur.

BEND REARWIRE COVER HERE

FORACCESS TO TERMINAL BLOCK

Figure 2

This appliance is manufactured with

the frame grounded by connection of a grounding

strap between the neutral power supply terminal

and the frame, if used in USA, in a new branch

circuit installation (1996 NEC), mobile home or

recreational vehicule, where local code do not

permit grounding through neutral (white) wire

or in Canada; remove the grounding strap from

the frame and cut the other end, near the neutral

terminal. Connect the appliance in usual manner.

Page 6

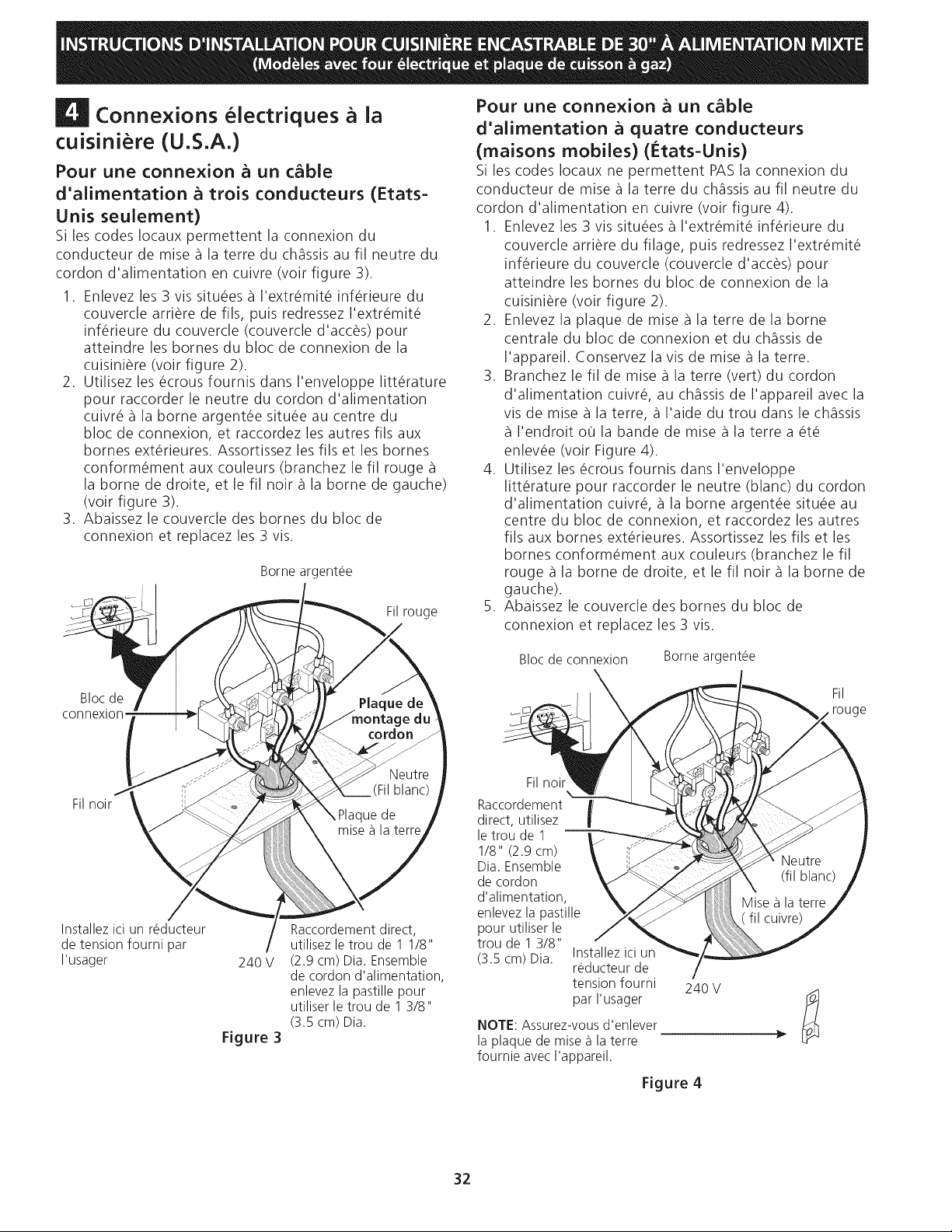

| Electrical Connection to the

Range (U.S.A.)

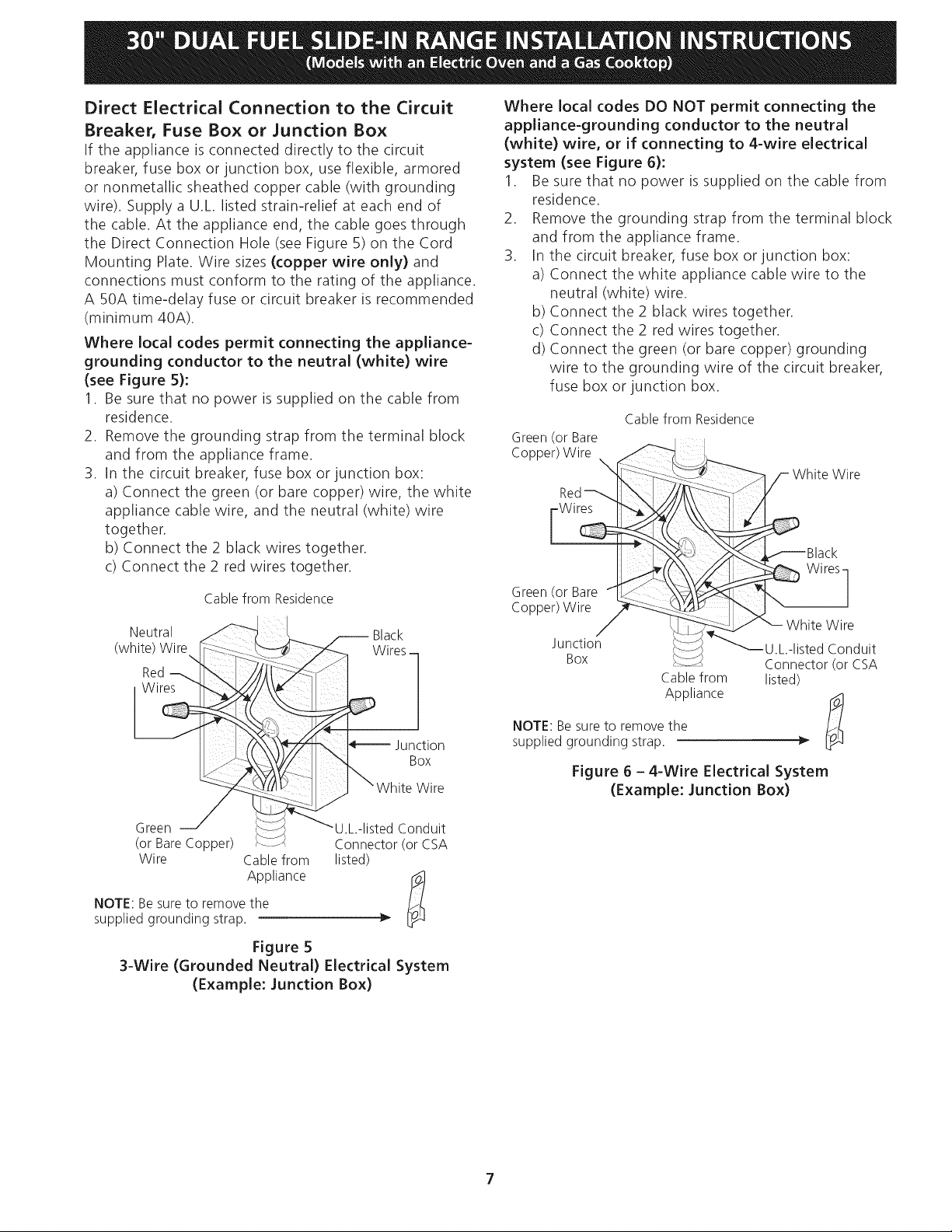

Three Conductor Wire Connection to Range

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power

supply cord (see Figure 3):

1. Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear

wire cover (access cover) upward to expose range

terminal connection block (see Figure 2).

2. Using the nuts supplied in the literature package,

connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal) (see figure 3).

3. Lower the terminal cover and replace the 3 screws.

Silver Colored Terminal

Red Wire

Terminal

Block

Four Conductor Wire Connection to Range

Where local codes does NOT permit connection of the

frame grounding conductor to the neutral wire of the

copper power supply cord (see Figure 4):

1. Remove the 3 screws at the lower end of the rear

wire cover, then raise the lower end of the rear

wire cover (access cover) upward to expose range

terminal connection block (see figure 2).

2. Remove the grounding strap from the terminal block

and from the appliance frame.

3. Using the nuts supplied with the literature package,

connect the ground wire (green) of the copper

power supply cord to the frame of the appliance

with the ground screw, using the hole in the frame

where the ground strap was removed (see Figure 4).

4. Connect the neutral of the copper power supply

cord to the center silver-colored terminal of the

terminal block, and connect the other wires to the

outer terminals. Match wires and terminals by color

(red wires connected to the right terminal, black

wires connected to the left terminal).

5. Lower the terminal cover and replace the 3 screws.

Terminal Block Silver Colored Terminal

Red

Wire

Wire

A User Supplied

Strain-relief Must

Be Installed at This

Location.

To240 V

Receptacle

Figure 3

1 1/8" (2.9 cm) Dia.

Direct Connection

Hole. Punch Out

Knockout for 1 3/8"

(3.5 cm) Dia. Cord

Kit Hole.

BlackWire

1 1/8" (2.9cm)f

Dia.Direct

I!

Connection

Hole.Punch

Out Knockout

for 13/8"

(3.5cm)Dia.

Cord Kit Hole.

A User Supplied

Strain-relief Must

Be Installed at This

Location

NOTE: Besure to remove the

supplied grounding strap.

To 240 V Receptacle

Figure 4

Page 7

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L. listed strain-relief at each end of

the cable. At the appliance end, the cable goes through

the Direct Connection Hole (see Figure 5) on the Cord

Mounting Plate. Wire sizes (copper wire only) and

connections must conform to the rating of the appliance.

A 50A time-delay fuse or circuit breaker is recommended

(minimum 40A).

Where local codes permit connecting the appliance-

grounding conductor to the neutral (white) wire

(see Figure 5):

1. Be sure that no power is supplied on the cable from

residence.

2. Remove the grounding strap from the terminal block

and from the appliance frame.

3. In the circuit breaker, fuse box or junction box:

a) Connect the green (or bare copper) wire, the white

appliance cable wire, and the neutral (white) wire

together.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

Cable from Residence

Neutral _ I _ Black

(white) Wire _ -__ Wires

Red ":":::::_i_::;-_S

Where local codes DO NOT permit connecting the

appliance-grounding conductor to the neutral

(white) wire, or if connecting to 4-wire electrical

system (see Figure 6):

1. Be sure that no power is supplied on the cable from

residence.

2. Remove the grounding strap from the terminal block

and from the appliance frame.

3. In the circuit breaker, fuse box or junction box:

a) Connect the white appliance cable wire to the

neutral (white) wire.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

d) Connect the green (or bare copper) grounding

wire to the grounding wire of the circuit breaker,

fuse box or junction box.

Cablefrom Residence

Green(or Bare

Copper)Wire '_ _,,_:_.---_

White Wire

_(,_..__ Wires]

Green(or Bare ___4,,I _dp. /

Copper)Wi

__'_-- White Wire

Junction _t_ -_LLL-listed Conduit

Box _::_x_ .......

............... Connector(or CSA

Cablefrom listed)

i_jdres_ _ !_IWires -

[_]b _->.._\_ I Junction

__ _"" WhiteB_/_ire

Green J _L_/_ "U.L.-listed Conduit

(or Bare Copper) X-7is Connector (or CSA

Wire Cable from listed)

Appliance

NOTE: Be sure to remove the

supplied grounding strap.

Figure 5

3-Wire (Grounded Neutral) Electrical System

(Example: Junction Box)

NOTE:Besureto removethe

suppliedgrounding strap. _"

Appliance

Figure 6 - 4-Wire Electrical System

(Example: Junction Box)

7

Page 8

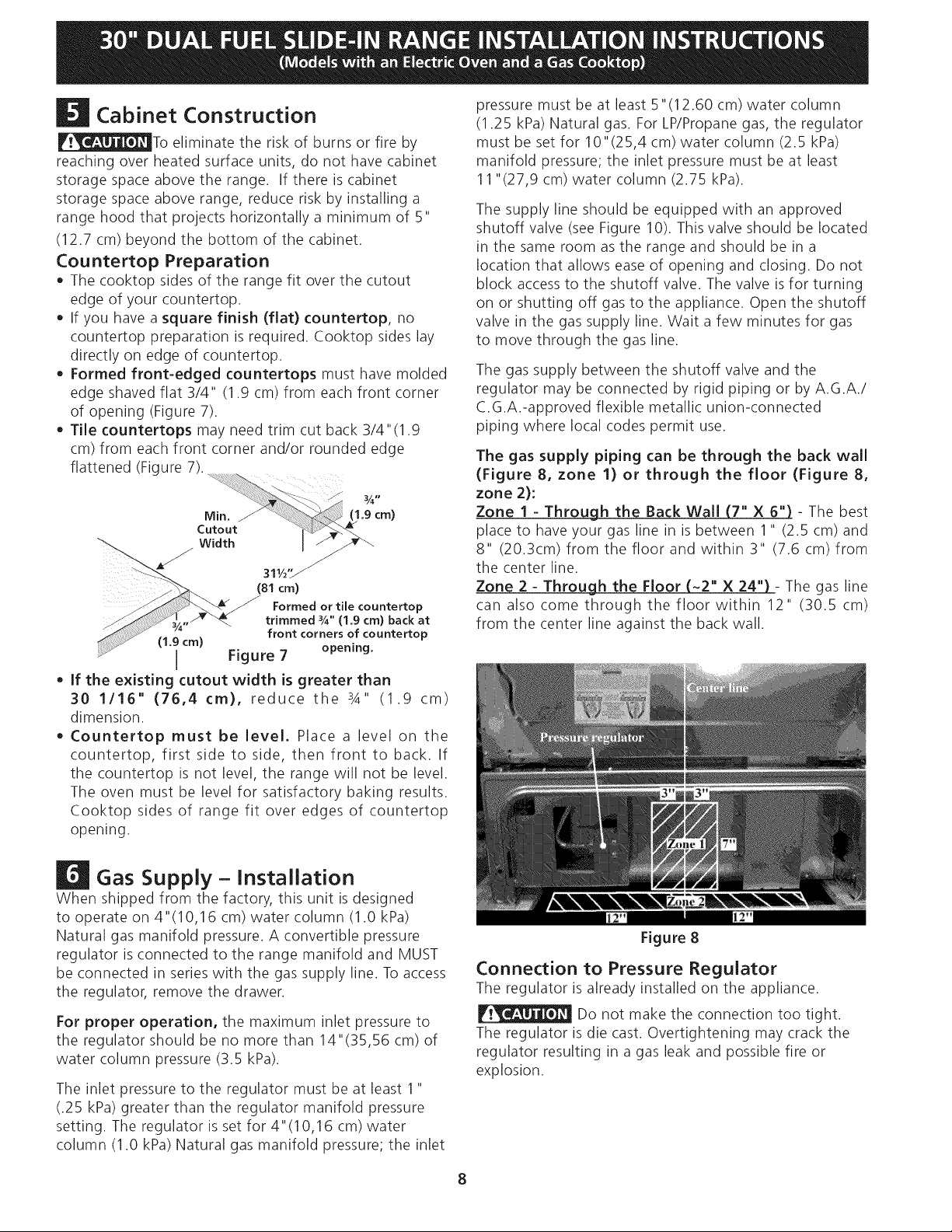

| Cabinet Construction

_To eliminate the risk of burns or fire by

reaching over heated surface units, do not have cabinet

storage space above the range. If there is cabinet

storage space above range, reduce risk by installing a

range hood that projects horizontally a minimum of 5"

(12.7 cm) beyond the bottom of the cabinet.

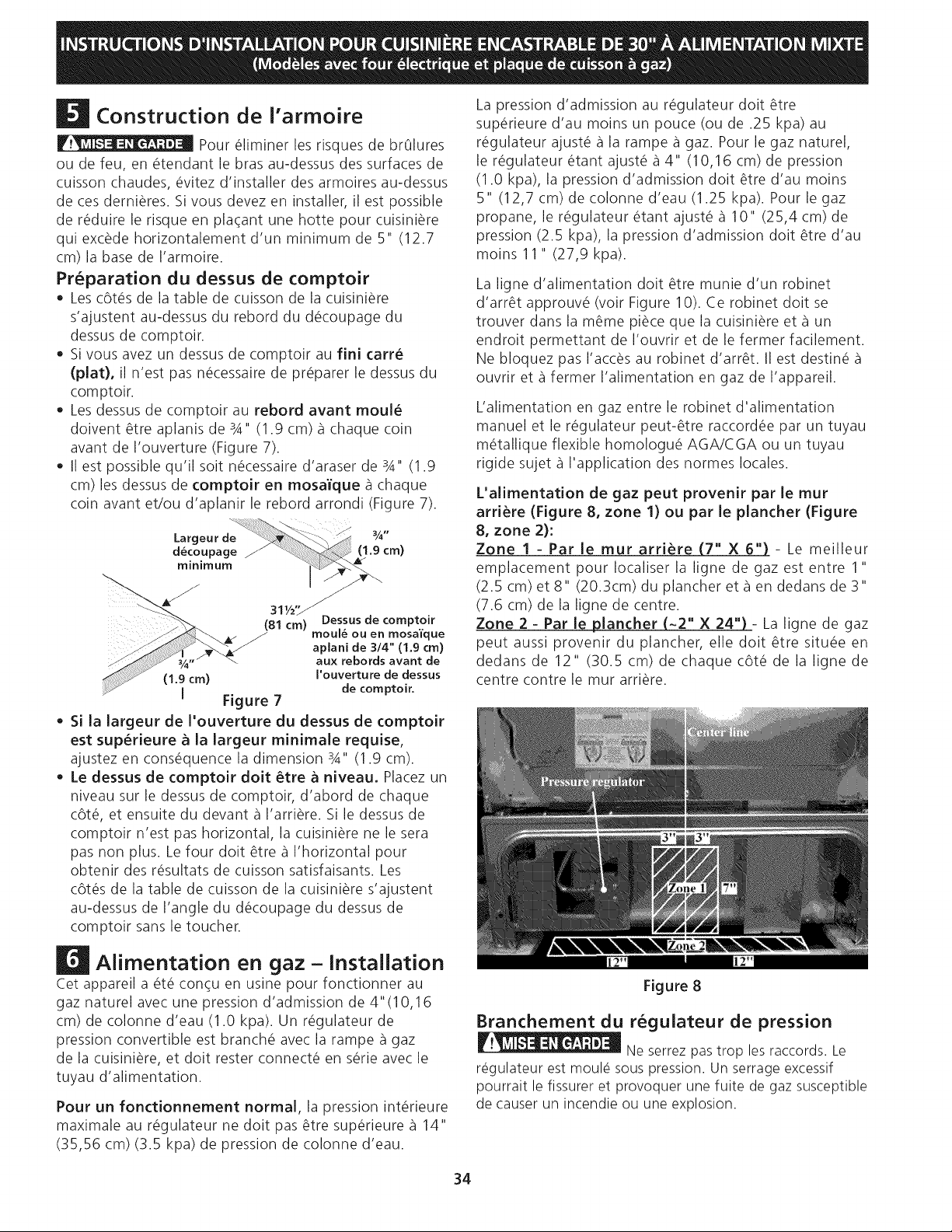

Countertop Preparation

• The cooktop sides of the range fit over the cutout

edge of your countertop.

• If you have a square finish (flat) countertop, no

countertop preparation is required. Cooktop sides lay

directly on edge of countertop.

Formed front-edged countertops must have molded

edge shaved flat 3/4" (1.9 cm) from each front corner

of opening (Figure 7).

Tile countertops may need trim cut back 3/4"(1.9

cm) from each front corner and/or rounded edge

flattened (Figure 7).

311/2,,j_j

(81cm)

Formed or tile countertop

trimmed %" (1_9 cm) back at

(1.9 cm) opening,

I Figure 7

• If the existing cutout width is greater than

30 1/16" (76,4 cm), reduce the 3A" (1.9 cm)

dimension.

Countertop must be level, Place a level on the

countertop, first side to side, then front to back. If

the countertop is not level, the range will not be level.

The oven must be level for satisfactory baking results.

Cooktop sides of range fit over edges of countertop

opening.

front corners of countertop

pressure must be at least 5"(12.60 cm) water column

(1.25 kPa) Natural gas. For LP/Propane gas, the regulator

must be set for 10"(25,4 cm) water column (2.5 kPa)

manifold pressure; the inlet pressure must be at least

11 "(27,9 cm) water column (2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 10). This valve should be located

in the same room as the range and should be in a

location that allows ease of opening and closing. Do not

block access to the shutoff valve. The valve is for turning

on or shutting off gas to the appliance. Open the shutoff

valve in the gas supply line. Wait a few minutes for gas

to move through the gas line.

The gas supply between the shutoff valve and the

regulator may be connected by rigid piping or by A.G.A./

C.G.A.-approved flexible metallic union-connected

piping where local codes permit use.

The gas supply piping can be through the back wall

(Figure 8, zone 1) or through the floor (Figure 8,

zone 2):

Zone I - Through the Back Wall (7" X 6") - The best

place to have your gas line in is between 1" (2.5 cm) and

8" (20.3cm) from the floor and within 3" (7.6 cm) from

the center line.

Zone 2 - Through the Floor (~2" X 24") - The gas line

can also come through the floor within 12" (30.5 cm)

from the center line against the back wall.

Gas Supply - Installation

When shipped from the factory, this unit is designed

to operate on 4"(10,16 cm) water column (1.0 kPa)

Natural gas manifold pressure. A convertible pressure

regulator is connected to the range manifold and MUST

be connected in series with the gas supply line. To access

the regulator, remove the drawer.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm) of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1"

(.25 kPa) greater than the regulator manifold pressure

setting. The regulator is set for 4"(10,16 cm) water

column (1.0 kPa) Natural gas manifold pressure; the inlet

Figure 8

Connection to Pressure Regulator

The regulator is already installed on the appliance.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Page 9

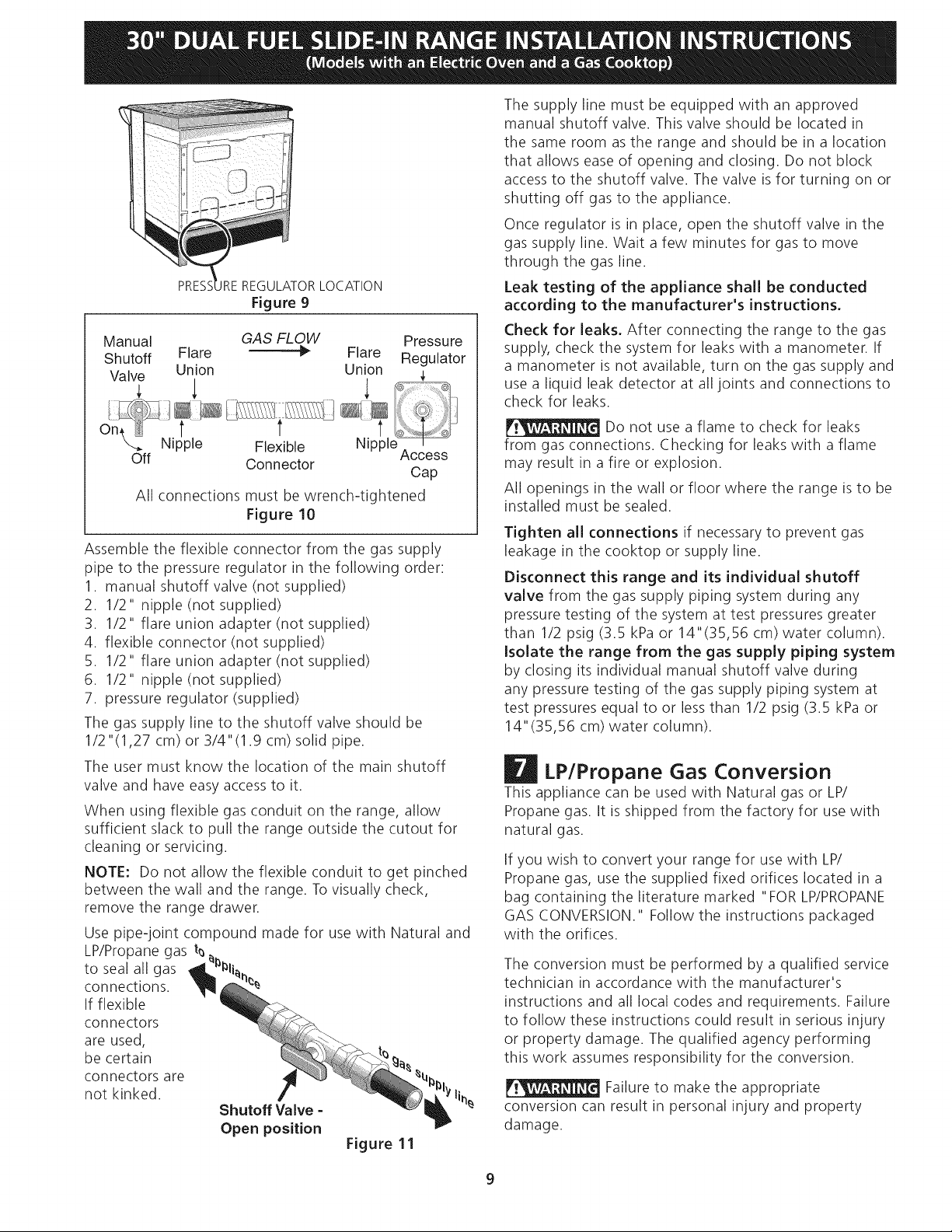

PRES'_ JRE REGULATOR LOCATION

Figure 9

Manual GAS FLOW Pressure

Shutoff Flare _ Flare Regulator

Valve Union Union

/

Nipple Flexible Nipple

Off Connector

All connections must be wrench-tightened

Figure 10

Assemble the flexible connector from the gas supply

pipe to the pressure regulator in the following order:

1. manual shutoff valve (not supplied)

2. 1/2" nipple (not supplied)

3. 1/2" flare union adapter (not supplied)

4. flexible connector (not supplied)

5. 1/2" flare union adapter (not supplied)

6. 1/2" nipple (not supplied)

7. pressure regulator (supplied)

The gas supply line to the shutoff valve should be

1/2"(1,27 cm) or 3/4"(1.9 cm) solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

When using flexible gas conduit on the range, allow

sufficient slack to pull the range outside the cutout for

cleaning or servicing.

NOTE: Do not allow the flexible conduit to get pinched

between the wall and the range. To visually check,

remove the range drawer.

Use pipe-joint compound made for use with Natural and

@/Propane gas t_

to seal all gas

connections.

If flexible

connectors

are used,

be certain

connectors are

not kinked.

Shutoff Valve -

Open position

Figure 11

Access

Cap

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in

the same room as the range and should be in a location

that allows ease of opening and closing. Do not block

access to the shutoff valve. The valve isfor turning on or

shutting off gas to the appliance.

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

Leak testing of the appliance shall be conducted

according to the manufacturer's instructions,

Check for leaks, After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector at all joints and connections to

check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where the range is to be

installed must be sealed.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Disconnect this range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of the system at test pressures greater

than 1/2 psig (3.5 kPa or 14"(35,56 cm) water column).

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig (3.5 kPa or

14"(35,56 cm) water column).

LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

If you wish to convert your range for use with LP/

Propane gas, use the supplied fixed orifices located in a

bag containing the literature marked "FOR LP/PROPANE

GAS CONVERSION." Follow the instructions packaged

with the orifices.

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in personal injury and property

damage.

9

Page 10

Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer (warmer drawer on some models) and open the

oven door. Lift the range at the front and slide it out

of the cut-out opening without creating undue strain

on the flexible gas conduit. Make sure not to pinch

the flexible gas conduit at the back of the range when

replacing the unit into the cut-out opening. Replace

the drawer, close the door and switch on the electrical

power and gas to the range.

Range Installation

Important Note: Door removal is not a requirement for

installation of the range, but is an added convenience.

Refer to the Use and Care Guide for oven door removal

instructions.

Standard Installation

_[I The range cooktop overlaps the countertop at the

sides and the range rests on the floor. The cooktop

is 311/2" (80 cm) wide.

O

Install base cabinets 30" (76.2 cm) apart. Make

sure they are plumb and level before attaching

cooktop. Shave raised countertop edge to clear

311/2" (80 cm) wide range top rim.

®

Install cabinet doors 31 " (78.7 cm) min. apart so as

not to interfere with range door opening.

_[tCutout countertop exactly as shown on page 1.

_Make sure the four leveling legs are setup higher

than the height of the cabinet (shown on page 3).

_I_ Install the anti-tip bracket at

this point before placing the range at its

final position. Follow the installation instructions

on page 13 or on the anti-tip bracket template

supplied with the range.

O

To provide an optimum installation, the top surface

of the countertop must be level and flat (lie on the

same plane) around the 3 sides that are adjacent

to range cooktop. Proper adjustments to make

the top flat should be made or gaps between the

countertop and the range cooktop may occur.

_ _J_i_ To reduce the risk of damaging your

appliance, do not handle or manipulate it by the

cooktop. Manipulate with care.

_Position range in front of the cabinet opening.

_Make sure that the underside of the cooktop

clears the countertop. If necessary, raise the unit

by lowering the front leveling legs and the back

leveling wheels.

O Level the range (see section 10). The floor

where the range is to be installed must be level.

Follow the instructions under "Leveling the

Range".

_lb Slide the range into the cutout opening.

If Accessories Needed :

Installation With Backguard

The cutout depth of (21 3/4" (55.2 cm)Min., 22 1/8"

(56.2cm) Max.) needs to be increased to 24" (61 cm)

when installing a backguard.

Installation With End Panel

A End Panel kit can be ordered through a Service

Center.

Installation With Side Panels

A Side Panels kit can be ordered through a Service

Center. Note: Install cabinet doors 31 " (78.7 cm) min.

apart so as not to interfere with range door opening.

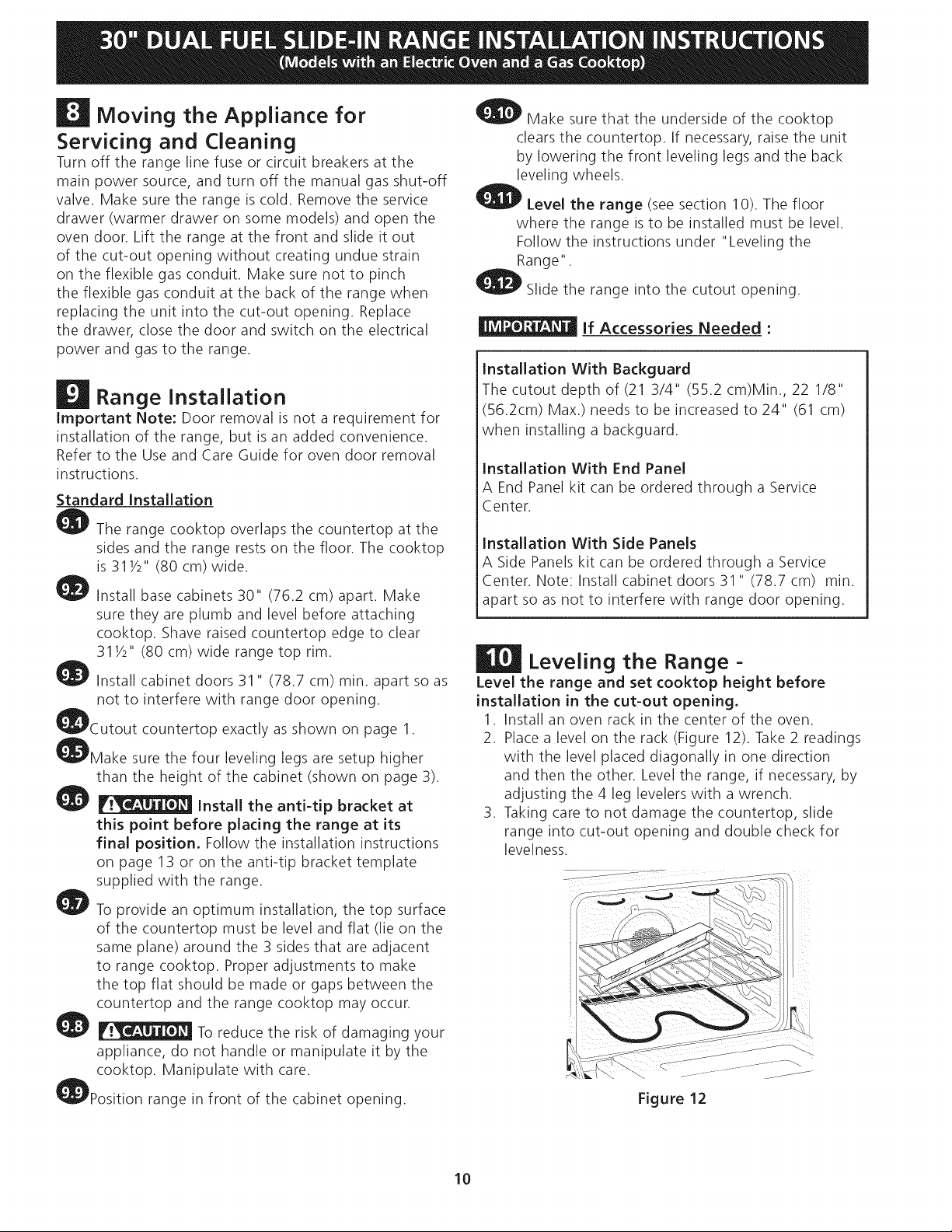

Leveling the Range -

Level the range and set cooktop height before

installation in the cut-out opening.

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (Figure 12). Take 2 readings

with the level placed diagonally in one direction

and then the other. Level the range, if necessary, by

adjusting the 4 leg levelers with a wrench.

3. Taking care to not damage the countertop, slide

range into cut-out opening and double check for

levelness.

Figure 12

10

Page 11

Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

Do not touch the elements or burners. They may be hot

enough to cause burns.

Remove all packaging from the oven before testing.

O Install Burner Caps and Grates

This range is equipped with sealed burners.

1. Remove all packaging material.

2. Discard the packaging material (if needed).

3. Install the burner grates and burners caps on the unit

burners.

NOTE: There are no burner adjustments necessary on

this range.

O Turn on Electrical Power and Open Main

Shutoff Gas Valve

Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting:

1.Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

2. The surface burner should light when gas is available

to the top burner. Each burner should light within

four (4) seconds in normal operation after air has been

purged from supply lines. Visually check that burner

has lit.

3.Once the burner lights, the control knob should be

rotated out of the LITEposition.

There are separate ignition devices for each burner. Try

each knob separately until all burner valves have been

checked.

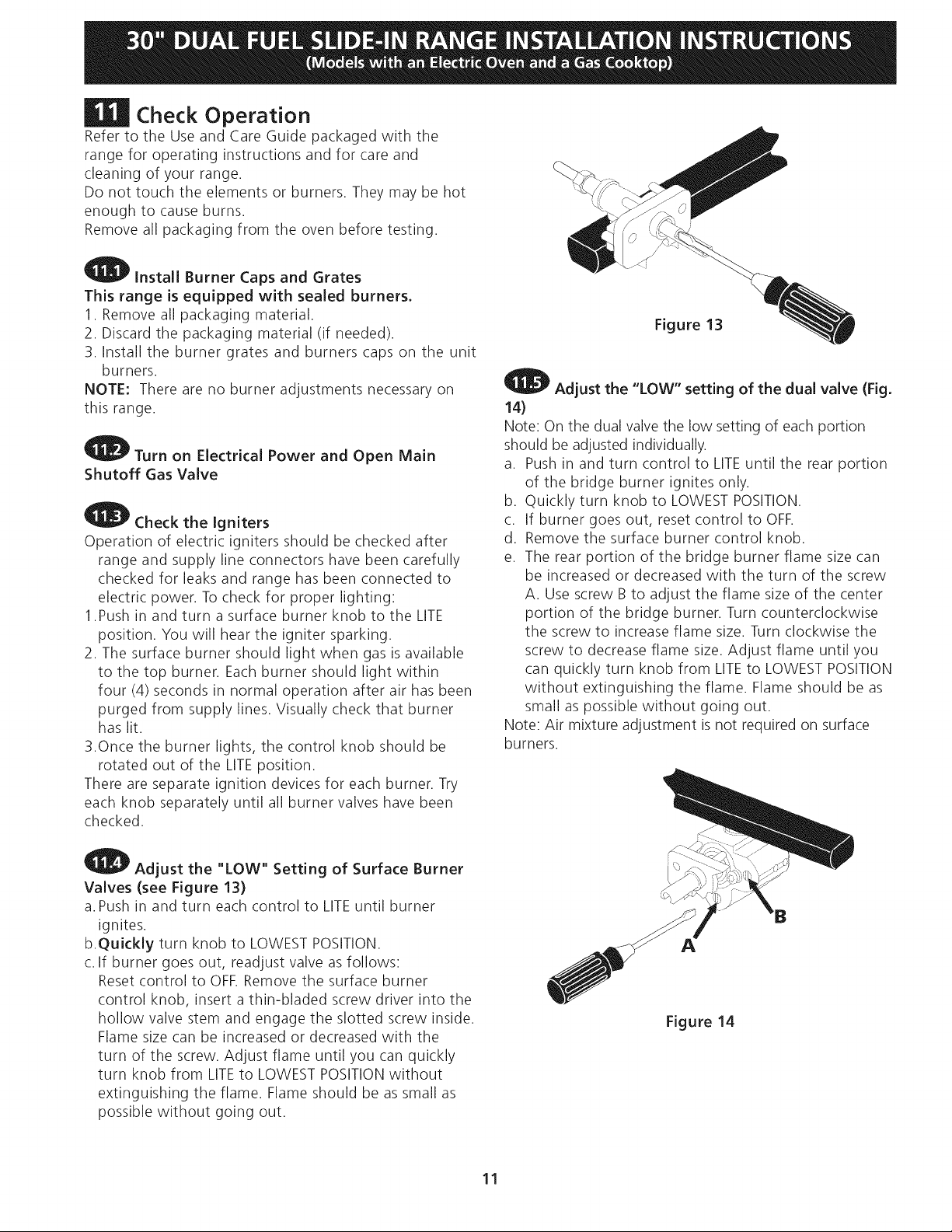

Figure 13

O Adjust the "LOW" setting of the dual valve (Fig.

14)

Note: On the dual valve the low setting of each portion

should be adjusted individually.

a. Push in and turn control to LITEuntil the rear portion

of the bridge burner ignites only.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. The rear portion of the bridge burner flame size can

be increased or decreased with the turn of the screw

A. Use screw B to adjust the flame size of the center

portion of the bridge burner. Turn counterclockwise

the screw to increase flame size. Turn clockwise the

screw to decrease flame size. Adjust flame until you

can quickly turn knob from LITEto LOWEST POSITION

without extinguishing the flame. Flame should be as

small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

Adjust the ""LOW"" Setting of Surface Burner

Valves (see Figure 13)

a.Push in and turn each control to LITEuntil burner

ignites.

b.Quickly turn knob to LOWESTPOSITION.

c. If burner goes out, readjust valve as follows:

Reset control to OFF.Remove the surface burner

control knob, insert a thin-bladed screw driver into the

hollow valve stem and engage the slotted screw inside.

Flame size can be increased or decreased with the

turn of the screw. Adjust flame until you can quickly

turn knob from LITEto LOWEST POSITIONwithout

extinguishing the flame. Flame should be as small as

possible without going out.

Figure 14

11

Page 12

O Operationof OvenElements

Theovenisequippedwithanelectronicovencontrol.Each

ofthefunctionshasbeenfactorycheckedbeforeshipping.

However,itissuggestedthatyouverifytheoperation

oftheelectronicovencontrolsoncemore.Refertothe

ElectronicOvenControlGuideforoperation.Followthe

instructionsfortheClock,Timer,Bake,Broil,Convection

(somemodels)andCleanfunctions.

Bake-Aftersettingtheovento350°F(177°C)for

baking,thelowerelementintheovenshouldbecome

red.

Broil-Whentheovenissetto BROIL,theupperelement

intheovenshouldbecomered.

Clean-Whentheovenissetforaself-cleaningcycle,the

upperelementshouldbecomeredduringthepreheat

portionofthecycle.Afterreachingtheself-cleaning

temperature,thelowerelementwillbecomered.

Convection(somemodels)-Whentheovenissetto

CONV.BAKE/ROASTat350°F(177°C),theconvection

elementcyclesonandoffandtheconvectionfanturns.

Theconvectionfanwillstopturningwhentheovendoor

isopenedduringconvectionbakingorroasting.

WarmerDrawer(somemodels)-Setthecontrolknob

toHIandchecktoseethedrawerisheating.

When All Hookups are Complete

MakesureallcontrolsareleftontheOFFposition.

Makesuretheflowofcombustionandventilationairtothe

rangeisunobstructed.

Model and Serial Number Location

The serial plate is located on the oven front frame behind

the oven door (some models) or on the drawer side frame

(some models).

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the range was adjusted

for when it left the factory.

Serial Plate

Location

Before You Call for Service

Readthe Avoid Service Checklist and operating instructions

in your Use and Care Guide. It may save you time and

expense. The list includes common occurrences that are

not the result of defective workmanship or materials in

this appliance.

Refer to the warranty and service information in your

Use and Care Guide for phone number and address.

Please call or write if you have inquiries about your range

product and/or need to order parts.

12

Page 13

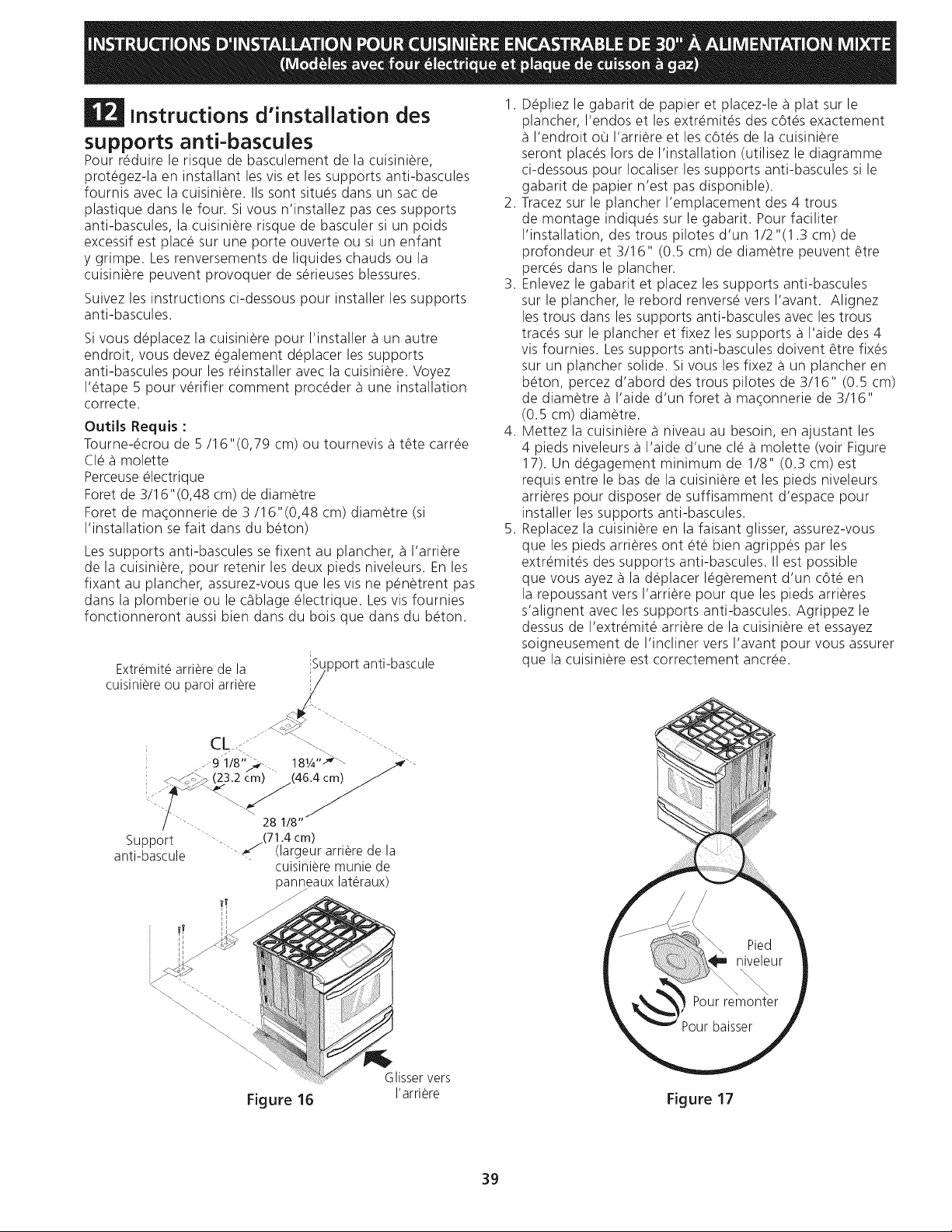

Anti-Tip Brackets Installation

instructions

To reduce the risk of tipping of the range,

the range must be secured to the floor by properly

installed anti-tip brackets and screws packed with the

range. Those parts are located in a plastic bag in the

oven. Failure to install the anti-tip brackets will allow the

range to tip over if excessive weight is placed on an open

door or if a child climbs upon it. Serious injury might

result from spilled hot liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-

tip brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" (0,79 cm) Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16" (0,48 cm) Diameter Drill Bit

3/16" (0,48 cm) Diameter Masonry Drill Bit (if installing

in concrete)

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram below to locate

brackets if template is not available (Figure 15)).

2. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16" (0.5 cm) diameter pilot holes 1/2"(1,27 cm)

(1.3 cm) deep can be drilled into the floor.

3. Remove template and place brackets on floor

with turned up flange to the front. Line up holes

in brackets with marks on floor and attach with 4

screws provided. Brackets must be secured to solid

floor. If attaching to concrete floor, first drill 3/16"

(0.5 cm) dia. pilot holes using a masonry drill bit.

4. Level range if necessary, by adjusting 4 leg levelers

with wrench. (See Figure 16 below.) A minimum

clearance of 1/8" (0.8 cm)is required between the

bottom of the range and the rear leg levelers to

allow room for the anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to

be shifted slightly to one side as it is being pushed

back to allow rear legs to align with brackets. You

may also grasp the top rear edge of the range and

carefully attempt to tilt it forward to make sure

range is properly anchored.

BackEdgeof /

Rangeor RearWall <¢-,,

CL. y _-_<. "-......

f.-9i/8';>.... ....

,_-._,:/_ (23.2 cm) ,(46.4 cm)

/ _ -, 281/8"

Anti-Tip Bracket".... _,/(71.4 cm)

'" .... (Rearwidth of range

with bodysides)

Figure 15

Anti-Tip Bracket

Figure 16

Slide Back

13

Page 14

LAINSTALACION Y ELSERVICIO DEBEN SEREFECTUADOS POR UN

INSTALADOR CAUFICADO. IMPORTANTE: GUARDE ESTAS INSTRUCCIONES

PARA USO DEL iNSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

exactamente, puede ocurrir un incendio o explosion causando daffos

{ !I'__ Si la informaciOn contenida en este manual no es seguida

materiales, lesion personal o la muerte.

PARASU SEGURIDAD:

-- No almacene ni utilice gasolina u otros vapores y liquidos inflamables en la

proximidad de _ste o de cualquier otto artefacto.

-- QUEDEBEHACERSIPERClBEOLORA GAS:

• No trate de encender ningun artefacto.

• No toque ningun interruptor el_ctrico; no use ningun tel_fono en su edificio.

• Llameasu proveedordegasdesdeeltel_fonodeunvedno. Sigalas

instruccionesdel proveedor de gas.

• Si no Iogra comunicarsecon su proveedor de gas, Ilame al departamento de

bomberos.

-- La instalad6n y el servicio de mantenimiento deben set efectuados pot un

instaladorcalificado,la agencia de servicio o el proveedor de gas.

@

Refierasea su placa de serie

para la certificaciOn de la

agencia aplicable

Aparatos Instalados en el

estado de Massachusetts;

Este Aparato s61o puede ser

instalado en el estado de

Massachusetts por un plomero

o ajustados de gas licenciado de

Massachusett.

Este aparato se debe instalar con

un largo conector flexible de gas de

tres (3) pies/36 pulgadas.

Una wilvula manual de gas de tipo

manija de forma de "T" se debe

insta/ar en la Ifnea del suministro de

gas de este aparato.

No instale la PARED

unidad en el gabinete si no ha _crn I_in.)

30" Min.

leidoesta p_igina. Lasuperficiedebeestar _--_| _-_

plana y nivelada (area _._ .... _ .... L I

sombreada). _ _u ,v._l/. , _ \13"

\ '/b.Z cm Ivnn.) "r (33 cm)

'vOala nota 3) 18" Min.

E 1!/4"

31 1/2" 112" _nin.

(81 cm)

Exacto

(4.8 cm)

Acepille el

borde

subido a

que deje

espacio

para un

borde 31 Y2"

(81 cm) de anchura

de estufa

Localice las puertas del armario 1"(2.5

cm) min del hueco de la abertura.

Min. 5" t12.7 cm)

de la pared, (45.7 cm) Min.

ambos lados. \

G 1 Approx. 1 7/8"

/

La caja de empalmes o el enchufe con puesta a tierra deberia situarse de 8" a 17"

(20.3 cm a 43.2 cm) del armario derecho y de 2" a 4" (5.1 cm a 10.2 cm) del suelo.

24" Min.

(61 cm Min.)

A ALTURA B. ANcI4URA C. ANCHURA D: PROFUNDIDAD A E: ANcHuRA F: PROFUNDIDAD DE 6. ALTURA DEL

(Debajo de !a DE LA PLANCHA LA FRENTEDE LA I DE RECORTADO*** RECORTADO MOSTRADOR

cubierta) DE COCINAR " ESTUFA (encirna y arrnario) -

35 7/8" (91,1 cm) 30" (76,2 cm) 31 1/2" 28 5/16" (71,9 cm) 30_+1/16" 21 3/4" (55,2 cm) Min. 35 7/8" (91,1 cm) Min.

36 5/8" (93 cm) 24" (61 cm) Min. con 36 5/8" (93 cm) Max.

NOTA: Se adjunta el diagrama de cables de esta cocina al final de este libreta.

Imprimido en losEstadosUnidos

(80 cm) (76,2_+0,15 cm) 22 1/8" (56,2 cm) Max

un protector trasero.

P/N 318201690 (1007) Rev. A

English - pages 1-13

EspaAol- p_iginas 14-26

Fran_ais - pages 27-39

Diagrama de la instalaci6n akimbrica - p_iginas 40

Page 15

NOTAS:

1. No pellizque el cord6n electrico o el

conducto flexible de gas entre la estufa y

la pared.

2. No selle la estufa a los armarios de lado.

3. Un espacio minimo de 24" (61 cm) entre

la superficie de la estufa y el fondo del

armario cuando el fondo del armario

de madera o metal est,1 protegido por

no menos de 1/4" (0.64 cm) de madera

resistente al fuego cubierta por una

I_imina met_ilica de MSG, numero 28,

0.015" (0.4 ram) de acero inoxidable,

0.024" (0.6 mm) de aluminio, o 0.02"

(0.5 ram) de cobre.

Un espacio minimo de 30" (76.2 cm)

cuando el armario no est,1 protegido.

4. Para los recortados menos que 22

7/8", el electrodomestico apareceria

ligeramente en el exterior del armario.

5. Deje por los 19 1A" (48.9 cm) de espacio

libre para la profundidad de la puerta

cuando esta abierta.

I

C

Puerta abierta

lateral

*** IMPORTANTE: Para el corte a Io ancho (dimensi6n E) de m_s de 30 1/16" (76,4 cm) para

evitar que se rompa el vidrio, asegurese que el artefacto est_ centrado en la abertura de

la mesada mientras Io presiona. Levante las patas de nivelaci6n hasta la posid6n m_xima;

inserte el artefacto en la mesada y luego nivele. Asegurese de que la unidad este

apoyada en las patas de nivelacion y no en el vidrio liso.

IMPORTANTE: El ancho de la cubierta y el

armario debe de ser igual al ancho del torte.

E

E

PARTEDELANTERA

DELARMARIO

22 7/8" (58.1 cm) rain.

23 1/4" (59.05 cm) max.

-- (nota 4)

_ 11/8"

1 (2.86 cm)

FRef_

...............................................................Ji...................

A. ALTURA B. ANCHURA ' C: ANCHURA

(Debajo de la DE LA PLANCHA

cubierta) - DE COCINAR

35 7/8" (91,1 cm) 30" (76,2 cm) 31 1/2"

(80 cm)

36 5/8" (93 cm)

[_: PROFUNDIDAD A

LA FRENTEDE LA

ESTUFA

28 5/16" (71,9 cm)

E: ANCHURA ' F. PROFUNDIDAD DE G: ALTURA DEL

DERECORTADO I RECORTADO MOSTRADOR

(encima y armario) i i

30_+1/16" 21 3/4" (55,2 cm) Min. 35 7/8" (91,1 cm) Min.

(76,2_+0,15 cm) 22 1/8" (56,2 cm) Max

24" (61 cm) Min. con 36 5/8" (93 cm) Max.

un protector trasero.

15

Page 16

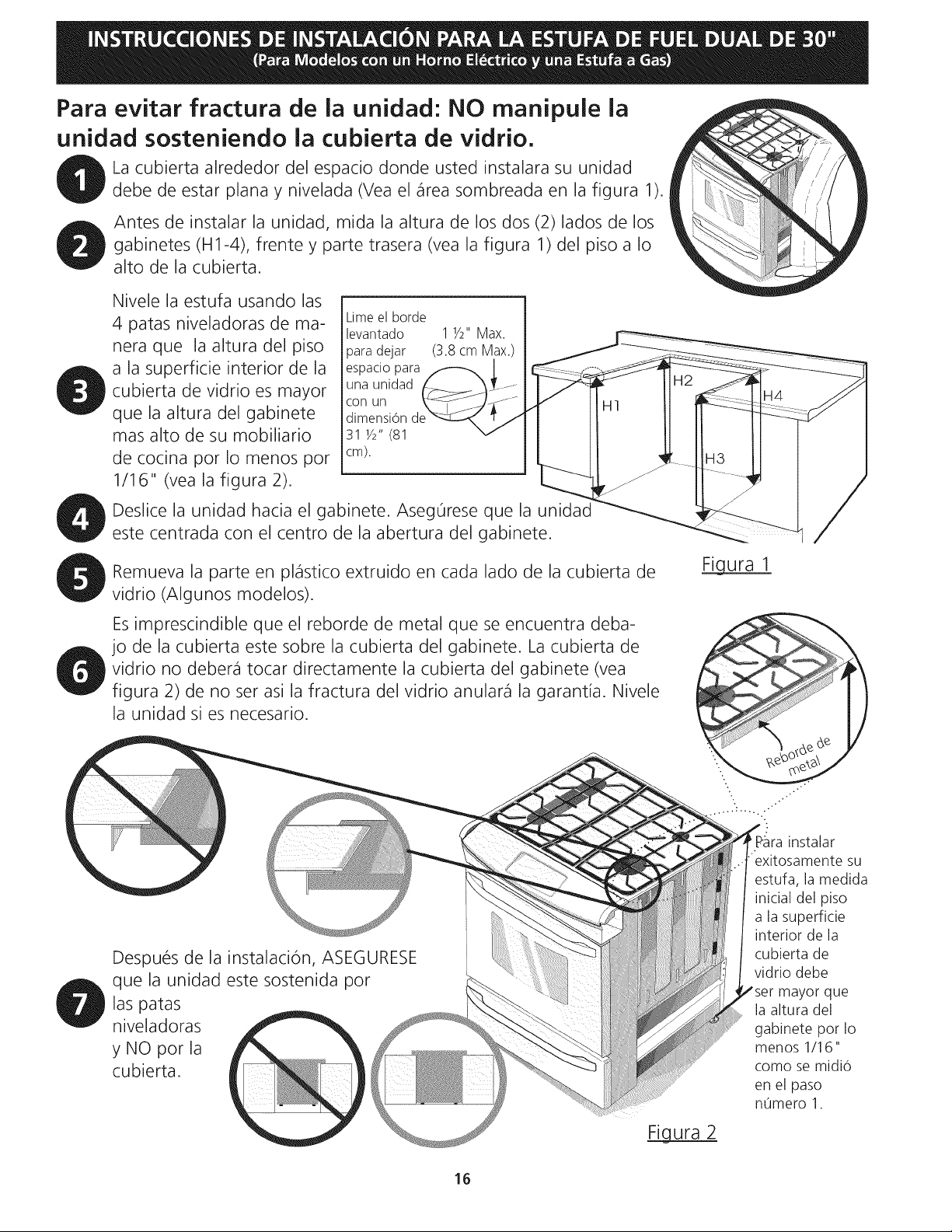

Para evitar fractura de la unidad: NO manipule la

unidad sosteniendo la cubierta de vidrio.

La cubierta alrededor del espacio donde usted instalara su unidad

debe de estar plana y nivelada (Vea el _qreasombreada en la figura 1).

Antes de instalar la unidad, mida la altura de los dos (2) lados de los

gabinetes (H1-4), frente y parte trasera (yea la figura 1) del piso a Io

alto de la cubierta.

Nivele la estufa usando las

4 patas niveladoras de ma-

nera que la altura del piso

a la superficie interior de la

cubierta de vidrio es mayor

que la altura del gabinete

mas alto de su mobiliario

de cocina pot Io menos pot

1/16" (yea la figura 2).

Deslice la unidad hacia el gabinete. Aseg0rese que la unidad

este centrada con el centro de la abertura del gabinete.

Lime el borde

levantado

para dejar

espacio para

una unidad

con un

dimensi6n d_

31 Y2"(81

cm).

1 1/2"Max.

(3.8cm Max.)

Remueva la parte en pl_qstico extruido en cada lado de la cubierta de

vidrio (Algunos modelos).

Esimprescindible que el reborde de metal que se encuentra deba-

]o de la cubierta este sobre la cubierta del gabinete. La cubierta de

vidrio no deber_qtocar directamente la cubierta del gabinete (yea

figura 2) de no set asi la fractura del vidrio anular_q la garantia. Nivele

la unidad si es necesario.

Despues de la instalacion, ASEGURESE

que la unidad este sostenida por

las patas

niveladoras

y NO por la

cubierta.

Figura 1

instalar

SU

estufa, la medida

inicial del piso

a la superficie

interior de la

cubierta de

vidrio debe

mayor que

la altura del

gabinete pot Io

menos 1/16"

como se midi6

en el paso

nOmero 1.

16

Figura 2

Page 17

Notas importantes para el Instalador

1.Lea todas las instrucciones contenidas en este manual antes

de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento del homo antes de conectar el suministro

electrico o de gas a la estufa.

3. Observe todos los codigos y reglamentos pertinentes.

4. Deje estas instrucciones con el comprador.

5. Nota: Para la utilizacion a m_is de 2 000 pies de altura, la

potencia del aparato deber_i ser reducida de 4 por ciento a

cada 1 000 pies adicionales.

Nota Irnportante para el Consurnidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

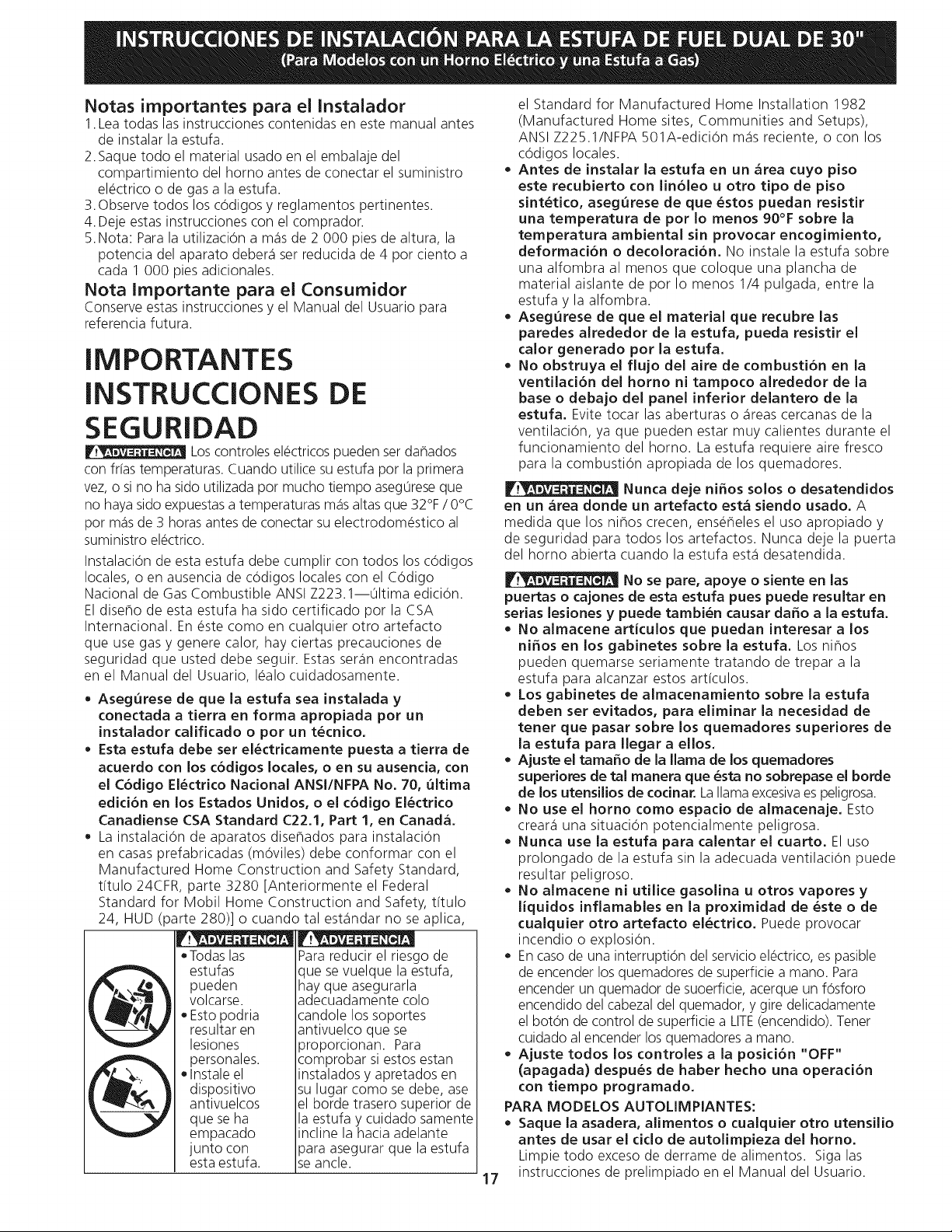

IMPORTANTES

INSTRUCCIONES DE

SEGURIDAD

Los controles electricos pueden set dahados

con if[as temperaturas. Cuando utilice su estufa pot la primera

vez, o si no ha sido utilizada pot mucho tiempo aseg0rese que

no haya sido expuestas a temperaturas m_isaltas que 32°F / 0°C

pot m_isde 3 horas antes de conectar su electrodomestico al

suministro electrico.

Instalacion de esta estufa debe cumplir con todos los codigos

locales, o en ausencia de codigos locales con el Codigo

Nacional de Gas Combustible ANSI Z223.1--01tima edicion.

El diseho de esta estufa ha sido certificado pot la CSA

Internacional. En este como en cualquier otto artefacto

que use gas y genere calor, hay ciertas precauciones de

seguridad que usted debe seguir. Estas set,in encontradas

en el Manual del Usuario, lealo cuidadosamente.

• Asegurese de que la estufa sea instalada y

conectada a tierra en forrna apropiada pot un

instalador calificado o pot un tecnico.

• Esta estufa debe set electricarnente puesta a tierra de

acuerdo con los codigos locales, o en su ausencia, con

el Codigo Electrico Nacional ANSI/NFPA No. 70, ultirna

edici6n en los Estados Unidos, o el c6digo Electrico

Canadiense CSA Standard C22.1, Part 1, en Canada.

La instalacion de aparatos disehados para instalacion

en casas prefabricadas (moviles) debe conformar con el

Manufactured Home Construction and Safety Standard,

t[tulo 24CFR, parte 3280 [Anteriormente el Federal

Standard for Mobil Home Construction and Safety, t[tulo

24, HUD (parte 280)] o cuando tal est_indar no se aplica,

Todas las

estufas

pueden

volcarse.

• Esto podria

resultar en

lesiones

personales.

• Instale el

dispositivo

antivuelcos

que se ha

empacado

junto con

esta estufa.

Para reducir el riesgo de

que se vuelque la estufa,

hay que asegurarla

adecuadamente colo

candole los soportes

antivuelco que se

proporcionan. Para

comprobar si estos estan

instalados y apretados en

su lugar como se debe, ase

el borde trasero superior de

la estufa y cuidado samente

incline la hacia adelante

para asegurar que la estufa

seancle.

el Standard for Manufactured Home Installation 1982

(Manufactured Home sites, Communities and Setups),

ANSI Z225.1/NFPA 501A-edicion m_is reciente, o con los

c6digos locales.

• Antes de instalar la estufa en un _rea cuyo piso

este recubierto con linoleo u otto tipo de piso

sintetico, asegurese de que estos puedan resistir

una ternperatura de pot Io rnenos 90°F sobre la

ternperatura arnbiental sin provocar encogirniento,

deformaciOn o decoloracion. No instale la estufa sobre

una alfombra al menos que coloque una plancha de

material aislante de pot Io menos 1/4 pulgada, entre la

estufa y la alfombra.

• Asegurese de que el material que recubre las

paredes alrededor de la estufa, pueda resistir el

calor generado pot la estufa.

• No obstruya el flujo del aire de cornbustion en la

ventilaci6n del homo ni tarnpoco alrededor de la

base o debajo del panel inferior delantero de la

estufa. Evite tocar las aberturas o _ireas cercanas de la

ventilacion, ya que pueden estar muy calientes durante el

funcionamiento del homo. La estufa requiere aire fresco

para la combustion apropiada de los quemadores.

I!_ Nunca deje ni_os solos o desatendidos

en un _rea donde un artefacto est_ siendo usado. A

medida que los nihos crecen, enseheles el uso apropiado y

de seguridad para todos los artefactos. Nunca deje la puerta

del homo abierta cuando la estufa est,1 desatendida.

No se pare, apoye o siente en las

puertas o cajones de esta estufa pues puede resultar en

serias lesiones y puede tarnbien causar daEo a la estufa.

• No alrnacene articulos que puedan interesar a los

niEos en los gabinetes sobre la estufa. Los nihos

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos art[culos.

Los gabinetes de almacenamiento sobre la estufa

deben set evitados, para elirninar ia necesidad de

tener que pasar sobre los quernadores superiores de

la estufa para Ilegar a eHos.

• Ajuste el tarna_o de ia Harna de los quernadores

superiores de tal manera que esta no sobrepase el borde

de los utensilios de cocinar. La llama excesiva es peligrosa.

• No use el homo como espacio de almacenaje. Esto

create1una situacion potencialmente peligrosa.

• Nunca use la estufa para calentar el cuarto. El uso

prolongado de la estufa sin la adecuada ventilacion puede

resultar peligroso.

• No alrnacene ni utilice gasoiina u otros vapores y

liquidos inflarnabies en la proxirnidad de este o de

cuaiquier otto artefacto electrico, Puede provocar

incendio o explosion.

En caso de una interruption del servicio electrico, es pasible

de encender los quemadores de superficie a mano. Para

encender un quemador de suoerficie, acerque un fosforo

encendido del cabezal del quemador, y gire delicadamente

el boton de control de superficie a LITE(encendido). Tenet

cuidado al encender los quemadores a mano.

Ajuste todos los controles a la posici6n "OFF"

(apagada) despues de haber hecho una operaci6n

con tiernpo prograrnado.

PARA MODELOS AUTOLIMPIANTES:

Saque la asadera, alimentos o cualquier otto utensilio

antes de usar el cido de autolirnpieza del homo.

Limpie todo exceso de derrame de alimentos. Siga las

instrucciones de prelimpiado en el Manual del Usuario.

17

Page 18

Cordon de fuente de energia

conectado de fabrica (Canada

solamente)

Esta estufa viene de fabrica equipada con un cordon

de fuente de energia (vea a la figura 1). El cordon debe

de set conectado a una toma de corriente a tierra de

120/240 voltios o de 120/208 voltios. Si no hay una

toma de corriente a tierra en la habitaciOn, debe de set

instalada por un t_cnico calificado.

Estilo Canada1

Figura 1

Peligro de choque electrico

o La conexi6n a tierra es requerida para este

electrodom_stico.

No conecte al suministro electrico hasta que

el electrodom_stico este conectado a tierra de

manera permanente,

Desconecte el suministro electrico hacia la

caja de empalmes antes de hacer la conexi6n

electrica,

Este electrodom_stico debe set conectado a un

sistema de alambres permanentes, met_licos,

conectados a tierra o una puesta a tierra

debe set conectada al terminal de tierra o un

emplonbado al electrodom_stico.

El no seguir ninguna de estas instrucciones podr{a

causar fuego, heridas personales o choques

electricos.

| Estuche de cable del suministro

electrico (U.S.A.)

El utilizador es responsable de la conexiOn del cable del

suministro el@ctricoal bloque de conexi6n situado detr_is

del panel de acceso.

El electrodom@stico se puede conectar a trav@s de un

cableado permanente "cableado duro"; cable de cobre

blindado armado o cable no-met_qlico flexible (cuando el

c6digo local Io permite) o pot medio de un kit de cable de

alimentaci6n. Vea la gr_ifica (en la p_igina siguiente) para

encontrar el tamaho minimo del cable a utilizarse (el listado

general de la UL, c6digo local puede diferenciar).

NOTA: La cocina corrediza el_ctrica viene de fabrica con

un agujero de di_imetro 1 1/8" (2.9 cm) come se muestra

en la figura 4. Si un agujero mas largo est,1 necesario

retire la arandela de la pre-cortada.

F_ El riesgo de fuego o de choque

el_ctrico puede aparecer si usa el tama_o de cable

incorrecto, si las instrucdones de instalaci6n no son

seguidas o si retira la abrazadera de releva.

Para casas sobre ruedas, nuevas instalaciones, en los

vehiculos de recreativos o en las lugares donde los cOdigos

locales no permiten la conexiOn del conductor de tierra

al neutro, un ensamble de suministro el_ctrico de 4

conductores para estufas, calificado a 125/250 voltios

minimo, 30 Amperes minimo, debe de set utilizado (vet la

figura 5).

No desajuste las tuercas que

aseguran la conexi6n de ia codna al bloque

terminal cuando est_ instalandola, El corte o la

perdida de corriente electrica puede ocurrir.

| Acceso a la terminal dei bloque y

la correa de tierra (E.E.U.U.)

INCLINE AQU{ LA CUBIERTA DELALAMBRE TRASERO PARA

TENERACCEO AL ACOPLAMIENTO ELECTRICO

Figura 2

F_ Este electrodom_stico rue fabricado

con el marco aterrizado a traves de una correa

de conexion entre el neutral de la fuente de

alimentaci6n y el marco, Si es utilizado en los E,E.

U.U,, con un circuito nuevo de instalaci6n (1996

NEC), en casa sobre ruedas o vehiculo recreativo,

donde el codigo local no permite el atterizaje

a trav_s del cable neutro (blanco) o en Canada;

remueva la correa de aterrizaje del marco y corte

el otro extremo, cerca de la terminal de neutral.

Conecte el electrodom_stico de la forma usual.

18

Page 19

| Conexi6n electrica a la codna

(Estados Unidos)

Conexi6n del cable a tres alambres ia cocina

Si los c6digos locales permiten la conexi6n del conductor a

tierra del armaz6n al alambre neutral del cable de bronce

del suministro el@ctrico(vea figura 3).

1. Retire los 3 tornillos de la parte baja de la cubierta

del cable trasero (cubierta de acceso), luego levante

la cubierta hacia arriba para tener acceso al bloque

de conexi6n del borne terminal (vea figura 2).

2. Utilizar los tuercas suministraron en el paquete de la

literatura para conectar la parte neutral del cable de

bronce de suministro el_ctrico al terminal plateado

que se encuentra al centro del bloque terminal y,

conectar los otros alambres a los terminales externos.

Aparee los alambres y los terminales seg0n el color

(alambres rojos conectados al terminal derecho,

alambres negros conectados al terminal izquierdo)

(vea figura 3).

3. Baje la cubierta del terminal y vuelva al colocar los 3

tornillos.

Conexi6n del cable de cuatro conductores a

ia codna.

1. Retire los 3 tornillos de la parte baja de la cubierta

del cable trasero, luego levante la cubierta hacia

arriba para tener acceso (cubierta de acceso) al

bloque de conexi6n del borne terminal (vea figura 2).

2. Retire la correa de la base del bloque terminal y del

armaz6n del electrodom@stico. Retenga el tornillo de

la base.

3. Utilizar los tuercas suministraron en el paquete de la

literatura para conectar el alambre de tierra (verde)

del cable de bronce del suministro el@ctrico al

armaz6n del electrodom@stico con el tornillo de la

base, usando el hoyo del armaz6n por donde retir6

la correa de la base (vea figura 4).

4. Conecte el alambre neutral (blanco) del cable de

cobre del suministro el@ctrico al terminal plateado

del centro del bloque terminal y, conecte los otros

alambres a los terminales externos.

5. Baje la cubierta del terminal y vuelva al colocar los 3

tornillos.

Bloque terminal Terminal plata

Bloque

terminal

Negro

Una arazadera de releva

provista debe de estar

instalada a est,1ubicaci6n.

Terminal plata

Hacia el 240 V

Recept_iculo.

Figura 3

Alambre

rojo

1 1/8" (2.9 cm)

Agujero de la

conexi6n directa.

Retira la arandela

pre-cortada para

1 3/8" (3.5 cm)

Dia. agujero.

Alambre

Nec

1 1/8" (2.9 cm)

Dia. A,

de la conexi6n

directa. Retira

la arandela pre-

cortada para 1

3/8" (3.5 cm)

dia. agujero.

Una arazadera de

releva provista debe de

estar instalada a est,1

ubicaci6n.

NOTA: Asegurese de quitar

la banda de puesta atierra

provista.

Alambre

Hacia el 240 V recept_iculo

Figura 4

19

Page 20

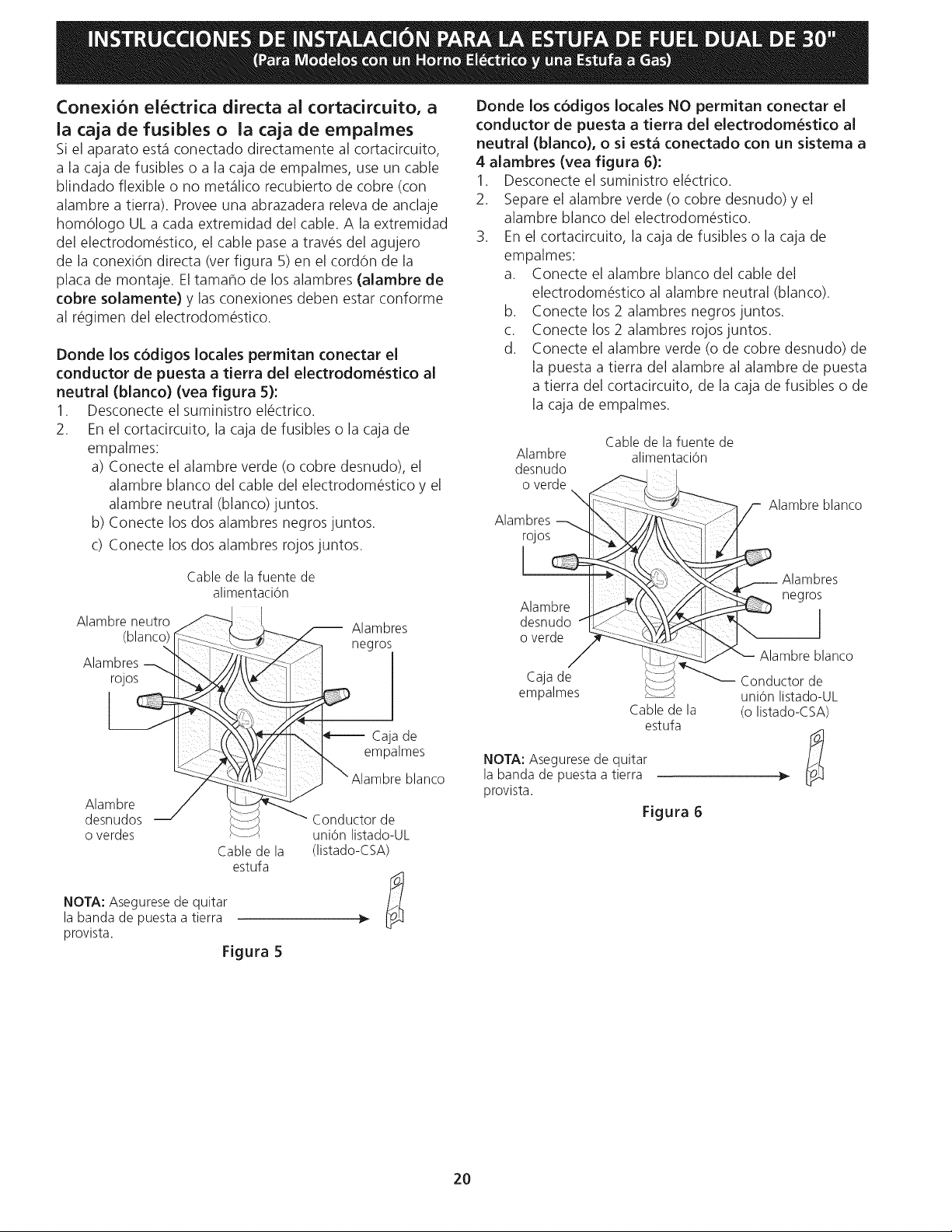

Conexi6n electrica directa ai cortacircuito, a

ia caja de fusibles o ia caja de empaimes

Si el aparato est_Sconectado directamente al cortacircuito,

a la caja de fusibles o a la caja de empalmes, use un cable

blindado flexible o no met_qlicorecubierto de cobre (con

alambre a tierra). Provee una abrazadera releva de anclaje

hom61ogo ULa cada extremidad del cable. A la extremidad

del electrodom_stico, el cable pase a trav_s del agujero

de la conexi6n directa (vet figura 5) en el cord6n de la

placa de montaje. El tamaho de los alambres (alambre de

cobre solamente) y las conexiones deben estar conforme

al r_gimen del electrodom_stico.

Donde los c6digos locales permitan conectar el

conductor de puesta a tierra del electrodom_stico al

neutral (blanco) (vea figura 5):

1. Desconecte el suministro el_ctrico.

2. En el cortacircuito, la caja de fusibles o la caja de

empalmes:

a) Conecte el alambre verde (o cobre desnudo), el

alambre blanco del cable del electrodom_stico y el

alambre neutral (blanco)juntos.

b) Conecte los dos alambres negros juntos.

c) Conecte los dos alambres rojos juntos.

Cable de la fuente de

alimentaciOn

Donde los c6digos locales NO permitan conectar el

conductor de puesta a tierra del electrodom_stico al

neutral (blanco), o si est_ conectado con un sistema a

4 alambres (vea figura 6):

1. Desconecte el suministro el_ctrico.

2. Separeel alambre verde (o cobre desnudo) y el

alambre blanco del electrodom6stico.

3. Enel cortacircuito, la caja de fusibles o la caja de

empalmes:

a. Conecte el alambre blanco del cable del

electrodom6stico al alambre neutral (blanco).

b. Conecte los 2 alambres negros juntos.

c. Conecte los 2 alambres rojos juntos.

d. Conecte el alambre verde (o de cobre desnudo) de

la puesta a tierra del alambre al alambre de puesta

a tierra del cortacircuito, de la caja de fusibles o de

la caja de empalmes.

Cablede lafuente de

Alambre

alimentaci6n

desnudo __

overde \ _ -'_.._

Alambreblanco

Alamb[es

Alambres

Alambre neutro Alambres

(blanco) negros

Alambres

rojos

empalmes

Alambre

desnudos

o verdes

Cable de la

estufa

NOTA:Asegurese de quitar

la banda de puesta a tierra

provista.

Figura 5

Conductor de

uni6n listado-UL

(listado-CSA)

Caja de

blanco

desnudo tTJ_ "_,_i_

o verde _Q_

Cajade >":-J

empalmes

Cable de la

estufa

Conductorde

uni6n listado-UL

(o listado-CSA)

NOTA:Aseguresede quitar ///u!

la bandade puestaatierra -- _,

provista.

Figura 6

2O

Page 21

Construccion del armario

Para eliminar el riesgo de quemaduras

o de fuego tratando de alcanzar algo pot encima de las

zonas calientes, evite de colocar articulos sobre la cocina.

Si cree necesitar este espacio, el riesgo puede disminuir

si instala un sombrerete que proteja horizontalmente un

minimo de 5" (12.7cm) sobre la base del armario.

Preparacion del mostrador

• Las extremidades de la cocina sobrepasan el horde de

su mostrador.

• Si tiene un mostrador con las extremidades

cuadradas (planas), no se necesita ninguna

preparaci6n del mostrador.

El reborde de frente de mostradores moldeados

deben tenet hordes moldeados a 3/4" (1.9cm) a partir

de cada extremidad de la apertura (Figura 7).

Los mostradores enazulejos deber_in necesitar un

recorte de 3/4" (1.9 cm) a partit de cada extremidad

y/o un horde redondeado aplanado (Figura 7).

3/4H

(1.9 cm)

(81 cm)

Mostrador moldeado o

enazulejo recortado 3/4"

(1.9 cm) (1.9 cm) hacia atr,is en las

I abertura del mostrador.

Figura 7

Si el ancho de la abertura del mostrador es

mas grande que 30 1/16" (76,4 cm), ajuste a las

dimensiones como para el 3/4" (1.9).

El mostrador deber ser nivelado. Coloque un

nivelador sobre el mostrador, primero de lado a lado

y luego del frente hacia atr_is. Si el mostrador no est,1

nivelado, la cocina no estate1nivelada. El homo debe

set nivelado para tenet resultados satisfactorios al

hornear. Las extremidades de la plancha de la cocinar

sobrepasan los hordes de la abertura del mostrador.

esquinas de frente de la

La presi6n de entrada al regulador debe set pot Io menos

1 pulgada m_isgrande que la wilvula distribuidora (.25

kPa). El regulador ha sido ajustado para gas natural

a 4 pulgadas de presi6n para la wilvula distribuidora

(1.0 kPa). La presi6n de entrada debe set pot Io menos

de 5 pulgadas (1.25 kPa). Para propano liquido a 10

pulgadas de presi6n para la wilvula distribuidora (2.5

kPa) la presi6n de entrada debe set pot Io menos de 11

pulgadas (2.75 kPa).

La tuberia deberia set equipada con una wilvula de cierre

aprobada (Figura 10). Esta wilvula debe ubicarse en la

misma habitaci6n que la estufa en un lugar que permita

una facilidad de abrir y cerrar. No bloque@ el acceso a

la wilvula de cierre. La wilvula es para abrir o cerrar el

suministro de gas al aparato.

Abra la wilvula de cierre en la linea de suministro de gas.

Espere unos minutos a que el gas se mueva pot el tubo.

El suministro de gas entre la wilvula de cierre y el

regulador se puede conectar con tuberia rigida o con

tuberia flexible uni6n met_ilica conectada y aprobada pot

la AGA/CGA donde los c6digos locales permiten.

La tuberia de suministro de gas puede salir tanto de

la pared (Figura 8, zona 1) o como del piso (Figura 8,

zona 2):

Zona I - Por medio de pared (7" X 6") - El mejor

espacio para la linea de gas esta dentro de 1" (2.5 cm) y

8" (20.3cm) distancia con respecto al piso y 3" (7.6 cm)

del centro de la linea.

Zona 2 - Por medio del piso (~2" X 24") - La linea de

gas puede salir del suelo con 12" (30.5 cm) del centro de

la linea con respecto al la pared de atr_is.

Instalacion de la alimentacion de

gas

Esta unidad ha sido ajustada para operar con un m01tiple

de admisi0n para gas natural de 4"(10,16 cm) (1.0 kPa).

Un regulador de presiOn convertible esta conectado a la

wilvula distribuidora y DEBEset conectado en serie con la

tuberia de suministro de gas.

Para la operation apropiada, la m_ixima presi0n de

entrada al regulador no debe exceder la presi0n de una

columna de agua de 14 pulgadas (3.5 kPa).

Figure 8

Conecte el Regulador de PresiOn

El regulador de presiOn esta ya instalada para la estufa.

No haga que la conexion este demasiado

apretada. El regulador est,1fundido a troquel. Apret_indolo

demasiado podrfa romper el regulador resultando en escape

de gas y posiblemente un incendio o explosion.

21

Page 22

UBICACIONDEL

REGULADORDEPRESION

Figura 9

Valvula de FLUJO DEL GAS Regulador

cierre Uni6n Uni6n

manual 4,

(on) _ Boquilla Conector II

Apagado flexible Tapa de

(Off) entrada

_I_ de presi6n

Todas las conexiones deben ser apretadas

con una Ilave inglesa

Figura 10

ReOnael conector flexible del tubo del suministro de gas

al regulador de la presidn en la orden siguiente:

1. V_ilvula de cierre manual (no incluido)

2. Boquilla de 1/2" (no incluido)

3. 1/2" Adaptador de unidn (no incluido)

4. Conector flexible (no induido)

5. 1/2" Adaptador de unidn (no incluido)

6. Boquilla de 1/2" (no induido)

7. regulador de presidn (incluido)

La linea del suministro se debe de ser equipada de una

wilvula de cierre manual aprobada. Esta wilvula se debe

Iocalizar en el mismo cuarto que la estufa y debe estar en

una Iocalizaci6n que permita la facilidad de la abertura y

del cierre. No bloquee el acceso a la wilvula. La wilvula es

para encender o apagar el gas del aparato.

Una vez que regulador est,1 en su lugar, abra la wilvula

en la linea del suministro de gas. Espere algunos

minutos para que el gas pueda moverse a trav@s de la

linea de gas.

Para verificar si hay fugas en el electrodornestico se

debe de seguir las instrucciones del fabricante.

Asegurese de que no haya escapes de gas. Despues

de conectar la estufa al suministro de gas, compruebe el

sistema con un men6metro. Si no tiene un man6metro,

abre el gas y use un detector de fugas Ifquido en todas las

junturas y conexiones para averiguar si hay escapes de gas.

No use llama para controlar que no

hayan perdidas de gas. La comprobaciOn de perdidas de gas

con una llama puede resultar en un incendio o explosion.

Se debe sellar todas las aberturas en la pared o el piso donde

la estufa se instala.

Apriete todas las conexiones si hace falta para prevenir

fugas de gas en la superficie de la estufa o en la linea de

suministro.

Desconecte esta estufa y su v_lvula individual de

cierre del sistema del siministro de gas durante cualquier

prueba de presion de ese sistema a presiones mayores de

1/2 psig (3.5 kPa o 14"(35,56 cm) columna de agua).

Aisla la estufa del sisterna del surninistro de gas

cerrando su v_ilvula manual de cierre individual durante

cualquier prueba de presion del suministro del gas a

presiones iguales a menos de 1/2 psig (3.5 kPa o 14"(35,56

cm) columna de agua).

La tuberfa de suministro de gas debe set de 1/2 "(1.27 cm) o

3/4"(1,9 cm) D.I.

El consumidor debe saber la posicion de la wilvula principal

de cierre y tenet acceso f_icil a ello.

Cuando se usa un conducto flexible en la estufa, permita

suficiente flojedad como para sacar la estufa fuera del

recortado para la limpieza y el servicio.

NOTA: No permita que el conducto se pellizque entre la

pared y la estufa. Para verlo, saque el cajon.

Use un compuesto _,1

para junturas de

tuberfa hecho para

uso con gas natural

y de LP/Propano

para sellar todas las

conexiones del gas. Si

se usan los conectores

flexibles aseg0rese

de que no esten

enroscados.

V_lvula de cierre -

Abierta

Figura 11

Conversion para uso de Propano

Liquido

Este aparato puede set usado con gas natural o propano

Ifquido. Ha sido ajustado en la f_ibrica para operar con gas

natural solamente.

Si desea convertir su estufa para uso con propano Ifquido,

use los orificios provistos ubicados en el bolso que contiene

la literatura titulada "FOR LP/PROPANE GAS CONVERSION."

Siga las instrucciones que vienen con los orificios.

La conversion debe set efectuado pot un tecnico de servicio

capacitado, de acuerdo con las instrucciones del fabricante

y con todos los codigos y requisitos de las autoridades

correspondentes. El no seguir las instrucciones podrfa dar

como resultado lesiones graves o dahos a la propiedad. El

organismo autorizado para Ilevar a cabo este trabajo asume

la responsabilidad de la conversion.

La falta de una conversion apropiada

puede resultar en lesiones graves y dahos a la propiedad.

22

Page 23

La mudanza del aparato para

reparaciones o limpieza

Apague la corriente el_ctrica a la estufa a la fuente de po-

der principal, y apague la wilvula de cierre manual de gas.

Aseg0rese de que la estufa est_ fresca. Quite el cajOn de

servicio (el cajOn calentador en algunos modelos) y abre la

puerta del homo. Levante la frente de la estufa y deslicela

fuera de la abertura sin crear tension desmedida sobre el

conducto flexible de gas. Aseg0rese de no pellizque el con-

ducto flexible de gas detr_is de la estufa al reemplazar la

unidad en la abertura. Reemplace el cajOn, cierre la puerta

y enciende el gas y la corriente el_ctrica a la estufa.

| Instalacion de la cocina

Nota importante: No es necesario, pero si es

conveniente, quitar la puerta para instalar el horno,

Consulte las instrucciones para retirar la puerta en la Guia

de Uso y Cuidado,

InstalaciOn sin panel(es) lateral(es).

_La plancha de cocinar se sobrepone por encima del

mostrador con sus extremidades y la cocina reposa

sobre el suelo. La plancha de cocinar es 311/2'` (81

cm) de ancho.

_lnstale la base de los armarios a 30" (76.2 cm)

de espacio entre elias. Aseg0rese que estos est_n

verticales y alineados antes de instalar la plancha de

cocinar. Lije el horde del mostrador para obtener las

311/2" (81 cm) en la parte superior del mostrador.

_ Instale las puertas del armario a 31 " (78,7 cm) de

espacio entre elias para que no interfieran con la

abertura de la puerta de la cocina.

_ Corte el mostrador exactamente como en la primera

p_igina.

_ Aseg0rese que el frente de las patas niveladoras

y el dispositivo de nivelaciOn posterior est_n

ajustados mas altos que la altura del gabinete.

_ 1__ Instale el soporte anti-

inclinacion de acuerdo a las instrucdones del

patron anti-inclinaci0n.

_Para una instalaciOn Optima, la superficie superior

de la cubierta debe estar nivelada y ser plana (sobre

el mismo piano) en los 3 lados adyacentes a la

cocina. Se deben hacer los ajustes correspondientes

para hacer que la parte superior quede plana, de Io

contrario podr_in quedar espacios entre la cubierta y

la cocina.

_ Coloque la cocina enfrente de la abertura del

armario.

O Aseg0rese de que el vidrio que est,1colgado

sobre la cubierta deje despejada la cubierta. Si es

necesario, levante la unidad bajando las patas de

nivelaci6n.

Nivele la cocina (vea NivelaciOn de la estufa). El

piso donde se instala la cocina debe estar nivelado.

Siga las instrucciones "nivelaciOn de la estufa-

modelos equipado con un sistema de dispositivo de

nivelaciOn ").

Deslice la unidad hacia el gabinete y central antes

de nivelarla.

Instalacion con el repuesto.

La profundidad del corte de (21¾" (55.2 cm) Min., 22

1/8" (56.2cm) Max.) necesita ser aumentada a 24"

(61 cm) cuando instala el repuesto.

Instalacion con el juego de termino de panel.

Un juego de termino de panel puede ser pedido con

su representante.

Instalacion con Paneles Laterales Llenos

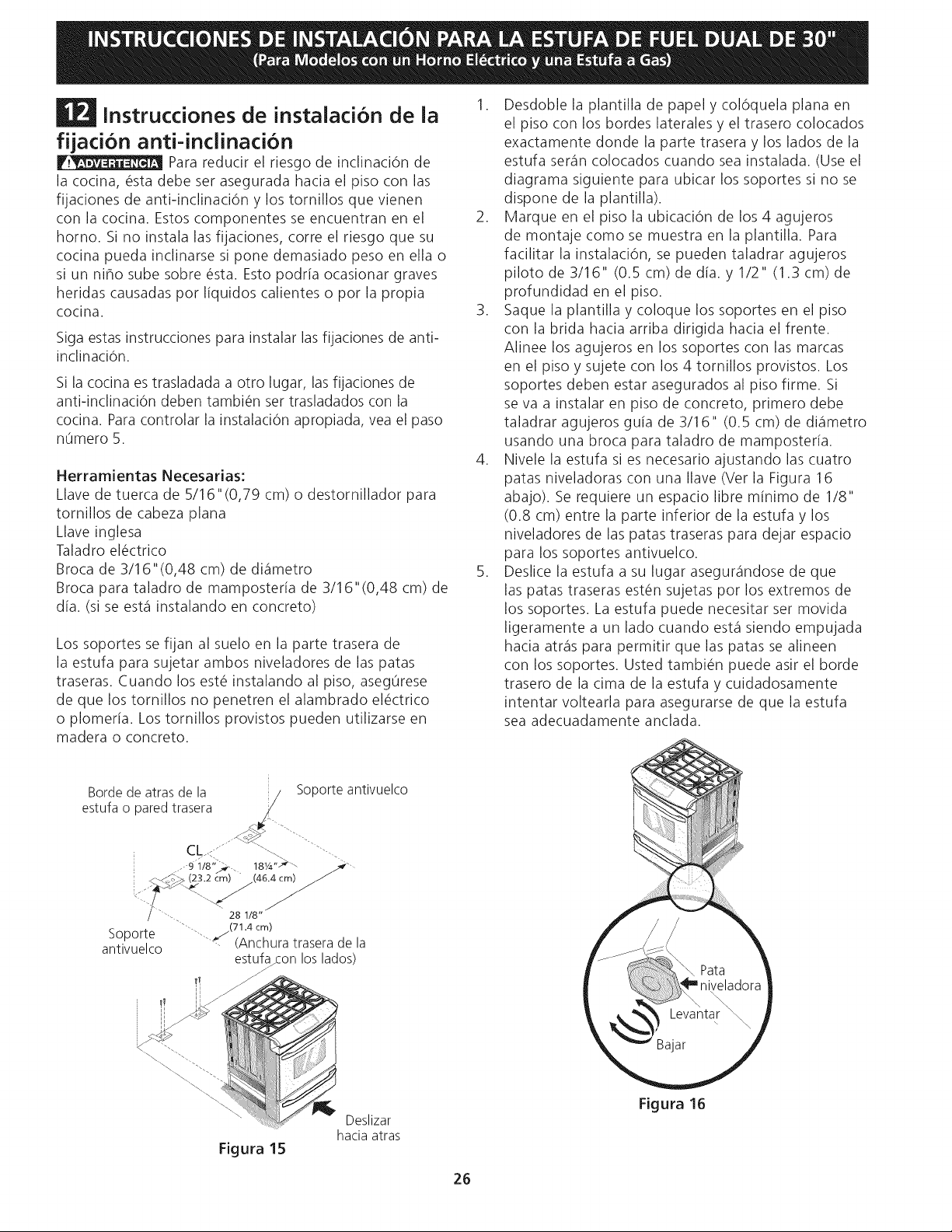

Paneles Laterales puede ser pedido con su